Successful Innovation Transfer through Pre-Standardization: A Case Study

Abstract

1. Introduction

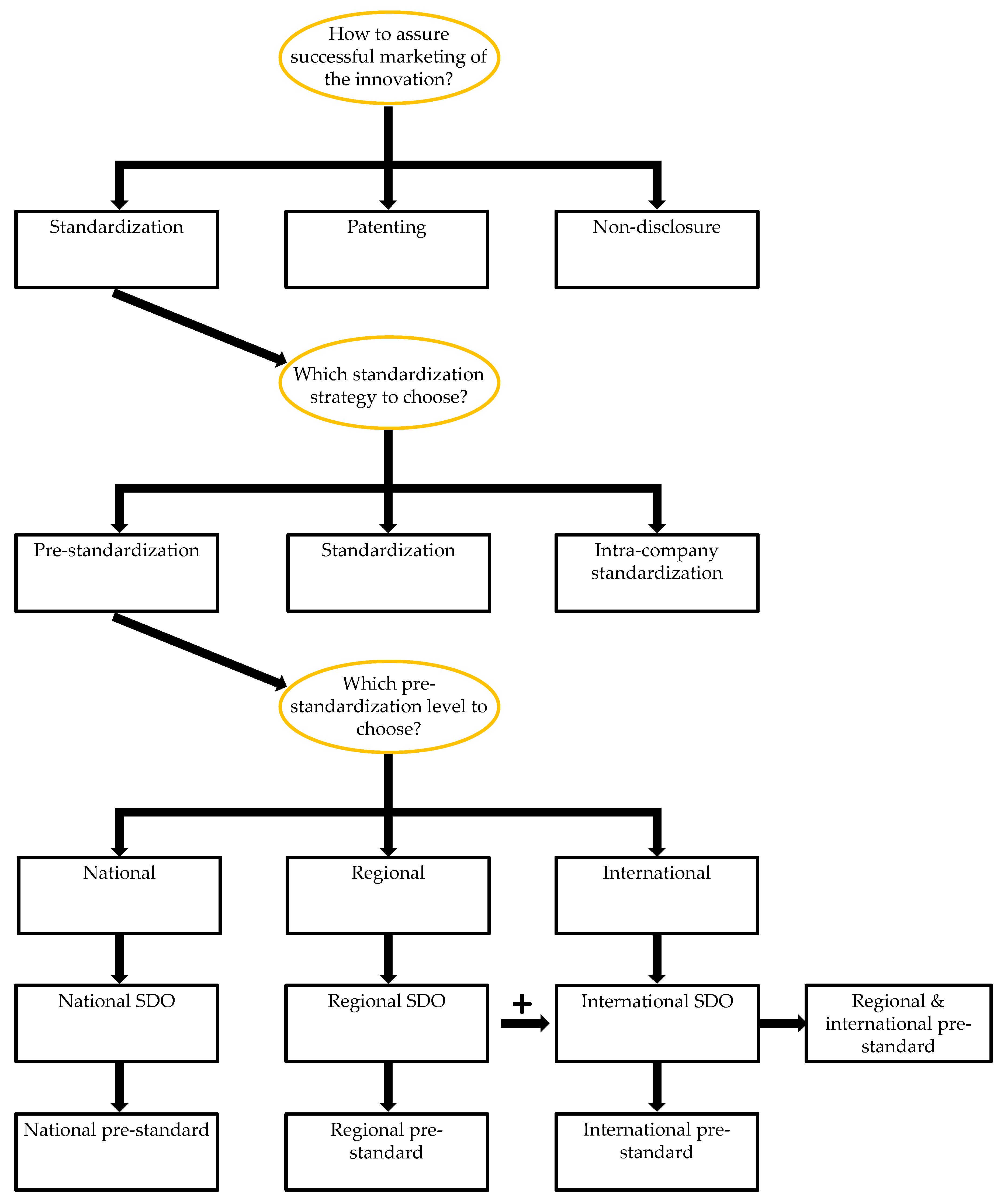

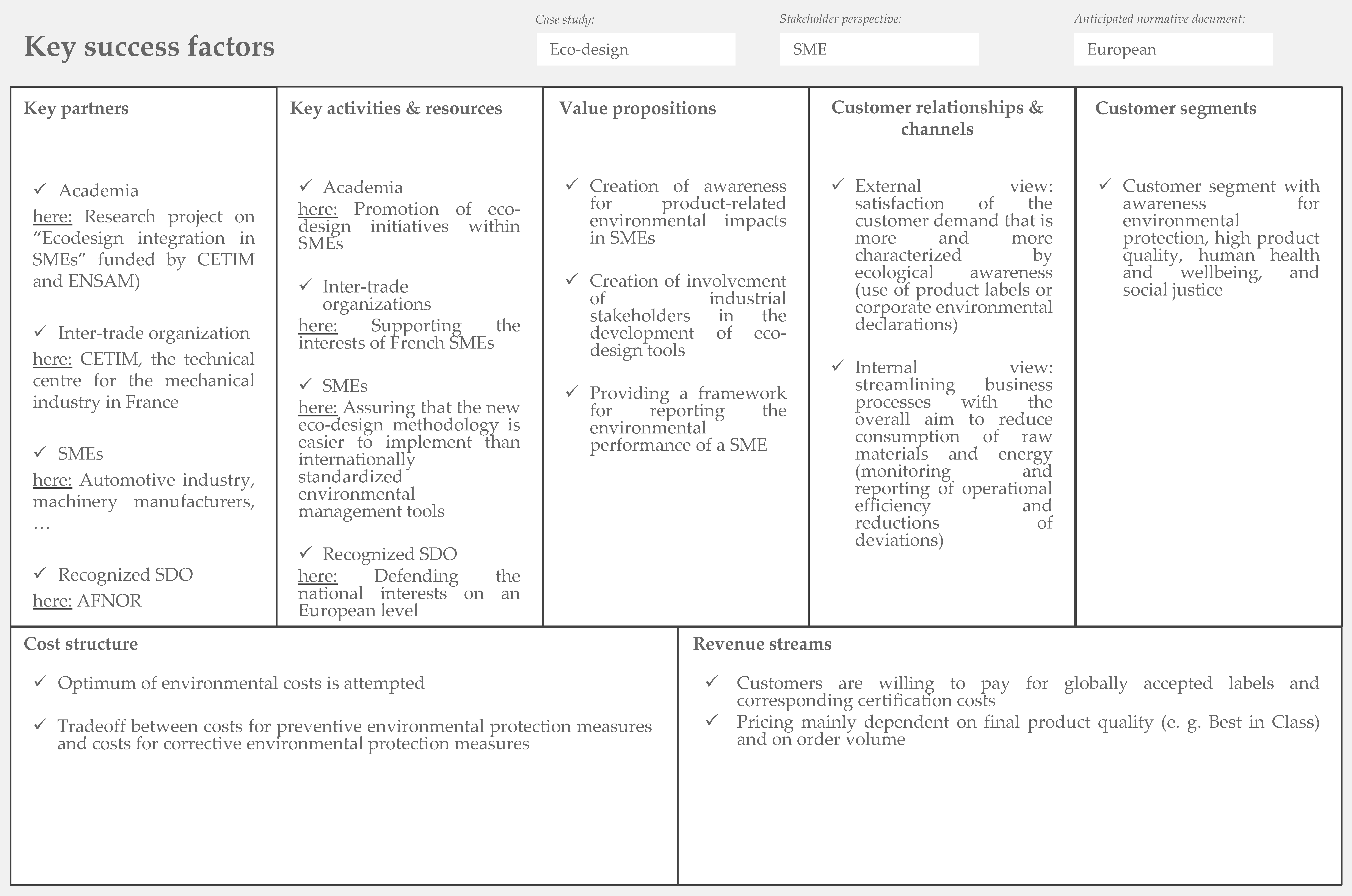

2. Assessing Corporate Standardization Strategies Using Key Success Factors

3. Case Study: Assessing the Strategy of Pre-Standardization for the Reduction of Environmental Impacts in Product Design and Development

3.1. Description of the Pre-Standardization Pathway

3.2. Success Factors for the Pre-Standardization Pathway

3.2.1. Key Partners

- ✓

- The strategic partnership with key partners provides access to the relevant target group (the prospective users of the anticipated (pre-)standard)).

- ○

- The coverage in the relevant industrial sector can be assessed based on the number of companies involved in the standardization activity. Furthermore, the market share of involved companies in the relevant business domain might serve as indicator to assess whether a critical mass for achieving consensus in the (pre-)standardization activity is reached.

- ✓

- Besides the sheer number of supporters, it is important to distinguish between conservative partners that tend to represent trusted and established scientific and technical results and innovative partners that tend to represent emerging and rapidly evolving scientific and technical results.

