Integrating CRM, Lean Practices, and Use of IT to Enhance Operational Performance: The Mediating Role of Quality Information Sharing

Abstract

1. Introduction

- (a)

- To examine the relationship among selected SCMPs, including CRM, LPs, UIT, and QIS, with OP.

- (b)

- To ascertain the mediating role of QIS in such relationships in supply chains, especially in the RMG industry of Bangladesh.

2. Theoretical Background and Hypotheses

2.1. Customer Relationship Management (CRM) and OP

2.2. Lean Practices (LPs) and OP

2.3. UIT and OP

2.4. Quality of Information Sharing (QIS) and OP

2.5. Mediating Effect of QIS

2.6. Proposed Research Framework

3. Research Methods

3.1. Sampling and Data Collection Process

3.2. Procedure and Measurement

3.3. Data Analysis Method

4. Results and Analyses

4.1. Assessment of Measurement Model

4.2. Common Methods Bias

4.3. Assessment of Structural Model and Hypothesized Relationships

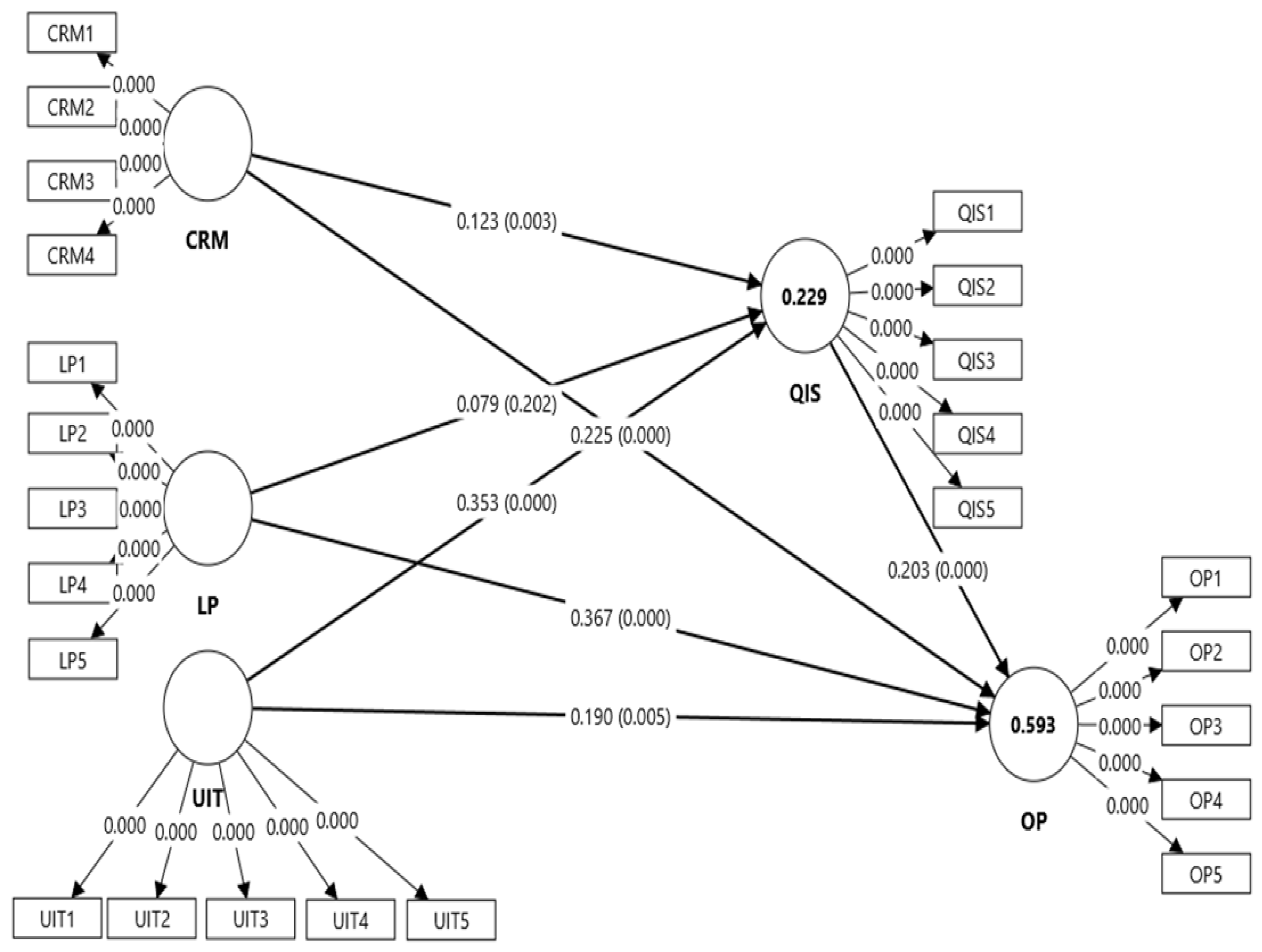

4.4. Validation of the Hypotheses in the Proposed Model

5. Discussions

5.1. Practical Implications

5.2. Theoretical Implications

6. Conclusions

Limitations and Recommendations for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Survey Questionnaire | |||||

| Please answer the following questions by marking “√” in the appropriate box: | |||||

