Abstract

Background: Emerging economies face a strategic imperative to transform their supply chains, aiming for economic resilience, environmental responsibility, and social inclusivity. Methods: This study, employing the Decision-Making Trial and Evaluation Laboratory (DEMATEL) method, identified and prioritized key drivers for this sustainable transformation. Results: Expert input from supply chain professionals in various industrial sectors revealed five critical factors: top management commitment, stakeholder engagement, regulatory alignment, technological capability, and internal integration. Notably, technological capability and internal integration emerged as the most influential causal drivers, acting as crucial enablers for deeper, systemic change. These findings offer actionable insights for decision-makers in designing more effective transition strategies for logistics and supply chain systems, especially amidst rapid industrialization and escalating sustainability pressures. Conclusions: This research significantly contributes to the growing literature on strategic supply chain redesign, providing practical guidance for firms navigating sustainability transitions within complex, resource-constrained environments.

1. Introduction

The sustainable redesign of supply chains within industrial systems is a complex and pressing challenge, as organisations are increasingly confronted with intensifying environmental constraints, operational disruptions, and the need for technological transformation [1]. Global disturbances, including supply shocks, demand variability, logistical congestion, and decarbonisation targets, frequently result in inconsistent deliveries and operational inefficiencies, thereby undermining the performance and reliability of supply chains [1,2,3]. The effectiveness of sustainable transformation initiatives is largely influenced by the identification of relevant enabling conditions and by a comprehensive understanding of the interdependencies among these factors [4]. Recurrent barriers that adversely affect implementation timelines, cost structures, and environmental outcomes have been identified as operational discontinuities [5,6], limited end-to-end visibility [7], fragmented internal coordination [8], and insufficient stakeholder alignment [8].

Existing literature on logistics and supply chain management [4,9,10] highlights the limitations of isolated improvement initiatives, indicating the necessity of adopting a systemic perspective when managing complex transitions. Despite growing academic interest, there is still no consensus on how to best integrate strategic, technological, and organisational elements to improve the sustainability performance of supply chains [10]. Furthermore, conventional assessment models, which are often based on linear or additive assumptions, fail to adequately capture the multifactorial and interactive nature of transformation processes [8,11,12]. In this context, multi-attribute decision-making methods (MADMs) have gained recognition for their ability to evaluate multiple interrelated variables simultaneously [9]. These techniques provide a structured approach to prioritisation and planning within multidimensional problem spaces [13]. However, many commonly used MADMs approaches, such as the Analytic Hierarchy Process (AHP), the Best–Worst Method (BWM), and Stepwise Weighted Assessment Ratio Analysis (SWARA), focus on static rankings or binary selections [8,13]. This limits their ability to provide insight into the structural interactions that influence decision-making processes [12]. Other methods of studying sustainable supply chains include hybrid models such as the DEMATEL-MABAC combination [8]. This combination is intended to improve decision-making by enabling a more concrete, operational-level assessment and prioritisation of alternatives based on their causal roles [8].

To address these analytical limitations, the present study applies the Decision-Making Trial and Evaluation Laboratory (DEMATEL) method. DEMATEL provides a rigorous framework for modelling causal relationships and quantifying influence pathways among system variables [12]. DEMATEL, which was originally developed by the Battelle Geneva Foundation, enables researchers to identify the most influential drivers and dependent variables by constructing a structured map of interactions [14]. The method has previously been applied extensively in the context of supply chains to analyse various sustainability and transformation challenges. For instance, Agi et al. [14] employed DEMATEL to comprehend the enablers of blockchain technology adoption in sustainable supply chains, whereas Sun adopted a DEMATEL-based model for military budget allocation [11]. These applications demonstrate DEMATEL’s ability to model causal relationships and quantify the influence of system variables, which is particularly important for supply chain transformation scenarios involving nonlinear, feedback-rich systems.

This research aims to model the structural interdependencies among critical transformation drivers and develop a prioritisation framework to inform decision-making in sustainable supply chain redesign. Through the application of DEMATEL, the study aims to support strategic planning processes by distinguishing between influential and responsive variables, enabling targeted interventions based on systemic leverage. The proposed methodological framework contributes to advancing decision-support tools for complex logistical systems undergoing sustainability-driven reconfiguration.

This paper is structured as follows. Section 2 provides a theoretical framework, delving into the DEMATEL method and detailing the five key factors assessed in this study: top management commitment, stakeholder engagement, regulatory alignment, technological capability, and internal integration. Section 3 outlines the materials and methods used, including the qualitative research approach, expert selection, data collection, and the specific formulas employed in the DEMATEL analysis. Section 4 presents the results, showcasing the direct influence matrix, inverse matrix, and total influence matrix, alongside an evaluation of each factor’s influence and causality. Section 5 discusses these results in the context of existing literature. Finally, Section 6 concludes the study by summarising the findings, highlighting the contributions of the research, and suggesting avenues for future research.

