1. Introduction

The flotation of fine particles in a fluid is crucial for mineral separation in the mining industry [

1,

2]. The effect of the particle size, pulp density, air flowrate, and impeller speed on the flotation performance is very important. The recovery of coarse and fine particles in flotation is generally controlled by a combination of bubble–particle attachment and detachment [

3,

4,

5,

6]. Multiple factors influence flotation behavior, including the particle shape and size, contact angle, and wettability [

7,

8,

9]. Extensive research has focused on particle floatability and lateral capillary interactions [

10,

11]. In the field of liquid wetting dynamics, Gao [

12] demonstrated the existence of a maximum wetting speed through thermodynamic analysis, while Liu et al. [

13] developed a method to estimate the critical fall height in film flotation, considering the effects of the three-phase contact line velocity. Recent studies have explored the manipulation of floating states through three-phase contact line control, with particular applications in micro-objects [

14]. Extensive experimental investigations have been carried out on the flotation of both single sphere and multiple particles at a free surface [

11,

13,

14,

15,

16,

17].

When two or more particles undergo flotation, hydrodynamic interaction can become important. The viscous force usually dominates in cases where fine particles are used in flotation, which leads to high liquid viscosity, or at high particle velocities, which is the case for fine flotation. The buoyancy force and the distortion of the shape of the liquid bridge due to gravity can be neglected for particle sizes less than 1 mm, which is the case for fine flotation. When a spherical object rises, the fluid surface deforms around the particle under the combined action of gravity, buoyancy, and capillary forces. Due to the highly nonlinear nature of the Young–Laplace equation and the requirement for a force balance on the particle, most research has focused on numerical solutions [

18,

19,

20,

21,

22,

23]. Previous attempts have been made to develop analytic solutions for the distorted free surface around the particle [

24,

25]. This research seeks to obtain explicit analytical solutions that describe the equilibrium shape of the free surface, expressed as a function of both the density ratio and the three-phase contact angle. A key challenge lies in determining the filling angle

, which is governed by the balance between body forces and capillary forces, the latter becoming increasingly significant for smaller particles [

19,

21,

22]. The force balance on a spherical particle at the interface provides a constraint for determining the three-phase contact points.

In flotation problems, two characteristic length scales are typically employed: the particle radius

and the capillary length

. Vella et al. [

26] utilized the capillary length to make all lengths dimensionless in an axisymmetric geometry and approximated the maximum density for flotation in terms of the contact angle for small particle radii. For analyzing particle-induced deformation, using the particle radius as a length scale proves more appropriate [

27]. Since the capillary length exceeds the particle radius in fine particle flotation, the ratio of these length scales serves as a perturbation parameter for obtaining approximate solutions. Previous studies have sought analytic solutions for the meniscus around a cylinder using matched asymptotic expansions [

28,

29]. In these analyses, the particle radius was used to derive the inner solution near the particle, while the capillary length determined the outer solution far from the particle.

The method of matched asymptotic expansions provides an efficient approach to solving singular perturbation problems. This technique employs separate expansions for regions near and far from the object of interest, deriving successive solutions with undetermined coefficients, where each expansion satisfies a distinct set of physical boundary conditions. The final asymptotic solutions are determined through a matching procedure for the undetermined coefficients. Proudman and Pearson [

30] applied this approach to obtain higher order approximations for the flow past a sphere and circular cylinder at small non-zero Reynolds numbers. Following Van Dyke’s development of efficient asymptotic matching principles, the approach has been successfully applied across various fields in fluid mechanics [

31,

32]. James [

28] and Lo [

29] both used asymptotic expansions to find analytical solutions that determine the shape of the meniscus near the surface of a floating cylinder. The particle radius is used as a length scale to derive the inner solution near a particle, while the capillary length is used to obtain the outer solution far from the particle. James [

28] employed the method of matched asymptotic expansions to determine the meniscus profile on the outside of a vertical cylinder. However, Fraenkel [

33] warned that erroneous results can occur when the gauge functions in the asymptotic expansions combine powers and logarithms of the perturbation quantity. Subsequently, Lo [

29] corrected the second approximation for the meniscus height by taking Fraenkel’s warning into consideration.

