2. Materials and Methods

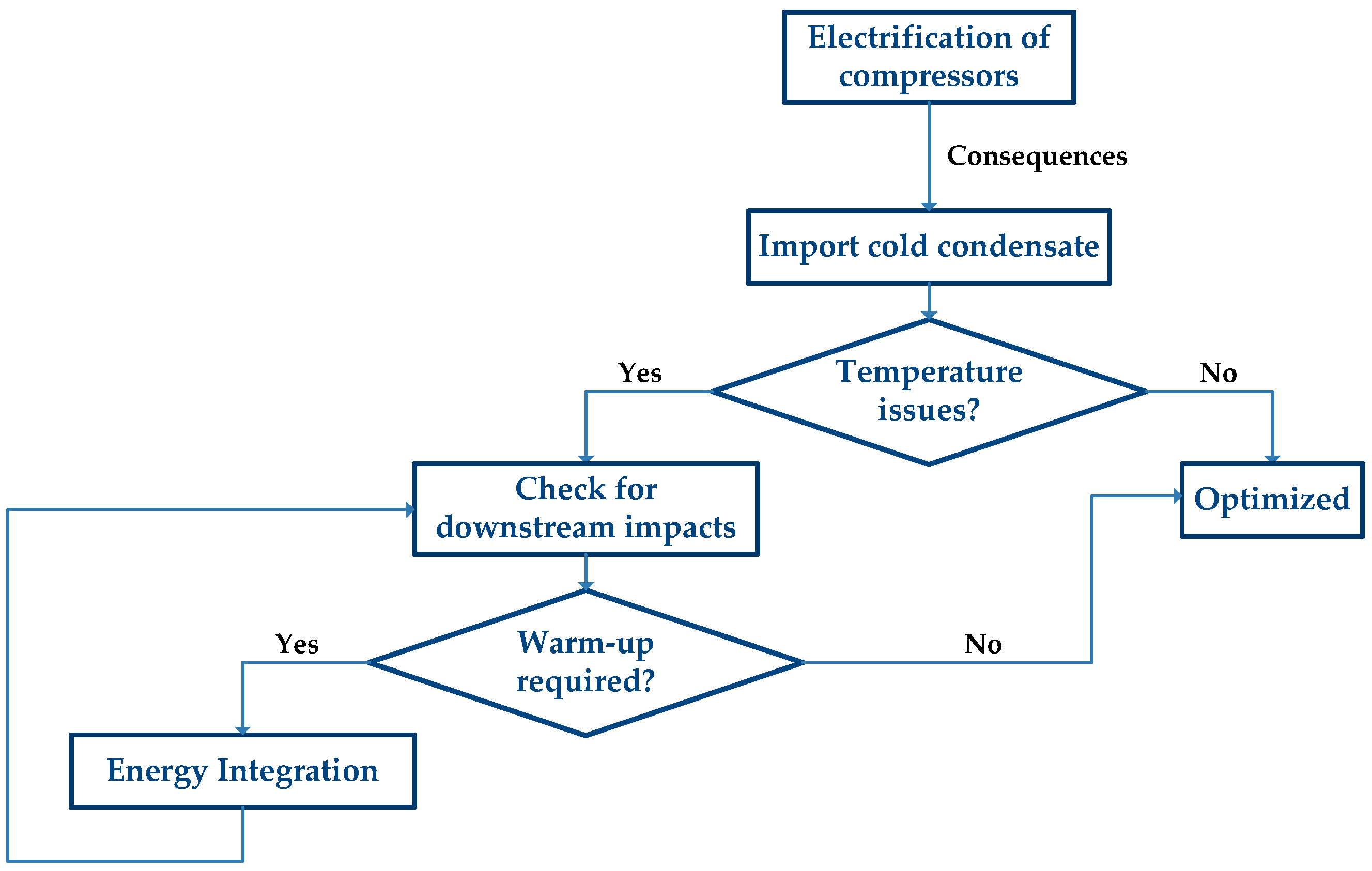

The case study was conducted following a series of discrete steps, which are grouped into larger stages (see

Figure 3).

