Valorization of Lignocellulosic Biomass to Biofuel: A Systematic Review

Abstract

1. Introduction

1.1. Conversion of LCB to Biofuel

1.2. Challenges and Opportunities

1.3. Objectives

2. Methodology

2.1. Protocol

2.2. Integrative Search Approach

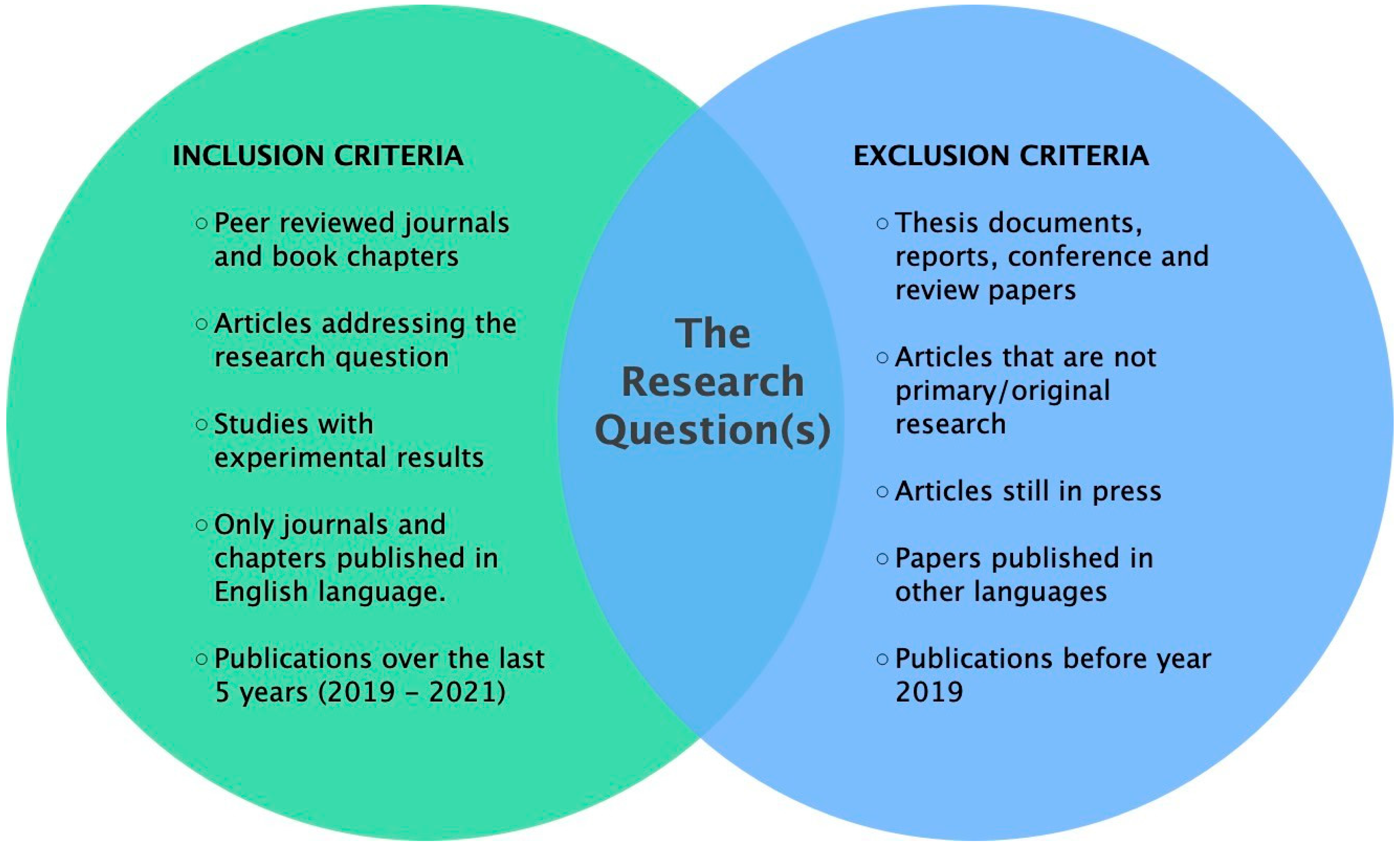

2.3. Screening and Selection of Eligible Studies

2.4. Quality Control

2.5. Data Analysis

3. Results

3.1. Overview of Included Studies

| Pre-Treatment Method Type | Delignification Rate (%) | Bioethanol Yield | Reference |

|---|---|---|---|

| Deep eutectic solvent | 90.45 | 8.8 g per 100 g | [39] |

| Organosolv | 49.7 | 41.4 g/L | [40] |

| Sequential alkaline extraction | 62 | N/A | [41] |

| Hydrothermal | 94.6 | 0.48 g/g | [42] |

| Steam explosion | 63.9 | N/A | [43] |

| Dilute-acid hydrolysis | N/A | 0.47 g of ethanol per gram of glucose | [44] |

| Deep eutectic solvent | 78.88 | N/A | [45] |

| Ternary deep eutectic solvent | 55.81 | N/A | [46] |

| Organosolv | N/A | 28.7 g/L | [47] |

| Ethanol (20 wt%)-assisted deep eutectic solvent | 64–69 | N/A | [48] |

| Pre-Treatment Process | Cost-Effectiveness | Sustainability | Reference |

|---|---|---|---|

| Ball milling | Low-cost availability and efficient conversion processes. | Remarkable renewable nature, reduced greenhouse gas emissions, and promotes circular economy practices. | [35] |

| Gluconic acid | Use of low-cost Cu-biochar catalysts lowering production costs significantly. | Offers a green alternative to traditional catalysts. | [36] |

| Xylonic acid | Can be cost-effective when optimized. | Reduced reliance on harmful chemicals, supporting a more circular economy. | [37] |

| Dilute-acid hydrolysis | Economically viable for large-scale operations. | Minimizes environmental impacts by lowering the overall carbon footprint when compared to conventional processes. | [44] |

| Deep eutectic solvent | Offer a cost-effective solution for biomass pre-treatment by being derived from renewables. | Eco-friendly and biocompatible, making them an attractive alternative to traditional toxic solvents. | [49] |

| Organosolv | Cost-effective due to the use of relatively low-cost solvents. | More sustainable pre-treatment method because it uses environmentally friendly solvents. | [38] |

| Ternary deep eutectic solvent | Cost-effective because they can be synthesized from inexpensive, biodegradable components. | Ternary DESs are sustainable due to their environmentally friendly nature. | [46] |