2. Theoretical Framework

The DEMATEL method is a powerful tool used to analyze and visualize the complex cause-and-effect relationships among multiple factors influencing a system [8,11,12]. DEMATEL enables researchers to identify the most influential drivers and dependent variables by constructing a structured map of interactions, which is particularly useful in multidimensional, feedback-rich environments like sustainable supply chain transformation.

Key Factors Assessed

In this study, five critical factors affecting sustainable supply chain redesign were identified through expert consultation and literature review: top management commitment, stakeholder engagement, regulatory alignment, technological capability, and internal integration. Each factor is briefly described below to contextualize its role and relevance within the system.

These factors were selected because they represent core dimensions that are often emphasised in literature as being important for sustainable transformation. However, their specific interdependencies and causal hierarchy in the context of rapidly industrialising emerging economies remain under-explored.

Top management commitment defines the degree to which an organization’s senior leadership prioritizes and actively supports sustainability initiatives [15] within supply chain operations [4]. This commitment is essential because it determines the allocation of critical resources such as financial capital, human expertise, and technological assets required to implement sustainable practices effectively [16,17]. Leadership involvement influences the strategic direction of the organization, ensuring that sustainability is embedded as a core business objective rather than treated as a secondary or compliance-related issue. Furthermore, senior leaders shape the organizational culture by promoting values of environmental responsibility, social accountability, and long-term economic resilience. Without explicit and visible support from top executives, sustainability initiatives risk being deprioritized or resisted by middle management and operational staff [18] who may view these efforts as disruptive or irrelevant to existing processes. The engagement of top management acts as a driving force for change by legitimizing sustainability goals, motivating internal stakeholders, and communicating a clear commitment to external partners. Thus, top management commitment plays a central role in enabling and accelerating the transformation of supply chains towards sustainable models by influencing strategic planning, operational activities, and the diffusion of innovation.

Stakeholder engagement involves the deliberate and systematic involvement of diverse actors inside and outside the organization, including suppliers, customers, regulators, non-governmental organizations, and local communities [19]. This engagement is critical to ensure that sustainability initiatives align with the needs, expectations, and values of all parties affected by the supply chain. Effective engagement promotes transparency and fosters mutual trust, which are necessary to overcome information gaps and conflicting interests that can obstruct sustainability efforts [1]. By integrating diverse perspectives, organizations can collaboratively develop resilient and adaptable supply chain solutions that address environmental, social, and economic dimensions comprehensively. Engagement mechanisms, such as collaborative workshops, joint monitoring efforts, and open communication channels, facilitate the negotiation of trade-offs, reconciliation of differing priorities, and the spread of innovation throughout the supply chain network [20]. Additionally, stakeholders who perceive their input as valued tend to demonstrate stronger commitment to collective sustainability objectives, supporting smoother implementation, continuous improvement, and the development of long-lasting partnerships.

Regulatory alignment refers to the extent to which supply chain strategies comply with existing environmental laws, industry standards [18], and public policies at various jurisdictional levels. This alignment defines the legal and institutional context in which organizations operate, serving both as a constraint and an enabler for sustainable innovation. Compliance with regulations is essential to fulfill legal obligations, but also to mitigate risks associated with penalties, litigation, and damage to reputation [19]. Beyond compliance, regulatory alignment can provide access to benefits such as financial incentives, preferential contracts, or enhanced market legitimacy, which improve the economic feasibility of sustainability investments [21]. Given the dynamic nature of regulatory frameworks, particularly in response to global challenges like climate change and resource scarcity, organizations that proactively monitor and engage with policy developments can anticipate future requirements, adjust strategies accordingly, and participate in policy shaping processes. Such proactive engagement strengthens organizational agility, reinforces legitimacy, and enhances competitive advantage in an increasingly regulated sustainability landscape.

Technological capability describes an organization’s ability to acquire, implement, and utilize advanced technologies that support sustainability objectives within supply chain management [22]. This includes digital tools such as sensor networks for real-time monitoring, data analytics for predictive insights, automation to optimize resource use, and environmentally efficient production techniques that reduce negative impacts. Organizations equipped with advanced technological capabilities achieve higher levels of supply chain transparency, traceability, and responsiveness, enabling the accurate monitoring of sustainability metrics and the timely resolution of operational issues [8]. Technology also enables optimization of material flows and logistics, reducing environmental footprints while lowering costs. Furthermore, technological capability fosters innovation by supporting the development of new business models like circular economy frameworks and comprehensive product lifecycle management [11,23]. However, technological investments must align with organizational capacity and strategy to ensure effective adoption and long-term utilization. Therefore, technological capability is a critical enabler for transforming traditional supply chains into sustainable, resilient, and adaptive systems.

Internal integration refers to the degree of coordination and collaboration among different functional units within an organization [13,16], such as procurement, production, logistics, and quality assurance, to jointly pursue sustainability goals. High internal integration reduces organizational silos that often impede information flow and create misalignment between operational activities and strategic objectives. Through enhanced communication and cross-functional collaboration, organizations can better align workflows, allocate resources efficiently, and balance environmental, social, and economic outcomes. Internal integration facilitates the harmonization of key performance indicators, enabling a comprehensive approach to sustainability that considers all relevant dimensions [20]. Integrated systems and communication channels also support real-time data sharing, rapid problem-solving, and continuous learning, thereby fostering an adaptive organizational culture. This holistic approach ensures that sustainability principles are embedded throughout the entire supply chain lifecycle, from sourcing to final delivery, enabling effective and coherent redesign efforts.

In conclusion, the five identified factors are essential for the sustainable transformation of supply chains. These factors do not operate in isolation, but interact with each other in complex ways, influencing the strategic trajectory of organisations in transition. A deep understanding of the role of each factor enables decision-makers to prioritise interventions and allocate resources more efficiently by considering the systemic impact and causal interdependencies between variables. By integrating these critical dimensions into a coherent analytical framework, the study establishes a robust foundation for applying the DEMATEL method in subsequent chapters, thereby supporting informed decision-making in the context of sustainably reconfiguring logistics systems.

3. Materials and Methods

This qualitative research study is based on the expertise of professionals who were intentionally selected for their experience in the field, rather than on a large sample designed for statistical generalisation. While quantitative research aims to capture broad trends across many respondents, this qualitative approach focuses on gathering in-depth insights from specialists with direct managerial experience in industrial supply chains.

Respondents were selected based on their managerial roles in the logistics departments of industrial organisations, as well as on their having a minimum of two years’ experience in supply chain management. Their input was crucial for evaluating the interactions between the critical factors involved in the sustainable transition of supply chains. Specifically, the expert panel comprised four professionals from different large industrial organisations within the European Union. These organisations operate in sectors such as manufacturing and automotive. This ensures a diverse yet relevant perspective on supply chain management challenges.

The DEMATEL methodology, an established technique in multi-criteria decision analysis, was applied to identify and measure the mutual influence among key variables. As recommended in the literature [8,11], this approach requires a small expert panel of four to five respondents. In this study, four professionals from European industrial organisations participated in the evaluation [8,11].

Data were collected in June 2025 using a structured questionnaire in the form of a direct-relation matrix that contained 5 factors. Each respondent was asked to assess the degree of influence between all pairs of factors (a total of 25 pairwise evaluations) using a five-point scale:

0—no influence

1—low influence

2—moderate influence

3—strong influence

4—very strong influence.

These assessments were used as input for the DEMATEL analysis, which identifies the cause-and-effect relationships that are critical for strategic decision-making. In the initial stage, the influence matrix was derived from matrix , which contains the average influence score assigned by each respondent. The relationship between the matrices is expressed as follows:

where is the number of factors analysed.

Having defined the number of factors analysed (denoted by n) and obtained the direct influence matrix , the next step is to derive the total influence matrix , which reflects the direct and indirect effects of each factor on the others.

To calculate the matrix, first find the inverse of the difference matrix between the identity matrix (Table 1) and the matrix. This operation is expressed by the following formula:

Table 1.

Inverse matrix.

Therefore, the matrix is obtained by multiplying the Y matrix by its inverse.

This matrix integrates both direct and indirect influences between factors, providing a complete picture of the relationships in the system.

To establish the significance threshold in interpreting influences, the following formula is used:

where , this represents the total number of possible relationships between the factors in the matrix .

After calculating the total matrix , two essential scores are determined for each factor:

The impact score , which reflects the total influence exerted by factor on the others, and the causality score , which expresses the total influence received by factor from the other factors.

is the total number of relationships or elements in the influence matrix, where .

The impact score for each factor is calculated as the sum of its influence on all other factors:

where .

The causal score for each factor is calculated as the sum of the influence of the factors on it:

where .

4. Results

The mutual influences between the factors were analysed using the DEMATEL methodology, which enabled several matrices to be constructed that reflect their interdependencies.

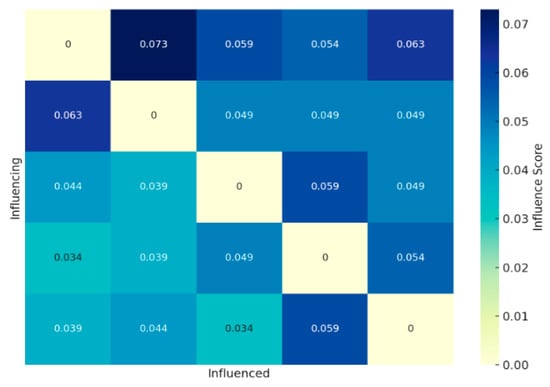

Figure 1 presents the direct influence matrix, containing the influence scores assigned to each pair of factors. This matrix was derived from the participants’ responses, with each value indicating the degree to which one factor influences another directly. For example, the value of 0.073 in the first row and second column (‘A influencing B’) indicates the direct influence score of ‘top management commitment’ on ‘stakeholder engagement’. This score reflects the average expert judgement of the strength of the direct impact of ‘Top management commitment’ on ‘stakeholder engagement’. Due to the normalisation process used in DEMATEL, the values in this direct influence matrix are expected to be relatively small, typically ranging from 0 to 1, as they represent normalised degrees of influence rather than raw scores. Therefore, values less than 0.08 are normal in this context.

Figure 1.

Direct influence matrix.

Table 1 contains the inverse matrix, which is used to assess indirect influences between factors. This matrix is essential for calculating the total influence matrix, as it captures relationships that are mediated by other variables.

Table 2 shows the total influence matrix, which combines direct and indirect influences to provide a comprehensive overview of the system’s interdependencies. In this matrix, the cumulative impact of each factor on the others can be observed.

Table 2.

Total influence matrix highlighting (*) factors with significant influence ().

To identify significant influences, a significance threshold was calculated with a value of . All values in the total influence matrix that are greater than or equal to this threshold have been highlighted to indicate relationships of high systemic relevance.

Table 3 provides a detailed analysis of the direct influence (), received influence (), total influence () and net influence () of each factor, offering an assessment of their influence and causal nature. The values in the table reflect the degree to which each factor influences other factors in the system () and the extent to which it is influenced by others (). The total influence indicates the factor’s overall importance in the network of interdependencies, while the difference highlights its systemic role. A positive net influence value () suggests that the factor predominantly acts as a cause, significantly influencing others. Conversely, a negative value suggests that the factor predominantly plays an effect role, being more receptive to influences from other factors in the system.

Table 3.

Assessment of the influence and causality of factors.

The application of the DEMATEL method provided a structured representation of the causal relationships among key factors involved in sustainable supply chain transformation. The analysis revealed a network of asymmetric interdependencies, where certain variables exert significant systemic influence, while others predominantly absorb external effects.

According to the results presented in Table 3, technological capability (Factor D) and internal integration (Factor E) demonstrated the highest net positive influence scores ( and , respectively), thus positioning them as causal drivers within the system. These factors initiate influence across the network, suggesting that strategic investments in technological readiness and cross-functional integration may yield broad, systemic improvements throughout the supply chain.

Conversely, top management commitment (factor A) and Stakeholder engagement (factor B) exhibit negative net influence values ( and , respectively), indicating that they function primarily as effect factors. Their evolution appears to be contingent on shifts initiated by upstream drivers, rather than serving as original sources of change. While vital to implementation and continuity, these elements likely require prior development of enabling capabilities to be effectively activated.

Regulatory alignment (factor C) stands out due to its neutral net influence (), marking it as a mediating variable. This equilibrium suggests that regulatory frameworks simultaneously exert influence on, and are shaped by, other transformation dimensions. The central positioning of this factor within the network reflects its dual function as both enabler and constraint, reinforcing its strategic importance in balancing compliance requirements with operational flexibility.

The total influence scores (D + R), despite being negative as a result of the matrix inversion technique, offer a meaningful comparative basis. The range of values ( to ) indicates relatively high systemic relevance across all variables. Notably, top management commitment shows the highest total influence magnitude, implying a pivotal—albeit reactive—role in sustaining long-term transformation outcomes.

A significance threshold of was applied to the total influence matrix to distinguish priority interactions. Relationships exceeding this value were interpreted as critical pathways for targeted managerial interventions.

5. Discussion

The structure identified through DEMATEL aligns closely with contemporary research on sustainable supply chain transformation. The prominent role of technological capability as a causal driver is strongly supported in the literature. For instance, Sahoo et al. [24] emphasize its centrality in Industry 4.0 adoption and green innovation through supply chain integration. Similar findings are reported by Agi et al. [14], who identified technological capacity as a primary enabler in DEMATEL-based studies of sustainability drivers. Likewise, Yadav et al. [25] associate technological readiness with the successful implementation of closed-loop systems and digitally connected operations. These studies reinforce the idea that technological foundations are not merely support mechanisms, but rather strategic enablers that reconfigure entire value creation logics within the supply chain. In the automotive industry, for example, advanced sensor networks and AI-driven analytics enable real-time tracking of components from raw material sourcing to final assembly. This significantly improves traceability and enables more efficient reverse logistics for recycling or remanufacturing. These specific instances demonstrate how technological capabilities can directly translate into tangible improvements in sustainable supply chain practices.

Internal integration is also widely recognized as a key enabler of supply chain adaptability and long-term resilience. Singh et al. [1] highlight its role in reinforcing circular economy practices through process cohesion in procurement and remanufacturing. In a more recent study, Le et al. [26] demonstrate that integrated data platforms and real-time coordination mechanisms improve responsiveness, particularly in volatile market environments. These findings validate the causal role observed in our analysis and support the argument that internal integration provides not only operational efficiency but also the structural backbone for implementing and scaling sustainability initiatives. Furthermore, integration facilitates organizational learning and cross-functional alignment, which are critical for overcoming silos and fostering system-wide coherence.

