Abstract

This paper introduces arguments in favor of the intensive use of standards in both teaching the Machine Elements discipline and solving the first projects of mechanical design (gearboxes, jacks, pumps, tanks, etc.). The paper presents a SWOTT approach to the use of new in-force standards in teaching the design of machine elements. The use of information from standards in courses and design handbooks is regulated by various standardization associations at different levels internationally, such as the ISO (International Organization of Standardization), IEC (International Electrotechnical Commission), and ITU (International Telecommunication), and regional associations such as the CEN (European Commission for Standardization), CENELEC (European Committee for Electrotechnical Standardization) and ETSI (European Telecommunications Standards Institute), and national associations (for instance, the ASRO—Association of Standardization of Romania). In general, the conditions for using partial information from standards vary, but the authors present common lines and recommendations for introducing information from standards in books and design handbooks for engineering students. The use of information from standards for terms, materials, calculation models, test methods etc. is beneficial for students. This will provide them a good professional education towards adapting to a specific job in the field of mechanical engineering, where conformity to norms and standards is required by the dynamics of production, product quality and, not least, the safety of machines and operators.

1. The Role of Standards in Teaching the Discipline of Machine Elements

The discipline of knowing, designing, and improving technical system components that could be designed in an autonomous way, knowing their material characteristics, their external loads, and imposed restrictions due to the entire system application, has been described under various titles, including Machine Elements [1,2]; Design of Machine Elements [3,4,5]; Machine Elements Design and Calculation in Mechanical Engineering [6]; Machine Design, Fundamentals of Machine Components [7]; Machine Design. Theory and Practice [8]; Analysis and Design of Machine Elements [9]; and Design of Machinery. An Introduction to The Synthesis and Analysis of Mechanisms and Machines [10]. Even the word ‘standard’ is included in the title “Standard Handbook of Machine Design”, used for several editions [11]. Also, “Shigley’s Mechanical Engineering Design (IS Units)” is well known [12]. In recent decades, books that feature software dedicated to design machine components have been published. For example, “Analysis of Machine Elements Using SOLIDWORKS Simulation” in 2017 [13], and “The Finite Element Method in Engineering” [14].

Many books deal with only one family of machine components, such as gears [15,16,17,18], belts and chains [19], rolling bearings [20,21], shafts [22], springs [23], couplings, clutches, and brakes [24], sealings [25], etc.

Many catalogues of products provide simplified calculations regarding the correct selection of a certain machine component.

Teaching approaches have evolved from traditional lectures to more student-centered, constructivist models that encourage active learning. This is especially relevant in machine element design, where students need to both understand technical knowledge and apply it creatively to solve real problems. Maffei et al. [26] emphasize the importance of constructive alignment, which means ensuring consistency between what students are expected to learn (ILOs), the activities they engage in (LAs), and how they are assessed (ATs). Design tasks often require high-level thinking—such as creating and evaluating—which are at the top of Bloom’s taxonomy. However, not every part of a design must be new or innovative. Students can propose innovative solutions, like a novel coupling, while still relying on standard parts—such as bolts or fittings—that serve as proven, compatible building blocks. For example, in designing a new type of coupling, students do not need to invent new materials; instead, they are expected to select standard, readily available materials that suit their design requirements. These standards help ensure that their solutions are not only innovative, but also feasible and practical to build. In this way, remote and flexible consultation activities can support their progress and problem-solving process, while maintaining alignment with the course objectives and assessment strategies.

In designing machine components, but also in teaching the design process, standards play a key role in the training of students to be future engineers, providing a set of internationally, regionally, or nationally recognized rules and specifications that ensure a high level of quality, compatibility, and safety in design and manufacture. Machine elements are the individual components that make up more complex mechanical assemblies, and the application of standards in teaching has the following implications:

- -

- Uniformity and consistency: by using standards, students learn to design mechanical components to the same dimensions, materials, and tolerances, regardless of region or industry;

- -

- Safety and reliability: the standards include clear and validated recommendations for strength, safety, and durability, reducing the risk of design errors that could lead to accidents or failures;

- -

- Structured learning: the use of standards in education provides a well-structured framework that helps students approach technical problems in an organized and methodical way, to develop effective solutions, and to collaborate more easily with other specialists;

- -

- Interdisciplinarity: students in engineering fields become familiar with standards presented for different disciplines (from materials, technologies, design methods for machine components etc.) and they use them in solving problems and projects.

Advantages of using standards in the design of machine components:

- -

- Reduced design time: standards offer predefined solutions for most components and assemblies, which reduces the time needed to design from scratch; standardized sizes and shapes can be used for bolts, nuts, bearings, gears, etc.;

- -

- Compatibility and interoperability: designing machine components according to standards ensures compatibility between components produced by different manufacturers, facilitating the exchange of components and their integration into more complex systems;

- -

- Reliability and safety: standards are developed on the grounds of detailed studies and industry experience, guaranteeing a certain level of performance, durability, and operational safety;

- -

- Reduced costs: using standards reduces production costs by using standardized materials and technological processes, as well as by reducing the error rate or the need to create customized components;

- -

- Globalization: by applying international standards, companies and engineers can collaborate effectively on a global basis, without compatibility issues of the components or assemblies, and with access to a global market.

The disadvantages of using standards in designing machine components could include the following:

- -

- Lack of flexibility: the strict use of standards can limit creativity and innovation, as engineers have to conform to strict rules, which could prevent the development of more innovative or customized solutions;

- -

- High upfront costs: in some cases, meeting certain standards may involve additional costs, especially if they require the use of specific materials or technologies that are more expensive than alternatives;

- -

- Frequent updating of standards: standards change and are regularly updated, and companies or engineers need to keep up with these changes, which may involve investing in continuous training and adapting production processes;

- -

- Generalized solutions: standards may offer generalized solutions, which are not always ideal for very specific applications; for example, some complex projects may require customized components, and standards may be too restrictive in this respect;

- -

- Bureaucracy and complexity: sometimes complying with all the rules and regulations can add an extra layer of complexity to the design process, which can slow down progress, especially for small companies without dedicated compliance resources.

In conclusion, the use of standards in designing machine components is essential to ensure the reliability, safety, and efficiency of mechanical components, but it must be accompanied by a balanced approach between compliance with standards and the possibility to innovate. In teaching “Machine Components”, the integration of standards helps students understand the importance of rigorous and efficient design, preparing them for the demands of modern industry.

2. SWOTT Analysis of the Introduction of Standards in Teaching of Machine Elements Discipline

SWOTT (Strengths, Weaknesses, Opportunities, Threats, Trends) analysis is a useful tool when evaluating issues related to the introduction and use of standards in teaching Machine Elements. It helps to identify strengths and weaknesses, opportunities, threats, and trends regarding the integration of standards into the educational process. For education and research organizations, “trends” must be added to the “classical” SWOT analysis, as students and even researchers have to gain new trends on the progress of the already studied disciplines or for their research subjects. Pereira et al. [27] proposed a SWOTi variant that includes open innovation, sustainability, and environment in the strategic development of a firm. Innovation is a key term in students’ education as academic stuff has to prepare them to conceive, design, and produce new systems, products, and technologies when they are integrated into the labor market. In a recent paper, Puyt et al. [28] pointed out the origins of the SWOT analysis, emphasizing the need for it to be flexible so as to be adequate to the requirements of the present times, and enrich its participatory managerial nature. The authors will add that this aspect is a particular characteristic of academic organizations.