| Organosolv | Provides cost-effectiveness by using readily available solvents and offering efficient delignification. | Pre-treatment is favorable as it generates fewer toxic byproducts compared to other methods, making it an environmentally friendly option for biofuel production. | [47] |

| Ethanol (20wt%)-assisted deep eutectic solvent | The use of this method demonstrates cost-effectiveness due to the low-cost, renewable nature of ethanol and the simple equipment required for processing. | Sustainability is achieved by utilizing a green solvent system that reduces the need for harsh chemicals. | [48] |

| Supramolecular deep eutectic solvent (SUPRA-DES) | Potentially reduces the associated costs of waste disposal with its green approach. | It aligns with the principles of sustainability and minimizes dependence on fossil fuels. | [39] |

| Alkaline—16 wt% KOH | Optimizes the enzymolysis process and maximizes the utilization of agricultural waste, providing an economically viable pathway for biomass valorization. | Contributes to the circular economy and reduces reliance on fossil resources. | [34] |

| FeCl3 catalyzation which increased the release of cellulase | It can be cost-effective due to its low cost and efficiency in promoting enzymatic activity, but its economic viability depends on the scale of application and downstream process integration. | The enzyme-undigestible residues were effectively used as bio-sorbents for cadmium adsorption, demonstrating a circular approach to biomass utilization. | [33] |

| Steam explosion pre-treatment enhances the enzymatic digestibility | The method is a clean and practical choice for producing biofuel on a big scale without requiring any chemical additions. | The work promotes production of biofuel from commercial biofuel production LCB systems by demonstrating how steam explosion pre-treatment can improve the valorization of tiger nut biomass. | [43] |

| Fermenting, hydrothermally pre-treating, and using enzyme hydrolysis | Increase in the value of agricultural waste by turning pineapple leaves known as waste and consequently lowering disposal expenses. | Sustainability promoted by utilizing abundant pineapple leaf waste, and agricultural waste disposal is addressed while producing renewable energy. | [50] |

| Organosolv-pretreated outer-tunic biomass in biofuel production | The entire biomass is used, whilst biogas and fertilizer are produced from the inner portion of the tunic. | Tunicates are a marine resource that does not compete with land utilized for food production, minimizes dependency on fossil fuels, and is a sustainable strategy. | [40] |

| Hydrolysis of cellulose by alkaline extraction | Reduction in the cost of producing bioethanol by increasing the yields of fermentable sugars from ryegrass through the optimization of the extraction and hydrolysis process. | Process viewed as a sustainable alternative to fossil fuels. By improving the pre-treatment processes and enzymatic conversion efficiencies, a more sustainable biofuel production system is promoted. | [51] |

| Larvae fed hydrolyzed digestate | An alternative microbial pre-treatment, which uses naturally occurring organisms to boost nutrient availability without incurring the high expenses associated with enzymes, may be a more economical option. | From a sustainability standpoint, employing BSF larvae as a technique to valorize anaerobic digestate has a dual benefit: lowering waste and potentially transforming it into high-value biomass for animal feed or other purposes. | [32] |

3.2. Pre-Treatment Technologies

3.2.1. Physical Pre-Treatment

3.2.2. Chemical Pre-Treatment

3.2.3. Biological Pre-Treatment

3.2.4. Combined Pre-Treatment Methods

3.3. Economic and Environmental Assessment

3.3.1. Physical Pre-Treatment Methods

3.3.2. Chemical Pre-Treatment Methods

3.3.3. Biological Pre-Treatment Methods

3.3.4. Combined Pre-Treatment Approaches

4. Discussion

5. Conclusions and Way Forward

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASTM | American Society for Testing and Materials |

| LCB | Lignocellulosic biomass |

| LCA | Life cycle assessment |

| PRISMA | Preferred Reporting Items for Systematic reviews and Meta-Analyses |

| DES | Deep eutectic solvent |

| SUPRA-DES | Supramolecular deep eutectic solvent |

| XOS | Xylooligosaccharide |

| AA-OH | Alkaline-assisted ohmic heating |

| BSF | Black soldier fly |

| LCNF | Lignin nanoparticle |

| CCR | Corncob residue |

| PFI | Permeabilized fiber |

References

- Singhvi, M.S.; Gokhale, D.V. Lignocellulosic Biomass: Hurdles and Challenges in Its Valorization. Appl. Microbiol. Biotechnol. 2019, 103, 9305–9320. [Google Scholar] [CrossRef]

- Devi, A.; Bajar, S.; Kour, H.; Kothari, R.; Pant, D.; Singh, A. Lignocellulosic Biomass Valorization for Bioethanol Production: A Circular Bioeconomy Approach. Bioenergy Res. 2022, 15, 1820–1841. [Google Scholar] [CrossRef]

- Martínez, S.H.; van Eijck, J.; da Cunha, M.P.; Guilhoto, J.J.; Walter, A.; Faaij, A. Analysis of Socio-Economic Impacts of Sustainable Sugarcane–Ethanol Production by Means of Inter-Regional Input–Output Analysis: Demonstrated for Northeast Brazil. Renew. Sustain. Energy Rev. 2013, 28, 290–316. [Google Scholar] [CrossRef]

- Morais, A.R.; Bogel-Lukasik, R. Green Chemistry and The Biorefinery Concept. Sustain. Chem. Process. 2013, 1, 18. [Google Scholar] [CrossRef]

- Wyman, C.E. Ethanol from Lignocellulosic Biomass: Technology, Economics, and Opportunities. Bioresour. Technol. 1994, 50, 3–15. [Google Scholar] [CrossRef]

- Lian, Z.; Zhou, X. Lignocellulosic Biomass Decomposition and Bioconversion. Fermentation 2024, 10, 480. [Google Scholar] [CrossRef]

- Jatoi, A.S.; Abbasi, S.A.; Hashmi, Z.; Shah, A.K.; Alam, M.S.; Bhatti, Z.A.; Maitlo, G.; Hussain, S.; Khandro, G.A.; Usto, M.A. Recent Trends and Future Perspectives of Lignocellulose Biomass for Biofuel Production: A Comprehensive Review. Biomass Convers. Biorefinery 2021, 13, 6457–6469. [Google Scholar] [CrossRef]

- Inyang, V.; Laseinde, O.; Kanakana, G.M. Techniques and Applications of Lignocellulose Biomass Sources as Transport Fuels and Other Bioproducts. Int. J. Low-Carbon Technol. 2022, 17, 900–909. [Google Scholar] [CrossRef]

- Dutta, S.; Saravanabhupathy, S.; Anusha; Rajak, R.C.; Banerjee, R.; Dikshit, P.K.; Padigala, C.T.; Das, A.K.; Kim, B.S. Recent Developments in Lignocellulosic Biofuel Production with Nanotechnological Intervention: An Emphasis on Ethanol. Catalysts 2023, 13, 1439. [Google Scholar] [CrossRef]