Consider a manufacturing firm that successfully integrates its procurement, production, and logistics departments: This holistic approach enables synchronized planning for sustainable sourcing, minimizes waste through optimized production schedules, and reduces carbon footprint by consolidating shipments and optimizing delivery routes. This level of cross-functional collaboration demonstrates the profound impact of internal integration on achieving sustainable supply chain goals.

In contrast, the classification of top management commitment as an effect factor finds a more nuanced reflection in the literature. While some studies emphasize leadership as a catalyst for resilience (e.g., during disruptions in food supply chains), others highlight its reactive character—especially in contexts where strategic decisions are shaped by prior technological or regulatory changes. Singh et al. [1] and Lu et al. [27] note that managerial support often materializes in response to performance benchmarks or external incentives, rather than as a precursor to transformation. This reactive nature suggests that leadership engagement, though indispensable for institutionalization, may depend on the activation of more tangible operational levers before it translates into sustained strategic direction.

The stakeholder engagement factor, similarly reactive in our results, aligns with critical perspectives in the literature that question its autonomy in early transformation stages. Agi et al. [14] identify barriers related to institutional inertia, information asymmetry, and coordination gaps that limit stakeholder involvement in sustainability efforts. Tseng et al. [28], writing in the International Journal of Logistics Management, emphasize that effective collaboration across partners requires a baseline of internal maturity and technological infrastructure. Stakeholder engagement, therefore, is often conditioned by upstream investments in integration and digital connectivity. This interpretation suggests that stakeholder alignment is not a spontaneous dynamic but rather a dependent variable that emerges once enabling structures are in place.

Regulatory alignment, positioned as a mediating factor in our analysis, resonates with its dual nature as both constraint and enabler. Agi et al. [14] emphasize the strategic ambiguity of regulatory systems—neither fully proactive nor entirely passive. A 2023 Deloitte report [29] similarly observes that the success of digital and sustainability transitions increasingly depends on how firms internalize and operationalize ESG-related regulatory signals. These findings reflect a growing consensus that regulation, when treated not merely as compliance but as strategic foresight, can facilitate innovation, legitimacy, and stakeholder trust. Moreover, Bechtsis et al. [24] demonstrate that proactive engagement with regulatory frameworks can create differentiation opportunities and accelerate the adoption of circular practices. Thus, the intermediate position of regulatory alignment reflects its systemic role as a bridge between institutional expectations and operational execution.

Both the present study and that conducted by Estiri et al. [8] use the DEMATEL method to analyse the causal structures of complex systems. However, differences in context and applicability generate distinct conclusions and complementary analytical approaches. DEMATEL was chosen in both cases precisely because of its ability to capture direct and indirect influences between interdependent factors, providing a structural representation of the analysed system. While one study focuses solely on DEMATEL to highlight causal relationships between strategic variables, the other combines it with the MABAC method and introduces a stage for prioritising alternatives. This allows for a more concrete, operational-level assessment.

In the DEMATEL-MABAC hybrid model, if DEMATEL is used to classify variables into causal and effect factors, the systemic roles of initiator and receiver of change are identified. This distinction is integrated into a broader decision-making framework that aims to select the optimal alternatives. In the case of Estiri et al. [8], for example, the influences between human resource outcomes are quantified to determine the weight of each criterion. This is then used to rank the most effective human capital management practices. This additional step introduces a tactical decision-making component oriented towards selection, whereas the other study remains in the strategic domain, where the primary objective is to clarify the hierarchy of influence among the system’s key variables.

The relational structure derived through DEMATEL is asymmetrical in both cases, revealing differences between factors that initiate change and those that absorb influences. In one case, technological capability and internal integration are recognised as major causal factors, while management commitment and stakeholder involvement appear as effect factors. In the other case, human resource outcomes such as satisfaction, commitment, and turnover are analysed to determine the weight of the decision-making process in selecting the most effective HR practices. It is concluded that performance-based pay and employee involvement are the most influential practices in generating these outcomes.

There is also a difference in the level of applicability. One of the studies addresses the issue on a systemic scale, with implications for institutional strategies and industrial policies in contexts characterised by sustainable pressures. In contrast, Estiri et al.’s study is set in the well-defined organisational framework of the banking sector and aims to optimise micro-level decisions within a specific economic entity [8]. It uses robust decision analysis methods to support management in efficiently allocating resources.

Both studies criticise the limitations of linear models and traditional AHP or BWM methods, arguing in favour of approaches capable of capturing the interactive and multifactorial nature of the analysed systems. In this sense, DEMATEL is considered superior for diagnosing systemic influences, and integrating it with MABAC in the hybrid model adds value by providing a gradual decision-making mechanism sensitive to relational dynamics between criteria.