The SWOTT analysis including trends is a step forward in the evolution of the classic SWOT framework. This allows organizations, especially academic ones, to examine emerging external factors and shifts that would impact future strategic decisions. This new iteration enhances flexibility, allowing organizations to align with modern, rapidly changing environments by providing insights not only into static strengths, weaknesses, opportunities, and threats, but also into dynamic trends that could shape these factors over time.

We, the authors of this paper, consider that this aspect of the SWOTT analysis should be included as presented here since it reflects innovation, sustainability, and care for environmental health, which will continue to be of interest in the future.

Introducing the SWOTT analysis to universities and research institutes could be a powerful tool to strategic planning by helping these organizations adapt to rapid changes in education, technology, the labor market, and societal expectations. The traditional SWOT analysis already serves many universities in assessing their strengths, weaknesses, opportunities, and threats, but by adding the ‘trends’ factor, it provides a forward-looking dimension, critical for staying relevant in today’s academic landscape.

Figure 1 presents the same approach for introducing standards in teaching the design of machine elements.

Figure 1.

SWOTT analysis of the use of standards in the machine components discipline.

Strengths:

- -

- Uniformity and consistency: the introduction of standards in teaching ensures a coherent and uniform approach to designing machine components, allowing students to learn and apply internationally recognized standardized methods.

- -

- Safety and reliability: the standards are based on detailed studies and industry experience, ensuring reliable and safe solutions for designing mechanical components.

- -

- Professionalism: students’ familiarization with international, regional, and national standards increases their level of professionalism and prepares them for the labor market requirements in the mechanical engineering field.

- -

- Improved design efficiency: by using standards, students learn to save time and resources, having access to predefined solutions for common design issues.

- -

- Global compatibility: knowledge of international standards enables students to design components that are globally compatible, facilitating collaboration and integration into larger systems.

Weaknesses:

- -

- Lack of flexibility: teaching focused on the strict use of standards can limit students’ creativity and restrict their ability to develop innovative or customized solutions.

- -

- Initial complexity: students may have initial difficulties in understanding and applying the standards, especially if they are complex or technically detailed.

- -

- Standards’ modifications: as standards are revised regularly, the academic staff should constantly update their knowledge and teaching materials, which can be difficult to manage in the long term.

- -

- Generalization: in some cases, standards provide generalized solutions that may not be appropriate for very specific or innovative issues, which can limit students’ ability to design particular solutions.

Opportunities:

- -

- Alignment to labor market demands: integrating standards into education can increase the employability of graduates, who could be better prepared for industry demands, where compliance with standards is essential.

- -

- Access to international resources: internationally recognized standards provide access to a variety of educational and technological resources, facilitating learning and collaboration with institutions and companies around the world.

- -

- Developing certification programs: integrating standards into education can lead to the development of specific courses or certifications that give students additional advantages in the labor market.

- -

- Support for industrial innovation: once students understand and comply with the standards, they could contribute to innovations in industry by developing new solutions that fall within accepted and safe parameters.

Threats:

- -

- Delay in the introduction of new information: here, educational institutions may have issues with standards acquisition, and the information within already published books and design handbooks could be old enough not to contain the standards in-force.

- -

- Over-reliance on standards: exclusive standards-based learning can limit students’ critical thinking, encouraging them to rely too much on existing solutions and not explore innovative approaches.

- -

- Fragmentation of standards: this issue may need to be taught, complicating the curriculum and, sometimes, creating confusion.

Trends:

- -

- The lack of compatibility in the digitization of ‘standards’ libraries in universities in the future; standards have been increasingly accessible through digital platforms, simplifying the process of implementing and using them for teaching. Students should be able to access the latest breakthroughs and resources online, from their university e-library.

- -

- Integration with advanced technologies: technological progress and developments in areas such as computer-aided design (CAD) and additive manufacturing can influence the way standards are applied, making it necessary to adapt them to new technological realities.

- -

- Globalization of the economy: speaking of the mechanical engineering field alone, which is becoming increasingly globalized with a pronounced interdisciplinary character (especially regarding electronics), increases the need for students to become familiar with international standards in order to be able to work in multicultural teams.

- -

- Sustainability and environmental standards: there is a growing trend to integrate sustainability and environmental criteria into industry standards, which engineering disciplines will need to adopt.

In conclusion, the SWOTT analysis, as presented here, highlights the multiple benefits of integrating standards in teaching the discipline of Machine Elements, such as providing structured learning, aligning with industry requirements, and promoting safety and reliability. However, there are also challenges, such as limiting innovation and the costs of updating. Overall, the use of standards in education helps to keep engineers competitive in the global market. But it is important that this educational process maintains a balance between meeting the requirements of standards and stimulating creativity and innovation.

3. Standards for Each Chapter of “Machine Elements” Discipline

Each chapter of the discipline in Machine Elements requires knowledge of specific standards. Table 1 shows only examples of technical committees and some of the standards that can be brought up in the students’ course and/or project.

Table 1.

Chapters in the course on machine elements, technical committees for standardization, and examples of standards that can be discussed/used for the course and/or the project.

In general, the Machine Elements discipline is structured in 9 chapters. Sometimes transmissions are presented in separate chapters due to the large amount of information.

For each chapter, a professor should structure the information as follows:

- Definition of the machine element, with typical applications, advantages and disadvantages of its use;

- Constructive solutions;

- Design methods, verification of an already designed solution;

- Materials and technologies involved in its construction and operation;

- Possible failures and their causes.

Using the expressions “standard construction”, “standard solution”, and not referring to a specific standard, relates to a common solution. This attribute is often found in English and French literature, but also in Romanian books.

Students use the recent ISO 6336 family of standards (from 2019), parts 1 to 4, for gear calculation, and Part 5 for gear material quality (from 2016), but there are also gear calculation standards of interest for students’ projects and theory on gears, though parts of these standards only cover special chapters in master topics (e.g., parts 20, 21, 22, and 30, 31, see Table 2). The more recent standard ISO 10300 Calculation of load capacity of bevel gears (with 6 parts) presents calculation models for bevel gears.

Table 2.

Several standards for the calculation of gears, under the responsibility of ISO/TC 60/SC 2 Gear capacity calculation [29].

Standards contain fewer constructive solutions than those known by specialists and often do not suggest the design solution. Information contained in standards concentrates on dimensional and material recommendations for known material grades (especially in the sense of easily procurable). The information on a material includes composition, mechanical properties, and heat treatments, and goes as far as structure and percentages of structure constituents (see standards for bearing steels). In terms of design methods, the standards mostly contain methods for verifying an already designed solution, but a designer can use them for designing, such as the relationships for determining the distance between shafts for fatigue strength or bending at the base of the gear tooth. There are also standards used for assessing the damage or failure of machine components, giving terminology and definitions, and examples on how to calculate, which could be important for reporting and evaluating incidents and establishing the actual causes of a machine part failure.

Terminology and vocabulary standards related to machine parts are important. For example, ISO/TC 60 Gears with two subcommittees. Subcommittee SC 1 Nomenclature and worm gearing concerns several standards that use these terms and their explanations:

- ISO 1122-1:1998 Vocabulary of gear terms. Part 1: Definitions related to geometry;

- ISO 1122-2:1999 Vocabulary of gear terms—Part 2: Definitions related to worm gear geometry;

- ISO 10828:2024 Worm gears—Worm profiles and gear mesh geometry;

- ISO 21771:2007 Gears. Cylindrical involute gears and gear pairs. Concepts and geometry.