- Maitra, M.; Sruthi, S.; Rao, P.M.; Avanthi, V.; Radha, P. Lignocellulosic Biomass for Sustainable Production of Renewable Fuels: Embracing Natural Resources. In Circular Bioeconomy Perspectives in Sustainable Bioenergy Production; Springer: Berlin/Heidelberg, Germany, 2024; pp. 37–89. [Google Scholar]

- Machineni, L. Lignocellulosic Biofuel Production: Review of Alternatives. Biomass Convers. Biorefinery 2020, 10, 779–791. [Google Scholar] [CrossRef]

- Mishra, K.; Siwal, S.S.; Nayaka, S.C.; Guan, Z.; Thakur, V.K. Waste-to-Chemicals: Green Solutions for Bioeconomy Markets. Sci. Total Environ. 2023, 887, 164006. [Google Scholar] [CrossRef] [PubMed]

- Shahbeik, H.; Peng, W. The Significance of Biomass in Achieving a Global Bioeconomy. Planet. Sustain. 2024, 2, 35–52. [Google Scholar]

- Rahul, S.; Dhanuprabha, D.; Prabakaran, S.; Arumugam, A. An Integrated Biorefinery of Madhuca Indica for Co-Production of Biodiesel, Bio-Oil, and Biochar: Towards A Sustainable Circular Bioeconomy. Ind. Crops Prod. 2024, 221, 119409. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, L.; Khoo, K.S.; Gupta, V.K.; Sharma, M.; Show, P.L.; Yap, P.-S. Exploitation of Lignocellulosic-Based Biomass Biorefinery: A Critical Review of Renewable Bioresource, Sustainability and Economic Views. Biotechnol. Adv. 2023, 69, 108265. [Google Scholar] [CrossRef]

- KN, Y.; TM, M.U.; Sachdeva, S.; Thakur, S. Lignocellulosic Biorefinery Technologies: A Perception into Recent Advances in Biomass Fractionation, Biorefineries, Economic Hurdles and Market Outlook. Fermentation 2023, 9, 238. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y.; Sun, P.; Peng, C. A Review on Renewable Energy: Conversion and Utilization of Biomass. Smart Mol. 2024, 2, e20240019. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, Z.F.; Zhang, C.C.; Nan, J.; Ren, N.Q.; Lee, D.J.; Chen, C. Advances in Pre-Treatment of Lignocellulosic Biomass for Bioenergy Production: Challenges and Perspectives. Bioresour. Technol. 2022, 343, 126123. [Google Scholar] [CrossRef] [PubMed]

- Soomro, S.A.; Ahmad, H.; Asif, M. Lignin Used as a Green and Sustainable Agriculture Biomass for Renewable Application. A Comprehensive Review. J. Chem. Nutr. Biochem. 2023, 4, 47–55. [Google Scholar]

- Olayokun, O.; Anyaegbuna, B.; Onokwai, A.; Faola, D.; Muslim, I.; Eruobodo, A.; Adiatu, A. Review of Biomass as a Renewable Energy for Sustainable Environment. In Proceedings of the 2024 International Conference on Science, Engineering and Business for Driving Sustainable Development Goals (SEB4SDG), Omu-Aran, Nigeria, 2–4 April 2024; pp. 1–7. [Google Scholar]

- Lee, J.; Kim, S.; You, S.; Park, Y.K. Bioenergy Generation from Thermochemical Conversion of Lignocellulosic Biomass-Based Integrated Renewable Energy Systems. Renew. Sustain. Energy Rev. 2023, 178, 113240. [Google Scholar] [CrossRef]

- Nargotra, P.; Sharma, V.; Lee, Y.-C.; Tsai, Y.-H.; Liu, Y.-C.; Shieh, C.-J.; Tsai, M.-L.; Dong, C.-D.; Kuo, C.-H. Microbial Lignocellulolytic Enzymes for the Effective Valorization of Lignocellulosic Biomass: A Review. Catalysts 2022, 13, 83. [Google Scholar] [CrossRef]

- Booth, A.; James, M.-S.; Clowes, M.; Sutton, A. Systematic Approaches to a Successful Literature Review; SAGE Publications Ltd.: London, UK, 2021. [Google Scholar]

- Alizadeh, R.; Lund, P.D.; Soltanisehat, L. Outlook on Biofuels in Future Studies: A Systematic Literature Review. Renew. Sustain. Energy Rev. 2020, 134, 110326. [Google Scholar] [CrossRef]

- Mengist, W.; Soromessa, T.; Legese, G. Method for Conducting Systematic Literature Review and Meta-Analysis for Environmental Science Research. MethodsX 2020, 7, 100777. [Google Scholar] [CrossRef] [PubMed]

- Frampton, G.K.; Livoreil, B.; Petrokofsky, G. Eligibility Screening in Evidence Synthesis of Environmental Management Topics. Environ. Evid. 2017, 6, 27. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Prisma Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Ann. Intern. Med. 2009, 151, 264–269. [Google Scholar] [CrossRef]

- Mahood, Q.; Van Eerd, D.; Irvin, E. Searching for Grey Literature for Systematic Reviews: Challenges and Benefits. Res. Synth. Methods 2014, 5, 221–234. [Google Scholar] [CrossRef]

- McDonagh, M.; Peterson, K.; Raina, P.; Chang, S.; Shekelle, P. AHRQ Methods for Effective Health Care Avoiding Bias in Selecting Studies. In Methods Guide for Effectiveness and Comparative Effectiveness Reviews; Agency for Healthcare Research and Quality (US): Rockville, MD, USA, 2008. [Google Scholar]

- Fatriasari, W.; Nurhamzah, F.; Raniya, R.; Laksana, R.; Anita, S.H.; Iswanto, A.H.; Hermiati, E. Enzymatic Hydrolysis Performance of Biomass by The Addition of a Lignin Based Biosurfactant. J. Korean Wood Sci. Technol. 2020, 48, 651–665. [Google Scholar] [CrossRef]

- Lin, T.-S.; Kheshgi, H.S.; Song, Y.; Vörösmarty, C.J.; Jain, A.K. Which Crop Has the Highest Bioethanol Yield in The United States? Front. Energy Res. 2023, 11, 1070186. [Google Scholar] [CrossRef]

