Characterization and Thermal Evaluation of a Novel Bio-Based Natural Insulation Material from Posidonia oceanica Waste: A Sustainable Solution for Building Insulation in Algeria

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

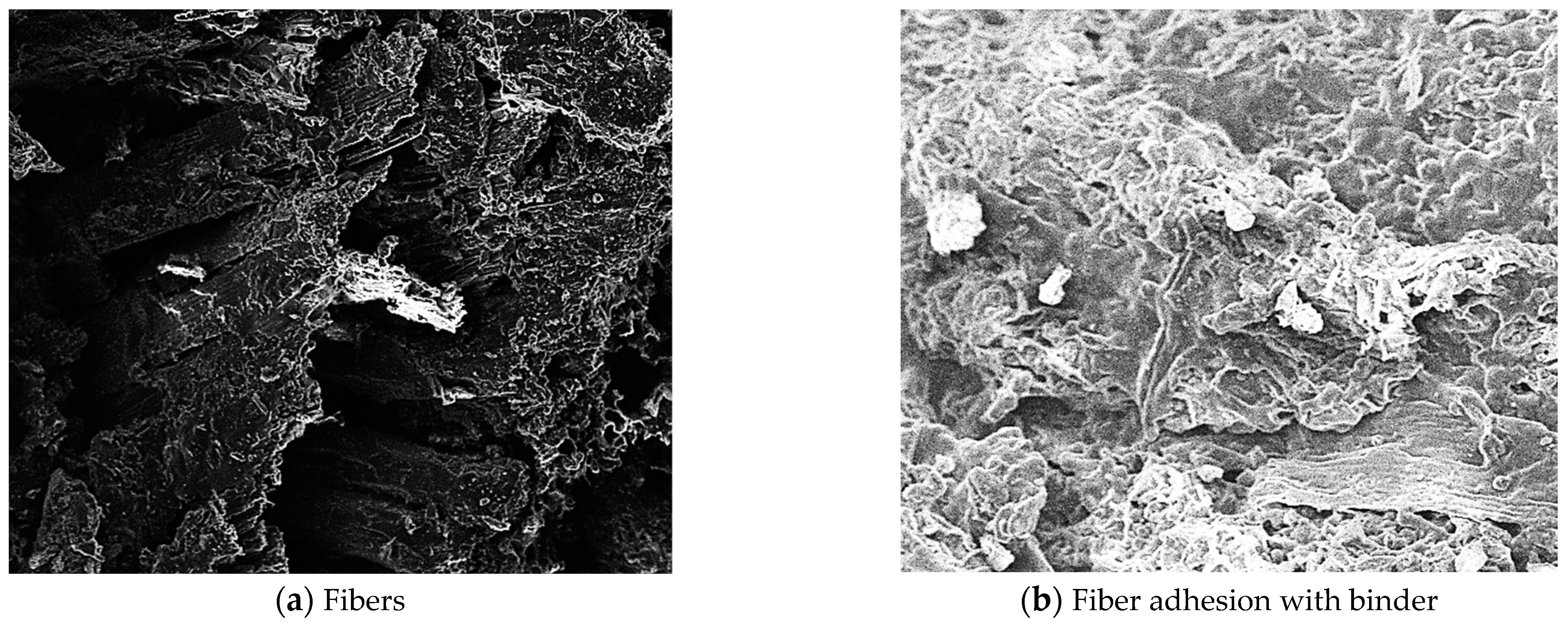

- The fibers used were waste from the PO plant, found on the coastal of the Tipaza province. The fibers were collected from the plant’s dead leaves ensuring lengths ranging from 2 to 5 cm.

- The fibers were mechanically ground to achieve the desired size.

- The binder used was a natural starch-based adhesive. The volume fractions of binder used were 15%, 20%, 25%, and 30%. The selected range aimed to strike a balance between the need for mechanical strength and the desire to maintain low thermal conductivity [33]. The adhesive was prepared by mixing water and starch in a water-to-starch ratio of 0.15.

- Specimens with dimensions of 15 × 10 × 4 cm3 were used for thermal tests.

- After fabrication, the specimens were stored in a room at room temperature for 48 h. Then, they were stored for 28 days to allow for curing.