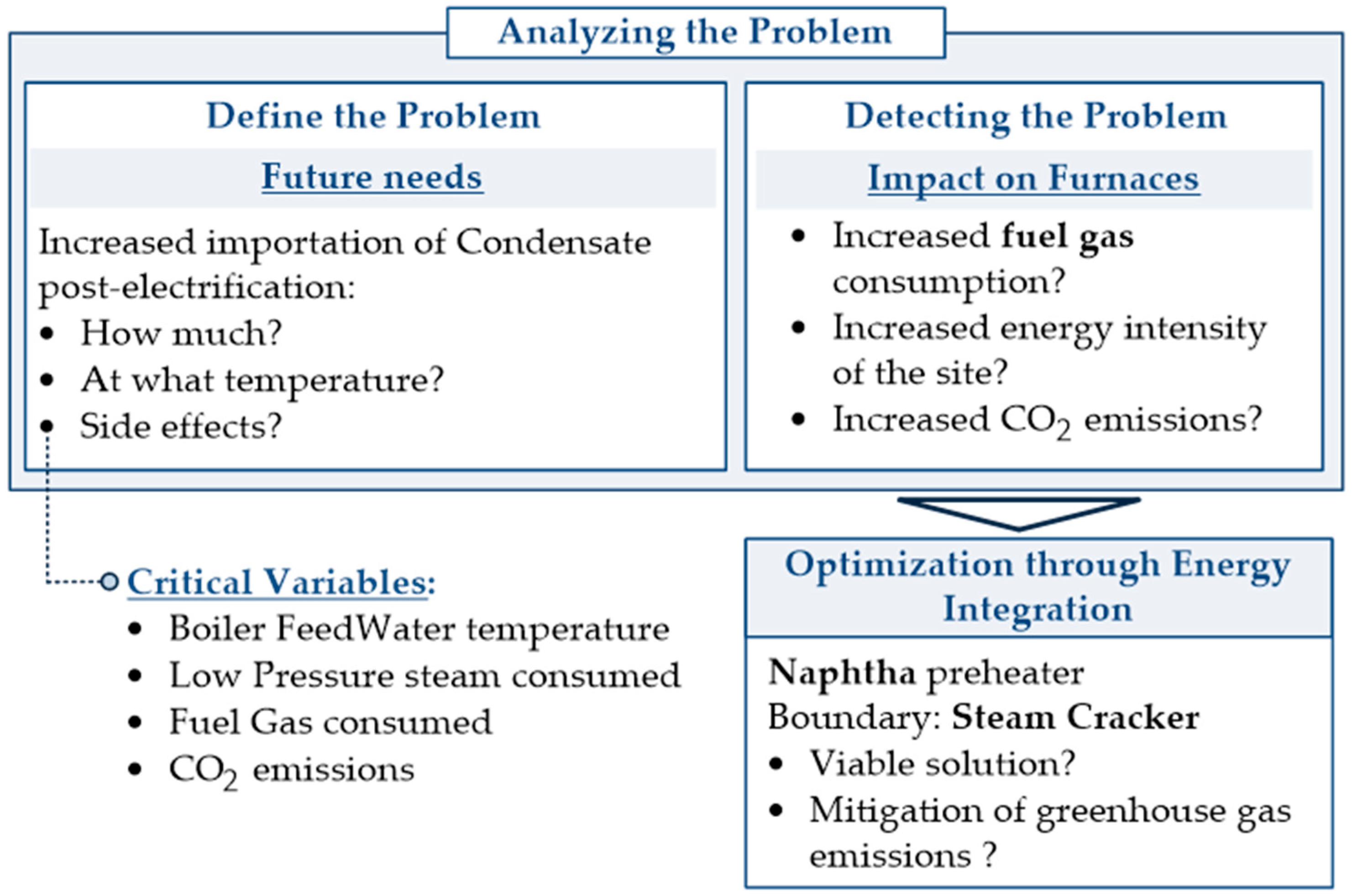

The problem analysis was delineated into problem definition and problem detection, as illustrated in

Figure 4. Problem definition pertains to the perception of the impact that electrification will realize. Problem detection refers to the identification of the root cause intended to be rectified through improvement actions. Within this parameter, energy integration is incorporated, aiming to correct potential deviations from the normal process.

For the development of this study, Aspen Hysys

® V11 software was employed to simulate the steam cracker’s BFW system before and after electrification (see

