Achieving Sustainable Supply Chains: Applying Group Concept Mapping to Prioritize and Implement Sustainable Management Practices

Abstract

1. Introduction

“Overall, the results indicate that the definitions for GSCM were generally more narrowly focused than those for SSCM, with an overwhelming emphasis on environmental issues. Though some definitions of SSCM show considerable overlap with definitions of GSCM, it is clear that SSCM is essentially an extension of GSCM.” (p. 334)

- What SSCM and GSCM practices, tools, and techniques are deployed across supply chains that impact enterprises’ efforts to be socially and environmentally sustainable and improve sustainability performance?

- What are the potential solutions, or solution concepts, that can be implemented to facilitate enterprises’ desire to redirect their supply chains to be more socially and environmentally sustainable?

- How can companies create action plans to deploy recognized practices, tools, and techniques to restructure and fundamentally change supply chains that are not sustainable?

2. Materials and Methods

3. Results

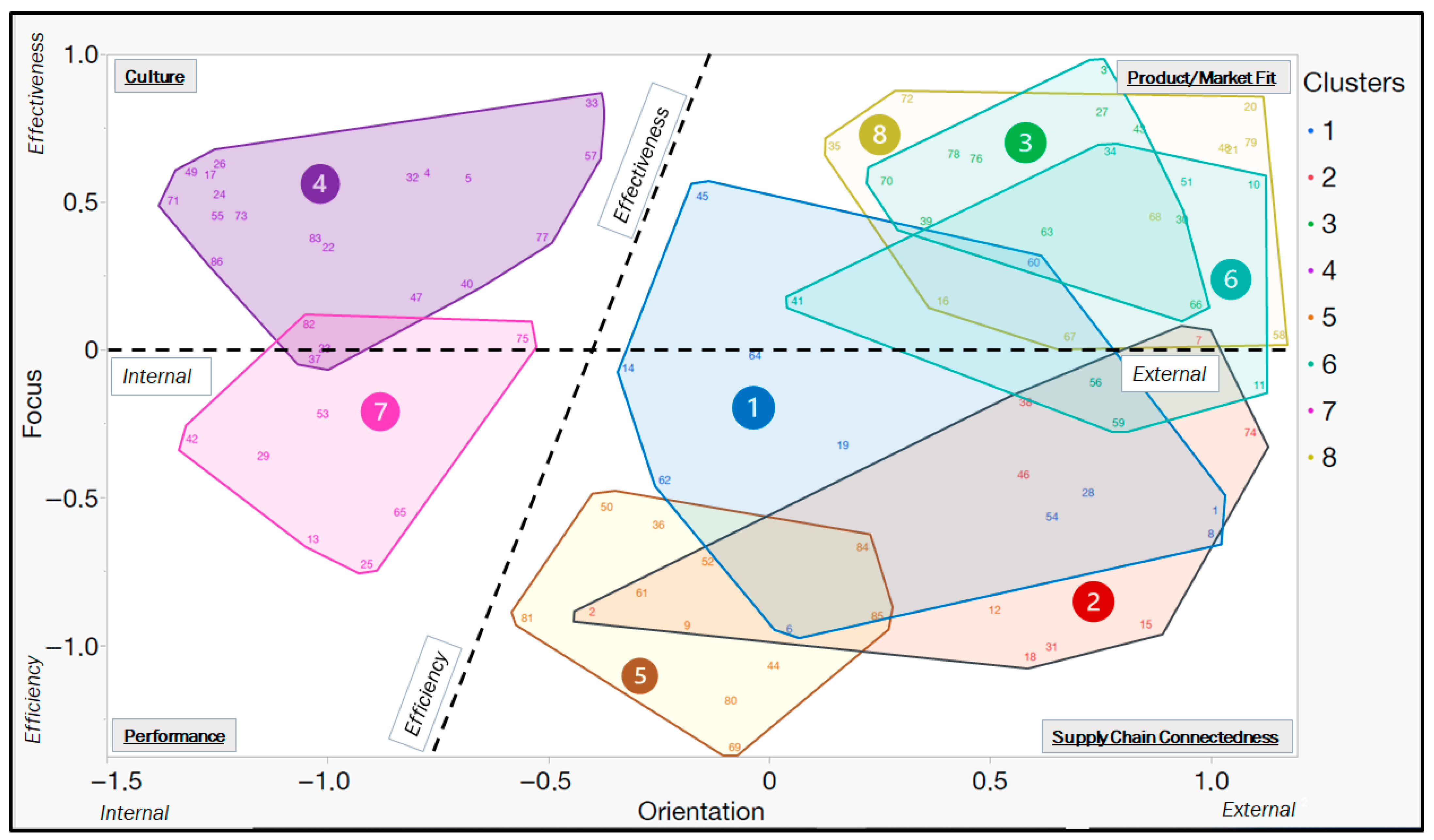

3.1. Priority Matrix of Implementation

3.2. Interpretation of Overlapping Clusters

3.3. Interpreting Quadrants in the Concept Map and Priority Matrix

3.3.1. Interpretation of the Culture Quadrant

