1. Introduction

In Central Asian nations such as Kyrgyzstan, where abundant gold reserves significantly increase national income, gold mining is crucial to economic development and the region. Gold mining is a cornerstone of economic growth in Kyrgyzstan, contributing significantly to national GDP [

1]. However, inefficiencies in logistics, outdated technology, and inadequate waste management hinder sustainability and productivity [

2]. Key challenges include long-distance transportation (300–700 km) through mountainous terrain, reliance on Soviet-era equipment, limited smelting capacity, and environmental degradation from cyanide tailings [

3]. Additionally, a lack of automation and outdated equipment decreases manufacturing efficiency, resulting in lower gold recovery rates and financial losses. These issues result in high operational costs, reductions in gold recovery, and lost economic value due to exporting unprocessed concentrates [

4]. The handling and disposal of gold waste are further significant problems. Incorrect handling of tailings, which are by-products of the gold extraction process, can result in severe environmental problems like forest destruction, pollution from heavy metals, and cyanide exposure. Due to the lack of smelting infrastructure in the region, numerous companies are compelled to export unprocessed gold concentrates to China and Kazakhstan, thereby reducing the economic value gained by the region. To overcome such an unproductive process, companies must rely on imports due to a lack of domestic equipment for mining production, which increases operating costs and leads to maintenance delays. This study investigates how advanced logistics and technologies, such as AI, IoT, and localized smelting, can enhance efficiency and sustainability in gold production. Using a case study approach in Kyrgyzstan, we employ qualitative interviews and system dynamics (SD) modeling to compare current practices with technology-integrated processes. This study intends to explore the current logistical practices, propose a technology-driven process, and recommend strategies for sustainable gold mining in Kyrgyzstan. This study will provide valuable insights for legislators and business executives aiming to modernize gold-mining operations, reduce inefficiencies, and implement sustainable practices by addressing these logistical, technological, and environmental challenges. The results highlight the need for the gold-mining industry to incorporate automation, smart logistics, and production localization to increase profitability while maintaining environmental responsibility.

Research Question and Objectives

This study aims to explore gold mining in Kyrgyzstan, focusing on sustainable practices. The main research question is,

How can advanced logistics and technologies enhance efficiency and sustainability in Kyrgyzstan’s gold mining?

The objectives are as follows:

Assess the current gold-mining process in light of existing logistical support for the industry.

Explore how a revised production process using advanced and improved logistics can make mining more efficient, especially in its management of gold waste.

Develop recommendations for future gold-mining processes using technology-based logistics.

2. Literature Review

2.1. Gold Mining in Central Asia: Historical Legacy and Modern Implications

2.1.1. Ancient Roots and Soviet-Era Expansion

Central Asia, including Uzbekistan, Kyrgyzstan, Kazakhstan, and Tajikistan, has a rich history of metallurgy and mining that spans thousands of years [

5]. This legacy evolved through various stages, from early extraction techniques to sophisticated Soviet-era developments. The 20th-century rise of the USSR marked a critical period of industrialization across the region, with gold mining playing a central economic role. Geological surveys in Kyrgyzstan revealed significant gold reserves in the 1960s and 1970s [

6]. Among these, the Kumtor deposit stands out with an estimated 700 tons of gold, contributing about 20 percent of the country’s industrial output [

7]. Exploration began in the late 1970s, setting the stage for future mining ventures. Gold extraction expanded further in the 1980s with operations at the Makmal mine, but following the Soviet collapse, production declined due to economic instability [

8]. The challenges Kyrgyzstan faced in managing its mining sector reflect the broader struggles of post-Soviet states.

2.1.2. Modernization and Political Transformation

The early 21st century brought renewed investment to Kyrgyzstan’s gold industry, primarily from Russian and Chinese firms. These partnerships improved infrastructure and spurred economic growth. A turning point came in 2021 when President Zhaparov nationalized Kumtor, ensuring that revenues supported public infrastructure, including new roads and other facilities [

9]. Tailings from gold processing, once considered waste, are increasingly viewed as valuable materials for construction. Their reuse aligns with the Sustainable Development Goals and helps to reduce environmental impact. As the industry grows, managing logistics and reprocessing tailings will be essential for long-term viability and ecological responsibility.

2.1.3. Historical Discoveries and Regional Significance

Placer gold mining in Central Asia was first recorded near the Amu River and Chirchik, as early as the 8th century. These early findings influenced Russian strategic plans, including the Khiva campaign in the early 1700s [

10]. After Russia annexed the region in the 19th century, private enterprises began exploring mineral wealth, but large-scale development occurred only during the Soviet era. A milestone was reached in 1958 when geologists Mordvintsev and Khramyshkin discovered the Muruntau deposit, now one of the largest gold mines globally [

11]. The Navoi Mining and Metallurgical Plant was established that same year, becoming a world leader in gold production. In 1969 the Zarafshan facility refined its first gold bar from Muruntau ore [

12]. Kyrgyzstan’s mining dates back to the 1800s, during the Russian Empire’s expansion [

4]. However, World War II disrupted development, as did the dissolution of the USSR [

13]. The Kumtor project, though discovered earlier, only advanced in 1996 after a Canadian firm engaged the Kyrgyz government.

2.1.4. Current State and Projections

Kyrgyzstan is undergoing exploration, improving mining methods, and ensuring the growth of the industry around existing gold deposits [

4]. The Kyrgyz government aims to produce 32 tons of gold in 2023 [

14]. The government has committed to supportive policies, infrastructure investments, and regulatory frameworks [

1]. Recent policy changes and gold prices have brought numerous benefits to environmental concerns and geopolitical stability [

4]. Economically, this industry brings increased revenue, job opportunities, and economic growth.

2.1.5. Geographical Landscape

The transportation of raw materials and finished products poses significant challenges in Central Asia’s mountainous terrain. Unlike more accessible regions, the lack of developed government-funded infrastructure makes operations more complex. Companies must meet basic needs, such as water, electricity, and food, which are crucial for sustaining their operations. They also have to build roads leading to processing facilities and mining sites. Because of the rugged landscape, the roads are mostly gravel. For this reason, companies use specialized 4 × 4 wheeler vehicles with custom tires to navigate challenging terrains efficiently. Utilizing these robust vehicles is necessary, demonstrating the adaptability companies need in such harsh locations. Moreover, the factories are situated far from community centers, and transporting products to the Kara Balta refinery, which is located 300 to 700 kilometers away from various mining sites, is a significant challenge.

2.2. Gold Mining and Logistics Challenges

Gold mining in Kyrgyzstan faces logistical and technological barriers that limit efficiency and sustainability [

2,

4]. Long-distance transportation (300–700 km) through mountainous terrain increases costs and emissions, while reliance on outdated Soviet-era equipment reduces productivity [

1]. Limited smelting capacity forces the export of unprocessed concentrates, diminishing the economic value of the gold resource [

1]. Globally, similar challenges are evident in Peru, where logistical inefficiencies and environmental degradation from gold mining have been documented [

3]. In contrast, Australia’s BHP has deployed autonomous trucks and IoT technologies at sites like the Jimblebar mine, achieving haulage cost reductions of around 20% and advancing broader efforts to cut operational emissions through electrification and renewable energy projects [

15,

16].

2.3. Technology Adoption in Mining

Technological advancements, such as AI, IoT, and automation, offer solutions to logistical inefficiencies. AI-driven predictive maintenance can reduce equipment downtime by up to 30% [

17], while IoT-based fleet tracking optimizes transport routes [

18]. Sustainable waste management, including tailings reprocessing, mitigates environmental impacts [

19]. However, Kyrgyzstan lags in adopting these technologies, due to infrastructure constraints and high initial costs [

20]. In addition, the absence of localized smelting facilities and limited digital integration across the supply chain hinders the full realization of the benefits of smart mining. Global case studies on such approaches as autonomous haulage systems and digital twins demonstrate the potential for operational transformation when these technologies are deployed strategically. Integrating such tools could significantly improve gold recovery rates, reduce environmental risks, and align Kyrgyzstan’s mining sector with global sustainability standards. This study explores these prospects through a simulation model designed to evaluate the impact of technological adoption on mining efficiency and long-term sustainability outcomes.

2.4. Key Problems in Kyrgyzstan’s Gold-Mining Industry

The following key problems were identified through interviews conducted with industry experts and employees actively engaged in Kyrgyzstan’s gold-mining sector. Their firsthand insights offer a grounded understanding of the sector’s current challenges.

Limited Smelting Capacity—Having only one major smelting facility in Kara-Balta leads to logistical inefficiencies and the export of unfinished gold.

Long-Distance Transportation—Gold ore needs to be transported for 300–700 km through mountainous terrain, which increases time and cost.

Outdated Soviet-Era Equipment—Inefficient machinery leads to frequent breakdowns, higher maintenance costs, and reductions in productivity.

High Environmental Impact—Poorly managed cyanide tailings and emissions from diesel transport contribute to environmental degradation.

Export of Unprocessed Gold—Due to limited processing facilities, gold concentrates are exported to China and Kazakhstan, reducing the economic benefits gained by Kyrgyzstan.

High Operational Costs—Dependence on imported mining equipment and a lack of local manufacturing increase the financial burden.

Inefficient Waste Management—The disposal of tailings, heavy metals, and slag creates environmental hazards and resource losses.

Lack of Technological Integration—The minimal use of AI, IoT, and automation leads to inefficiencies in tracking, refining, and gold conversion.

Logistics and Supply Chain Challenges—The logistical challenges in gold-mining operations are many, and include building the necessary infrastructure, constructing specialized roads, using the right vehicles, and managing long distances between sites and the refinery. Overcoming these challenges requires creativity, resourcefulness, and a profound understanding of the unique geographical constraints presented by the mountainous landscape.

2.5. The Current Gold Production Process

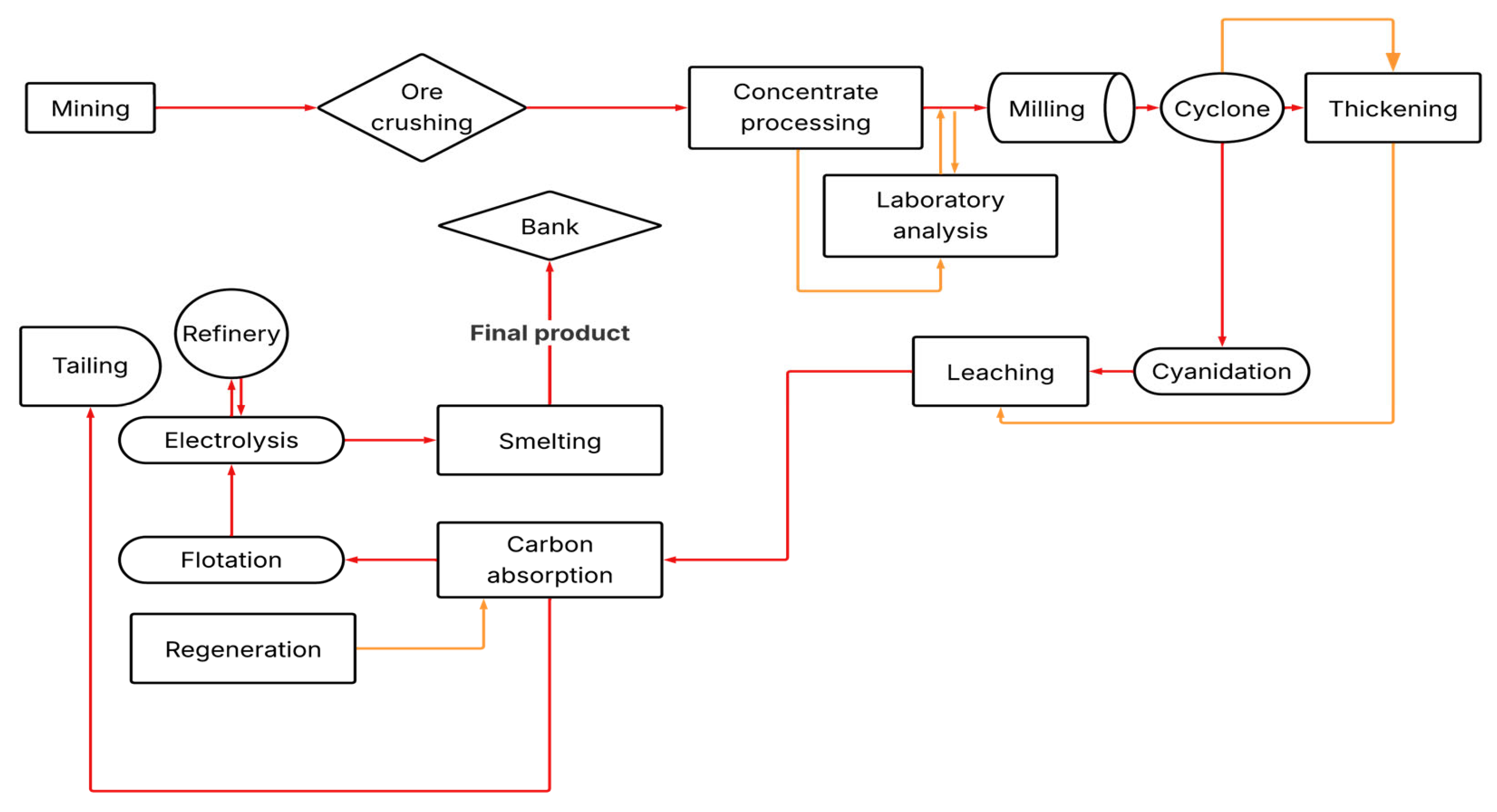

The gold-mining process chain, vital to government operations, unfolds as a multi-faceted journey from extraction to distribution, as shown in

Figure 1. According to the mining employees, it begins with mining companies extracting gold ore from the mining site and transporting it to a processing factory for thorough cleaning. The gold ore undergoes its primary processing stages at the processing facility, including crushing, washing, milling, and concentration. Smaller particles then undergo cyanidation, in which gold is leached from the ore, dissolved, and adsorbed onto activated carbon. After desorption, the gold is present in a gold-saturated solution, setting the stage for subsequent processing phases. Following refinement, the product undergoes electrolysis, extraction, and fire treatment, resulting in a gold–silver alloy with a minimum gold content of 70%. After further treatment, this alloy achieves a purity level of 99.99% gold. The refined gold is then presented to the National Bank for potential purchase in compliance with legislative mandates. If the National Bank chooses to buy the gold, it is securely stored in its facilities. The National Bank may sell the gold to foreign counterparts depending on market demand. If the National Bank declines the purchase, mining companies can offer the gold to international entities abroad. This detailed overview provides insights into the key components of the gold-mining supply chain, emphasizing the importance of eco-conscious practices and innovative methodologies in enhancing the sustainability of gold-mining operations.

2.5.1. Current Logistical Support in Gold Mining

Existing Practices in Mining Logistics: Gold-mining logistics play a critical role in ensuring the efficiency of supply chains. Current practices involve the transportation of equipment, materials, and personnel to remote mining sites, typically using a combination of trucks, rail, and shipping vessels. This multimodal logistics strategy ensures the continuous flow of incoming commodities (such as raw materials and tools) and outgoing commodities (such as ore and gold) Logistics encompasses storage and inventory management, facilitating a balance between supply and demand in mining operations. To minimize idle time, optimize routes, and ensure timely delivery dates, efficient mining logistics often rely on technology such as real-time fleet tracking to prevent delays in mining operations. This logistics operation focuses on transporting commodities and ensuring safety and adherence to regulations, particularly in challenging terrains such as Central Asia.

2.5.2. Operational Challenges Based on Advanced Logistics

Kyrgyzstan’s gold-mining industry faces substantial logistical and operational challenges, which are exacerbated by the lack of sufficient domestic smelting facilities, lengthy transportation distances, and the reliance on outdated mining equipment. The existence of problems does not enhance efficiency; on the contrary, they increase costs and limit the potential economic benefits the country could gain from the gold mining industry.

2.5.3. Limited Smelting Capacity

Kyrgyzstan has only one central smelting facility in Kara-Balta, which processes a limited range of gold concentrates. For example, companies in the southern and central parts of the country often find it difficult to transport their unfinished product (gold concentrate) over mountainous distances. The following shows the distances from the main cities of the regions where gold-mining companies operate, illustrating the challenges:

Naryn to Kara-Balta covers a 350 km distance over a mountainous road.

Osh to Kara-Balta covers over 600 km of mountainous road.

The Talas to Kara-Balta covers around 130 km through a mountainous road.

The longest route from Zhalal-Abad to Kara Balta spans approximately 533 kilometers, passing through mountainous roads.

These remote locations make transportation time-consuming, with the harsh terrain adding further logistical challenges. The Kara-Balta plant cannot process all types of gold concentrates due to technological differences within the methods and the complexity of the various gold concentrates. This situation forces some companies to export their unfinished products to China or Kazakhstan for further processing. This has resulted in lost value for Kyrgyzstan, as the gold concentrate also contains other valuable metals, which are then not fully capitalized upon domestically.

2.5.4. Lack of Mining Equipment Manufacturing

Another problem in Kyrgyzstan’s mining industry is the lack of factories that manufacture mining equipment. During the USSR era, essential mining machinery, including milling and crushing equipment, was manufactured and assembled in the Russian Soviet Republic., including the milling and crushing equipment. Later, After the dissolution of the USSR, modern Kyrgyzstan continued to rely on imports from Russian companies and, more recently, has also depended on Chinese manufacturers, particularly for supplying spare parts for old equipment. This dependency on crucial spare parts increases costs and delays, particularly for companies that are in remote areas and are state financed. For instance, a mining company based in Kazarman, Kyrgyzstan, relies on regular imports of machinery and spare parts for its outdated machines from Russia and sources chemical products from China. Generally, many modern mining companies in Kyrgyzstan rely on chemical products from China. Primary mining operations in Kyrgyzstan continue to utilize outdated Soviet-era equipment. The machines used for milling, crushing, and processing are inefficient, prone to breakdowns, and consume more energy than correlative machinery using modern technologies. Using such equipment results in lower productivity and higher maintenance costs, further straining the economic viability of gold mining in the region.

2.5.5. Export of Unfinished Products

Many mining companies ship gold concentrates overseas by truck for further processing due to restrictions on their domestic processing capabilities. Companies in the central and southern regions of the country reflect this trend by exporting their semi-finished products to markets in China and Kazakhstan.

2.5.6. Economic and Environmental Impact

The combined challenges of outdated equipment, long-distance transportation, and reliance on foreign smelters reduce profitability and increase the environmental footprint of the mining industry. High energy consumption from old machinery and increases in emissions from long-haul transportation contribute to environmental degradation, especially in ecologically sensitive mountain regions.

2.6. Gold Production Wastes

The characteristics and chemical composition of gold-mine tailings are critical for understanding their behavior at final disposal sites, as well as for assessing associated liabilities and environmental impacts [

19]. Efficient waste management is critical to gold production. Waste is managed in tailing ponds, dams, or tips, adhering to local legislation. Recycling is explored where technically feasible to minimize waste generation and resource depletion. Effective waste management practices are essential for sustainable mining operations [

21].

The mining sector has historically been associated with significant environmental consequences resulting from its waste management. These factors are intricately tied to various social impacts and challenges, presenting varying degrees of complexity [

22]. Gold-mining operations in Kyrgyzstan are conducted on a large scale, spanning all seven regions of the country. The geographical features (e.g., mountains, valleys, rivers, terrain), scales involved, and methods employed are highlighted below:

Mountainous terrain covers eighty percent of the land;

The geography is dominated by the Tian Shan range;

There are numerous tall peaks, glaciers, and high-altitude lakes;

Ninety-four percent of the country lies at elevations exceeding 1000 m;

Average elevation: approximately 2750 m [

23].

The complexity and high-altitude geographical features pose challenges that amplify the costs associated with gold mine development. The associated complexity and high-altitude geographical features make it costly to develop a gold mine. There is a single refinery factory in the country that serves all mining companies. The largest gold-mining companies are Kumtor Gold Company CJSC (Yssyk-Kol region, Republic of Korea), Altynken LLC (Chui region, Republic of Korea), Alliance Altyn LLC (Talas region, Republic of Korea), Kaz Minerals Bozymchak LLC (Jalal-Abad region, Republic of Korea, and Makmal Gold Company LLC (Jalal-Abad region, Republic of Korea) [

24]. The presence of only one refinery factory in all of Kyrgyzstan, serving all mining companies, compounds the geographical intricacies. Notable mining entities, according to 2022 reports, include the following:

Kumtor Gold Company: produced 17,305 kg of gold [

25];

Altynken LLC: 4130.11 kg of gold [

26];

Alliance Altyn LLC: 4158.5 kg of gold [

27];

Kaz Minerals Bozymchak LLC: 1185 kg of gold [

28];

Due to their distance from villages and civilization, these mining companies in remote areas characterized by high mountains have established independent water, food, and clothing sources. This self-sufficiency responds to the challenging terrain and remote locations, which necessitate self-reliance for basic sustenance needs. Cyanide-based leaching technology, widely used by gold-mining companies in Kyrgyzstan, raises environmental concerns. While efficient in gold extraction, this technology highlights the importance of sustainable practices in the mining sector. Integrating environmentally responsible methods is crucial to balancing economic gains and preserving Kyrgyzstan’s unique and delicate mountainous ecosystems.