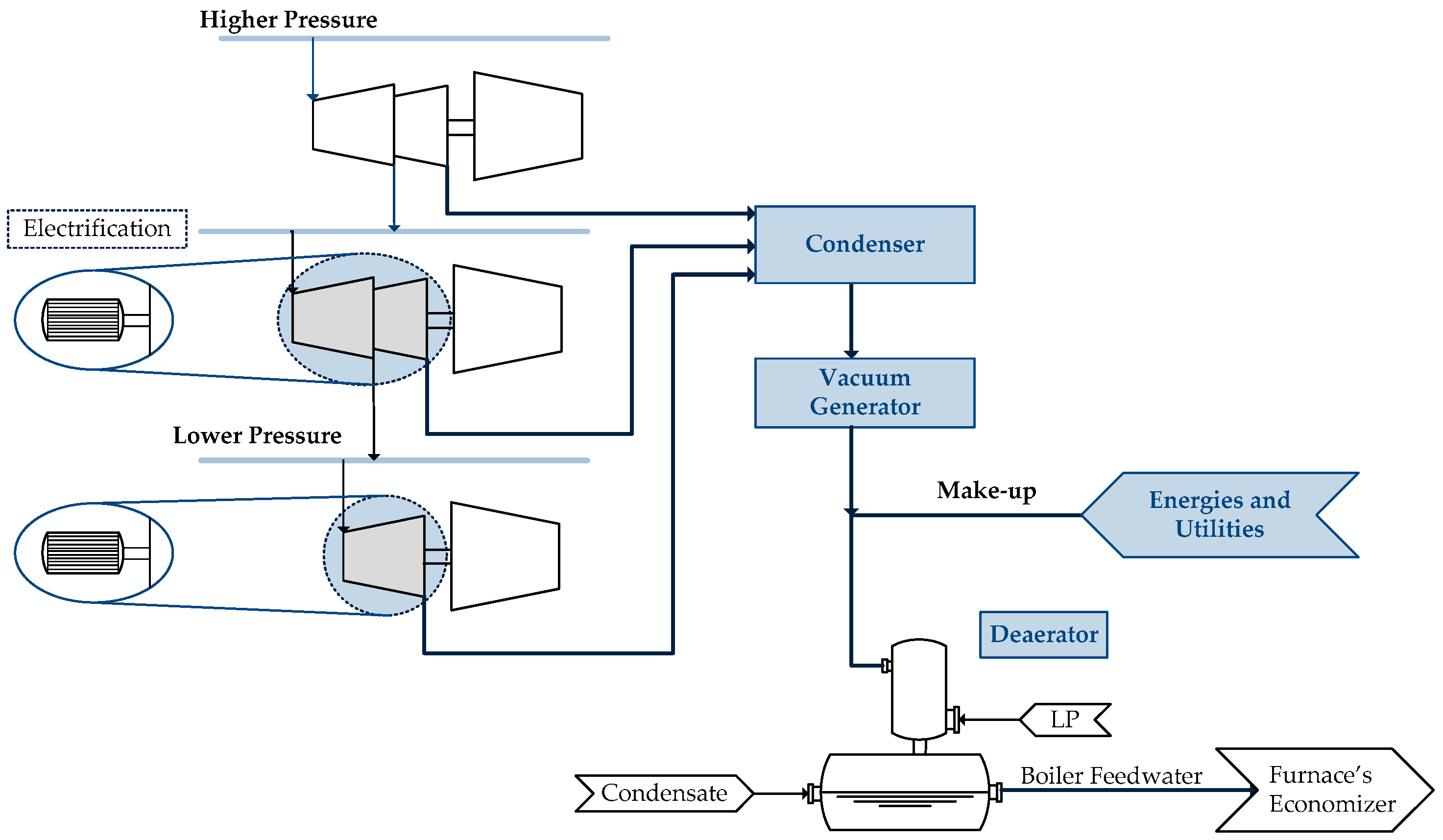

Table 1). The simulation of the steam cracker’s condensate network, prior to electrification, was conducted utilizing equipment specification data (illustrated in

Figure 2) and design conditions. Its validation was performed using actual operational values provided by the plant.

For the development of the simulation, only water was included as a component. Subsequently, the ASME Steam property package was employed, given its basis in the ASME 1967 steam tables. The associated limitation is the absence of inert gases or air in the simulation, as their presence can alter heat transfer within the air cooler, consequently reducing its efficiency. Operation was conducted under steady-state conditions, and energy loss in the piping was considered negligible, although certain equipment, such as the deaerator, would benefit from a more detailed analysis under transient conditions.

In terms of equipment mechanics, an air cooler was utilized as the condenser, chosen for its efficient heat exchange facilitated by its fin design and twelve fans. The number of fans can be adjusted according to the heat transfer requirements. Each fan has two operational modes: high and low power. In the post-electrification scenario, the air cooler exhibits oversizing due to the condensate flow rate, necessitating cooling being reduced by a factor of 2.3. As a consequence, it became feasible to optimize the air cooler through iterative adjustments to the quantity of operational fans and their respective power output. The optimization of the air cooler was effectuated through iterative modifications to the number of operational fans and their corresponding power output (high or low). Ergo, the indirect correlation between the air cooler’s operational capability and the energy expenditure of the fans was leveraged. Consequently, it was posited that the electrical energy expenditure (relative to the power output echelon of each fan) was commensurate with indirect carbon dioxide emissions. These emissions are classified under Scope 2 of CO2 emissions—encompassing purchased electricity for proprietary utilization. The inherent constraints within the air cooler simulation, when employing the rudimentary design functionalities of Aspen Hysys® V11, are attributable to the ambiguity surrounding the fan blade pitch, the recirculation of thermally elevated air returning to the intake flow, which consequently impairs operational efficacy, the ambient wind speed, and the precise arrangement of fans intended for activation at each designated power output stratum.

The first critical variable evaluated (see

Figure 4) was the BFW temperature. The thermal analysis of the BFW was conducted to forestall an escalation in fuel gas consumption within the furnaces. To this end, an energy balance calculation (see Equation (1)) was employed to ascertain the BFW temperature at the deaerator outlet under conditions where the imported cold condensate stream is not heated and no additional steam is consumed in the deaerator.

where

is flow rate (kg/h),

is the specific heat isochoric (kcal/kg°C),

T is temperature (°C),

is time (h),

and

specify enthalpy (kcal/kg),

is heat transferred (kcal/h), and

is work (kcal/h).

However, the main limitation of this programming model lies in the assumption of steady state (i.e., transient operation was not considered), according to Equation (2). The reference state considered was 25 °C, 1 atm, and water in the liquid state.

SPYRO suit 7 software was utilized to quantify two supplementary critical variables: the excess fuel gas consumed by the furnace as well as the resultant carbon dioxide emissions. The purpose of

Table 2 is to evaluate the CO

2 emissions typically emitted by a furnace, considering the combustion of fuel gas. The advantage of fuel gas lies in the fact that it uses a percentage of hydrogen (approx. 10–20%), which reduces CO

2 emissions. According to Chemical Reaction 3, the estimated ratio of CO

2 emissions per fuel gas consumed is 2.5.