For bearings, an example of a standard containing terms is ISO 1132–1:2000 Rolling bearings. Tolerances. Part 1: Terms and definitions. Many terms and definitions for rolling bearings may be found in bearing catalogs [30,31,32], helping students, designers, and practitioners to use these machine components; one is particularly well presented and educational [33]. In this SKF catalogue, the term “ISO” is used 351 times, in two different contexts: first—to underline that the information is contained in international standards, and second—as an international standard given by number or/and title.

For springs, ISO 26909:2009 Springs. Vocabulary [34] proposes definitions also used in calculations in English language books (with scarce exceptions, synonyms of terms listed in the standard).

Definitions and terms from the ISO/IEC Guide 99:2007 International vocabulary of metrology. Basic and general concepts and associated terms (VIM) [35] may be introduced in laboratory and/or project classes.

The information contained in standards, as information agreed upon by stakeholders as actors in the market and social life (producers, research specialists, users, and public institutions), for having quality products and services which may not be the newest solutions, but are the result of good practices that the student must perceive and understand. As just one example, in a commercial agreement for gears, the client could require that gears would be checked according to ISO 6336:2019 or ANSI/AGMA 2101-D04 Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth (Metric Edition) and not according to the latest issues discussed in books or articles for gear design.

Some published courses, in Romanian, have introduced references to standards:

- Pop D., Haragâș S., Buiga O., Organe de mașini (Machine Elements), Vol. 2, Risoprint, 2021 [36];

- Săvescu D., Organe de mașini. Transmisii mecanice de putere (Machine Elements. Mechanical Power Transmissions). Editura RisoPrint, Cluj—Napoca, 2018 [37];

- Pustan M., Belcin O., Bârleanu C., Organe de mașini. Asamblări demontabile, arbori drepți, Arcuri metalice (Machine Elements. Demountable assemblies, Straight Axles And Shafts, Metal Springs, UTPress, Cluj-Napoca, 2013 [38];

- Haragâș S., Organe de mașini, Napoca Star, 2014 [39];

- Grigore N., Machine Elements. Mechanical transmissions. Ploiești University Publishing House, 2003 [40];

- Ștefănescu I., Spânu C., Organe de mașini, volume 1, Europlus, 2009, Galati [41];

- Tomescu (Deleanu) L., Elemente de mecanică fină (Machine Elements for Precision Mechanics), Editura Fundației Universitare “Dunărea de Jos” Galati, 2001 [42];

- Jula A., Lateș M., Organe de mașini, Editura Universității Transilvania, Brașov, 2004 [43];

- Bostan I., Dulgheru V., Grigoraș Ș., Transmisii planetare, precesionale și armonice. Atlas. Editura Tehnică București—“Tehnica” Chișinău, Republic of Moldova, 1997 [44];

- Gafițanu M., Bostan I., Dulgheru V., Racocea C., Hagiu G., Jula A., Chișu E., Moldovan G., Organe de mașini. Vol. 2. Ed. Tehnică, București, 2002 [45];

- Ianuș G., Organe de mașini. Volumul 1 (Machine Elements, Part I), Politehnium, Iași 2010 [46].

The authors of “Machine Elements” [36] consider the mention of standards in the following context: “Errors made by neglecting certain factors are compensated by the use of existing norms and standards, which represent the synthesis of experience in the design, manufacture and operation of machines. By calculation, the main dimensions of the part are determined, which as a rule are rounded to standardized values; the other dimensions are adopted constructively, taking into account technological, assembly, economic, etc. criteria.”.

“Through these international and local standards and norms, a standardization of production in the field of basic machine parts has been achieved, thus creating the opportunity of interchangeability of machine parts, with huge implications on the reliability and maintenance of machines” [46].

In 2017, Robert Juvinall and Kurt Marshek, in the 6th edition of their book “Fundamentals of Machine Component Design”, in subchapter 1.2.2, Techniques and Guidelines, specify a requirement for realizing a design: “Check government and industry standards (such as OSHA and ANSI) and the pertinent technical literature to be sure that legal requirements are complied with, and that advantage is taken of the relevant safety experience of others” [7].

We should point out that some of older courses and handbooks for machine component design referred to the standards in force at the time of their edition and we think this is praiseworthy. The problem arose when some authors did not find such updates necessary. Books and handbooks with canceled or withdrawn standards at the time of publication are undesirable, non-professional, and misleading, both in terms of quality and usefulness for students. For example, in Romanian technical books, the expression “STAS” (the abbreviation for Romanian standards during the socialist regime) should no longer be attached as an index to specify a standardized dimension or parameter that is in a sequence of calculus in design handbooks. One can use “standard”, “standardized”, or “SR”, which is the current abbreviation of the Romanian standard adopted in our country through the Association of Standardization of Romania (ASRO) [47]. We disagree with the use of expressions such as: “Choice of construction variant—cast carbon steels in STAS parts”, which could be replaced by “standardized parts” or “standard parts”.

Another example is “Calculate d (bore diameter of a rolling bearing) so that it is a multiple of 5 because the STAS of the bearings is 5 by 5. For inside diameters between 10 mm and 20 mm, sizes of 12 mm and 17 mm are also allowed.” Aside from certain standards specifying this, bearing catalogues from the major manufacturers on the market promote this lexis and also add information to the symbolization system for rolling bearings. “The boundary dimensions for metric bearings are standardized in the ISO (International Organization for Standardization) general plans: ISO 15 for radial rolling bearings, except insert bearings, some types of needle roller bearings and tapered roller bearings, ISO 104 for thrust bearings, ISO 355 for tapered roller bearings” [32] (p. 27). Students have to understand that not mentioning the year of the standards in use means that the latest available edition may have slightly different symbolization from the major manufacturers, especially for extreme sizes of rolling bearing bore diameters (very small or very large), in terms of suffixes and prefixes and it is therefore necessary to consult their catalogues.

Expressions such as “D—outside diameter of the bearing according to STAS” could still be found in current Romanian handbooks, while the outside diameter of the bearing is not standardized, and in the bearing catalogue of a manufacturer several variants (series) of the rolling bearing can be found, with different outside diameters, for the same design solution and the same inside diameter [32].

The design of machine elements involves the use of standards, and we do not agree with using old (withdrawn) standards towards student education. Even so, students are introduced to the Machine Elements discipline in their 2nd or 3rd year, and, by the time they finish their bachelor’s or master’s degree, it is likely the standards that they have already used could be outdated or modified. The professors should develop their ability to search for the standard they are interested in and how to make adequate use of it.

Two gear design handbooks could be examples for good practice for using standards (extracts and references from standards), elaborated by Prof. Simion Haragâș, PhD [48] from the Technical University of Cluj and Prof. Lorena Deleanu, PhD, with a team from “Dunarea de Jos” University of Galati [49]. We also mention a similar handbook [50], but written in English, a preferred language for technical documents.

From this point of view, we consider the initiative promoted by the Faculty of Engineering (“Dunarea de Jos” University of Galati, Romania) for the master specialization “Modeling and Simulation in Mechanical Engineering” (MSIM) to be proficient, as students are taught, in detail, aspects regarding the use of standards, through a new discipline “Fundamentals of Standardization”.

4. Arguments in Favor of Using Standards in Force

The use of current standards in teaching Machine Elements is essential to ensure the relevance and applicability of knowledge in practice. Several strong arguments that support the use of current standards instead of old (withdrawn) standards, which have been superseded or have outdated technical content, are presented in the following text.

Alignment to modern industry

The use of current standards ensures that students are prepared to obey industry requirements and practices. The design and fabrication of mechanical components must concur with current standards in order to comply with legislation and quality requirements in industries, such as automotives, aeronautics, and machine building.

There is a disadvantage in teaching by old standards. If outdated standards are taught, students will be unprepared for the actual industry challenges, and the knowledge passed down to them will not be relevant against modern processes and technologies in the field.

Improved safety and reliability

Modern standards are updated according to the latest technical breakthroughs and safety studies, making them more reliable and effective at ensuring the functionality and durability of machine parts. They include strict criteria for testing, performance evaluation, and the use of safe materials.

Old or withdrawn standards do not account for recent advances in areas such as strength of materials, tolerance calculations, vibration analysis, and other critical technologies, thus, their use can result in risky designs or even serious design flaws.

Integrating new manufacturing technologies and processes

Current standards reflect technological advances and new manufacturing methods such as computer-aided design (CAD), additive manufacturing (3D printing), CNC and the use of advanced materials. Students need to be familiar with modern technologies, construction solutions, and materials to remain competitive in the job market.

Teaching by old standards does not take these innovations into account, which could leave students with a major gap between what they have learned and what the industry demands, leaving future engineers unable to cope with new equipment and materials.

Compliance with international law

Standards are also created to comply with and harmonize national and international legislation (e.g., EU directives or international regulations for trade and various industries). By using them, students learn to design components that are legally and technically compliant to international markets.

Old standards may not comply with current legal and safety regulations. In many cases, they are already legally and technically outdated, and applying them could induce flaws in the students’ work.

Increasing competitiveness in the labor market

Graduates familiar with up-to-date standards will have a significant advantage in the labor market through having gained the ability to directly apply the knowledge and practices required by employers. In addition, understanding international standards increases employability in a globalized economy.

Graduates who worked with outdated standards may find it difficult to integrate into the labor market, as their knowledge does not concur with modern employer requirements, resulting in incomplete training and the need for additional refresher courses.

Sustainability and energy efficiency

Modern standards reflect a growing concern for energy efficiency, the use of sustainable materials, and environmental protection. In the current context of climate change and the demands to reduce the carbon footprint, it becomes essential that students are prepared to design and develop solutions that are environmentally friendly and energy efficient.

Old standards do not reflect these contemporary concerns, which means that students will miss out on the opportunity to learn how to design products that meet modern sustainability and energy efficiency standards, which are increasingly important for industry.

Adapting to rapid changes in technology

Standards in force are constantly updated to keep up with technological advances, so students will learn to be flexible and adapt to innovation. This is essential in a field where technology is rapidly evolving and engineers need to be prepared for continuous change.

Using the old standards encourages rigid thinking and an outdated mindset, which is never beneficial in an evolving world. Students risk falling behind to new approaches and emerging technologies.

Access to modern resources and support

The latest editions of standards intertwine with numerous digital resources, guidelines, and tools (simulation software, databases, online platforms) that facilitate learning and design application.

In conclusion, the use of current standards in teaching Machine Elements is essential to ensure a relevant, safe, and well-adapted education that ultimately meets requirements and trends in the industry. Standards in force enable alignment with international legislation, preparation for new technologies, and sustainability and competitiveness in the labor market. Using withdrawn standards in teaching risks creating a generation of engineers unprepared for the challenges and needs of modern industry, affecting both the safety and efficiency of the projects they will be involved in.

5. Arguments in Favor of Using Updated Standards

5.1. Introduction

In a subchapter entitled “Use of Standards in Design”, Bhandari V.B. [3] (p. 9) mentioned the mandatory nature of standards, but failed to specify compulsory conditions. “Standardization is defined as obligatory norms, to which various characteristics of a product should conform. The characteristics include materials, dimensions and shape of the component, method of testing and method of marking, packing and storing of the product.” Standards (international, regional—as are the European ones, or national) are voluntary. Indeed, technical standards are voluntary in nature and only become mandatory in certain specific contexts, such as when they are included in legislation or when they are requested and included in commercial contracts.

Some standards are integrated into national and international legal regulations. In these cases, compliance with standards becomes mandatory to ensure legal compliance (e.g., in product safety, environmental protection, etc.).

In the case of a contract between two parties, if it is clearly specified that certain standards must be followed, they become legally binding. For example, in public procurement contracts or large industrial projects, it is common practice for technical specifications to require compliance with ISO, EN, ASME, or other national standards.

For voluntary documents by definition, standards provide recommendations or best practices for optimal design, manufacture, and other processes, and are adopted by industry to ensure a certain quality, compatibility, or safety.

Standards become mandatory in the following instances:

- -

- In national legislation: the safety of electrical equipment standards are integrated into most countries’ laws so as to protect consumers.

- -

- In European and international regulations: ISO or EN standards are often adopted by countries as mandatory for certain types of products to facilitate cross-border trade or to protect the environment and public safety.

- -

- In compliance documents: certain certifications (such as ISO quality or safety certification) impose mandatory standards for certain industries (e.g., automotive, aeronautics).

For instance, ISO 9001 (quality management systems) is a voluntary standard, but many companies consider it mandatory in order to win commercial contracts and participate in tenders.

Safety standards (e.g., EN 81 for lifts or ISO 12100 for machinery safety) are included in some legislations, thus becoming mandatory for manufacturers or designers.

Norton and Higgins [10] have introduced a subchapter dedicated to standards, “Design and Safety Codes”, the application of standards being clearly discussed. “Many engineering societies and government agencies have developed codes for specific areas of engineering design. Most are only recommendations, but some have the force of law. The ASME (American Society of Mechanical Engineers) provides recommended guidelines for safety factors to be used in particular applications, such as steam boilers and pressure vessels. … Safety factors are sometimes specified in these codes and may be quite high. … Clearly, where human safety is involved, high values of N (safety coefficients) are justified. However, they come with a weight and cost penalty, as components must often be made heavier to achieve large values of N. The design engineer must always be aware of these codes and standards and adhere to them where applicable.” [10] (p. 19).

5.2. Differences Between Steel Grades, as Presented in Withdrawn Against Current Standards (with Reference to ISO 683), in Terms of Composition, Mechanical Properties, Heat Treatments, etc

Steel grades presented in current standards (with reference to ISO 683 [51,52,53]) reflect advances in metallurgy, new manufacturing technologies and the requirements of modern industry. The steel grade differences manifest in chemical composition, mechanical and thermal properties, and heat treatment requirements. Here is an analysis of the main differences.

Chemical composition

Withdrawn standards

Steels in older standards tend to have a less optimized and simpler chemical composition based on traditional manufacturing processes.

In the past, the allocation of alloying elements (such as chromium, molybdenum, vanadium, and nickel) was conducted by taking into account the technological limitations and testing equipment available at that time the standard had been elaborated.

Composition variations were often larger, which could affect the consistency of mechanical and thermal properties between different batches.

ISO 683 (current standards)

The chemical composition of steels is much more precisely regulated, which ensures better control of alloying elements and impurities. Tolerances for chemical element concentrations are stricter.

In current standards, steel grades are better defined in terms of chemical composition, including for microalloys, allowing properties to be more adequate for the application.

More detailed measures are in place to control levels of impurities, such as phosphorus and sulphur, which adversely affect ductility and toughness.

Mechanical properties used in machine component design

Withdrawn standards

Steel grades defined in older editions tend to have less consistent mechanical properties, with greater variation in tensile strength, hardness, and elongation values. Old steel grades could not always account for modern requirements of fatigue strength or extreme temperature behavior.

ISO 683 (current standards)

The mechanical properties are much more clearly defined and include detailed specifications for tensile strength, yield strength, ductility, and toughness, including in corrosive, low or high temperature environments.

In updated standards, the focus is on optimizing fatigue life and behavior under dynamic loading, such as for automotive, aerospace, and building applications.

Greater focus on hardness and toughness at low temperatures improves performances in extreme environments (especially for steels used in the oil and gas industry).

Thermal properties

Withdrawn standards

The steel grades in older editions did not always consider thermal behavior in detail and the requirements for resistance to high or low temperatures were less precisely addressed.

The values of thermal expansion and thermal conductivity coefficients were defined with large approximations.

ISO 683 (current standards)

In today’s standards, thermal properties are better specified and the behavior of steel under high and low temperature conditions is better understood and defined.

More rigorous testing results include creep resistance (the deformation of steel at high temperatures and under constant loads) and thermal shock resistance.

In the case of steels for special applications (e.g., turbine steels or chemical processing equipment), high temperature oxidation resistance is specified, an aspect absent from the old standards.

Heat treatments

Withdrawn standards

In the past, the requirements for heat treatments (such as hardening, annealing, or normalizing) were more general and the related treatment technologies were less advanced, ergo they provide basic instructions for obtaining the desired mechanical properties.

A lack of advanced monitoring equipment resulted in fewer options for heat treatments, and exact process control was not always possible.

ISO 683 (current standards):

Modern standards offer more detailed and precisely-defined heat treatment procedures. For example, ISO 683 provides clear specifications for treatment temperatures, holding times, and cooling rates to achieve optimum mechanical properties.

Microstructure control is essential in modern standards, mostly to achieve martensitic, bainite, or ferritic structures, depending on the desired application.

Special attention is given to the differentiated heat treatment of different types of steels (e.g., tool steels, bearing steels, stainless steels, etc.), with precise instructions for each category.

Classification and symbols of steels

Withdrawn standards

The old steel symbolization systems were not standardized globally, each country having its own classification system. For example, DIN standards were used in Europe, AISI or ASTM standards in the USA, and GOST standards in the former USSR.

This led to confusion and difficulties in interpreting steel marks, especially in the context of international trade.

ISO 683 (current standards)

ISO 683 unifies international nomenclature so that steel grades are easily recognized and identified, globally. It facilitates integration in a globalized market where compatibility and consistency are essential.

A more precise and detailed classification of steels is presented on the basis of chemical composition and specific applications (alloy steels, non-alloy steels, bearing steels, nitriding steels, etc.).

In conclusion, the differences between the steel grades in the old (withdrawn) standards and those in force, such as ISO 683, only reflect the evolution of the metallurgic industry and the need for higher performance and increased safety. The standards in force regulate much more precisely chemical composition, mechanical and thermal properties, and heat treatments that ensure steels with optimal characteristics for ultimate requirements. These advances make it possible to produce materials that perform better and are safer and more suitable for complex and demanding applications, whereas old standards may not suffice for modern technical requirements.

5.3. Examples of Designing Machine Components That Are More Flexible, Using Standards for Assemblies, Welds, Gears, Chains, and Couplings

Making the design of machine components more flexible is a growing trend due to technological developments and new requirements for industrial and consumer products. The removal of old standards and their replacement with more flexible approaches reflect the adaptation to modern realities, where rigid standardization is no longer as necessary due to advanced technologies such as computer-aided manufacturing (CAD), CNC machining, 3D printing, and mechatronic systems integration.

Here are some examples of how modern standards can make the design of machine parts more flexible.

Threading and fitting assemblies

In the past, the standards for screws, nuts, and other threaded parts were very precise, including strict specifications for thread pitch, length, and tolerances and their fits.

At present, CNCs and high-precision machine-tools allow threads to be produced for customized tolerances, making the old standards that employ more rigid tolerances no longer necessary. Today, flexible fitting systems are used where the component can be more easily adapted to other parts of the assembly, thus reducing rigid standardization requirements. Tolerances for threaded fits were previously set by strict standards (e.g., ISO 965–1 or equivalent DIN, ANSI standards). Today, many designers use customized stress and strain analysis for more efficient fits, depending on the specific materials and application.

Welds

The old standards for welds required fixed shapes and sizes for the weld beads, and strict specifications for the types of accepted welds.

Modern automatic welding technologies, that makes use of industrial robots and lasers, have made the welding process more flexible, so there is no need for strict specifications around weld bead shape and size.

Laser welding and Friction Stir Welding (FSW) offer the possibility to create more accurate and efficient welds, reducing the dependence on rigid standard specifications. In the past, the old editions of standards, such as ISO 2553 Welding and allied processes, featured symbolic representations on drawings. Welded joints [54] imposed strict weld shapes, whereas, nowadays, the specifications focus on the end result of the weld (the mechanical and durability properties), regardless of the process.

Toothed gears

Obsolete standards, which referred to the tooth root fillet radius of the basic rack for cylindrical gears, have several strict values, not emphasizing the flexibility of gear production, and the optimization of other components of gear systems such as housing, bearings, CNC machining, etc.

Housing optimization and custom gear production allowed fine tuning of the gears to improve mechanical efficiency and reduce noise and wear.

The normal modulus (chosen from a given range of values) and the pressure (or gearing) angle, which is 20° for cylindrical gears, have remained standardized (note that for bevel gears with curved teeth, this angle depends on the machining technology and the machine tool handbook should be consulted).

Transmission chains

Withdrawn editions of standards for drive chains (e.g., roller chains) strictly specified chain dimensions and the number of links per unit length, as well as specific parameters for tension and loads.

Updated standards allow for chain customization according to the needs of the application, instead of imposing the same standardized dimensions for all applications. Modern manufacturing technology allows for specific loads to be adjusted for different applications, the focus being on chain performance (efficiency, low noise, minimal maintenance) and their integration into flexible mechanical systems. Withdrawn editions of standards, such as DIN 8187 [55] or ANSI B29.1 [56], specified strict dimensions for drive chains. Nowadays, many producers allow chains to be customized for particular dynamic loads and operating conditions, especially for chains used in extreme environments. Highly specialized companies have invested in their own development and incorporated new knowledge into the same commercial programs, still unavailable to others.

Couplings

In the past, rigid and semi-rigid couplings had strict specifications regulating dimensions, tolerances, and assembly methods. These standards were intended to ensure correct operation and minimize backlash between components.

