1. Introduction

Climate change and global warming from the emission of greenhouse gases (GHG) are currently defined as major threats to humanity. A series of international measures and actions have been taken to mitigate the GHG effect. Recently, in Glasgow, the 26th UN Climate Change Conference of the Parties (COP26) was conducted. The participants emphasised the commitment to deep GHG emissions cuts and support the 1.5 °C global warming limit goal [

1]. One of the most effective ways to cut emissions is using the thermal conversion of sustainable biomass into energy, where this biomass is assumed to utilise renewable carbon within its lifecycle.

Municipal solid waste (MSW) is one of the most inexpensive and available alternative fuels. The landfilling of non-recycled MSW in some countries such as Qatar is a challenging disposal method due to the lack of land and emissions from landfills [

2]. Alternatively to landfill, the non-recycled MSW in Qatar can potentially be gasified to produce valuable synthesis gas (syngas) consisting of CO, CO

2, CH

4, and H

2 [

3].

The study herein was driven by the Qatar National Vision 2030 for better MSW management. Adopting biomass gasification in Qatar will minimise the air pollutants emitted from the combustion of fossil fuels and landfills. Currently, the Domestic Solid Waste Management Centre (DSWMC) in Doha generates 30 MW of electricity from MSW as a part of the Waste-to-Energy (WtE) program [

4].

Subcoal™ is a promising fossil fuel substitute consisting of a non-recyclable mixture of plastics and paper waste and is produced by the N + P Group [

5]. It comes with unique properties such as high energy content, low sulphur content, and good hydrophobicity. Due to these properties, this material has been used as a solid fuel in different industries such as steel and cement production. The kinetics of Subcoal™ gasification have received limited attention in the reported literature [

6]. It can be prepared from the MSW in Qatar as a feedstock for a gasification plant.

Biomass fluidised bed gasification takes place widely over bed materials, which are a mixture of sand and catalyst particles. However, the production of tar during gasification may lead to serious problems in the system such as condensation and clogging, therefore, a tar removal method is usually required [

7]. In the case of municipal solid waste, the amount of material involved is likely to be very large, so the reactor residence time and length scales are the major design criteria of technical interest [

2]. Therefore, a catalyst is necessary to enhance the reaction for the production of syngas. Another role of the catalyst is the cracking of tar including thermal and hydrocracking [

5]. The hydrocarbons are adsorbed in their dissociative form after hydrogen is removed catalytically [

6].

Synthetic and natural catalysts have been used in biomass gasification. Natural mineral catalysts are found in the Earth’s crust such as dolomite and olivine [

8,

9,

10]. They are commonly used because they are abundantly available and are inexpensive compared to refined and precious metals [

8]. The formation of dolomite in the Khor Al-Adaid sabkha in Qatar has been reported in the work of DiLoreto et al. [

11].

Olivine is a rock-forming mineral that is naturally available with a general chemical formula of magnesium iron silicate (Mgx, Fe1−x)

2 SiO

4. The catalytic activity of olivine for tar reduction can be related to iron oxide (Fe

2O

3), magnesite (MgO), and nickel (Ni) portions. Iron is effective when it is found on the surface of the catalyst. Oxidation and/or calcination of olivine helps to transfer iron to the surface. Olivine is mainly deactivated by the formation of coke, which covers the active sites and reduces the surface area of a catalyst [

12]. The catalytic influence of olivine on biomass gasification has been examined in several studies [

13,

14,

15,

16].

Dolomite is a widespread inexpensive mineral that forms in rocks over a significant underground area. It is a common tar conversion catalyst that is composed of calcium magnesium carbonate CaMg(CO

3)

2 [

17,

18]. The composition of dolomite may vary depending on the geographical location [

19], however, the major compounds found in dolomite are calcium oxide (CaO), magnesium oxide (MgO), and CO

2 [

20]. Dolomite may also contain traces of silica (SiO

2), aluminium oxide (Al

2O

3), and Fe

2O

3 [

21].

This paper aimed to investigate the effects of dolomite and olivine concentrations on the Subcoal™ CO2 gasification using TGA. The XRD data of Subcoal™ fuel and ash will be provided as part of the catalytic effect investigation. The thermal behaviour and kinetic parameters in the presence of the catalyst will be examined using the Coats–Redfern (CR) method. In addition, this study is regarded as foundational knowledge for future Subcoal™ gasification with catalyst research. However, this paper aimed to investigate the effects of mineral-based catalysts, namely, dolomite and olivine on the Subcoal™ CO2 gasification using TGA. Subcoal™ as a fuel is a novel and new material type that is segregated from municipal solid waste (MSW), which can be used effectively in gasification technology to generate power in countries suffering from MSW landfilling and fossil fuel emissions such as in Qatar. In our previous studies, we presented the behaviour and kinetics of uncatalysed Subcoal™ gasification using a model free method. Some mineral catalysts such as dolomite and olivine are abundant in the Middle East region. It would be useful to achieve an understanding of the catalysis performance of these minerals in the gasification process. The influence of inexpensive mineral catalysts on the gasification of Subcoal has received insufficient or no attention. This is the first study that also included reaction kinetics investigations, which contribute to the better design of a Subcoal™ gasifier in the presence of CO2 and a mineral catalyst. CO2 as a gasifying agent offers unique features over air or steam to ensure better gasification performance and as a way of CO2 utilisation. Finally, the present study is regarded as foundational knowledge for future Subcoal™ gasification with catalyst research.

4. Discussion

The gasification of Subcoal™ PAF in the TGA occurs according to consecutive steps, namely dehydration, devolatilisation, and char decomposition. In the first step, moisture was removed from a sample at a temperature between 150 to 250 °C. However, in this step, the sample mass insignificantly changed as a function of time. The second step consisted of two stages in which the volatile organic compounds decomposed into condensable and non-condensable gases. This process causes a sudden reduction in a sample mass in a temperature range from 250 to 650 °C [

3]. In the final step, a small change in the conversion of biomass was observed due to the decomposition of char into non-condensable gases. The final step occurred from 600 °C to 750 °C. However, as the temperature was below 600 °C, the calcination of dolomite yielded active species such as CaO and MgO, as shown in the reactions (Equations (15) and (16)).

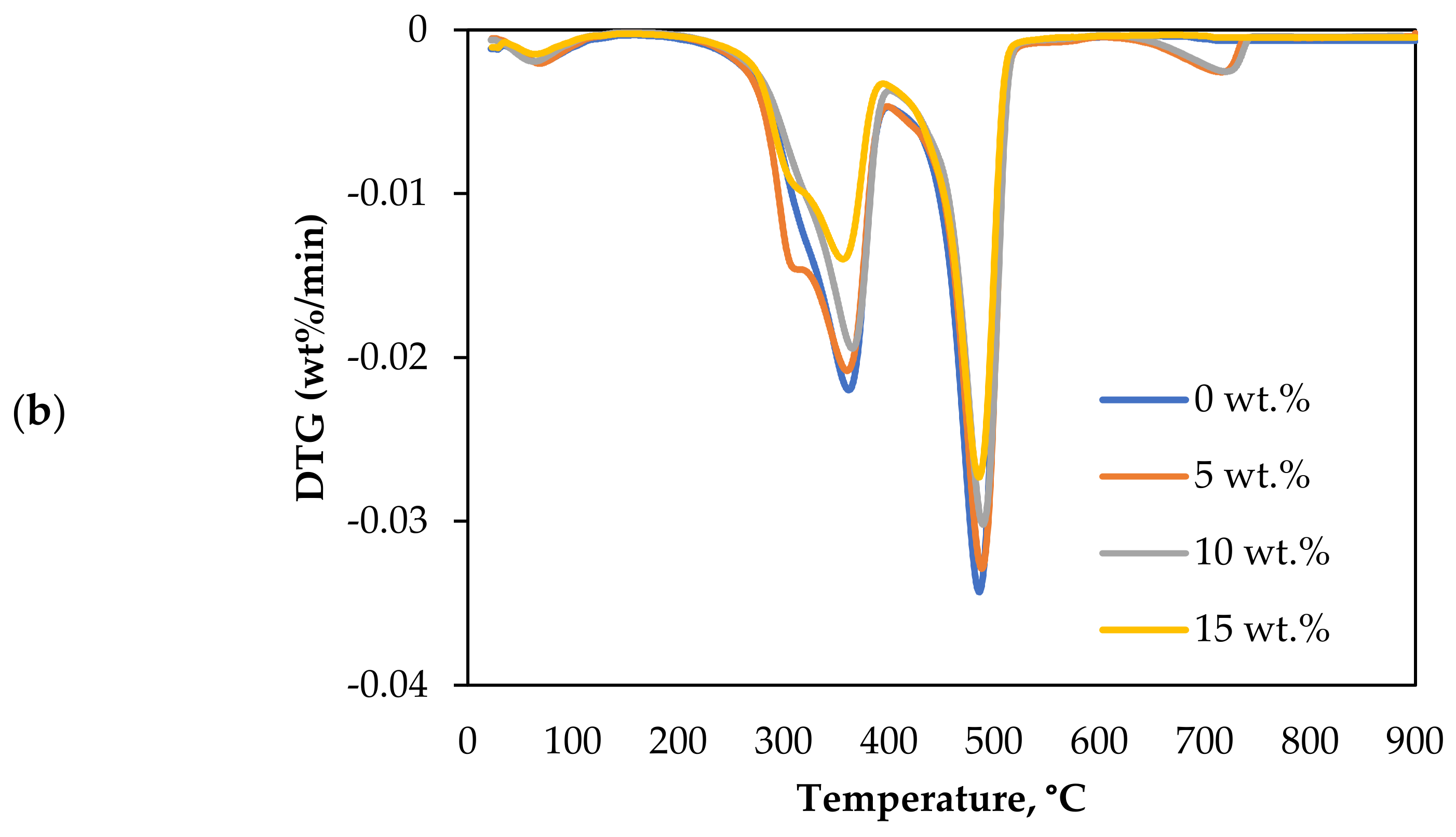

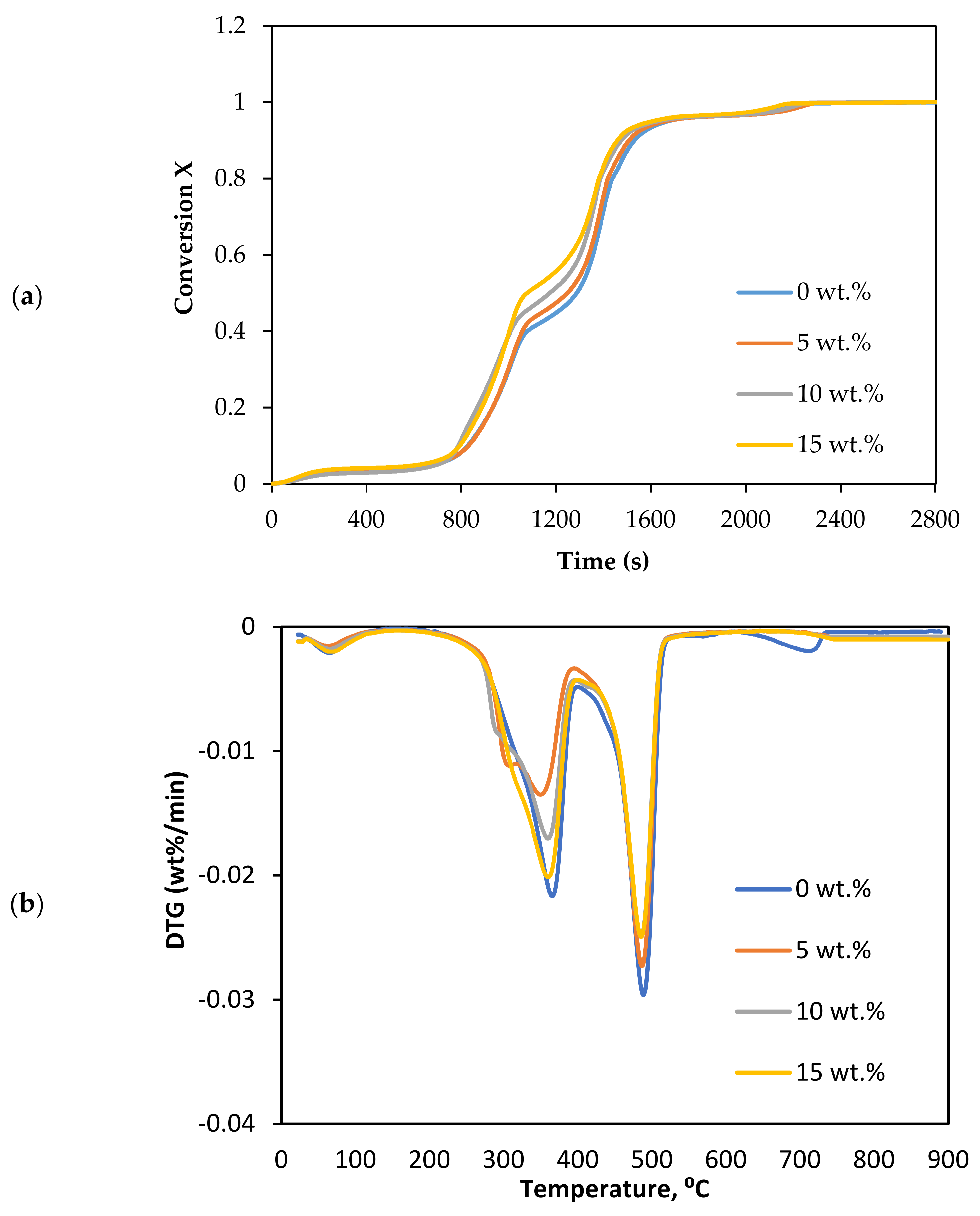

The CO

2 gasification in the presence of dolomite showed lower Tm peaks than olivine. The findings indicate that 15 wt.% of dolomite accelerates the reactions by lowering the Tm of Subcoal™ PAF decomposition. The abnormality of DTG peaks in the second stage can be attributed to the presence of O

2 and interactions of the catalyst [

41]. However, the DTG analysis with olivine is quite organised and sharpened compared to the dolomite case [

42].

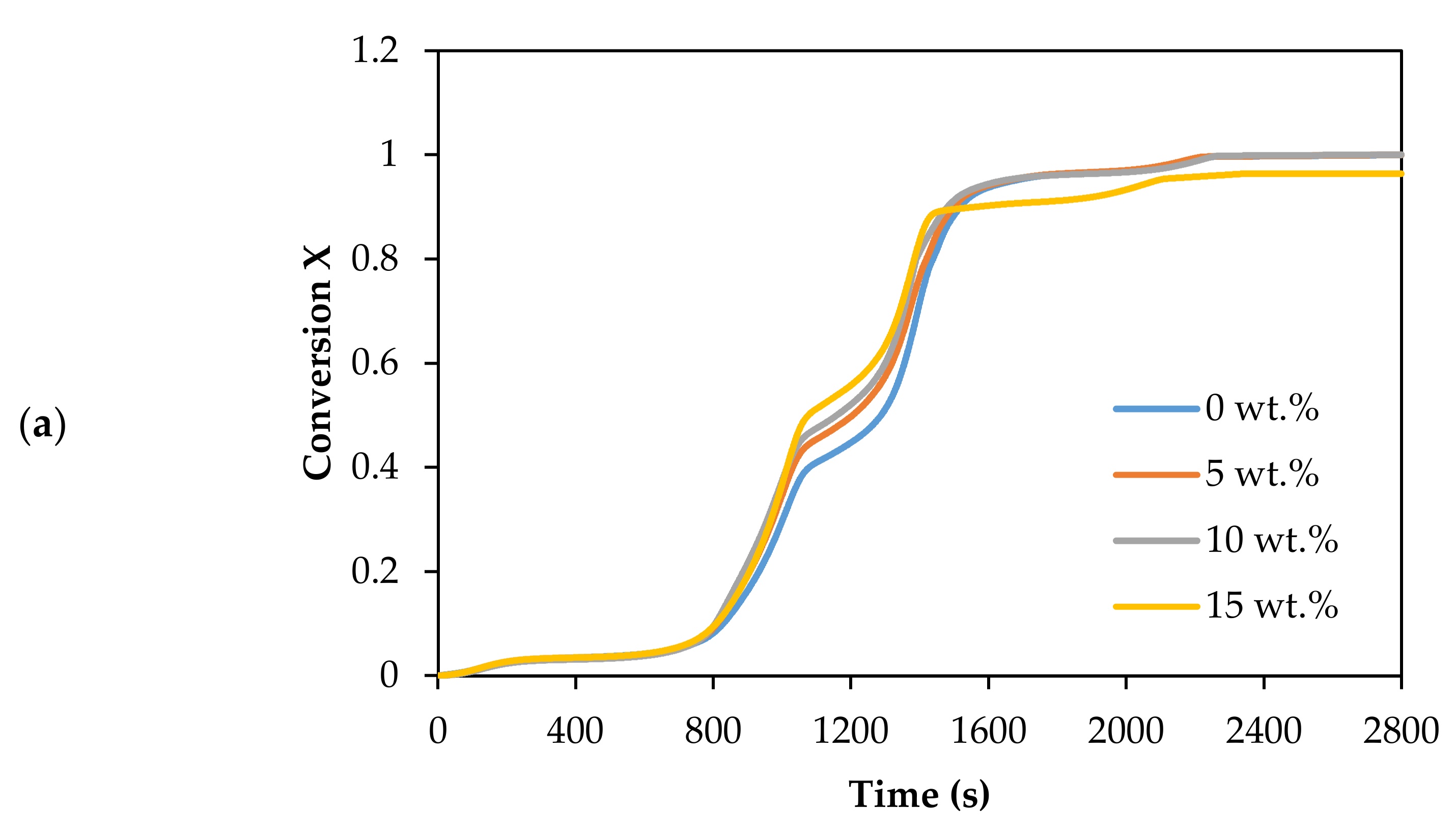

Olivine and dolomite catalysts have a significant and measurable impact on the conversion rate when compared with the heating rate impact [

22]. The presence of a catalyst reduced the induction time of the thermal decomposition. It also shifted the conversion curve to a lower temperature as the catalyst concentration increased, indicating a shorter decomposition reaction time. TGA plots of conversion degree were divided into two main degradation regions: 0.2 to 0.45, and then from 0.45 to 0.8. This can be explained by the successive reactions of decomposition.