2.2. Testing Methods

3. Results and Discussion

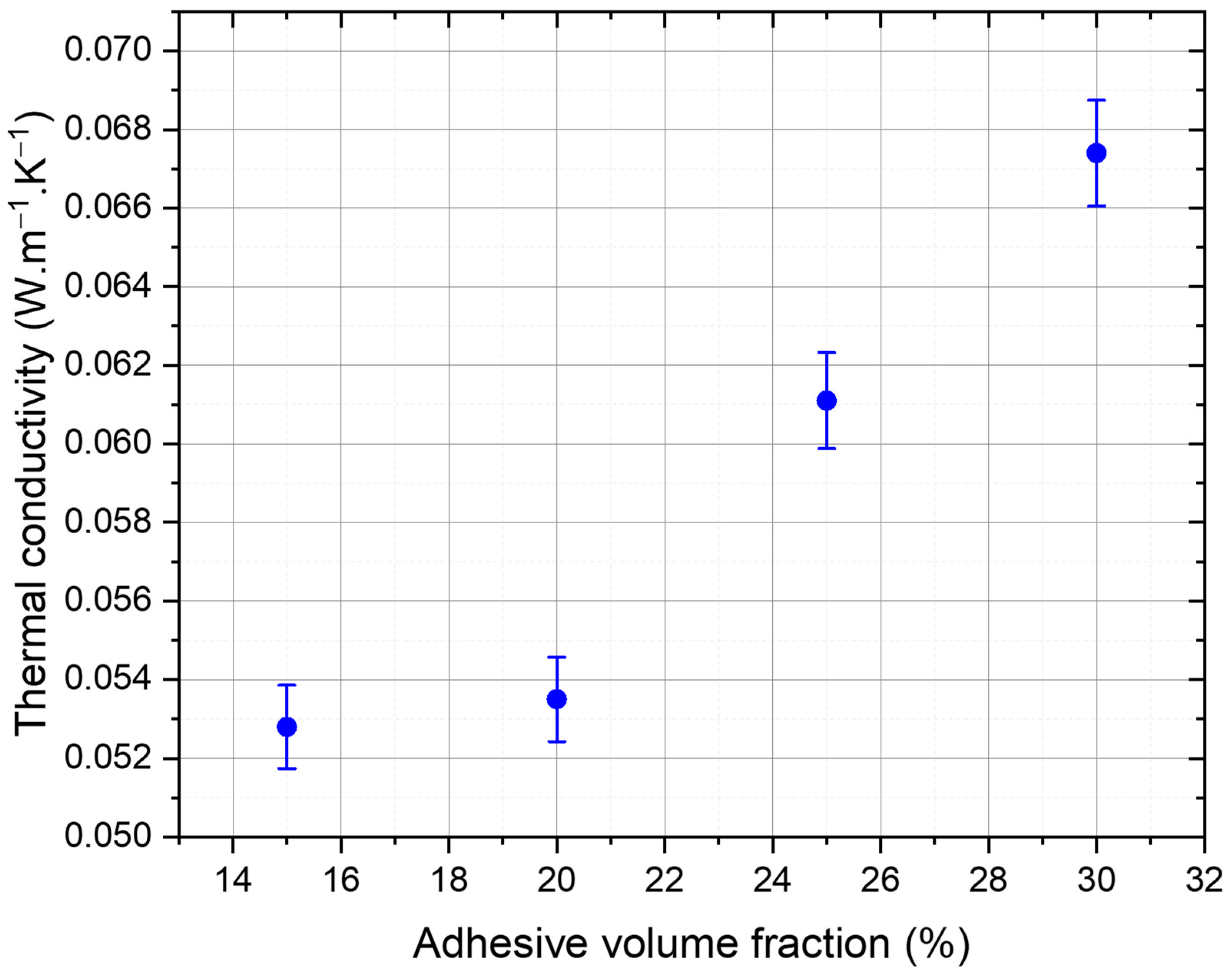

3.1. Thermal Conductivity

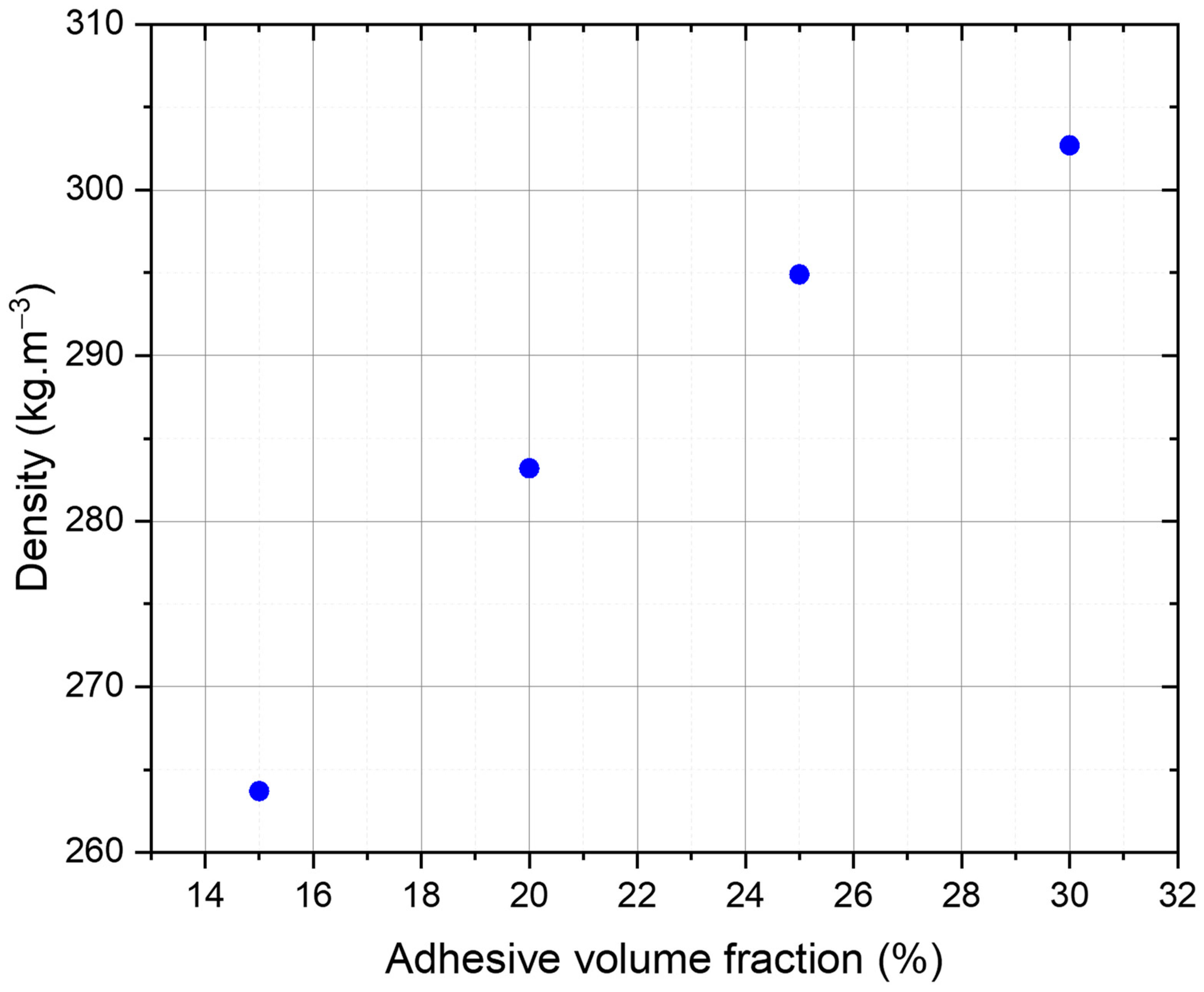

3.2. Density

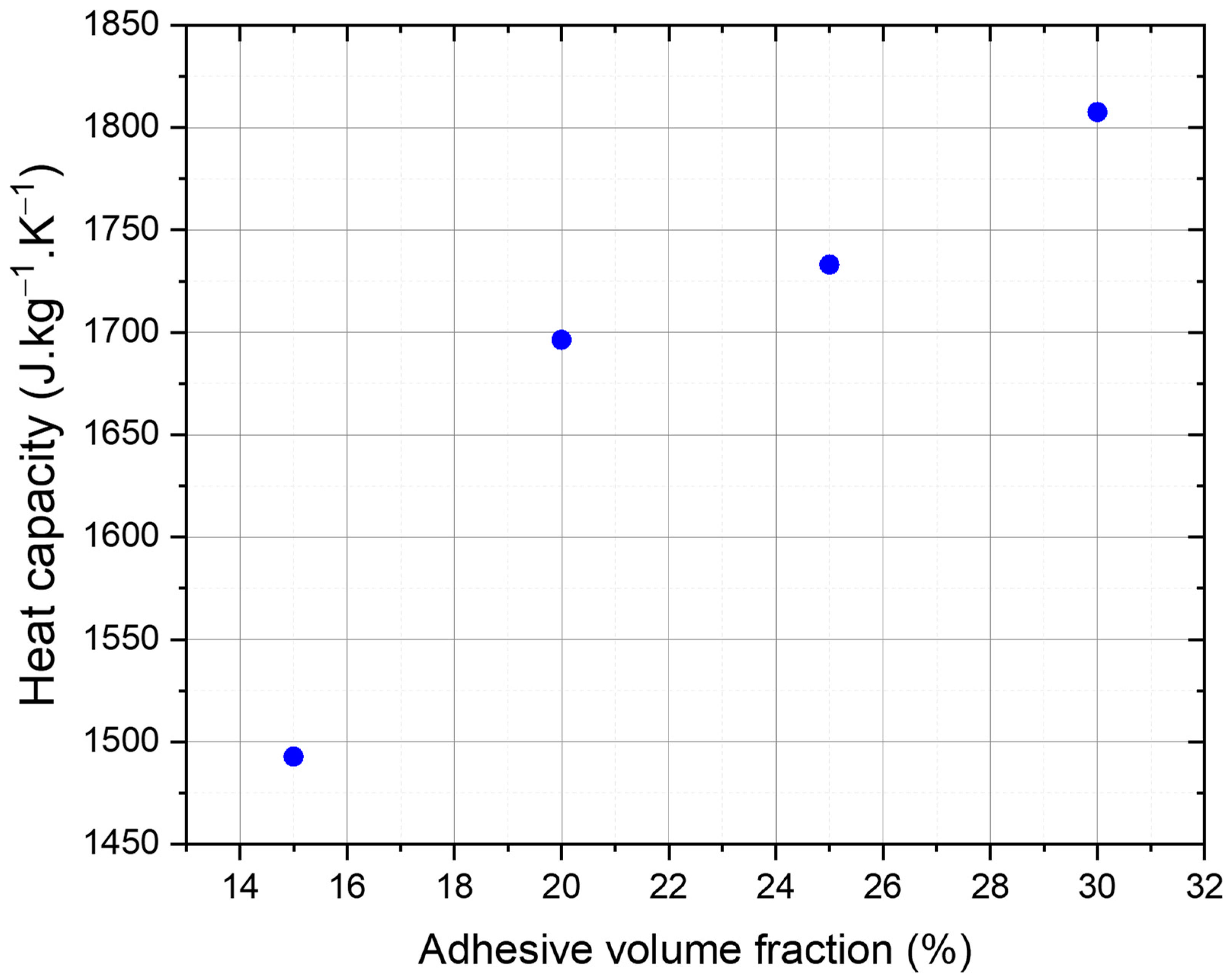

3.3. Heat Capacity

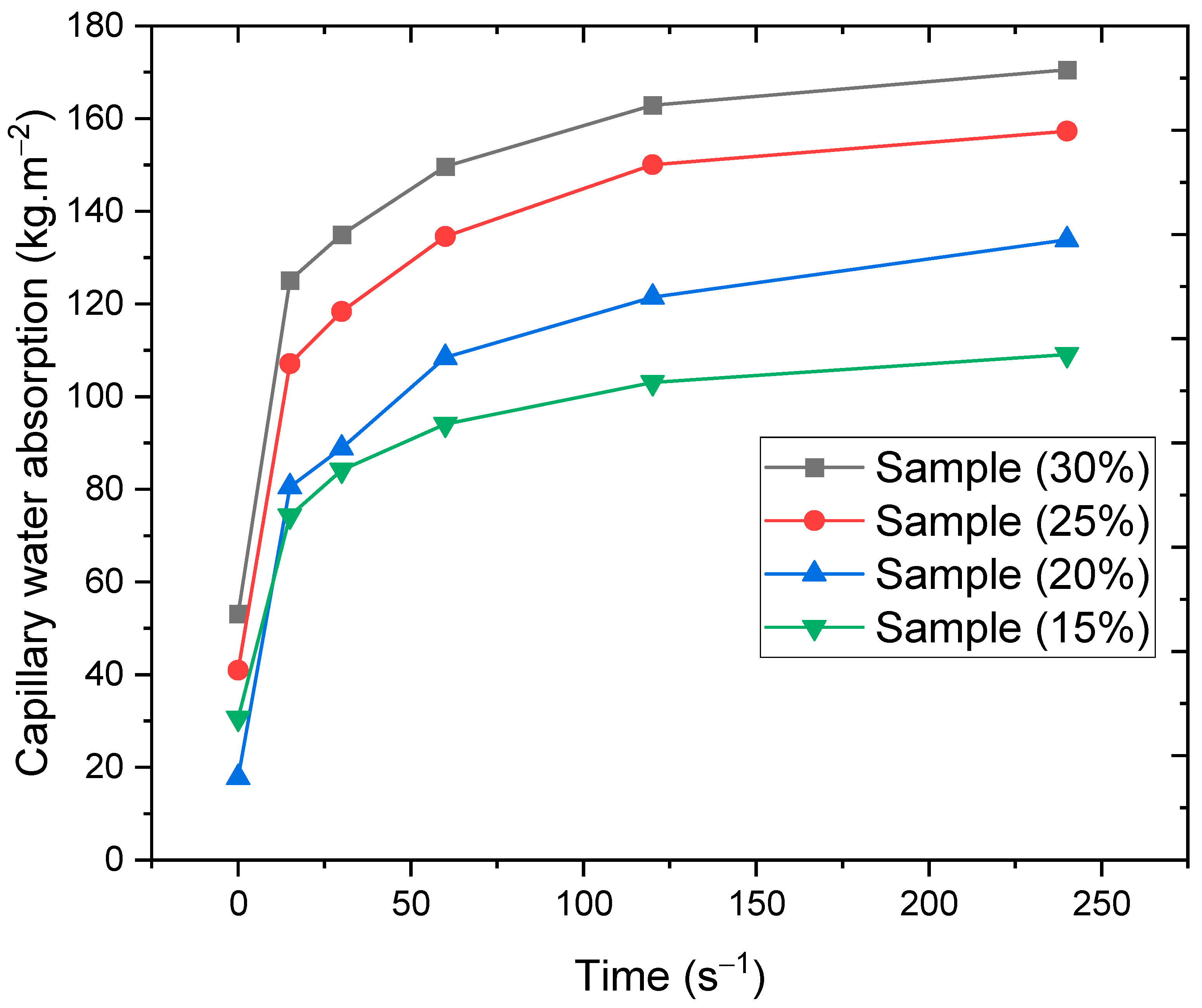

3.4. Capillary Absorption

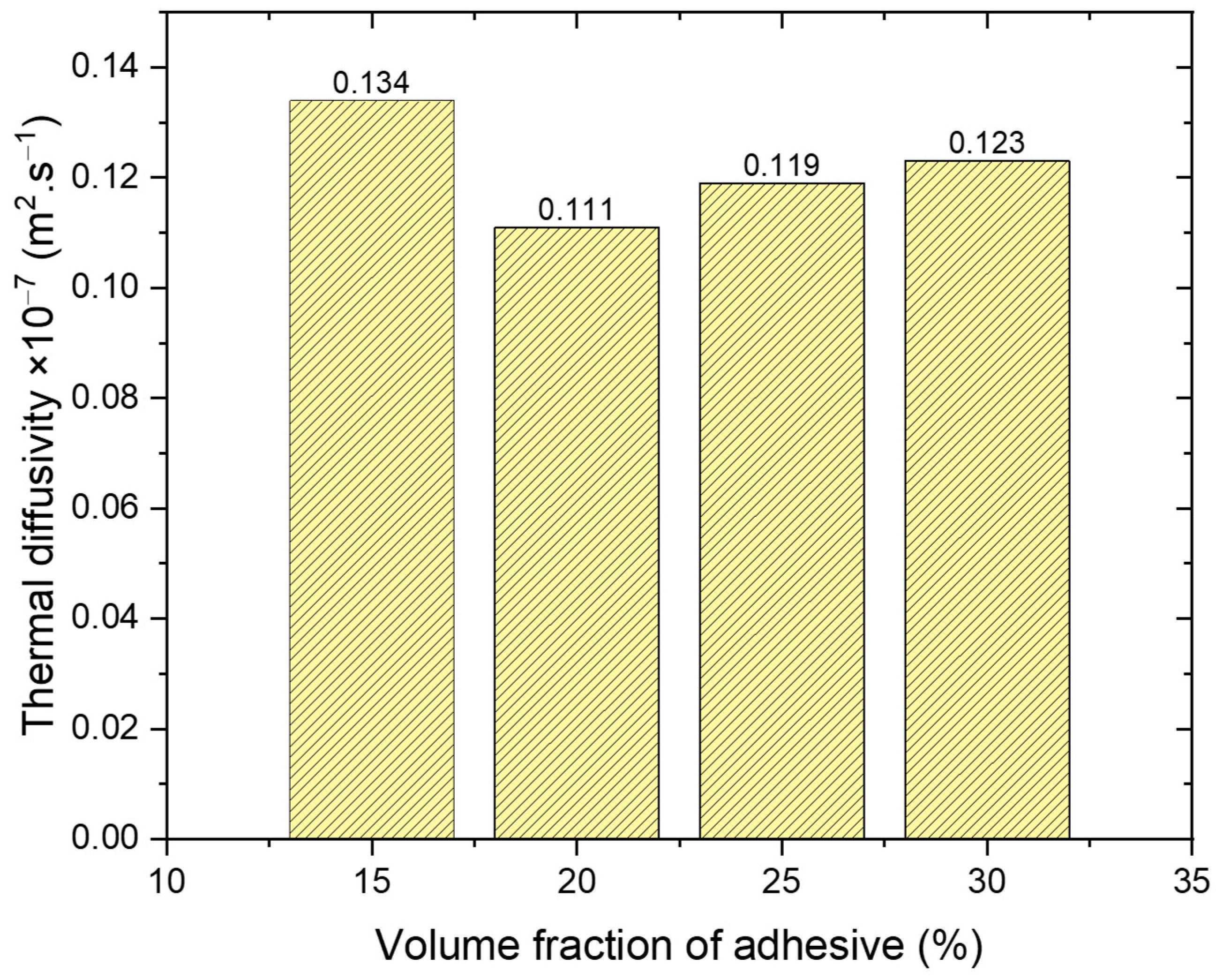

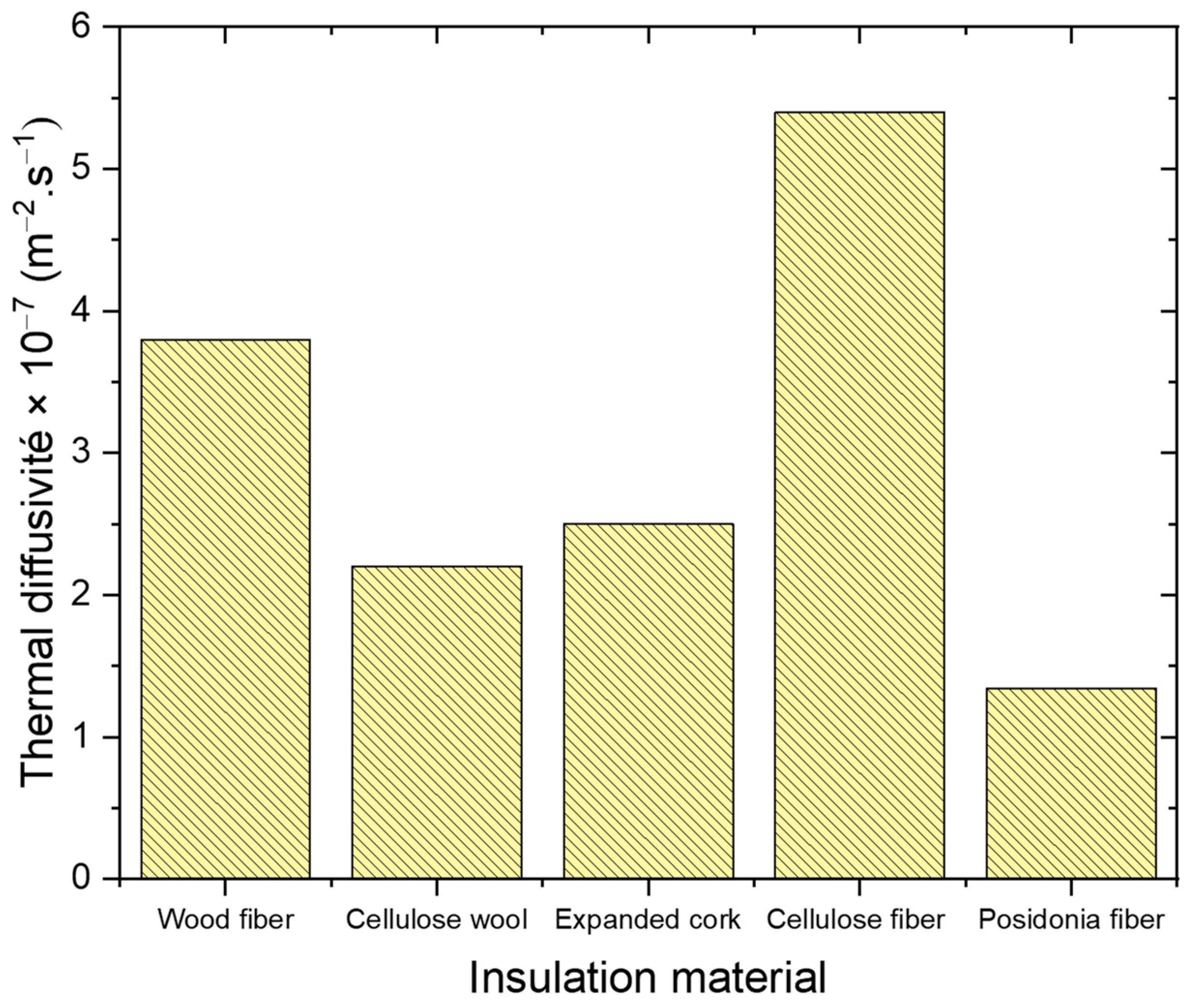

3.5. Thermal Diffusivity

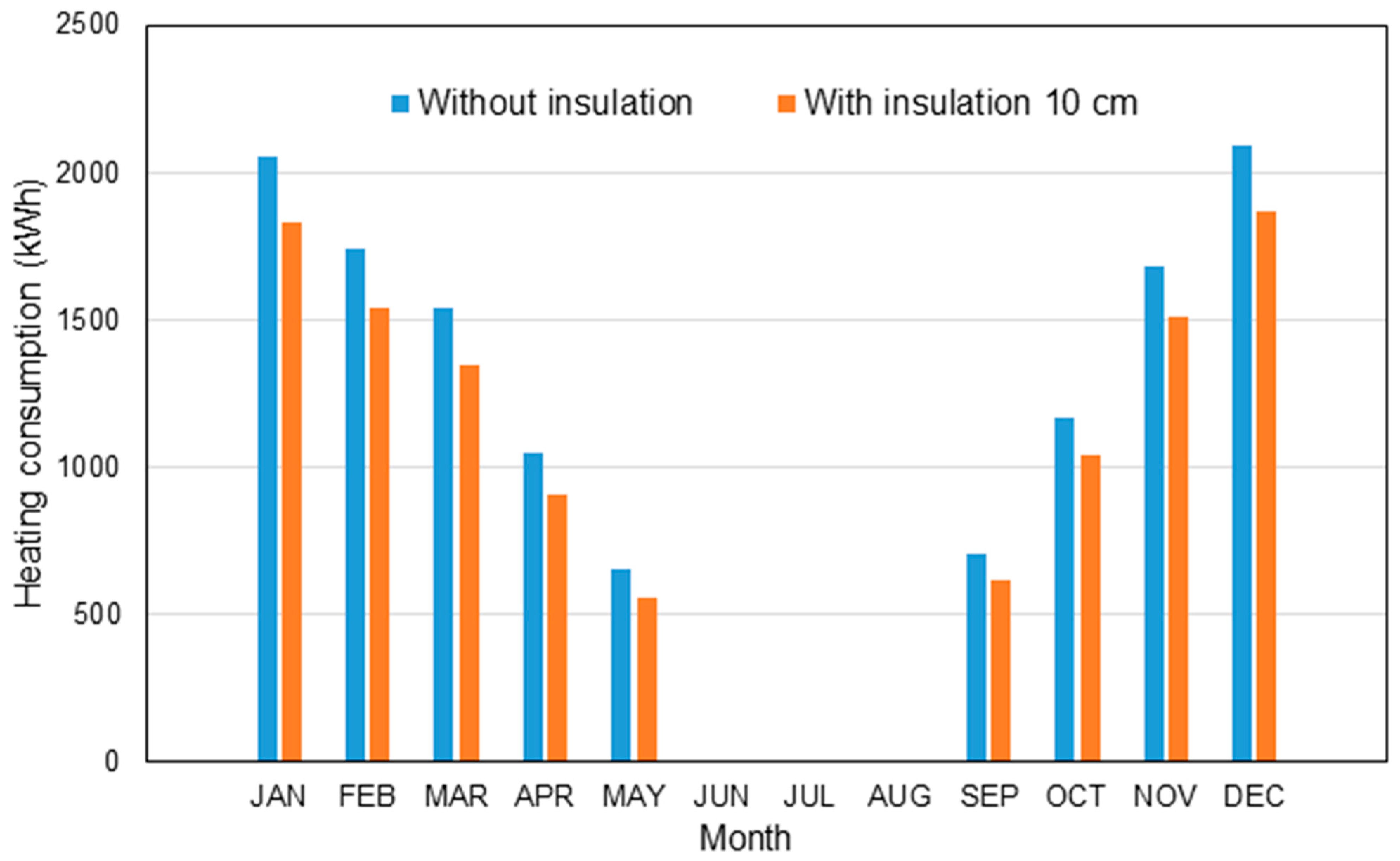

3.6. Heating Energy Consumption

4. Conclusions

- -

- The measured thermal conductivity of the PO fiber is found to be ranged from 0.0528 to 0.0674 W.m–1.K–1, with a diffusivity between 1.11 × 10–7 and 1.23 × 10–7 m2.s–1. The obtained values make the material a promising candidate to compete with other industrial insulators.

- -

- The obtained values of heat capacity of PO fibers vary from 1807 J.kg–1.K–1 to 1492 J.kg–1.K–1. These fibers could be considered an interesting insulation material because of their relatively high Cp-values.

- -

- Increasing the adhesive volume fraction in PO fibers effectively increases the mass of the material without significantly changing its volume. This results in a denser material, which can have advantages in terms of structural stability and thermal performance, although it may slightly reduce the material’s insulation properties.

- -

- Increasing the concentration of adhesive on a material’s surface effectively reduces its water absorption capacity by enhancing bonding, reducing porosity, increasing hydrophobicity, and improving water resistance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ghedamsi, R.; Settou, N.; Gouareh, A.; Khamouli, A.; Saifi, N.; Recioui, B.; Dokkar, B. Modeling and forecasting energy consumption for residential buildings in Algeria using bottom-up approach. Energy Build. 2016, 121, 309–317. [Google Scholar] [CrossRef]

- Semahi, S.; Benbouras, M.A.; Mahar, W.A.; Zemmouri, N.; Attia, S. Development of spatial distribution maps for energy demand and thermal comfort estimation in Algeria. Sustainability 2020, 12, 6066. [Google Scholar] [CrossRef]

- Oral, G.K.; Yener, A.K.; Bayazit, N.T. Building envelope design with the objective to ensure thermal, visual and acoustic comfort conditions. Build. Environ. 2004, 39, 281–287. [Google Scholar] [CrossRef]

- Zhao, J.R.; Zheng, R.; Tang, J.; Sun, H.J.; Wang, J. A mini-review on building insulation materials from perspective of plastic pollution: Current issues and natural fibres as a possible solution. J. Hazard. Mater. 2022, 438, 129449. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance evaluation and research of alternative thermal insulations based on sheep wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- Ouakarrouch, M.; Bousshine, S.; Bybi, A.; Laaroussi, N.; Garoum, M. Acoustic and thermal performances assessment of sustainable insulation panels made from cardboard waste and natural fibers. Appl. Acoust. 2022, 199, 109007. [Google Scholar] [CrossRef]

- Wei, K.; Lv, C.; Chen, M.; Zhou, X.; Dai, Z.; Shen, D. Development and performance evaluation of a new thermal insulation material from rice straw using high frequency hot-pressing. Energy Build. 2015, 87, 116–122. [Google Scholar] [CrossRef]

- Korjenic, A.; Petránek, V.; Zach, J.; Hroudová, J. Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. Energy Build. 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef]

- Chopra, S.S.; Dong, L.; Kaur, G.; Len, C.; Sze, C.; Lin, K. Sustainable process design for circular fashion: Advances in sustainable chemistry for textile waste valorisation. Curr. Opin. Green Sustain. Chem. 2023, 39, 100747. [Google Scholar] [CrossRef]

- Khairul, M.; Nasrin, U.; Islam, M. Textile-apparel manufacturing and material waste management in the circular economy: A conceptual model to achieve sustainable development goal (SDG) 12 for Bangladesh. Clean. Environ. Syst. 2022, 4, 100070. [Google Scholar] [CrossRef]

- Piribauer, B.; Bartl, A. Textile recycling processes, state of the art and current developments: A mini review. Waste Manag. Res. 2019, 37, 112–119. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.N.D.; Zhang, Z. The use of hemp fibres as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Woodhead Publishing: Sawston, UK, 2015; pp. 86–103. [Google Scholar]

- Hadded, A.; Benltoufa, S.; Jemni, A. Thermo physical characterization of recycled textile materials used for building insulating. J. Build. Eng. 2015, 5, 34–40. [Google Scholar] [CrossRef]

- Restaino, O.F.; Giosafatto, C.V.L.; Mirpoor, S.F.; Cammarota, M.; Hejazi, S.; Mariniello, L.; Schiraldi, C.; Porta, R. Sustainable Exploitation of Posidonia oceanica Sea Balls (Egagropili): A Review. Int. J. Mol. Sci. 2023, 24, 7301. [Google Scholar] [CrossRef] [PubMed]

- Renzi, M.; Guerranti, C.; Anselmi, S.; Provenza, F.; Leone, M.; La Rocca, G.; Cavallo, A. A multidisciplinary approach to Posidonia oceanica detritus management (Port of Sperlonga, Italy): A story of turning a problem into a resource. Water 2022, 14, 2856. [Google Scholar] [CrossRef]

- Hamdaoui, O.; Limam, O.; Ibos, L.; Mazioud, A. Thermal and mechanical properties of hardened cement paste reinforced with Posidonia oceanica natural fibers. Constr. Build. Mater. 2021, 269, 121339. [Google Scholar] [CrossRef]

- Boumhaout, M. Lecture Notes in Mechanical Engineering Advances in Mechatronics, Manufacturing, and Mechanical Engineering; Springer Nature: Cham, Switzerland, 2023; Volume 2. [Google Scholar] [CrossRef]

- Olacia, E.; Pisello, A.L.; Chiodo, V.; Maisano, S.; Frazzica, A.; Cabeza, L.F. Sustainable adobe bricks with seagrass fibres. Mechanical and thermal properties characterization. Constr. Build. Mater. 2020, 239, 117669. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kamperidou, V.; Konstantinidis, A.; Koltsou, P.; Papadopoulos, S. Use of Posidonia oceanica fibres in lime mortars. Constr. Build. Mater. 2021, 298, 123881. [Google Scholar] [CrossRef]

- Kuqo, A.; Mai, C. Mechanical properties of lightweight gypsum composites comprised of seagrass Posidonia oceanica and pine (Pinus sylvestris) wood fibers. Constr. Build. Mater. 2021, 282, 122714. [Google Scholar] [CrossRef]

- Kilian Mayer, A.; Kuqo, A.; Koddenberg, T.; Mai, C. Seagrass- and wood-based cement boards: A comparative study in terms of physico-mechanical and structural properties. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106864. [Google Scholar] [CrossRef]

- Jedidi, M.; Abroug, A. Valorization of Posidonia oceanica balls for the manufacture of an insulating and ecological material. Jordan J. Civ. Eng. 2020, 14, 417–430. [Google Scholar]

