Circumventing Unintended Impacts of Waste N95 Facemask Generated during the COVID-19 Pandemic: A Conceptual Design Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. Modelling Approach

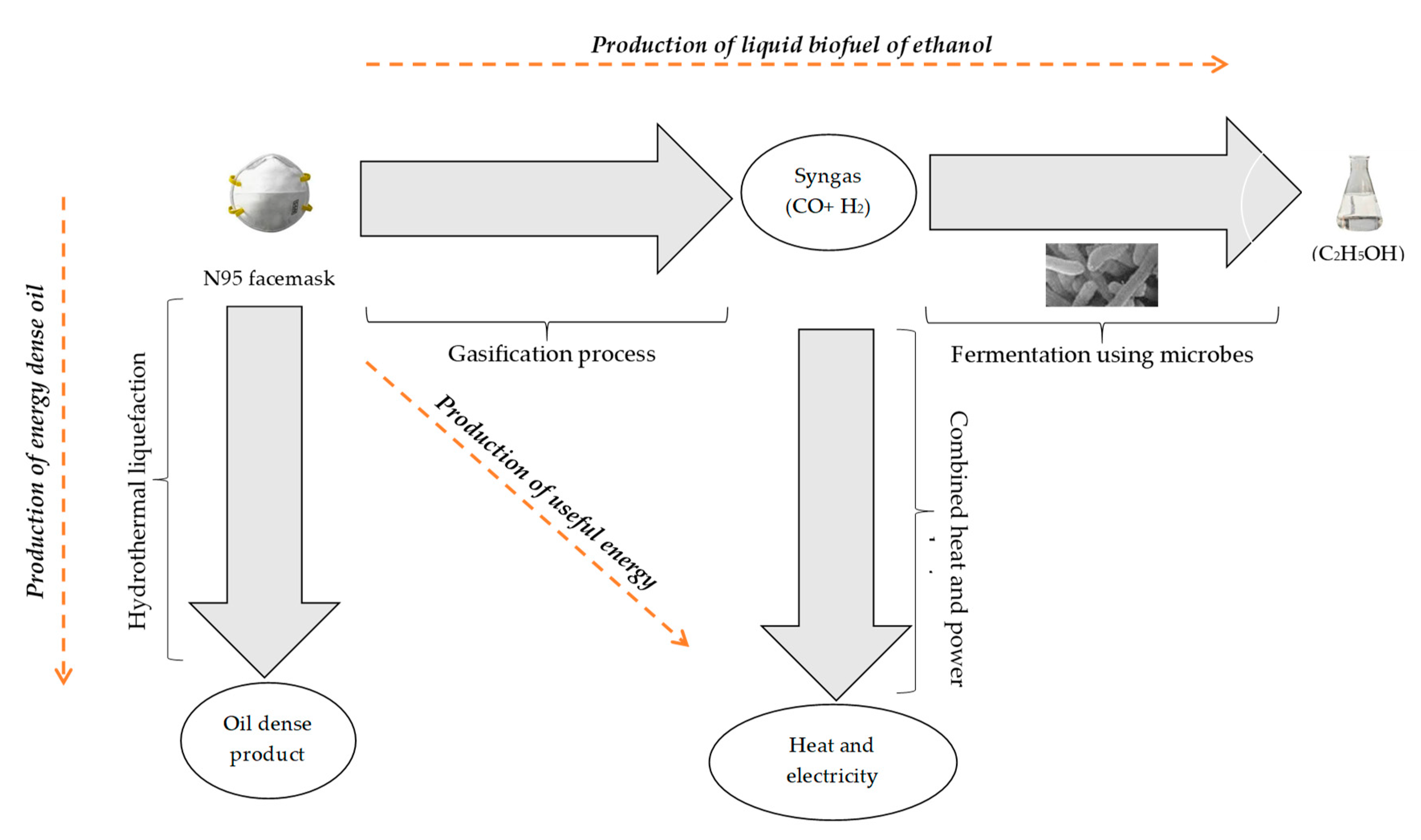

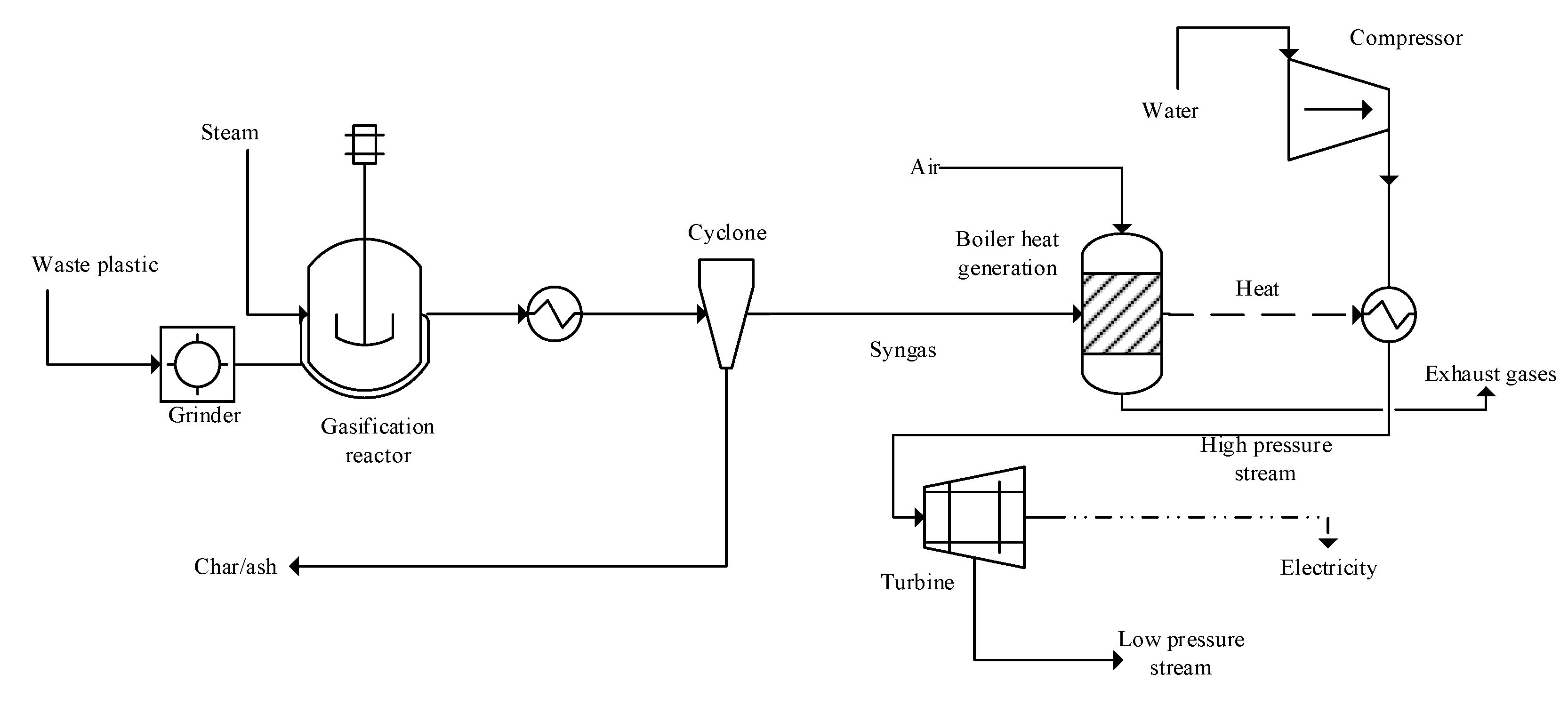

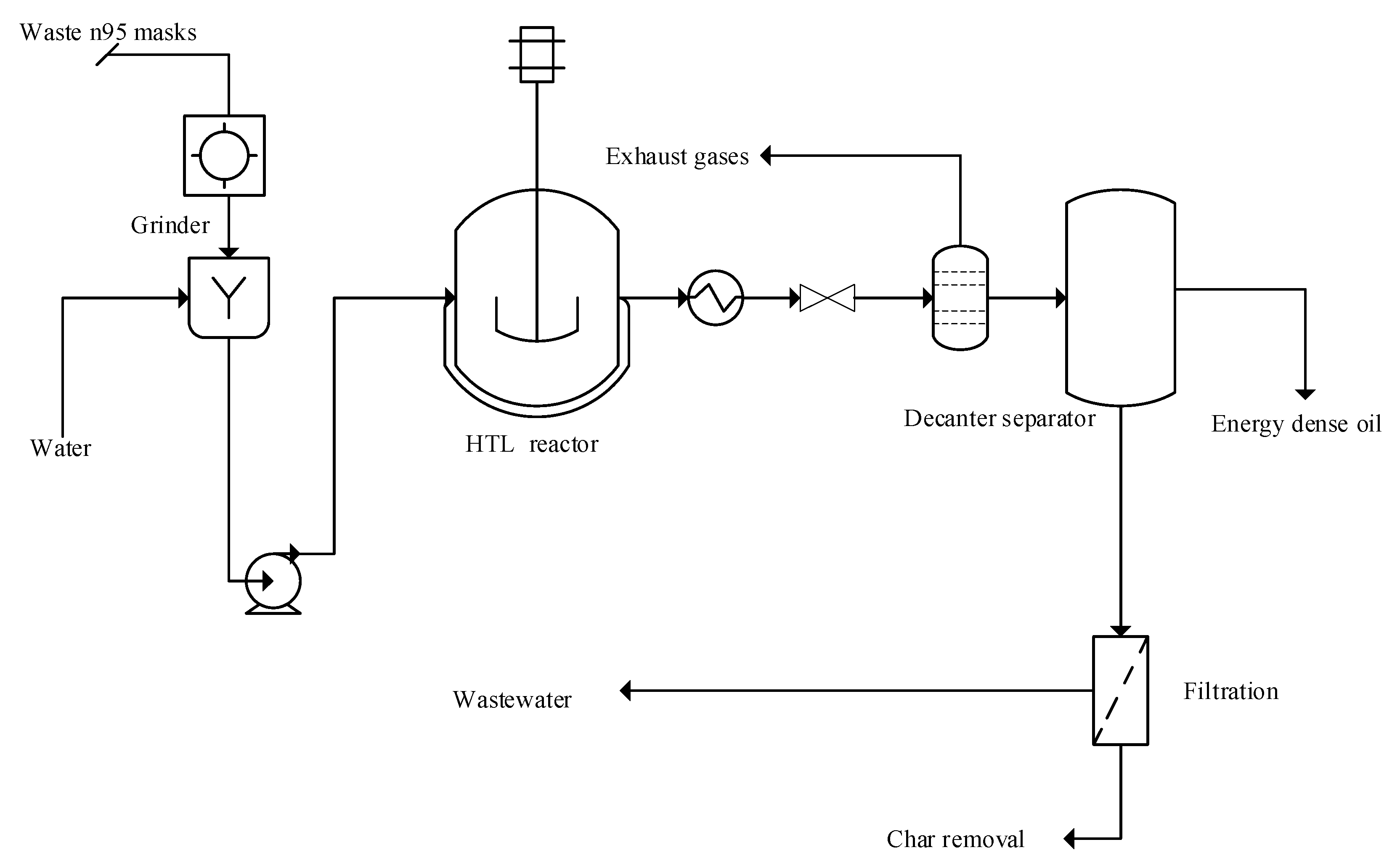

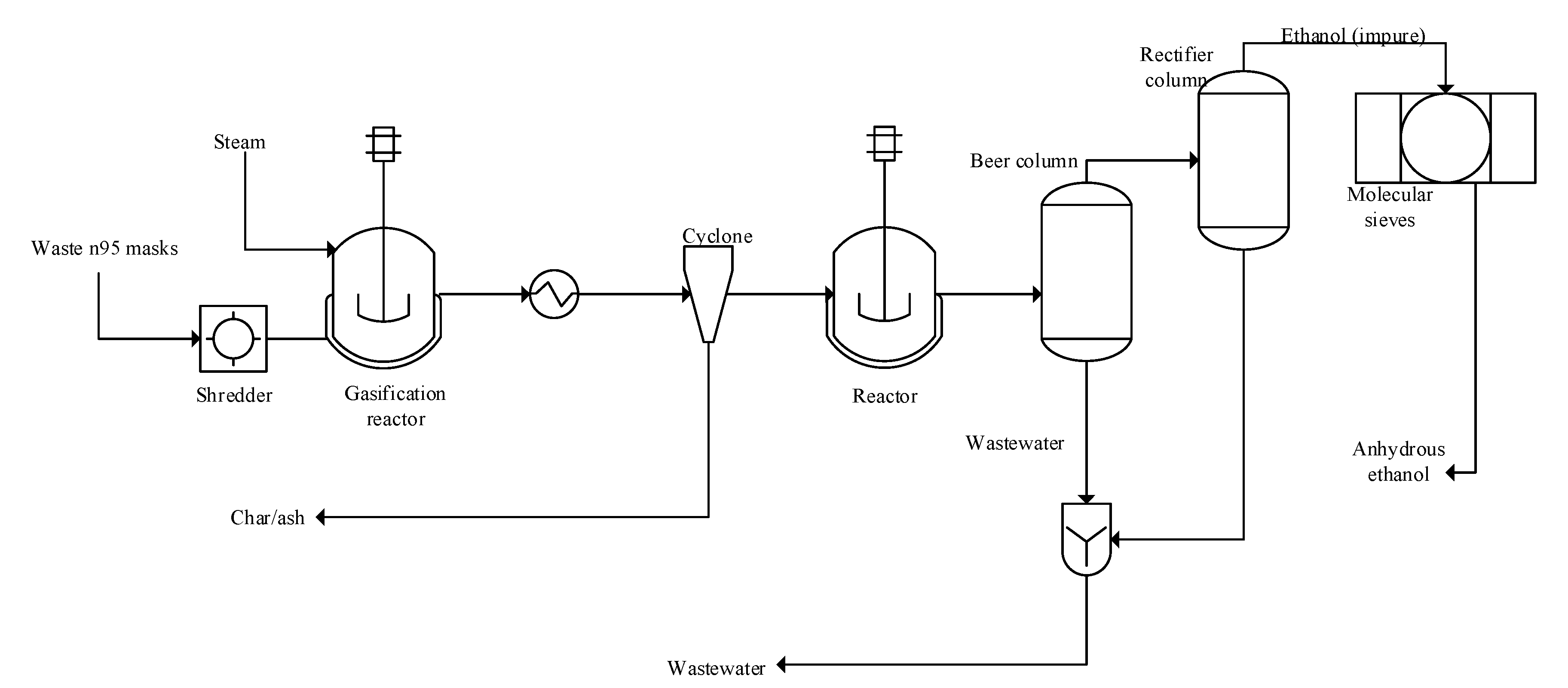

2.2. Process Description

2.3. Economic Performance Measure

2.4. Environmental Performance Assessment

3. Results and Discussion

Study Considerations and Limitations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Cascella, M.; Rajnik, M.; Cuomo, A.; Dulebohn, S.C.; Di Napoli, R. Features, evaluation and treatment coronavirus (COVID-19). In Statpearls [Internet]; StatPearls Publishing: Treasure Island, FL, USA, 2020. [Google Scholar]

- Rothan, H.A.; Byrareddy, S.N. The epidemiology and pathogenesis of coronavirus disease (COVID-19) outbreak. J. Autoimmun. 2020, 109, 102433. [Google Scholar]

- Allison, A.L.; Ambrose-Dempster, E.; Aparsi, T.D.; Bawn, M.; Arredondo, M.C.; Chau, C.; Chandler, K.; Dobrijevic, D.; Hailes, H.C.; Lettieri, P.; et al. The environmental dangers of employing single-use face masks as part of a COVID-19 exit strategy. UCL Open Environ. Prepr. 2020. [Google Scholar] [CrossRef]

- European Centre for Disease Prevention and Control. COVID-19 Situation Update Worldwide, as of 19 June 2020. Available online: https://www.ecdc.europa.eu/en/geographical-distribution-2019-ncov-cases (accessed on 19 June 2020).