| Job Title/Position: | |||||

| General Manager | |||||

| Plant Manager | |||||

| Production/Operations Manager | |||||

| Supply Chain Manager | |||||

| Assistant Supply Chain Manager | |||||

| Inventory Manager | |||||

| Merchandiser | |||||

| IT Manager | |||||

| Others | |||||

| Your Work Experience: | |||||

| Above 10 years | |||||

| 6–10 years | |||||

| 4–6 years | |||||

| 2–4 Years | |||||

| Below 2 Years | |||||

| Number of employees in your company: | |||||

| Over 20,000 | |||||

| 15,000–20,000 | |||||

| 10,000–15,000 | |||||

| 5000–10,000 | |||||

| 1000–5000 | |||||

| Number of lines in your company: | |||||

| Over 35 lines | |||||

| 25–35 lines | |||||

| 15–25 lines | |||||

| 5–15 Lines | |||||

| Below 5 Lines | |||||

| What is the age of the supply chain department of your organization? | |||||

| Above 10 years | |||||

| 6–10 years | |||||

| 4–6 years | |||||

| 2–4 Years | |||||

| Below 2 Years | |||||

| Supply Chain Management Practice: Customer Relationship Management Completely agree = 5, agree = 4, neutral = 3, Disagreed = 2, Completely disagree = 1 | |||||

| 1 | 2 | 3 | 4 | 5 | |

| There is effective management of customer complaints | |||||

| Customers have helped the Organization in the preparation of specifications. | |||||

| A long-term relationship with customers improves customer satisfaction | |||||

| Meetings are frequently held between customers and the firm’s management. | |||||

| Customers help with clear instructions about new product development | |||||

| Supply Chain Management Practice: Quality of Information Sharing Completely agree = 5, agree = 4, neutral = 3, Disagreed = 2, Completely disagree = 1 | |||||

| There is efficient internal communication. | |||||

| There is an adequacy of IT systems throughout the supply chain. | |||||

| Exchange of information between suppliers and the Organization is reliable. | |||||

| Data is shared between the organization and the suppliers to enhance productivity | |||||

| There is an automated ordering system for major suppliers | |||||

| Supply Chain Management Practice: Lean Practices Completely agree = 5, agree = 4, neutral = 3, Disagreed = 2, Completely disagree = 1 | |||||

| Your organization is focused on value creation. | |||||

| Your organization eliminates any waste or defects during the production process. | |||||

| Your organization follows 5S (Sort, Straighten, Shine, Standardize, Sustain) or JIT (just-in-time) to eliminate wastes. | |||||

| You use quality control tools like Pareto Chart, Fish-Bone Diagram, Histogram, Control Charts, Scatter Diagram, etc. | |||||

| Your organization follows specific processes to complete orders in the shortest possible time. | |||||

| Supply Chain Management Practice: Use of IT Completely agree = 5, agree = 4, neutral = 3, Disagreed = 2, Completely disagree = 1 | |||||

| Your organization encourages the use of technology | |||||

| Your company uses Electronic Data Interchange (EDI) | |||||

| Your organization is constantly updated with the latest information technology | |||||

| Managers of your company have sound knowledge of IT | |||||

| Use of software like ERP, inventory management system, etc. is common in your organization | |||||

| Please indicate the degree to which you agree with the following statements concerning your Company’s operational performance Completely agree = 5, agree = 4, neutral = 3, Disagreed = 2, Completely disagree = 1 | |||||

| Our Company requires less Lead Time compared to our competitors for delivering products. | |||||

| Our Company strives to reduce manufacturing costs, providing benefits to our buyers. | |||||

| Our Company maintains a very Low Level of Inventory through efficient planning. | |||||

| Our Company ensures Improved Product Quality for the buyers. | |||||

| Our Company consistently maintains the Delivery Schedule | |||||

| If you have any other comments, please write here. | |||||

References

- Ali, B.J.A.; Alawamleh, H.A.; Allahham, M.I.O.; Alsaraireh, J.M.; Al-Zyadat, A.T.; Badadwa, A.A.H. Integration of Supply Chains and Operational Performance: The Moderating Effects of Knowledge Management. Inf. Sci. Lett. 2022, 11, 1069–1076. [Google Scholar] [CrossRef]

- Chen, Z.; Hammad, A.W. Mathematical modelling and simulation in construction supply chain management. Autom. Constr. 2023, 156, 105147. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Li, G.; Xu, J. Sustainable supply chain management practices and performance: The moderating effect of stakeholder pressure. Humanit. Soc. Sci. Commun. 2025, 12, 1–12. [Google Scholar] [CrossRef]

- Fu, Q.; Rahman, A.A.A.; Jiang, H.; Abbas, J.; Comite, U. Sustainable Supply Chain and Business Performance: The Impact of Strategy, Network Design, Information Systems, and Organizational Structure. Sustainability 2022, 14, 1080. [Google Scholar] [CrossRef]

- Moktadir, A.; Mahmud, Y.; Banaitis, A.; Sarder, T.; Khan, M.R. Key performance indicators for adopting sustainability practices in footwear supply chains. E+M Èkon. Manag. 2021, 24, 197–213. [Google Scholar] [CrossRef]

- Bag, S. Restorative supply chain practices in a circular economy and supply chain sustainability performance: The moderating effect of the perceived professional status of supply chain managers. Benchmarking Int. J. 2025, 32, 166–193. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Hasan, M.A. Exploring the Intricate Future of Bangladesh in the Context of Regional Geopolitical Dynamics. Outl. Glob. Transform. Politi. Econ. Law 2025, 17, 110–127. [Google Scholar] [CrossRef]

- Wang, X.; Zhuang, J.; Peng, Q.; Li, Y. A general strategy for nanocrystal synthesis. Nature 2005, 437, 121–124. [Google Scholar] [CrossRef]

- Al-Rawashdeh, O.M.; Jawabreh, O.; Ali, B.J.A. Supply Chain Management and Organizational Performance: The Moderating Effect of Supply Chain Complexity. Inf. Sci. Lett. 2023, 12, 1673–1684. Available online: https://digitalcommons.aaru.edu.jo/isl/vol12/iss3/50/ (accessed on 28 May 2025).

- The Balanced Scorecard—Measures that Drive Performance. Available online: https://hbr.org/1992/01/the-balanced-scorecard-measures-that-drive-performance-2 (accessed on 21 July 2025).

- Zahara, Z.; Muslimin, M.; Rumijati, A.; Rony, Z.T. Competitive Advantage as Mediating Role to Enhance MSMES Performance. J. Small Bus. Strat. 2024, 34, 109–117. [Google Scholar] [CrossRef]

- Sutanto, J.E. An Empirical of Supply Chain Management Strategy as Mediation on Organizational and Operation Performance: A Study on Indonesia’s Retail Shops’. Int. J. Supply Chain Manag. 2021, 10, 81–94. Available online: https://ojs.excelingtech.co.uk/index.php/IJSCM/article/view/5828 (accessed on 28 May 2025).

- Hani, J.S.B. The moderating role of lean operations between supply chain integration and operational performance in Saudi manufacturing organizations. Uncertain Supply Chain Manag. 2021, 9, 169–178. [Google Scholar] [CrossRef]

- Abu Jahed, M.; Quaddus, M.; Suresh, N.C.; Salam, M.A.; Khan, E.A. Direct and indirect influences of supply chain management practices on competitive advantage in fast fashion manufacturing industry. J. Manuf. Technol. Manag. 2022, 33, 598–617. [Google Scholar] [CrossRef]

- El-Garaihy, W.H.; Badawi, U.A.; Seddik, W.A.S.; Torky, M.S. Design, building and validating a measuring scale for the supply chain management practices of industrial organizations by assessing their efficiency on SCM measures. Uncertain Supply Chain Manag. 2022, 10, 49–68. [Google Scholar] [CrossRef]

- Hwihanus, H.; Wijaya, O.Y.A.; Nartasari, D.R. The role of supply chain management on Indonesian small and medium enterprise competitiveness and performance. Uncertain Supply Chain Manag. 2022, 10, 109–116. [Google Scholar] [CrossRef]

- Ikhwana, A.; Dianti, S. The Influence of Information Technology and SCM on Competitive Advantage to Improve MSMEs Performance. Int. J. Comput. Inf. Syst. 2022, 3, 6–11. [Google Scholar] [CrossRef]

- Green, K.W.; Inman, R.A.; Sower, V.E.; Zelbst, P.J. Impact of JIT, TQM and green supply chain practices on environmental sustainability. J. Manuf. Technol. Manag. 2019, 30, 26–47. [Google Scholar] [CrossRef]

- Phan, A.C.; Nguyen, H.A.; Trieu, P.D.; Matsui, Y. Impact of supply chain quality management practices on operational performance: Empirical evidence from manufacturing companies in Vietnam. Supply Chain Manag. Int. J. 2019, 24, 855–871. [Google Scholar] [CrossRef]

- The Role of Critical Success Factors of Knowledge Stations in the Development of Local Communities in Jordan: A Managerial Perspective. Available online: https://www.abacademies.org/articles/the-role-of-critical-success-factors-of-knowledge-stations-in-the-development-of-local-communities-in-jordan-a-managerial-perspect-9764.html (accessed on 21 July 2025).

- Karamouz, S.S.; Kahnali, R.A.; Ghafournia, M. Supply chain quality management performance measurement: Systematic review. Int. J. Qual. Reliab. Manag. 2021, 38, 484–504. [Google Scholar] [CrossRef]

- Lal, K. Information Technology and Exports: A Case Study of Indian Garments Manufacturing Enterprises. Discuss. Pap. 1999, 15, 1–24. [Google Scholar] [CrossRef]

- Tarigan, Z.J.H.; Siagian, H. The Effects of Strategic Planning, Purchasing Strategy and Strategic Partnership on Operational Performance. 2021. Available online: http://growingscience.com/uscm/Vol9/uscmv9no2.html (accessed on 21 July 2025).

- Sharma, S.; Modgil, S. TQM, SCM and operational performance: An empirical study of Indian pharmaceutical industry. Bus. Process. Manag. J. 2020, 26, 331–370. [Google Scholar] [CrossRef]

- Ellram, L.M.; Zsidisin, G.A.; Siferd, S.P.; Stanly, M.J. The Impact of Purchasing and Supply Management Activities on Corporate Success. J. Supply Chain Manag. 2002, 38, 4–17. [Google Scholar] [CrossRef]

- Li, S.; Ragu-Nathan, B.; Ragu-Nathan, T.; Rao, S.S. The impact of supply chain management practices on competitive advantage and organizational performance. Omega 2006, 34, 107–124. [Google Scholar] [CrossRef]

- Zaman, S. Researching the garment sector in Bangladesh: Fieldwork challenges and responses. In Field Guide for Research in Community Settings; Edward Elgar Publishing: Cheltenham, UK, 2021. [Google Scholar]

- Ali, M.; Rahman, S.M.; Frederico, G.F. Capability components of supply chain resilience for readymade garments (RMG) sector in Bangladesh during COVID-19. Mod. Supply Chain Res. Appl. 2021, 3, 127–144. [Google Scholar] [CrossRef]

- Agarwal, S.; Tyagi, M.; Garg, R.K. Restorative measures to diminish the covid-19 pandemic effects through circular economy enablers for sustainable and resilient supply chain. J. Asia Bus. Stud. 2022, 16, 538–567. [Google Scholar] [CrossRef]

- Shahadat, M.M.H.; Chowdhury, A.H.M.Y.; Nathan, R.J.; Fekete-Farkas, M. Digital Technologies for Firms’ Competitive Advantage and Improved Supply Chain Performance. J. Risk Financ. Manag. 2023, 16, 94. [Google Scholar] [CrossRef]

- Barney, J.B. Is the resource-based “view” a useful perspective for strategic management research? Yes. Acad. Manag. Rev. 2001, 26, 41–56. [Google Scholar] [CrossRef]

- Epelbaum, F.M.B.; Martinez, M.G. The technological evolution of food traceability systems and their impact on firm sustainable performance: A RBV approach. Int. J. Prod. Econ. 2014, 150, 215–224. [Google Scholar] [CrossRef]

- Chavez, R.; Yu, W.; Jajja, M.S.S.; Song, Y.; Nakara, W. The relationship between internal lean practices and sustainable performance: Exploring the mediating role of social performance. Prod. Plan. Control. 2022, 33, 1025–1042. [Google Scholar] [CrossRef]

- Rahman, A.S.; Raju, V. Impact of Supply Chain Management (SCM) in Bangladesh Textile-Clothing Industry: Comprehending the Role of Sourcing. Spec. Ugdym. 2022, 1, 323–346. Available online: http://sumc.lt/index.php/se/article/view/37 (accessed on 21 July 2025).

- Fawcett, S.E.; Osterhaus, P.; Magnan, G.M.; Brau, J.C.; McCarter, M.W.; Croom, S. Information sharing and supply chain performance: The role of connectivity and willingness. Supply Chain Manag. Int. J. 2007, 12, 358–368. [Google Scholar] [CrossRef]

- Eckstein, D.; Goellner, M.; Blome, C.; Henke, M. The performance impact of supply chain agility and supply chain adaptability: The moderating effect of product complexity. Int. J. Prod. Res. 2015, 53, 3028–3046. [Google Scholar] [CrossRef]

- Using the Balanced Scorecard as a Strategic Management System. Available online: https://hbr.org/2007/07/using-the-balanced-scorecard-as-a-strategic-management-system (accessed on 21 July 2025).

- Bhagwat, R.; Sharma, M.K. Performance measurement of supply chain management: A balanced scorecard approach. Comput. Ind. Eng. 2007, 53, 43–62. [Google Scholar] [CrossRef]

- Diamantopoulos, A.; Riefler, P.; Roth, K.P. Advancing formative measurement models. J. Bus. Res. 2008, 61, 1203–1218. Available online: https://ideas.repec.org/a/eee/jbrese/v61y2008i12p1203-1218.html (accessed on 21 July 2025). [CrossRef]

- De Muylder, C.; La Falce, J.L.; Guerra, J.R.L.; Viana, J.A.; Reinhold, O. Model of acceptance and use of social customer relationship management in micro and small enterprises. Int. J. Innov. 2025, 13, e27096. [Google Scholar] [CrossRef]

- Ijomah, T.I.; Nwabekee, U.S.; Agu, E.E.; Abdul-Azeez, O.Y. The impact of customer relationship management (CRM) tools on sales growth and customer loyalty in emerging markets. Int. J. Manag. Entrep. Res. 2024, 6, 2964–2988. [Google Scholar] [CrossRef]

- Rahman, M.S.; Bag, S.; Gupta, S.; Sivarajah, U. Technology readiness of B2B firms and AI-based customer relationship management capability for enhancing social sustainability performance. J. Bus. Res. 2023, 156, 113525. [Google Scholar] [CrossRef]

- Herman, L.E.; Sulhaini, S.; Farida, N. Electronic Customer Relationship Management and Company Performance: Exploring the Product Innovativeness Development. J. Relatsh. Mark. 2021, 20, 1–19. [Google Scholar] [CrossRef]

- Saura, J.R.; Ribeiro-Soriano, D.; Palacios-Marqués, D. Setting B2B digital marketing in artificial intelligence-based CRMs: A review and directions for future research. Ind. Mark. Manag. 2021, 98, 161–178. [Google Scholar] [CrossRef]

- Chatterjee, S.; Rana, N.P.; Tamilmani, K.; Sharma, A. The effect of AI-based CRM on organization performance and competitive advantage: An empirical analysis in the B2B context. Ind. Mark. Manag. 2021, 97, 205–219. [Google Scholar] [CrossRef]

- Coltman, T.; Devinney, T.M.; Midgley, D.F. Customer relationship management and firm performance. J. Inf. Technol. 2011, 26, 205–219. [Google Scholar] [CrossRef]

- Alshurideh, M.T.; Al Kurdi, B.; Alhamad, A.; Hamadneh, S.; Alzoubi, H.M.; Ahmad, A. Does social customer relationship management (SCRM) affect customers’ happiness and retention? A service perspective. Uncertain Supply Chain Manag. 2023, 11, 277–288. [Google Scholar] [CrossRef]

- Flynn, B.B.; Flynn, E.J. Synergies between supply chain management and quality management: Emerging implications. Int. J. Prod. Res. 2005, 43, 3421–3436. [Google Scholar] [CrossRef]

- Holweg, M. The genealogy of lean production. J. Oper. Manag. 2007, 25, 420–437. [Google Scholar] [CrossRef]

- Garcia-Buendia, N.; Kristensen, T.B.; Moyano-Fuentes, J.; Maqueira-Marín, J.M. Performance measurement of lean supply chain management: A balanced scorecard proposal. Prod. Plan. Control. 2024, 35, 618–638. [Google Scholar] [CrossRef]

- Nasiri, M.; Saunila, M.; Ukko, J. Digital orientation, digital maturity, and digital intensity: Determinants of financial success in digital transformation settings. Int. J. Oper. Prod. Manag. 2022, 42, 274–298. [Google Scholar] [CrossRef]

- Sousa-Zomer, T.; Neely, A.; Martinez, V. Digital transforming capability and performance: A microfoundational perspective. Int. J. Oper. Prod. Manag. 2020, 40, 1095–1128. [Google Scholar] [CrossRef]

- Rahman, N.A.A.; Sharif, S.M.; Esa, M.M. Lean Manufacturing Case Study with Kanban System Implementation. Procedia Econ. Financ. 2013, 7, 174–180. [Google Scholar] [CrossRef]

- Guo, D.; Mantravadi, S. The role of digital twins in lean supply chain management: Review and research directions. Int. J. Prod. Res. 2025, 63, 1851–1872. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Flynn, B.B.; Schroeder, R.G.; Flynn, E. World class manufacturing: An investigation of Hayes and Wheelwright’s foundation. J. Oper. Manag. 1999, 17, 249–269. [Google Scholar] [CrossRef]

- Powell, D.J.; Coughlan, P. Rethinking lean supplier development as a learning system. Int. J. Oper. Prod. Manag. 2020, 40, 921–943. [Google Scholar] [CrossRef]

- Cua, K.O.; McKone, K.E.; Schroeder, R.G. Relationships between implementation of TQM, JIT, and TPM and manufacturing performance. J. Oper. Manag. 2001, 19, 675–694. [Google Scholar] [CrossRef]

- Duarte, S.; Cruz-Machado, V. Modelling lean and green: A review from business models. Int. J. Lean Six Sigma 2013, 4, 228–250. [Google Scholar] [CrossRef]

- Imai, M. Gemba Kaizen: A Commonsense Approach to a Continuous Improvement Strategy, 2nd ed.; McGraw Hill Professional: New York, NY, USA, 2018. [Google Scholar]

- Tortorella, G.L.; Fettermann, D.C. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Netland, T.H.; Ferdows, K. The S-Curve Effect of Lean Implementation. Prod. Oper. Manag. 2016, 25, 1106–1120. [Google Scholar] [CrossRef]

- Hines, P.; Holweg, M.; Rich, N. Learning to evolve: A review of contemporary lean thinking. Int. J. Oper. Prod. Manag. 2004, 24, 994–1011. [Google Scholar] [CrossRef]

- Rahman, S.; Laosirihongthong, T.; Sohal, A.S. Impact of lean strategy on operational performance: A study of Thai manufacturing companies. J. Manuf. Technol. Manag. 2010, 21, 839–852. [Google Scholar] [CrossRef]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Lean, green and resilient practices influence on supply chain performance: Interpretive structural modeling approach. Int. J. Environ. Sci. Technol. 2015, 12, 15–34. [Google Scholar] [CrossRef]

- Prashar, A. The interplay of lean practices and digitalization on organizational learning systems and operational performance. Int. J. Prod. Econ. 2024, 270, 109192. [Google Scholar] [CrossRef]

- Panigrahi, S.; Al Ghafri, K.K.; Al Alyani, W.R.; Khan, M.W.A.; Al Madhagy, T.; Khan, A. Lean manufacturing practices for operational and business performance: A PLS-SEM modeling analysis. Int. J. Eng. Bus. Manag. 2023, 15, 18479790221147864. [Google Scholar] [CrossRef]

- Davenport, T.H.; Short, J.E. The New Industrial Engineering: Information Technology and Business Process Redesign. MIT Sloan Management Review. July 1990. Available online: https://sloanreview.mit.edu/article/the-new-industrial-engineering-information-technology-and-business-process-redesign/ (accessed on 21 July 2025).

- Laudon, K.C.; Laudon, J.P. Manajemen Information System: Managing the Digital Firm; Pearson Educación: London, UK, 2014. [Google Scholar]

- AL-Khatib, A.W. The impact of Industry 4.0 capabilities on operational performance: The mediating effect of supply chain ambidexterity. TQM J. 2025, 37, 125–149. [Google Scholar] [CrossRef]

- Ruan, W.; Sheng, Q.Z.; Yao, L.; Li, X.; Falkner, N.J.; Yang, L. Device-free human localization and tracking with UHF passive RFID tags: A data-driven approach. J. Netw. Comput. Appl. 2018, 104, 78–96. [Google Scholar] [CrossRef]

- Weill, P. The relationship between investment in information technology and firm performance: A study of the valve manufacturing sector. Inf. Syst. Res. 1992, 3, 307–333. [Google Scholar] [CrossRef]

- Powell, T.C.; Dent-Micallef, A. Information technology as competitive advantage: The role of human, business, and technology resources. Strateg. Manag. J. 1997, 18, 375–405. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Napitupulu, D.; Syafrullah, M.; Rahim, R.; Abdullah, D.; Setiawan, M. Analysis of user readiness toward ICT usage at small medium enterprise in south Tangerang. J. Phys. Conf. Ser. 2018, 1007, 012042. [Google Scholar] [CrossRef]

- Bag, S.; Gupta, S.; Kumar, A.; Sivarajah, U. An integrated artificial intelligence framework for knowledge creation and B2B marketing rational decision making for improving firm performance. Ind. Mark. Manag. 2021, 92, 178–189. [Google Scholar] [CrossRef]

- Atieh, A.A.; Abu Hussein, A.; Al-Jaghoub, S.; Alheet, A.F.; Attiany, M. The Impact of Digital Technology, Automation, and Data Integration on Supply Chain Performance: Exploring the Moderating Role of Digital Transformation. Logistics 2025, 9, 11. [Google Scholar] [CrossRef]

- Rasool, M.; Murtza, M.H.; Rasheed, M.I.; Leong, A.M.W.; Okumus, F.; Bai, J. Information technology competency and supply chain performance: Role of risk management orientation and supply chain agility. J. Hosp. Tour. Technol. 2025, 16, 158–173. [Google Scholar] [CrossRef]

- Basu, R.; Bhola, P. Modelling interrelationships of quality management, information technology and entrepreneurial culture and their impact on performance from Indian IT enabled service SMEs. Benchmarking Int. J. 2022, 29, 2177–2201. [Google Scholar] [CrossRef]

- Nhung, T.T.B.; Thuy, T.T.P. Vietnam’S Textile and Garment Industry: An Overview. Bus. IT 2018, 8, 45–53. [Google Scholar] [CrossRef]

- Sarkar, B.; Takeyeva, D.; Guchhait, R.; Sarkar, M. Optimized radio-frequency identification system for different warehouse shapes. Knowl.-Based Syst. 2022, 258, 109811. [Google Scholar] [CrossRef]

- Kırmızı, S.D.; Ceylan, Z.; Bulkan, S. Enhancing Inventory Management through Safety-Stock Strategies—A Case Study. Systems 2024, 12, 260. [Google Scholar] [CrossRef]

- Paulraj, A.; Chen, I.J. Strategic Buyer–Supplier Relationships, Information Technology and External Logistics Integration. J. Supply Chain Manag. 2007, 43, 2–14. [Google Scholar] [CrossRef]

- Information Distortion in a Supply Chain: The Bullwhip Effect on JSTOR. Available online: https://www.jstor.org/stable/2634565 (accessed on 21 July 2025).

- Jermsittiparsert, K.; Rungsrisawat, S. The supply chain management and information sharing as antecedents of operational performance: A case of SMEs. Humanit. Soc. Sci. Rev. 2019, 7, 495–502. [Google Scholar] [CrossRef]

- Prananta, A.W.; Hidayat, K. Influence of Supply Chain Integration, Information Sharing, and Supplier Relationships on Operational Efficiency of Manufacturing Companies. Int. J. Bus. Law Educ. 2024, 5, 1681–1688. [Google Scholar] [CrossRef]

- Guchhait, R.; Sarkar, B. A decision-making problem for product outsourcing with flexible production under a global supply chain management. Int. J. Prod. Econ. 2024, 272, 109230. [Google Scholar] [CrossRef]

- Sarkar, B.; Guchhait, R. Ramification of information asymmetry on a green supply chain management with the cap-trade, service, and vendor-managed inventory strategies. Electron. Commer. Res. Appl. 2023, 60, 101274. [Google Scholar] [CrossRef]

- Zheng, G.; Ivanov, D.; Brintrup, A. An adaptive federated learning system for information sharing in supply chains. Int. J. Prod. Res. 2025, 63, 3938–3960. [Google Scholar] [CrossRef]

- Mehmood, S.; Nazir, S.; Fan, J.; Nazir, Z. Achieving supply chain sustainability: Enhancing supply chain resilience, organizational performance, innovation and information sharing: Empirical evidence from Chinese SMEs. Mod. Supply Chain Res. Appl. 2024, 7, 2–29. [Google Scholar] [CrossRef]

- Wagner, S.M.; Bode, C. An empirical investigation into supply chain vulnerability. J. Purch. Supply Manag. 2006, 12, 301–312. [Google Scholar] [CrossRef]

- Stevens, G.C.; Johnson, M. Integrating the Supply Chain … 25 years on. Int. J. Phys. Distrib. Mater. Manag. 2016, 46, 19–42. [Google Scholar] [CrossRef]

- Alzoubi, H.M.; Yanamandra, R. Investigating the mediating role of information sharing strategy on agile supply chain. Uncertain Supply Chain Manag. 2020, 8, 273–284. [Google Scholar] [CrossRef]

- Elshaer, I.A.; Azazz, A.M.S.; Elsaadany, H.A.S.; Elnagar, A.K. Social CRM Strategies: A Key Driver of Strategic Information Exchange Capabilities and Relationship Quality. Information 2024, 15, 329. [Google Scholar] [CrossRef]

- Binsaeed, R.H.; Yousaf, Z.; Grigorescu, A.; Chitescu, R.I.; Nassani, A.A.; Samoila, A. Customer Engagement and Customer Relationship Management Capabilities’ Effects on Innovation Performance and Customer Distrust’s Moderating Role. Sustainability 2023, 15, 9475. [Google Scholar] [CrossRef]

- Firmansyah, H.S.; Siagian, H. Impact of Information Sharing on Supply Chain Performance through Supplier Quality Management, Supply Chain Agility, and Supply Chain Innovation. Petra Int. J. Bus. Stud. 2022, 5, 119–131. [Google Scholar] [CrossRef]

- Marodin, G.; Frank, A.G.; Tortorella, G.L.; Netland, T. Lean product development and lean manufacturing: Testing moderation effects. Int. J. Prod. Econ. 2018, 203, 301–310. [Google Scholar] [CrossRef]

- Nawanir, G.; Teong, L.K.; Othman, S.N. Impact of lean practices on operations performance and business performanceSome evidence from Indonesian manufacturing companies. J. Manuf. Technol. Manag. 2013, 24, 1019–1050. [Google Scholar] [CrossRef]

- Birhanu, Y.; Gizaw, T.; Teshome, D.; Boche, B.; Gudeta, T. The mediating effect of information sharing on pharmaceutical supply chain integration and operational performance in Ethiopia: An analytical cross-sectional study. J. Pharm. Policy Pract. 2022, 15, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Fainshmidt, S.; Pezeshkan, A.; Frazier, M.L.; Nair, A.; Markowski, E. Dynamic Capabilities and Organizational Performance: A Meta-Analytic Evaluation and Extension. J. Manag. Stud. 2016, 53, 1348–1380. [Google Scholar] [CrossRef]

- Hamdat, A.; B, C.; Samalam, A.G.; Rizal, M.; Lawalata, I.L. The Impact of Management Information Systems on Decision-Making Efficiency. Vifada Manag. Digit. Bus. 2024, 1, 56–74. [Google Scholar] [CrossRef]

- Mashat, R.M.; Abourokbah, S.H.; Salam, M.A. Impact of Internet of Things Adoption on Organizational Performance: A Mediating Analysis of Supply Chain Integration, Performance, and Competitive Advantage. Sustainability 2024, 16, 2250. [Google Scholar] [CrossRef]

- Brent, E.; Leedy, P.D. Practical Research: Planning and Design. Teach. Sociol. 1990, 18, 248. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); SAGE Publ. Inc.: London, UK, 2022; pp. 5–24. [Google Scholar]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Hair, J.F.; Sarstedt, M.; Hopkins, L.; Kuppelwieser, V.G. Partial least squares structural equation modeling (PLS-SEM): An emerging tool in business research. Eur. Bus. Rev. 2014, 26, 106–121. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M.; Thiele, K.O. Mirror, mirror on the wall: A comparative evaluation of composite-based structural equation modeling methods. J. Acad. Mark. Sci. 2017, 45, 616–632. [Google Scholar] [CrossRef]

- Talukder, S.C.; Lakner, Z.; Temesi, Á. Interplay of Influencing Factors Shaping Entrepreneurial Intention: Evidence from Bangladesh. Adm. Sci. 2024, 14, 136. [Google Scholar] [CrossRef]

- Shahadat, M.M.H.; Chowdhury, A.H.M.Y.; Abu Jahed, M.; Nathan, R.J.; Fekete-Farkas, M. Innovativeness, visibility, and collaboration effect on supply chain performance: Moderating role of digital supply chain integration. Cogent Bus. Manag. 2024, 11, 2390168. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Podsakoff, N.P. Sources of method bias in social science research and recommendations on how to control it. Annu. Rev. Psychol. 2012, 63, 539–569. [Google Scholar] [CrossRef]

- Fuller, C.M.; Simmering, M.J.; Atinc, G.; Atinc, Y.; Babin, B.J. Common methods variance detection in business research. J. Bus. Res. 2016, 69, 3192–3198. [Google Scholar] [CrossRef]

- Kock, N. Common method bias in PLS-SEM: A full collinearity assessment approach. Int. J. e-Collab. 2015, 11, 1–10. [Google Scholar] [CrossRef]

- Kock, N.; Lynn, G.S. Lateral collinearity and misleading results in variance-based SEM: An illustration and recommendations. J. Assoc. Inf. Syst. 2012, 13, 546–580. [Google Scholar] [CrossRef]

- Henseler, J. On the convergence of the partial least squares path modeling algorithm. Comput. Stat. 2009, 25, 107–120. [Google Scholar] [CrossRef]

- Elshaer, I.A.; Azazz, A.M.S.; Fayyad, S.; Mohamed, S.A.; Fouad, A.M.; Fathy, E.A. From Data to Delight: Leveraging Social Customer Relationship Management to Elevate Customer Satisfaction and Market Effectiveness. Information 2025, 16, 9. [Google Scholar] [CrossRef]

- Ciccullo, F.; Pero, M.; Caridi, M.; Gosling, J.; Purvis, L. Integrating the environmental and social sustainability pillars into the lean and agile supply chain management paradigms: A literature review and future research directions. J. Clean. Prod. 2018, 172, 2336–2350. [Google Scholar] [CrossRef]

- Ahmed, J.U.; Hossain, T. Industrial safety in the readymade garment sector: A developing country perspective. Sri Lankan J. Manag. 2009, 14, 1–13. [Google Scholar]

- Bashar, A.; Hasin, A.A.; Sakib, N.; Bashar, N.B. Lean implementation barriers in the apparel industry in Bangladesh. Int. J. Lean Six Sigma 2024, 15, 906–924. [Google Scholar] [CrossRef]

- Siagian, H.; Yuliana, O.Y.; Purwanto, G.R. The Effect of Information Technology Implementation on Supply Chain Performance through Information Sharing and Supply Chain Collaboration. Curr. Appl. Sci. Technol. 2022, 22, 14. [Google Scholar] [CrossRef]