This study analyzes the meniscus around a floating particle using an analytical approach, offering a new perspective for understanding the behavior of micro-particles at the interface. This is significant for designing efficient mineral separation processes and controlling the buoyancy of micro/nano-scale objects. The method of matched asymptotic expansions effectively addresses singular perturbation problems by separately handling areas close to and far from the target region. This method provides high-order approximate solutions and ensures the consistency of solutions through matching. In this study, we have made corrections to mitigate potential errors from combining power and logarithmic functions, as noted in Fraenkel’s warning, ensuring solution accuracy.

2. Problem Statement

This work aims to derive asymptotic solutions using matched asymptotic expansions for the Young–Laplace equation describing the meniscus induced by a spherical floating particle. This section focuses on deriving asymptotic solutions for regions both near and far from the spherical floating particle, where the particle’s depth from the unbounded free surface and the filling angle are determined through numerical iteration.

A spherical particle with a radius of

is suspended at the deformable free interface under the action of gravity, as shown in

Figure 1, where the densities

,

, and

represent the upper fluid, lower fluid, and spherical particle, respectively.

is the contact angle, and

is the filling angle. Additionally,

is the angle measured from the horizontal plane and equals

based on the geometrical information.

y is the vertical coordinate, and the free surface is described by a function of the lateral coordinate

x. The axisymmetric free surface around a spherical particle is governed by the Young–Laplace equation as

where

is the surface tension between the two fluids.

Two boundary conditions are given by

In this formulation,

is the vertical position between the triple contact point and the unbounded free surface. This depth is subsequently determined by the balance of forces acting on the particle, including gravity, buoyancy, and the capillary force.

The matched asymptotic approach is applied to solve Equation (

1) with the boundary conditions Equations (

2) and (

3). Using the particle radius

as a length scale for non-dimensionalization, i.e.,

,

, the governing equation for the inner region from Equation (

1) can be recast into

where

is defined by the ratio of the particle radius to the capillary length,

, and serves as a perturbation parameter. Note that

denotes the Bond number,

, which is normally less than unity, and Equation (

4) is valid only in the region close to the floating particle. The normalized boundary condition can be written as

For the outer solution far from the particle, we apply the capillary length to scale

x while maintaining

y scaling with

, i.e.,

and

, which, when applied to Equation (

1), yields

The corresponding boundary condition is

Following Fraenkel’s warning [

33], the inner and outer solutions are assumed to have the form

The undetermined coefficients in each inner and outer solution are determined by Van Dyke’s matching principle [

32]:

Here,

and

represent the

i-term outer and inner expansions, respectively, where

i is an integer.

2.1. The First Approximation

The second-order differential equation for the outer solution of

from Equation (

6) can be obtained by neglecting all terms containing

as

The solution satisfying the boundary condition

at

is

where

is a solution of the modified Bessel function of the zeroth order and

is an undetermined constant that must be matched with the inner solution. It should be noted that

behaves like a logarithm at a small

t, i.e.,

where

is the Euler constant. Consequently,

in the inner region can be represented by

and

since

. Based on the information from the outer solution, we can express

The equation for

can be derived from Equation (

4) as

Letting , an integration yields

With the boundary condition

at

, the integration constant becomes

.

The resulting general solution for

is

To determine the undetermined constants and , the matching principle of is applied to the solutions of . Using the asymptotic behavior of the modified Bessel function of the second kind, at a small Z, the matching rule yields

This gives

and

. Therefore, the solution for

from the matching principle is

Comparing this with Equation (

14) yields

and

, where

.