3.3.2. Interpretation of the Product/Market Fit Quadrant

3.3.3. Interpretation of the Performance Quadrant

3.3.4. Interpretation of the Supply Chain Connectedness Quadrant

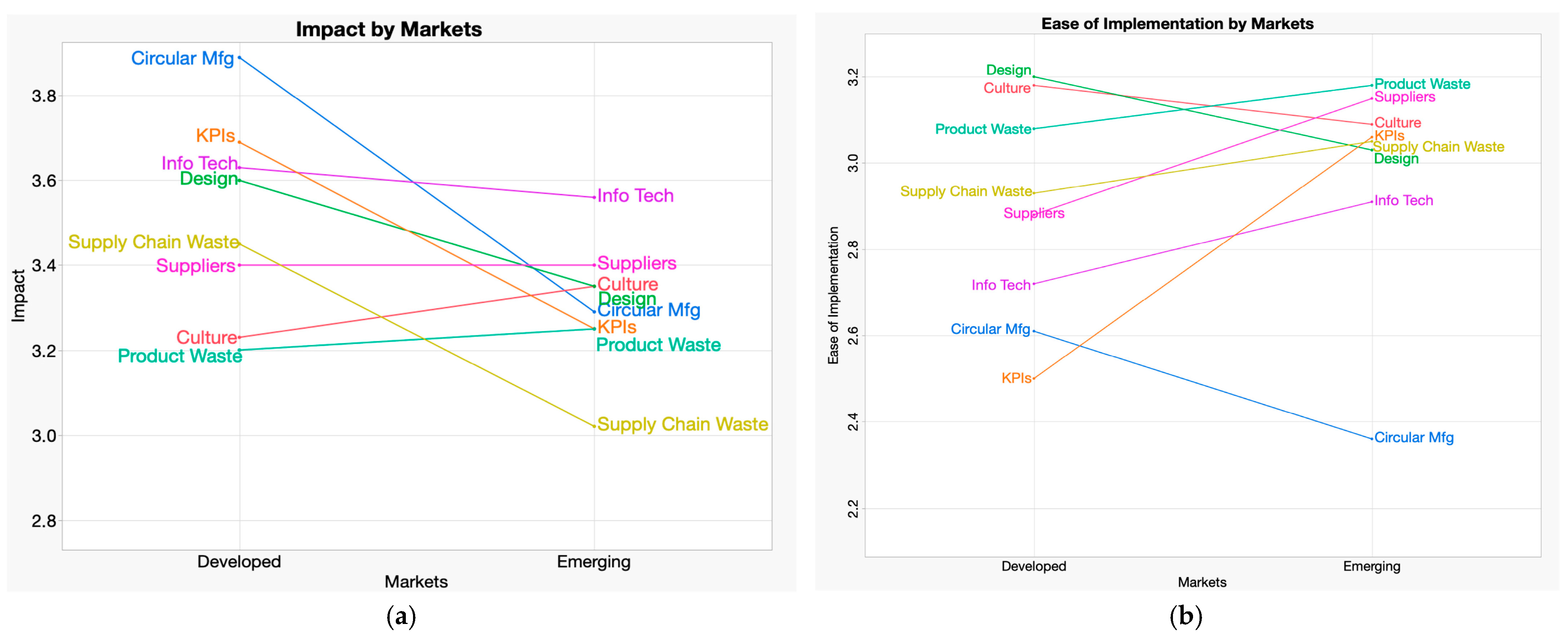

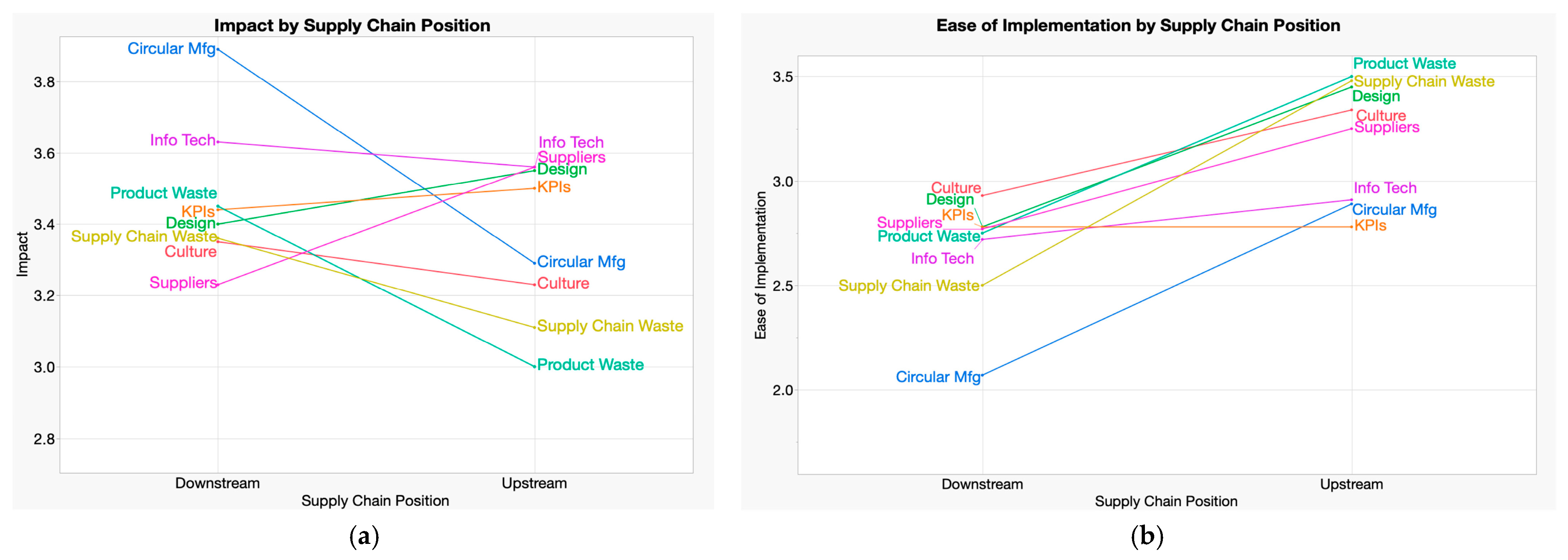

3.4. Pattern Matching

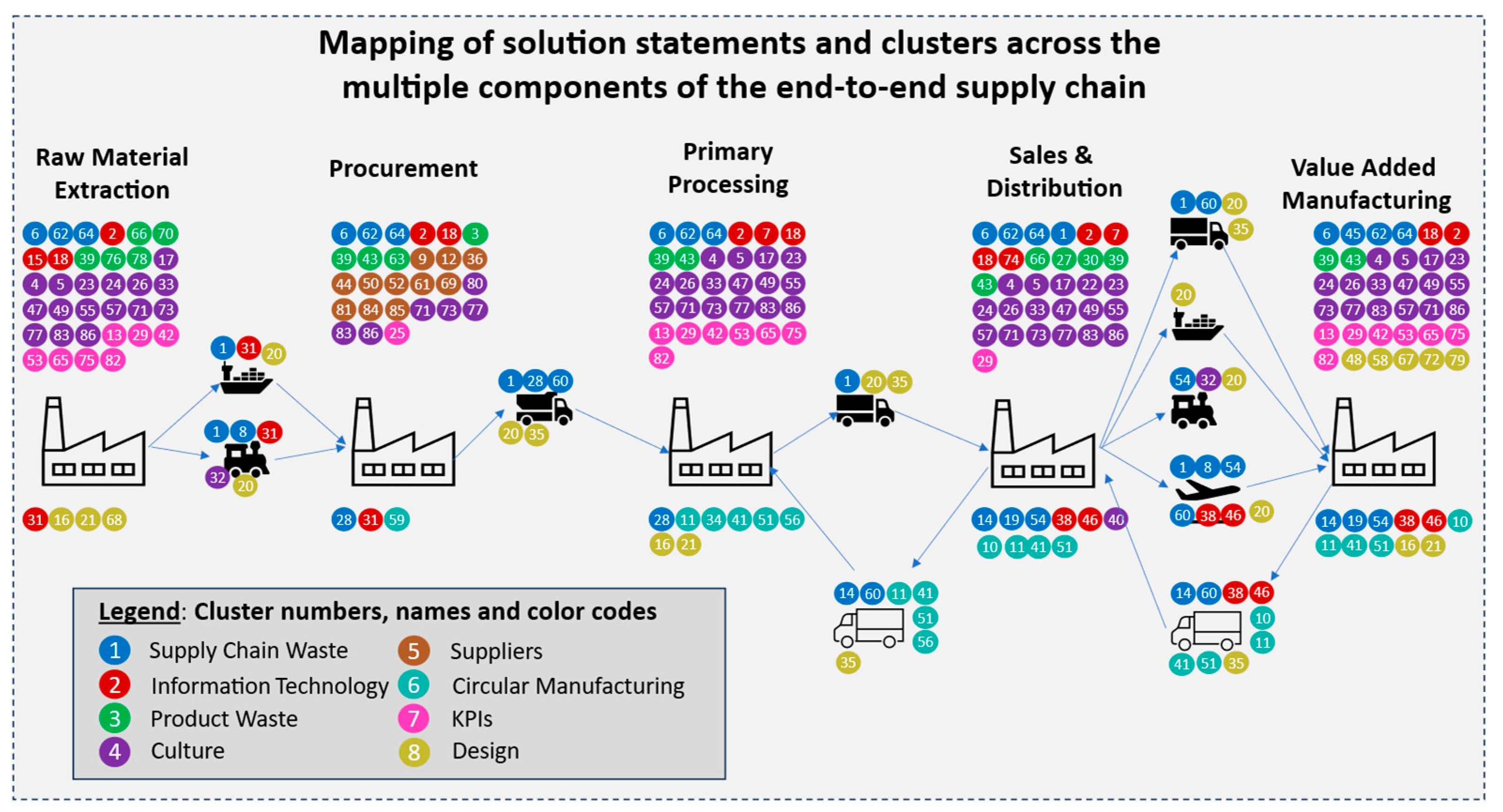

3.5. Qualitative Analysis: Mapping the Value Chain

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SCM | Supply chain management |

| SSCM | Sustainable supply chain management |

| GCM | Group concept mapping |

| HCA | Hierarchical cluster analysis |

| I | Impact |

| EoI | Ease of implementation |

| MDS | Multidimensional scaling |

| SD | Sustainable development |

| TBL | Triple bottom line |

| KPIs | Key performance indicators |

Appendix A. [16] (pp. 189–92)

| Cluster | Statement | EoI (E) | Impact (I) | |

| 1. ‘Supply Chain Waste’: Reducing waste and resource usage in the supply chain delivery system. | 1 | Using 3D printing to print parts for the customer to reduce transport and fuel consumption | 2.75 | 3 |

| 6 | Using standardized international environmental management systems (EMS) to ensure compliance with sustainable supply chain standards | 3.25 | 3.25 | |

| 8 | Product distribution approaches that use rail (more local) versus air (e.g., overseas, China, etc.) | 3 | 3.5 | |