- Filligent (HK) Limited. N95-FDA; Center for Devices and Radiological Health: Hong Kong, China, 2013. Available online: https://www.accessdata.fda.gov/cdrh_docs/pdf12/K122702.pdf (accessed on 16 May 2020).

- Thomasnet. How to Make N95 Masks. 2020. Available online: https://www.thomasnet.com/articles/plant-facility-equipment/how-to-make-n95-masks/ (accessed on 18 June 2020).

- Klemeš, J.J.; Van Fan, Y.; Tan, R.R.; Jiang, P. Minimising the present and future plastic waste, energy and environmental footprints related to COVID-19. Renew. Sustain. Energy Rev. 2020, 127, 109883. [Google Scholar] [CrossRef]

- Ennomotive. 6 Types of Masks and their Effectiveness against COVID-19. 2020. Available online: https://www.ennomotive.com/types-of-masks-covid-19/ (accessed on 16 May 2020).

- Huang, J. Polymer waste management -biodegradation, incineration, and recycling. J. Macromol. Sci. 1995, 32, 593–597. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F. Recycling of waste from polymer materials: An overview of the recent works. Polym. Degard. Stabil. 2013, 98, 2801–2812. [Google Scholar] [CrossRef]

- Verma, R.; Vinoda, K.S.; Papireddy, M.; Gowda, A.N.S. Toxic Pollutants from Plastic Waste—A Review. Procedia Environ. Sci. 2016, 35, 701–708. [Google Scholar] [CrossRef]

- Burra, K.G.; Gupta, A.K. Synergistic effects insteam gasification of combined biomass and plastic waste mixtures. Appl. Energy 2018, 211, 230–236. [Google Scholar] [CrossRef]

- Okoro, O.V.; Sun, Z.; Birch, J. Meat processing waste as a potential feedstock for biochemicals and biofuels —A review of possible conversion technologies. J. Clean. Prod. 2017, 142, 1583–1608. [Google Scholar] [CrossRef]

- Sun, X.; Atiyeh, H.K.; Huhnke, R.L.; Tanner, R.S. Syngas fermentation process development for production of biofuels and chemicals: A review. Bioresour. Technol. Rep. 2019, 7, 100279. [Google Scholar] [CrossRef]

- Filligent. FDA Government. 2012. Available online: https://www.accessdata.fda.gov/cdrh_docs/pdf19/K192105.pdf (accessed on 12 June 2020).

- Okoro, O.V.; Sun, Z.; Birch, J. Catalyst-Free Biodiesel Production Methods: A Comparative Technical and Environmental Evaluation. Sustainability 2018, 10, 127. [Google Scholar] [CrossRef]

- Bousquet, J. Thermal Data for natural and synthetic fuels by siddhartha gaur (VSLR Sciences -Dallas, TX) and Thomas B. REED (Colorado School of Mines-Golden, CO)Marcel DEKKER, 1988, 258 pages., Price 167, 71 euros. Can. J. Chem. Eng. 2005, 83, 389. [Google Scholar] [CrossRef]

- Li, D.-T.; Li, W.; Li, B.-Q. CO-Carbonization of Coking-Coal with Different Waste Plastics. J. Fuel Chem. Technol. 2001, 29, 19–23. [Google Scholar]

- Nakayama, T.; Sagara, H.; Arai, K.; Saito, S. High pressure liquid-liquid equilibria for the system of water, ethanol and 1,1-difluoroethane at 323.2 K. Fluid Phase Equilibria 1987, 38, 109–127. [Google Scholar] [CrossRef]

- Geanã, D.; Feroiu, V. Prediction of Vapor−Liquid Equilibria at Low and High Pressures from UNIFAC Activity Coefficients at Infinite Dilution. Ind. Eng. Chem. Res. 1998, 37, 1173–1180. [Google Scholar] [CrossRef]

- Totsch, W.; Gaensslen, H. Polyvinylchloride: Environmental Aspects of a Common Plastic; Elsevier: London, UK, 2012. [Google Scholar]

- Bhaskar, T.; Balagurumurthy, B.; Singh, R.; Poddar, M.K. Chapter 12—Thermochemical Route for Biohydrogen Production. In Biohydrogen; Pandey, A., Chang, J.-S., Hallenbecka, P.C., Larroche, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 285–316. [Google Scholar] [CrossRef]

- Gagliano, A.; Nocera, F.; Bruno, M.; Cardillo, G. Development of an equilibrium-based model of gasification of biomass by Aspen Plus. Energy Procedia 2017, 111, 1010–1019. [Google Scholar] [CrossRef]

- Kaewluan, S.; Pipatmanomai, S. Potential of synthesis gas production from rubber wood chip gasification in a bubbling fluidised bed gasifier. Energy Convers. Manag. 2011, 52, 75–84. [Google Scholar] [CrossRef]