2.2. The Second Approximation

For the inner solution, we assume that has the following form:

Upon substituting Equation (

21) into Equation (

6) and collecting terms up to

, the equations for

,

, and

take the form

Applying identical boundary conditions to these three equations, namely that the first derivatives with respect to

z vanish at

, the solutions for

,

, and

are

where

Detailed derivations are provided in

Appendix A. Consequently, the inner solution

up to

can be expressed as

Here, the integration constants

will be determined by matching them with the outer solutions.

For the second approximation of the outer solution up to

, substituting Equation (

9) into Equation (

6) yields

The solution for

is readily obtained as

For a small

Z and with the boundary condition

at

, the general solution is

Therefore, the outer solution

takes the form

The derivation of Equation (

33) is provided in

Appendix A.

Following the matching principle,

and

are derived as

By comparing the coefficients between Equation (

35) and Equation (

36), we obtain

The complete expression for the equilibrium configuration, denoted by

, can be represented by

The normalized total force,

, acting on the floating particle vanishes at the static equilibrium condition [

27]:

where

D is the density ratio

and

, as shown in

Figure 1. The first term represents the capillary force, the second and third terms represent the net buoyancy force, and the last term represents the gravity force. The normalized depth

is given by

At the triple contact line, i.e.,

, the following condition must be satisfied:

Given the density ratio, perturbation parameter, and contact angle, the first error, , is determined by using an initial guess for the filling angle , and the second error, , is computed similarly. The filling angle is then updated using the Newton–Raphson rule:

The computation continues until the error

falls below the tolerance of

. The inner, outer, and final asymptotic solutions for the deformed free surface are then computed with the final

to generate the plots in

Section 3.

At the three-phase contact line, substituting the position of the contact line into the inner solution of Equation (

29) corresponds to the depth obtained from the force balance on the particle in the vertical direction given by Equation (

40). This relationship provides insight into the sinking or floating behavior in terms of

,

,

, and

D, where

must be determined iteratively with the other parameters fixed.

We define as

where

,

, and

.

The particle can maintain its position at the free interface when

.