Now, couplings have evolved to be more flexible and adaptable. Modern standards focus on the overall performance of the coupling system, including vibration damping and misalignment compensation, which offers wider customization options for specific applications. Modern couplings, such as those with elastic elements, offer more flexibility in design, without being restricted by fixed dimensions or strict tolerances imposed by standards. Old standards, such as DIN 740–1:1986–08 Power transmission engineering, flexible shaft couplings, and technical delivery conditions or equivalent [57], required fixed dimensions for couplings. Nowadays, customized couplings for different types of equipment (such as electric motors or industrial gearboxes) are chosen based on dynamic system parameters.

Bearings

Withdrawn standards for plain and rolling bearings imposed strict specifications on dimensions and tolerances, limiting solutions for certain applications.

Now, bearings are manufactured with a wide range of customizable sizes and features, some of them being from standards, for instance [58,59], tailored to the specific needs of the application. Manufacturing flexibility and new materials, such as ceramic, composite, or hybrid bearings, offer a range of options which no longer require rigid standards.

The conclusion is that a more flexible design of machine parts through the use of modern standards has made it possible for engineers to optimize mechanical systems and adapt them to the specific requirements of each application. Technological progress has allowed greater freedom in design and production. This translates into increased efficiency, better component integration, and a greater adaptability to the diverse requirements of modern industries. Standards have become less restrictive.

Another approach worthy of mentioning is that in an ISO document about teaching standards “Standards are a vehicle for sharing knowledge, technology and good practices. …. Whether they (the students) become engineers, economists, lawyers, business managers or administrators within central or local government, they will be the ones to gain the most advantage from standards—and the ones to decide the future role and features of standardization.” [60].

The Romanian body for standardization, ASRO, has been outlining that “in today’s market, where competition is fierce and resources are limited, there has never been a better time to learn and use, for its multiple benefits, about standards and standardization. Education about standardization is necessary, regardless of age and educational level, in order to be able to use in practice all the advantages that standardization can offer: higher quality of products and services, implementation of organizational policies referenced to standards, easy penetration of the EU internal market, increased competitiveness of offered products/services, bringing long-term benefits” [61]. We would add that education on knowing and applying standards in engineering also supports the sustainability of the development of human society.

6. How Should Information from Standards Be Used for Courses and Design?

The use of information from standards in courses and design guidance is regulated by various associations, such as ISO [62], CEN, and CENELEC [63]. These organizations protect standards by copyright and impose certain conditions for the use of information extracted from them. In general, the conditions vary, but there are some common lines.

Standards are copyrighted documents and standards organizations own these rights. To use content from a standard (text or/and figures) in courses or design handbooks, it is necessary to adhere to the following rules:

- -

- Licensing: most of the time, to use the content of a standard, publicly or commercially, it is necessary to purchase a license or obtain permission directly from the rights-holding organization;

- -

- Citation of source: when citing or referencing standards, the original source, including the title of the standard, the identification number, and the standardizing organization, must be stated.

Depending on local legislation and the policies of standards organizations, it is possible to use excerpts or abstracts from standards without infringing copyright, if this is within the limits of fair use. However, this type of use has strict restrictions in order to be accepted as fair use, such as the following:

- -

- Use only a small percentage of the total content of the standard;

- -

- Use for educational and non-commercial purposes (e.g., teaching in universities);

- -

- Present as summaries or critical commentaries, not exact reproductions of the text.

If information from standards is used for commercial courses, design guidance involving paid consultancy or other commercial purposes, it is usually mandatory to have commercial licensing. A commercial license may be obtained to reproduce or distribute information from the standard; sometimes, a fee to the standards organization that owns the standard is acceptable.

Publication or reproduction in its entirety for any purpose without explicit permission is considered copyright infringement. As a general rule, standards organizations only allow consultation of legally purchased or accessed standards. The full reproduction of a standard for distribution or teaching is prohibited without a specific license.

If the information in the standards is to be used to create courses and design guides, textbooks, or other forms of learning materials, it is usually permissible to use interpretations or adaptations of the information. However, even in this case, some principles of ‘fair use’ should be observed. Credit must be given to the original source (the standard in question). It is not allowed to present an adaptation as equivalent or identical to the standard without clearly stating that it is an interpretation.

Each standardization organization has its own detailed policies and guidelines related to the use of standards. For example, ISO and CEN have strict policies on copyright and commercial use, requiring licenses for any reproduction. ASRO follows the same copyright rules, but may have specific arrangements for educational use.

Specific conditions for using a particular standard are attainable through consulting the standards organization directly (via their official website). Most organizations have forms for requesting permission to use.

In summary, using information from the standards for educational or commercial purposes involves respecting copyright and, in many cases, obtaining a license.

Fair use is a legal concept that allows for a limited use of copyrighted material without obtaining permission from the rights holder under certain circumstances. For technical standards (e.g., ISO, European, or Romanian standards), fair use can be applied, though with restrictions due to the commercial nature and strict copyright protection of these documents.

Here are some examples of the fair use of information contained by standards.

- Short quotes for educational references. In an undergraduate course on mechanical engineering, a professor may quote short excerpts from a standard on geometric tolerances to illustrate a theoretical concept. These quotations should be limited in size and used for educational purposes without reproducing large sections of the standard. It should be emphasized that the material is taken from a copyrighted standard, and bibliographical references should be included (e.g., standard number and title).

- Tables or diagrams to explain a technical principle. In a design handbook that is not intended for sale, an engineer may include a table or diagram provided by a standard in order to explain a calculation method. However, this extract should be only a small part of the original document and the information is intended for a restricted audience (e.g., students or colleagues); these diagrams should be properly cited and it should be clearly stated that they are used under fair use provisions.

- Paraphrasing concepts for technical discussions. An author of technical articles may describe and paraphrase a technical concept from a standard without directly using the text of the standard. For example, in a publication on machine construction, the author may explain the principles of mechanical tolerances defined by an ISO standard, but without reproducing the exact text of the standard; the paraphrased concept should be accompanied by clear references to the standard and should avoid reproduction of sections of the document.

- Critical commentary or analysis. An expert, a teacher, or even a student can analyze or comment on a section of a standard to discuss its technical implications or impact on industry, without copying the full text of the standard. For example, in an academic article, the author may criticize certain requirements in an ISO standard for plastics and explain why they should be revised. The critical comment should be accompanied by appropriate references and include only short extracts to support the point of view.

- Using the summary or abstract of a standard. A professor or a student may use the public summary of a standard for educational purposes or to guide students toward acquiring the full document. For instance, in project classes, a teacher may present the summary of ISO 683 (Heat-treatable steels, alloy steels, and automating steels), especially Part 1 [51], Part 2 [52], and Part 3 [53] to students to inform them about the importance of the standard, without reproducing sections of the standard and may give examples of steel grades included in the standard. It is important not to distribute the actual content of the standard, but only the publicly available summary.

- Short references in technical handbooks. In books, reference may be made to a particular standard, and/or to a set of technical requirements, but without reproducing the content of the standard. For instance, a handbook for designing an electrical system may state that installers should comply with ISO/IEC 60364 for the safety of electrical installations, without reproducing details from the standard. Only the reference to the standard should be mentioned and users should be directed to purchase the official document for details.

Fair use limits for standards include, but are not limited to, the following:

- The reproduction of small parts, but not all or substantial sections of a standard, even for educational purposes;

- Proportionate use, justified by educational, critical, or commentary purpose.

Commercial purposes limit fair use and for such purposes, a license is required.