2.7. Challenges in Logistics for Gold Mining

Despite progress in mining operations, some problems still need to be solved. The primary difficulty is that many gold-mining sites are located in remote areas, particularly in Central Asia, where infrastructure is often underdeveloped. Transport networks that are difficult to access, roads in poor condition, and lengthy supply lines can all lead to delays and increased costs. Rules regarding the environment and rising fuel costs also affect the carbon footprints of transport activities. Geopolitical issues, such as resource nationalism and trade wars, can also pose challenges for mining businesses and compromise the security of their supply chains. A level of demand that is difficult to predict is another significant problem, one that requires flexible shipping plans to accommodate changes in global markets. As mines strive to be environmentally friendly, they must address challenges such as managing waste and the environmental impact of their operations.

2.8. Comparative Global Perspectives on Mining Logistics and Sustainability

Research from regions outside Central Asia reveals parallel challenges and actionable solutions relative to those faced in Kyrgyzstan. In Peru, artisanal gold mining has caused nearly 100,000 hectares of deforestation, mercury contamination, and long-term ecological degradation due to suction-based extraction methods [

3]. In Ghana, small-scale gold mining has led to severe land and water degradation; however, geospatial technologies and remote sensing have supported effective site monitoring and environmental management [

29]. Australia has adopted artificial intelligence and real-time data systems to monitor tailings dams, significantly reducing the risk of structural failure [

30]. The Mount Lyell Remediation Program in Tasmania stands out as a successful example of post-mining rehabilitation, involving river clean-up, tailings containment, and ecological restoration [

31]. In Papua New Guinea, the environmental disaster at the Ok Tedi Mine led to the implementation of stricter tailings-containment policies, community compensation frameworks, and government oversight [

32]. Similarly, South Africa’s Witwatersrand Basin, including the Mponeng Mine, has implemented tailings stabilization techniques such as liming and vegetative capping to reduce airborne pollution and reclaim mine-impacted lands [

33]. Also, in Australia, autonomous haulage systems (AHS) have been successfully deployed in iron ore mines, with autonomous trucks operating 24 h a day, reducing operating costs and improving safety. These global cases demonstrate that the integration of digital technologies, robust environmental regulation, and community-focused remediation is essential and is a transferable strategy for addressing the challenges currently affecting Kyrgyzstan’s mining sector.

The identification of key problems in Kyrgyzstan’s gold-mining sector is the result of a systematic synthesis of findings presented across

Section 2.1,

Section 2.2,

Section 2.3,

Section 2.4,

Section 2.5,

Section 2.6,

Section 2.7 and

Section 2.8. Through a detailed review of scholarly literature, industry reports, and regional case studies, we identified recurring challenges such as inefficient logistics and long-distance transport delays [

4,

29], reliance on outdated Soviet-era mining and processing equipment [

1,

16], and environmental risks stemming from unmanaged tailings and cyanide waste [

3,

33]. These findings are further corroborated by primary data collected through in-depth interviews with mining professionals and former policymakers, which provided operational insights and helped prioritize the most pressing systemic issues. Rather than offering a generalized assessment, this study focuses on addressing a core subset of these problems—specifically, logistical inefficiencies, outdated technology, and sustainability gaps—through a scenario-based system dynamics model. While broader environmental and policy dimensions are noted, our analysis is intentionally scoped to explore how digital technologies such as AI, IoT, and local smelting solutions can enhance efficiency and sustainability within Kyrgyzstan’s gold-mining supply chain. This approach provides a structured foundation for future studies to expand into other interconnected challenges, such as regulatory enforcement, community impact, and detailed environmental remediation.

3. Materials and Methods

This study employs a comprehensive review of the existing literature, government reports, and personal experiences to investigate the dynamics and trends in Kyrgyzstan’s mineral industry. It specifically focuses on adopting a sustainable-development approach. The methodology is primarily qualitative, focusing on synthesizing information from diverse sources to gain insights into key aspects of the mineral sector.

3.1. Data Collection

This study utilized primary and secondary data sources to comprehensively analyze logistical inefficiencies and technological gaps in Kyrgyzstan’s gold-mining sector. Primary data were gathered through semi-structured, in-depth interviews with ten stakeholders: eight senior managers from two major gold-mining firms (Makmal Gold Company LLC and Solton-Sary Mining LLC) and two former officials from the Ministry of Natural Resources. Interviews were conducted via phone and in-person visits, supported by observational field notes and company fact sheets obtained during site interactions. These interviews captured expert insights on logistical bottlenecks, smelting constraints, and operational inefficiencies. As for secondary information, a thorough review of previous research articles, academic journals, government reports, and industry publications provided the foundational knowledge necessary to understand the historical context, regulatory frameworks, and trends influencing Kyrgyzstan’s mineral industry relative to sustainable production processes and development. Data were sourced from government reports [

24], company reports [

25], and peer-reviewed journals (2015–2025) via Scopus and Web of Science. These provided historical production data, environmental impact assessments, and technological benchmarks. Government documents, policy briefs, mining laws, and investment reports were examined to determine essential policy actions, regulatory modifications, and investment incentives aiming to foster sustainable mineral exploration and development practices in Kyrgyzstan. Particular emphasis was placed on papers that underscore activities for environmental stewardship, community participation, and economic diversification.

3.2. Literature Selection and Screening Method

A structured literature review was conducted to ensure that the sources used in this study were both credible and thematically relevant. The search covered the period of 2015 to 2024, using databases such as Scopus, Web of Science, and Google Scholar, applying keywords including “gold mining,” “sustainability,” “logistics,” “technology adoption,” and “Central Asia.” An initial screening of 150 abstracts was followed by a full-text review of 60 selected documents, after which 43 sources were retained based on predefined criteria. The inclusion criteria were the following: (i) peer-reviewed journal articles or (ii) government or industry reports; (iii) a focus on gold mining, logistics, technology, or sustainability; and (iv) relevance to Kyrgyzstan or similar mining regions (e.g., Peru, Ghana, and South Africa). The exclusion criteria included the following: (i) non-peer-reviewed or unverifiable sources, (ii) studies published before 2015 unless critically relevant, (iii) content unrelated to mining, and (iv) studies lacking geographical relevance. The final 43 sources comprised 30 peer-reviewed journal articles, 10 industry and government reports, and three conference papers. To complement this academic base, we included 13 contextual sources, including six technical reports, three news articles, and four web-based resources [

11]. All sources were thematically organized under three categories—logistical inefficiencies, technology adoption, and environmental impacts—to inform the literature review and simulation framework.

3.3. Simulation Model Development

This study employs a simulation-based approach to analyze and optimize the logistical challenges in gold-mining operations. The paper followed the simulation model development process outlined by Shamsuddoha [

18,

34,

35] while drawing on a gold-mining simulation process based on a case industry. The methodology integrates data collection, model calibration, and validation to assess the efficiency of existing logistics processes and propose improvements through advanced technological solutions. A discrete-event simulation model was developed to replicate the logistics processes in gold mining, including transportation, processing, smelting, and waste management. The model considers the following elements:

Mine-to-processing transport routes (considering mountainous terrain and infrastructure limitations).

Processing delays and inefficiencies due to outdated equipment.

Supply chain bottlenecks in gold ore transportation and smelting.

Environmental impacts include tailings management and emissions.

The model integrates IoT tracking, AI-powered predictive maintenance, and fleet optimization to test efficiency gains through technological interventions. The information provided in

Appendix A outlines the variables, input parameters, equations, and units used in the system dynamics simulation model specifically for the technology-adoption scenario, including key factors such as leaching efficiency, ore quantity, and gold conversion rates.

Appendix B complements this by presenting additional variables, equations, and unit specifications relevant to the overall structure of the SD simulation model. These appendices provide the foundational data and assumptions supporting the model’s computational framework.

3.4. Model Calibration and Validation

The model was calibrated using historical gold production data and logistical performance metrics. Key calibration steps included the following:

Fine-tuning transport times based on real traffic and terrain conditions.

Adjusting processing rates to reflect equipment constraints.

Incorporating failure rates of mining machinery to mirror real operational downtime.

To validate the model, simulated outputs were compared against actual mining performance metrics, ensuring accuracy in the following:

Ore transportation efficiency (correlation with past transport records).

Processing cycle times (aligned with industrial benchmarks).

Cost estimations and emissions impact (verified against real company expenditures).

3.5. Scenario Analysis

Table 1 highlights the improvements in gold mining logistics when integrating IoT and AI-based solutions. The optimized scenario reduces transport time by 25%, enhances equipment uptime by 30%, and increases gold extraction by 15% through the use of regional smelting plants. Waste recycling and electric mining vehicles also lower emissions by 30%, improving environmental sustainability. These advancements result in cost savings, increased efficiency, and higher profitability, making technology adoption a crucial factor in the modernization of gold-mining operations. To explore potential optimizations, different scenarios were simulated:

The results provide insights into how technological advancements and logistics optimizations can enhance efficiency, reduce operational costs, and minimize environmental impact in gold-mining operations.

4. Gold Waste in Mining Operations

The process of gold mining is followed by the accumulation of waste from ores and chemicals stored in tailings. Tailings are a waste product of mining that contains chemicals like cyanide. If not managed properly, they can damage the local environment. Some mining companies have begun to explore methods that are more environmentally friendly in the management of mining waste, such as dry stacking of tailings and implementing closed-loop water recycling systems. The second has already been practiced for a long time. Gold waste mainly comprises minerals, including waste rock and a minimum of valuable components. As an established rule, tailings are not suitable for further processing.

4.1. Gold-Mining Waste

Table 2 presents various gold-mining wastes, their environmental impacts, and potential operational techniques usable to mitigate damage. Focusing on crucial waste categories, including tailings, cyanide, heavy metals, slag, destruction of forests, air pollution, water pollution, worker security issues, and resource depletion, it can be seen that each is related to substantial environmental and safety concerns. In particular, increases in slag generation lead to air pollution and greenhouse gas emissions, while tailings and heavy metals can trigger soil and water cross-contamination. Deforestation also results in a decline in biodiversity, and the depletion of resources impacts the natural environment, particularly in regions affected by extreme temperatures. The suggested adjustments emphasize sustainable techniques, including wastewater disposal, forest restoration projects, emission reduction regulations, enhanced safety standards, and recycling programs. These strategies will help the gold-mining sector mitigate its adverse environmental impacts while promoting long-term sustainability, thereby ensuring a balance between financial benefits and environmental responsibility.

4.2. Impact of Logistics on Gold Waste Management

4.2.1. Role of Logistics in Waste Management

Managing logistics is a vital part of controlling gold-mine waste well. Moving waste to approved treatment facilities requires well-functioning disposal systems. Advanced shipping technologies, such as online monitoring sensors, enable the operation to monitor ongoing processes closely and ensure transportation safety.

4.2.2. Technological Solutions for Waste Reduction

Existing technical solutions, such as automated sorting, decrease waste by properly filtering out ore of poor quality. IoT devices can track the movements of waste materials, enabling the company to improve its environmental standards and increase productivity.

4.2.3. Innovative Technologies in Mining Logistics

Automation and robots have the potential to increase mining logistical efficiency. Mines that use an automated system to track gold processing operations reduce accidents by minimizing human intervention in hazardous settings.

4.3. Developing a Revised Logistical Process for Gold Mining

In the context of the gold-mining process in Kyrgyzstan, considering the current problems and challenges, we suggest using several updates in the current gold-mining logistics.

Figure 2 suggests adopting an IoT tracking system across transportation routes from the mining site to the processing facility and from the refinery to the smelting factory. This method increases the control systems, ensuring increased safety and time efficiency throughout transportation. Another suggestion is to develop a local mining equipment production industry, making it easier to modernize and change old equipment to newer models.

Integrating improved chemical recovery systems into both cyanidation and leaching operations is another vital improvement that reduces environmental impact while enhancing gold extraction efficiency. Improvements in waste management approaches, such as regeneration and tailing treatment, will additionally decrease the ecological impact and improve resource efficiency. Furthermore, deploying more smelting facilities may optimize the last stages of gold refinement by eliminating bottlenecks and ensuring smoother processing. Lastly, the automation and deployment of digital control technologies in the flotation process, as well as the electrolysis and refinery stages, will significantly enhance operational accuracy, reduce human error, and improve supply chain productivity in the gold-mining industry. Thus, large traditional factories can effectively address waste reduction and increase gold extraction percentages. Another crucial change in the gold processing supply chain is the construction of new smelting facilities in various parts of the country, which could cater to different geological components of local gold concentrates, thereby making the process more effective for the local economy.

Table 3 summarizes significant advances in gold-mining logistics that enhance cost-effectiveness, sustainability, and efficiency. For instance, drone-assisted location surveying enables faster and more accurate evaluations for better decision-making, while automated material handling using robotics, elevators, or conveyors enhances operational efficiency and reduces labor costs. Logistics can be optimized by applying real-time fleet management and autonomous vehicle transport, which minimize idle time and improve delivery routes. Likewise, blockchain technology enhances supply chain transparency while reducing fraud, and AI-powered predictive maintenance minimizes equipment downtime. While IoT-enabled inventory tracking optimizes stock levels and prevents shortages, automated waste sorting decreases waste and improves environmental sustainability. Mobility powered by renewable sources reduces carbon emissions, and production scheduling based on artificial intelligence (AI) enhances workflow planning and minimizes delays. Everything is considered; these developments enhance supply chain resilience, improve sustainability, and streamline mining procedures.

4.4. Enhancing Gold-Mining Logistics: Innovations, Sustainability, and Industry Practice

With the aid of sustainability-focused strategies and technological innovations, gold-mining logistics are adapting to increase efficiency, reduce expenses, and mitigate adverse environmental impacts. The following sections examine significant logistics developments that have demonstrated their efficacy in enhancing the gold-mining industry, including the use of automation, tracking devices, and environmentally friendly procedures, in the context of real-life examples.

Integrating Advanced Logistics for a Rigorous Mining Process: Advanced logistics systems can simplify mining operations, from ore extraction to distribution. Fleet management systems, real-time tracking, and automatic dispatch systems keep goods and workers on schedule, resulting in decreases in delays and enhancing efficiency. Mining businesses may streamline operations and avoid bottlenecks by simulating logistical situations using digital twins, virtual representations of actual assets.

Sustainability and Environmental Considerations in Logistical Revisions: Sustainability is gaining importance in gold-mining logistics. Electric cars reduce carbon gas emissions, the optimization of routes reduces fuel usage, and renewable energy sources support operations. Logistical planning also includes waste reduction and water recycling to ensure mining operations satisfy regulatory standards and reduce their environmental impacts.

Successful Process Revisions in Other Mining Operations: Many mining case studies show successful logistical changes. South American mining corporations use drones for real-time inventory monitoring, decreasing waste and expenses. A Canadian mining business used an autonomous fleet to optimize routes and eliminate needless stops, reducing fuel consumption by 15%, in addition to reductions in delivery times. These changes have increased efficiency, cost savings, and sustainability.

Sustainable Development of Gold Mining: Kyrgyzstan’s mining sector relies on sustainable development, along with the UN and its partners, in pursuing the SDGs [

43]. Kyrgyz firms prioritize sustainable growth and environmental preservation due to the possibility of mining-related environmental effects, and those from related industries [

20]. Companies must donate part of their revenue to environmental preservation programs designated by the local government.

5. Simulation Model and Results

5.1. Key Aspects of the Model

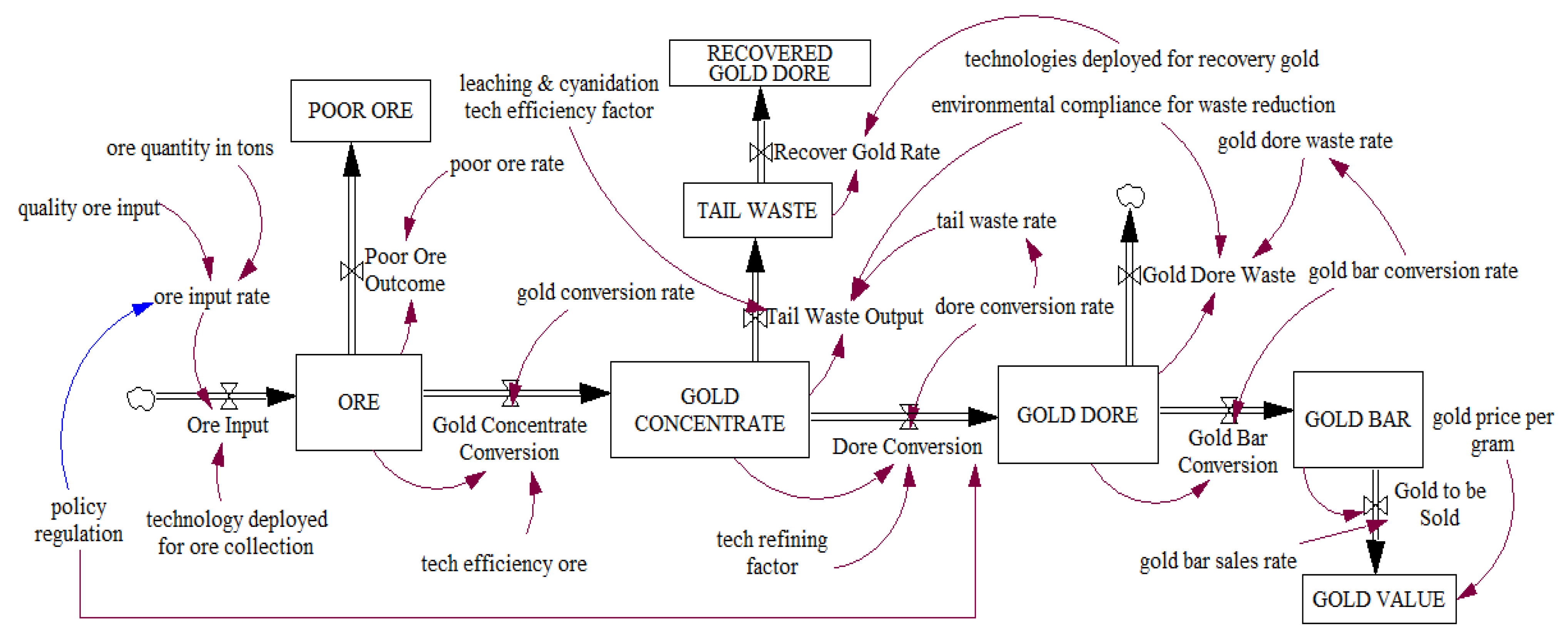

The gold-mining process illustrated in the diagram follows a structured stock and flow system, in which raw ore is processed, refined, and converted into marketable gold bars. This system plays a critical role in determining gold recovery efficiency, waste management, and overall economic value.

Figure 3 presents a system dynamics model illustrating the interconnected processes of ore processing, gold conversion, waste generation, and value creation in Kyrgyzstan’s gold-mining industry. In this study, all capitalized variables represent box or stock variables, indicating quantities that accumulate over time and are determined by one or more other variables. Each capitalized variable denotes a determined rate connected to the stock variable. Lowercase variables represent individual constant or dynamic variables that directly connect to the rate or box, influencing system behavior. The model identifies key stocks in bold letters (ORE, GOLD CONCENTRATE, GOLD DORE, GOLD BAR, and GOLD VALUE), in addition to flows governed by efficiency, technology deployment, and environmental compliance. It includes both reinforcing loops and balancing loops, which are described in

Section 5.2. For instance, one reinforcing loop (R1) shows how improved technology increases gold recovery, reducing tail waste and boosting gold doré production. One balancing loop (B2) demonstrates how increases in tail waste trigger stricter environmental regulations, encouraging waste reduction measures. Arrows indicate causal relationships, such as how “ore input rate” and “tech efficiency” affect conversion, or how “gold bar sales rate” influences final economic value. This figure provides a visual framework for understanding how technological interventions and regulatory measures influence overall system performance, ensuring both economic gain and environmental responsibility are considered in mining logistics.

Several key aspects emerge after analyzing the above stock and flow simulation model:

- I.

Efficiency in Gold Extraction and Refining

The model highlights the importance of technological efficiency in different stages of gold mining.

Leaching and cyanidation technology significantly impact the gold conversion rate, determining how much gold is extracted from the ore.

Gold refining efficiency also influences the quantity of high-purity gold obtained from the gold doré.

Investing in advanced refining techniques can reduce gold loss in tail waste and doré waste, improving overall yield.

- II.

Impact of Waste Management and Recovery

Tail waste and doré waste are significant concerns in the mining process.

The diagram shows that advanced technology can extract recovered gold doré from waste.

Environmental compliance with waste reduction is crucial to ensuring sustainable mining practices.

A significant portion of gold can be lost without proper waste management, reducing overall profitability.

- III.

Economic and Market Influence on Gold Value

The gold price per gram determines the final gold value, which fluctuates in the global market.

The efficiency of gold bar conversion and the sales rate directly impact the revenue generated from mining operations.

A higher conversion rate and lower level of waste lead to better profitability and sustainability in the gold supply chain.

- IV.

Role of Policy and Technology in Improving Performance

Regulatory policies can influence the efficiency of gold mining by enforcing environmental standards and safety measures.

The use of automated tracking, AI-driven refining, and IoT-based monitoring can optimize extraction and waste management.

Investing in newer technologies ensures higher gold recovery rates, making mining more efficient and less wasteful.

The model demonstrates how technological advancements, waste management, and refining efficiency impact the overall gold supply chain. By enhancing recovery methods and reducing inefficiencies, mining companies can increase gold output while ensuring sustainability and compliance with environmental standards.