- Okoro, O.V.; Faloye, F.D. Comparative Assessment of Thermo-Syngas Fermentative and Liquefaction Technologies as Waste Plastics Repurposing Strategies. AgriEngineering 2020, 2, 378–392. [Google Scholar] [CrossRef]

- Chen, W.-T.; Jin, K.; Linda Wang, N.-H. Use of Supercritical Water for the Liquefaction of Polypropylene into Oil. ACS Sustain. Chem. Eng. 2019, 7, 3749–3758. [Google Scholar] [CrossRef]

- Möller, M.; Harnisch, F.; Schröder, U. Hydrothermal liquefaction of cellulose in subcritical water—The role of crystallinity on the cellulose reactivity. RSC Adv. 2013, 3, 11035–11044. [Google Scholar] [CrossRef]

- Valdez, P.J.; Tocco, V.J.; Savage, P.E. A general kinetic model for the hydrothermal liquefaction of microalgae. Bioresour. Technol. 2014, 163, 123–127. [Google Scholar] [CrossRef]

- Jones, S.; Zhu, Y.; Anderson, D.; Hallen, R.; Elliot, D.; Schmidt, A.; Albrecht, K.; Hart, T.; Butcher, M.; Drennan, C.; et al. Process Design and Economics for the Conversion of Algal Biomass to Hydrocarbons: Whole Algae Hydrothermal Liquefaction and Upgrading; Pacific Northwest National Laboratory: Springfield, MI, USA, 2014.

- Vardon, D.R.; Sharma, B.K.; Scott, J.; Yu, G.; Wang, Z.; Schideman, L.; Zhang, Y.; Strathmann, T.J. Chemical properties of biocrude oil from the hydrothermal liquefaction of Spirulina algae, swine manure, and digested anaerobic sludge. Bioresour. Technol. 2011, 102, 8295–8303. [Google Scholar] [CrossRef]

- Ukpong, M.N.; Atiyeh, H.K.; De Lorme, M.J.; Liu, K.; Zhu, X.; Tanner, R.S.; Wilkins, M.R.; Stevenson, B.S. Physiological response of Clostridium carboxidivorans during conversion of synthesis gas to solvents in a gas-fed bioreactor. Biotechnol. Bioeng. 2012, 109, 2720–2728. [Google Scholar] [CrossRef] [PubMed]

- Tanner, R.S.; Miller, L.M.; Yang, D. Clostridium ljungdahlii sp. nov., an acetogenic species in clostridial rRNA homology group I. Int. J. Syst. Evol. Microbiol. 1993, 43, 232–236. [Google Scholar] [CrossRef] [PubMed]

- Phillips, J.R.; Klasson, K.T.; Clausen, E.C.; Gaddy, J.L. Biological production of ethanol from coal synthesis gas. Appl. Biochem. Biotechnol. 1993, 39, 559–571. [Google Scholar] [CrossRef]

- Amigun, B.; Petrie, D.; Görgens, J. Feedstock and Technology Options for Bioethanol Production in South Africa: Technoeconomic Prefeasibility Study. Energy Fuels 2012, 26, 5887–5896. [Google Scholar] [CrossRef]

- Engineering ToolBox. Fuels—Higher and Lower Calorific Values. 2003. Available online: https://www.engineeringtoolbox.com/fuels-higher-calorific-values-d_169.html (accessed on 10 June 2020).

- Kemp, I.C. Pinch Analysis and Process Integration: A User Guide on Process Integration for the Efficient Use of Energy; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Mupondwa, E.; Li, X.; Tabil, L.; Falk, K.; Gugel, R. Technoeconomic analysis of camelina oil extraction as feedstock for biojet fuel in the Canadian Prairies. Biomass Bioenergy 2016, 95, 221–234. [Google Scholar] [CrossRef]

- Násner, A.M.L.; Lora, E.E.S.; Palacio, J.C.E.; Rocha, M.H.; Restrepo, J.C.; Venturini, O.J.; Ratner, A. Refuse Derived Fuel (RDF) production and gasification in a pilot plant integrated with an Otto cycle ICE through Aspen plus™ modelling: Thermodynamic and economic viability. Waste Manag. 2017, 69, 187–201. [Google Scholar] [CrossRef]

- Arjunan, K. IRR Performs Better than NPV: A Critical Analysis of Cases of Multiple IRR and Mutually Exclusive and Independent Investments. SSRN Electron. J. 2017. [Google Scholar] [CrossRef]

- Environment. The Potential of Recycled Plastics; Plastics Industry Association: Washington, DC, USA, 2020. [Google Scholar]

- ETSAP. Combined Heat and Power. Energy Technology Network: Energy Technology Systems Analysis Programme. 2010. Available online: https://iea-etsap.org/E-TechDS/PDF/E04-CHP-GS-gct_ADfinal.pdf (accessed on 7 March 2020).

- Dutta, A.; Talmadge, M.; Hensley, J.; Worley, M.; Dudgeon, D.; Barton, D.; Groendijk, P.; Ferrari, D.; Stears, B.; Searcy, E.M. Process Design and Economics for Conversion of Lignocellulosic Biomass to Ethanol: Thermochemical Pathway by Indirect Gasification and Mixed Alcohol Synthesis; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2011.

- Rickman, W.S. Handbook of Incineration of Hazardous Wastes (1991); CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Alibaba. Plastic Machinery Hdpe Polycarbonate. 2020. Available online: https://www.alibaba.com/product-detail/Plastic-Machinery-hdpe-polycarbonate-7-5_62538362812.html?spm=a2700.galleryofferlist.0.0.48fd258aHoj76o (accessed on 20 February 2020).