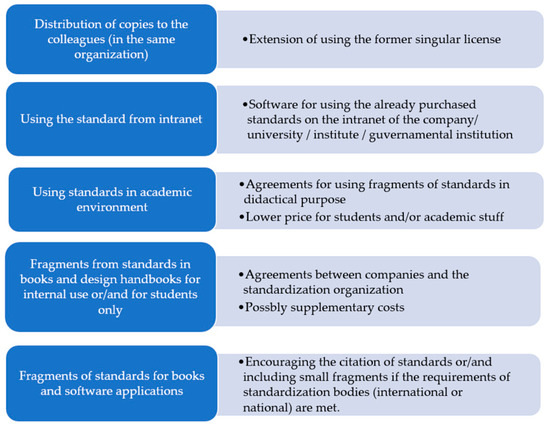

Examples of copyright-compliant options for using standards are given in Figure 2.

Figure 2.

Options for fair use of standards while respecting copyright.

The use of standards as references and the use of information from standards, such as terms, material characteristics, and calculation models, are beneficial for students because it better prepares them for a specific job in engineering fields, where the introduction and observance of norms and standards are required by fabrication dynamics, product quality and, not least, the safety of machines and operators.

However, a balance between general or particularized calculation models for families of machine components and information from standards (which can sometimes exceed the comprehension capacity of the second- and third-year students) must be ensured.

The authors emphasize the importance of using updated versions of the standards when conveying the information to the student (orally or in writing, through lecture notes, presentations, lectures, and design guidance), and against using withdrawn standards, which have been substantially modified.

In conclusion, fair use for standards allows the use of small fragments and only for clearly defined purposes, such as education or critical analysis. In all cases, the source must be acknowledged and copyright limits respected.

7. Conclusions

An important point worth mentioningnis that both technical universities and standardization bodies (international, regional, and national) collaborate for introducing knowledge on standardization and standards in academic curricula and point out the benefits of using standards in design and research.

“Machine Elements” is a very important discipline not only for teaching design principles, but also for getting students used to applying standard requirements in their projects and homework. They will use standards in a correlated way in relation to materials, dimensions, and standard calculation models in order to find solutions for their homework, which is a good practice for their future career in engineering.

Our university, “Dunarea de Jos” of Galati, Romania has, for several years, been promoting disciplines related to understanding and using standards, at different levels, from master specialization (a course entitled “Fundamentals of Standardization”) to doctoral studies (“Standardization as Support in Research”) and it has a collaboration for translating and verifying the texts of standards with the national standardization body, ASRO. We have noticed, also, that students are interested in novelties in this field and that they are eager to help promote standards, especially because they are related to a future career as a designer or field engineer.

Author Contributions

Conceptualization, L.D., C.G. and G.G.O.; methodology, L.D., C.P.; software, A.V.V.; validation, L.D. and C.P.; formal analysis, A.V.V.; investigation, C.P. and L.D.; writing—original draft preparation, L.D.; writing—review and editing, C.G. and G.G.O.; visualization, A.V.V.; supervision, L.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are contained in the paper.

Conflicts of Interest

Author George Ghiocel Ojoc was employed by the company Autonomous Flight Technologies. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Mott, R.; Vavrek, E.; Wang, J. Machine Elements in Mechanical Design (What’s New in Trades & Technology), 6th ed.; Pearson: New York, NY, USA, 2018. [Google Scholar]

- Schmid, S.R.; Hamrock, B.J.; Jacobson, B.O. Fundamentals of Machine Elements; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Bhandari, V.B. Design of Machine Elements, 3rd ed.; Tata McGraw Hill Education Private Limited: New Delhi, India, 2010. [Google Scholar]

- Rao, T.K. Design of Machine Elements; I.K. International Publishing House Pvt. Ltd.: New Dheli, India, 2011; Volume 1. [Google Scholar]

- Rao, T.K. Design of Machine Elements; I.K. International Publishing House Pvt. Ltd.: New Dheli, India, 2019; Volume 2. [Google Scholar]

- Niemann, G. Machine Elements Design and Calculation in Mechanical Engineering; Fundamentals, Connections, Bearings, Shafts and Accessories; Springer: Berlin/Heidelberg, Germany, 1978; Volume 1. [Google Scholar]

- Juvinall, R.; Marshek, K. Fundamentals of Machine Component Design; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Deutschmann, A.D. Machine Design Theory and Practice; Pearson College Div.: Vancouver Island, BC, Canada, 2017. [Google Scholar]

- Jiang, W. Analysis and Design of Machine Elements; John Wiley & Sons Singapore Pte. Ltd.: Singapore, 2019. [Google Scholar]

- Norton, R.L.; Higgins, M.P., II. Machine Design. An Integrated Approach, 6th ed.; Pearson Education, Inc.: Hoboken, NJ, USA, 2020. [Google Scholar]

- Shigley, J.E.; Mischke, C.R.; Brown, T.H., Jr. Standard Handbook of Machine Design, 3rd ed.; McGraw Hill: New York, NY, USA, 2004. [Google Scholar]

- Budynas, R.G.; Nisbett, K.J. Shigley’s Mechanical Engineering Design (SI Units), 11th ed.; McGraw-Hill Education: New York, NY, USA, 2022. [Google Scholar]

- Steffen, J.R.; Nudehi, S.S. Analysis of Machine Elements Using SOLIDWORKS Simulation; SDC Publications: Mission, CA, USA, 2017. [Google Scholar]

- Rao Singiresu, S. The Finite Element Method in Engineering, 6th ed.; (Instructor′s Edu Resource 1 of 2, Solution Manual) (Solutions); Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- Stokes, A. Manual Gearbox Design, SAE International Society of Automotive Engineering; Butterworth-Heinemann Ltd.: Oxford, UK, 1992. [Google Scholar]

- Radzevich, S.P. Dudley’s Handbook of Practical Gear Design and Manufacture; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Radzevich, S.P.; Storchak, M. Advances in Gear Theory and Gear Cutting Tool Design; Springer: Sterling Heights, MI, USA, 2022. [Google Scholar]

- Dudiță, F.; Jula, A.; Velicu, D. Proiectarea angrenajelor evolventice; Scrisul Românesc: Craiova, Romania, 1989. [Google Scholar]

- Hilgers, M. Transmissions and Drivetrain Design, 2nd ed.; Springer-Verlag GmbH: Berlin, Germany, 2023. [Google Scholar]

- Harris, T.A. Analysis of Rolling Bearings; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2001. [Google Scholar]

- Nguyen-Schafer, H. Computational Design of Rolling Bearings; Springer: Berlin, Germany, 2016. [Google Scholar]

- Hopkins, R.B. Design Analysis of Shafts and Beams (A Practical Approach), 2nd ed.; Robert E. Krieger Pub. Co.: Malabar, FL, USA, 1987. [Google Scholar]

- Kobelev, V. Fundamentals of Springs Mechanics, 3rd ed.; Spinger: Berlin, Germany, 2024. [Google Scholar]

- Orthwein, W.C. Clutches and Brakes Design and Selection, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Martini, L.J. Practical Seal Design; CRC Press: Boca Raton, FL, USA; Taylor and Francis: Oxford, UK; Mechanical Engineering (Marcel Dekker Inc.): New York, NY, USA, 2017. [Google Scholar]

- Maffei, A.; Boffa, E.; Lupi, F.; Lanzetta, M. On the design of constructively aligned educational unit. Educ. Sci. 2022, 12, 438. [Google Scholar] [CrossRef]

- Pereira, L.; Pinto, M.; Costa, R.L.; Dias, Á.; Gonçalves, R. The New SWOT for a Sustainable World. J. Open Innov. Technol. Mark. Complex. 2021, 7, 18. [Google Scholar] [CrossRef]

- Puyt, R.W.; Birger Lie, F.; Wilderom, C.P.M. The origins of SWOT analysis. Long Range Plan. 2023, 56, 102304. [Google Scholar] [CrossRef]

- ISO/TC 60/SC 2 Gear Capacity Calculation. Available online: https://www.iso.org/committee/49242.html (accessed on 3 November 2024).

