Abstract

Background: This study explores the relationship among various supply chain management practices, including customer relationship management, lean practices, use of information technology, and quality of information sharing with operational performance in the readymade garments industry of Bangladesh. It also examines the mediating role of quality of information sharing in these relationships. Methods: Data were collected from 80 readymade garment companies across five different geographical locations, with companies of varying sizes (large, medium, and small), involving 365 respondents with a response rate of 65%. A self-administered questionnaire survey was conducted, and Partial Least Squares Structural Equation Modeling (PLS-SEM) was applied for the analysis. Results: The results indicate that all four practices significantly enhance operational performance, while customer relationship management and use of information technology also improve performance indirectly through quality of information sharing, unlike lean practices. Conclusions: The findings suggest that supply chain managers and stakeholders can improve operational performance by implementing supply chain management practices and understanding the complexities of their interrelationships.

1. Introduction

Supply chain management has become one of the most important fields for researchers and industries in recent decades. It is becoming a strategic resource for firms across all sectors to remain competitive in the present era [1] and involves managing the interaction and integration of stakeholders involved in the provision of goods and services, from the point of material extraction to the point of consumption [2,3]. The Council of Supply Chain Management Professionals (CSCMP) has defined SCM as the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. To strengthen their positions, companies have focused on achieving supply chain sustainability by developing information systems, establishing agile networks, and implementing advanced technologies [4,5]. Effective implementation of SCM becomes imperative for companies desiring to improve sustainable performance and minimize their impact on environmental degradation [6]. But managing today’s globalized SC is a daunting task because of unprecedented uncertainties in the geopolitical, economic, and technological spheres, making the SC network highly complex and vulnerable to risks, turbulence, and disruptions [7]. Bangladesh serves as a vital nexus between South and Southeast Asia, holding considerable strategic importance for all major regional and global players within the context of complex regional geopolitical dynamics [8]. This will influence Bangladesh’s RMG export performance, and the impact of such a challenge would be unveiled through future research endeavors.

On the other hand, supply chain management practices (SCMPs) play a crucial role in enhancing organizational performance, including both operational and financial outcomes for various business organizations. Many researchers have explored diverse aspects of SCMPs in their studies to understand its relationship with different performance metrics across industries, and according to Wang et al. [9], SCMPs involve managing a company’s SC most effectively through coordinated activities. These activities include customer relationship management (CRM), cycle-time reduction, supplier partnership, quality of information sharing (QIS), and the use of information technology (UIT). Similarly, Rawashdeh et al. [10] examined SCMPs using CRM, focusing on the levels of information sharing, sharing postponement, QIS, and strategic supplier partnerships. They found a positive relationship between SCMPs and organizational performance in Jordan’s tourism industry, except for CRM. The definition of organizational performance varies depending on the industry being studied. Kaplan and Norton [11], in their Balanced Scorecard (BSC) Theory, proposed various methods for measuring organizational performance, including accounting measures, value measures, operational performance (OP), and long-term survival. Flynn et al. [12] noted that most researchers focused on operational and business performance as key measures of firms’ performance. OP is defined as a company’s ability to effectively utilize its existing resources to achieve its goals [13]. Additionally, OP can be viewed as the alignment of all sub-units within an organization to ensure that they cooperate and support each other in achieving core business objectives [14]. This study measures OP using concepts from BSC Theory, focusing on five key metrics: lead time reduction, reduced manufacturing costs, reduced inventory, improved product quality, and enhanced delivery schedules. The efficient implementation of SCMPs can enhance supply chain agility, thereby contributing to improved global competitiveness, with the mediating effect of partnership quality, particularly in the fast fashion apparel industry [15]. El-Garaihy et al. [16] identified that SCMPs—encompassing strategic partnerships with suppliers, CRM, QIS, LPs, and reverse logistics—significantly improved OP within Saudi Arabia’s manufacturing sector. Similarly, a study by Hwihanus et al. [17] demonstrated that SCMPs had a significant impact on OP in Indonesian small and medium-sized enterprises (SMEs). In the same year, Ikhwana & Dianti [18] conducted research on Italian SMEs and found that SCMPs had a substantial influence on OP. Green et al. [19] considered SCMPs in the context of manufacturing companies, focusing on integration, IS, strategic supplier partnerships, postponement, and LPs. In contrast, organizations need to understand the concepts and practices of SCM and recognize their role in achieving competitive advantage and enhancing profitability [20,21,22]. Likewise, Lal [23] analyzed the factors influencing the export performance of Indian garments manufacturing firms and found that the use of information technology had a significant contribution to achieving competitive advantage over other Asian countries and to export performance. Again, Tarigan & Siagian [24] conducted a study on the use of SC elements to improve OP and found that all the elements used as SCMPs contributed to OP in the manufacturing industries of Indonesia. Previous research has consistently indicated that SCMPs positively impact OP across various organizations [20,25]. Similarly, a study by Tan [26] found a positive relationship between SCMPs and overall organizational performance across different industries. Li et al. [27] conducted a study on 196 US organizations and found a positive relationship between companies’ SCMPs and organizational performance.

Bangladesh has the second largest volume of garment exports globally, with China remaining in first place for the last few decades [28]. Moreover, in the last 25 years, the RMG industry has been the most significant source of foreign earnings for the Bangladesh economy [29]. The SC of the RMG industry has been considered complex since its nature varies by company and environment [29]. Therefore, it is very susceptible to disruptions, particularly in an emerging economy. Moreover, the recent Russia–Ukraine war has had adverse effects on the sustainability of the SC of the RMG industries in developing countries [30]. The Bangladesh RMG market is worth billions of dollars. However, there are few studies examining the relationship between SCMPs and OP with the influence of QIS as a mediating variable in the context of Bangladesh. Numerous studies have been conducted to understand the relationships between SCMPs and OP across different industries and countries while considering different moderating/mediating variables. This study integrated the most relevant SCMPs into a holistic framework and assessed their combined impact on OP. This integration is novel in the Bangladesh RMG sector, where the adoption of these practices is still emerging, and their synergistic effects have not been comprehensively studied. Moreover, an emphasis on the mediating role of QIS on the relationship between SCMPs and OP added more uniqueness to this study, highlighting how the effectiveness of CRM and IT integration in supply chains is contingent on timely and accurate information sharing—something that has not been explicitly explored in previous studies in the Bangladesh RMG industry. This study also contextualized global SCMPs in relation to the specific challenges of the Bangladeshi RMG industry, infrastructure limitations, fragmented supply chains, and reliance on manual processes, For example, in the recent study by Shahadat et al. [31], the authors found that ICT implementation barriers in the context of Bangladeshi SMEs included challenges such as limited financial resources, inadequate infrastructure, low awareness, and lack of government support. Moreover, the lack of top management innovativeness is also a challenge for ICT implementation in supply chain practices.

Given this backdrop, the aim of this study is to examine the relationship between SCMPs and OP, with a particular focus on the mediating role of quality of information sharing in the ready-made garment industry of Bangladesh. To assess this relationship, this study seeks to answer the following research questions: (1) What is the relationship between SCMPs and operational performance? (2) Does the quality of information sharing mediate the relationship between SCMPs and OP? (3) To what extent does QIS mediate the relationship between specific SCMP dimensions and OP? In answering these questions, the following two objectives need to be achieved:

- (a)

- To examine the relationship among selected SCMPs, including CRM, LPs, UIT, and QIS, with OP.

- (b)

- To ascertain the mediating role of QIS in such relationships in supply chains, especially in the RMG industry of Bangladesh.

This study contributes to RBV theory by positioning SCMPs as scarce and valuable resources that enhance OP in the RMG sector. IT extends RBV by showing how these practices, particularly when integrated, act as sources of competitive advantage for the RMG industry of Bangladesh. It highlights that effective SCMPs, such as CRM and IT, are not only rare but also difficult to imitate in the local context due to challenges like infrastructure and skills gaps, thereby reinforcing the RBV concept of resource uniqueness. This paper is structured into six sections. In the following section, the theoretical framework and research hypotheses are discussed, establishing the foundation for the study. Section 3 and Section 4 cover the research methodology, explaining the approach and data collection process, and present the results and analyses with a focus on key findings. Finally, Section 5 and Section 6 provide a discussion of the findings, connecting them to the broader context and implications, and conclude the study with a summary of contributions, limitations, and suggestions for future research.