- Pas, C.; Brodeur, D.; Deschamps, M.H.; Lebeuf, Y.; Adjalle, K.; Barnabé, S.; Eeckhout, M.; Vandenberg, G.; Vaneeckhaute, C. Valorization of Pretreated Biogas Digestate with Black Soldier Fly (Hermetia Illucens, L.; Diptera: Stratiomyidae) Larvae. J. Environ. Manag. 2022, 319, 115529. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.; Peng, H.; Li, T.; Liu, P.; Gao, H.; Wang, Y.; Tang, J.; Li, Q.; Qi, Z.; et al. Full-Chain FeCl(3) Catalyzation Is Sufficient to Boost Cellulase Secretion and Cellulosic Ethanol Along with Valorized Supercapacitor and Biosorbent Using Desirable Corn Stalk. Molecules 2023, 28, 2060. [Google Scholar] [CrossRef]

- Xu, R.; Du, H.; Wang, H.; Zhang, M.; Wu, M.; Liu, C.; Yu, G.; Zhang, X.; Si, C.; Choi, S.E.; et al. Valorization of Enzymatic Hydrolysis Residues from Corncob into Lignin-Containing Cellulose Nanofibrils and Lignin Nanoparticles. Front. Bioeng. Biotechnol. 2021, 9, 677963. [Google Scholar] [CrossRef]

- Chen, X.; He, D.; Hou, T.; Lu, M.; Mosier, N.S.; Han, L.; Xiao, W. Structure-Property-Degradability Relationships of Varisized Lignocellulosic Biomass Induced by Ball Milling on Enzymatic Hydrolysis And Alcoholysis. Biotechnol. Biofuels Bioprod. 2022, 15, 36. [Google Scholar] [CrossRef] [PubMed]

- Dong, L.; Gao, Y.; Liu, C.; Yu, G.; Asadollahi, M.A.; Wang, H.; Li, B. Co-Production of High-Concentration Fermentable Sugar and Lignin-Based Bio-Adhesive from Corncob Residue via an Enhanced Enzymatic Hydrolysis. Int. J. Biol. Macromol. 2024, 276, 133739. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, Y. Eco-Friendly Consolidated Process for Co-Production of Xylooligosaccharides and Fermentable Sugars Using Self-Providing Xylonic Acid as Key Pretreatment Catalyst. Biotechnol. Biofuels 2019, 12, 272. [Google Scholar] [CrossRef]

- Dedes, G.; Karnaouri, A.; Marianou, A.A.; Kalogiannis, K.G.; Michailof, C.M.; Lappas, A.A.; Topakas, E. Conversion of Organosolv Pretreated Hardwood Biomass into 5-Hydroxymethylfurfural (Hmf) by Combining Enzymatic Hydrolysis and Isomerization With Homogeneous Catalysis. Biotechnol. Biofuels 2021, 14, 172. [Google Scholar] [CrossRef]

- Tan, J.; Huang, J.; Yuan, J.; Chen, J.; Pei, Z.; Li, H.; Yang, S. Novel Supramolecular Deep Eutectic Solvent-Enabled In-Situ Lignin Protection for Full Valorization of All Components of Wheat Straw. Bioresour. Technol. 2023, 388, 129722. [Google Scholar] [CrossRef] [PubMed]

- Hrůzová, K.; Matsakas, L.; Karnaouri, A.; Norén, F.; Rova, U.; Christakopoulos, P. Valorization of Outer Tunic of the Marine Filter Feeder Ciona Intestinalis Towards the Production of Second-Generation Biofuel and Prebiotic Oligosaccharides. Biotechnol. Biofuels 2021, 14, 32. [Google Scholar] [CrossRef]

- Sun, S.F.; Yang, J.; Wang, D.W.; Yang, H.Y.; Sun, S.N.; Shi, Z.J. Enzymatic Response of Ryegrass Cellulose and Hemicellulose Valorization Introduced by Sequential Alkaline Extractions. Biotechnol. Biofuels 2021, 14, 72. [Google Scholar] [CrossRef] [PubMed]

- Douglas, L. Conversion of Lignocellulosic Biomass to Ethanol. In Energy Applications Of Biomass; CRC Press: Boca Raton, FL, USA, 1985; pp. 195–206. [Google Scholar]

- Zhao, Z.M.; Yu, W.; Huang, C.; Xue, H.; Li, J.; Zhang, D.; Li, G. Steam Explosion Pretreatment Enhancing Enzymatic Digestibility of Overground Tubers of Tiger Nut (Cyperus esculentus L.). Front. Nutr. 2022, 9, 1093277. [Google Scholar] [CrossRef]

- Aristizábal-Marulanda, V.; Poveda-Giraldo, J.A.; Cardona Alzate, C.A. Comparison of Furfural and Biogas Production Using Pentoses as Platform. Sci. Total Environ. 2020, 728, 138841. [Google Scholar] [CrossRef]

- Wang, Z.K.; Li, H.; Lin, X.C.; Tang, L.; Chen, J.J.; Mo, J.W.; Yu, R.S.; Shen, X.J. Novel Recyclable Deep Eutectic Solvent Boost Biomass Pretreatment for Enzymatic Hydrolysis. Bioresour. Technol. 2020, 307, 123237. [Google Scholar] [CrossRef]

- Muryanto; Amelia, F.; Nurbayti, S.; Gozan, M. Utilization of Potassium Carbonate-Ethylene Glycol as Deep Eutectic Solvent to Delignification Oil Palm Empty Fruit Bunch for Furfural and Ethanol Production. J. Sains Mater. Indones. 2024, 25, 100–106. [Google Scholar] [CrossRef]

- Sharma, P.; Sharma, N. Rsm Approach to Pre-Treatment of Lignocellulosic Waste and A Statistical Methodology for Optimizing Bioethanol Production. Waste Manag. Bull. 2024, 2, 49–66. [Google Scholar] [CrossRef]

- Yong, K.J.; Wu, T.Y. Fractionation of Oil Palm Fronds Using Ethanol-Assisted Deep Eutectic Solvent: Influence of Ethanol Concentration on Enhancing Enzymatic Saccharification and Lignin Β-O-4 Content. Environ. Res. 2024, 250, 118366. [Google Scholar] [CrossRef]

- Wang, J.-X.; Asano, S.; Kudo, S.; Hayashi, J.-i. Deep Delignification of Woody Biomass by Repeated Mild Alkaline Treatments With Pressurized O2. ACS Omega 2020, 5, 29168–29176. [Google Scholar] [CrossRef] [PubMed]

- Saini, R.; Chen, C.W.; Patel, A.K.; Saini, J.K.; Dong, C.D.; Singhania, R.R. Valorization of Pineapple Leaves Waste for the Production of Bioethanol. Bioengineering 2022, 9, 557. [Google Scholar] [CrossRef]