| Items | Factor Loading | α | Rho A | CR | AVE | Items | VIF |

|---|---|---|---|---|---|---|---|

| CRM1 | 0.931 | 0.945 | 0.952 | 0.960 | 0.858 | CRM1 | 1.382 |

| CRM2 | 0.917 | CRM2 | 1.823 | ||||

| CRM3 | 0.906 | CRM3 | 1.833 | ||||

| CRM4 | 0.949 | CRM4 | 2.08 | ||||

| LP1 | 0.929 | 0.962 | 0.963 | 0.970 | 0.868 | LP1 | 1.828 |

| LP2 | 0.940 | LP2 | 1.901 | ||||

| LP3 | 0.919 | LP3 | 2.113 | ||||

| LP4 | 0.937 | LP4 | 2.073 | ||||

| LP5 | 0.933 | LP5 | 2.161 | ||||

| OP1 | 0.942 | 0.965 | 0.966 | 0.973 | 0.878 | OP1 | 2.084 |

| OP2 | 0.936 | OP2 | 2.263 | ||||

| OP3 | 0.936 | OP3 | 2.623 | ||||

| OP4 | 0.932 | OP4 | 2.591 | ||||

| OP5 | 0.939 | OP5 | 2.081 | ||||

| QIS1 | 0.932 | 0.962 | 0.963 | 0.971 | 0.868 | QIS1 | 1.492 |

| QIS2 | 0.928 | QIS2 | 1.40 | ||||

| QIS3 | 0.924 | QIS3 | 1.532 | ||||

| QIS4 | 0.937 | QIS4 | 1.53 | ||||

| QIS5 | 0.937 | QIS5 | 1.49 | ||||

| UIT1 | 0.932 | 0.962 | 0.962 | 0.970 | 0.867 | UIT1 | 1.32 |

| UIT2 | 0.935 | UIT2 | 1.627 | ||||

| UIT3 | 0.925 | UIT3 | 1.527 | ||||

| UIT4 | 0.932 | UIT4 | 1.176 | ||||

| UIT5 | 0.931 | UIT5 | 1.512 |

| Discriminant Validity (Fornell–Larcker) | |||||

|---|---|---|---|---|---|

| CRM | LP | OP | QIS | UIT | |

| CRM | 0.926 | ||||

| LP | 0.370 | 0.932 | |||

| OP | 0.479 | 0.696 | 0.937 | ||

| QIS | 0.270 | 0.423 | 0.506 | 0.932 | |

| UIT | 0.333 | 0.845 | 0.668 | 0.460 | 0.931 |

| Discriminant Validity (HTMT) | |||||

| CRM | |||||

| LP | 0.383 | ||||

| OP | 0.498 | 0.721 | |||

| QIS | 0.281 | 0.438 | 0.525 | ||

| UIT | 0.346 | 0.845 | 0.693 | 0.478 | |

| OP | QIS | |

|---|---|---|

| CRM | 1.180 | 1.161 |

| LP | 3.220 | 3.112 |

| QIS | 1.297 | |

| UIT | 3.267 | 3.296 |

| Endogenous Variables | R-Square | R-Square Adjusted |

|---|---|---|

| OP | 0.593 | 0.588 |

| QIS | 0.229 | 0.223 |

| Path | f-Square |

|---|---|

| CRM -> OP | 0.16 |

| CRM -> QIS | 0.17 |

| LP -> OP | 0.19 |

| LP -> QIS | 0.20 |

| QIS -> OP | 0.18 |

| UIT -> OP | 0.24 |

| UIT -> QIS | 0.26 |

| Q2 of Prediction | |

|---|---|

| OP | 0.552 |

| QIS | 0.214 |

| Q2 Predict | PLS-SEM_MAE | LM_MAE | |

|---|---|---|---|

| OP1 | 0.452 | 0.745 | 0.758 |

| OP2 | 0.485 | 0.809 | 0.787 |

| OP3 | 0.478 | 0.794 | 0.815 |

| OP4 | 0.475 | 0.780 | 0.781 |

| OP5 | 0.529 | 0.783 | 0.782 |

| QIS1 | 0.205 | 0.934 | 0.951 |

| QIS2 | 0.183 | 0.941 | 0.968 |

| QIS3 | 0.163 | 0.948 | 0.993 |

| QIS4 | 0.208 | 1.063 | 1.074 |

| QIS5 | 0.165 | 0.884 | 0.926 |

| Hypotheses | Path | Path Coefficient (β) | T Values | CI (LL 5%) | CI (UL 95%) | p Values | Decision |

|---|---|---|---|---|---|---|---|

| H1 | CRM -> OP | 0.225 | 5.855 | 0.165 | 0.290 | 0.000 * | supported |

| H2 | LP -> OP | 0.367 | 4.700 | 0.235 | 0.494 | 0.000 * | supported |

| H3 | UIT -> OP | 0.190 | 2.593 | 0.077 | 0.318 | 0.005 * | supported |

| H4 | QIS -> OP | 0.203 | 4.394 | 0.127 | 0.279 | 0.000 * | supported |

| H5 | CRM -> QIS -> OP | 0.025 | 2.267 | 0.010 | 0.047 | 0.012 ** | Supported |

| H6 | LP -> QIS -> OP | 0.016 | 0.806 | −0.012 | 0.055 | 0.210 | Not supported |

| H7 | UIT -> QIS -> OP | 0.072 | 2.809 | 0.036 | 0.122 | 0.002 * | Supported |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, A.H.M.Y.; Shahadat, M.M.H.; Talukder, S.C.; Csonka, A.; Farkas, M.F. Integrating CRM, Lean Practices, and Use of IT to Enhance Operational Performance: The Mediating Role of Quality Information Sharing. Logistics 2025, 9, 123. https://doi.org/10.3390/logistics9030123

Chowdhury AHMY, Shahadat MMH, Talukder SC, Csonka A, Farkas MF. Integrating CRM, Lean Practices, and Use of IT to Enhance Operational Performance: The Mediating Role of Quality Information Sharing. Logistics. 2025; 9(3):123. https://doi.org/10.3390/logistics9030123

Chicago/Turabian StyleChowdhury, A. H. M. Yeaseen, M. M. Hussain Shahadat, Saurav Chandra Talukder, Arnold Csonka, and Maria Fekete Farkas. 2025. "Integrating CRM, Lean Practices, and Use of IT to Enhance Operational Performance: The Mediating Role of Quality Information Sharing" Logistics 9, no. 3: 123. https://doi.org/10.3390/logistics9030123

APA StyleChowdhury, A. H. M. Y., Shahadat, M. M. H., Talukder, S. C., Csonka, A., & Farkas, M. F. (2025). Integrating CRM, Lean Practices, and Use of IT to Enhance Operational Performance: The Mediating Role of Quality Information Sharing. Logistics, 9(3), 123. https://doi.org/10.3390/logistics9030123