2. Theoretical Background and Hypotheses

The research model for this study has been derived from the core concepts of the Resource-Based View (RBV) and the BSC theory. The RBV [32,33] is a management concept that argues that firms gain and sustain a competitive advantage through their unique resources and competencies that are valued, uncommon, imperfectly imitable, and non-substitutable [34]. In dynamic business situations, success depends on how quickly and effectively a firm can realign its unique resources and competencies to take advantage of opportunities and meet market demands [35]. This study considered four different SCMPs as unique and inimitable resources, including CRM, LPs, UIT, and QIS, for obtaining a competitive advantage through achieving higher OP. It is worth mentioning that organizational performance through SC consists of two major aspects: one is OP [36,37] and the other is competitive performance [36]. On the other hand, BSC theory [38] of performance measurement has been considered for measuring OP. It is vital to understand the level of complexity in which organizations are competing in this era of competition. Despite the numerous models and frameworks available, the BSC is the most popular approach to performance measurement. This model translates the mission and strategy of the organization into different performance indicators. It measures organizational performance from four different perspectives: financial, customer, learning and growth, and internal processes. These perspectives provide a balance between financial and non-financial measures, encompassing both external (customer and financial) and internal (business processes and learning and growth) perspectives. Bhagwat & Sharma [39] developed a BSC for SCM that measures and evaluates day-to-day business operations following the basic theory. The constructs, dependent and independent variables with different indicators for measuring those variables, have been adapted from these underpinning theories and prior literature. The research model used for this study is also a measurement model utilizing the required data and appropriate tools and techniques for the required analyses. Partial Least Squares Structural Equation Modeling (PLS-SEM) was used to assess the model. This method required classifying the model used for appropriate analysis into formative and reflective models. The relationship between a construct and its measurement item determines whether a model is a reflective or formative one. Considering the context and the types of relationships that exist between latent variables/constructs and the dependent variable, this research model is categorized as a reflective model. The rationale for such categorization is that causality flows from constructs/latent variables to the items. Moreover, in a reflective model, the underlying construct drives the indicators, which have positive and high intercorrelations [40].

2.1. Customer Relationship Management (CRM) and OP

CRM is a strategy adopted by the organization to build and enhance relationships with customers, with the intention of receiving customer feedback and identifying customer preferences in order to adjust the operational process. CRM significantly enhances operational management by streamlining customer interactions and improving decision-making processes through better data integration and communication [41]. CRM harnesses people, technology, and organizational capabilities to ensure connectivity amongst the company, its customers, and collaborating firms. It deals with the efficient management of customer complaints, building relationships with customers and customer satisfaction. This relationship may be able to forecast demand that leads to better operational efficiency [27]. Ijomah et al. [42] argued that effective customer relationships—fostered through training, improved communication systems, and strong management support—enhance demand analysis, leading to more efficient material and resource planning. It also helps organizations to gain a competitive edge by understanding their demand patterns and delivering products in a timely manner, all while maintaining the highest customer satisfaction.

However, CRM must be meticulously integrated with other performance enablers, and in this regard, [43] found a positive and significant relationship between CRM capability and information and communication technology. Firms’ AI-driven CRM capability is a source of competitiveness that enables firms to understand their customers’ changing preferences and optimize their relationship [44,45]. Chatterjee et al. [46] found that AI-based CRM, combined with RBV theory of management, has a positive influence on organizational performance across firms of varying sizes, ages, and industries. A study by Coltman et al. [47] found a positive and significant relationship between a superior CRM capability and firm performance. Meanwhile, Alshurideh et al. [48] found significant and positive effects of the most social CRM elements on customer happiness, another measure of firm’s performance. Flynn & Flynn [49] opined that sharing product information, efficient order booking management, and timely delivery of products improve customers’ confidence and satisfaction. Against this backdrop, the following hypothesis has been formulated:

H1:

CRM has a positive relationship with OP.

2.2. Lean Practices (LPs) and OP

LPs, a foundational approach in operational management, have been extensively studied for over 30 years, originating from the Toyota Production System [50]. Recognized globally by manufacturers, LPs are key to enhancing the OP of organizations [51,52,53]. LPs focus on systematic waste reduction, productivity enhancement, and quality improvement, minimizing unnecessary investments in inventory and infrastructure like redundant assembly lines [54]. Lean supply chain practices focus on enhancing efficiency and cutting costs by eliminating waste and encouraging close collaboration between businesses across the supply chain [55]. By integrating people, processes, and technologies, LPs support unique performance improvements [56]. Various LPs, such as cellular manufacturing, cycle time reduction, continuous improvement, and self-directed work teams, contribute to better OP [57,58]. Cua et al. [59] categorized LPs into total quality management (TQM), just in time (JIT), and total preventive maintenance (TPM), suggesting that bundling these practices enhances their impact on OP. However, the effective implementation of LPs remains a challenge, with many organizations facing difficulties like inconsistent measurement standards across countries [60]. LPs are built on continuous incremental improvements rather than radical changes [61], combining social and technical practices [62]. They promote a learning culture within organizations, which supports OP improvement through waste reduction and cost efficiency [63,64]. In addition, in supply chain practices, lean management enhances supply chain performance by streamlining processes, reducing waste, and improving operational efficiency, which leads to faster delivery and lower costs [65]. Additionally, integrating lean with sustainable and resilient practices further strengthens supply chain responsiveness and overall performance [66]. Therefore, lean practices (LPs) are crucial for the Bangladesh RMG industry, which operates in a complex global value chain where agility, coordination, and reliability are essential. LPs streamline sourcing, logistics, inventory, and distribution, reducing lead times and enhancing responsiveness, cost efficiency, and sustainability. They also support meeting global buyers’ requirements for speed, transparency, coordination, and digital visibility, while standardizing process control and traceability to pass audits.

Research consistently highlights a positive relationship between LPs and OP [67]. However, some studies, like Panigrahi et al. [68], suggest that while LPs can explain OP, they do not always translate to overall business success.

H2:

Lean practices have a positive relationship with OP.

2.3. UIT and OP

Based on the reviewed literature, a significant relationship between IT investment and firm performance has been observed, with results varying across different studies. Information and communication technologies (ICTs), including software, hardware, and peripherals, play a crucial role in transforming data into actionable information and supporting organizations in achieving OP and competitive advantages [69,70]. Emerging IT tools like Industrial IoT, AI, and big data analytics enable manufacturing transformation by enhancing the intelligence of devices and systems [68,71]. IT has evolved with technologies like RFID and Wi-Fi, proving to be essential for effective organizational management [72]. Some studies [73,74] have noted a negative relationship between IT investment and firm performance, while others [31,75,76] have found a positive relationship. Napitupulu et al. [77] emphasized the role of IT in enhancing information integration and collaboration across SC. Recent studies also highlighted how advanced ICTs, with capabilities like AI and big data analytics, can lead to more efficient decision-making, better coordination of resources, and increased adaptability within a digitally transformed environment [78,79,80]. Yuliana et al. [81] found that IT integration in SCM improves collaboration and communication, leading to better OP. In the same way, Vietnam’s RMG industry is employing modern technologies, information technology, quality management systems, labor management and environmental management in compliance with international standards to ensure the sustainable and efficient development of the industry [82]. Moreover, Sarkar, B et al. [83] opined that the use of radio-frequency identification systems by manufacturers for the better control of inventories provides an edge in improving the organization’s overall performance.

H3:

The use of IT has a positive relationship with OP.

2.4. Quality of Information Sharing (QIS) and OP

Previous studies have highlighted the importance of QIS in SCM. QIS involves sharing critical product information with SC partners, facilitating a smooth flow of information and resources [84]. Such sharing enhances targeted performance by promoting better collaboration between SC partners [85]. Effective information sharing (IS) is crucial for successful SCM, while information distortion can significantly impair performance [86]. Jermsittiparsert & Rungsrisawat [87] suggest that integrated IS systems are essential for the survival of small and medium enterprises (SMEs), particularly in emerging economies. The timely exchange of accurate information across SC entities enhances organizational efficiency and decision-making [88]. However, challenges like unprofessional conduct and information asymmetry can impact QIS quality. Again, Guchhait, R. and Sarkar, B. [89] found that product information sharing by manufacturers with retailers helps to improve decision-making in global outsourcing for organizations, which ultimately optimizes SCP. On the other hand, Sarkar, B et al. [90] found that asymmetric information sharing among supply chain players affects supply chain profit, though sometimes, it can improve profit for a few supply chain players for a short period of time. Quality information sharing enhances supply chain resilience and innovation, leading to improved organizational performance. It also enables accurate, collaborative decision-making while maintaining data privacy [91,92]. Timely and accurate QIS can reduce production costs and improve customer satisfaction, making it a critical success factor for global organizations. Nonetheless, both insufficient and excessive information sharing can be detrimental. Organizations should view information as a strategic resource, ensuring its timely flow to relevant parties [93,94]. Alzoubia & Yanamandrab [95] found that IS plays a key role in achieving agility in SC, thereby enhancing performance.