5.2. Balancing and Reinforcing Loops in the Gold-Mining Process Model (Figure 1)

In the system dynamics diagram of the gold-mining process, we can identify balancing loops (B) and reinforcing loops (R) that regulate and influence the system’s efficiency.

- I.

Reinforcing Loops (R)—Positive Feedback Loops

Reinforcing loops amplify changes within the system, leading to exponential growth or decline.

R1: Technology-Driven Gold Recovery

More advanced technology deployment → Higher gold recovery rate → More recovered gold doré → Less tail waste → Higher overall gold yield.

More gold is recovered if better refining techniques are applied, increasing overall efficiency.

R2: Higher Gold Value and Profitability

Higher gold bar sales → Higher gold value generation → Increased investment in gold refining and mining technology → Higher levels of efficiency and production → More gold bars.

This loop continuously improves the gold supply chain as more profits encourage technological upgrades.

R3: Poor Ore and Tail Waste Accumulation (Negative Impact)

More ore processed → More poor ore and tail waste → Increased environmental burden → Higher cost for waste management → Decreased efficiency.

If waste management is not improved, the mining process will become less sustainable over time.

- II.

Balancing Loops (B)—Negative Feedback Loops

Balancing loops regulate the system, aiming to maintain stability and prevent uncontrolled growth or decline.

B1: Gold Conversion and Waste Reduction

B2: Environmental Compliance and Waste Control

More tail waste generation → Stricter environmental regulations → Higher costs for waste reduction → Investment in eco-friendly technology → Lower levels of tail waste over time.

Government policies and environmental regulations help control excessive mining waste, ensuring sustainability.

B3: Ore Processing Efficiency Control

More ore input → Higher processing burden → Increased energy and labor costs → Slower processing rate → Regulated ore input rate.

This prevents excessive mining beyond the system’s capacity and stabilizes production efficiency.

Reinforcing loops (R1 and R2) help increase efficiency, the level of gold production, and revenue through better technology and refining techniques.

Balancing loops (B1 and B2) help control waste, environmental impact, and resource management in order to prevent inefficiencies.

Mining operations can achieve higher levels of sustainability and profitability by optimizing reinforcing loops while maintaining balancing loops.

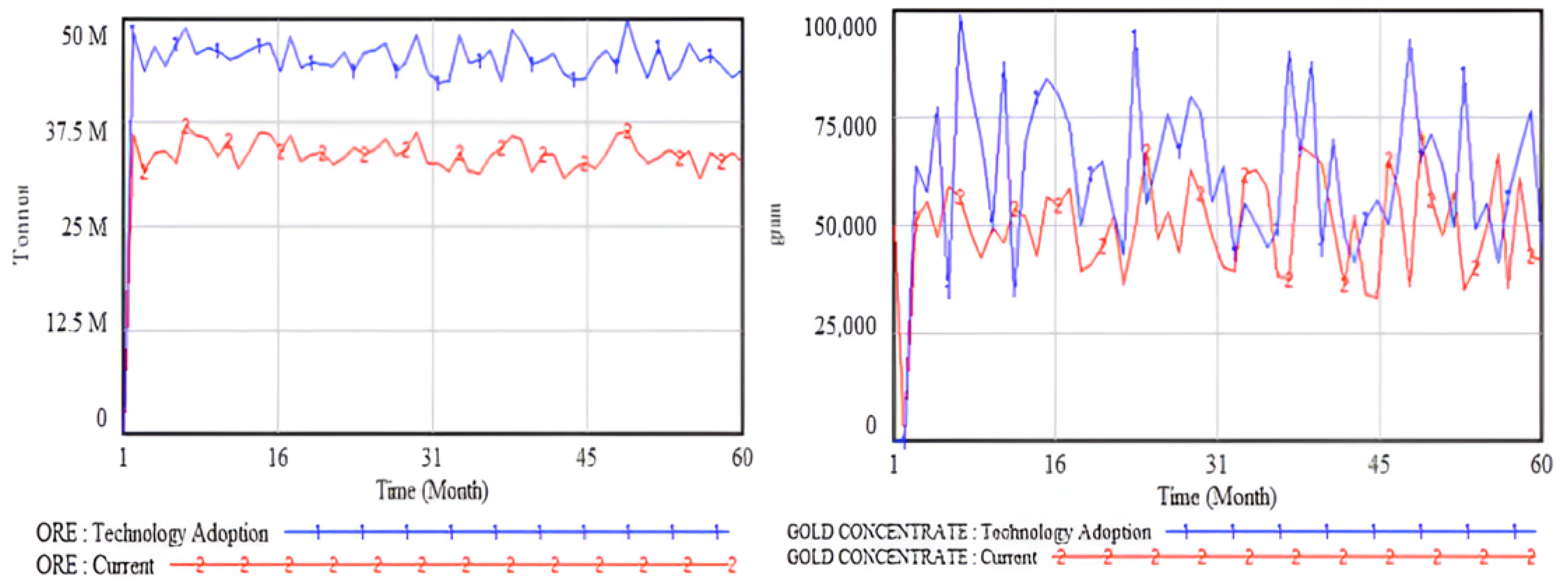

5.3. Impact of Technology Adoption on Ore Processing and Gold Concentrate Output

Figure 4 shows ore quantity (in tonnes) over 60 months; technology adoption (blue line) maintains a higher ore input (~45–50M tonnes) compared to the current system (red line) at ~30–37.5M tonnes. The right graph tracks gold concentrate output (grams); technology adoption leads to increased fluctuation but overall increased production (~50,000–100,000 g) compared to the current system (~25,000–75,000 g). The positive slope trends in both graphs suggest technology adoption enhances ore processing and gold recovery efficiency over time.

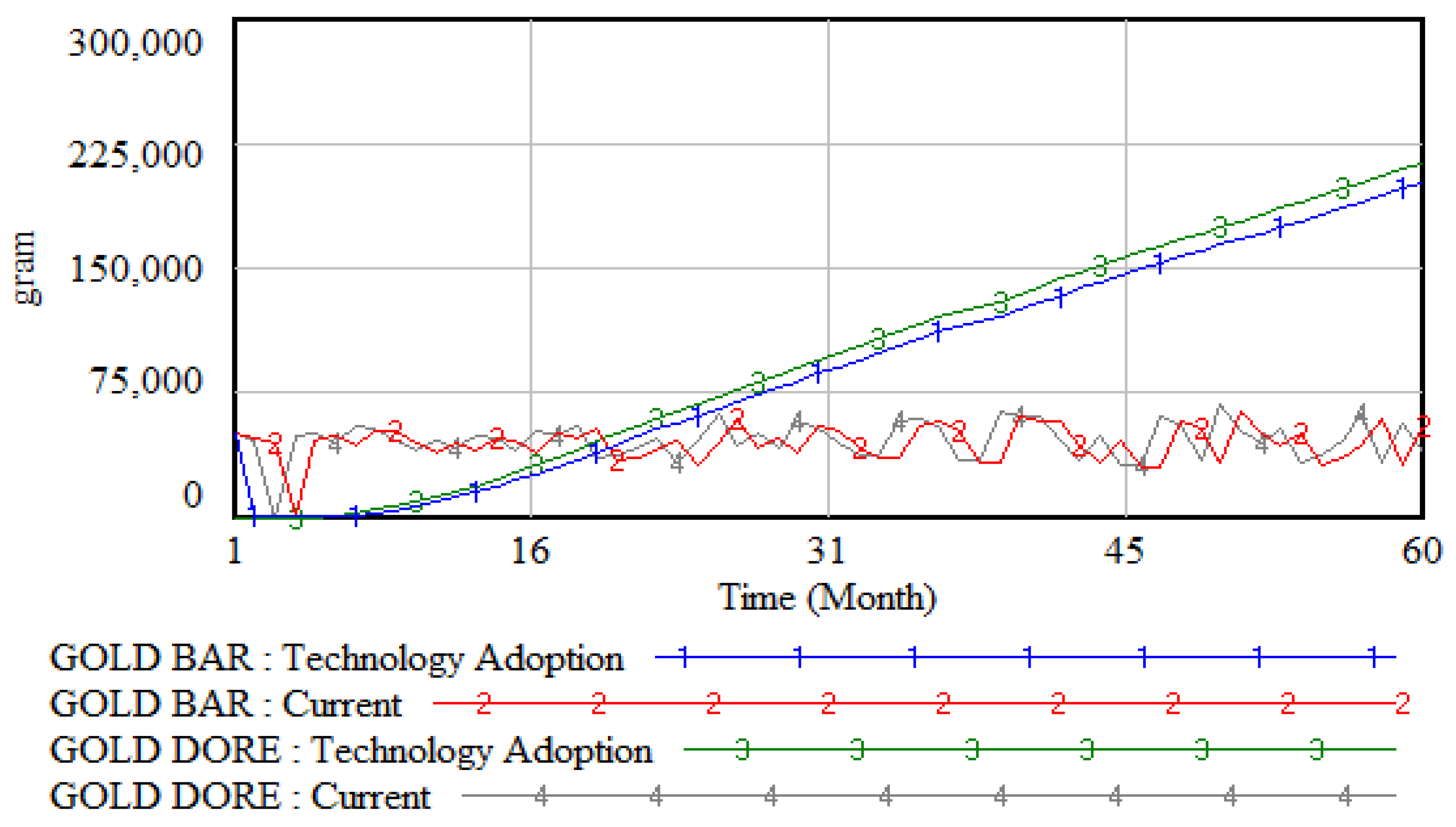

5.4. Impact of Technology Adoption on Gold Doré and Gold Bar Production

Figure 5 illustrates gold doré and gold bar production (grams) over 60 months, comparing technology adoption (blue and green lines) with the current system (red and gray lines). The technology-adoption scenario shows a steady upward trend, in which gold doré production (green) and gold bar production (blue) increase consistently, reaching approximately 250,000–300,000 g by month 60. In contrast, the current system (red and gray lines) fluctuates significantly and remains below 75,000 g throughout the duration. The results indicate that technological improvements significantly enhance gold conversion efficiency and production output over time.

The industry experts estimated a 30% reduction in emissions, a finding derived from simulated outputs based on fuel usage, waste handling, and equipment activity changes, modeled under the technology-adoption scenario. While this is not tested based on ISO 14064 [

44] or other certified emissions accounting protocols, it reflects relative reductions estimated to be accrued through improvements in transport efficiency, reductions in equipment downtime, and optimized smelting processes, as captured in the model.

5.5. Logistical Assessment and Model-Based Evidence

The assessment of current logistical support in Kyrgyzstan’s gold-mining industry is directly grounded in both the qualitative insights gathered through stakeholder interviews (

Section 3.2) and the simulation model developed and calibrated using real-world logistical parameters (

Section 3.3). The evaluation highlights systemic inefficiencies such as long-distance transport delays (300–700 km), frequent equipment breakdowns, and low smelting capacity, which were incorporated into the baseline scenario of the simulation model. The sensitivity analysis (

Figure 6,

Figure 7 and

Figure 8) reinforces these findings by quantifying the impacts of varying levels of technology adoption. For instance, under the current logistics configuration, cumulative gold bar production remains below 75,000 g over 60 months, whereas full logistics adoption of AI and IoT would exceed 1.8 million grams. Similarly, the model predicts a near-stagnant gold value under current logistics, compared to over

$2.75 billion with complete optimization. These comparative outputs demonstrate that the inefficiencies reported in the logistical assessment are consistent with stakeholder testimony and validated quantitatively through model simulation and sensitivity testing. Therefore, this section offers critical evidence supporting the urgency of technological intervention designed to resolve current logistical constraints.

5.6. Sensitivity Analyses

Sensitivity analysis examines how changes in input parameters affect a model’s output, helping to assess uncertainty and robustness in decision-making [

45]. In the context of gold mining, sensitivity analysis helps evaluate the impact of technology-adoption levels on gold concentrate production, ensuring that strategic investments in mining technology yield consistent results. This approach is crucial for risk assessment, process optimization, and enhancing operational efficiency, particularly in dynamic environments such as those found in gold extraction and refining.

Figure 6 illustrates the gold concentrate output (in grams) over a 60-month period, comparing different technology-adoption levels (50%, 75%, 95%, and 100%) with the current system (red line). The stacked, colored regions represent different adoption levels, with higher levels of adoption leading to increased production, peaking above 375,000 g in some months. The current system (red line) remains significantly lower, indicating that higher levels of technology integration result in better and more stable gold recovery over time. The fluctuations suggest that even partial adoption (75–95%) provides noticeable improvements, reinforcing the importance of continuous investment in mining technology.

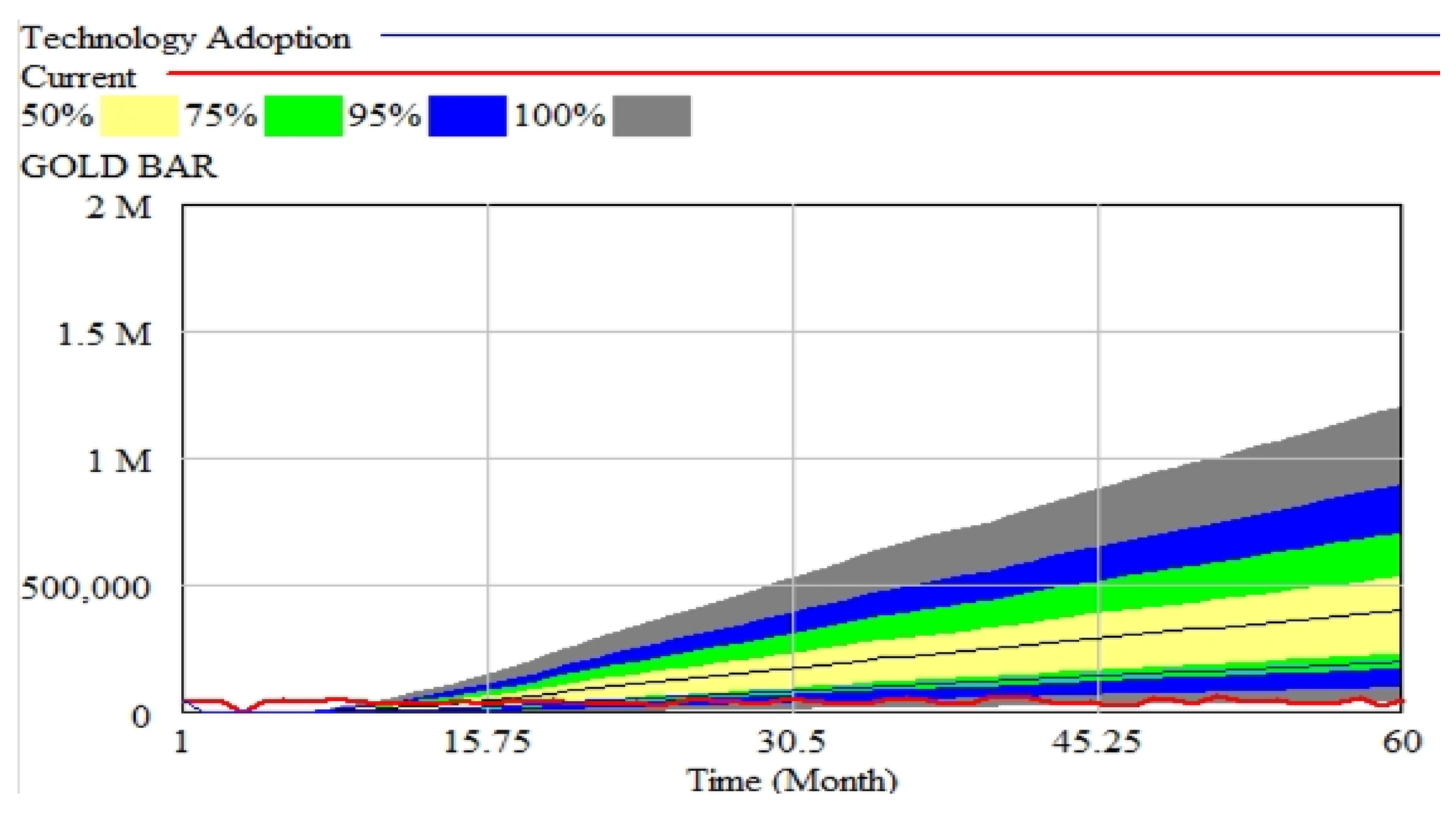

Figure 7 displays the cumulative gold bar production (in grams) over 60 months, illustrating the impacts of varying technology-adoption levels (50%, 75%, 95%, and 100%) compared to the current system (red line). The stacked colored regions indicate that higher levels of technology adoption lead to exponential growth, with full adoption (gray area, which is the top of the graph lines) surpassing 1.8 million grams by month 60. In contrast, the current system remains stagnant, producing a minimal number of gold bars. This demonstrates that higher levels of technological integration significantly enhance gold bar output, making long-term investments in automation and refining essential for the maximization of production efficiency.

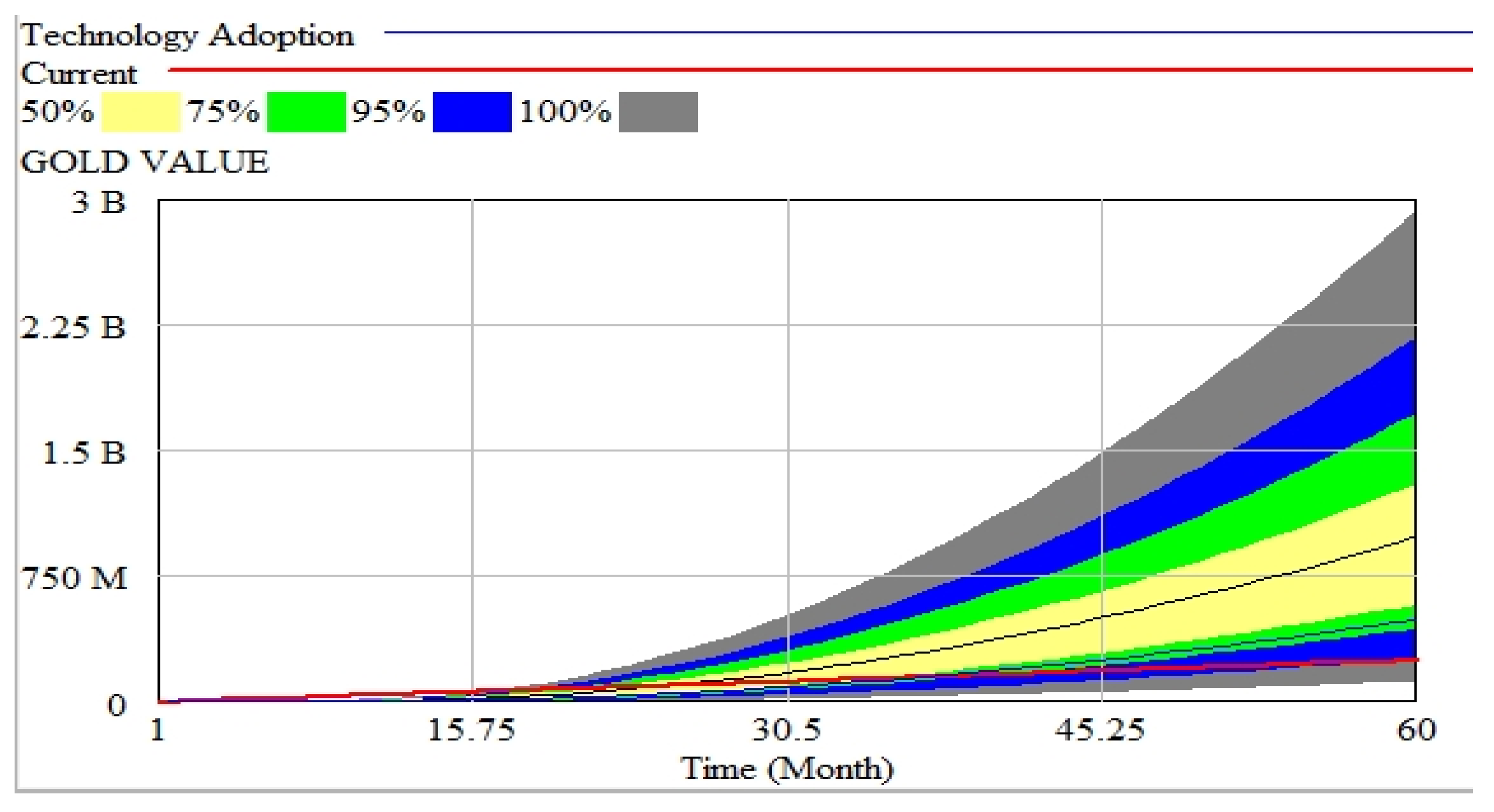

Figure 8 presents the cumulative gold value (in billions) over 60 months, comparing different levels of technology adoption (50%, 75%, 95%, and 100%) with the current system (red line). The stacked, colored regions indicate that higher levels of technology adoption result in exponential revenue growth, with full adoption (gray area) surpassing

$2.75 billion by month 60. In contrast, the current system (red line) remains nearly flat, reflecting minimal revenue generation. The results highlight that advanced mining and refining technologies significantly enhance economic output, making technological investment essential for maximizing profitability in the gold industry.

6. Results

6.1. Assessment of Current Logistical Support in the Existing Gold-Mining Industry

The present logistical infrastructure relies on conventional transport and storage techniques, with little technological integration. According to the evaluation, supply chain inefficiencies result from manual tracking and simple scheduling systems. According to current statistics, poor coordination between transportation companies and remote mining locations causes logistical delays.