- Towler, G.; Sinnott, R. Chemical Engineering Design: Principles, Practice and Economics of Plant and Process Design; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Okoro, V.O.; Sun, Z. Desulphurisation of Biogas: A Systematic Qualitative and Economic-Based Quantitative Review of Alternative Strategies. ChemEngineering 2019, 3, 76. [Google Scholar] [CrossRef]

- Chemengonline. 2019 Chemical Engineering Plant Cost Index Annual Average. 2020. Available online: https://www.chemengonline.com/2019-chemical-engineering-plant-cost-index-annual-average/ (accessed on 2 July 2020).

- Magnehi. Chemical Engineering Plant Cost Index (Averaged Over Year). 2011. Available online: http://folk.ntnu.no/magnehi/cepci_2011_py.pdf (accessed on 2 July 2020).

- Moncada, J.; Tamayo, J.A.; Cardona, C.A. Integrating first, second, and third generation biorefineries: Incorporating microalgae into the sugarcane biorefinery. Chem. Eng. Sci. 2014, 118, 126–140. [Google Scholar] [CrossRef]

- Rincón, L.E.; Jaramillo, J.J.; Cardona, C.A. Comparison of feedstocks and technologies for biodiesel production: An environmental and techno-economic evaluation. Renew. Energy 2014, 69, 479–487. [Google Scholar] [CrossRef]

- Young, D.M.; Cabezas, H. Designing sustainable processes with simulation: The waste reduction (WAR) algorithm. Comput. Chem. Eng. 1999, 23, 1477–1491. [Google Scholar] [CrossRef]

- Gangadharan, P.; Kanchi, K.C.; Lou, H.H. Evaluation of the economic and environmental impact of combining dry reforming. Chem. Eng. Res. Des. 2012. [Google Scholar] [CrossRef]

- Mustafa, A.; Calay, R.K.; Mustafa, M.Y. A techno-economic study of a biomass gasification plant for the production of transport biofuel for small communities. Energy Procedia 2017, 112, 529–536. [Google Scholar] [CrossRef]

- Rutberg, P.G.; Kuznetsov, V.A.; Serba, E.O.; Popov, S.D.; Surov, A.V.; Nakonechny, G.V.; Nikonov, A.V. Novel three-phase steam–air plasma torch for gasification of high-caloric waste. Appl. Energy 2013, 108, 505–514. [Google Scholar] [CrossRef]

- Lee, J.W.; Yu, T.U.; Lee, J.W.; Moon, J.H.; Jeong, H.J.; Park, S.S.; Yang, W.; Lee, U.D. Gasification of mixed plastic wastes in a moving-grate gasifier and application of the producer gas to a power generation engine. Energy Fuels 2013, 27, 2092–2098. [Google Scholar] [CrossRef]

- Saebea, D.; Ruengrit, P.; Arpornwichanop, A.; Patcharavorachot, Y. Gasification of plastic waste for synthesis gas production. Energy Rep. 2020, 6, 202–207. [Google Scholar] [CrossRef]

- Kunwar, B.; Chandrasekaran, S.R.; Moser, B.R.; Deluhery, J.; Kim, P.; Rajagopalan, N.; Sharma, B.K. Catalytic Thermal Cracking of Postconsumer Waste Plastics to Fuels. 2. Pilot-Scale Thermochemical Conversion. Energy Fuels 2017, 31, 2705–2715. [Google Scholar] [CrossRef]

- Rajagopalan, S.; Datar, R.P.; Lewis, R.S. Formation of ethanol from carbon monoxide via a new microbial catalyst. Biomass Bioenergy 2002, 23, 487–493. [Google Scholar] [CrossRef]

- Shen, Y.; Brown, R.; Wen, Z. Enhancing mass transfer and ethanol production in syngas fermentation of Clostridium carboxidivorans P7 through a monolithic biofilm reactor. Appl. Energy 2014, 136, 68–76. [Google Scholar] [CrossRef]

- Akhtar, J.; Amin, N.A.S. A review on process conditions for optimum bio-oil yield in hydrothermal liquefaction of biomass. Renew. Sustain. Energy Rev. 2011, 15, 1615–1624. [Google Scholar] [CrossRef]

- Midgett, J.S. Assessing a Hydrothermal Liquefaction Process Using Biomass Feedstocks. Master’s Thesis, Louisiana State University, Baton Rouge, LA, USA, 2008. [Google Scholar]

- Remón, J.; Randall, J.; Budarin, V.L.; Clark, J.H. Production of bio-fuels and chemicals by microwave-assisted, catalytic, hydrothermal liquefaction (MAC-HTL) of a mixture of pine and spruce biomass. Green Chem. 2019, 21, 284–299. [Google Scholar] [CrossRef]