H4:

QIS has a positive relationship with OP.

2.5. Mediating Effect of QIS

The relationship between CRM and OP is often influenced by QIS, which acts as a mediating factor. Strong CRM promotes higher OP if it is well integrated with QIS, which ensures better decision-making, agility, and responsiveness to the customer demand. Chavez et al. [34] found that QIS partially mediates the relationship between CRM and various dimensions of OP. QIS plays a critical mediating role in this relationship as it enables smoother communication, real-time decision-making, and overall integration across business functions. CRM improves the OP of the manufacturing companies, particularly when integrated with high QIS. CRM drives the firms’ performance through strategic alignment and high QIS in enhancing CRM activities [96]. CRM capabilities promote innovation and operational efficiency, with the emphasis that high QIS enhances CRM’s impact on these outcomes [97]. Against this backdrop, the following hypothesis has been considered for this study:

H5:

QIS mediates the relationship between CRM and OP.

The relationship between LPs and OP is well documented in recent research, which emphasizes that LPs improve operational efficiency, cost reduction, and quality improvement. However, the effectiveness of LPs in improving OP is significant when QIS acts as a mediator. QIS enables the successful implementation of LPs, allowing organizations to thrive with superior OP. Supply chain innovation improves operational metrics, including cost, quality, and delivery time, only when QIS mediates the relationship [98]. LPs contributes to improving the OP of manufacturing companies only when a system of effective information sharing is in place. On the other hand, Marodin et al. [99] conducted a robust empirical study investigating how lean practices influence operational performance in manufacturing firms, particularly analyzing whether Information and Communication Technologies (ICT) moderate that relationship. Furthermore, Nawanir et al. [100] In one of their studies, they argued that QIS acts as a catalyst for LPs to influence the OP positively. With this pretext, the following hypothesis is made:

H6:

QIS mediates the relationship between LPs and OP.

The relationship between UIT and OP has been widely examined and a growing body of research suggests positive relationships through improving internal and external communication, streamlining processes, and enabling data-driven decision-making. Birhanu et al. [101] provide empirical evidence that information sharing significantly mediates the relationship between supply chain integration, comparable to upstream information technologies (UIT), and key operational performance indicators, including cost efficiency, quality, delivery reliability, and flexibility. The positive impact of this relationship is realized only when information is shared accurately and in a timely manner. Again, Fainshmidt et al. [102] argued that UIT positively impacts organizational agility, particularly when high QIS is present in Jordanian manufacturing companies. Furthermore, a study by Hamdat et al. [103] suggests that IT systems enhance firms’ performance by supporting the timely and accurate discrimination of information, which ultimately facilitates effective decision-making and operational responsiveness, thereby highlighting the crucial role of QIS. Finally, Mashat et al. [104] found that the impact of IT on OP is not solely direct; it is mediated by how well information is shared and integrated across different parts of the SC. Against this background, the following hypothesis is considered:

H7:

QIS mediates the relationship between Use of IT and OP.

2.6. Proposed Research Framework

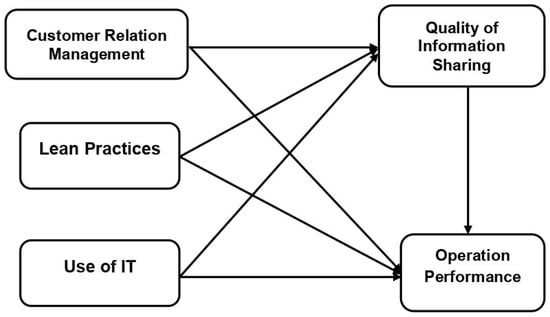

Upon examining the pertinent literature and theories, we propose a conceptual model to evaluate our hypotheses. The model illustrated in Figure 1.

Figure 1.

Authors’ model.

3. Research Methods

The general approach defines the research method the researcher adopts in carrying out the research project [105]. Quantitative research with questionnaire surveys was employed for this study. Managers of eight categories of RMG factories were selected as participants, from whom requested data were collected. Collected data were analyzed using SPSS (Version 29.0.1.0) as well as Smart PLS 4.0 (Version 4.1.1.1). Finally, the information is presented through different relevant tables with necessary explanations.

3.1. Sampling and Data Collection Process

In this study, a random stratified sampling approach was employed, incorporating elements of cluster sampling. The study’s clusters consisted of RMG factories located in four regions of Bangladesh, Gazipur, Narayanganj, Dhaka, and Chittagong, representing three factory sizes, large, medium, and small. The study population comprised all managers from woven garment factories within these clusters. This selection was made for several reasons, including the fact that managers with previous experience in the SC departments of other companies are often employed in firms lacking a dedicated SC department. To facilitate effective data collection, a total of 560 questionnaires were distributed using a mixed-method approach. Both online (via Google Forms) and offline (paper-based) survey methods were employed to reach managers from 80 ready-made garment (RMG) factories. Various strategies were implemented to reduce the potential for respondent bias linked to mixed-mode data collection (online and paper-based). The questionnaire items, formatting, and instructions were maintained consistently across all formats to guarantee functional similarity. Secondly, data collection occurred within a specified timeframe following a consistent set of instructions to minimize potential temporal variance. Finally, anonymity and privacy were ensured in both modes to mitigate social desirability bias, and participation was voluntary to reduce forceful or inattentive responses. For online data collection, survey links were shared through official email communications and relevant social media platforms. Multiple follow-up reminders were issued to maximize response rates. Ultimately, 385 complete questionnaires were received, meeting the required sample size. Data was collected from the respondents on the following selected constructs used in this study: customer relationship management, lean practices, use of information technology, quality of information sharing, and operational performance. Bangladesh’s RMG industry stands at the intersection of global supply chain integration and local operational challenges, and as the second-largest apparel exporter, this provides an impactful context for this study. The industry has relevance for multiple inter-linked factors, including global significance, contextual challenges, economic importance as the backbone for Bangladesh, and also for practical relevance. The questionnaire for data collection is provided in Appendix A.

3.2. Procedure and Measurement

This study adopts an applied research approach, aiming to address practical challenges related to the measurement of supply chain management practices (SCMPs) and organizational performance (OP). Quantitative research design was employed to investigate the proposed conceptual framework. The survey instrument was developed based on established constructs from the research model, encompassing independent variables (SCMP), the dependent variable (OP), and the mediating variable. Each construct was operationalized using multiple items adapted from validated sources in the existing literature, ensuring content relevance and theoretical association. To ensure the validity of the measurement instrument, a two-stage validation process was conducted. Initially, the questionnaire was reviewed by a panel of subject-matter experts, including industry practitioners and academic scholars, to assess content validity, clarity, and relevance. Subsequently, a pilot study was conducted to validate the measurement instrument statistically. This included tests for construct validity (e.g., convergent and discriminant validity) and reliability (e.g., Cronbach’s alpha, composite reliability), confirming that the instrument met the necessary standards for use in empirical analysis.

3.3. Data Analysis Method

This research utilized Partial Least Squares Structural Equation Modeling (PLS-SEM) as an analytical method based on various methodological factors. The research model is reflective, utilizing reflective indicators for all constructs, thus rendering PLS-SEM suitable for analyzing complex relationships among latent variables [106]. The study’s primary objective was focused on prediction and theory development, rather than theory testing, which is consistent with the strengths of PLS-SEM in managing exploratory and prediction-oriented research [107]. PLS-SEM is appropriate for analyzing models with small to medium sample sizes and does not require strict assumptions regarding multivariate normality, which aligns well with the characteristics of our dataset. The model incorporated various constructs and pathways, for which PLS-SEM provides strong estimation capabilities and facilitates the simultaneous evaluation of both measurement and structural models. The selection of PLS-SEM was determined by model complexity, construct characteristics, and the study’s emphasis on prediction, aligning with recognized methodological standards [108,109]. PLS-SEM is a vigorous, variance-based statistical technique widely recognized in social science research, particularly in operations and strategic supply chain management, as well as in marketing, management, and environmental studies [109,110,111]. The analysis was conducted using Smart PLS 4.0, which facilitated the assessment of both the measurement (outer) model and the structural (inner) model. In the measurement model, reliability and validity were examined through indicators such as construct reliability, composite reliability, convergent validity, and discriminant validity. For the structural model, path coefficients were evaluated through a bootstrapping procedure using 10,000 resamples and a one-tailed significance test. This comprehensive analytical approach ensured the robustness of the model and the validity of the causal relationships among the latent constructs.