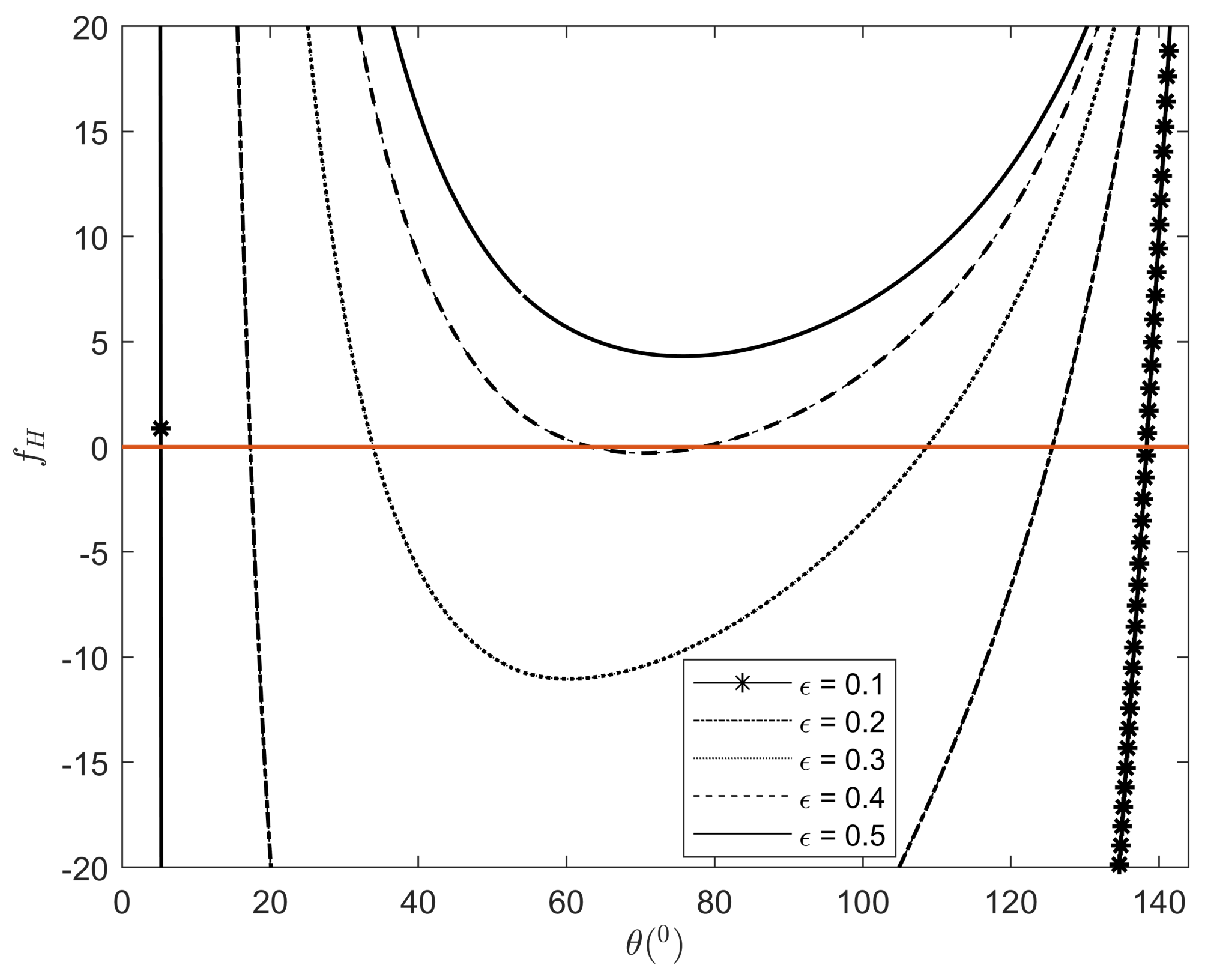

Figure 2 demonstrates the existence of two steady-state equilibrium configurations as a function of

for a fixed contact angle and density ratio, where

and

represents a hydrophilic case and

represents a hydrophobic case. The figures reveal two steady interface configurations at a small

, but no solutions exist for a large

. This occurs because increasing

allows a particle to be more easily pulled off the interface due to the net body force exceeding the capillary force. The stability of each steady interface configuration will be examined in the next section. For a hydrophobic particle (

), the probability of flotation is much larger. This phenomenon will be analyzed in detail in

Section 3.

2.3. Stability Analysis of Steady Configuration

From

Figure 2, we observe that two solutions exist, satisfying the condition of

. To distinguish between stable and unstable steady solutions, we examine small displacements in the vertical direction

y for each equilibrium solution. With

and

, where the superscript ∗ denotes evaluation at a small displacement of

, the unbalanced force acting on the particle becomes

We define the net unbalanced force as . The system achieves stability when becomes positive for any negative displacement or negative for any positive displacement, i.e., , as the net force opposes the displacement. Therefore, stable configurations are characterized by negative values of .

The net unbalanced force can be expressed as a truncated series in

:

Since

,

takes the form

Figure 3 and

Table 1 demonstrate the existence of two steady-state particle–interface configurations as a function of

, for

and

. The results indicate that two steady interface configurations exist only below

, beyond which no steady configurations exist. In this case,

lies between

and

. For particles with a large

, the magnitude of the net buoyancy force can exceed that of the capillary force.

The stability analysis reveals that the steady interface shape with negative

values (

Table 1) represents the stable configuration. The function

provides crucial information about the maximum values of

and

. This investigation focuses on the steady particle–interface shapes characterized by negative values of

. The limitations in Lee’s previous work [

27] stemmed from two factors: the computation of unstable solutions due to the improper selection of initial values in the numerical analysis, and the inability to verify the existence of dual solutions through differential equation methods.

2.4. Numerical Solution

In this section, we describe the numerical implementation method used to validate the asymptotic solutions. We introduce the parameter

as the angle of meniscus inclination, defined by the relation

. Using this parameterization, Equation (

1) can be decomposed into two ordinary differential equations:

where

is given by

Detailed derivations can be found in [

27,

34].