- Sun, S.-F.; Yang, H.-Y.; Yang, J.; Shi, Z.-J.; Deng, J. Revealing The Structural Characteristics of Lignin Macromolecules from Perennial Ryegrass During Different Integrated Treatments. Int. J. Biol. Macromol. 2021, 178, 373–380. [Google Scholar] [CrossRef]

- Rezania, S.; Oryani, B.; Cho, J.; Talaiekhozani, A.; Sabbagh, F.; Hashemi, B.; Rupani, P.F.; Mohammadi, A.A. Different Pretreatment Technologies of Lignocellulosic Biomass for Bioethanol Production: An Overview. Energy 2020, 199, 117457. [Google Scholar] [CrossRef]

- Chen, A.; Guan, Y.J.; Bustamante, M.; Uribe, L.; Uribe-Lorío, L.; Roos, M.M.; Liu, Y. Production of Renewable Fuel and Value-Added Bioproducts Using Pineapple Leaves in Costa Rica. Biomass Bioenergy 2020, 141, 105675. [Google Scholar] [CrossRef]

- Zhang, Z.-S.; Jia, H.-J.; Qin, H.; Wei, Y.-Y.; Li, B.-Z.; Liu, Y.-L.; Wei, A.-C.; Zhu, W.-X.; Wang, Y. Effect of Steam Pretreatment on the Microstructure of Tiger Nuts (Cyperus esculents L.) and Quality Properties of Its Oil. LWT 2023, 184, 114985. [Google Scholar] [CrossRef]

- Mihiretu, G.T.; Chimphango, A.F.; Görgens, J.F. Steam Explosion Pre-Treatment of Alkali-Impregnated Lignocelluloses For Hemicelluloses Extraction and Improved Digestibility. Bioresour. Technol. 2019, 294, 122121. [Google Scholar] [CrossRef]

- Wu, Y.; Ge, S.; Xia, C.; Mei, C.; Kim, K.-H.; Cai, L.; Smith, L.M.; Lee, J.; Shi, S.Q. Application of Intermittent Ball Milling to Enzymatic Hydrolysis for Efficient Conversion of Lignocellulosic Biomass into Glucose. Renew. Sustain. Energy Rev. 2021, 136, 110442. [Google Scholar] [CrossRef]

- Zoghlami, A.; Refahi, Y.; Terryn, C.; Paës, G. Multimodal Characterization of Acid-Pretreated Poplar Reveals Spectral and Structural Parameters Strongly Correlate with Saccharification. Bioresour. Technol. 2019, 293, 122015. [Google Scholar] [CrossRef] [PubMed]

- Raj, S. Pretreatment of Lignocellulosic Biomass for Bioethanol Production. J. Multidiscip. Res. 2024. [Google Scholar] [CrossRef]

- Ci, Y.H.; Yu, F.; Zhou, C.X.; Mo, H.E.; Li, Z.Y.; Ma, Y.Q.; Zang, L.H. New Ternary Deep Eutectic Solvents for Effective Wheat Straw Deconstruction Into Its High-Value Utilization Under Near-Neutral Conditions. Green Chem. 2020, 22, 8713–8720. [Google Scholar] [CrossRef]

- Liu, Y.; Deak, N.; Wang, Z.; Yu, H.; Hameleers, L.; Jurak, E.; Deuss, P.J.; Barta, K. Tunable and Functional Deep Eutectic Solvents for Lignocellulose Valorization. Nat. Commun. 2021, 12, 5424. [Google Scholar] [CrossRef]

- Tsegaye, B.; Jaiswal, S.; Jaiswal, A.K. Emerging Pretreatment Technologies Applied to Waste Biorefinery. In Handbook of Waste Biorefinery: Circular Economy of Renewable Energy; Springer: Cham, Switzerland, 2022; pp. 69–91. [Google Scholar]

- Rani, P.; Bansal, M.; Pathak, V.V. Experimental and Kinetic Studies for Improvement of Biogas Production from Koh Pretreated Wheat Straw. Curr. Res. Green Sustain. Chem. 2022, 5, 100283. [Google Scholar] [CrossRef]

- Jankovičová, B.; Hutňan, M.; Imreová, Z.; Zakhar, R. Increased Biogas Production from Lignocellulosic Biomass by Soaking in Water. Agron. Res. 2023, 21, 120–134. [Google Scholar]

- Zdeb, M. Anaerobic Digestion of Wheat Straw Pretreated with Soaking in Water and Alkali Medium. J. Ecol. Eng. 2021, 22, 246–254. [Google Scholar] [CrossRef]

- Sun, D.; Lv, Z.-W.; Rao, J.; Tian, R.; Sun, S.-N.; Peng, F. Effects of Hydrothermal Pretreatment on the Dissolution and Structural Evolution of Hemicelluloses and Lignin: A Review. Carbohydr. Polym. 2022, 281, 119050. [Google Scholar] [CrossRef]

- Sun, D.; Sun, S.-C.; Wang, B.; Sun, S.-F.; Shi, Q.; Zheng, L.; Wang, S.-F.; Liu, S.-J.; Li, M.-F.; Cao, X.-F. Effect of Various Pretreatments on Improving Cellulose Enzymatic Digestibility of Tobacco STALK and the structural Features of Co-Produced Hemicelluloses. Bioresour. Technol. 2020, 297, 122471. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, Y.; Chang, J.-S.; Lee, D.-J. Enzymes and Enzymatic Mechanisms in Enzymatic Degradation of Lignocellulosic Biomass: A Mini-Review. Bioresour. Technol. 2023, 367, 128252. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Feng, S.; Deng, J.; Yu, B.; Wang, Y.; He, B.; Peng, H.; Li, Q.; Hu, R.; Peng, L. Altered Carbon Assimilation and Cellulose Accessibility to Maximize Bioethanol Yield Under Low-Cost Biomass Processing in Corn Brittle Stalk. Green Chem. 2019, 21, 4388–4399. [Google Scholar] [CrossRef]

- Quek, J.D.; Lee, K.M.; Lim, S.; Tey, W.Y.; Kang, H.-S.; Quen, L.K. Delignification of Oil Palm Empty Fruit Bunch via Ultrasound-Assisted Deep Eutectic Solvent Pretreatment. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 012007. [Google Scholar] [CrossRef]

- Amin, U.K.; Lando, A.T.; Djamaluddin, I. Potential of Black Soldier Fly Larvae in Reduction Various Types Organic Waste. Ecol. Eng. Environ. Technol. (EEET) 2024, 25, 190–201. [Google Scholar] [CrossRef]

