1. Introduction

Arsenic exists in nature mainly in the form of trivalent and pentavalent compounds; trivalent compounds are more toxic than pentavalent compounds [

1,

2]. Arsenic mainly comes from the smelting of non-ferrous metals, the mining of arsenic-containing minerals, and the application of arsenic-containing compounds in industrial production, such as paint, glass, textile, semiconductor, and nitrogen fertilizer [

3,

4]. Arsenic compounds often exist in the form of by-products, and in the wastewater discharged into the environment, causing harm to the human body, such as neurasthenia, cardiovascular disease, diabetes and so on [

5]. Therefore, the World Health Organization (WHO) recommends a maximum concentration limit of 10 μg/L for drinking water [

6].

Currently, arsenic removal methods include chemical precipitation [

7], adsorption [

8], and microbial methods [

9]. Each method has its own advantages and disadvantages, but currently, adsorption is considered the most promising method because of its high efficiency, suitability for industrial application, low cost, simple operation, and high regeneration capacity [

10,

11]. In the past, a variety of adsorbents have been developed and applied for the treatment of arsenic-containing wastewater. For example, Ahmad Sadeghi Chevinli et al. [

12] synthesized a Mg-Fe LDH-GO adsorbent with high adsorption capacity for both As (III) and As (V) by the co-precipitation method. Xiaoli Song et al. [

13] loaded Fe

3O

4 on halloysite nanotubes (HNTs), and experiments have shown that the nanocomposites have highly efficient arsenic removal performance and recyclability. Conventional adsorbents such as activated carbon, clay, zeolite, and agricultural wastes exhibit limited arsenic removal efficiency, and thus new adsorbent materials have been developed for the removal of arsenic from industrial wastewater [

14,

15].

Metal–organic frameworks (MOFs) are composed of metal ions or clusters coordinated with organic linkers, which exhibit an exceptional affinity toward metal ions, and are used as a new type of nanomaterial due to their high specific surface area, large pore size, and good stability [

16,

17,

18]. MOF materials can be used for the removal of various pollutants from water, as shown by Hongfei Ma et al. [

19], who investigated the synthesis of La-MOFs in different morphologies by altering the solvothermal temperature and applied them for the removal of fluoride ions (F

−) from water. Hossein Molavi et al. [

20] prepared a series of Ce-MOF materials by using different solvents and thoroughly investigated the effect of such materials on the organic dyes’ adsorption properties. However, single MOFs have fewer applications in the practical treatment of wastewater due to their poor selectivity and weak capture ability. Modifying MOFs is an inevitable trend aimed at increasing the number of adsorption active sites and enable a wider range of applications. The current methods of MOF modification include the doping of metals [

21], changing the organic ligands [

22], the generation of induced defects [

23], the introduction of functional groups [

24], etc. In addition, two different forms of MOF are mixed together to obtain new materials with different structures and properties [

25].

Spinel ferrites (MnFe

2O

4) possess excellent chemical stability and abundant surface functional groups, which are advantageous for removing various toxic pollutants from water [

26]. Ting Pan et al. [

27] synthesized MnFe

2O

4@S-ZnO and investigated its performance in removing norfloxacin (NOF). Tao Zhang et al. [

28] successfully prepared a composite material, MnFe

2O

4/rGO, through defect engineering, which demonstrated efficient electrochemical arsenic removal performance along with excellent stability. Rauf Foroutan et al. [

29] modified biochar (BCSO) to synthesize BCSO/MnFe

2O

4@La-MOF for the highly efficient removal of fluoride ions (F

−) from water. With the increasing awareness of environmental protection, the development of green and eco-friendly materials has become a hot research topic. For example, Sonia Jemli et al. [

30] used sunflower seed husk (SFSH) and β-cyclodextrin (β-CD) to green-synthesize a crosslinked adsorbent (SFSH-β-CD) for the removal of phenol and cyclohexane carboxylic acid. Xiang Chen et al. [

31] synthesized an eco-friendly adsorbent, 2D/2D Na

+-MXene/LDH composite, for cesium adsorption in salt lakes.

In this paper, the doping of metals and introduction of spinel ferrite (MnFe2O4) are carried out to modify MOF materials. Zirconium-based metal–organic frameworks have demonstrated extensive applications due to their high surface area, good stability, and strong adsorption capacity. MnFe2O4@Fe-UiO-67 composites were used for the adsorption of arsenic from industrial wastewater in this study. The structure and adsorption mechanism of the adsorbent were explored by characterization methods such as X-ray diffraction (XRD), scanning electron microscopy (SEM), Fourier transform infrared (FT-IR), and X-ray photoelectron spectroscopy (XPS), combined with the use of adsorption kinetics and isotherm modeling. In addition, the adsorption performance of the material was explored in terms of pH value and adsorbent dosage.