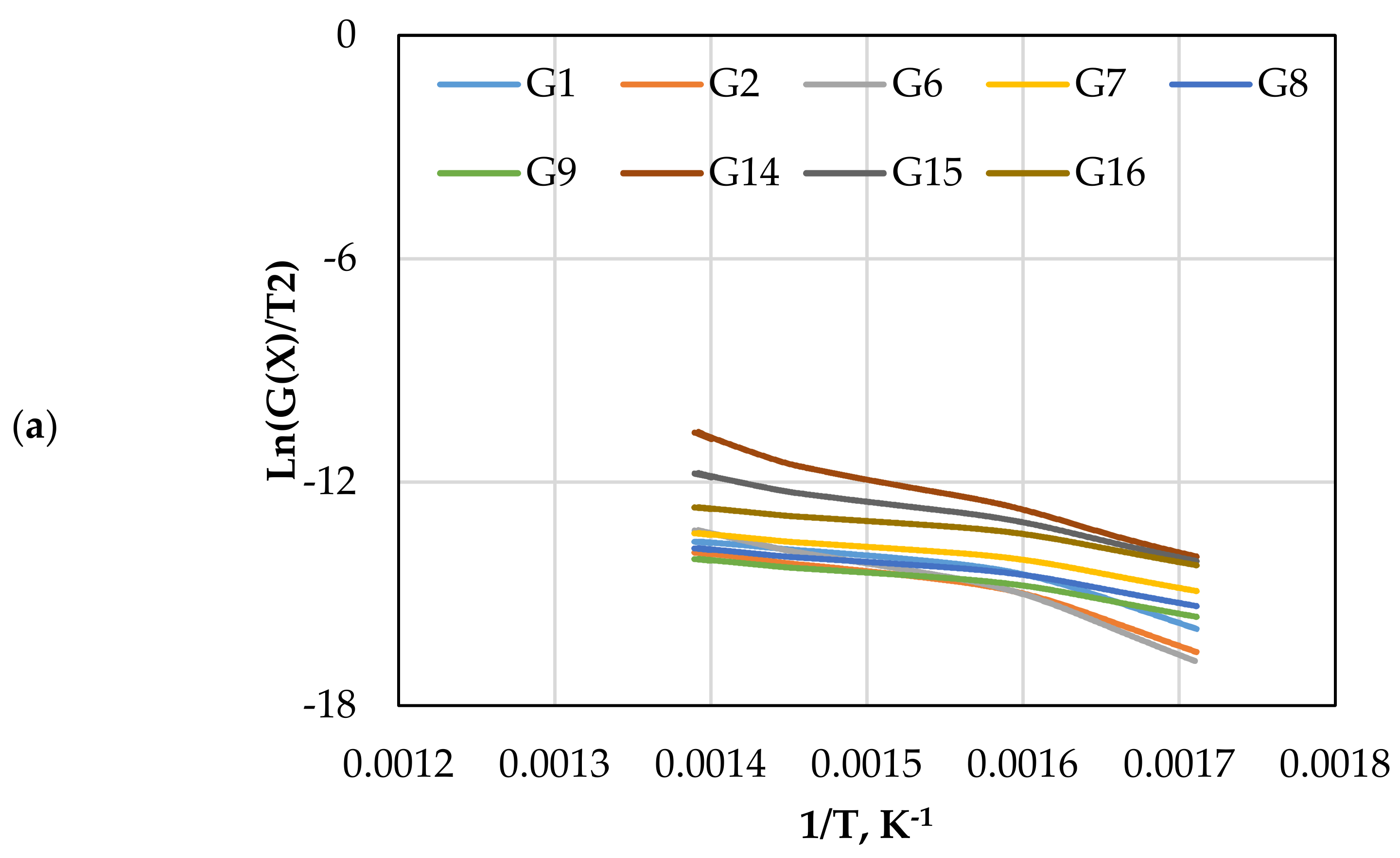

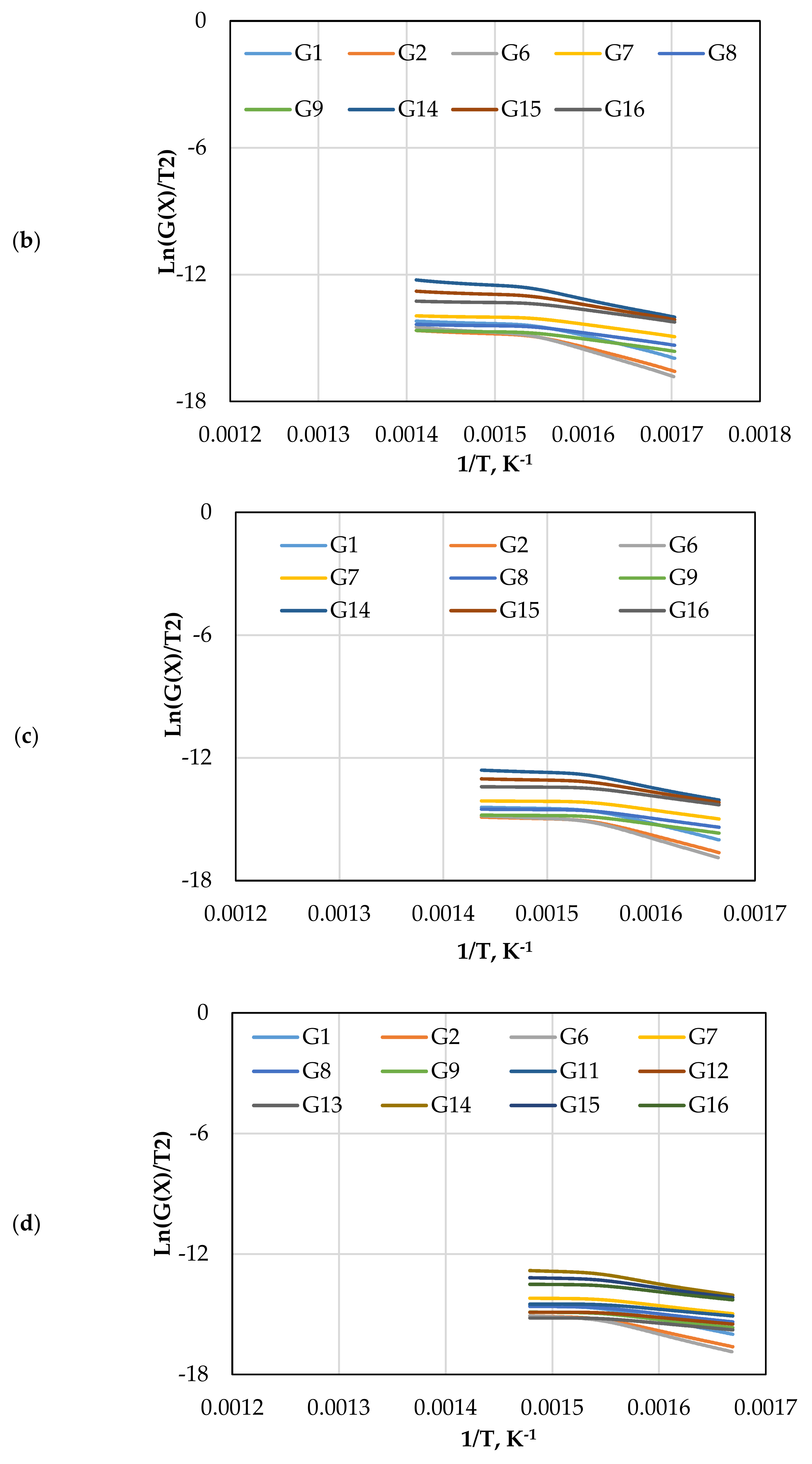

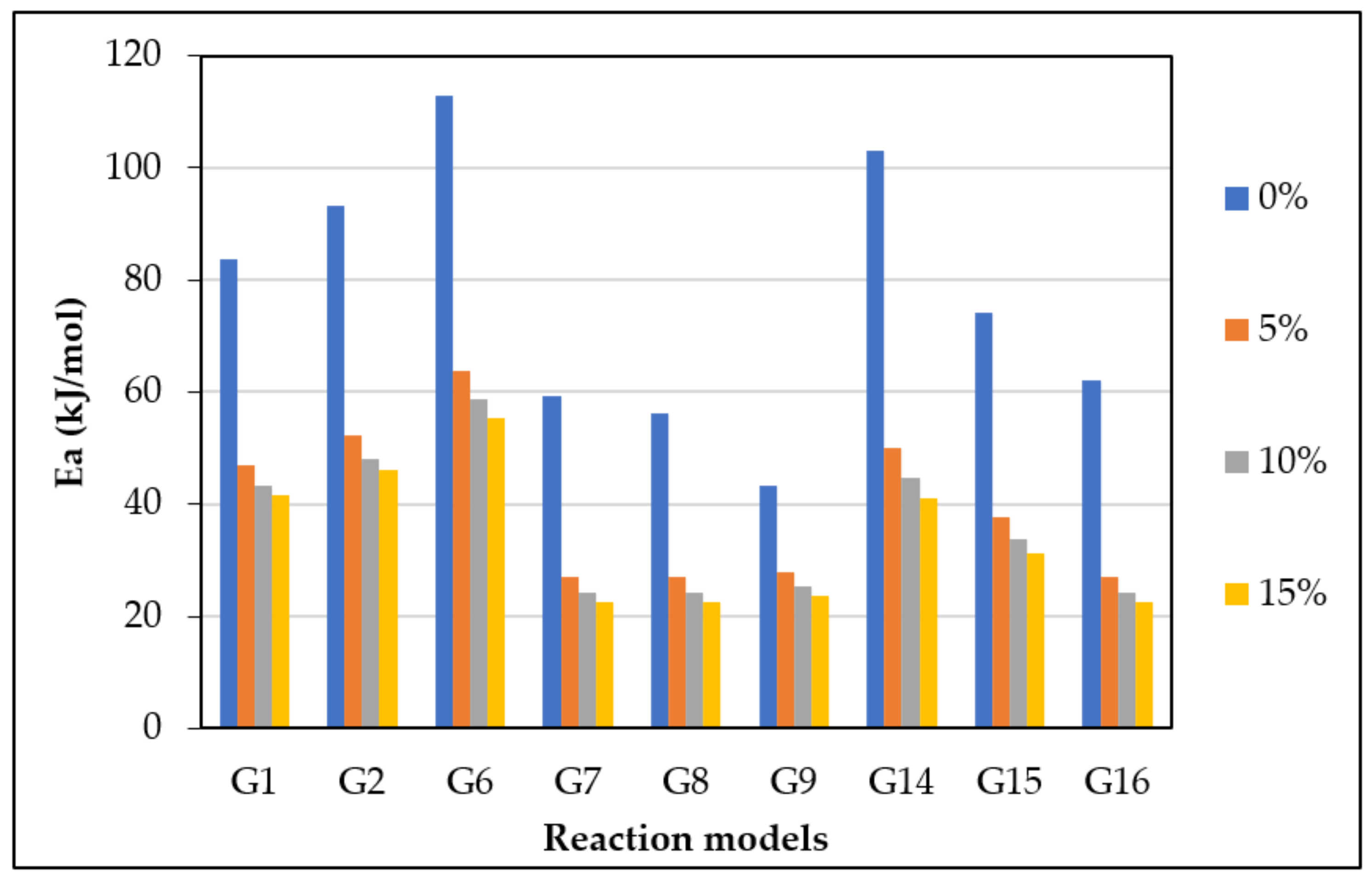

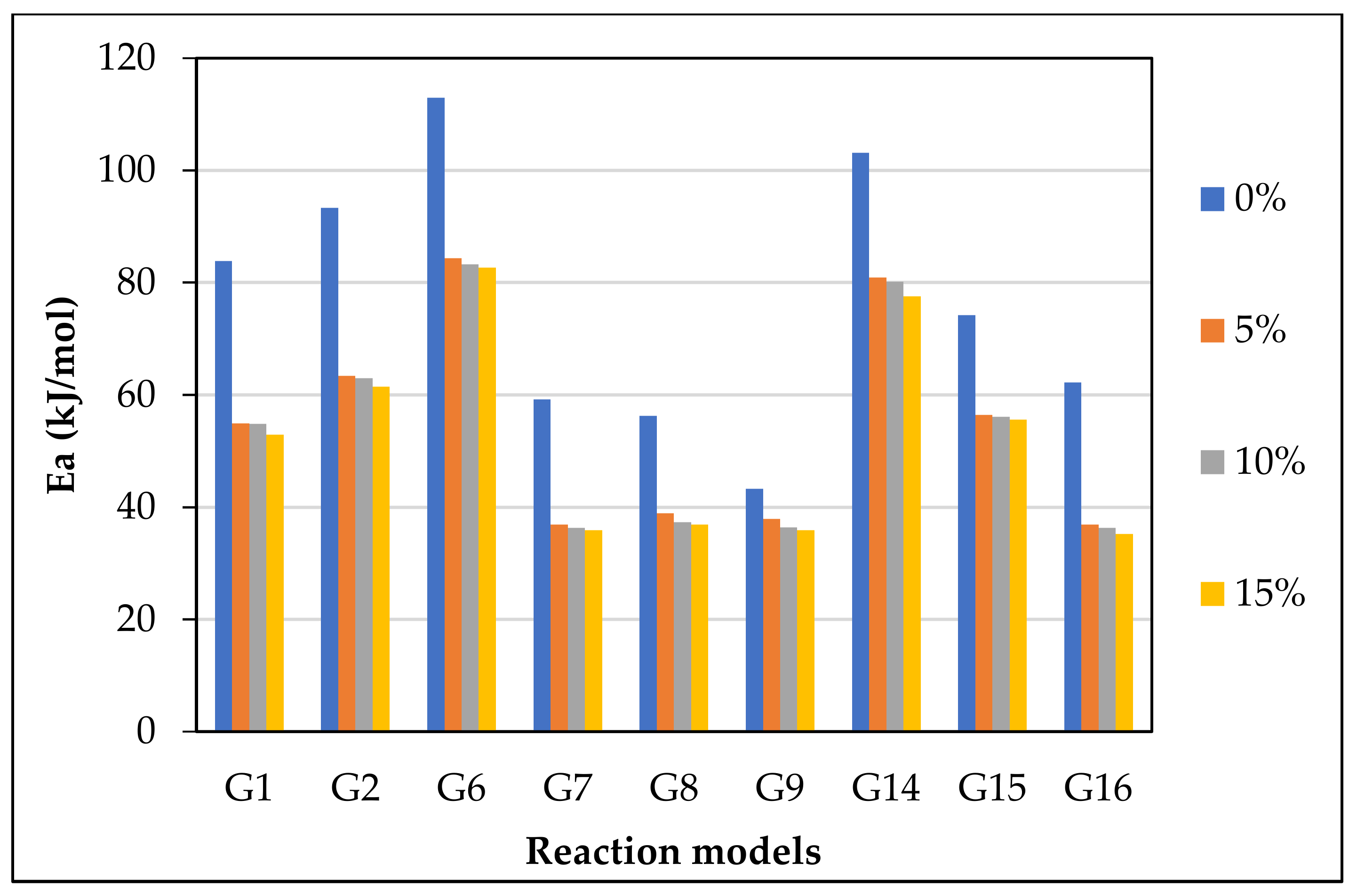

The accurate estimation of the kinetic parameters of the heterogeneous and non-isothermal reaction is a substantial step in a design of a biomass gasifier. In this work, the model-fitting CR method was used to estimate the

and A of the CO

2 gasification process in the presence of olivine and dolomite as catalysts. The method models (G1–G19) were tested to obtain the most fitted graph. In the presence of dolomite or olivine, the

was significantly reduced with the increase in the catalyst loading [

43]. However, dolomite had a better kinetic performance in comparison with olivine. The degradation process is a chemical reaction-controlled in the first step (reaction extent less than 0.2). In the second and third steps of degradation, when the reaction extent is between 0.2 and 0.8, the process is controlled by three-dimensional diffusion and chemical reaction. Finally, at a reaction extent greater than 0.8, the decomposition is solely controlled by the three-dimensional diffusion mechanism [

44]. This reveals that the reaction mechanism of Subcoal™ PAF gasification in the fixed bed is complex and occurs in a multistage thermal decomposition. The higher the complexity of the dehydration mechanism, the greater the variation of

[

45]. In the DTG analysis, the degradation rate in wt.%/min was plotted against the temperature. Four peaks appeared in the graph showing the amount of degradation that occurred at a specific temperature. Thermal gasification reaction with the catalyst was evaluated according to DTG and Tm values. The results showed two small peaks corresponding to degradation in the first and fourth stages, respectively, as well as two large peaks of the stages in the devolatilisation stage [

46]. The Tm peaks overlapped, and the irregularity of the peak shape indicated the occurrence of simultaneous gasification reactions. Additionally, the presence of oxygen in the reaction mixture led to several oxidation reactions that impact the evaluation of DTG. Dolomite has a better degradation performance at constant catalyst concentration than olivine. For model G14, the

reduced by 62 kJ/mol as the dolomite concentration increased from 0 to 15 wt.%, while only a 25.6 kJ/mol reduction was obtained by olivine. The lower the

, the lower the gasification temperature. For both catalysts, the

decreased as the loading of the catalyst increased. The higher the loading of catalysts, the lower the Tm peak obtained [

47]. Dolomite causes a higher reduction in Tm value and better DTG outcomes compared with olivine. The fitting of curves showed that models G14 and G15 provided relatively high correlation coefficient

R2 for both catalysts. The mechanism of the catalytic gasification accordingly varied between second- to third-order chemical reactions. Dolomite enhances tar cracking by promoting the water–gas reaction [

48]. The tar elimination in the presence of dolomite can attain 100%, as demonstrated by Simell et al. [

17]. Syngas products and an active carbon deposit are formed when a benzene ring is incorporated on the active sites of CaO. The active carbon deposit undergoes a reaction with steam or ends with coke formation on CaO. MgO breaks the H

2 bonding in water, forming OH, which is absorbed on the active sites of MgO. The OH group then combines with the remaining active carbon to form formate. A spill over of OH takes place, leading to decomposition of formate to syngas and the removal of coke [

49,

50]. Kim et al. [

51] carried out a kinetic study on the

gasification of Chinese low-rank lignite coal and found that the dolomite minimises the

and reaction time of biomass gasification.

Dolomite calcination includes the formation of MgO and CaO by thermal cracking [

20]. The following chemical reactions describe the calcination of dolomite over two ranges of temperatures [

52]:

As can be seen in the reactions, the equilibria of calcination are sensitive to CO

2 gas release. It is preferred that the partial pressure of CO

2 stays under the equilibrium pressure to avoid catalyst deactivation [

53]. Besides the process pressure, temperature plays a crucial role in controlling the calcination and carbonation reactions [

54]. Other factors that influence the calcination process include heating rate, the quantity of the catalyst, and particle size [

55]. The purpose of dolomite calcination is to increase the size of the catalyst pores, which is then responsible for mass transfer enhancement. The time and temperature of calcination increase the surface area of the catalyst, hence the catalysis activity increases [

56].

It has been revealed that olivine increases the yield of syngas and tar conversion and reduces the production of CH

4 and CO

2 [

12,

57]. The gasification in the CO

2 atmosphere causes the oxidation of olivine in the combustion zone, producing binary iron oxide hematite (Fe

2O

3), SiO

2, and iron-depleted olivine. The formed Fe

2O

3 is subsequently reduced by the organic compounds in biomass to FeO, CO, and H

2. In gasification with the synthesis of olivine (Mg0.5 Fe0.5)

2 SiO

4, about 10% of iron content in olivine is oxidised at 300 s according to thermogravimetric analysis [

58]. Moreover, olivine is capable of accommodating excess oxygen from a gasifying agent, as shown in the reaction below:

The gained oxygen in olivine is used to partially oxidise methane in the gasification zone when the partial pressure of O

2 is low [

58]:

In the CO

2 biomass gasification, olivine undergoes a cycle of oxidation and reduction to produce the active iron and then to regenerate the catalyst. The oxidation of iron in olivine takes place during the calcination at a temperature of 400–1400 °C in two steps. The purpose of olivine oxidation is to produce the Fe

2O

3, wch promotes the tar removal reactions [

59].

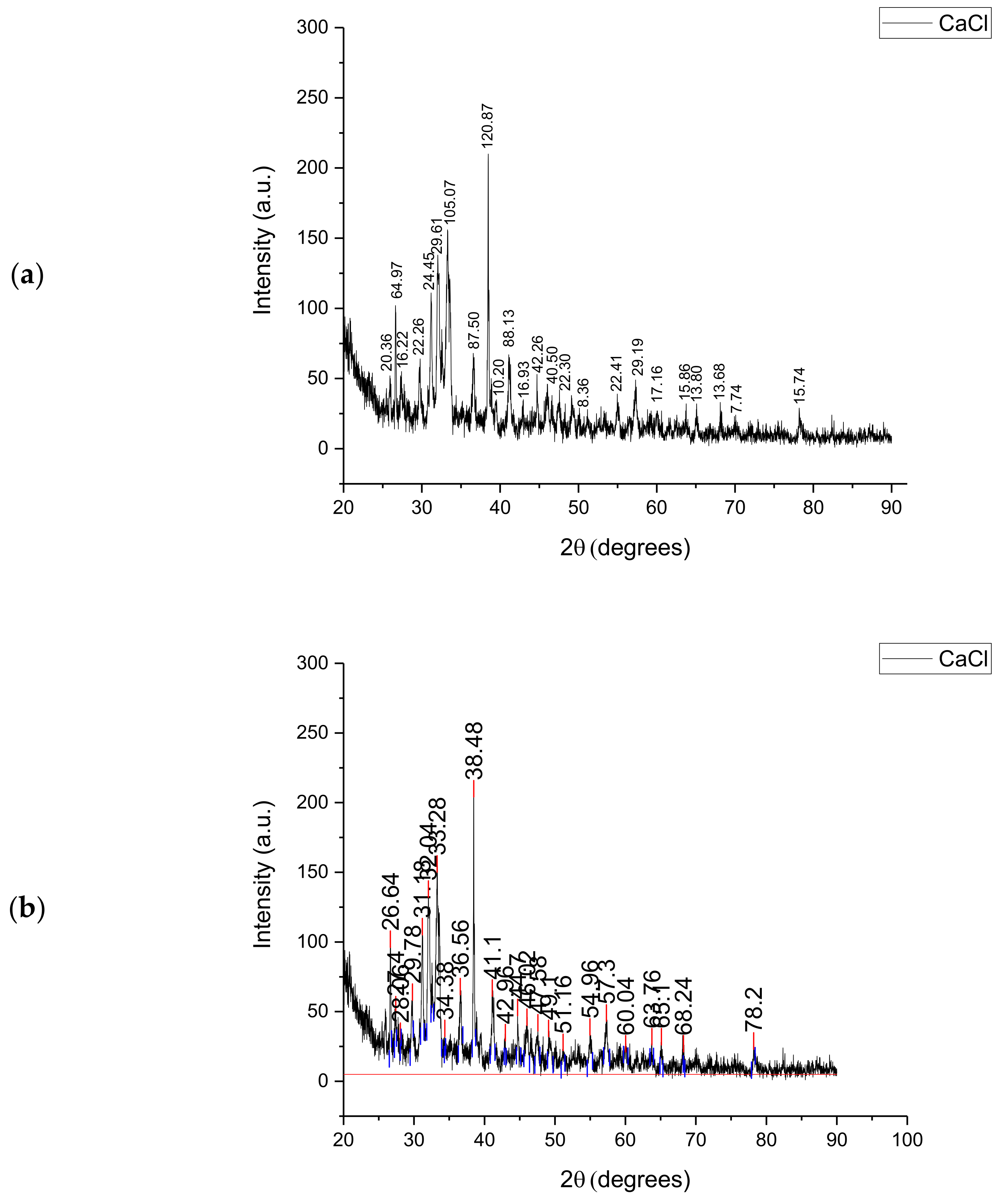

The crystallinity and mineral content in the Subcoal™ sample and ash may contribute to the catalysis process of CO

2 gasification. The XRF analysis showed that the Subcoal™ ash contained 38 and 18.3 wt.% CaO and Al

2O

3, respectively, which is considered as an effective catalyst of char decomposition reactions [

30,

60]. The crystallinity of ash and biomass minerals also plays an important role in catalytic activity. Furthermore, there is a positive correlation between the crystallinity of biomass and decomposition temperature and activation energy [

61].

The gasification of MSW, specifically Subcoal™, vitally contributes to the Qatar National Vision 2030 through reducing the MSW landfill and generating renewable power. The availability of naturally occurring minerals in Qatar improves the potential of using Subcoal™ gasification as an alternative to natural gas power plants. Mineral catalysts such as dolomite enhance the gasification efficiency and producer gas quality.