6.2. Key Results

Unreliable transport routes cause an increase of 20–30% in the supply delays between the mine and processing facilities. Inefficient stockpiling leads to an over 15% increase in raw material misplacement or transit delay cases.

The impact of revised logistical support on gold production and waste management is examined.

The introduction of advanced logistical support, including automation and real-time tracking systems, has led to significant improvements in automated fleet management and the use of IoT-enabled devices for real-time data collection, which have decreased idle times and increased production capacity by 25%.

6.3. Key Metrics

An approximately 30% reduction in equipment downtime can be attained with predictive maintenance supported by AI-driven analytics.

An approximately 15% improvement in production flow efficiency can be attained by integrating route optimization and fleet management systems.

6.4. Impact on Gold Waste Management

The revised process has also improved gold waste management practices. Technologies such as blockchain for tracking waste disposal and IoT-based sensors for monitoring tailings have streamlined waste disposal logistics, reducing the mining operation’s overall environmental footprint. Key findings of the present study include a 20% reduction in waste material mismanagement, indicating improved efficiency in handling tailings and by-products. Additionally, the implementation of automated reporting systems has enhanced compliance with environmental regulations by enabling the tracking of waste flows to be more accurate and timely.

7. Discussion

Current Logistical Support and Its Implications

Analysis of Current Logistical Shortcomings

Research indicates that inefficient technology and laborious procedures in Central Asian gold mines lead to delays and losses. These inefficiencies raise operational expenses and lower productivity. Logistics management needs digital change, according to the statistics.

Implications for the Industry

The findings suggest that Central Asian miners will suffer relative to the global industry if they fail to modernize their logistical systems. The adoption of digital tools and automated systems is no longer optional but essential for maintaining profitability and environmental compliance.

Enhancing Production through Logistics Innovation

The results clearly show that the integration of advanced technologies into the logistical process can substantially improve production efficiency. IoT, AI, and automated systems have reduced delays and optimized resource allocation. This directly supports the hypothesis that logistical innovation is a key factor in enhancing the overall efficiency of gold-mining operations. The findings align with previous studies that show similar productivity gains in other mining sectors when advanced logistics solutions are adopted. The central challenge remains the initial investment in technology, often a barrier for smaller mines.

Improved Waste Management and Environmental Impact

The implementation of waste management technologies like blockchain and IoT sensors has reduced environmental damage. These solutions enhance hazardous waste tracking and disposal, meeting regulatory requirements. The research suggests that modern logistics increases gold-mining productivity and minimizes environmental impact, which is crucial in today’s sustainability-focused market.

8. Theoretical and Practical Contributions

This study utilizes advanced logistics technology in the context of Central Asia’s mining sector, aiming to optimize gold output management. It examines the specific issues that gold-mining firms encounter in remote, mountainous areas, drawing on logistics management, supply chain optimization, and resource-based view (RBV) theories. The study further extends on the diffusion of innovation theory by illustrating how resource-constrained enterprises might benefit from technological adoption despite infrastructure constraints. It also enhances awareness of logistical efficiency and resource extraction, especially as to developing nations with limited processing capacities. This report provides realistic solutions to the problems of Kyrgyzstan’s gold-mining industry. After identifying logistical inefficiencies and old equipment, the research recommends improving transit, modernizing production, and implementing technology-based logistics systems. It offers policymakers and business stakeholders concrete suggestions as to the following:

Improving Domestic Processing Capacity: Enhancing smelting capacities, reducing export reliance, and retaining the economic value of national gold assets.

Modernizing Equipment: Transitioning from Soviet-era equipment to energy-efficient, high-performing equipment.

Logistics Optimization: Implementing innovative technologies, such as real-time tracking and automated route optimization, to enhance operations and reduce transportation expenses.

Policy Reforms: Proposing regulatory changes that aim to encourage infrastructure investment, modern technology, and sustainable mining practices.

The research aims to enhance the efficiency, profitability, and sustainability of Kyrgyzstan’s gold-mining industry and other relevant sectors.

9. Recommendations

The present research, based on a study of Kyrgyzstan’s gold-mining industry’s difficulties and logistical inefficiencies, suggests numerous actions:

Build new Smelting Facilities: Kyrgyzstan should prioritize establishing new smelting facilities in the south and central regions. This would eliminate the need for long-distance shipping of gold concentrates and allow more mining businesses to process their products domestically, thereby enhancing economic value.

Modernize Mining Equipment: Investments in contemporary machinery from global vendors to upgrade antiquated Soviet-era equipment should be prioritized. Smaller enterprises may benefit from long-term leasing or financing agreements with manufacturers in China, Russia, or the West.

Adopt Advanced Logistics Technologies: IoT-based tracking, automated route optimization, and fleet management software can enhance the efficiency of mining businesses in transporting raw materials through mountainous locations. This would cut gasoline expenses and delays and boost production.

Promote Local Mining Equipment Production: Local capabilities should be developed, using a long-term plan, to lessen dependency on foreign suppliers. Tax advantages or subsidies might encourage international investors to build factories in Kyrgyzstan or the surrounding areas.

Enhance Environmental Regulations: Mining businesses should adopt sustainable practices, including the use of cleaner energy and efficient waste management. Tax discounts or incentives from the government should encourage the adoption of sustainable technology.

Adopting Future Technologies: AI, driverless cars, and blockchain are essential for achieving logistical efficiency and a competitive advantage. These technologies are crucial for reducing operational costs and enhancing productivity.

Moving Toward Sustainable Mining: Gold mining will prioritize sustainability in the future. Green logistics technologies, such as electric trucks, and the integration of green energy can help protect the environment and create savings in long-term operational expenses.

Long-term Environmental Benefits: Mines adopting sustainable logistics systems may better meet future environmental standards and attract investors keen on sustainability metrics.

Technological Integration for Improved Efficiency: Based on the analysis, integrating cloud-based Warehouse Management Systems (WMS) and advanced transportation technologies, such as autonomous vehicles, are recommended in seeking to improve operational efficiency. These technologies may boost productivity by 35% and cut logistical expenses by 20%.

Sustainability and Environmental Considerations: The results emphasize the need for sustainability. The use of electric vehicles and renewable energy for on-site activities cuts carbon emissions. The present study suggests that green logistics solutions might reduce CO2 emissions by 40% over time.

10. Conclusions

Kyrgyzstan’s gold-mining sector has logistical, technological, and operational constraints that restrict its development and economic potential. The long distances to Kara-Balta’s single smelting plant, antiquated Soviet-era equipment, and the practice of exporting incomplete goods for further processing all contribute to inefficiencies and lost economic value. Due to the absence of indigenous mining equipment manufacturers, firms must import expensive and modern technological equipment from reliable sources, thereby increasing operational expenses. This research recommends incorporating sophisticated logistics technologies, including IoT-based tracking systems, automated route optimization, and fleet management software, to improve gold production management. These technologies address industrial challenges by reducing transportation costs, improving equipment performance, and promoting sustainable mining practices. Such technologies also improve waste reduction and convert pure gold from gold wastes, which will help the industry make more economic gains, allowing it to deploy technologies step-by-step for sustainable achievements in production and environmental restoration. To address these challenges, Kyrgyzstan’s mining sector must invest in infrastructure, smelting, equipment production, and technology-driven logistics. The industry may become more competitive, retaining more economic value, which in turn encourages long-term growth and sustainability. Although this study’s methodology provides valuable insights into the mining business from a sustainable-development standpoint, it has limitationsWhile this study provides valuable insights into the subject matter, it is not without limitations that may affect the generalizability and scope of its findings.These include potential literature bias due to limited region-specific research, restricted access to proprietary data from private mining companies, and a lack of extensive primary data collection through interviews or surveys. The study also does not include a comparative analysis relative to other regional or global mining systems, which could provide useful benchmarks. Moreover, operational challenges such as ore quality inconsistencies, shortages of skilled human resources, and locational disadvantages—particularly the distance to smelting infrastructure—may limit the practical application of the proposed technologies. Future research should explore detailed financial cost–benefit and ROI analyses to assess the economic feasibility of technological adoption. Comparative studies of emerging innovations (e.g., AI, IoT, and automation) are needed to determine which solutions offer the best performance under the specific conditions associated with Kyrgyzstan. Additional attention should be given to understanding the influences of political context, budgetary constraints, regulatory frameworks, environmental compliance enforcement, and community engagement in shaping sustainable mining strategies. As technologies evolve rapidly, continuous reassessment of their implications, adaptability, and policy alignment will be essential for long-term impact and resilience in Kyrgyzstan’s gold-mining sector.

Author Contributions

Conceptualization, M.S., T.N. and A.K.; methodology, M.S.; software, M.S.; validation, M.S., A.K. and T.N.; formal analysis, M.S. and T.N.; investigation, A.K. and M.S.; resources, A.K. and M.S.; data curation, M.S., A.K. and T.N.; writing—original draft preparation, M.S., A.K. and T.N.; writing—review and editing, M.S., A.K. and T.N.; visualization, M.S., A.K. and T.N.; supervision, M.S.; project administration, M.S.; funding acquisition, Not Applicable. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