Applying the non-dimensionalization and yields

Here,

is the Bond number, which is equivalent to

discussed in the previous section. At the three-phase contact point

where

, the boundary condition Equation (

2) becomes

The far-field boundary condition as

approaches zero is

Following [

27], we obtain numerical solutions using Chebyshev nodes for the discretization of

. The calculations for

X and

Y proceed iteratively until the value of

at the last Chebyshev node falls below the tolerance of

. The position of the contact line

is determined relative to the unbounded flat interface, which is zero in the vertical direction. This approach of transforming the nonlinear equation into two ordinary differential equations parameterized by the inclination angle and discretization using Chebyshev nodes provides enhanced resolution near the triple contact points and at the infinity boundary [

27]. This numerical solution was validated against Singh’s experimental data [

22], showing agreement within 10% for different cases [

27].

3. Results

We begin by comparing three different approaches: the matched asymptotic expansion, our numerical solution, and the classical numerical results of [

18], as shown in

Table 2. The comparison uses the following parameters: the density ratio

, particle radius

mm,

, and contact angle

. The matched asymptotic solutions from Equation (

29) and Equation (

38) show excellent agreement with the numerical results from Equation (

49) for both the filling angle,

, and the depth from the unbounded free surface,

, despite showing small differences from the numerical results of [

18]. Here,

represents the normalized depth at

, which will be discussed in detail later.

To further evaluate the accuracy of the matched asymptotic expansion, we calculated the filling angle

and the depth

for different values of

while maintaining fixed conditions of

and

. These results are summarized in

Table 3.