2. Experimental Parts

2.1. Experimental Materials

Zirconium chloride (ZrCl4, 98%), acetic acid (CH3COOH, 99.5%), ferric nitrate nine water (Fe(NO3)3·9H2O, 99.99%), potassium permanganate (KMnO4, AR), ferrous sulfate heptahydrate (FeSO4·7H2O, 99%), N,N-dimethylformamide (DMF, 99%), 4-4′-biphenyldicarboxylic acid (4,4′-H2BPDC, 98%), methanol (CH3OH, 99.5%) and ethanol (CH3CH2OH, 75%) were used. All reagents were analytical-grade reagents in this experiment.

The industrial wastewater used in this experiment was from a copper smelting plant and contained Cu, Cd, Ni and other heavy-metal elements; it had a complex composition and high toxicity, as shown in

Table 1.

2.2. Preparation of Adsorbents

2.2.1. Preparation of MnFe2O4

MnFe

2O

4 was synthesized by dissolving 0.015 mol of KMnO

4 and 0.045 mol of FeSO

4·7H

2O in 200 mL of ultrapure water [

32]. The potassium permanganate solution was stirred, and the ferrous sulfate solution was slowly added to the potassium permanganate solution, while 5 M NaOH solution was added to adjust the pH to 10, and after stirring for 3 h, it was static-aged, washed with ultrapure water and dried.

2.2.2. Preparation of MnFe2O4@Fe-UiO-67

The 4,4′-H

2BPDC (0.5808 g), ZrCl

4 (0.2796 g), and acetic acid (2.28 mL) were added to 90 mL of DMF, and stirred until the sample was completely dissolved. Fe(NO

3)

3·9H

2O (0.4848 g) was added and stirred homogeneously, and then 0.1 g of MnFe

2O

4 was added and stirred homogeneously. The obtained mixture was transferred to a 200 mL PTFE-lined autoclave and kept at 120 °C for 24 h. After the reaction, the reactor was allowed to cool to room temperature. The solid product was separated by centrifugation, washed with DMF, CH

3OH, and CH

3CH

2OH and dried [

33,

34].

2.3. Methods of Analysis

The crystal structure of the adsorbents was determined using an X-ray diffractometer (XRD, MiniFlex600, Rigaku Corporation, Akishima, Japan) with a scanning range of 0–90° and a scanning speed of 5°/min; a field emission scanning electron microscope (SEM, Apreo 2S, Thermo Fisher Scientific, Waltham, MA, USA) was used to view the microscopic morphology of the adsorbents and surface elements, and the adsorption–resolution isotherm of N2 was determined using a Micromeritics ASAP 2460 instrument (Norcross, GA, USA), while the specific surface area of the adsorbent was calculated by the Brunauer–Emmett–Teller (BET) method and the pore volume and pore size distribution were analyzed by the Barrett–Joyner–Halenda (BJH) method. Infrared spectra in the range of 400–4000 cm−1 were collected using a Fourier transform infrared spectrometer (FTIR, Thermo Scientific Nicolet iS20, USA) in order to analyze the changes in the chemical bonding of the materials before and after adsorption. X-ray photoelectron spectroscopy (XPS, Thermo Scientific K-Alpha, USA) was used to analyze the elemental composition and content of the adsorbent, and the changes in the valence. An Inductively Coupled Plasma Atomic Emitter (ICP-OES, PQ9000, Jena, Germany) was used to measure the concentration of arsenic ions in solution.

2.4. Adsorption Experiments

There are many factors affecting the adsorption performance of adsorbents, and the batch experiments focused on investigating the effects of solution pH, adsorption time, adsorbent dosage, and arsenic solution concentration.

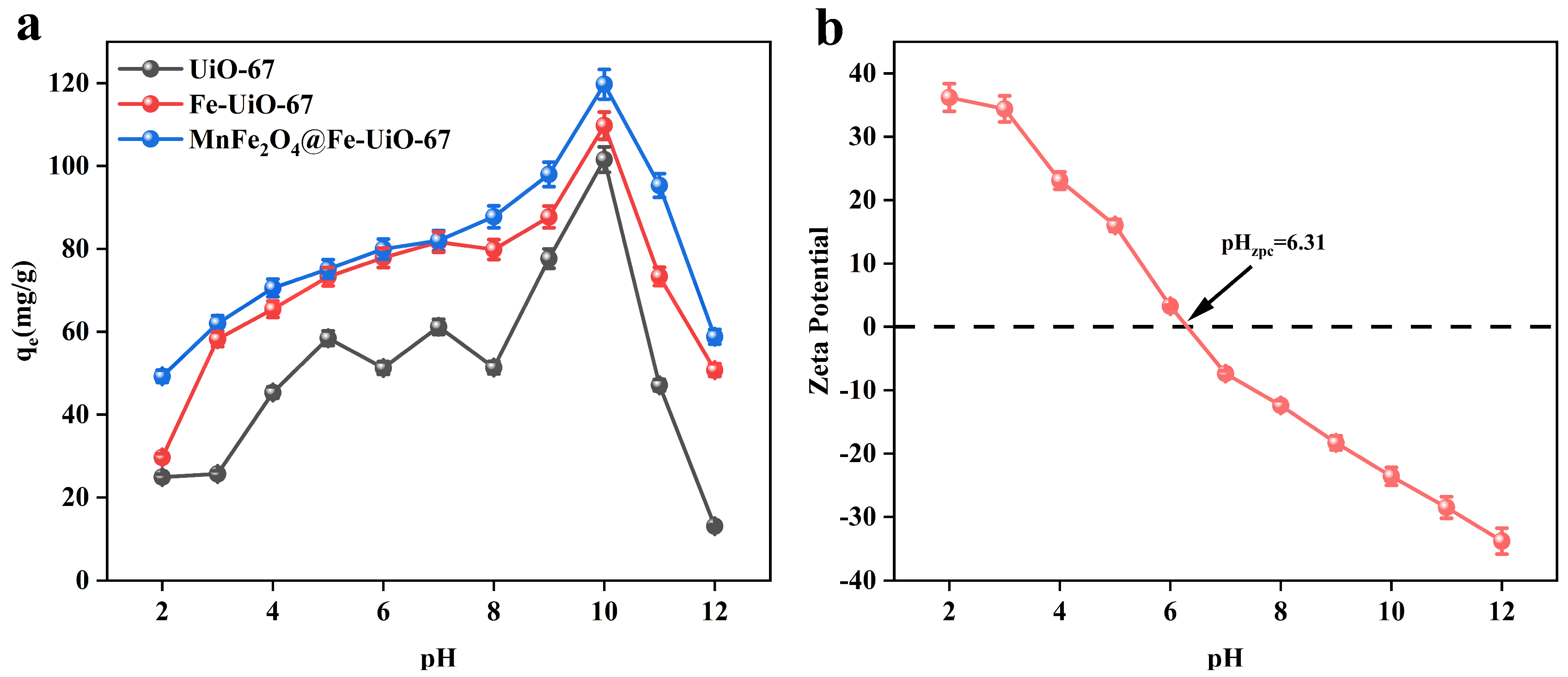

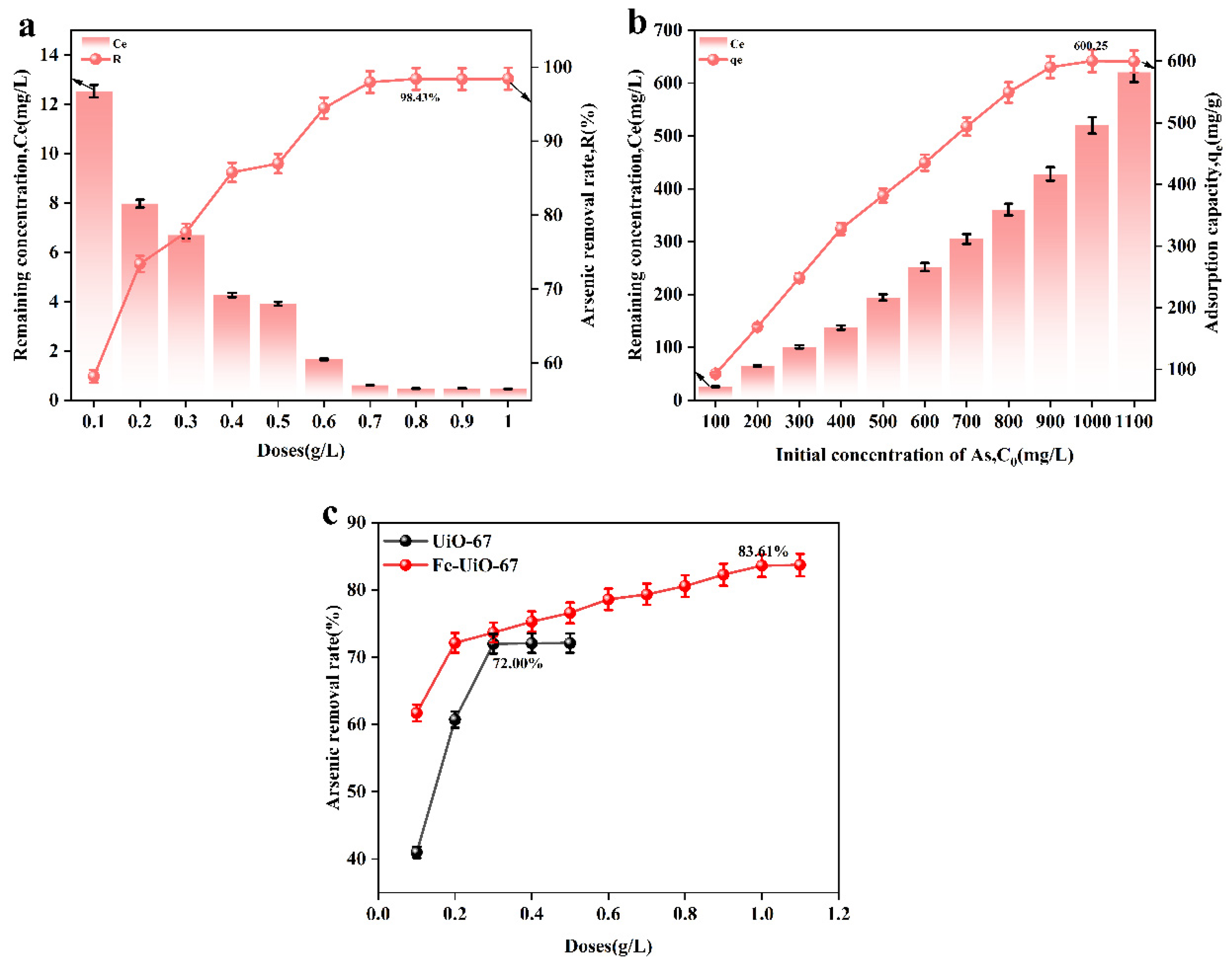

The pH of the arsenic solution was adjusted to 2–12, and then 10 mg of adsorbent was added to 50 mL of the arsenic solution. We then determined the As ion concentration after 24 h of reaction. An amount of 10 mg of the adsorbent was added to 50 mL of the arsenic solution at the optimal pH = 10, and vacuum-filtered through a 0.45 μm membrane the solution at a specific point of time, after which we determined the concentration of As ions. Under optimal reaction conditions (arsenic solution pH = 10, reaction time 3 h), a certain amount of adsorbent (0.1–1 g/L) was added to 50 mL of the As solution to determine the maximum arsenic removal rate. Different concentrations of arsenic solutions (100 mg/L, 200 mg/L, 300 mg/L, 400 mg/L, 500 mg/L, 600 mg/L, 700 mg/L, 800 mg/L, 900 mg/L, 1000 mg/L and 1100 mg/L) were configured to investigate the maximum adsorption amount of MnFe

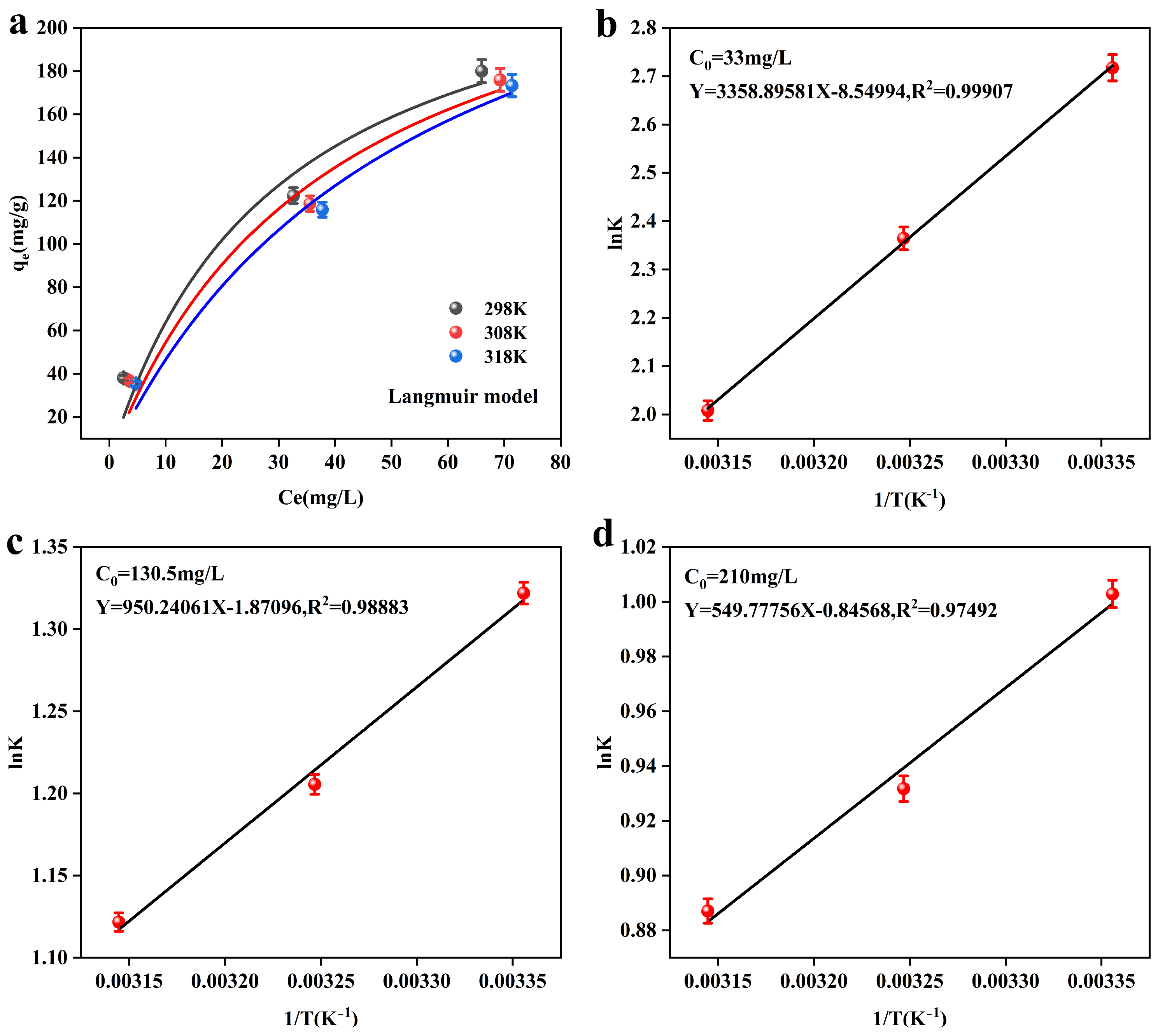

2O

4@Fe-UiO-67 under the conditions of pH = 10 and 3 h of reaction, and the dosage of the adsorbent was 0.8 g/L. In order to systematically explore the adsorption thermodynamic properties of the adsorbent, MnFe

2O

4@Fe-UiO-67, this study selected three temperatures (298 K, 308 K, and 318 K) with which to carry out the experiments. Solutions with initial arsenic concentrations of 33 mg/L, 130.5 mg/L, and 210 mg/L were prepared, and the pH value of the solutions was adjusted to 10. Then, 50 mL of the above-mentioned arsenic solution was taken, and 0.8 mg/L of the adsorbent was added to it. The reaction was carried out for 3 h at different temperatures. Finally, the experimental data were collected and their thermodynamic properties are analyzed. In the experiments, to investigate the optimal pH, adsorption time, and adsorbent dosage, arsenic solutions with an initial concentration of 30 mg/L were used. To avoid errors, the above experiments were conducted three times. The As removal rate and adsorption capacity were calculated using Equations (1) and (2):

where

R (%) is the arsenic removal rate,

C0 (mg/L) is the initial arsenic solution concentration,

Ce (mg/L) is the arsenic solution concentration after adsorption,

qe (mg/g) is the adsorbed amount,

V (L) is the volume of the arsenic solution, and

m (g) is the mass of the adsorbent, MnFe

2O

4@Fe-UiO-67.

2.5. Equations for Adsorption Kinetics, Isotherms and Thermodynamic Analysis

Time is an important factor affecting the adsorption performance of an adsorbent. We used the pseudo-first-order model (PFO), pseudo-second-order model (PSO) and intraparticle diffusion model to study the adsorption process [

35]. The equations are as follows:

where

qe (mg/g) is the adsorbed amount at the equilibrium adsorption time, and

qt (mg/g) is the adsorbed amount at a specific time.

k1 (1/min),

k2 (mg/g·min), and

k3 (mg/g·min

0.5) represent the rate constants for PFO and PSO.

t is the reaction time (min).

In addition to time, the concentration of the arsenic solution is also an important factor affecting the adsorption performance of MnFe

2O

4@Fe-UiO-67. To investigate the adsorption isotherms, Langmuir, Freundlich and Temkin models were used to fit the isotherms to the experimental data [

36]. The adsorption model equations are given below:

where

qe and

qm are the adsorption amount at the adsorption equilibrium and the maximum adsorption amount of the adsorbent (mg/g), respectively;

KL (L/mg),

KF (L/mg), and

KT (L/g) are the Langmuir adsorption constant, Freundlich’s constant, and Temkin’s constant, respectively;

n is Freundlich’s model coefficient, and

R is the gas constant (8.314 J/mol/K).

On the other hand, temperature is a factor that cannot be ignored in the adsorption process. Adsorption thermodynamics -reveals the variations in energy and entropy during the adsorption process, allowing us to make judgments about the direction and extent of the adsorption reaction, and thus enabling a profound understanding of the adsorption mechanism. The relevant thermodynamic formulas are as follows:

Among them, the Gibbs free energy change (ΔG0), enthalpy change (ΔH0), and entropy change (ΔS0) are the core thermodynamic parameters, with units of kJ/mol, kJ/mol, and kJ/mol/K, respectively; K is the adsorption equilibrium constant, qe (mg/g) is the adsorption capacity, Ce (mg/L) is the remaining arsenic concentration after adsorption, R is the gas constant with a value of 8.314 J/mol/K. and T (K) is the adsorption temperature.

4. Reaction Mechanisms

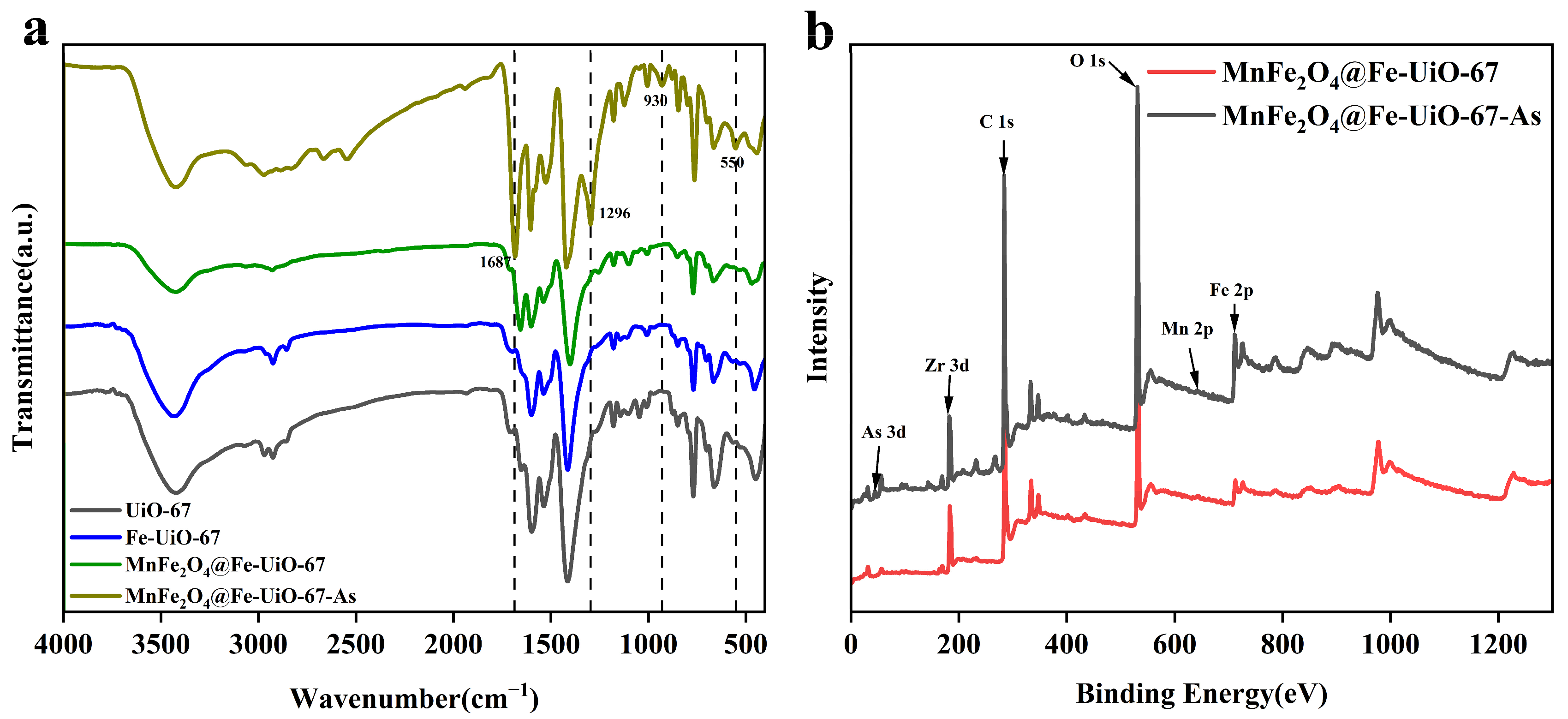

As shown in

Figure 8a, the IR spectra of UiO-67 and Fe-UiO-67 are the same, indicating that they are structurally the same. The four extra bonds after the adsorption of MnFe

2O

4@Fe-UiO-67 are Fe-O bonds (550 cm

−1) [

34]; the peaks at 930 cm

−1 correspond to the As-O bond [

46], indicating that the active sites on the adsorbent form coordination bonds with As ions, thereby enabling the removal of arsenic. The peaks observed at 1296 cm⁻¹ and 1687 cm⁻¹ may emerge due to structural modifications induced by the adsorption process.

Figure 8b shows the total XPS spectra before and after adsorption, in which the content of the element Fe increased after adsorption and As appeared, indicating that the structure of MnFe

2O

4@Fe-UiO-67 changed after adsorption and arsenic ions were adsorbed on it, and that there was no obvious peak for Mn due to the trace amounts of it.

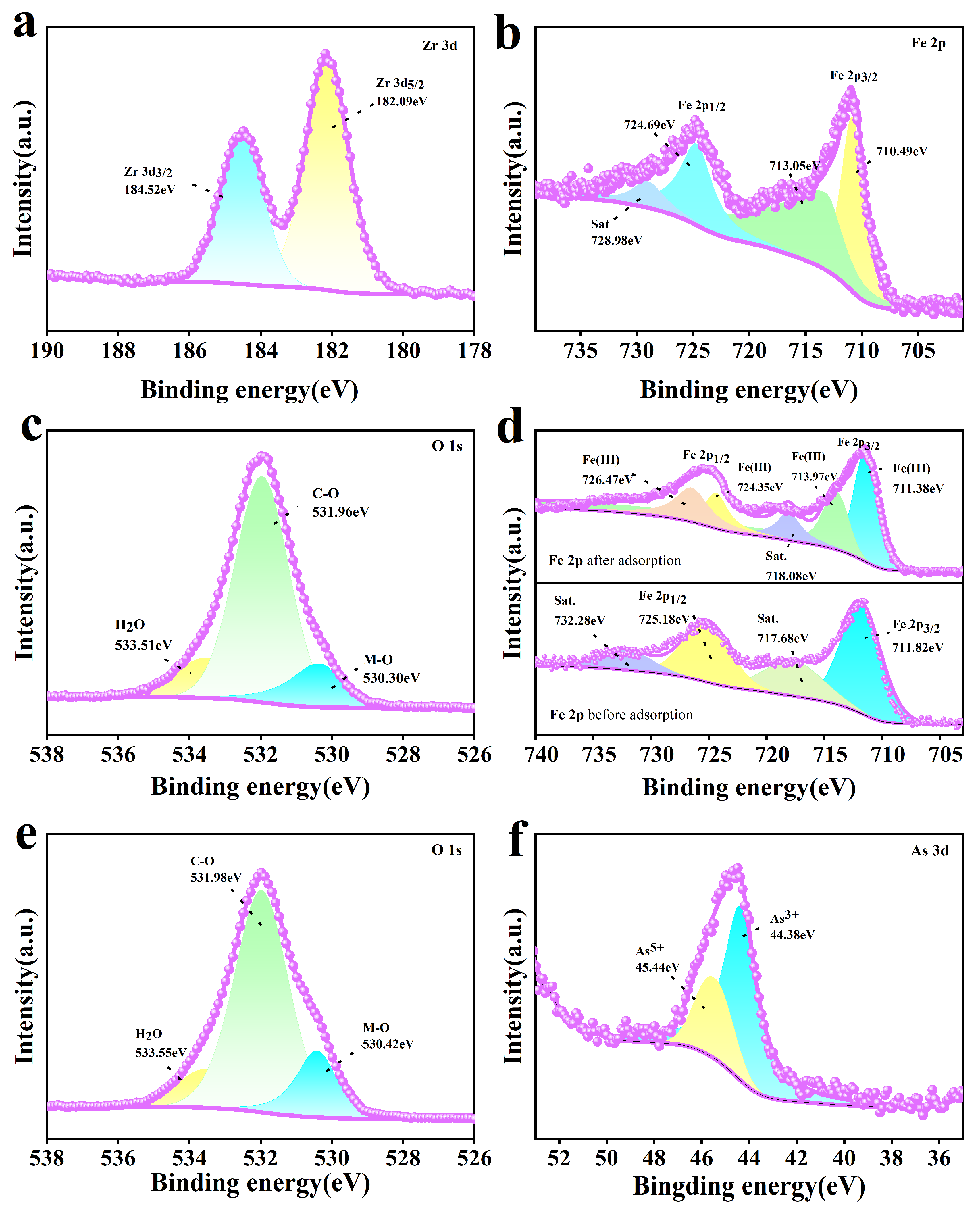

Figure 9 shows the XPS spectra of the adsorbent. The Zr 3d and Fe 2p spectra of Fe-UiO-67 are shown in

Figure 9a and b, respectively. In the Zr 3d spectrum, two characteristic peaks are shown at 182.09 eV and 184.52 eV, attributed to Zr 3d

5/2 and Zr 3d

3/2, respectively [

47,

48]. In the Fe 2p spectra, the characteristic peaks at 710.49 eV and 724.69 eV are attributed to Fe 2p

3/2 and Fe 2p

1/2, and the appearance of the characteristic peaks at 713.05 eV and 728.98 eV can be assigned to the satellite peaks, confirming the successful doping of Fe

3+ on UiO-67 [

49,

50]. According to the O 1s spectra of MnFe

2O

4@Fe-UiO-67 before and after adsorption (

Figure 9c,e), the peak area of the M–O bond after adsorption was significantly increased, which, in combination with the FT-IR spectra (

Figure 8a), indicates the generation of an As–O bond and Fe–O bond.

Figure 9d shows the Fe 2p mapping; the peaks at 711.82 eV and 725.81 eV before adsorption can be attributed to Fe 2p

3/2 and Fe 2p

1/2, while 717.68 eV and 732.28 eV are satellite peaks [

49]. After adsorption, the characteristic peaks of the Fe 2p spectra were at 711.38 eV/713.97 eV and 724.35 eV/726.47 eV, and the satellite peaks were 718.08 eV and 726.47 eV. The peaks were significantly changed compared to those before adsorption, which indicates that a chemical reaction occurred in the system.

Figure 9f shows the As 3D spectrum with peaks at 44.38 eV and 45.44 eV for As

3+ and As

5+ respectively [

51]. It indicates that arsenic ions were adsorbed onto the MnFe

2O

4@Fe-UiO-67.

Figure 10 shows the SEM plots (a, b, c, d) of MnFe

2O

4@Fe-UiO-67 after adsorption. By comparing the morphologies before and after adsorption (