- Manahan, S.E. Environmental Chemistry; CRC Press: New York, NY, USA, 2017. [Google Scholar]

| Proximate Analysis | Ultimate Analysis | |||||||

|---|---|---|---|---|---|---|---|---|

| Waste N95 Facemask | Ash a (wt%) | Volatiles a (wt%) | FC a (wt%) | Carbon b (wt%) | Hydrogen b (wt%) | Oxygen b (wt%) | Nitrogen b (wt%) | Sulphur b (wt%) |

| (C3H6)n | 0.82 | 99.18 | 0 | 83.75 | 13.98 | 2.27 | 0 | 0 |

| C6H10O5 | 0 | 0 | 0 | 44.44 | 6.17 | 49.38 | 0 | 0 |

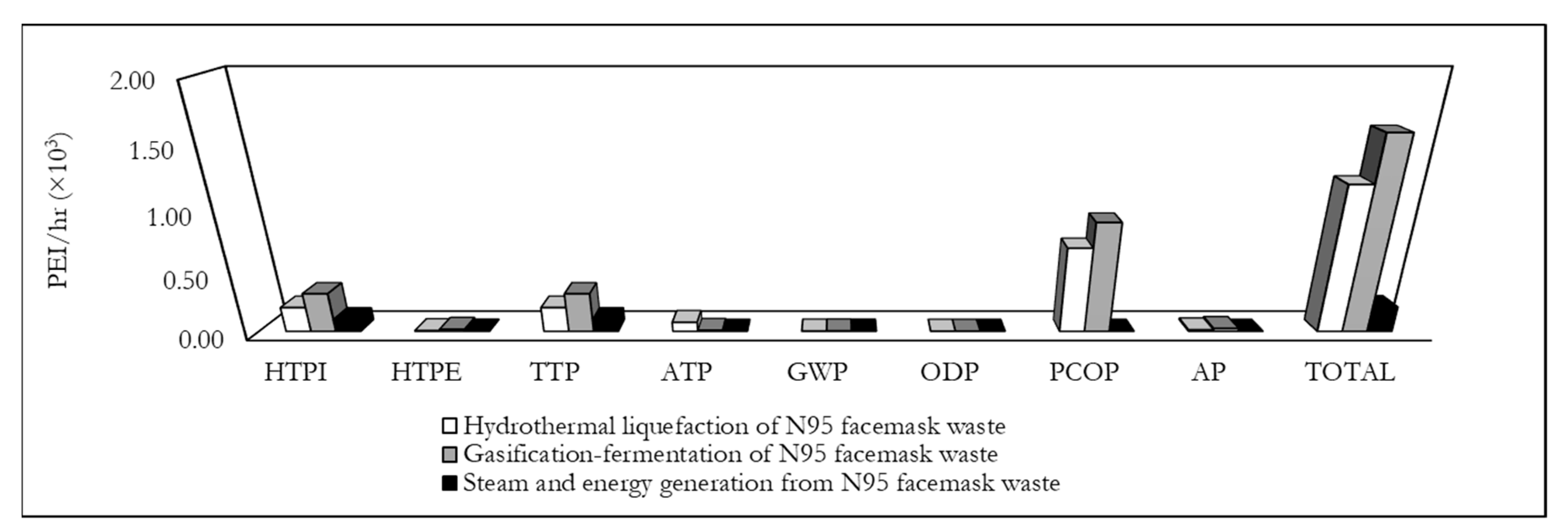

| General Impact Category | Impact Category | Measure of Impact Category |

|---|---|---|

| Human toxicity | Ingestion (HTPI) | LD50 |

| Inhalation/dermal (HTPE) | OSHA PEL | |

| Ecological toxicity | Aquatic toxicity (ATP) | Fathead Minnow LC50 |

| Terrestrial toxicity (TTP) | LD50 | |

| Global atmospheric impacts | Global warming potential (GWP) | GWP |

| Ozone depletion potential (ODP) | ODP | |

| Regional atmospheric impacts | Acidification potential (AP) | AP |

| Photochemical oxidation potential (PCOP) | PCOP |

| Stream Property. | Waste N95 Facemask | Cellulose Fraction | Polypropylene Fraction | Syngas | Ash | Steam |

|---|---|---|---|---|---|---|

| Temperature (°C) | 25 | 25 | 25 | 1000 | 25 | 349.5 |

| Pressure (atm) | 1 | 1 | 1 | 1 | 1 | 1 |

| Mass Fractions (x) | ||||||

| Water | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 1.00 |

| Polypropylene | 0.75 | 0.00 | 1.00 | 0.00 | 0.00 | 0.00 |

| Hydrogen | 0.00 | 0.00 | 0.00 | 0.12 | 0.00 | 0.00 |

| Carbon monoxide | 0.00 | 0.00 | 0.00 | 0.27 | 0.00 | 0.00 |

| Carbon dioxide | 0.00 | 0.00 | 0.00 | 0.61 | 0.00 | 0.00 |

| Ash | 0.00 | 0.00 | 0.00 | 0.00 | 1.00 | 0.00 |

| Cellulose | 0.25 | 1.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Mass Flows (kg/h) | 1770 | 442.5 | 1327.5 | 5310.0 | 13.1 | 10000 |

| Molar Composition of Syngas | This Study | Pure PP a Feed [56] |

|---|---|---|

| Hydrogen | 71 | 67.25 |

| Carbon monoxide | 17 | 25.24 |

| Carbon dioxide | 12 | 7.33 |

| Methane | 0 | 0.18 |

| Stream Property | Waste N95 Facemask | Cellulose Fraction | Polypropylene Fraction | HTL Product Mix | Oil Product | Gas Product |