4. Results and Analyses

4.1. Assessment of Measurement Model

The model consists of five components, CRM, LPs, UIT, QIS, and OP, which stand for customer relationship management, lean practices, use of IT, quality of information sharing, and operation performance, respectively. The researchers checked the measurement model’s outer loadings in the first stage and afterwards discovered that all factor loadings, ranging from 0.906 to 0.940, were satisfactory. It is also evident from Table 1 that all of the evaluated indicators sufficiently meet the thresholds: the Cronbach’s alpha, composite reliability, and average variance extracted of all of these values are higher than the minimum recommended values (0.7, 0.7, and 0.5, respectively) [109]. Variance inflation factor (VIF) values were analyzed to evaluate multicollinearity among indicators. Several indicators exhibited VIF values approaching the upper acceptable limit (e.g., 2.62), indicating moderate intercorrelation. However, because the variance inflation factor (VIF) values for each item in the structural model range from 1.176 to 2.623, being below the threshold value of 5.0, neither multicollinearity nor negative effects between items or predictors are present [109]. To address potential multicollinearity in instrument development, items were meticulously examined to ensure conceptual clarity and prevent redundancy. A pre-test and expert review phase were conducted to refine item wording and structure. The implemented steps improved content clarity and minimized overlap among constructs, thus reinforcing the discriminant validity and internal consistency of the measurement model. These results show that there is enough discriminant validity, and the constructs are statistically distinct from each other. Table 2 shows the result of the discriminant validity evaluation. At the first stage, the Fornell–Larcker criterion was used for this evaluation. The inter-construct correlations were smaller than the square root of AVE. If the item-level factor loadings are greater than the aggregate cross-loadings, then the construct is considered to have discriminant validity [108]. Table 2 clearly shows that the correlations in the subsequent rows of the same column must be less than the square root of the extracted variance (bolded). In addition, Heterotrait–Monotrait (HTMT) ratios were employed in the second approach, which ensured discriminant validity up to the upper limit of 0.90 as an acceptable threshold [107,109].

Table 1.

Evaluation of measurement model (reliability and validity with VIF).

Table 2.

Discriminate validity (the Fornell–Larcker and HTMT criteria).

4.2. Common Methods Bias

To ensure that there were no common method bias (CMB) issues in the data, the researchers followed the recommendation of Podsakoff and used Harman’s single-factor test before testing the hypotheses [112]. The results from the tests indicated that CMB was not an issue; a single factor explained just 41% of the variance, which is far lower than the 50% cutoff [113], proving that CMB was not present in the dataset. Furthermore, we used a different method called the inner VIF collinearity approach to identify CMB; this approach included evaluating the collinearity variance inflation factor (VIF) with Smart PLS. According to the results, VIF values were below the allowed range of 3.30 [114,115], which further indicates that there are no CMB issues in the data.

4.3. Assessment of Structural Model and Hypothesized Relationships

The research examined the structural model by calculating the coefficient of determination R2, the effect size f2, the predictive relevance Q2, and the statistical significance of the structural path coefficients after ensuring the measurement model’s validity and reliability [106]. Based on the VIF coefficient, it appears that the structural model does not have any evidence of multicollinearity among the dimensions of the research variables. All of the values in Table 3 are lower than the cutoff value of 5 [106].

Table 3.

Collinearity statistics (VIF).

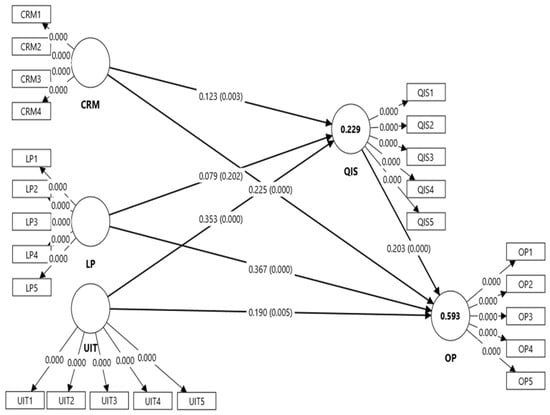

R2 is a measure of the model’s predictive accuracy that can take on values between 0 and 1. The dependent variable of the model, OP, has an R2 value of 0.593, as illustrated in Table 4. This indicates that CRM, LPs, UIT, and QIS can account for 59.3% of the variation in OP among Bangladeshi RMG factories. On the other hand, the remaining variation is attributable to other factors. The results also indicate that CRM, LPs, and UIT were responsible for 22.9% of the variability in QIS in the factories surveyed. The structural model’s explanatory power is substantial in the model and validated by these values [110,116].

Table 4.

Coefficient of determination R2.

The effect size (f2) represents the increase in R2 compared to the percentage of the endogenous latent variable’s variance that cannot be explained [107]. f2 values are classified as small if they exceed 0.02, medium if they fall between 0.15 and 0.35, and large if they exceed 0.35 [106]. f2 results are presented in Table 5, indicating a medium effect.

Table 5.

Effect size (f2).

The predictive relevance of the model was evaluated using the PLS-predict procedure. The values of Q2 for the predicted values for all dependent variables are statistically significant and satisfactory, as they exceed zero [106]. This is illustrated in Table 6. The predictive power of the model was evaluated by comparing the PLS-SEM_MAE values with the naïve LM_MAE benchmark for the Q2 of predicted values in the analysis. Table 7 suggests that the model has medium predictive power, as most of the PLS-SEM_MAE values for OP and QIS indicators are lower than the naïve LM_MAE benchmark [106].

Table 6.

Values of predictive relevance, Q2.

Table 7.

Q2 of predicted values for endogenous constructs.

4.4. Validation of the Hypotheses in the Proposed Model

SRMR was 0.034, which is less than 0.08, and NFI was 0.855, which is close to 0.90. These values indicate an adequate fit for testing the hypotheses in the model. Utilizing the predictive relevance (Q2) and R-squared (R2) values of the endogenous constructs, the predictive relevance and predictive power of the proposed research model were assessed, and these values were also satisfactory. In general, the analyses mentioned indicate that a structural model was suitable. The following section will describe and analyze direct relationships and mediate the proposed hypotheses. The path coefficients are significant for the relationships between CRM and OP at β = 0.225, p < 0.01; as a result, these findings support H1. The path coefficients are significant for the relationships between LPs and OP at β = 0.367, p < 0.01; hence, H2 is supported. H3 is also accepted, as the path coefficients of the relationships between UIT and OP are significant at β = 0.190, p < 0.01. The path coefficient is also significant for the relationships between QIS and OP at β = 0.203, p < 0.01; consequently, H4 is supported. To evaluate the mediation effect of the variables, this investigation utilized the methodologies proposed by [109]. Table 8 illustrates that the variable (QIS) partially mediates the relationship between CRM and OP, as well as the relationship between UIT and OP. The relationship between CRM and OP was mediated by QIS (β = 0.025, p < 0.05), hence H5 is supported. On the other hand, the relationship between LPs and OP is not mediated by QIS (β = −0.016, p > 0.05), resulting in H6 being insignificant and not supported. Additionally, the relationship between UIT and OP was partially mediated by QIS (β = 0.072, p < 0.01), hence H7 is significant and supported. Table 8 and Figure 2 illustrate the entire structural model analysis.

Table 8.

Results of hypothesis.

Figure 2.

Results of the structural model.

5. Discussions

The objective of this study is to examine the relationship between SCMPs and OP in the RMG industry of Bangladesh, utilizing RBV theory and the BSC model as the conceptual frameworks. In line with these theories, SCMPs are postulated as critical strategies for enhancing OP, focusing on the variables of CRM, LPs, UIT, and QIS. This study adopts a positivist methodological approach, emphasizing empirical hypothesis development and testing. Partial Least Squares Structural Equation Modeling (PLS-SEM) was employed to assess the hypothesized relationships between SCMPs and OP, with particular attention paid to the mediating role of QIS. The statistical analysis results indicate that six of the proposed hypotheses were supported, while one mediating hypothesis was not supported.