To counteract the increased use of fossil fuels and the emission of greenhouse gases into the atmosphere, an energy analysis of the hot section of the steam cracker was conducted.

Initially, the SC unit was designed to consume only naphtha as a raw material. With industrial evolution, the furnaces were adapted to receive different raw materials, such as ethane and propane, as they have a higher yield in the cracking reaction for the production of ethylene and propylene [

38]. The amount of naphtha for cracking and co-cracking was moderated, and consequently, the preheating system was out of service most of the time. The repurposing of the idled heat exchanger was studied in this article.

The bottom of the Water Quench (see

Figure 1) is rich in quench water. Quench water is a process stream that inherently carries substantial energy due to its high flow rate. This stream is commonly utilized in steam crackers to preheat process stages, typically through process energy integration to recover the heat present in the quench water.

One of the streams preheated with quench water is the furnace-fed naphtha. However, this preheating system was designed for an exclusive naphtha feed scenario; therefore, this exchanger will be utilized to preheat the condensate streams. For this proposal, it was considered that the naphtha is fully preheated with the quench oil removed in the primary fraction. The heat exchanger was designed to work with quench water in the shell, while the dirtier fluid, naphtha, remains inside the tubes. In this case, it is proposed to replace the passage of naphtha with the condensate stream in the exchanger tubes.

The tool used was AspenEDR

® V11, as it allows for detailed equipment specification, approximating real-world operating conditions and resulting in more accurate and robust results. The ASME Steam property package was used, as the two fluids involved are again water. In this case, the characteristics of an existing heat exchanger were utilized. According to Tubular Exchangers Manufacturing Association standards, the heat exchanger type is a horizontal AES (removable bundle, internal split ring floating head) [

39].

Finally, economic analysis was conducted to forecast the project’s cost estimates. The global carbon dioxide emission balance is observed post-electrification and after the implementation of the present study’s improvement proposal.

3. Results and Discussion

3.1. Validation of the Steam Cracker Condensate Network

The validation of the steam cracker plant’s condensate network was executed for the pre-electrification scenario. Therefore, after network calibration, it becomes practicable to extrapolate the simulation to the post-electrification scenario. However, due to a confidentiality agreement, the precise operational values of the plant cannot be divulged. Notwithstanding this limitation, the simulation demonstrates a maximum error of 17%.

The BFW flow rate at the deaerator outlet has an error of 13% compared to the data sheet, resulting in a deviation of 25 t/h. This is primarily due to variations in condensate consumption by customers and condensate export. It was assessed that the most critical scenarios, exhibiting a relative error exceeding 10%, do not significantly impact the inlet temperature of the deaerator. Emphasizing the most critical scenarios, a 12% variation in the air cooler outlet temperature corresponds to a 9% variation in the vacuum generator outlet temperature, and a 15% variation in the vacuum generator outlet flow rate only impacts its outlet temperature by 2%.

Inasmuch as the computed relative error is diminished for parameters encompassing flow rate, temperature, and energy, it is posited that the simulation furnishes a propitious approximation of empirical reality and may be employed for the prognostication of prospective scenarios. Considering the utilization of an extant steam cracker facility operating under actual process conditions, the calibration of the simulation and the intrinsic mathematical framework of AspenTech’s suite were meticulously developed to closely approximate real-world behavior, thus substantiating the reliability of the derived results.

3.2. Effects of Reduced Condensate Post-Electrification

The simulation outcomes pertaining to the SC plant’s condensate network are presented in the form of ratios (pre-/post-electrification), with the objective of facilitating a more readily discernible comparison regarding the impact that the electrification of the compressors shall exert upon the BFW network.

Table 3 delineates the results expressed as a ratio comparing pre-electrification and post-electrification. Heat transferred by the condenser is significantly greater pre-electrification due to the vacuum expansion of the three turbines (which reduced the expansion by a factor of 2.30). The simulation of the condensate system concluded that condensate imports from the Energies and Utilities Plant (E&U) would increase by a factor of four, with approximately 60% of the imported condensate being cold condensate, relative to operational data. Furthermore, the energy balance revealed discrepancies in the BFW temperature at both the deaerator inlet and outlet, compared to the current operating data.

The temperature at the deaerator inlet and outlet are, approximately, 30% and 15%, respectively, higher before compressor electrification in the steam cracker. This temperature decrease will impact the BFW preheating stage at the furnace economizer level.

Section 3.4 studies the furnace process adaptations and their environmental impacts.

3.3. Condenser Optimization in Steam Cracker’s BFW System

Subsequent to the findings presented in

Section 3.2, the ratio of the condensate flow rate pre- and post-electrification undergoes diminution by a factor of 2.30. This consequential curtailment in the condensate supplied to the BFW network correspondingly mitigates the imperative for efficacious energy transfer across the air cooler.

As meticulously elucidated within

Section 2, the parameters susceptible to alteration comprised the aggregate of operational fans and their corresponding power output echelon. This resultant finding engendered the understanding that, contingent upon a diminished quantity of fans in service, the electrical energy expenditure is attenuated, a condition likewise observed with a lower power output echelon. The mean emission coefficient of carbon dioxide per unit of electrical energy expenditure within a designated geographical area was subjected to scrutiny. This coefficient facilitates the transformation between the curtailment in electrical energy consumption subsequent to electrification and the consequent indirect carbon dioxide emissions.