| 14 | Compliance with relevant regulations for electronic waste | 3.25 | 3.25 | |

| 19 | Investing in green infrastructure, e.g., green warehouses and facilities which use renewable energy, water recycling, automated lights, waste recycling | 2.5 | 4 | |

| 28 | Deploying sustainable mining practices | 2 | 3.5 | |

| 45 | Prioritizing battery electric vehicle (BEV) products to encourage less energy consumption during use | 3.75 | 2.25 | |

| 54 | Reducing JIT delivery practices that rely on air transport (less sustainable) vs. rail transport (more sustainable) | 2.25 | 4 | |

| 60 | Investing in fuel efficiency for our products and our customers | 2.75 | 3.75 | |

| 62 | Actively seeking to reduce the carbon footprint of the supply chain, mainly for financial reasons | 2.75 | 3.5 | |

| 64 | Investing in technologies to measure and reduce the carbon footprint | 3 | 4 | |

| Mean | 2.84 | 3.45 | ||

| 2. ‘Information Technology’: Utilizing technology to gather information and support sustainability. | 2 | Supplying information promptly to support sustainability practices | 3.75 | 3 |

| 7 | Using equipment (e.g., refrigerators in supermarkets) with sensors to save energy as well as money | 3.25 | 3.5 | |

| 15 | Sustainable farming, which uses sensors to analyze soil and weather, enables more efficient production using less water | 2.5 | 3.25 | |