In Table 8, H1 is positive and significant, i.e., CRM has a positive and significant relationship with OP. This finding is consistent with that of previous studies [46,117]. It contributes to improving the OP, provided it is well integrated with other relevant SCMPs, including employment of appropriate IT. Moreover, the result is also consistent with another study conducted by [43] in various provinces in South Africa, in which data was collected from employees in the manufacturing sector, focusing on B2B business practices.

Similarly, in H2, the statistical findings of this study support that LPs positively influence OP. LPs emphasize waste reduction, continuous improvement, cycle time reduction, and resource utilization efficiently, resulting in improved productivity, quality, and overall OP of the organization. This result aligns with the previous studies [58,63,64], especially in manufacturing industries operating globally.

Moreover, in H3, the statistical results support the hypothesis that the UIT positively influences OP. This result is found to be consistent with the findings of previous research. [75,76], which highlights IT’s role in enhancing SC efficiency, communication, and decision-making processes, ultimately driving improved organizational performance. By integrating advanced technologies like AI, RFID, blockchain technology, and ERP systems, firms gain a competitive advantage, streamline operations, and foster collaboration, as evidenced by studies in various industries.

From the testing of H4, it was found that QIS positively impacts OP, which is statistically significant. Thus, H4 is supported. Prior studies reflect this positive result [95]. This supports the view that timely and accurate information sharing across the SC improves coordination, reduces costs, and enhances customer satisfaction. Effective QIS, facilitated by technologies like Electronic Data Interchange (EDI), ensures seamless communication, boosts SCP, and enables firms to respond quickly to market changes, thereby improving overall operational efficiency.

In addition, this study finds that QIS mediates the relationship between SCMPs and OP. Here, in support of H5, the statistical results verify that QIS acts as a significant mediator between CRM and OP. Based on the support from this empirical study on the mediating role of QIS, this study validated the finding that flow of information, products, and funds has a significant impact on CRM strategy to contribute to improved OP [85]. As stated above, this study found a positive relationship between QIS and OP, consistent with the findings of previous research [36,118]. This suggests that effective CRM practices, when paired with timely and accurate IS, enhance the overall operational efficiency and responsiveness of the organization. By facilitating better communication and collaboration across the SC, QIS enables firms to translate customer insights into operational improvements, thereby boosting performance outcomes.

On the other hand, the findings of this study do not support the mediating effect of QIS in the relationship between LPs and OP in the context of the RMG industry of Bangladesh. Thus, H6 is insignificant and not supported. A plausible explanation for this outcome may lie in the contextual limitations of the ready-made garment (RMG) industry in Bangladesh. The industry is characterized by a highly cost-competitive environment and a predominant focus on compliance-driven lean initiatives, often dictated by external buyers rather than internal process integration [119,120]. Consequently, lean practices may not be systematically aligned with information-sharing mechanisms, leading to the observed non-significant mediating effect. Although lean practices (LPs) have a substantial direct impact on operational performance (OP), they do not seem to have a significant indirect effect on quality of information sharing (QIS). This indicates that there is a gap between lean practices and the information-sharing infrastructure in the ready-made garment (RMG) sector of Bangladesh. This difference suggests that lean practice improvements may be developing at the process level without better information flows. This brings up critical operational issues, like the need to better match information-sharing platforms with lean initiatives, deal with possible cultural or structural hurdles to transparency, and rethink the role of QIS in determining performance outcomes. These results imply that RMG firms in Bangladesh could benefit from seeing QIS as more than just a support system, instead as a strategic competence that is part of lean practice implementation. Moreover, this could be due to several industry-specific challenges. The RMG industry of Bangladesh often faces structural limitations, such as inadequate technological infrastructure, fragmented SC, and a reliance on manual processes, which may hinder effective and timely IS. Additionally, LPs in this industry are often implemented in isolation, without fully integrating QIS mechanisms, resulting in less impact on OP.

Furthermore, the findings confirm that QIS plays a significant mediating role between the UIT and OP. Thus, H7 is significant and supported. This suggests that when organizations in the RMG industry effectively utilizes IT systems, coupled with timely and accurate IS, they can achieve better coordination, enhanced decision-making, and improved overall operational efficiency [121]. The integration of UIT with QIS ensures that data flows seamlessly across the SC, allowing firms to respond quickly to changes and optimize their performance. This underscores the importance of combining IT use with strong IS mechanisms to achieve superior OP [77].

5.1. Practical Implications

This study offers several practical insights for supply chain (SC) managers and practitioners, particularly in the context of the Bangladesh ready-made garment (RMG) industry, where competitive pressures and dynamic market conditions demand efficient and integrated supply chain strategies. The findings confirm that key supply chain management practices (SCMPs), specifically lean practices (LPs), customer relationship management (CRM), and use of information technology (UIT), have a direct and significant impact on operational performance (OP). Managers should therefore prioritize these practices as foundational drivers of supply chain success. In particular, the strong influence of CRM and UIT on both OP and quality information sharing (QIS) suggests that investing in customer-focused strategies and digital tools can enhance responsiveness, coordination, and agility across the supply chain. Although QIS mediates the effects of CRM and UIT on OP, it does not mediate the relationship between LPs and OP in this study. This suggests that, in the current RMG context, lean initiatives may be implemented in a more isolated or compliance-driven manner, without being fully integrated into broader information-sharing structures. Managers should recognize this gap and work toward better aligning lean practices with internal and external communication systems to realize their full potential.

To operationalize these insights, SC managers should invest in integrated CRM systems and IT platforms that facilitate real-time communication and data sharing with customers and suppliers. Additionally, we encourage the use of advanced technologies such as artificial intelligence (AI), enterprise resource planning (ERP), and radio-frequency identification (RFID) to improve decision-making, streamline processes, and enhance visibility across the supply chain. Moreover, SC managers should ensure that lean practices are not adopted in isolation, instead being supported by robust information-sharing processes and cross-functional coordination mechanisms.

By adopting a holistic and integrated approach to SCM rather than piecemeal implementation, organizations in the RMG sector can significantly enhance their operational performance and build resilience in a highly competitive global market.

5.2. Theoretical Implications

The theoretical implications of this study lie in its integration of the RBV and the BSC framework to examine how SCMPs can enhance OP. By presenting the RBV, this research highlights the role of unique, inimitable resources, namely CRM, LPs, UIT, and QIS, in driving competitive advantage and higher OP. This emphasizes the idea that readjusting such resources is critical in dynamic markets. Furthermore, this study adapts BSC theory to measure OP across the financial, customer, internal process, and learning and growth perspectives, providing a comprehensive approach to performance assessment in supply chains. This integration demonstrates how SCMPs can contribute not only to operational efficiency but also to sustained competitive performance, offering a multidimensional understanding of performance management in contemporary supply chain settings. Thus, this study contributes to both the RBV and BSC literature by linking unique resources to holistic performance outcomes in supply chain contexts. This study makes a unique theoretical contribution by integrating the Resource-Based View (RBV) and Balanced Scorecard (BSC) frameworks to examine their combined impact on supply chain practices and operational performance (OP). RBV emphasizes internal resources for competitive advantage, while BSC provides a multidimensional perspective on performance measurement. By connecting these frameworks, this study highlights how resource optimization and strategic performance metrics collectively enhance supply chain efficiency, providing a novel perspective on improving OP in a dynamic environment.

6. Conclusions

This research has been conducted to establish the relationship between SCMPs and OP in the RMG industry of Bangladesh using the RBV and the BSC theory as conceptual frameworks. A very systematic and scientific research design with an appropriate sample and study area has been used in conducting this study. The study findings provide contributions for different stakeholders, including policy makers, regulatory authorities, RMG factory owners, investors, and academics, in different ways. Four selected SCMPs, including CRM, LPs, UIT, and QIS, exhibit a statistically significant relationship with OP. The mediating role of QIS in these relationships is consistently positive and significant, except for LPs, which suggests a crucial role in enhancing operational efficiency by facilitating effective communication and decision-making. However, this study points out the importance of integrating advanced SCMPs and appropriate information-sharing mechanisms to optimize OP. These findings contribute to the understanding of how SCMPs can be strategically important to enhance performance outcomes, especially in dynamic and resource-constrained industries like RMG. However, supply chain practices still have some limitations. They are facing challenges related to ICT implementation due to limited financial resources, inadequate infrastructure, low awareness, and lack of government support, which ultimately hamper the overall performance. Though this study adapted SCMPs and indicators of OP from the prior literature, the inclusion of the mediating variable QIS for understanding the relationships in a far better way, which is unique and remains a contribution to the existing literature. After establishing these relationships, the owners will be motivated to implement SCMPs in their factories to improve competitiveness and OP. In addition to obtaining responses, the paucity of available literature in the context of the Bangladesh RMG industry on the research interest acted as a limitation. Further research on implementing SCMPs in the industry to encourage policymakers, owners, and other stakeholders is a potential future undertaking.