Figure 2d,e show the morphology before adsorption), slight changes occurred in the structure of the adsorbent, which confirms the conclusions drawn from

Figure 7a,b. The appearance of arsenic elements in the EDS plots (e, f, h, i) suggests that arsenic ions are adsorbed on it.

5. Environmental Applications Outlook

The adsorbent is synthesized with the help of a low-temperature energy-saving process using green materials as raw materials, which are not only environmentally friendly but also economically feasible. The adsorbent can be recycled many times, and thermodynamic analysis shows that the adsorbent can achieve high adsorption efficiency at room temperature without additional energy consumption, which reduces energy costs. The core component of the adsorbent is Zr-MOF with a fcu topology, which can be introduced into the defective sites by modulators to form more open Zr sites (Lewis acid sites), resulting in superior adsorption performance [

52,

53]. Meanwhile, both Zr-MOF and MnFe₂O₄ exhibit excellent adsorption performance toward various heavy metal ions (such as Pb

2+, Cd

2+, Cu

2+, etc.) and organic pollutants, which endows them with a broader application scope [

54,

55,

56].

Currently, as a leader in the industry, BASF has taken the lead in overcoming technical challenges and successfully established a commercial production chain for MOF materials [

57]. With an annual production capacity of hundreds of tons, it has laid a solid material foundation for the in-depth application and rapid popularization of MOF materials in the field of technology. With the continuous progress of materials science, on the one hand, through the refined improvement of the synthesis process and the exploration of the potential for large-scale production, the preparation cost of MOFs materials has been significantly reduced. This not only broadens the application market and endows the materials with broad application prospects, but also remarkably enhances the cost–performance ratio of MOF adsorbents, making their promotion and application in small and medium-sized enterprises more smooth. On the other hand, these measures have promoted the integration of MOF materials into multiple industries such as environmental protection, chemical engineering, energy, biomedicine, and electronics, helping to solve practical problems. This further highlights the huge development potential of MOF materials and paves the way for a broader future for them.