Table 4 illustrates a significant 60% decrease in carbon dioxide emissions when contrasting the air cooler dimensions prior to and subsequent to electrification. Post-electrification, the implementation of an optimized air cooler design facilitates a reduction in electrical energy requirements and, as a result, diminishes indirect CO

2 emissions. This ecological assessment elucidates a substantial incremental benefit within the carbon dioxide abatement trajectory, grounded upon the principles of Scope 2 emissions.

In this case, as the flow rate received by the condenser significantly reduces by half post-electrification, it is anticipated that the requirement for the number of fans will decrease as well as the electrical energy consumed for fan rotation. This scenario demonstrates an additional advantage to the electrification project, since an indirect reduction in CO2 emissions is expected due to lower energy consumption by the power plant.

In a broader context, the extent of steam expansion through the turbines will diminish proportionally to the quantity of electrified compressors. Nevertheless, the analysis concludes that a recalibration of the condenser within the boiler feedwater circuit is imperative, with the feasibility of parameter adjustments contingent upon the specific utility utilized (e.g., air, cooling water, process water).

3.4. Decarbonization

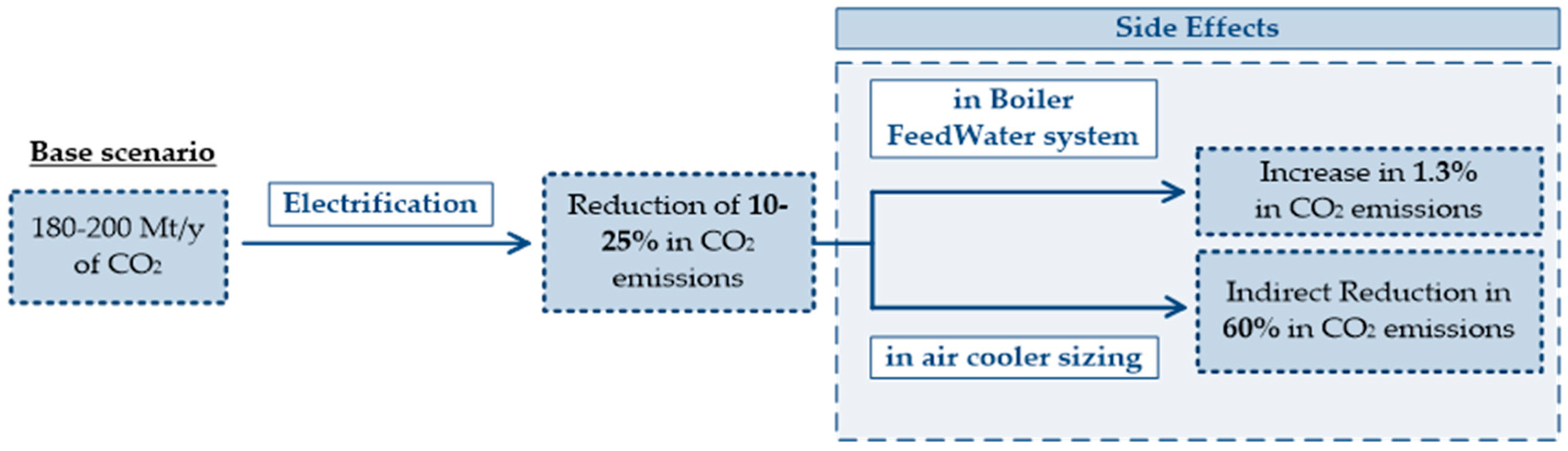

This section examines in detail the impacts of electrification on the condensate network and its downstream effects on the furnaces. While electrification is a valuable asset for the complex’s decarbonization, there are side effects on the deaerator inlet stream. The increase presented in

Table 5 is relative to the post-electrification scenario and demonstrate the bottleneck created by the electrification of the compressors. While the electrification scenario reduces approximately 10 to 25% of emissions [

14], an additional 1.3% increase in CO

2 emissions is expected.

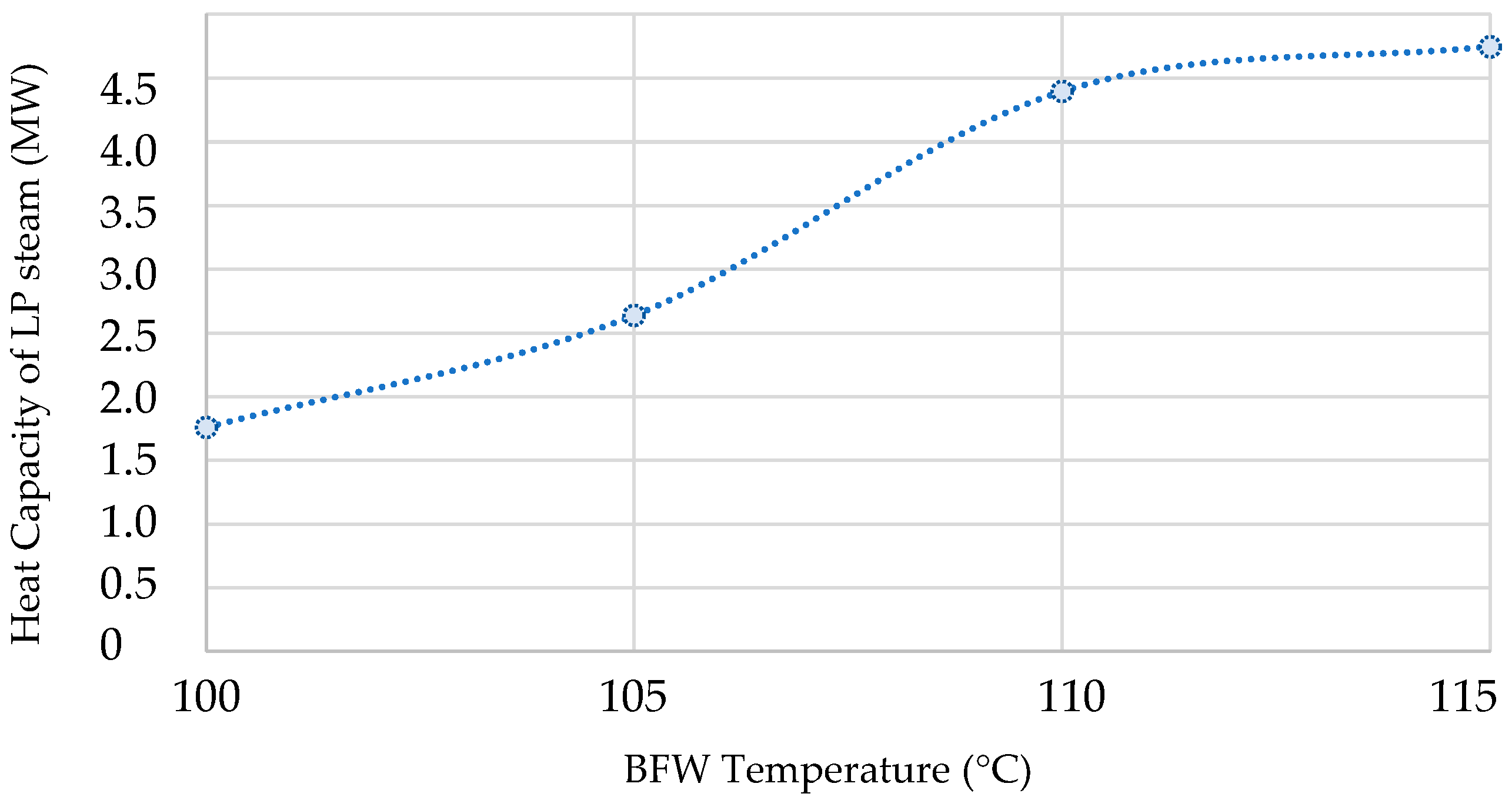

The temperature decrease may compromise the deaerator’s efficiency, as described in

Section 1.4. Following the energy balance performed on the deaerator with the simulation results, it was possible to predict the impact that the temperature decrease would have on the BFW temperature, FG consumption, and CO

2 emissions, using SPYRO, a furnace simulator. An increase in FG consumption in the furnaces can be observed (see

Figure 5) with the objective of raising the temperature at the furnace economizer level.

As observed in

Section 1.2, steam cracker plants tend to augment their carbon dioxide emissions in the order of millions of tonnes per annum. The initial phase involves the implementation of electrification, followed by the reduction in energy resources and the mitigation of associated CO

2 emissions. It was possible to compare the pre-electrification and post-electrification scenarios for CO

2 emissions exclusively taking into account the effects generated on the condensate system.

Table 6 examines the impact that the electrification of compressors will have on fuel gas consumption in furnaces due to BFW heating in the economizer. The viability of this analysis was attributed to SPYRO simulation, incorporating the precise conditions of the furnaces and the calibration of generated HP steam.

Despite this difference representing an insignificant fraction of the total annual CO

2 emissions (200 MtCO

2/y [

8]), it is a value that must be addressed to move closer to achieving the objectives of the Paris Agreement.

Table 7 delineates the impact of the findings upon the ratios derived from the literature. This marginal deviation manifests solely within the consequential domain of electrification.

In order to avoid increasing the ecological footprint through fossil fuel consumption, an energy integration strategy was utilized. An energy requirement of approximately 2035 kW is needed to heat the deaerator inlet stream when using only cold condensate, and 1824 kW for the total imported condensate. The implementation of a preventive measure requires immediate study upstream of the deaerator, as a result of equipment efficiency and operational constraints.

3.5. Process Integration

The next step involved repurposing the heat exchanger idled by the unit. This heat exchanger utilizes quench water in counter-current flow for its heat exchange. The simulation validation resulted in a heat transfer area error of 4%, resulting in a deviation of 12 m2.

The heat exchanger allocated in the SC with the newly proposed stream modification can be visually observed in

Figure 6. This is an effective and viable strategy for over-dimensioned steam crackers to crack a large amount of naphtha. Despite naphtha’s heat capacity being approximately two times lower than water’s, the thermal equilibrium of the quench water is not compromised.