- Allègue, L.; Zidi, M.; Sghaier, S. Mechanical properties of Posidonia oceanica fibers reinforced cement. J. Compos. Mater. 2015, 49, 509–517. [Google Scholar] [CrossRef]

- Zannen, S.; Halimi, M.T.; Hassen, M.B.; Abualsauod, E.H.; Othman, A.M. Development of a Multifunctional Wet Laid Nonwoven from Marine Waste Posidonia oceanica Technical Fiber and CMC Binder. Polymers 2022, 14, 865. [Google Scholar] [CrossRef]

- Hamdaoui, O.; Ibos, L.; Mazioud, A.; Safi, M.; Limam, O. Thermophysical characterization of Posidonia oceanica marine fibers intended to be used as an insulation material in Mediterranean buildings. Constr. Build. Mater. 2018, 180, 68–76. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; De Baynast, H.; Sun, S.; Lebert, A.; Petit, E.; Michaud, P. Polysaccharidic binders for the conception of an insulating agro-composite. Compos. Part A Appl. Sci. Manuf. 2015, 78, 152–159. [Google Scholar] [CrossRef]

- Benzerara, M.; Guihéneuf, S.; Belouettar, R.; Perrot, A. Combined and synergic effect of algerian natural fibres and biopolymers on the reinforcement of extruded raw earth. Constr. Build. Mater. 2021, 289, 123211. [Google Scholar] [CrossRef]

- Harb, E.; Maalouf, C.; Bliard, C.; Tenpierik, M.; Lachi, M.; Bogard, F.; Polidori, G. Thermal performance of starch/beet-pulp composite bricks for building insulation at a wall scale. Case Stud. Constr. Mater. 2023, 18, e01851. [Google Scholar] [CrossRef]

- Muizniece, I.; Blumberga, D. Thermal Conductivity of Heat Insulation Material Made from Coniferous Needles with Potato Starch Binder. Energy Procedia 2016, 95, 324–329. [Google Scholar] [CrossRef]

- Bourdot, A.; Moussa, T.; Gacoin, A.; Maalouf, C.; Vazquez, P.; Thomachot-Schneider, C.; Bliard, C.; Merabtine, A.; Lachi, M.; Douzane, O.; et al. Characterization of a hemp-based agro-material: Influence of starch ratio and hemp shive size on physical, mechanical, and hygrothermal properties. Energy Build. 2017, 153, 501–512. [Google Scholar] [CrossRef]

- Umurigirwa-Vasseur, B.S. Elaboration et Caractérisation d’ un Agromatériau Chanvre-Amidon Pour le Bâtiment. Ph.D. Thesis, University of Reims Champagne-Ardenne, Reims, France, 2014. [Google Scholar]

- Ali, M.E.; Alabdulkarem, A. On thermal characteristics and microstructure of a new insulation material extracted from date palm trees surface fibers. Constr. Build. Mater. 2017, 138, 276–284. [Google Scholar] [CrossRef]

- Badouard, C.; Bogard, F.; Bliard, C.; Lachi, M.; Abbes, B.; Polidori, G. Development and characterization of viticulture by-products for building applications. Constr. Build. Mater. 2021, 302, 124142. [Google Scholar] [CrossRef]

- NF EN 993–15; Test Methods for Dense Shaped Refractories—Part 15: Determination of Thermal Conductivity by the Hot Wire Method (Parallel). AFNOR: Paris, France, 2005.

- NF EN 13057; Products and Systems for the Protection and Repair of Concrete Structures—Test methods—Determination of Capillary Absorption. AFNOR: Paris, France, 2002.

- Kremensas, A.; Vaitkus, S.; Vėjelis, S.; Członka, S.; Kairytė, A. Hemp shivs and corn-starch-based biocomposite boards for furniture industry: Improvement of water resistance and reaction to fire. Ind. Crops Prod. 2021, 166, 113477. [Google Scholar] [CrossRef]

- Ismail, B.; Belayachi, N.; Hoxha, D. Optimizing performance of insulation materials based on wheat straw, lime and gypsum plaster composites using natural additives. Constr. Build. Mater. 2020, 254, 118959. [Google Scholar] [CrossRef]

- Dénes, T.O.; Tămaş-Gavrea, D.R. Natural fibre composite panels for thermal insulation of buildings: A review. Sci. Pap. 2019, 19, 71–78. [Google Scholar]

- Panyakaew, S.; Fotios, S. New thermal insulation boards made from coconut husk and bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef]

- Bakatovich, A.; Davydenko, N.; Gaspar, F. Thermal insulating plates produced on the basis of vegetable agricultural waste. Energy Build. 2018, 180, 72–82. [Google Scholar] [CrossRef]

- Pyda, M. Conformational contribution to the heat capacity of the starch and water system. J. Polym. Sci. Part B Polym. Phys. 2001, 39, 3038–3054. [Google Scholar] [CrossRef]

- Saito, K. Chemical Physics of Molecular Condensed Matter; Springer Nature: Singapore; Berlin, Germany, 2020. [Google Scholar]

- Marques, B.; Tadeu, A.; António, J.; Almeida, J.; Brito, J. De Mechanical, thermal and acoustic behaviour of polymer-based composite materials produced with rice husk and expanded cork. Constr. Build. Mater. 2020, 239, 117851. [Google Scholar] [CrossRef]

- Ndagi, M.; Kolawole, A.T.; Olawale, F.M.; Sulaiman, A. Investigation of the Thermo-Physical and Mechanical Properties of Coir and Sugarcane Bagasse for Low Temperature Insulation. Int. J. Eng. Mater. Manuf. 2021, 6, 340–356. [Google Scholar] [CrossRef]

- Raza, M.; Al Abdallah, H.; Kozal, M.; Al Khaldi, A.; Ammar, T.; Abu-Jdayil, B. Development and characterization of Polystyrene–Date palm surface fibers composites for sustainable heat insulation in construction. J. Build. Eng. 2023, 75, 106982. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal properties of clayey plasters with olive fibers. Constr. Build. Mater. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Hounkpatin, H.W.; Chegnimonhan, V.K.; Donnou, H.E.V.; Hounguè, G.H.; Kounouhewa, B.B. Thermal characterisation of insulation panels based on vegetable typha domengensis and starch. Sci. Afr. 2023, 21, e01786. [Google Scholar] [CrossRef]