- NTN Rolling Bearings Handbook, CAT. No. 9012-/E. Available online: https://www.ntnglobal.com/en/products/catalog/pdf/9012E.pdf (accessed on 11 October 2024).

- Download Catalogs. Available online: https://koyo.jtekt.co.jp/en/support/catalog-download/ (accessed on 7 September 2024).

- Shaeffer Rolling Bearings. Technical Principles and Product Data for the Design and Rolling Bearing Arrangements. Available online: https://www.schaeffler.ro/ro/news_media/media_library/?tab=mediathek-pub&subfilter=app:dc;language-vid:167;language-pub:167;mediatyp-pub:3748;referencetyp-pub:0&uid=386195 (accessed on 18 October 2024).

- Rolling Bearings. Available online: https://cdn.skfmediahub.skf.com/api/public/0901d196802809de/pdf_preview_medium/0901d196802809de_pdf_preview_medium.pdf (accessed on 18 October 2024).

- ISO 26909:2009; Springs—Vocabulary. Technical Committee ISO/TC 227: Tokyo, Japan, 2025.

- ISO/IEC Guide 99:2007; International Vocabulary of Metrology—Basic and General Concepts and Associated Terms (VIM). International Organization for Standardization: Geneva, Switzerland, 2007.

- Pop, D.; Haragâș, S.; Buiga, O. Organe de Mașini; RisoPrint: Cluj-Napoca, Romania, 2021; Volume 2. [Google Scholar]

- Săvescu, D. Organe de Mașini. Mechanical Power Transmissions; RisoPrint: Cluj-Napoca, Romania, 2018. [Google Scholar]

- Pustan, M.; Belcin, O.; Bârleanu, C. Machine Elements. Demountable Assemblies, Straight Axles and Shafts, Metal Springs; UT Press: Cluj-Napoca, Romania, 2013. [Google Scholar]

- Haragâș, S. Organe de Mașini; Napoca Star: Cluj-Napoca, Romania, 2014. [Google Scholar]

- Grigore, N. Machine Elements. Mechanical Transmissions; Ploiești University Publishing House: Ploiești, Romania, 2003. [Google Scholar]

- Ștefănescu, I.; Spânu, C. Organe de Mașini; Editura Europlus: Galati, Romania, 2009; Volume 1. (In Romanian) [Google Scholar]

- Tomescu (Deleanu), L. Elemente de Mecanică Fină; Editura Fundației Universitare “Dunărea de Jos”: Galați, Romania, 2001. [Google Scholar]

- Jula, A.; Lateș, M. Organe de Mașini; Editura Universității Transilvania: Brașov, Romania, 2004. (In Romanian) [Google Scholar]

- Bostan, I.; Dulgheru, V.; Grigoraș, Ș. Transmisii Planetare, Precesionale și Armonice—Atlas; Editura Tehnică București-“Tehnica”: Chișinău, Republic of Moldova, 1997. [Google Scholar]

- Gafițanu, M.; Bostan, I.; Dulgheru, V.; Racocea, C.; Hagiu, G.; Jula, A.; Chișu, E.; Moldovan, G. Organe de Mașini; Editura Tehnică: Bucharest, Romania, 2002; Volume 2. [Google Scholar]

- Ianuș, G. Organe de Mașini; Partea I, Politehnium: Iași, Romania, 2010. [Google Scholar]

- About Standardization. Available online: https://www.asro.ro/en/about-asro/ (accessed on 11 October 2024).

- Haragâș, S. Reductoare cu o Treaptă. Calcule și Proiectare; RisoPrint: Cluj-Napoca, Romania, 2014. [Google Scholar]

- Deleanu, L.; Pîrvu, C.; Georgescu, C.; Ojoc, G.G.; Titire Chiper, L. Proiectarea Reductoarelor cu Roți Dințate; Galati University Press (GUP): Galati, Romania, 2021. [Google Scholar]

- Stoica, G.F.; Greculescu, A. Mechanical Transmissions Based on One Step Reducer (Design Guidebook); Politehnica Press: Bucharest, Romania, 2013. [Google Scholar]

- SR EN ISO 683-1:2018; Heat-Treatable Steels, Alloy Steels and Steels for Automatics. Part 1: Non-Alloy Steels for Quenening and Tempering. BSI: Sydney, Australia, 2018.

- SR EN ISO 683-2:2018; Heat-Treatable Steels, Alloy Steels and Steels for Automatics. Part 2: Alloy Steels for Quenening and Tempering. BSI: Sydney, Australia, 2018.

- SR EN ISO 683-3:2022; Heat-Treatable Steels, Alloy Steels and Steels for Automatics. Part 3: Case Hardening Steels. Danish Standards: København, Denmark, 2022.

- ISO 2553:2019; Welding and Allied Processes—Symbolic Representation on Drawings—Welded Joints. Stockholm, Standardiseringskommissionen I Sverige: Stockholm, Sweden, 2019.

- DIN 8187; European Type Chains. German Institute for Standardisation: Berlin, Germany, 1987.

- ANSI B29.1; Precision Power Transmission Roller Chains, Attachments, and Sprockets 2011 (R2022). American Society of Mechanical Engineers: New York, NY, USA, 2022.

- DIN 740-1:1986-08; Power Transmission Engineering, Flexible Shaft Couplings, Technical Delivery Conditions or Equivalent. German Institute for Standardisation: Berlin, Germany, 1986.

- ISO 15:2017; Rolling Bearings—Radial Bearings. Boundary Dimensions, General Plan; International Organization for Standardization: Geneva, Switzerland, 2017.

- DIN 625-1:2011; Rolling Bearings—Radial Deep Groove Ball Bearings—Part 1: Single Row. German Institute for Standardisation: Berlin, Germany, 2011.

- Teaching Standards. Good Practices for Collaboration Between National Standards Bodies and Universities, 2014. Available online: https://www.iso.org/files/live/sites/isoorg/files/store/en/PUB100354.pdf (accessed on 2 October 2024).

- De ce să învățăm Despre Standarde? (Why Learning About Standards) (In Romanian). Available online: https://www.asro.ro/educatia-despre-standardizare/ (accessed on 11 October 2024).

- How to Best Use IEC and ISO Standards. A User Guide on Licensing Options and Respecting Copyright. Available online: https://www.iso.org/files/live/sites/isoorg/files/store/en/PUB100206.pdf (accessed on 9 October 2024).

- Education on Standardization in Europe. Available online: https://www.cencenelec.eu/news-and-events/events/2024/2024-06-17_18-hlf-eas/ (accessed on 10 September 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).