- ○

- The business strategy (vision and mission) of key partners serves as an indicator to characterize partners either as conservative or as innovative.

3.2.2. Key Activities and Resources

- ✓

- Each key partner should provide appropriate resources to achieve the desired outcome of the (pre-)standardization activity in an efficient manner.

- ○

- During the initial phase of the (pre-)standardization activity, each key partner should inform about its key competences and the corresponding cost structure for prospective services. Information on similar reference projects might help to identify the right partner for the right task within the (pre-)standardization activity.

- ✓

- It might be helpful to distinguish between various types of key resources.

- ○

- The suitability of key resources for the desired outcome of a (pre-)standardization activity might be assessed in the categories of physical, intellectual, human or financial resources.

3.2.3. Value Propositions

- ✓

- The characteristics of the prospective added value of the (pre-)standardization activity need to be clearly depicted.

- ○

- The outcome of a (pre-)standardization activity can be grouped into, e.g., degree of novelty, performance, design, reputation, price, costs, operational risk, accessibility, convenience.

- ✓

- It is also highly recommended to link the expected outcome of the (pre-)standardization activity with a return-on-investment consideration.

- ○

- This consideration might take into account, e.g., due dates and payback periods.

3.2.4. Customer Relationships and Channels

- ✓

- The success of (pre-)standardization activity is also strongly dependent on how the anticipated customer segments are addressed. This implies that the customer relationship must be defined.

- ○

- The level of customer relationship ranges from the manual allocation of information to automated services and must be adapted to the prospective customer segment.

- ✓

- Different channels are associated with different costs that must be accounted for.

- ○

- Cost-effectiveness is an adequate measure for the assessment of different channels.

3.2.5. Customer Segments

- ✓

- Initially, it must be specified for whom the (pre-)standardization activity creates added value.

- ○

- Typically, it is defined whether a normative document is intended for customer segments of the mass market or the niche market.

- ✓

- A further characterization of the respective customer segment helps to identify the most important customers.

- ○

- Customer segmentation usually resorts to attributes such as customer expectations, demographic features, the behavioral patterns of customers, preferred markets, features of the customer’s personality and the customer’s lifestyle.

3.2.6. Cost Structure

- ✓

- It must be clearly stated whether the (pre-)standardization effort is cost-driven, value-driven or resorts to a hybrid approach.

- ○

- The cost structure is strongly correlated to the overarching strategy (cost leadership, differentiation strategy or niche strategy).

- ✓

- The identification of the relevant costs implied by the prospective normative document must be discussed in a traceable manner. The most expensive key activities and resources required for the (pre-)standardization effort should be identified.

- ○

- Cost structures are typically analyzed with respect to capital investment and operating costs.

3.2.7. Revenue Streams

- ✓

- Success can be measured based on the revenue streams.

- ○

- Revenue streams can be grouped into, e.g., sales, user fees, rental fees, licenses, service fees.

- ✓

- Revenue streams can be characterized by different pricing models.

- ○

- Pricing models are typically analyzed with respect to fixed prices and dynamic prices.

3.3. Evaluation of the Pre-Standardization Strategy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. Notices from European Union institutions, bodies, offices and agencies. Guidelines on the Applicability of Article 101 of The Treaty on the Functioning of the European Union to Horizontal Co-Operation Agreements. Off. J. Eur. Union 2011, 4, 1–72. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A52011XC0114%2804%29 (accessed on 7 January 2023).

- Märtson, I. The essence of standardization and a way of calculating its benefits. In EURAS Yearbook of Standardization (EYS), 2nd ed.; Holler, M.J., Ed.; Accedo: München, Germany, 1999; pp. 401–415. [Google Scholar]

- Department of Trade and Industry, London. The Empirical Economics of Standards; DTI Economics Paper; DTI: London, UK, 2005; Volume 12, Available online: https://www.immagic.com/eLibrary/ARCHIVES/GENERAL/UK_DTI/T050602D.pdf (accessed on 7 January 2023).