| 18 | Using software (EcoVadis) to screen suppliers based on sustainability criteria and ensure compliance with the code of conduct, sustainability criteria, health and safety criteria, and circularity of the supply chain | 2.5 | 3.75 | |

| 31 | Promoting a connected farm/supply chain that uses resources more efficiently | 2.25 | 2.5 | |

| 38 | Implementing systems which allow our parts and services division to know where the equipment is located, what phase of the lifecycle it is in, and customers’ demand for parts and services | 3 | 3 | |

| 46 | Digitalization, which can help replace parts with less downtime, less materials consumption, less space, energy, and fuel | 2.5 | 3.5 | |

| 74 | Using equipment (e.g., pipe cleaning in pubs is necessary for brand attributes) with sensors to save energy and money | 2.75 | 2.75 | |

| Mean | 2.81 | 3.16 | ||

| 3. ‘Product Waste’: Reducing waste and resource usage in products. | 3 | Eliminating consumables that are contaminated with non-recyclable elements, toxins, etc. | 2.5 | 3 |

| 27 | Eliminating the use of unsustainable packaging to meet consumers’ demand for convenience | 3 | 3.25 | |

| 30 | Increased use of sustainable packaging to meet consumers’ demand for reusability and recyclability | 2.75 | 3.75 | |

| 39 | