Material Flow Analysis for Demand Forecasting and Lifetime-Based Inflow in Indonesia’s Plastic Bag Supply Chain

Abstract

1. Introduction

2. Theoretical Background

2.1. Material Flow Analysis (MFA) Applications in Sustainability

2.2. Supply Chain Management Sustainability and Demand Forecasting

2.3. Lifetime-Based Inflow Management in Supply Chain Sustainability

2.4. Integration of MFA with SC Sustainability: Existing Studies and Limitations

2.5. Research Gap and Contribution

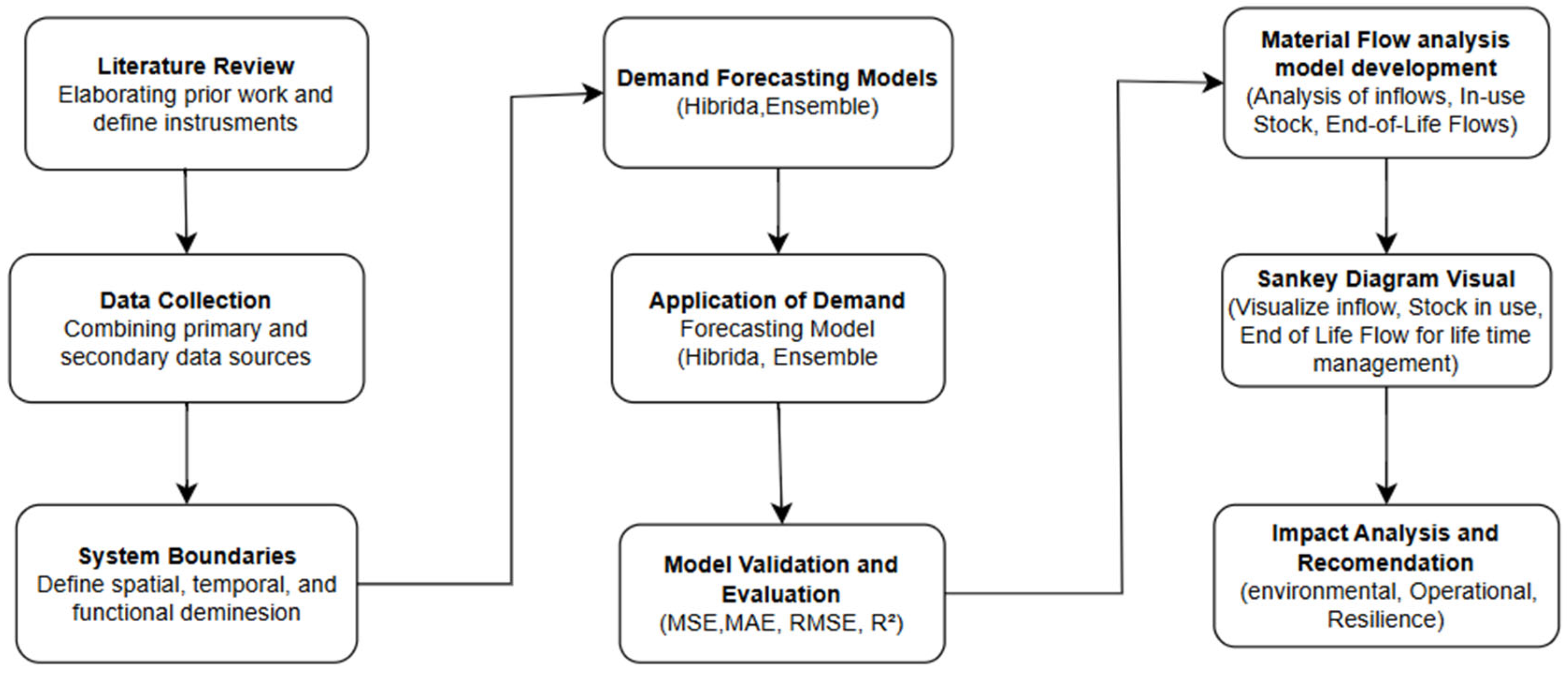

3. Research Method

3.1. Data Collection Methods

3.2. System Boundaries

3.3. Machine Learning for Demand Prediction

3.4. Demand Forecasting Model

3.5. MFA as a Modeling and Simulation Tool

- Top-Down Polymer-Based MFA ApproachThe study applies a top-down polymer-based MFA framework to map and quantify the flow of plastic shopping bags throughout the supply chain. This approach relies on aggregate sectoral data, which is then disaggregated into specific polymer streams, such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE), using market composition ratios and product-specific material data. By leveraging polymer-level analysis, the study can identify material-specific inefficiencies, recycling bottlenecks, and environmental leakages. The top-down perspective allows the research to capture the entire system scope, from upstream resin production to midstream manufacturing and retail distribution, and ultimately to downstream waste management, recycling, incineration, or disposal. This polymer-focused approach strengthens the analysis by aligning it with international material flow reporting frameworks and ensuring the recommendations are relevant not only to operational practices but also to material efficiency and CE goals.

- MFA Scenario AnalysisTo strengthen the system analysis, the study develops MFA-specific scenarios that simulate the impact of material-system interventions on the overall mass balance, circularity, and sustainability performance. These scenarios complement the operational SCM scenarios by focusing directly on the physical material dynamics and polymer flows.

- The polymer substitution scenario, where a defined percentage (e.g., 20%) of virgin HDPE or LDPE inputs is replaced with recycled or bio-based alternatives, assessing the potential reduction in upstream resource extraction and dependency;

- The closed-loop recycling enhancement scenario, modeling an increase in domestic recycling yields (e.g., from 10% to 25%), thereby reducing the demand for virgin resin inputs and lowering end-of-life waste generation;

- The collection and sorting improvement scenario, simulating the impact of higher mechanical sorting and collection efficiencies, especially for thin-film plastics, which are typically under-captured in conventional waste streams;

- The combined intervention scenario, integrating multiple levers (substitution, recycling enhancement, and improved collection) under varying production growth or reduction assumptions, to project a best-case pathway toward circularity goals.

3.6. Impact Analysis and Recommendations

- Environmental Impact EvaluationUsing MFA outputs, the volume of plastic entering, being used, and ending up as waste is calculated. This analysis identifies the contribution of plastic shopping bags to waste accumulation and the potential for impact reduction through enhanced reuse and recycling practices. The evaluation is based on principles of industrial ecology and the CE framework [60].

- Operation Supply Chain Impact EvaluationIn this study, supply chain performance is evaluated across three critical dimensions: efficiency, stability, and adaptability. Efficiency is measured by assessing the material flow through the input–output ratio, which reflects how effectively resources are converted into final products [61]. Stability pertains to the consistency of in-use stock levels and the associated risks of product scarcity, highlighting the importance of maintaining adequate inventory to ensure service continuity [62]. Lastly, adaptability refers to the supply chain’s responsiveness to demand fluctuations, particularly in alignment with predictions generated by the forecasting model, which is crucial for mitigating the impact of market volatility [63]. These dimensions collectively provide a comprehensive framework for analyzing supply chain performance under dynamic conditions.

- Supply Chain Resilience EvaluationSupply chain resilience in this study is evaluated through sensitivity analysis using simulation scenarios that incorporate demand fluctuations and plastic-related policy changes. This approach assesses the system’s capacity to sustain operations under shifting market conditions, providing insights into its adaptive robustness [64].

- where

- 5. Model XGBoost:

- is the predicted value for observation i;

- is the total number of trees;

- is regression tree , a member of the function space ;

- is the input feature vector.

- 6. Mean Squared Error (MSE):

- is the predicted value for the i-th observation;

- is the actual (true) value for the i-th observation;

- is the total number of observations.

- 7. Mean Absolute Error (MAE):

- 8. is the predicted value for the i-th observation;

- 9. is the actual (true) value for the i-th observation;

- 10. is the total number of observations.

- 11. Root Mean Squared Error (RMSE):

- RMSE is derived from the MSE formula by taking its square root;

- Useful for interpreting errors in the same units as the original data.

- 12. R-squared (R2):

- is the predicted value;

- is the actual value;

- is the mean of the actual values;

- Measures the proportion of variance explained by the model.

- 13. Mass Balance Principle:

- Input refers to all material flows entering the system (e.g., raw materials and intermediate goods).

- Output includes all material flows exiting the system (e.g., products, emissions, and waste).

- or accumulation represents the net change in material stock within the system over a defined period. It can be positive (stock increase) or negative (stock depletion).

4. Results and Discussion

4.1. Forecasting of Plastic Bag Material Flows in 2025

4.2. Model Performance and Accuracy Evaluation

4.3. Evaluation Metrics

4.4. Model Performance Across Material Flow Components

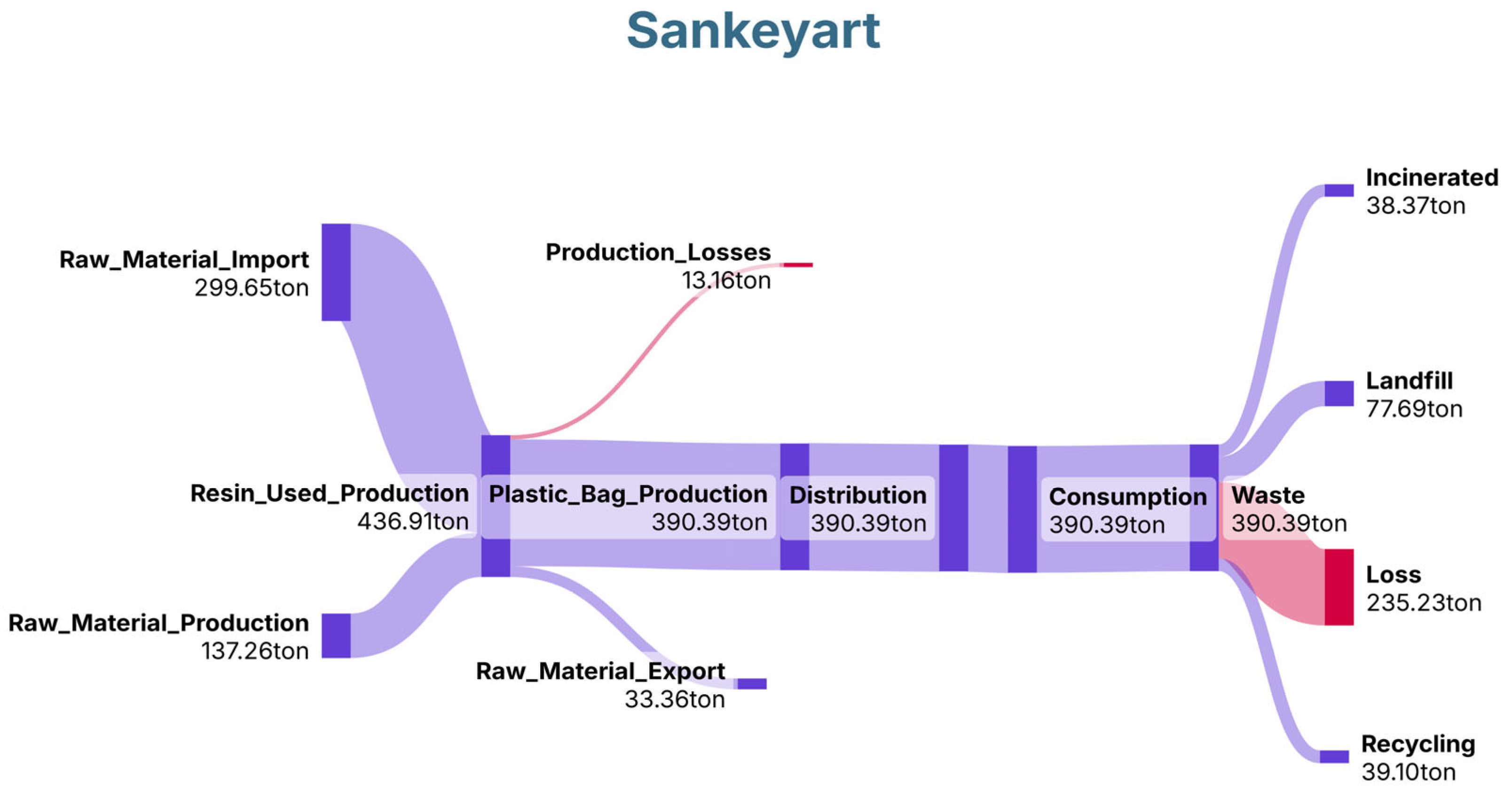

4.5. Material Flow Analysis (MFA) of Shopping Plastic Bags

4.6. Overview of the Plastic Bag System

4.7. Sectoral and Flow-Specific Analysis

4.8. Scenario Analysis

4.9. Theoretical Implications and Integration

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Grover, V.; Dogra, M.M.; Sahu, M.D.; Nandal, M.; Gnaguly, A. Supply Chain Management Strategy and Practices: Traditional vs. Advanced. In Blockchain, IoT, and AI Technologies for Supply Chain Management: Apply Emerging Technologies to Address and Improve Supply Chain Management; Grover, D.V., Balusamy, D.B.B., Milanova, D.M., Felix, D.A.Y., Eds.; Apress: Berkeley, CA, USA, 2024; pp. 1–43. [Google Scholar]

- Kužmarskytė, K. Relations Between Life Cycle Assessment, Material Flow Analysis, and Dynamic Business Capabilities for Circular Economy Implementation in Companies; Vilniaus Universitetas: Vilnius, Lithuania, 2023. [Google Scholar]

- Abu-Bakar, H.; Charnley, F. Developing a Strategic Methodology for Circular Economy Roadmapping: A Theoretical Framework. Sustainability 2024, 16, 6682. [Google Scholar] [CrossRef]

- Hossain, M.U.; Thomas Ng, S. Influence of waste materials on buildings’ life cycle environmental impacts: Adopting resource recovery principle. Resour. Conserv. Recycl. 2019, 142, 10–23. [Google Scholar] [CrossRef]

- Nagashima, M.; Wehrle, F.T.; Kerbache, L.; Lassagne, M. Impacts of adaptive collaboration on demand forecasting accuracy of different product categories throughout the product life cycle. Supply Chain Manag. Int. J. 2015, 20, 415–433. [Google Scholar] [CrossRef]

- Rehman, M.; Petrillo, A.; Ortíz-Barrios, M.; Forcina, A.; Baffo, I.; De Felice, F. Sustainable fashion: Mapping waste streams and life cycle management. J. Clean. Prod. 2024, 444, 141279. [Google Scholar] [CrossRef]

- Faiqoh, L.; Fahri, H.M.; Masudin, I.; Restuputri, D.P. Exploring Blockchain’s Role in Supply Chain: Bibliometric Analysis. In Sustainable Advanced Manufacturing and Logistics in ASEAN; Sakalayen, Q.M.H., Almunawar, M.N., Yeakub Ali, M., Eds.; IGI Global: Hershey, PA, USA, 2025; pp. 229–248. [Google Scholar]

- Islam, M.T.; Huda, N. Material flow analysis (MFA) as a strategic tool in E-waste management: Applications, trends and future directions. J. Environ. Manag. 2019, 244, 344–361. [Google Scholar] [CrossRef] [PubMed]

- Withanage, S.V.; Habib, K. Life Cycle Assessment and Material Flow Analysis: Two Under-Utilized Tools for Informing E-Waste Management. Sustainability 2021, 13, 7939. [Google Scholar] [CrossRef]

- Allwood, J.M.; Gutowski, T.G.; Serrenho, A.C.; Skelton, A.C.; Worrell, E. Industry 1.61803: The transition to an industry with reduced material demand fit for a low carbon future. Philos. Trans. R. Soc. A: Math. Phys. Eng. Sci. 2017, 375, 20160361. [Google Scholar] [CrossRef] [PubMed]

- Moretti, A.; Ivan, H.L.; Skvaril, J. A review of the state-of-the-art wastewater quality characterization and measurement technologies. Is the shift to real-time monitoring nowadays feasible? J. Water Process Eng. 2024, 60, 105061. [Google Scholar] [CrossRef]

- Berkhout, F.; Howes, R. The adoption of life-cycle approaches by industry: Patterns and impacts1. Resour. Conserv. Recycl. 1997, 20, 71–94. [Google Scholar] [CrossRef]

- Seyedan, M.; Mafakheri, F. Predictive big data analytics for supply chain demand forecasting: Methods, applications, and research opportunities. J. Big Data 2020, 7, 53. [Google Scholar] [CrossRef]

- Li, Y. Analysis and Research on Intelligent Logistics Data under Internet of Things and Blockchain. Appl. Artif. Intell. 2024, 38, 2413824. [Google Scholar] [CrossRef]

- Shekhar, A.; Farlessyost, W.; Singh, S. Dynamics and Resilience for Design of Sustainable Processes, Industrial Networks and Supply Chains: Review and Perspective. ChemRxiv 2025. [Google Scholar] [CrossRef]

- Aljohani, A. Predictive Analytics and Machine Learning for Real-Time Supply Chain Risk Mitigation and Agility. Sustainability 2023, 15, 15088. [Google Scholar] [CrossRef]

- Pasupuleti, V.; Thuraka, B.; Kodete, C.S.; Malisetty, S. Enhancing Supply Chain Agility and Sustainability through Machine Learning: Optimization Techniques for Logistics and Inventory Management. Logistics 2024, 8, 73. [Google Scholar] [CrossRef]

- Hülagü, S.; Dullaert, W.; Eruguz, A.S.; Heijungs, R.; Inghels, D. Integrating life cycle assessment into supply chain optimization. PLoS ONE 2025, 20, e0316710. [Google Scholar] [CrossRef]

- Hazen, B.T.; Russo, I.; Confente, I.; Pellathy, D. Supply chain management for circular economy: Conceptual framework and research agenda. Int. J. Logist. Manag. 2021, 32, 510–537. [Google Scholar] [CrossRef]

- Allesch, A.; Brunner, P.H. Material flow analysis as a decision support tool for waste management: A literature review. J. Ind. Ecol. 2015, 19, 753–764. [Google Scholar] [CrossRef]

- Baars, J.; Rajaeifar, M.A.; Heidrich, O. Quo vadis MFA? Integrated material flow analysis to support material efficiency. J. Ind. Ecol. 2022, 26, 1487–1503. [Google Scholar] [CrossRef]

- Nakamura, S. A Practical Guide to Industrial Ecology by Input-Output Analysis; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Khan, M.T.; Pettenella, D.; Masiero, M. Material Flow Analysis of the Wood-Based Value Chains in a Rapidly Changing Bioeconomy: A Literature Review. Forests 2024, 15, 2112. [Google Scholar] [CrossRef]

- Sevigné-Itoiz, E.; Gasol, C.M.; Rieradevall, J.; Gabarrell, X. Methodology of supporting decision-making of waste management with material flow analysis (MFA) and consequential life cycle assessment (CLCA): Case study of waste paper recycling. J. Clean. Prod. 2015, 105, 253–262. [Google Scholar] [CrossRef]

- Streeck, J.; Wieland, H.; Pauliuk, S.; Plank, B.; Nakajima, K.; Wiedenhofer, D. A review of methods to trace material flows into final products in dynamic material flow analysis: Comparative application of six methods to the United States and EXIOBASE3 regions, Part 2. J. Ind. Ecol. 2023, 27, 457–475. [Google Scholar] [CrossRef]

- Gbaja, C. Next-Generation Edge Computing: Leveraging AI-Driven IoT for Autonomous, Real-Time Decision Making and Cybersecurity. J. Artif. Intell. Gen. Sci. 2024, 5, 357–371. [Google Scholar] [CrossRef]

- Li, C.; Mogollón, J.M.; Tukker, A.; Dong, J.; von Terzi, D.; Zhang, C.; Steubing, B. Future material requirements for global sustainable offshore wind energy development. Renew. Sustain. Energy Rev. 2022, 164, 112603. [Google Scholar] [CrossRef]

- Seetharaman, A.; Sreenivasan, J.; Bathamenadan, R.; Sudha, R. The impact of Just-in-Time on costing. Int. J. Manag. Enterp. Dev. 2007, 4, 635–651. [Google Scholar] [CrossRef]

- Kara, S.; Hauschild, M.; Sutherland, J.; McAloone, T. Closed-loop systems to circular economy: A pathway to environmental sustainability? CIRP Ann. 2022, 71, 505–528. [Google Scholar] [CrossRef]

- Garrab, H.E.; Lemoine, D.; Lazrak, A.; Heidsieck, R.; Castanier, B. Predicting the reverse flow of spare parts in a complex supply chain: Contribution of hybrid machine learning methods in an industrial context. Int. J. Logist. Syst. Manag. 2023, 45, 131–158. [Google Scholar] [CrossRef]

- Nweje, U.; Taiwo, M. Leveraging Artificial Intelligence for predictive supply chain management, focus on how AI-driven tools are revolutionizing demand forecasting and inventory optimization. Int. J. Sci. Res. Arch. 2025, 14, 230–250. [Google Scholar] [CrossRef]

- Masudin, I.; Alfarisi, S.; Suhartin, E.; Restuputri, D.P.; Shariff, S.S.R. Hotspot Identification for Improving Cane-Sugar Sustainable Supply Chain Through the Integration of Life Cycle Assessment and Value Stream Mapping. Process Integr. Optim. Sustain. 2025, 9, 605–624. [Google Scholar] [CrossRef]

- Millette, S.; Williams, E.; Hull, C.E. Materials flow analysis in support of circular economy development: Plastics in Trinidad and Tobago. Resour. Conserv. Recycl. 2019, 150, 104436. [Google Scholar] [CrossRef]

- Dzhuguryan, T.; Deja, A. Sustainable Waste Management for a City Multifloor Manufacturing Cluster: A Framework for Designing a Smart Supply Chain. Sustainability 2021, 13, 1540. [Google Scholar] [CrossRef]

- Hendriks, C.; Obernosterer, R.; Müller, D.; Kytzia, S.; Baccini, P.; Brunner, P.H. Material Flow Analysis: A tool to support environmental policy decision making. Case-studies on the city of Vienna and the Swiss lowlands. Local Environ. 2000, 5, 311–328. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M.A. A multiple objective optimization based QFD approach for efficient resilient strategies to mitigate supply chain vulnerabilities: The case of garment industry of Bangladesh. Omega 2015, 57, 5–21. [Google Scholar] [CrossRef]

- Bhambri, P.; Rani, S.; Khang, A. AI-driven Digital Twin and Resource Optimization in Industry 4.0 Ecosystem. In Intelligent Techniques for Predictive Data Analytics; Wiley-IEEE Press: Hoboken, NY, USA, 2024; pp. 47–69. [Google Scholar]

- Hader, M.; Tchoffa, D.; Mhamedi, A.E.; Ghodous, P.; Dolgui, A.; Abouabdellah, A. Applying integrated Blockchain and Big Data technologies to improve supply chain traceability and information sharing in the textile sector. J. Ind. Inf. Integr. 2022, 28, 100345. [Google Scholar] [CrossRef]

- Askar, R.; Karaca, F.; Salles, A.; Lukyanenko, A.; Cervantes Puma, G.C.; Tavares, V.; Khaidarova, A.; Nadaždi, A.; Pineda-Martos, R.; Díaz-Cabrera, J.M.; et al. Driving the Built Environment Twin Transition: Synergising Circular Economy and Digital Tools. In Circular Economy Design and Management in the Built Environment: A Critical Review of the State of the Art; Bragança, L., Griffiths, P., Askar, R., Salles, A., Ungureanu, V., Tsikaloudaki, K., Bajare, D., Zsembinszki, G., Cvetkovska, M., Eds.; Springer Nature Switzerland: Cham, Switzerland, 2025; pp. 459–505. [Google Scholar]

- Mageto, J. Big Data Analytics in Sustainable Supply Chain Management: A Focus on Manufacturing Supply Chains. Sustainability 2021, 13, 7101. [Google Scholar] [CrossRef]

- Papageorgiou, A.; Björklund, A.; Sinha, R. Applying material and energy flow analysis to assess urban metabolism in the context of the circular economy. J. Ind. Ecol. 2024, 28, 885–900. [Google Scholar] [CrossRef]

- Widiyanti, A.; Rancak, G.T.; Ramadan, B.S.; Hanaseta, E. Comprehensive literature review of material flow analysis (MFA) of plastics waste: Recent trends, policy, management, and methodology. J. Mater. Cycles Waste Manag. 2025, 27, 1–18. [Google Scholar] [CrossRef]

- Karuppiah, K.; Virmani, N.; Sindhwani, R. Toward a sustainable future: Integrating circular economy in the digitally advanced supply chain. J. Bus. Ind. Mark. 2024, 39, 2605–2619. [Google Scholar] [CrossRef]

- Karuppiah, K.; Sankaranarayanan, B.; Ali, S.M. Evaluating the challenges to Life Cycle Assessment using Best-Worst Method and Decision-Making Trial and Evaluation Laboratory. Environ. Prog. Sustain. Energy 2023, 42, e13991. [Google Scholar] [CrossRef]

- Pundir, A.K.; Jagannath, J.D.; Chakraborty, M.; Ganpathy, L. Technology Integration for Improved Performance: A Case Study in Digitization of Supply Chain with Integration of Internet of Things and Blockchain Technology. In Proceedings of the 2019 IEEE 9th Annual Computing and Communication Workshop and Conference (CCWC), Las Vegas, NV, USA, 7–9 January 2019; pp. 0170–0176. [Google Scholar]

- Zaghdaoui, H.; Jaegler, A.; Gondran, N.; Montoya-Torres, J. Material Flow Analysis to Evaluate Sustainability in Supply Chains. In Proceedings of the 20th World Congress The International Federation of Automatic Control, Toulouse, France, 9 July 2017. [Google Scholar]

- Cerchione, R.; Morelli, M.; Passaro, R.; Quinto, I. A critical analysis of the integration of life cycle methods and quantitative methods for sustainability assessment. Corp. Soc. Responsib. Environ. Manag. 2025, 32, 1508–1544. [Google Scholar] [CrossRef]

- Stafford, W.; Russo, V.; Nahman, A. A comparative cradle-to-grave life cycle assessment of single-use plastic shopping bags and various alternatives available in South Africa. Int. J. Life Cycle Assess. 2022, 27, 1213–1227. [Google Scholar] [CrossRef]

- Yang, S.; Yang, D.; Chen, J.; Zhao, B. Real-time reservoir operation using recurrent neural networks and inflow forecast from a distributed hydrological model. J. Hydrol. 2019, 579, 124229. [Google Scholar] [CrossRef]

- Schützenhofer, S.; Kovacic, I.; Rechberger, H.; Mack, S. Improvement of Environmental Sustainability and Circular Economy through Construction Waste Management for Material Reuse. Sustainability 2022, 14, 11087. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental management—Life cycle assessment—Requirements and guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Feizabadi, J. Machine learning demand forecasting and supply chain performance. Int. J. Logist. Res. Appl. 2022, 25, 119–142. [Google Scholar] [CrossRef]

- Mahin, M.P.R.; Shahriar, M.; Das, R.R.; Roy, A.; Reza, A.W. Enhancing Sustainable Supply Chain Forecasting Using Machine.Learning for Sales Prediction. Procedia Comput. Sci. 2025, 252, 470–479. [Google Scholar] [CrossRef]

- Hussain, F.; Hasanuzzaman, M.; Rahim, N.A. Multivariate machine learning algorithms for energy demand forecasting and load behavior analysis. Energy Convers. Manag. X 2025, 26, 100903. [Google Scholar] [CrossRef]

- Badulescu, Y.; Hameri, A.-P.; Cheikhrouhou, N. Evaluating demand forecasting models using multi-criteria decision-making approach. J. Adv. Manag. Res. 2021, 18, 661–683. [Google Scholar] [CrossRef]

- Sattar, M.U.; Dattana, V.; Hasan, R.; Mahmood, S.; Khan, H.W.; Hussain, S. Enhancing Supply Chain Management: A Comparative Study of Machine Learning Techniques with Cost–Accuracy and ESG-Based Evaluation for Forecasting and Risk Mitigation. Sustainability 2025, 17, 5772. [Google Scholar] [CrossRef]

- Koppiahraj, K.; Bathrinath, S.; Venkatesh, V.G.; Mani, V.; Shi, Y. Optimal sustainability assessment method selection: A practitioner perspective. Ann. Oper. Res. 2023, 324, 629–662. [Google Scholar] [CrossRef]

- Robert, U.A.; Leslie, W.A. A Handbook of Industrial Ecology; Edward Elgar Publishing Limited: Cheltenham, UK, 2004. [Google Scholar]

- Pernici, A.; Stancu, S.; Bălă, D.E.; Vulpe, M.-I. Measuring the Circular Economy Inside European Union, Using Sankey’s Diagram of Material Flows and Fuzzy Clustering. In Rethinking Business for Sustainable Leadership in a VUCA World; Springer: Cham, Switzerland, 2024; pp. 263–282. [Google Scholar]

- Ioppolo, G.; Cucurachi, S.; Salomone, R.; Shi, L.; Yigitcanlar, T. Integrating strategic environmental assessment and material flow accounting: A novel approach for moving towards sustainable urban futures. Int. J. Life Cycle Assess. 2018, 24, 1269–1284. [Google Scholar] [CrossRef]

- Wang, P.-C.; Lee, Y.-M.; Chen, C.-Y. Estimation of Resource Productivity and Efficiency: An Extended Evaluation of Sustainability Related to Material Flow. Sustainability 2014, 6, 6070–6087. [Google Scholar] [CrossRef]

- Klug, F. Analysing the interaction of supply chain synchronisation and material flow stability. Int. J. Logist. Res. Appl. 2017, 20, 181–199. [Google Scholar] [CrossRef]

- Aslam, H.; Blome, C.; Roscoe, S.; Azhar, T.M. Dynamic supply chain capabilities. Int. J. Oper. Prod. Manag. 2018, 38, 2266–2285. [Google Scholar] [CrossRef]

- Cardoso, S.R.; Barbosa-Póvoa, A.P.; Relvas, S.; Novais, A.Q. Resilience metrics in the assessment of complex supply-chains performance operating under demand uncertainty. Omega 2015, 56, 53–73. [Google Scholar] [CrossRef]

- Chai, T.; Draxler, R.R. Root mean square error (RMSE) or mean absolute error (MAE)?—Arguments against avoiding RMSE in the literature. Geosci. Model Dev. 2014, 7, 1247–1250. [Google Scholar] [CrossRef]

- Willmott, C.J.; Matsuura, K. Advantages of the mean absolute error (MAE) over the root mean square error (RMSE) in assessing average model performance. Clim. Res. 2005, 30, 79–82. [Google Scholar] [CrossRef]

- Legates, D.R.; McCabe, G.J. Evaluating the use of “goodness-of-fit” Measures in hydrologic and hydroclimatic model validation. Water Resour. Res. 1999, 35, 233–241. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Handbook of Material Flow Analysis_ For Environmental, Resource, and Waste Engineers, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Relich, M. A Data-Driven Approach for Improving Sustainable Product Development. Sustainability 2023, 15, 6736. [Google Scholar] [CrossRef]

- Heidbreder, L.M.; Steinhorst, J.; Schmitt, M. Plastic-free July: An experimental study of limiting and promoting factors in encouraging a reduction of single-use plastic consumption. Sustainability 2020, 12, 4698. [Google Scholar] [CrossRef]

- Basuhi, R.; Moore, E.; Gregory, J.; Kirchain, R.; Gesing, A.; Olivetti, E.A. Environmental and economic implications of U.S. postconsumer plastic waste management. Resour. Conserv. Recycl. 2021, 167, 105391. [Google Scholar] [CrossRef]

- Karuppiah, K.; Sankaranarayanan, B.; Lo, H.-W. A systematic literature review on the evolution of sustainable manufacturing practices: Key findings and implications. Clean. Eng. Technol. 2024, 22, 100798. [Google Scholar] [CrossRef]

- Hyndman, R.J.; Koehler, A.B. Another look at measures of forecast accuracy. Int. J. Forecast. 2006, 22, 679–688. [Google Scholar] [CrossRef]

- Makridakis, S.; Spiliotis, E.; Assimakopoulos, V. Statistical and Machine Learning forecasting methods: Concerns and ways forward. PLoS ONE 2018, 13, e0194889. [Google Scholar] [CrossRef] [PubMed]

- Dolgui, A.; Dmitry, I.; Sethi, S.P.; Sokolov, B. Scheduling in production, supply chain and Industry 4.0 systems by optimal control: Fundamentals, state-of-the-art and applications. Int. J. Prod. Res. 2019, 57, 411–432. [Google Scholar] [CrossRef]

- Quintana-Pedraza, G.A.; Vieira-Agudelo, S.C.; Muñoz-Galeano, N. A Cradle-to-Grave Multi-Pronged Methodology to Obtain the Carbon Footprint of Electro-Intensive Power Electronic Products. Energies 2019, 12, 3347. [Google Scholar] [CrossRef]

- Rahaman, M.T.; Pranta, A.D.; Ahmed, S. Transitioning from Industry 4.0 to Industry 5.0 for Sustainable and Additive Manufacturing of Clothing: Framework, Case Studies, Recent Advances, and Future Prospects. Mater. Circ. Econ. 2025, 7, 20. [Google Scholar] [CrossRef]

- Jerie, S.; Chireshe, A.; Shabani, T.; Shabani, T.; Maswoswere, P.; Mudyazhezha, O.C.; Mashiringwani, C.; Mangwandi, L. Environmental impacts of plastic waste management practices in urban suburbs areas of Zimbabwe. Discover Sustainability 2024, 5, 435. [Google Scholar] [CrossRef]

- Hira, A.; Pacini, H.; Attafuah-Wadee, K.; Vivas-Eugui, D.; Saltzberg, M.; Yeoh, T.N. Plastic Waste Mitigation Strategies: A Review of Lessons from Developing Countries. J. Dev. Soc. 2022, 38, 336–359. [Google Scholar] [CrossRef]

- Widayat, W.; Praharjo, A.; Putri, V.P.; Andharini, S.N.; Masudin, I. Responsible Consumer Behavior: Driving Factors of Pro-Environmental Behavior toward Post-Consumption Plastic Packaging. Sustainability 2022, 14, 425. [Google Scholar] [CrossRef]

- Smith, E.; Bilec, M.M.; Khanna, V. Evaluating the Global Plastic Waste Management System with Markov Chain Material Flow Analysis. ACS Sustain. Chem. Eng. 2023, 11, 2055–2065. [Google Scholar] [CrossRef]

- Ferraro, G.; Failler, P. Governing plastic pollution in the oceans: Institutional challenges and areas for action. Environ. Sci. Policy 2020, 112, 453–460. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 6. [Google Scholar] [CrossRef]

- Wohner, B.; Pauer, E.; Heinrich, V.; Tacker, M. Packaging-Related Food Losses and Waste: An Overview of Drivers and Issues. Sustainability 2019, 11, 264. [Google Scholar] [CrossRef]

- Nguyen, T.; Van Nguyen, T.; Zhou, L.; Duong, Q.H.; Ieromonachou, P. Assessing the impact of EU policies on recycling supply chain: A system dynamics perspective on advancing packaging recycling capacity. Ann. Oper. Res. 2025. [Google Scholar] [CrossRef]

- Amadei, A.M.; Rigamonti, L.; Sala, S. Exploring the EU plastic value chain: A material flow analysis. Resour. Conserv. Recycl. 2023, 197, 107105. [Google Scholar] [CrossRef]

- Bernat, K. Post-Consumer Plastic Waste Management: From Collection and Sortation to Mechanical Recycling. Energies 2023, 16, 3504. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Domenech, T.; Borrion, A. Embedding Circular Economy Principles into Urban Regeneration and Waste Management: Framework and Metrics. Sustainability 2022, 14, 1293. [Google Scholar] [CrossRef]

- Amadei, A.; Ardente, F. Modelling Plastic Flows in the European Union Value Chain—Material Flow Analysis of Plastic Flows at Sector and Polymer Level Towards a Circular Plastic Value Chain; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Kinn, M.C. An Innovative Approach to Closing the Loop in a Circular Plastic Economy by Upcycling Single-Use Post-consumer Thin Film Plastic Packaging Waste into Durable Plastic Products. Mater. Circ. Econ. 2024, 6, 59. [Google Scholar] [CrossRef]

- Samitthiwetcharong, S.; Chavalparit, O.; Suwanteep, K.; Murayama, T.; Kullavanijaya, P. Enhancing circular plastic waste management: Reducing GHG emissions and increasing economic value in Rayong province, Thailand. Heliyon 2024, 10, e37611. [Google Scholar] [CrossRef]

- Iacovidou, E.; Hahladakis, J.N.; Purnell, P. A systems thinking approach to understanding the challenges of achieving the circular economy. Environ. Sci. Pollut. Res. 2021, 28, 24785–24806. [Google Scholar] [CrossRef]

- Yusuf, M.F.; Mohamad Nasarudin, N.A.; Sorooshian, S.; Fauzi, M.A.; Kasim, N.M. Exploring the Impact of Contingency Theory on Sustainable Innovation in Malaysian Manufacturing Firms. Sustainability 2023, 15, 7151. [Google Scholar] [CrossRef]

- Masudin, I.; Selvia, A.; Zulfikarijah, F.; Nasyiah, T. Exploring the Role of Circular Economy Practices in Linking Green Logistics Management and IoT with Sustainability Performance in SMEs. Circ. Econ. Sustain. 2025. [Google Scholar] [CrossRef]

- Cimpan, C.; Bjelle, E.L.; Budzinski, M.; Wood, R.; Strømman, A.H. Effects of Circularity Interventions in the European Plastic Packaging Sector. Environ. Sci. Technol. 2023, 57, 9984–9995. [Google Scholar] [CrossRef]

| Name | Mathematical Formula | Description | Source |

|---|---|---|---|

| Model XGBoost | Ensemble regression model using decision trees with gradient boosting; supports temporal and non-linear patterns; robust to multicollinearity and missing values | [53] | |

| Mean Squared Error (MSE) | Mean of squared differences between actual and predicted values; lower MSE indicates better performance | [65,66] | |

| Mean Absolute Error (MAE) | MAE measures the average absolute difference between actual and predicted values; lower values indicate higher model accuracy | [65,66] | |

| Root Mean Squared Error (RMSE) | The square root of MSE; more sensitive to large errors or outliers than MAE | [65,66] | |

| Koefisien Determinasi (R2) | Indicates the proportion of variation in the dependent data explained by the model, with values close to 1 indicating better prediction | [67] | |

| Mass Balance Principle | Used in MFA to ensure that the entire material flow is calculated consistently | [68] |