- Bortolini, S.; Macavei, L.I.; Saadoun, J.H.; Foca, G.; Ulrici, A.; Bernini, F.; Malferrari, D.; Setti, L.; Ronga, D.; Maistrello, L. Hermetia illucens (L.) Larvae as Chicken Manure Management Tool for Circular Economy. J. Clean. Prod. 2020, 262, 121289. [Google Scholar] [CrossRef]

- Khan, S.; Hussain, A.; Hussain, M.I.; Aqeel, S.M.; Basharat, S.; Hussain, A.; Al-Ansi, W.; Abdulqader, A.; Yao, N. Metabolic Engineering of Saccharomyces Cerevisiae for Ethanol and Butanol Biofuel Production. Int. J. Environ. Agric. Biotechnol. 2023, 8, 47–56. [Google Scholar] [CrossRef]

- Hu, Y.; Zhu, Z.; Nielsen, J.; Siewers, V. Engineering Saccharomyces Cerevisiae Cells for Production of Fatty Acid-Derived Biofuels and Chemicals. Open Biol. 2019, 9, 190049. [Google Scholar] [CrossRef]

- Topaloğlu, A.; Esen, Ö.; Turanlı-Yıldız, B.; Arslan, M.; Çakar, Z.P. From Saccharomyces Cerevisiae to Ethanol: Unlocking the Power of Evolutionary Engineering in Metabolic Engineering Applications. J. Fungi 2023, 9, 984. [Google Scholar] [CrossRef]

- Sharma, J.; Kumar, V.; Prasad, R.; Gaur, N.A. Engineering of Saccharomyces Cerevisiae as A Consolidated Bioprocessing Host to Produce Cellulosic Ethanol: Recent Advancements and Current Challenges. Biotechnol. Adv. 2022, 56, 107925. [Google Scholar] [CrossRef]

- Li, X.; Ning, C.; Li, L.; Liu, W.; Ren, Q.; Hou, Q. Fabricating Lignin-Containing Cellulose Nanofibrils with Unique Properties from Agricultural Residues with Assistance of Deep Eutectic Solvents. Carbohydr. Polym. 2021, 274, 118650. [Google Scholar] [CrossRef]

- Lin, Q.; Yan, Y.; Liu, X.; He, B.; Wang, X.; Wang, X.; Liu, C.; Ren, J. Production of Xylooligosaccharide, Nanolignin, and Nanocellulose Through a Fractionation Strategy of Corncob for Biomass Valorization. Ind. Eng. Chem. Res. 2020, 59, 17429–17439. [Google Scholar] [CrossRef]

- Lad, B.; Coleman, S.; Alper, H. Microbial Valorization of Underutilized and Nonconventional Waste Streams. J. Ind. Microbiol. Biotechnol. 2022, 49, kuab056. [Google Scholar] [CrossRef] [PubMed]

- Lopes, M.; Miranda, S.M.; Belo, I. Microbial Valorization of Waste Cooking Oils for Valuable Compounds Production—A Review. Crit. Rev. Environ. Sci. Technol. 2020, 50, 2583–2616. [Google Scholar] [CrossRef]

- Son, J.; Lim, S.H.; Kim, Y.J.; Lim, H.J.; Lee, J.Y.; Jeong, S.; Park, C.; Park, S.J. Customized Valorization of Waste Streams by Pseudomonas Putida: State-of-the-Art, Challenges, and Future Trends. Bioresour. Technol. 2023, 371, 128607. [Google Scholar] [CrossRef]

- Alvarez-Gonzalez, G.; Chacόn, M.; Berepiki, A.; Fisher, K.; Gosalvitr, P.; Cuéllar-Franca, R.; Dixon, N. Complex Waste Stream Valorisation through Combined Enzymatic Hydrolysis and Catabolic Assimilation by Pseudomonas Putida. BioRxiv 2023, 13, 528311. [Google Scholar]

- Yao, L.; Cui, P.; Chen, X.; Yoo, C.G.; Liu, Q.; Meng, X.; Xiong, L.; Ragauskas, A.J.; Yang, H. A Combination of Deep Eutectic Solvent and Ethanol Pretreatment for Synergistic Delignification and Enhanced Enzymatic Hydrolysis for Biorefinary Process. Bioresour. Technol. 2022, 350, 126885. [Google Scholar] [CrossRef]

- Yao, F.; Shen, F.; Wan, X.; Hu, C. High Yield and High Concentration Glucose Production from Corncob Residues After Tetrahydrofuran+ H2O Co-Solvent Pretreatment and Followed by Enzymatic Hydrolysis. Renew. Sustain. Energy Rev. 2020, 132, 110107. [Google Scholar] [CrossRef]

- Lin, Q.; Yan, Y.; Wang, X.; Cheng, B.; Meng, L.; Yue, F.; Lan, W.; Sun, R.; Ren, J. Corncob Biorefinery for Platform Chemicals and Lignin Coproduction: Metal Chlorides as Catalysts. ACS Sustain. Chem. Eng. 2019, 7, 5309–5317. [Google Scholar] [CrossRef]

- Šelo, G.; Planinić, M.; Tišma, M.; Tomas, S.; Koceva Komlenić, D.; Bucić-Kojić, A. A Comprehensive Review on Valorization of Agro-Food Industrial Residues by Solid-State Fermentation. Foods 2021, 10, 927. [Google Scholar] [CrossRef]

- Saldarriaga-Hernández, S.; Velasco-Ayala, C.; Flores, P.L.-I.; de Jesús Rostro-Alanis, M.; Parra-Saldivar, R.; Iqbal, H.M.; Carrillo-Nieves, D. Biotransformation of Lignocellulosic Biomass into Industrially Relevant Products with the Aid of Fungi-Derived Lignocellulolytic Enzymes. Int. J. Biol. Macromol. 2020, 161, 1099–1116. [Google Scholar] [CrossRef]

- Kumla, J.; Suwannarach, N.; Sujarit, K.; Penkhrue, W.; Kakumyan, P.; Jatuwong, K.; Vadthanarat, S.; Lumyong, S. Cultivation of Mushrooms and Their Lignocellulolytic Enzyme Production Through the Utilization of Agro-Industrial Waste. Molecules 2020, 25, 2811. [Google Scholar] [CrossRef] [PubMed]

- Dhiman, S.; Kaur, P.; Narang, J.; Mukherjee, G.; Thakur, B.; Kaur, S.; Tripathi, M. Fungal Bioprocessing for Circular Bioeconomy: Exploring Lignocellulosic Waste Valorization. Mycology 2024, 15, 538–563. [Google Scholar] [CrossRef] [PubMed]