Limitations and Recommendations for Future Research

This study explored four core supply chain management practices (SCMPs), lean practices (LPs), customer relationship management (CRM), use of information technology (UIT), and quality information sharing (QIS), and their contribution to operational performance (OP) within the context of Bangladesh’s ready-made garment (RMG) industry. While the findings offer valuable insights, several limitations should be acknowledged. First, the study’s scope was limited to the selected SCMP variables, excluding other influential practices such as supplier collaboration, risk management, or sustainability initiatives. Future research could expand the framework to incorporate these dimensions for a more comprehensive understanding. Second, operational performance (OP) was measured using five key metrics, which, while relevant, do not fully capture the multi-dimensional nature of operational success. Future studies may consider a broader or more industry-specific set of performance indicators. Additionally, this study’s structural model was developed and tested using data exclusively from the Bangladeshi RMG industry. As such, the findings may reflect country-specific factors and may not be generalizable to other regional or global contexts. Future research should consider validating the model across different countries or industries to enhance the external validity and broader applicability of the results.

To strengthen the global competitiveness of Bangladesh’s RMG industry, regulatory bodies like the Ministry of Commerce and BGMEA should support the adoption of SCMPs through policies, incentives, and training programs, such as tax benefits for investments in ERP, AI, or lean systems. Academic research should further explore the long-term impact of SCMPs using longitudinal and cross-country studies, particularly in similar emerging economies or similar industries such as India or Vietnam. Industry stakeholders—including factory owners, managers, and labor groups—should jointly promote awareness, training, and infrastructure improvements to enhance supply chain efficiency and workplace standards. Together, these efforts can help to build a more resilient and high-performing RMG sector. In this regard, future studies could explore how technologies, including enterprise resources planning (ERP), the blockchain, and AI-driven forecasting, enhance visibility, traceability, resilience, risk mitigation, and sustainability of the supply chain of the RMG industry of Bangladesh. Also, future research should focus on the challenges and influencing factors of supply chain management practices for improving the operational performance of the Bangladesh RMG industry. Additionally, future research may consider applying this research model to other industries that require dynamic and adaptive supply chain strategies.

Author Contributions

Conceptualization, M.M.H.S. and A.H.M.Y.C.; methodology, A.H.M.Y.C.; software, S.C.T.; validation, M.M.H.S., A.H.M.Y.C. and S.C.T.; formal analysis, S.C.T.; investigation, M.M.H.S., A.C. and A.H.M.Y.C.; resources, M.M.H.S. and A.H.M.Y.C.; data curation, S.C.T. and M.M.H.S.; writing—original draft preparation, M.M.H.S., S.C.T. and A.H.M.Y.C.; writing—review and editing, M.F.F., M.M.H.S. and A.H.M.Y.C.; visualization, M.F.F. and M.M.H.S.; supervision, M.F.F. and A.C.; project administration, M.F.F. and M.M.H.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the ethical standards of the Hungarian University of Agriculture and Life Sciences. Ethical approval was obtained from the Interim Ethical Committee of the Doctoral School of Economic and Regional Sciences at its meeting on 26 February 2025 (Case No. 4/2025).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to privacy and ethical reasons.

Acknowledgments

We thank the Hungarian University of Agriculture and Life Sciences, Doctoral School of Economic and Regional Sciences for their support to this research.

Conflicts of Interest

All authors declare no conflicts of interest.

Appendix A

| Survey Questionnaire | |||||

| Please answer the following questions by marking “√” in the appropriate box: | |||||

| Job Title/Position: | |||||

| General Manager | |||||

| Plant Manager | |||||

| Production/Operations Manager | |||||

| Supply Chain Manager | |||||

| Assistant Supply Chain Manager | |||||

| Inventory Manager | |||||

| Merchandiser | |||||

| IT Manager | |||||

| Others | |||||

| Your Work Experience: | |||||

| Above 10 years | |||||

| 6–10 years | |||||

| 4–6 years | |||||

| 2–4 Years | |||||

| Below 2 Years | |||||

| Number of employees in your company: | |||||

| Over 20,000 | |||||

| 15,000–20,000 | |||||

| 10,000–15,000 | |||||

| 5000–10,000 | |||||

| 1000–5000 | |||||

| Number of lines in your company: | |||||

| Over 35 lines | |||||

| 25–35 lines | |||||

| 15–25 lines | |||||

| 5–15 Lines | |||||

| Below 5 Lines | |||||

| What is the age of the supply chain department of your organization? | |||||

| Above 10 years | |||||

| 6–10 years | |||||

| 4–6 years | |||||

| 2–4 Years | |||||

| Below 2 Years | |||||

| Supply Chain Management Practice: Customer Relationship Management Completely agree = 5, agree = 4, neutral = 3, Disagreed = 2, Completely disagree = 1 | |||||

| 1 | 2 | 3 | 4 | 5 | |

| There is effective management of customer complaints | |||||

| Customers have helped the Organization in the preparation of specifications. | |||||

| A long-term relationship with customers improves customer satisfaction | |||||

| Meetings are frequently held between customers and the firm’s management. | |||||

| Customers help with clear instructions about new product development | |||||

| Supply Chain Management Practice: Quality of Information Sharing Completely agree = 5, agree = 4, neutral = 3, Disagreed = 2, Completely disagree = 1 | |||||

| There is efficient internal communication. | |||||

| There is an adequacy of IT systems throughout the supply chain. | |||||

| Exchange of information between suppliers and the Organization is reliable. | |||||

| Data is shared between the organization and the suppliers to enhance productivity | |||||

| There is an automated ordering system for major suppliers | |||||

| Supply Chain Management Practice: Lean Practices Completely agree = 5, agree = 4, neutral = 3, Disagreed = 2, Completely disagree = 1 | |||||

| Your organization is focused on value creation. | |||||

| Your organization eliminates any waste or defects during the production process. | |||||

| Your organization follows 5S (Sort, Straighten, Shine, Standardize, Sustain) or JIT (just-in-time) to eliminate wastes. | |||||

| You use quality control tools like Pareto Chart, Fish-Bone Diagram, Histogram, Control Charts, Scatter Diagram, etc. | |||||

| Your organization follows specific processes to complete orders in the shortest possible time. | |||||

| Supply Chain Management Practice: Use of IT Completely agree = 5, agree = 4, neutral = 3, Disagreed = 2, Completely disagree = 1 | |||||

| Your organization encourages the use of technology | |||||

| Your company uses Electronic Data Interchange (EDI) | |||||

| Your organization is constantly updated with the latest information technology | |||||

| Managers of your company have sound knowledge of IT | |||||

| Use of software like ERP, inventory management system, etc. is common in your organization | |||||

| Please indicate the degree to which you agree with the following statements concerning your Company’s operational performance Completely agree = 5, agree = 4, neutral = 3, Disagreed = 2, Completely disagree = 1 | |||||

| Our Company requires less Lead Time compared to our competitors for delivering products. | |||||

| Our Company strives to reduce manufacturing costs, providing benefits to our buyers. | |||||

| Our Company maintains a very Low Level of Inventory through efficient planning. | |||||

| Our Company ensures Improved Product Quality for the buyers. | |||||

| Our Company consistently maintains the Delivery Schedule | |||||

| If you have any other comments, please write here. | |||||

References

- Ali, B.J.A.; Alawamleh, H.A.; Allahham, M.I.O.; Alsaraireh, J.M.; Al-Zyadat, A.T.; Badadwa, A.A.H. Integration of Supply Chains and Operational Performance: The Moderating Effects of Knowledge Management. Inf. Sci. Lett. 2022, 11, 1069–1076. [Google Scholar] [CrossRef]

- Chen, Z.; Hammad, A.W. Mathematical modelling and simulation in construction supply chain management. Autom. Constr. 2023, 156, 105147. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Li, G.; Xu, J. Sustainable supply chain management practices and performance: The moderating effect of stakeholder pressure. Humanit. Soc. Sci. Commun. 2025, 12, 1–12. [Google Scholar] [CrossRef]

- Fu, Q.; Rahman, A.A.A.; Jiang, H.; Abbas, J.; Comite, U. Sustainable Supply Chain and Business Performance: The Impact of Strategy, Network Design, Information Systems, and Organizational Structure. Sustainability 2022, 14, 1080. [Google Scholar] [CrossRef]