Combining the two studies enables the creation of an efficient working system that incorporates strategic sustainability in supply chains alongside the operational efficiency generated by advanced human resource management practices. Using the DEMATEL method to identify causal factors supporting the transition to sustainable logistics models establishes a macro-level decision-making infrastructure. Integrating the DEMATEL-MABAC model proposed by Estiri et al. [8] provides a robust tool for selecting and ranking micro-level interventions, particularly those related to human capital. Thus, a high-performance working system can be created by first strategically prioritising systemic factors, such as technological capability and internal integration, and then tactically selecting the most effective organisational practices, such as performance-based pay and employee engagement.

The combination of these two analytical frameworks offers a multi-layered approach, enabling organisations to manage strategic coherence and operational alignment simultaneously and operate in a sustainable, agile, and results-oriented manner. Therefore, the differences between the two approaches are complementary, not contradictory. One contributes to an understanding of systemic causality in contexts of organisational or sectoral transition, while the other provides a framework for the practical selection of intervention options. In both cases, DEMATEL’s central role confirms the need for structural thinking when analysing complex systems. Methodological convergence suggests that MADM is maturing in various fields, from logistics to human resources.

In Sun’s [11] article, the Fuzzy-Intuitionistic DEMATEL model is employed to determine decision-making priorities for military budget allocation, with ‘mission requirements’ identified as the primary causal factor. Both models use DEMATEL to identify dominant variables and guide resource allocation. They work with sets of factors grouped by conceptual dimensions and classify them as either cause or effect factors. They also use relational networks to visualise systemic influences. In one case, technological capability and internal integration are major causal factors. In contrast, in the other, mission requirements and combat threats drive the decision-making system, with ‘fiscal sufficiency’ emerging as a dependent factor. In both cases, the focus is on the system’s ability to respond to external and internal pressures by developing a structured understanding of critical variables.

These two approaches can be integrated to create a multi-layered decision-making system in which a causal analysis of strategic factors, such as technological capability, integration, and logistics, is followed by a contextual assessment of specific criteria using fuzzy tools to capture the nuances of practitioners’ expertise. This combination would enable investment, prioritization, and adaptation decisions to be justified by systemic impact and consistency with possible scenarios, fiscal constraints, and institutional maturity levels.

There are no contradictions between the two models; on the contrary, they support each other through the convergence of results. In both cases, factors related to response capacity, whether technological or operational, are identified as determinants. Factors such as taxation, regulations, and political acceptance appear as effects rather than initiators of change. This consistency further validates the use of DEMATEL as an analytical method in complex and uncertain decision-making contexts.

Overall, these interpretations reveal that sustainable supply chain transformation is not governed by a single linear logic, but rather by a constellation of interdependent dynamics. The DEMATEL-based structure proposed in this study offers a refined causal map that complements existing theoretical models while also addressing gaps in decision-making clarity. The findings also emphasize that sequencing of interventions matters: focusing on reactive elements without first addressing causal levers may lead to inefficient outcomes or institutional resistance. Therefore, both academics and practitioners may benefit from re-evaluating the timing, coordination, and focus of sustainability initiatives in light of the directional dependencies outlined in this study.

6. Conclusions

This study applied the DEMATEL method to disentangle the causal structure among key enablers of sustainable supply chain transformation. By moving beyond simple correlation analysis, the approach enabled the identification of directional influences and hierarchical roles within a complex system of interdependencies.

The findings establish a three-tiered influence structure: technological capability and internal integration function as primary causal drivers capable of initiating systemic change; top management commitment and stakeholder engagement are positioned as dependent response variables; and regulatory alignment operates as a central mediator between strategic and operational domains. This layered structure reflects the dynamic, path-dependent nature of sustainability transitions.

The main contribution of this research lies in offering a decision-oriented causal model that can support supply chain managers in prioritizing transformation efforts. Unlike models that treat all drivers as equally weighted or static, our findings clarify which factors act as levers and which require enabling conditions to become effective. By doing so, the study provides a practical framework for sequencing interventions and aligning technical, organizational, and institutional strategies. This clarification of interdependencies is not just a general organisational management issue; it also provides specific guidance on how to optimise logistics operations. This includes managing material flows and technological integration, as well as inter-departmental coordination and compliance with supply chain-specific regulations.

From a managerial perspective, the results suggest that long-term success in sustainable supply chain redesign depends less on isolated initiatives and more on activating systemic drivers capable of producing cascading change. Investment in digital capabilities and internal coordination mechanisms should precede broader stakeholder engagement and cultural alignment.

Despite its contributions, this study has limitations. Firstly, while the reliance on expert input from a relatively small panel of four professionals is appropriate for the DEMATEL method, the findings may not be generalisable to all industrial sectors or emerging economies. Selecting experts from the European Union, specifically from the manufacturing and automotive sectors, may introduce a regional bias. Secondly, while the DEMATEL method is effective in identifying causal relationships, it provides a snapshot in time. The dynamic nature of sustainable supply chain transformation means that these interdependencies could evolve. Future research could explore how this causal configuration evolves across industry contexts, maturity levels, or regulatory environments through longitudinal studies. Thirdly, while the study provides a framework for strategic prioritisation, it lacks specific performance metrics and detailed cost–benefit analyses, which would enhance its practical application.

Future research should explore how this causal configuration evolves across industry contexts, maturity levels, or regulatory environments. Longitudinal studies and integration with performance metrics could further enhance the prescriptive power of the model for real-world implementation.

Author Contributions

Conceptualization, I.G., R.-M.N., F.-P.-G.S. and C.-I.D.; methodology, I.G., R.-M.N., F.-P.-G.S., O.U. and C.-I.D.; formal analysis, R.-M.N., F.-P.-G.S. and C.C.; investigation, I.G., R.-M.N., F.-P.-G.S., O.U. and C.-I.D.; resources, I.G., O.U. and C.-I.D.; data curation, R.-M.N., F.-P.-G.S. and O.U.; writing—original draft preparation, R.-M.N., F.-P.-G.S., O.U. and C.C.; writing—review and editing, I.G., R.-M.N., F.-P.-G.S., O.U., C.-I.D. and C.C.; visualization, I.G. and O.U.; supervision, I.G., R.-M.N. and F.-P.-G.S.; project administration, I.G.; funding acquisition, I.G., C.-I.D. and C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National University of Science and Technology National University of Science and Technology POLITEHNICA Bucharest through the PubArt programme.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author up-on reasonable request.

Acknowledgments

This work has been supported by: (1) CERMISO Center—Project Contract no.159/2017, Program POC-A.1-A.1.1.1.1-F; (2) Research Program Nucleu within the National Research Development and Innovation Plan 2022–2027, carried out with the support of MCID, project no. PN 23 43 04 01; and (3) Support Center for International RDI Projects in Mechatronics and Cyber-Mix-Mechatronics, Contract no. 323/22.09.2020, project co-financed by the European Regional Development Fund through the Competitiveness Operational Program (POC) and the national budget.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Singh, K.; Chaudhuri, R.; Chatterjee, S. Assessing the Impact of Digital Transformation on Green Supply Chain for Achieving Carbon Neutrality and Accelerating Circular Economy Initiatives. Comput. Ind. Eng. 2025, 201, 110943. [Google Scholar] [CrossRef]

- Gavriluta, A.-C.; Proistosescu, M.-L. The Influence of ERP Systems on the Performance Indicators of the Supply Chain Management. BUP-JAUTO 2024, 1–8. [Google Scholar] [CrossRef]

- Ionescu, N.; Stirbu, L.-E.; Ionescu, L.-M.; Stirbu, C.; Mazare, A.-G. A Cloud Computing Solution for Quality Management Systems in Multi-Site Enterprises. In Proceedings of the 2024 IEEE 30th International Symposium for Design and Technology in Electronic Packaging (SIITME), Sibiu, Romania, 16–18 October 2024; pp. 421–425. [Google Scholar]

- Braziotis, C.; Bourlakis, M.; Rogers, H.; Tannock, J. Supply Chains and Supply Networks: Distinctions and Overlaps. Supply Chain Manag. Int. J. 2013, 18, 644–652. [Google Scholar] [CrossRef]

- Deselnicu, D.C.; Barbu, A.; Haddad, S.H. Risk Management in a Logistics Company. RISK 2023, 12, 14. [Google Scholar] [CrossRef]

- Nechita, R.-M.; Ulerich, O.; Radoi, E.-A. Risk Management in Research Projects. FAIMA Bus. Manag. J. 2024, 12. [Google Scholar]

- Grecu, I.; Nechita, R.-M.; Nechita, M.-I. Strategic Response to Risk in Digital Marketing. Bull. Transilv. Univ. Brasov. Ser. V Econ. Sci. 2024, 17, 19–30. [Google Scholar] [CrossRef]

- Estiri, M.; Dahooie, J.H.; Vanaki, A.S.; Banaitis, A.; Binkytė-Vėlienė, A. A Multi-Attribute Framework for the Selection of High-Performance Work Systems: The Hybrid DEMATEL-MABAC Model. Econ. Res.-Ekon. Istraživanja 2021, 34, 970–997. [Google Scholar] [CrossRef]

- Amiri, M.; Hashemi-Tabatabaei, M.; Ghahremanloo, M.; Keshavarz-Ghorabaee, M.; Zavadskas, E.K.; Banaitis, A. A New Fuzzy BWM Approach for Evaluating and Selecting a Sustainable Supplier in Supply Chain Management. Int. J. Sustain. Dev. World Ecol. 2021, 28, 125–142. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, S.; Yang, L. Motivating Innovation Alliance’s Environmental Performance Through Eco-Innovation Investment in a Supply Chain. J. Clean. Prod. 2020, 269, 122361. [Google Scholar] [CrossRef]

- Sun, C.-C. An Intuitionistic Linguistic DEMATEL-Based Network Model for Effective National Defense and Force Innovative Project Planning. IEEE Access 2021, 9, 130141–130153. [Google Scholar] [CrossRef]