A more conventional alternative would be the implementation of a new heat exchanger utilizing a hot utility, typically low-pressure (LP) steam. In this scenario, an energy equivalent to 1824 kW of steam would be required to heat the cold condensate stream. As all excess steam production is associated with CO

2 emissions, an increase of 4 tonnes of CO

2 per year is anticipated.

Table 8 is constructed for the conventional scenario employing a hot utility. The steam price is contingent upon the fossil fuel cost, the steam type (in this case, LP), and the boiler efficiency [

41]. For this case study, values from the Aspen Hysys

® simulation were utilized.

As discussed in

Section 1.2, in a scenario where emissions range between 180 and 200 MtCO

2/y [

8,

9], equipment electrification contributes to a reduction of 10 to 25% in emissions [

14]. In the present case study, an alternative to CO

2 emissions caused by low temperatures in the condensate system is further implemented, and a solution for energy integration with process streams, as opposed to the use of external utilities, is investigated. Thus, it is possible to further reduce CO

2 emissions by 1.3% as well as fuel gas consumption by 1.8%. Through the study of energy integration, a reduction of 1824 kW in hot utilities was achieved.

Economic Analysis

As this heat exchanger is already integrated into the plant’s process, the final concept would involve only modifying the piping, studying the piping material, and performing periodic maintenance. The investment allocated to the modifications that the exchanger will undergo is approximately EUR 135,000, as only the expenditures for piping alterations, the addition of fittings, control valves, and instrumentation were considered. The marginal augmentation of 1.3% in carbon dioxide emissions engenders consequential emission levies, coupled with a foreseeable 1.8% elevation in fuel gas consumption within the combustion chambers. Notwithstanding the proprietary nature of the corporation’s strategic framework, an anticipated financial advantage of circa EUR 2.3 million is forecasted upon the deployment of energy integration protocols. Regarding the environmental benefits, there is the possibility of reducing costs associated with CO

2 emissions and decreasing fuel gas consumption. The advantages of the case study are shown in

Table 9. As may be discerned, the payback period demonstrates commendable values; consequently, it is inferred that this undertaking possesses economic viability. The determination of the payback period was rendered practicable by virtue of the projected capital outlay for the heat exchanger conduit modification, the basis of which was the application of established engineering heuristics.

3.6. Deaerator: Consuming Excess of LP Steam

Industrial deaerators utilize low-pressure steam injection. The objective is to provide maximum agitation and contact between the steam and water flows to elevate the water to the requisite temperature. The incoming steam further serves to conduct the following [

35]:

An evaluation was conducted regarding the feasibility of augmenting LP steam injection into the deaerator to regulate the imported water temperature (see

Figure 7). Applying an energy balance to the deaerator, it was determined that 4396 kW of LP steam would be necessary to attain an optimal BFW temperature of 110 °C.

This represents an approximate three-fold increase in steam injection compared to the data sheet scenario, resulting in increased boiler steam generation, around 3.8 times. In accordance with the investigation presented in

Section 3.3, the augmentation of steam generation leads to consequential carbon dioxide emissions. A commensurate analysis was executed to determine the thermal energy cost arising from the steam differential within the deaerator (see

Table 10).

Notwithstanding operational expenditures, an overabundance of injection into the deaerator can precipitate equipment inefficiency. This phenomenon is attributable to the augmented volume of vented steam; the equipment may prove to be inadequately dimensioned for these altered conditions, thereby potentially inducing flooding and impeding the efficacious removal of dissolved gases. A sensitivity analysis of oxygen affinity in water should be performed according to the temperature profile in the deaerator to promote the remotion efficiency.

3.7. Overview of Global CO2 Emissions: A Balanced Perspective

The case study investigates the benefits and delineates the side effects of compressor electrification within the steam cracker facility. Although substantial and foreseen advantages concerning greenhouse gas emissions are anticipated with electrification, its repercussions necessitate scrutiny and, despite being diminished, mitigation.

Figure 8 provides a synopsis of the executed study.