- Knoop, H. Economic Benefits of Standardization—Result of a German Scientific Study. In Proceedings of the XXIII International FIG Congress INTERGEO, München, Germany, 8–13 October 2006. [Google Scholar]

- Blum, U. How standards make the world flat. Homo Oecon. 2006, 23, 347–377. [Google Scholar]

- Swann, G.M.P. The Economics of Standardization: Final Report for Standards and Technical Regulations Directorate—Department of Trade and Industry; DTI: Manchester, UK, 2000. [Google Scholar]

- Deutsches Institut für Normung e. V. The Economic Benefits of Standardization, An Update of the Study Carried out by DIN in 2000; Beuth: Berlin, Germany, 2011; Available online: https://www.din.de/blob/89552/68849fab0eeeaafb56c5a3ffee9959c5/economic-benefits-of-standardization-en-data.pdf (accessed on 7 January 2023).

- Standards Council of Canada. Economic Value of Standardization; The Conference Board of Canada: Ottawa, ON, Canada, 2007; Available online: https://www.scc.ca/en/system/files/publications/2007-10-25_EconomicValueStandardizationCanada_FinalReport-REVISED-web.pdf (accessed on 7 January 2023).

- Standards Australia. Standards and the Economy; Center for International Economics: Canberra, Australia; Sydney, Australia, 2006. Available online: https://www.pc.gov.au/inquiries/completed/standards/submissions/standards_australia_cie/subdr133.pdf (accessed on 7 January 2023).

- Berl Economics. The Economic Benefits of Standards to New Zealand; The Standards Council of New Zealand and the Building Research Association of New Zealand: Wellington, New Zealand, 2011; Available online: http://academico.une.org/Documents/BERLreportontheeconomicbenefitsofSNZAug2011.pdf (accessed on 7 January 2023).

- Association Française de Normalisation. The Economic Impact of Standardization; Association Française de Normalisation: Saint-Denis, France, 2009; Available online: https://normalisation.afnor.org/wp-content/uploads/2016/06/Etude-ImpactEcoNorm-GB2009.pdf (accessed on 7 January 2023).

- International Organization of Standardization/International Electrotechnical Commission. ISO/IEC Guide 2: Standardization and Related Activities—General Vocabulary; International Organization for Standardization: Geneva, Switzerland, 2004; Available online: https://www.iso.org/standard/39976.html (accessed on 7 January 2023).

- Leidecker, J.K.; Bruno, A.V. Identifying and using critical success factors. Long Range Plan. 1984, 17, 23–32. [Google Scholar] [CrossRef]

- Akhavan, P.; Jafari, M.; Fathian, M. Critical success factors of knowledge management systems: A multi-case analysis. Eur. Bus. Rev. 2006, 18, 97–113. [Google Scholar] [CrossRef]

- Holland, C.P.; Light, B.; Gibson, N. A critical success factors model for enterprise resource planning implementation. In Proceedings of the 7th European Conference on Information Systems, Copenhagen, Denmark, 23–25 June 1999. [Google Scholar]

- Osterwalder, A. The Business Model Ontology: A Proposition in a Design Science Approach. Ph.D. Thesis, University of Lausanne, Lausanne, Switzerland, 2004. [Google Scholar]

- Osterwalder, A.; Pigneur, Y.; Tucci, C.L. Clarifying business models: Origins, present, and the future of the concept. Commun. Assoc. Inf. Syst. 2005, 16, 1–25. [Google Scholar] [CrossRef]

- Sparviero, S. The case for a socially oriented Business Model Canvas: The Social Enterprise Model Canvas. J. Soc. Entrep. 2019, 10, 232–251. [Google Scholar] [CrossRef]

- EN 16524:2020; Mechanical Products—Methodology for Reduction of Environmental Impacts in Product Design and Development. Comité Européen de Normalisation: Brussels, Belgium, 2020. Available online: https://www.beuth.de/en/standard/din-en-16524/325514141 (accessed on 7 January 2023).

- Vinzio, P.; (KSB SE & Co. KGaA, Bordeaux, France). Personal communication, 2021.

- Le Pochat, S. Ecodesign Integrations in SMEs—Proposal for a Know-How Appropriation Method for Environmental Product Design. Ph.D. Thesis, Arts et Métiers ParisTech, Paris, France, 2005. [Google Scholar]

- Meleton, L.; (CETIM, Saint-Étienne, France). Personal communication, 2021.

- Dahlke, A.; (Deutsches Institut für Normung e. V., Berlin, Germany). Personal communication, 2021.

- Schridde, S. Die Manipulation des Verbrauchers. In Manipulation; Loureda, Ó., Ed.; Heidelberg University Publishing: Heidelberg, Germany, 2018; pp. 37–49. [Google Scholar]

- ISO 20887:2020; Sustainability in Buildings and Civil Engineering Works—Design for Disassembly and Adaptability—Principles, Requirements and Guidance. International Organization for Standardization: Geneva, Switzerland, 2020.

- Kreiß, C. Geplanter Verschleiß; Europa Verlag: Berlin, Germany, 2014. [Google Scholar]

- Andes, L.; Lützkendorf, T.; Ströbele, B.; Kopfmüller, J.; Rösch, C. Methodensammlung zur Nachhaltigkeitsbewertung—Grundlagen, Indikatoren, Hilfsmittel; Karlsruher Institut für Technologie: Karlsruhe, Germany, 2019; Available online: https://www.oew.kit.edu/downloads/Methodensammlung%20zur%20Nachhaltigkeitsbewertung.pdf (accessed on 7 January 2023).

- XP E01-005:2009; Mechanical Products—Eco-Design Methodology. Association Française de Normalisation: Paris, France, 2009.

- NF E01-005:2010; Mechanical Products—Eco-Design Methodology. Association Française de Normalisation: Paris, France, 2010.

- NF E01-005:2013; Mechanical Products—Methododlogy for Reduction of Environmental Impacts in Product Design and Development. Association Française de Normalisation: Paris, France, 2013.

- ISO 14020:2000; Environmental Labels and Declarations—General Principles. International Organization for Standardization: Geneva, Switzerland, 2000.

- ISO 14021:2016; Environmental Labels and Declarations—Self-Declared Environmental Claims (Type II Environmental Labelling). International Organization for Standardization: Geneva, Switzerland, 2016.

- EN ISO 14025:2011; Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures. Comité Européen de Normalisation: Brussels, Belgium; International Organization for Standardization: Geneva, Switzerland, 2011. Available online: https://www.beuth.de/en/standard/din-en-iso-14025/144319534 (accessed on 7 January 2023).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- CEN/TS 16524:2013; Mechanical Products—Methodology for Reduction of Environmental Impacts in Product Design and Development. Comité Européen de Normalisation: Brussels, Belgium, 2013. Available online: https://www.beuth.de/en/technical-rule/din-cen-ts-16524/168897295 (accessed on 7 January 2023).

- NF EN 16524:2020; Mechanical Products—Methodology for Reduction of Environmental Impacts in Product Design and Development. Association Française de Normalisation: Paris, France, 2020.

- www.iso.org. 04 Vienna Agreement (English). Available online: https://isotc.iso.org/livelink/livelink?func=ll&objId=4230458&objAction=browse&sort=subtype (accessed on 7 January 2023).

| Cluster | Question(s) |

|---|---|

| Key partner | Who are the relevant stakeholders in the standardization activity? |

| Key activity | What key activities do the value propositions require? What key activities do the distribution channels require? What key activities do the customer relationships require? What key activities do the revenue streams require? |

| Key resources | What key resources do the value propositions require? What key resources do the distribution channels require? What key resources do the customer relationships require? What key resources do the revenue streams require? |

| Value proposition | What value is delivered to the customer? Which customer problem is solved? What bundles of products and services are offered to each customer segment? Which customer needs are satisfied? |

| Customer relationships | What type of relationship does each customer segment require? Which relationships are established? How are the relationships integrated? How costly are the relationships? |

| Customer segments | For whom is value creation existing? Who are the most important customers? |

| Channels | Through which channels do customer segments want to be reached? How are the customer segments reached currently? How are channels integrated? Which channel works best? Which channels are most cost-efficient? How are channels integrated with customer routines? |

| Cost structure | What are the most important costs? Which key resources are most expensive? Which key activities are most expensive? |

| Revenue streams | What are customers willing to pay? For what do customers currently pay? |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nehr, S.; Jäckel, S. Successful Innovation Transfer through Pre-Standardization: A Case Study. Standards 2023, 3, 31-42. https://doi.org/10.3390/standards3010004

Nehr S, Jäckel S. Successful Innovation Transfer through Pre-Standardization: A Case Study. Standards. 2023; 3(1):31-42. https://doi.org/10.3390/standards3010004

Chicago/Turabian StyleNehr, Sascha, and Simon Jäckel. 2023. "Successful Innovation Transfer through Pre-Standardization: A Case Study" Standards 3, no. 1: 31-42. https://doi.org/10.3390/standards3010004

APA StyleNehr, S., & Jäckel, S. (2023). Successful Innovation Transfer through Pre-Standardization: A Case Study. Standards, 3(1), 31-42. https://doi.org/10.3390/standards3010004