- Mawardi, I.; Aprilia, S.; Faisal, M.; Rizal, S. Characterization of thermal bio-insulation materials based on oil palm wood: The effect of hybridization and particle size. Polymers 2021, 13, 3287. [Google Scholar] [CrossRef]

- Lacoste, C.; El Hage, R.; Bergeret, A.; Corn, S.; Lacroix, P. Sodium alginate adhesives as binders in wood fibers/textile waste fibers biocomposites for building insulation. Carbohydr. Polym. 2018, 184, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Trabelsi, A.; El Mankibi, M. Hygrothermal properties of insulation materials from rice straw and natural binders for buildings. Constr. Build. Mater. 2023, 372, 130770. [Google Scholar] [CrossRef]

- Ezziane, M.; Molez, L.; Messaoudene, I.; Kadri, T. Caractérisations non Destructive de Mortiers Renforcés Par des Fibres de Natures Différentes Soumis à Haute Température; NoMaD 2015; Nouveau Matériaux et Durabilité: Douai, France, 2015; Available online: https://hal.science/hal-01216239 (accessed on 11 December 2023).

- Boukhelkhal, D.; Guendouz, M.; Bourdot, A.; Cheriet, H.; Messaoudi, K. Elaboration of bio-based building materials made from recycled olive core. MRS Energy Sustain. 2021, 8, 98–109. [Google Scholar] [CrossRef]

- Mathews, J.M.; Vivek, B.; Charde, M. Thermal insulation panels for buildings using recycled cardboard: Experimental characterization and optimum selection. Energy Build. 2023, 281, 112747. [Google Scholar] [CrossRef]

- Chihab, Y.; Laaroussi, N.; Garoum, M. Thermal performance and energy efficiency of the composite clay and hemp fibers. J. Build. Eng. 2023, 73, 106810. [Google Scholar] [CrossRef]

- Paraschiv, S.; Paraschiv, L.S.; Serban, A. Increasing the energy efficiency of a building by thermal insulation to reduce the thermal load of the micro-combined cooling, heating and power system. Energy Rep. 2021, 7, 286–298. [Google Scholar] [CrossRef]

| Fibers | Binder | Percentage | Thermal Conductivity (W.m−1.K−1) | References |

|---|---|---|---|---|

| PO | Cement | Po = 0–20% | 0.0559–0.0778 | [19] |

| PO and straw | Adobe | Po = 0.5–1.5–3% | 0.63–0.83 | [21] |

| Coniferous needles | Potato starch | C/S ½–1/1.5–1/1 | 0.0478–0.0524 | [32] |

| Hemp | Wheat starch | H/S 0.14–0.16–0.19–0.21–0.24–0.27–0.31–0.38 | 0.05 | [34] |

| Wine industry by-products | Potato starch | Starch/Aggregate 20% | 0.075 | [36] |

| Materials | Binder | Density (kg.m−3) | Thermal Conductivity (W.m−1.K−1) | Heat Capacity (J.kg−1.K−1) | Thermal Diffusivity (m².s−1) | References |

|---|---|---|---|---|---|---|

| Cork Pellets (developed) and Rice Husks | Based on Toluene Diisocyanate Polyurethane (20%) | 199–390 | 0.045–0.080 | 1329–1793 | N/A * | [46] |

| Bagasse and Coconut Coconut Granules | Arabic Gum (33%) | 245–276 | 0.015 | 1141 | 5.15 × 10–5–9.14 × 10–5 | [47] |

| Date Palm Surface Fibers | Expanded Polystyrene (EPS) | 970–930 | 0.053 | 1400 | 4.5 × 10–8 | [48] |

| Olive Fiber | Clay + Sand | 958.91 | 0.428 | 1409 | 295 × 10–6–387 × 10–6 | [49] |

| Typha | Starch | 670.66–891.54 | 0.094–0.534 | 1590–1640 | 3.77 × 10–7–9.0 × 10–8 | [50] |

| Wood Particles (palm oil), Ramie Fiber | Tapioca Starch (30%) | 660–790 | 0.067–0.148 | N/A | N/A | [51] |

| Wood fibers/textile waste fibers | Sodium alginate | 308–333 | 0.078–0.089 | 1320–1402 | 193 × 10–7–236 × 10–7 | [52] |

| Rice straw | Sodium alginate and chitosan | 104–162 | 0.038–0.47 | 1428–1140 | N/A | [53] |

| Posidonia-Based insulation | Corn starch | 263–302 | 0.052–0.067 | 1493–1807 | 1.11 × 10–7–1.23 × 10–7 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben Hadj Tahar, D.; Triki, Z.; Guendouz, M.; Tahraoui, H.; Zamouche, M.; Kebir, M.; Zhang, J.; Amrane, A. Characterization and Thermal Evaluation of a Novel Bio-Based Natural Insulation Material from Posidonia oceanica Waste: A Sustainable Solution for Building Insulation in Algeria. ChemEngineering 2024, 8, 18. https://doi.org/10.3390/chemengineering8010018

Ben Hadj Tahar D, Triki Z, Guendouz M, Tahraoui H, Zamouche M, Kebir M, Zhang J, Amrane A. Characterization and Thermal Evaluation of a Novel Bio-Based Natural Insulation Material from Posidonia oceanica Waste: A Sustainable Solution for Building Insulation in Algeria. ChemEngineering. 2024; 8(1):18. https://doi.org/10.3390/chemengineering8010018

Chicago/Turabian StyleBen Hadj Tahar, Dhouha, Zakaria Triki, Mohamed Guendouz, Hichem Tahraoui, Meriem Zamouche, Mohammed Kebir, Jie Zhang, and Abdeltif Amrane. 2024. "Characterization and Thermal Evaluation of a Novel Bio-Based Natural Insulation Material from Posidonia oceanica Waste: A Sustainable Solution for Building Insulation in Algeria" ChemEngineering 8, no. 1: 18. https://doi.org/10.3390/chemengineering8010018

APA StyleBen Hadj Tahar, D., Triki, Z., Guendouz, M., Tahraoui, H., Zamouche, M., Kebir, M., Zhang, J., & Amrane, A. (2024). Characterization and Thermal Evaluation of a Novel Bio-Based Natural Insulation Material from Posidonia oceanica Waste: A Sustainable Solution for Building Insulation in Algeria. ChemEngineering, 8(1), 18. https://doi.org/10.3390/chemengineering8010018