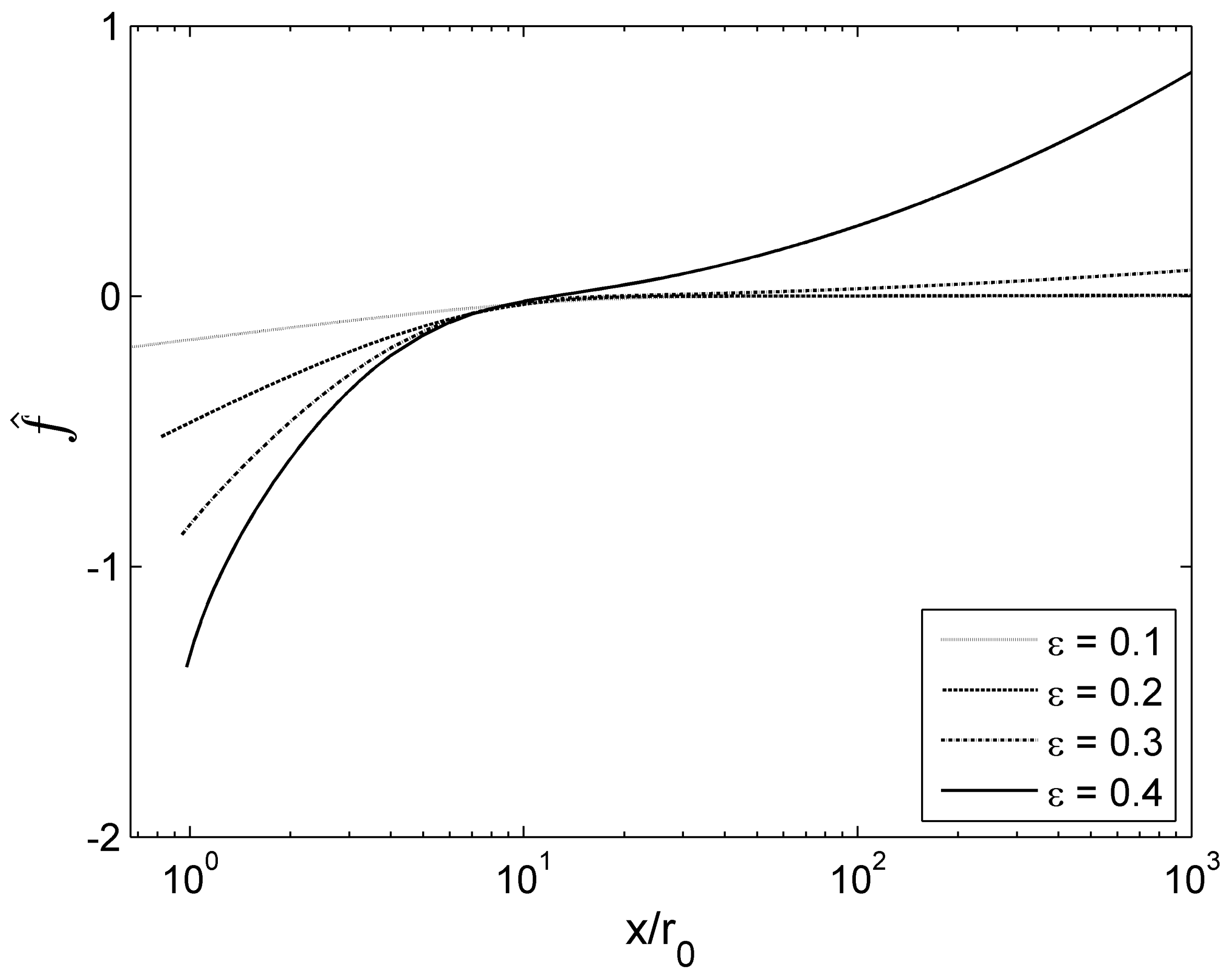

Figure 4 illustrates the matched asymptotic solution

for different values of

. The results demonstrate that the matched asymptotic solution maintains good accuracy across all values of

. While

Figure 4 reveals some discrepancies far from the particle for moderate

values, the solution provides excellent predictions for the filling angle

and the depth

near the particle, even at moderate

values.

To check the difference between the inner solution

f and the composite solution

, Equation (

38) can be expressed as

Therefore, near the particle at a small

, the difference reduces to only

terms, resulting in quite small values. Although the

terms contain components of

z,

,

, and

, their effect is negligible at a small

.

To examine the difference far from the particle, Equation (

38) can be rewritten as

As

z approaches infinity, the difference is again limited to only

terms. However, unlike the near-particle case, the effect of the

terms becomes significant. This occurs because

z,

,

, and

exhibit divergent behavior at infinity. Consequently, the graph with

in

Figure 4 shows divergence at a large

z. However, no divergence occurs in

for a sufficiently small

. When focusing on the filling angle and depth induced by a submerged particle, the matched asymptotic expansion provides satisfactory solutions even at a large

, as shown in

Table 3. This accuracy is maintained because

and

are determined at the contact line on the particle, not far from the particle.