- Moktadir, A.; Mahmud, Y.; Banaitis, A.; Sarder, T.; Khan, M.R. Key performance indicators for adopting sustainability practices in footwear supply chains. E+M Èkon. Manag. 2021, 24, 197–213. [Google Scholar] [CrossRef]

- Bag, S. Restorative supply chain practices in a circular economy and supply chain sustainability performance: The moderating effect of the perceived professional status of supply chain managers. Benchmarking Int. J. 2025, 32, 166–193. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Hasan, M.A. Exploring the Intricate Future of Bangladesh in the Context of Regional Geopolitical Dynamics. Outl. Glob. Transform. Politi. Econ. Law 2025, 17, 110–127. [Google Scholar] [CrossRef]

- Wang, X.; Zhuang, J.; Peng, Q.; Li, Y. A general strategy for nanocrystal synthesis. Nature 2005, 437, 121–124. [Google Scholar] [CrossRef]

- Al-Rawashdeh, O.M.; Jawabreh, O.; Ali, B.J.A. Supply Chain Management and Organizational Performance: The Moderating Effect of Supply Chain Complexity. Inf. Sci. Lett. 2023, 12, 1673–1684. Available online: https://digitalcommons.aaru.edu.jo/isl/vol12/iss3/50/ (accessed on 28 May 2025).

- The Balanced Scorecard—Measures that Drive Performance. Available online: https://hbr.org/1992/01/the-balanced-scorecard-measures-that-drive-performance-2 (accessed on 21 July 2025).

- Zahara, Z.; Muslimin, M.; Rumijati, A.; Rony, Z.T. Competitive Advantage as Mediating Role to Enhance MSMES Performance. J. Small Bus. Strat. 2024, 34, 109–117. [Google Scholar] [CrossRef]

- Sutanto, J.E. An Empirical of Supply Chain Management Strategy as Mediation on Organizational and Operation Performance: A Study on Indonesia’s Retail Shops’. Int. J. Supply Chain Manag. 2021, 10, 81–94. Available online: https://ojs.excelingtech.co.uk/index.php/IJSCM/article/view/5828 (accessed on 28 May 2025).

- Hani, J.S.B. The moderating role of lean operations between supply chain integration and operational performance in Saudi manufacturing organizations. Uncertain Supply Chain Manag. 2021, 9, 169–178. [Google Scholar] [CrossRef]

- Abu Jahed, M.; Quaddus, M.; Suresh, N.C.; Salam, M.A.; Khan, E.A. Direct and indirect influences of supply chain management practices on competitive advantage in fast fashion manufacturing industry. J. Manuf. Technol. Manag. 2022, 33, 598–617. [Google Scholar] [CrossRef]

- El-Garaihy, W.H.; Badawi, U.A.; Seddik, W.A.S.; Torky, M.S. Design, building and validating a measuring scale for the supply chain management practices of industrial organizations by assessing their efficiency on SCM measures. Uncertain Supply Chain Manag. 2022, 10, 49–68. [Google Scholar] [CrossRef]

- Hwihanus, H.; Wijaya, O.Y.A.; Nartasari, D.R. The role of supply chain management on Indonesian small and medium enterprise competitiveness and performance. Uncertain Supply Chain Manag. 2022, 10, 109–116. [Google Scholar] [CrossRef]

- Ikhwana, A.; Dianti, S. The Influence of Information Technology and SCM on Competitive Advantage to Improve MSMEs Performance. Int. J. Comput. Inf. Syst. 2022, 3, 6–11. [Google Scholar] [CrossRef]

- Green, K.W.; Inman, R.A.; Sower, V.E.; Zelbst, P.J. Impact of JIT, TQM and green supply chain practices on environmental sustainability. J. Manuf. Technol. Manag. 2019, 30, 26–47. [Google Scholar] [CrossRef]

- Phan, A.C.; Nguyen, H.A.; Trieu, P.D.; Matsui, Y. Impact of supply chain quality management practices on operational performance: Empirical evidence from manufacturing companies in Vietnam. Supply Chain Manag. Int. J. 2019, 24, 855–871. [Google Scholar] [CrossRef]

- The Role of Critical Success Factors of Knowledge Stations in the Development of Local Communities in Jordan: A Managerial Perspective. Available online: https://www.abacademies.org/articles/the-role-of-critical-success-factors-of-knowledge-stations-in-the-development-of-local-communities-in-jordan-a-managerial-perspect-9764.html (accessed on 21 July 2025).

- Karamouz, S.S.; Kahnali, R.A.; Ghafournia, M. Supply chain quality management performance measurement: Systematic review. Int. J. Qual. Reliab. Manag. 2021, 38, 484–504. [Google Scholar] [CrossRef]

- Lal, K. Information Technology and Exports: A Case Study of Indian Garments Manufacturing Enterprises. Discuss. Pap. 1999, 15, 1–24. [Google Scholar] [CrossRef]

- Tarigan, Z.J.H.; Siagian, H. The Effects of Strategic Planning, Purchasing Strategy and Strategic Partnership on Operational Performance. 2021. Available online: http://growingscience.com/uscm/Vol9/uscmv9no2.html (accessed on 21 July 2025).

- Sharma, S.; Modgil, S. TQM, SCM and operational performance: An empirical study of Indian pharmaceutical industry. Bus. Process. Manag. J. 2020, 26, 331–370. [Google Scholar] [CrossRef]

- Ellram, L.M.; Zsidisin, G.A.; Siferd, S.P.; Stanly, M.J. The Impact of Purchasing and Supply Management Activities on Corporate Success. J. Supply Chain Manag. 2002, 38, 4–17. [Google Scholar] [CrossRef]

- Li, S.; Ragu-Nathan, B.; Ragu-Nathan, T.; Rao, S.S. The impact of supply chain management practices on competitive advantage and organizational performance. Omega 2006, 34, 107–124. [Google Scholar] [CrossRef]

- Zaman, S. Researching the garment sector in Bangladesh: Fieldwork challenges and responses. In Field Guide for Research in Community Settings; Edward Elgar Publishing: Cheltenham, UK, 2021. [Google Scholar]

- Ali, M.; Rahman, S.M.; Frederico, G.F. Capability components of supply chain resilience for readymade garments (RMG) sector in Bangladesh during COVID-19. Mod. Supply Chain Res. Appl. 2021, 3, 127–144. [Google Scholar] [CrossRef]

- Agarwal, S.; Tyagi, M.; Garg, R.K. Restorative measures to diminish the covid-19 pandemic effects through circular economy enablers for sustainable and resilient supply chain. J. Asia Bus. Stud. 2022, 16, 538–567. [Google Scholar] [CrossRef]

- Shahadat, M.M.H.; Chowdhury, A.H.M.Y.; Nathan, R.J.; Fekete-Farkas, M. Digital Technologies for Firms’ Competitive Advantage and Improved Supply Chain Performance. J. Risk Financ. Manag. 2023, 16, 94. [Google Scholar] [CrossRef]

- Barney, J.B. Is the resource-based “view” a useful perspective for strategic management research? Yes. Acad. Manag. Rev. 2001, 26, 41–56. [Google Scholar] [CrossRef]

- Epelbaum, F.M.B.; Martinez, M.G. The technological evolution of food traceability systems and their impact on firm sustainable performance: A RBV approach. Int. J. Prod. Econ. 2014, 150, 215–224. [Google Scholar] [CrossRef]

- Chavez, R.; Yu, W.; Jajja, M.S.S.; Song, Y.; Nakara, W. The relationship between internal lean practices and sustainable performance: Exploring the mediating role of social performance. Prod. Plan. Control. 2022, 33, 1025–1042. [Google Scholar] [CrossRef]

- Rahman, A.S.; Raju, V. Impact of Supply Chain Management (SCM) in Bangladesh Textile-Clothing Industry: Comprehending the Role of Sourcing. Spec. Ugdym. 2022, 1, 323–346. Available online: http://sumc.lt/index.php/se/article/view/37 (accessed on 21 July 2025).