- Mehta, P.; Chelike, D.K. Utilizing Fungal Biodegradation for Valorisation of Lignocellulosic Waste Biomass and Its Diverse Applications. Appl. Res. 2024, 3, e202300119. [Google Scholar] [CrossRef]

- Ranjan, A.; Welz, P.J. Physical, Chemical and Biological Pre-Treatment of Lignocellulosic Biomass for Biorefinery Applications. In Ultrasound Technology for Fuel Processing; Bentham Science Publishers: Sharjah, United Arab Emirates, 2023; pp. 60–97. [Google Scholar]

- Ummalyma, S.B.; Herojit, N.; Sukumaran, R.K. Alkaline Hydrogen Peroxide Pretreatment of Bamboo Residues and Its Influence on Physiochemical Properties and Enzymatic Digestibility for Bioethanol Production. Front. Energy Res. 2024, 12, 1444813. [Google Scholar] [CrossRef]

- Barnwal, S.K.; Dhar, S.; Parayil, D.J.; Francis, D. Lignocellulosic Biomass as Feedstock for Biofuels: The State of the Science, Prospects, and Challenges. In Solid-Gaseous Biofuels Production; Wiley: Beverly, MA, USA, 2024; pp. 187–228. [Google Scholar]

- Vu, H.P.; Nguyen, L.N.; Vu, M.T.; Johir, M.A.H.; McLaughlan, R.; Nghiem, L.D. A Comprehensive Review on the Framework to Valorise Lignocellulosic Biomass as Biorefinery Feedstocks. Sci. Total Environ. 2020, 743, 140630. [Google Scholar] [CrossRef]

- Zheng, B.; Yu, S.; Chen, Z.; Huo, Y.-X. A Consolidated Review of Commercial-Scale High-Value Products from Lignocellulosic Biomass. Front. Microbiol. 2022, 13, 933882. [Google Scholar] [CrossRef]

- Muryanto, M.; Sudiyani, Y.; Darmawan, M.A.; Handayani, E.M.; Gozan, M. Simultaneous Delignification and Furfural Production of Palm Oil Empty Fruit Bunch by Novel Ternary Deep Eutectic Solvent. Arab. J. Sci. Eng. 2023, 48, 16359–16371. [Google Scholar] [CrossRef]

- Ab Aziz, I.F.; Man, H.C.; Hamzah, M.H.; Jamali, N.S.; Omar, R. Novel Pre-Treatment for Lignocellulosic Biomass Delignification Using Alkaline-Assisted Ohmic Heating. Pertanika J. Sci. Technol. 2023, 31, 3039–3057. [Google Scholar] [CrossRef]

- Ong, V.Z.; Wu, T.Y.; Chu, K.K.L.; Sun, W.Y.; Shak, K.P.Y. A Combined Pretreatment with Ultrasound-Assisted Alkaline Solution and Aqueous Deep Eutectic Solvent for Enhancing Delignification and Enzymatic Hydrolysis from Oil Palm Fronds. Ind. Crops Prod. 2021, 160, 112974. [Google Scholar] [CrossRef]

- Pham, L.T.M.; Choudhary, H.; Gauttam, R.; Singer, S.W.; Gladden, J.M.; Simmons, B.A.; Singh, S.; Sale, K.L. Revisiting Theoretical Tools and Approaches for the Valorization of Recalcitrant Lignocellulosic Biomass to Value-Added Chemicals. Front. Energy Res. 2022, 10, 863153. [Google Scholar] [CrossRef]

- Juneja, A.; Kumar, D.; Rajendran, K.; Mittal, A. Pretreatment technologies for lignocellulosic biomass refineries. In Advances in Lignocellulosic Biofuel Production Systems; Elsevier: Amsterdam, The Netherlands, 2023; pp. 81–106. [Google Scholar]

- Wu, Z.; Peng, K.; Zhang, Y.; Wang, M.; Yong, C.; Chen, L.; Qu, P.; Huang, H.; Sun, E.; Pan, M. Lignocellulose Dissociation with Biological Pretreatment Towards the Biochemical Platform: A Review. Mater. Today Bio 2022, 16, 100445. [Google Scholar] [CrossRef] [PubMed]

- Peguero, D.A.; Gold, M.; Vandeweyer, D.; Zurbrügg, C.; Mathys, A. A Review of Pretreatment Methods to Improve Agri-Food Waste Bioconversion by Black Soldier Fly Larvae. Front. Sustain. Food Syst. 2022, 5, 745894. [Google Scholar] [CrossRef]

| Type of Biomass | Example | Region | Region Availability | Reference |

|---|---|---|---|---|

| Agricultural wastes | Corn stover | USA | Midwestern states (corn belt) | [7] |

| Sugarcane bagasse | Brazil | São Paulo, Minas Gerais, and Paraná | ||

| Rice straw | Asia | Chang Jiang basin and Southern China (China), northern states (India), Java and Sumatra (Indonesia) | [8] | |

| Energy crops | Miscanthus | Europe, Asia and USA | United Kingdom, Germany, and Poland (Europe), parts of East Asia, and the Midwest/Southeast (USA) | [9] |

| Switchgrass | Europe, USA and Canada | Parts of Western Europe, the Great Plains, the Midwest and Southeast (USA), and southern provinces (Canada) | ||

| Forest residues | Wood chips and sawdust | South Africa | KwaZulu-Natal, Mpumalanga, and Eastern Cape provinces | [10] |

| Wood chips and forest thinning | Russia | Siberia, Northwest, and Far East | ||

| Sawmill residues and wood chips | North America | Pacific Northwest, Southeast (USA), and British Columbia (Canada) | ||

| Forest thinning, sawdust | Europe | Scandinavia and Eastern and Western Europe | ||

| Industrial wastes | Bagasse and paper mill sludge | South Africa | KwaZulu-Natal and Mpumalanga provinces | [11] |

| Brazil | São Paulo, Minas Gerais, Paraná (bagasse), and São Paulo, Paraná, and Santa Catarina (paper mill sludge) | |||

| India | Uttar Pradesh, Maharashtra, Tamil Nadu (bagasse) and Maharashtra, Tamil Nadu, and West Bengal (paper mill sludge) | |||

| Municipal solid wastes | Domestic waste, food, scraps, sewage | Global | Global | [12] |

| Paper Title | Objective and Contribution | Reference |

|---|---|---|

| A Review on Renewable Energy: Conversion and Utilization of Biomass | The article reviews how LCB can be transformed into high-quality chemicals and biofuels, promoting sustainable production and reducing reliance on fossil fuels. It examines the pros and cons of different pre-treatment methods for converting cellulose, hemicellulose, and lignin, offering guidance for optimizing their use in the future. | [17] |