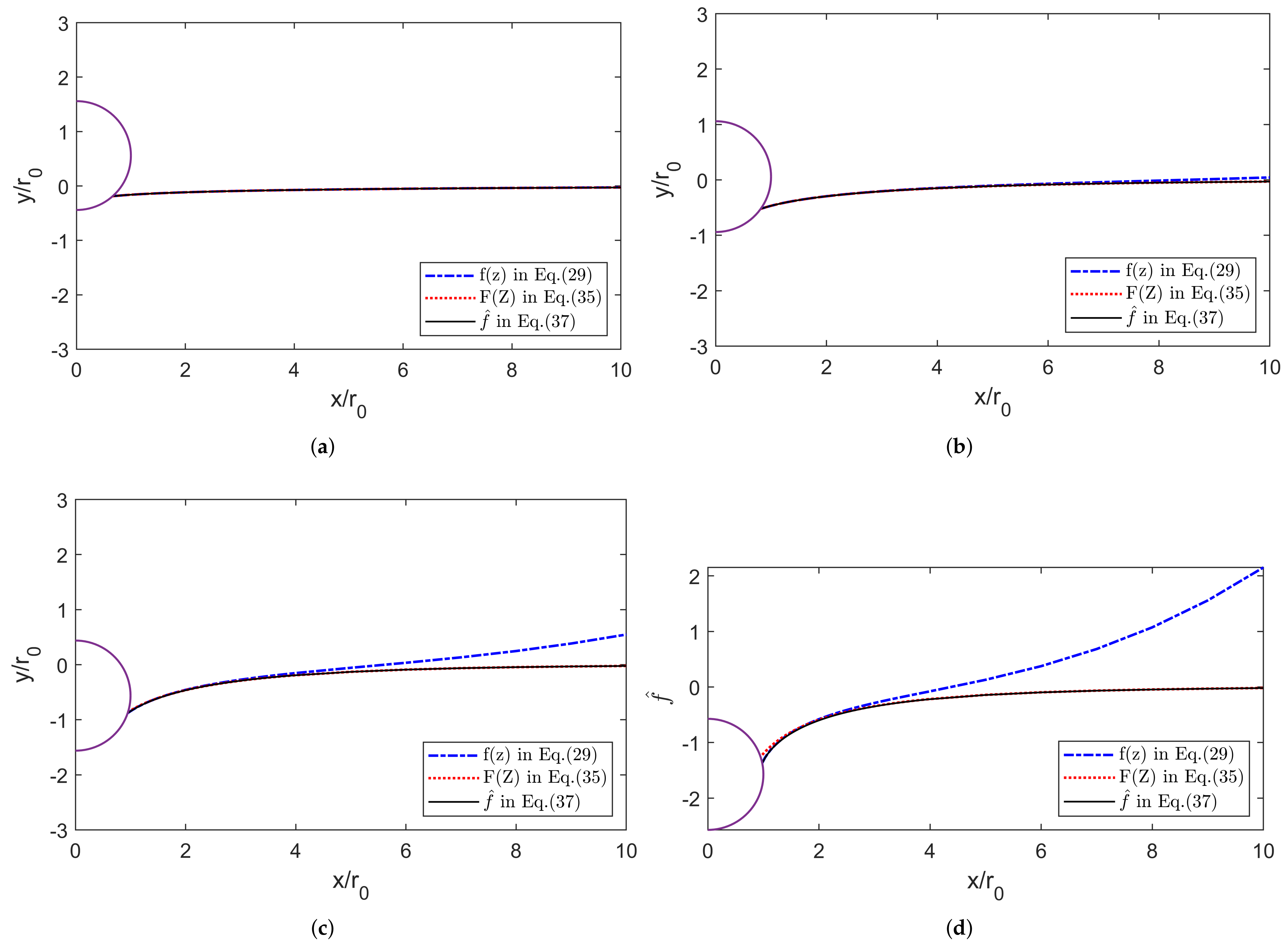

Figure 5 presents the inner (

f), outer (

F), and composite (

) asymptotic solutions with

and

. The inner solution

f agrees with the composite solution

near the particle; however, it diverges as

z approaches infinity for a large

, as shown by the dash-dotted line. The outer solution (dashed line) demonstrates excellent agreement with the composite solution in all regions, including at the unbounded free surface. For all cases, the asymptotic solution

within

approaches the unbounded free surface

asymptotically.