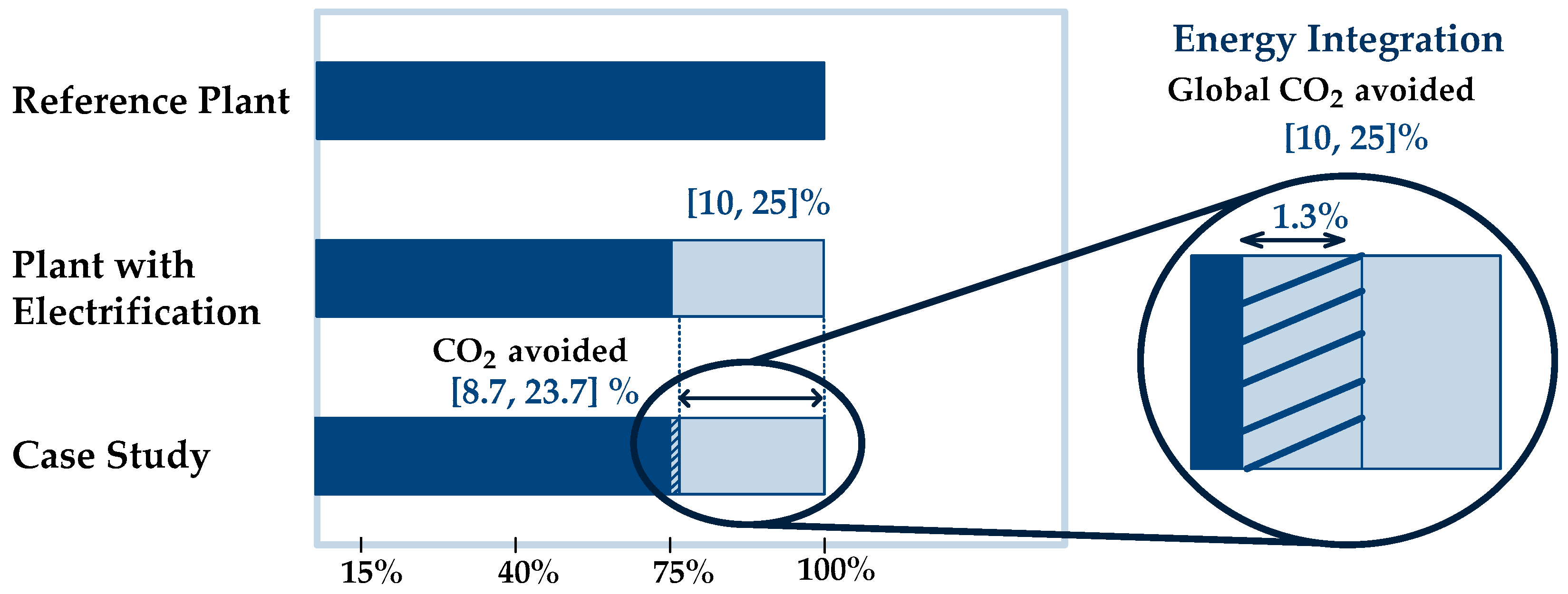

Therefore, the overall result of electrification is positive, with an expected substantial reduction in carbon dioxide emissions, despite downstream repercussions on the condensate network (see

Figure 9). As this study emphasizes the reduction in CO

2 emissions from the secondary effects of electrification, and employing energy integration, the annual ecological footprint’s impact has been entirely mitigated. The emission reduction values used for electrification were derived from the literature.

As depicted in

Figure 9, electrification exerts a considerable influence on CO

2 emissions, exhibiting a range of 10–25%, as documented in the literature [

14]. The effects on the condensate network represent a mere 1.3% fraction of the CO

2 emissions increase. Owing to the possibility of mitigating this GHG emissions increase through site energy integration, the total CO

2 balance is determined to be 25%.

4. Conclusions

This study originates from the compressor electrification project in a steam cracker plant, which resulted in an approximate 2.3-fold reduction in the expanded steam flow to the condensate system. This case study demonstrates the capability to introduce versatility into plants designed for high-volume naphtha processing, thereby rendering the process continuous, self-sufficient, and more competitive within the market.

Key aspects of this investigation include the condensate network simulation and energy integration aimed at preheating the imported cold condensate stream. For this purpose, the condensate network was simulated using Aspen Hysys® V11, employing data sheet conditions and the ASME Steam property package. Subsequent validation and calibration with operational conditions and historical data yielded a maximum error of 17%. Consequently, it was determined that a four-fold increase in condensate importation from the Energies and Utilities Plant (E&U) was needed. This importation revealed an increase in fuel gas (FG) consumption of 1.8% and a 1.3% increase in carbon dioxide (CO2) emissions, attributed to the low temperature of the condensates, resulting in annual costs of EUR 2.3 million.

The aforementioned increase in CO2 emissions manifests as an augmentation of 905.2 metric tonnes of CO2 per annum; concurrently, the fuel gas increment corresponds to an additional energy expenditure of 795.4 kW/furnace. Accordingly, energy integration methodologies were adopted to remediate this divergence. The energy integration involved a simulation within AspenEDR® V11, utilizing the specifications of a designated heat exchanger and the ASME Steam property package. The repurposing of an existing heat exchanger facilitated a reduction of 1824 kW in hot utilities (e.g., LP steam). The heat exchanger must be installed upstream of the deaerator to maintain the functional integrity of this equipment and to ensure undiminished performance and efficiency in the removal of dissolved gases.

Adjustments were implemented on the condensate network equipment, and a reduction in electrical energy consumption at the condenser is anticipated, yielding a 60% decrease in CO2 emissions, given that this equipment, subsequent to electrification, was over-specified.

In conclusion, a balance of carbon dioxide emissions was performed, and it was determined that the compressor electrification project for the steam cracker can reduce atmospheric CO2 emissions by up to 25%. Considering the collateral impact on the BFW network, a reduction of only 23.7% was initially projected. However, this discrepancy (1.3%) was effectively addressed through energy integration, resulting in a positive overall balance.

This methodology enhances the plant’s independence from external energy sources. While energy integration constitutes an industrial methodology that significantly contributes to the achievement of the Paris Agreement objectives and the tenets of the circular economy, further advancements are imperative. The subsequent phase will involve the implementation of green energy initiatives, encompassing electric furnaces, fuel gas with an elevated hydrogen content, the utilization of green hydrogen, and electricity derived from renewable sources.