Author Adil Kaibaliev was employed by the Legacy Fidelity Consulting LLC. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Appendix A. Variables, Input Parameters, Equations, and Units Used SD Simulation Model (Technology-Adoption Scenario)

| Variable Name | Equation/Data Input | Unit |

| “Leaching & Cyanidation Tech Efficiency Factor” | 0.95 | dmnl |

| Doré conversion rate | Random uniform (0.9, 0.95, 1000) | 1/gram |

| Environmental compliance for waste reduction | 0.95 | dmnl |

| Gold bar conversion rate | 0.95 | dmnl |

| Gold bar sales rate | 0.99 | dmnl |

| Gold conversion rate | Random uniform (0.001, 0.002, 1000) | dmnl |

| Gold doré waste rate | 1-gold-bar conversion rate | dmnl |

| Gold for Sell | GOLD BAR × gold bar sales rate | gram |

| Gold price per gram | Random uniform (93, 98.5, 100) | 1/dollars |

| Ore quantity in tonnes | Random uniform (34,000, 38,000, 1000) | Tonne/Months |

| Policy regulation | Random uniform (1.1, 1.2, 1000) | dmnl |

| Poor ore rate | Random uniform (0.998, 0.9999, 1000) | dmnl |

| Quality ore input | 1 | dmnl |

| Tech efficiency ore | 1.15 | dmnl |

| Tech refining factor | 1.1 | dmnl |

| Technology deploy for recovery gold | Random uniform (0.2, 0.25, 100) | 1/gram |

| Technology deployed for ore collection | 1.1 | dmnl |

Appendix B. Variables, Equations, and Units Used in the SD Simulation Model

| Variable Name | Equation | Unit |

| Tail waste rate | 1-doré conversion rate | 1/gram |

| GOLD BAR | Gold Bar Conversion-Gold for Sell | gram |

| GOLD CONCENTRATE | Gold Concentrate Conversion-Doré Conversion-Tail waste Output | gram |

| Doré Conversion | GOLD CONCENTRATE × doré conversion rate × tech refining factor × policy regulation | dmnl |

| Tail waste Output | GOLD CONCENTRATE × tail waste rate × “Leaching & Cyanidation Tech Efficiency Factor” × environmental compliance for waste reduction | kgs/day |

| Gold Bar Conversion | GOLD DORÉ × gold bar conversion rate | gram |

| Gold Doré Waste | GOLD DORÉ × gold doré waste rate × environmental compliance for waste reduction | gram |

| GOLD VALUE | Gold for Sell × gold price per gram | dollars |

| Ore Input | Ore input rate × technology deployed for ore collection | Kgs/day |

| ORE | Ore Input-Gold Concentrate Conversion-Poor Ore Outcome | Tonens |

| Ore input rate | Ore quantity in tons × 1000 × policy regulation × quality ore input | Kgs/day |

| Gold Concentrate Conversion | ORE × Gold conversion rate × tech efficiency ore | |

| Poor Ore Outcome | ORE × poor ore rate | |

| GOLD DORÉ | RECOVERED Gold Doré-Gold Bar Conversion-Gold Doré Waste | |

| TAIL WASTE | Tail waste Output-Recover Gold Rate | |

| Recover Gold Rate | TAIL WASTE × technology deploy for recovery gold | |

References

- Renaud, K.M. 2019 Minerals Yearbook, U.S. Geological Survey Minerals Yearbook, 2019, U.S. Geological Survey. Available online: https://www.usgs.gov/centers/national-minerals-information-center/minerals-yearbook-metals-and-minerals (accessed on 12 July 2025).

- Ghorbani, Y.; Nwaila, G.T.; Zhang, S.E.; Bourdeau, J.E.; Cánovas, M.; Arzua, J.; Nikadat, N. Moving towards deep underground mineral resources: Drivers, challenges and potential solutions. Resour. Policy 2023, 80, 103222. [Google Scholar] [CrossRef]

- Caballero Espejo, J.; Messinger, M.; Román-Dañobeytia, F.; Ascorra, C.; Fernandez, L.E.; Silman, M. Deforestation and forest degradation due to gold mining in the Peruvian Amazon: A 34-year perspective. Remote Sens. 2018, 10, 1903. [Google Scholar] [CrossRef]

- Verhozin, S.S. Gold Mining Industry of Kyrgyzstan. Review. 2019. Available online: https://zolotodb.ru/article/12255/?page=all (accessed on 19 August 2019).

- Hiro, D. Inside Central Asia: A Political and Cultural History of Uzbekistan, Turkmenistan, Kazakhstan, Kyrgyzstan, Tajikistan, Turkey, and Iran; Abrams: New York, NY, USA, 2011. [Google Scholar]

- Bogdetsky, V.; Stavinskiy, V.; Shukurov, E.; Suyunbaev, M. Mining Industry and Sustainable Development in Kyrgyzstan. Min. Miner. Sustain. Dev. 2001, 110, 23–37. [Google Scholar]

- Mogilevskii, R.; Abdrazakova, N.; Chalbasova, S. The Impact of Kumtor Gold Mine on the Economic and Social Development of the Kyrgyz Republic. Univ. Cent. Asia–Inst. Public Policy Adm. (IPPA) Work. Pap. 2015, 32. [Google Scholar] [CrossRef]

- Sagers, M.J. Gold Production in Central Asia. Post-Sov. Geogr. Econ. 1998, 39, 125–150. [Google Scholar] [CrossRef]

- Ivanov, Y. Revolutions in Kyrgyzstan. In Handbook of Revolutions in the 21st Century: The New Waves of Revolutions, and the Causes and Effects of Disruptive Political Change; Springer: Cham, Switzerland, 2022; pp. 517–547. [Google Scholar]

- Egidarev, E.; Simonov, E. Assessment of the Environmental Effect of Placer Gold Mining in the Amur River Basin. Water Resour. 2015, 42, 897–908. [Google Scholar] [CrossRef]

- NASA Jet Propulsion Laboratory. PIA25445: Muruntau Mine, Uzbekistan. JPL. 2022. Available online: https://www.jpl.nasa.gov/images/pia25445-muruntau-mine-uzbekistan/ (accessed on 12 July 2025).

- Verhozin, S. Gold Mining Industry of Uzbekistan. 2024. Available online: https://zolotodb.ru/article/12094 (accessed on 19 February 2024).

- Borisov, F.I.; Gorbaneva, T.V.; Zamaletdinov, T.S.; Karaev, Y.V.; Larina, T.V.; Nikonorov, V.V.; Tolsky, V.I. Gold of Kyrgyzstan. Book 1: Geology. Localization Conditions; Nasi Publishing: Bishkek, Kyrgyzstan, 2004. [Google Scholar]

- Bulletin, G.M. Kyrgyzstan Increased Production by 29% in 2022. 2023. Available online: https://gold.1prime.ru/news/20230220/484805.html (accessed on 20 February 2023).

- BHP (2023). Jimblebar Autonomous Haulage and Decarbonisation Initiatives. BHP Western Australia Operations. Available online: https://www.bhp.com/what-we-do/global-locations/australia/western-australia/jimblebar (accessed on 12 July 2025).

- Jang, H.; Topal, E. Transformation of the Australian Mining Industry and Future Prospects. Min. Technol. 2020, 129, 120–134. [Google Scholar] [CrossRef]

- Henderson, J.; Sanders, M. AI Driven Predictive Maintenance: Reducing Downtime and Enhancing Productivity in Manufacturing Environments. Preprints 2025, 202504.0602. [Google Scholar] [CrossRef]

- Shamsuddoha, M.; Nasir, T.; Hossain, N.U.I. A sustainable supply chain framework for dairy farming operations: A system dynamics approach. Sustainability 2023, 15, 8417. [Google Scholar] [CrossRef]

- Suzi, M. How to advance sustainable mining. IISD Earth Negot. Bull 2021, 12, 2–8. [Google Scholar]

- Rylnikova, M. Conditions and Principles of Sustainable Development of Mining Enterprises During a Period of Increased Risks and Global Challenges. *Innovative Technologies* 2022, 69–73. Available online: https://mining-media.ru/ru/article/newtech/17439-usloviya-i-printsipy-ustojchivogo-razvitiya-gornodobyvayushchikh-predpriyatij-v-period-povyshennykh-riskov-i-globalnykh-vyzovov (accessed on 12 July 2025).

- Aznar-Sánchez, J.A.; García-Gómez, J.J.; Velasco-Muñoz, J.F.; Carretero-Gómez, A. Mining Waste and Its Sustainable Management: Advances in Worldwide Research. Minerals 2018, 8, 284. [Google Scholar] [CrossRef]

- Gavin, M.M. Global trends in gold mining: Towards quantifying environmental and resource sustainability? Resour. Policy 2007, 32, 42–56. [Google Scholar] [CrossRef]

- The Library of Congress. Kyrgyzstan. 2010. Available online: https://www.loc.gov/today/placesinthenews/archive/2010arch/20100619_kyrgyzstan.html (accessed on 19 June 2010).

- Ministry of Natural Resources, Ecology and Technical Supervision. Economics. 2020. Available online: https://kabar.kg/news/krupnye-gornodobyvaiushchie-predpriiatiia-rabotaiut-bespereboino-s-sobliudeniem-sanitarnykh-norm-gkpen-kr/ (accessed on 15 September 2020).

- Kumtor Gold Company, C.J.S.C. Yearly Report. 2022. Available online: https://www.kumtor.kg/wp-content/uploads/2023/06/godovoj-otchet-za-2022j-god.pdf (accessed on 12 July 2025).

- Economist. Kyrgyzstan Received 16 Billion Soms in Dividends from Its Share in the Kyrgyz-Chinese Enterprise Altynken. 2023. Available online: https://economist.kg/dengi/2023/07/19/kyrghyzstan-poluchil-16-mlrd-somov-dividiendov-ot-doli-v-kyrghyzsko-kitaiskom-priedpriiatii-altynkien/ (accessed on 19 July 2023).

- Akchabar. In 2022, Alliance Altyn Produced More Than 4 Tons of Gold. 2023. Available online: https://www.akchabar.kg/ru/news/v-proshlom-godu-alyans-altyn-proizvel-bolshe-4-tysyach-kilogramm-zolota/ (accessed on 12 July 2025).

- Kazminerals. Brief Overview of Bozymchak. 2022. Available online: https://www.kazminerals.com/ru/%D0%B3%D0%BB%D0%B0%D0%B2%D0%BD%D0%B0%D1%8F/our-business/bozymchak/ (accessed on 12 July 2025).

- Manu, A.; Forkuo, E.K.; Boakye-Danquah, J. Geospatial techniques for environmental management in small-scale gold mining areas in Ghana. Remote Sens. 2020, 12, 911. [Google Scholar] [CrossRef]

- Mwanza, J.; Mashumba, P.; Telukdarie, A. A framework for monitoring stability of tailings dams in real time using digital twin simulation and machine learning. Procedia Comput. Sci. 2024, 232, 2279–2288. [Google Scholar] [CrossRef]

- Pepper, M.; Roche, C.; Mudd, G. Mining legacies—Understanding life-of-mine across time and space. In Proceedings of the Life-of-Mine Conference, Brisbane, Australia, 16–18 July 2014. [Google Scholar]

- Kirsch, S. Mining and environmental human rights in Papua New Guinea. In Transnational Corporations and Human Rights; Springer: Cham, Switzerland, 2003; pp. 115–136. [Google Scholar]

- Chadi, G.M. Environmental Impacts Resulting from Gold Mining Tailings Storage Facilities within the West Rand Area in South Africa. Ph.D. Thesis, University of South Africa, Pretoria, South Africa, 2022. [Google Scholar]

- Shamsuddoha, M.; Quaddus, M.A.; Woodside, A.G. Environmental sustainability through designing reverse logistical loops: Case research of poultry supply chains using system dynamics. J. Bus. Ind. Mark. 2022, 37, 823–840. [Google Scholar] [CrossRef]

- Shamsuddoha, M.; Woodside, A.G. Sustainability process innovations resulting in new value-added by-products: Principal lessons from second-order system-dynamics engineering (SOSDE). J. Bus. Ind. Mark. 2023, 38, 2403–2416. [Google Scholar] [CrossRef]

- Penny, C. Use of Shotcrete Made with Mine Waste to Reduce Costs and Environmental Impacts of Waste Disposal; Montana Tech Library: Butte, MT, USA, 2020. [Google Scholar]