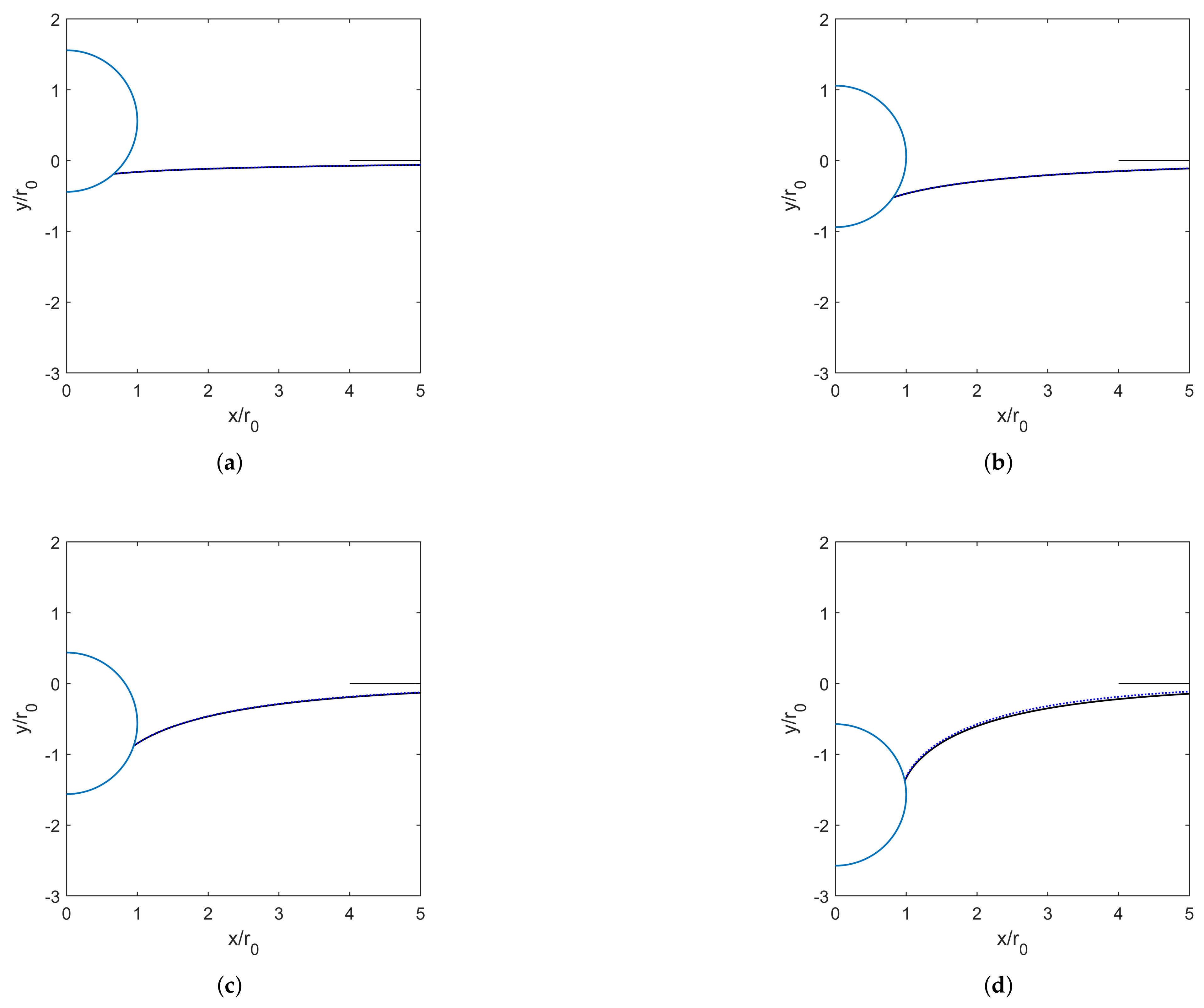

Figure 6 illustrates the surface trajectory deformed by a solid particle under the same conditions as

Figure 5. The asymptotic solutions

for different

values are compared with numerical results (represented by the dashed line). As

increases, the interface exhibits stronger curvature near the particle, and the depression depth of the submerged particle increases. Within the region

, both equilibrium configurations show excellent agreement. These results demonstrate that the matched asymptotic solutions accurately predict the equilibrium particle–interface configuration for a floating particle.

By comparing numerical and analytical methods, we observed that the particle radius to capillary length ratio () significantly affects stability. Smaller values of favor stability at the interface, while larger values may cause the particle to detach. Additionally, the contact angle () impacts buoyancy behavior, particularly for hydrophobic particles ( close to 0.8), which are more likely to float compared to hydrophilic particles ( close to 0.2).