| Flow Component | Value (tons) |

|---|---|

| Raw Material Import | 24.74 |

| Raw Material Production | 11.46 |

| Raw Material Export | 2.59 |

| Resin Used Production tons | 36.20 |

| Production Losses tons | 1.10 |

| Plastic Bag Production | 32.51 |

| Distribution | 32.51 |

| Consumption | 32.51 |

| Waste | 14.67 |

| Recycling | 4.09 |

| Incinerated | 32.51 |

| Flow Component | Value (tons) |

|---|---|

| Raw Material Import | 299.65 |

| Raw Material Production | 137.26 |

| Raw Material Export | 33.36 |

| Resin Used Production (tons) | 438.63 |

| Production Losses (tons) | 13.16 |

| Plastic Bag Production | 390.39 |

| Distribution | 390.39 |

| Consumption | 390.39 |

| Waste | 390.39 |

| Recycling | 39.10 |

| Incinerated | 38.37 |

| Landfill | 77.69 |

| Loss | 235.23 |

| Flow Component | MSE | MAPE |

|---|---|---|

| Raw Material Import | 0.05 | 0.72% |

| Raw Material Production | 0.02 | 0.67% |

| Raw Material Export | 0.02 | 3.37% |

| Resin Used Production (tons) | 0.06 | 0.58% |

| Production Losses (tons) | 0 | 0.75% |

| Plastic Bag Production | 0.12 | 0.84% |

| Distribution | 0.12 | 0.84% |

| Consumption | 0.12 | 0.84% |

| Waste | 0.12 | 0.84% |

| Recycling | 0.35 | 15.33% |

| Incinerated | 0.25 | 11.81% |

| Landfill_ | 0.1 | 3.76% |

| Loss_ | 0.07 | 1.20% |

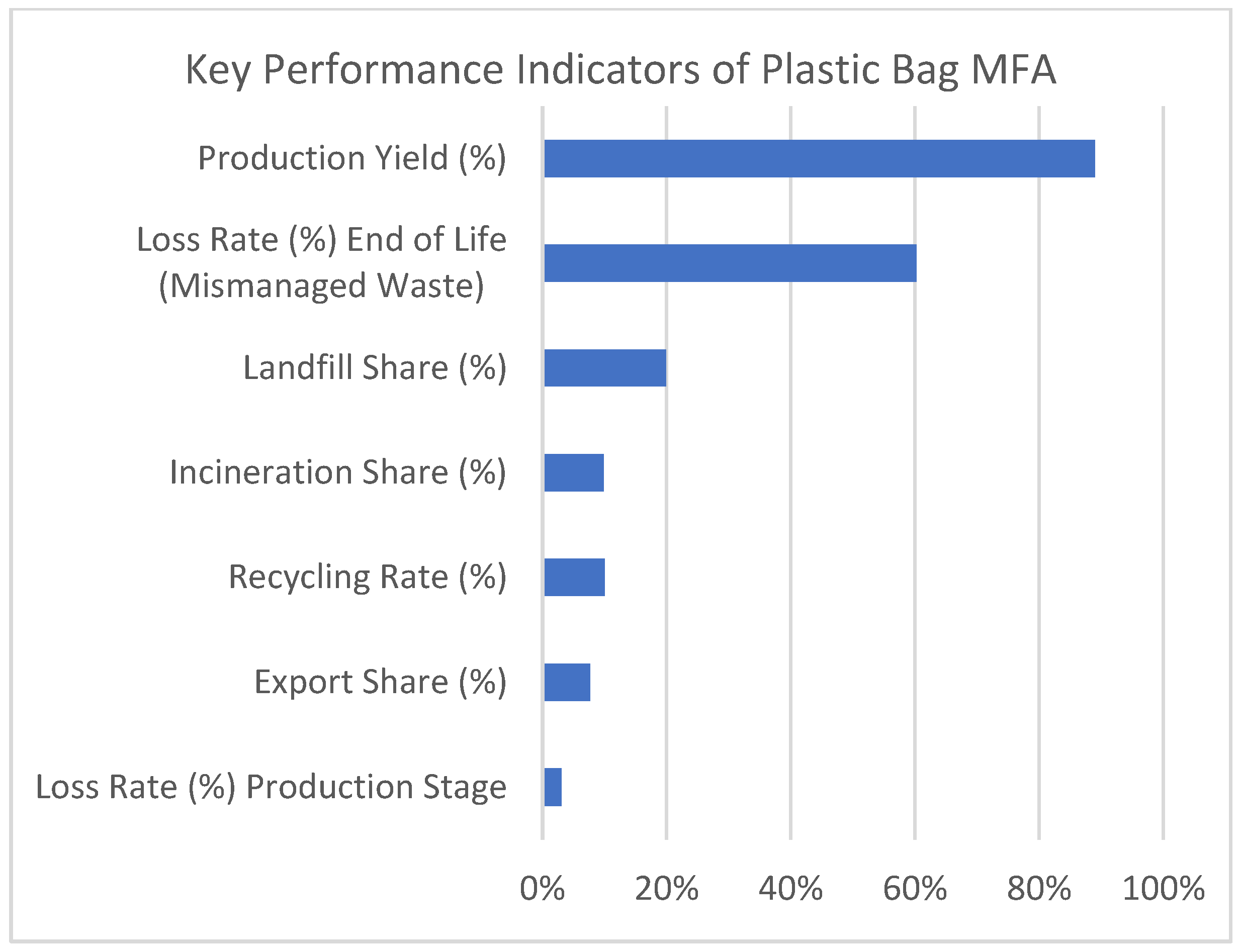

| Indicators | Value |

|---|---|

| Production Yield (%) | 89% |

| Loss Rate (%) Production Stage | 3% |

| Export Share (%) | 8% |

| Recycling Rate (%) | 10% |

| Incineration Share (%) | 10% |

| Landfill Share (%) | 20% |

| Loss Rate (%) or End of Life (Mismanaged Waste) | 60% |

| Material Flow | Value (tons) |

|---|---|

| Raw Material Import | 299.65 |

| Raw Material Production | 137.26 |

| Raw Material Export | 33.36 |

| Resin Used Production (tons) | 438.63 |

| Production Losses (tons) | 13.16 |

| Plastic Bag Production | 390.39 |

| Distribution | 390.39 |

| Consumption | 390.39 |

| Waste | 390.39 |

| Recycling | 39.10 |

| Incinerated | 38.37 |

| Landfill (tons) | 77.69 |

| Loss (tons) | 235.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Octaviani, E.; Masudin, I.; Khoidir, A.; Restuputri, D.P. Material Flow Analysis for Demand Forecasting and Lifetime-Based Inflow in Indonesia’s Plastic Bag Supply Chain. Logistics 2025, 9, 105. https://doi.org/10.3390/logistics9030105

Octaviani E, Masudin I, Khoidir A, Restuputri DP. Material Flow Analysis for Demand Forecasting and Lifetime-Based Inflow in Indonesia’s Plastic Bag Supply Chain. Logistics. 2025; 9(3):105. https://doi.org/10.3390/logistics9030105

Chicago/Turabian StyleOctaviani, Erin, Ilyas Masudin, Amelia Khoidir, and Dian Palupi Restuputri. 2025. "Material Flow Analysis for Demand Forecasting and Lifetime-Based Inflow in Indonesia’s Plastic Bag Supply Chain" Logistics 9, no. 3: 105. https://doi.org/10.3390/logistics9030105

APA StyleOctaviani, E., Masudin, I., Khoidir, A., & Restuputri, D. P. (2025). Material Flow Analysis for Demand Forecasting and Lifetime-Based Inflow in Indonesia’s Plastic Bag Supply Chain. Logistics, 9(3), 105. https://doi.org/10.3390/logistics9030105