- Chatzifoti, N.; Chountalas, P.T.; Agoraki, K.K.; Georgakellos, D.A. A DEMATEL Based Approach for Evaluating Critical Success Factors for Knowledge Management Implementation: Evidence from the Tourism Accommodation Sector. Knowledge 2025, 5, 2. [Google Scholar] [CrossRef]

- Grecu, I.; Nechita, R.-M.; Ulerich, O.; Dumitrescu, C.-I. Multi-Attribute Decision-Making for Intelligent Allocation of Human Resources in Industrial Projects. Adm. Sci. 2025, 15, 181. [Google Scholar] [CrossRef]

- Agi, M.A.N. Understanding the Enablers of Blockchain Technology Adoption in Sustainable Supply Chains: A DEMATEL-Based Analysis. IFAC-Pap. 2022, 55, 1962–1967. [Google Scholar] [CrossRef]

- Al-aloosy, K.F.Q.; Mirvalad, S.; Shabakhty, N. Evaluating the Impact of Internet Communication Quality in Human Resource Management on the Productivity of Construction Projects. Heliyon 2024, 10, e28500. [Google Scholar] [CrossRef] [PubMed]

- Vrchota, J.; Řehoř, P. Project Management in Manufacturing Enterprises. Serbian J. Manag. 2021, 16, 341–353. [Google Scholar] [CrossRef]

- Salih, S.; Abdelsalam, S.; Hamdan, M.; Ibrahim, A.O.; Abulfaraj, A.W.; Binzagr, F.; Husain, O.; Abdallah, A.E. The CSFs from the Perspective of Users in Achieving ERP System Implementation and Post-Implementation Success: A Case of Saudi Arabian Food Industry. Sustainability 2022, 14, 15942. [Google Scholar] [CrossRef]

- Dong, X.; Qiu, W. A Method for Managing Scientific Research Project Resource Conflicts and Predicting Risks Using BP Neural Networks. Sci. Rep. 2024, 14, 9238. [Google Scholar] [CrossRef]

- Åhlfeldt, E.; Isaksson, D.; Winblad, U. Factors Explaining Program Sustainability: A Study of the Implementation of a Social Services Program in Sweden. Health Soc. Care Community 2023, 2023, 1458305. [Google Scholar] [CrossRef]

- Nechita, R.-M.; Stochioiu, F.-P.-G.; Grecu, I. Synergy Between Research Projects. FAIMA Bus. Manag. J. 2025, 13. [Google Scholar]

- Lin, M.S.-M.; Lu, B.-S. Risk Assessment and Management in the Offshore Wind Power Industry: A Focus on Component Handling Operations in Ports. Saf. Sci. 2023, 167, 106286. [Google Scholar] [CrossRef]

- Istriteanu, S.; Bajenaru, V.; Badea, D.-M. Aspects Regarding Eco-Innovation Practice and Trends for a Sustainable Automotive Industry. Int. J. Mechatron. Appl. Mech. 2022, 1, 5. [Google Scholar] [CrossRef]

- Crasoveanu, F.-C.; Deselnicu, D.-C.; Dumitrescu, C.L.; Dobrescu, R.; Stanciu, D.R. The Impact of Artificial Intelligence on Sustainable IT Asset Lifecycle Management. FAIMA Bus. Manag. J. 2024, 12, 69–75. [Google Scholar]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Srai, J.S. Intelligent Autonomous Vehicles in Digital Supply Chains: A Framework for Integrating Innovations Towards Sustainable Value Networks. J. Clean. Prod. 2018, 181, 60–71. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A Framework to Overcome Sustainable Supply Chain Challenges Through Solution Measures of Industry 4.0 and Circular Economy: An Automotive Case. J. Clean. Prod. 2020, 254, 120112. [Google Scholar] [CrossRef]

- Le, T.T.; Nhu, Q.P.V.; Behl, A. Role of Digital Supply Chain in Promoting Sustainable Supply Chain Performance: The Mediating of Supply Chain Integration and Information Sharing. Int. J. Logist. Manag. 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Lu, H.; Mirza, S.S.; Huang, C. The Dynamics of ESG Peer Pressure and Corporate Resilience: Examining Through Firm-Perceived EPU and Governance Efficiency Perspectives. Corp. Soc. Responsib. Environ. Manag. 2025. [Google Scholar] [CrossRef]

- Tseng, M.L.; Wu, K.J.; Chien, C.F.; Ali, M.H. Circular Supply Chain Practices: Challenges, Innovation and Development. Int. J. Logist. Res. Appl. 2024, 27, 1–5. [Google Scholar] [CrossRef]

- Deloitte ESG Preparedness Report: Navigating Regulatory Change Through Digital Transformation. Deloitte Insights 2023. Available online: https://www.deloitte.com/global/en/pages/about-deloitte/articles/esg-preparedness.html (accessed on 12 June 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).