| Lignocellulosic Biomass Decomposition and Bioconversion | LCB is highlighted as a sustainable energy resource due to its abundance and degradability, making it a viable option for energy production. The paper emphasizes the environmental compatibility and non-toxic nature of LCB, which contributes to its cost-effectiveness as an energy source. | [6] |

| The Significance of Biomass in Achieving a Global Bio-economy | The paper explores different types of biomass, including lignocellulosic materials, organic waste, and algae, and their roles in the bio-economy. It also examines various conversion technologies, such as pyrolysis and gasification, and their contributions to energy and biofuel production. | [13] |

| Exploitation of Lignocellulosic-based Biomass Biorefinery: A Critical Review of Renewable Bioresource, Sustainability and Economic Views | The paper evaluates different pre-treatment methods for LCB, highlighting their pros and cons in improving biorefinery efficiency and enzymatic digestion. It also analyses biorefining’s economic and environmental impacts, promoting green chemistry and offering sustainable options to guide policy decisions on biorefinery technologies. | [15] |

| Lignin Used as a Green and Sustainable Agriculture Biomass for Renewable Applications: A Comprehensive Review | The paper highlights the significant production of lignin in the pulp and paper sector, which generates 50 to 70 million tonnes annually, primarily using it for energy recovery. This emphasizes lignin’s potential as a renewable energy source and its role in sustainable agriculture biomass applications. It also discusses the diverse applications of lignin, particularly in the production of polyurethanes (PUs) and other polymeric products, as well as its use in various industries, such as adhesives, furniture, building structures, and biomaterials. This showcases lignin’s versatility and importance in green and sustainable practices. | [19] |

| Review of Biomass as a Renewable Energy for Sustainable Environment | The paper emphasizes biomass’s potential as a renewable energy source, addressing pollution and waste management by using feedstocks like agricultural residues and municipal waste. It discusses how converting biomass into biofuels can reduce greenhouse gas emissions and promote sustainable energy while also highlighting the importance of responsible feedstock management. | [20] |

| Microbial Lignocellulolytic Enzymes for the Effective Valorization of Lignocellulosic Biomass: A Review | The paper discusses various types of lignocellulolytic enzymes and their modes of action. It also highlights the importance of solid-state fermentation and enzyme immobilization. | [22] |

| Bioenergy Generation from Thermochemical Conversion of Lignocellulosic Biomass-based Integrated Renewable Energy Systems | The paper systematically reviews the thermochemical conversion technologies for LCB, such as gasification and pyrolysis, and their integration with renewable energy systems like solar thermal and fuel cells. It emphasizes the importance of selecting suitable configurations to achieve sustainable power generation and enhance environmental benefits. | [21] |

| Keywords | Search Terms |

|---|---|

| Pre-treatment techniques | “pre-treatment techniques” |

| Enzymatic hydrolysis | “hydrolysis” “conversion” |

| Lignocellulosic | “lignocellulose” “lignocellulosic biomass” |

| Biomass | “agricultural waste” |

| Valorization | “valorization” “waste conversion” “bioconversion” |

| Biofuel | “bio-oil” |

| Database | Search Terms | Search String | No. of Articles | Search Date |

|---|---|---|---|---|

| Scopus | Primary search terms—title, abstract, and keywords | “pre-treatment techniques” AND “enzymatic hydrolysis” OR “hydrolysis” OR “conversion” AND “lignocellulosic” OR “lignocellulose” AND “lignocellulosic biomass” AND “biomass” OR “agricultural waste” AND “valorization” OR “waste conversion” OR “bioconversion” AND “biofuel” OR “bio-oil” | 1192 | 13 September 2024 |

| Google Scholar | Primary search items—title, abstract, and keywords | “pre-treatment techniques” “enzymatic hydrolysis”| “hydrolysis ”|“conversion” lignocellulosic “lignocellulose” “lignocellulosic biomass” “biomass ”|“agricultural waste” “valorization ”|“waste conversion ”|“bioconversion” biofuel “bio-oil” | 981 | 13 September 2024 |

| Crossref | Primary search terms—title, abstract, and keywords | “pre-treatment techniques” “enzymatic hydrolysis”| “hydrolysis ”|“conversion” lignocellulosic “lignocellulose” “lignocellulosic biomass” “biomass ”|“agricultural waste” “valorization ”|“waste conversion ”|“bioconversion” biofuel “bio-oil” | 1000 | 14 September 2024 |

| PubMed | Primary search terms—title, abstract, and keywords | “pre-treatment techniques” “enzymatic hydrolysis”| “hydrolysis ”|“conversion” lignocellulosic “lignocellulose” “lignocellulosic biomass” “biomass ”|“agricultural waste” “valorization ”|“waste conversion ”|“bioconversion” biofuel “bio-oil” | 1570 | 13 September 2024 |

| Semantic Scholar | Primary search terms—title, abstract, and keywords | “pre-treatment techniques” “enzymatic hydrolysis”| “hydrolysis ”|“conversion” lignocellulosic “lignocellulose” “lignocellulosic biomass” “biomass ”|“agricultural waste” “valorization ”|“waste conversion ”|“bioconversion” biofuel “bio-oil” | 231 | 14 September 2024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ntunka, M.G.; Khumalo, S.M.; Makhathini, T.P.; Mtsweni, S.; Tshibangu, M.M.; Bwapwa, J.K. Valorization of Lignocellulosic Biomass to Biofuel: A Systematic Review. ChemEngineering 2025, 9, 58. https://doi.org/10.3390/chemengineering9030058

Ntunka MG, Khumalo SM, Makhathini TP, Mtsweni S, Tshibangu MM, Bwapwa JK. Valorization of Lignocellulosic Biomass to Biofuel: A Systematic Review. ChemEngineering. 2025; 9(3):58. https://doi.org/10.3390/chemengineering9030058

Chicago/Turabian StyleNtunka, Mbuyu Germain, Siphesihle Mangena Khumalo, Thobeka Pearl Makhathini, Sphesihle Mtsweni, Marc Mulamba Tshibangu, and Joseph Kapuku Bwapwa. 2025. "Valorization of Lignocellulosic Biomass to Biofuel: A Systematic Review" ChemEngineering 9, no. 3: 58. https://doi.org/10.3390/chemengineering9030058

APA StyleNtunka, M. G., Khumalo, S. M., Makhathini, T. P., Mtsweni, S., Tshibangu, M. M., & Bwapwa, J. K. (2025). Valorization of Lignocellulosic Biomass to Biofuel: A Systematic Review. ChemEngineering, 9(3), 58. https://doi.org/10.3390/chemengineering9030058