|---|---|---|---|---|---|---|

| Temperature (°C) | 25 | 25 | 25 | 425 | 25 | 25 |

| Pressure (atm) | 1 | 1 | 1 | 227 | 1 | 1 |

| Mass Fractions (x) | ||||||

| Water | 0 | Trace | 0 | 0 | ||

| Polypropylene | 0.75 | 0 | 1 | 0 | 0 | 0 |

| CO | 0 | 0 | 0 | 0.204 | 0 | 0.773 |

| CO2 | 0 | 0 | 0 | 0.007 | 0 | 0.025 |

| Ash | 0 | 0 | 0 | 0.007 | 0 | 0 |

| C11H22 | 0 | 0 | 0 | Trace | Trace | 0 |

| C12H24 | 0 | 0 | 0 | 0.004 | 0.006 | 0 |

| C8H18 | 0 | 0 | 0 | 0.000 | Trace | 0 |

| C9H20 | 0 | 0 | 0 | 0.014 | 0.019 | 0 |

| C10H22 | 0 | 0 | 0 | 0.036 | 0.050 | 0 |

| C11H24 | 0 | 0 | 0 | 0.233 | 0.320 | 0 |

| C12H26 | 0 | 0 | 0 | 0.288 | 0.40 | 0 |

| C5H12 | 0 | 0 | 0 | 0.037 | 0.051 | 0 |

| C6H14 | 0 | 0 | 0 | 0.050 | 0.068 | 0 |

| C7H16 | 0 | 0 | 0 | 0.066 | 0.091 | 0 |

| CH4 | 0 | 0 | 0 | 0.013 | 0 | 0.048 |

| C2H6 | 0 | 0 | 0 | 0.005 | 0 | 0.021 |

| C3H8 | 0 | 0 | 0 | 0.012 | 0 | 0.046 |

| C4H10 | 0 | 0 | 0 | 0.023 | 0 | 0.088 |

| Cellulose | 0.25 | 1 | 0 | 0 | 0 | 0 |

| HMF | 0 | 0 | 0 | Trace | 0 | 0 |

| Mass Flows | 1770.0 | 442.5 | 1327.5 | 2002.9 | 1460.7 | 529.1 |

| Stream Property | Waste N95 Facemask | Cellulose Fraction | Polypropylene Fraction | Syngas | Ethanol | Waste Water |

|---|---|---|---|---|---|---|

| Temperature (°C) | 25 | 25 | 25 | 1000 | 25 | 25 |

| Pressure (atm) | 1 | 1 | 1 | 1 | 1 | 1 |

| Mass Fractions (x) | ||||||

| Water | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.48 |

| Polypropylene | 0.75 | 0.00 | 1.00 | 0.00 | 0.00 | 0.00 |

| Ethanol | 0 | 0 | 0 | 0 | 1 | 0.03 |

| Hydrogen | 0.00 | 0.00 | 0.00 | 0.12 | 0.00 | 0.00 |

| Carbon monoxide | 0.00 | 0.00 | 0.00 | 0.27 | 0.00 | 0.00 |

| Carbon dioxide | 0.00 | 0.00 | 0.00 | 0.61 | 0.00 | 0.00 |

| Acetic acid | 0.00 | 0.00 | 0.00 | 0.00 | 1.00 | 0.49 |

| Cellulose | 0.25 | 1.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Mass Flows (kg/h) | 1770 | 442.5 | 1327.5 | 5310.0 | 1113.9 | 3187.5 |

| Economic Parameter | Scenario i | Scenario ii | Scenario iii |

|---|---|---|---|

| Fixed capital investment (MU$) | 7.24 | 4.08 | 8.36 |

| Working capital investment (MU$) | 0.36 | 0.20 | 0.42 |

| Total capital investment (MU$) | 7.60 | 4.28 | 8.78 |

| Fixed operating cost (MU$) | 1.76 | 1.49 | 1.85 |

| Variable operating cost (MU$) | 10.23 | 1.26 | 11.55 |

| Total operating cost (MU$) | 11.99 | 2.75 | 13.40 |

| NPV (MU$) | 36.6 | 53.07 | −46.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okoro, O.V.; Nkrumah Banson, A.; Zhang, H. Circumventing Unintended Impacts of Waste N95 Facemask Generated during the COVID-19 Pandemic: A Conceptual Design Approach. ChemEngineering 2020, 4, 54. https://doi.org/10.3390/chemengineering4030054

Okoro OV, Nkrumah Banson A, Zhang H. Circumventing Unintended Impacts of Waste N95 Facemask Generated during the COVID-19 Pandemic: A Conceptual Design Approach. ChemEngineering. 2020; 4(3):54. https://doi.org/10.3390/chemengineering4030054

Chicago/Turabian StyleOkoro, Oseweuba Valentine, Adjoa Nkrumah Banson, and Hongxia Zhang. 2020. "Circumventing Unintended Impacts of Waste N95 Facemask Generated during the COVID-19 Pandemic: A Conceptual Design Approach" ChemEngineering 4, no. 3: 54. https://doi.org/10.3390/chemengineering4030054

APA StyleOkoro, O. V., Nkrumah Banson, A., & Zhang, H. (2020). Circumventing Unintended Impacts of Waste N95 Facemask Generated during the COVID-19 Pandemic: A Conceptual Design Approach. ChemEngineering, 4(3), 54. https://doi.org/10.3390/chemengineering4030054