- Fawcett, S.E.; Osterhaus, P.; Magnan, G.M.; Brau, J.C.; McCarter, M.W.; Croom, S. Information sharing and supply chain performance: The role of connectivity and willingness. Supply Chain Manag. Int. J. 2007, 12, 358–368. [Google Scholar] [CrossRef]

- Eckstein, D.; Goellner, M.; Blome, C.; Henke, M. The performance impact of supply chain agility and supply chain adaptability: The moderating effect of product complexity. Int. J. Prod. Res. 2015, 53, 3028–3046. [Google Scholar] [CrossRef]

- Using the Balanced Scorecard as a Strategic Management System. Available online: https://hbr.org/2007/07/using-the-balanced-scorecard-as-a-strategic-management-system (accessed on 21 July 2025).

- Bhagwat, R.; Sharma, M.K. Performance measurement of supply chain management: A balanced scorecard approach. Comput. Ind. Eng. 2007, 53, 43–62. [Google Scholar] [CrossRef]

- Diamantopoulos, A.; Riefler, P.; Roth, K.P. Advancing formative measurement models. J. Bus. Res. 2008, 61, 1203–1218. Available online: https://ideas.repec.org/a/eee/jbrese/v61y2008i12p1203-1218.html (accessed on 21 July 2025). [CrossRef]

- De Muylder, C.; La Falce, J.L.; Guerra, J.R.L.; Viana, J.A.; Reinhold, O. Model of acceptance and use of social customer relationship management in micro and small enterprises. Int. J. Innov. 2025, 13, e27096. [Google Scholar] [CrossRef]

- Ijomah, T.I.; Nwabekee, U.S.; Agu, E.E.; Abdul-Azeez, O.Y. The impact of customer relationship management (CRM) tools on sales growth and customer loyalty in emerging markets. Int. J. Manag. Entrep. Res. 2024, 6, 2964–2988. [Google Scholar] [CrossRef]

- Rahman, M.S.; Bag, S.; Gupta, S.; Sivarajah, U. Technology readiness of B2B firms and AI-based customer relationship management capability for enhancing social sustainability performance. J. Bus. Res. 2023, 156, 113525. [Google Scholar] [CrossRef]

- Herman, L.E.; Sulhaini, S.; Farida, N. Electronic Customer Relationship Management and Company Performance: Exploring the Product Innovativeness Development. J. Relatsh. Mark. 2021, 20, 1–19. [Google Scholar] [CrossRef]

- Saura, J.R.; Ribeiro-Soriano, D.; Palacios-Marqués, D. Setting B2B digital marketing in artificial intelligence-based CRMs: A review and directions for future research. Ind. Mark. Manag. 2021, 98, 161–178. [Google Scholar] [CrossRef]

- Chatterjee, S.; Rana, N.P.; Tamilmani, K.; Sharma, A. The effect of AI-based CRM on organization performance and competitive advantage: An empirical analysis in the B2B context. Ind. Mark. Manag. 2021, 97, 205–219. [Google Scholar] [CrossRef]

- Coltman, T.; Devinney, T.M.; Midgley, D.F. Customer relationship management and firm performance. J. Inf. Technol. 2011, 26, 205–219. [Google Scholar] [CrossRef]

- Alshurideh, M.T.; Al Kurdi, B.; Alhamad, A.; Hamadneh, S.; Alzoubi, H.M.; Ahmad, A. Does social customer relationship management (SCRM) affect customers’ happiness and retention? A service perspective. Uncertain Supply Chain Manag. 2023, 11, 277–288. [Google Scholar] [CrossRef]

- Flynn, B.B.; Flynn, E.J. Synergies between supply chain management and quality management: Emerging implications. Int. J. Prod. Res. 2005, 43, 3421–3436. [Google Scholar] [CrossRef]

- Holweg, M. The genealogy of lean production. J. Oper. Manag. 2007, 25, 420–437. [Google Scholar] [CrossRef]

- Garcia-Buendia, N.; Kristensen, T.B.; Moyano-Fuentes, J.; Maqueira-Marín, J.M. Performance measurement of lean supply chain management: A balanced scorecard proposal. Prod. Plan. Control. 2024, 35, 618–638. [Google Scholar] [CrossRef]

- Nasiri, M.; Saunila, M.; Ukko, J. Digital orientation, digital maturity, and digital intensity: Determinants of financial success in digital transformation settings. Int. J. Oper. Prod. Manag. 2022, 42, 274–298. [Google Scholar] [CrossRef]

- Sousa-Zomer, T.; Neely, A.; Martinez, V. Digital transforming capability and performance: A microfoundational perspective. Int. J. Oper. Prod. Manag. 2020, 40, 1095–1128. [Google Scholar] [CrossRef]

- Rahman, N.A.A.; Sharif, S.M.; Esa, M.M. Lean Manufacturing Case Study with Kanban System Implementation. Procedia Econ. Financ. 2013, 7, 174–180. [Google Scholar] [CrossRef]

- Guo, D.; Mantravadi, S. The role of digital twins in lean supply chain management: Review and research directions. Int. J. Prod. Res. 2025, 63, 1851–1872. [Google Scholar] [CrossRef]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Flynn, B.B.; Schroeder, R.G.; Flynn, E. World class manufacturing: An investigation of Hayes and Wheelwright’s foundation. J. Oper. Manag. 1999, 17, 249–269. [Google Scholar] [CrossRef]

- Powell, D.J.; Coughlan, P. Rethinking lean supplier development as a learning system. Int. J. Oper. Prod. Manag. 2020, 40, 921–943. [Google Scholar] [CrossRef]

- Cua, K.O.; McKone, K.E.; Schroeder, R.G. Relationships between implementation of TQM, JIT, and TPM and manufacturing performance. J. Oper. Manag. 2001, 19, 675–694. [Google Scholar] [CrossRef]

- Duarte, S.; Cruz-Machado, V. Modelling lean and green: A review from business models. Int. J. Lean Six Sigma 2013, 4, 228–250. [Google Scholar] [CrossRef]

- Imai, M. Gemba Kaizen: A Commonsense Approach to a Continuous Improvement Strategy, 2nd ed.; McGraw Hill Professional: New York, NY, USA, 2018. [Google Scholar]

- Tortorella, G.L.; Fettermann, D.C. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Netland, T.H.; Ferdows, K. The S-Curve Effect of Lean Implementation. Prod. Oper. Manag. 2016, 25, 1106–1120. [Google Scholar] [CrossRef]

- Hines, P.; Holweg, M.; Rich, N. Learning to evolve: A review of contemporary lean thinking. Int. J. Oper. Prod. Manag. 2004, 24, 994–1011. [Google Scholar] [CrossRef]

- Rahman, S.; Laosirihongthong, T.; Sohal, A.S. Impact of lean strategy on operational performance: A study of Thai manufacturing companies. J. Manuf. Technol. Manag. 2010, 21, 839–852. [Google Scholar] [CrossRef]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Lean, green and resilient practices influence on supply chain performance: Interpretive structural modeling approach. Int. J. Environ. Sci. Technol. 2015, 12, 15–34. [Google Scholar] [CrossRef]

- Prashar, A. The interplay of lean practices and digitalization on organizational learning systems and operational performance. Int. J. Prod. Econ. 2024, 270, 109192. [Google Scholar] [CrossRef]

- Panigrahi, S.; Al Ghafri, K.K.; Al Alyani, W.R.; Khan, M.W.A.; Al Madhagy, T.; Khan, A. Lean manufacturing practices for operational and business performance: A PLS-SEM modeling analysis. Int. J. Eng. Bus. Manag. 2023, 15, 18479790221147864. [Google Scholar] [CrossRef]

- Davenport, T.H.; Short, J.E. The New Industrial Engineering: Information Technology and Business Process Redesign. MIT Sloan Management Review. July 1990. Available online: https://sloanreview.mit.edu/article/the-new-industrial-engineering-information-technology-and-business-process-redesign/ (accessed on 21 July 2025).

- Laudon, K.C.; Laudon, J.P. Manajemen Information System: Managing the Digital Firm; Pearson Educación: London, UK, 2014. [Google Scholar]

- AL-Khatib, A.W. The impact of Industry 4.0 capabilities on operational performance: The mediating effect of supply chain ambidexterity. TQM J. 2025, 37, 125–149. [Google Scholar] [CrossRef]

- Ruan, W.; Sheng, Q.Z.; Yao, L.; Li, X.; Falkner, N.J.; Yang, L. Device-free human localization and tracking with UHF passive RFID tags: A data-driven approach. J. Netw. Comput. Appl. 2018, 104, 78–96. [Google Scholar] [CrossRef]

- Weill, P. The relationship between investment in information technology and firm performance: A study of the valve manufacturing sector. Inf. Syst. Res. 1992, 3, 307–333. [Google Scholar] [CrossRef]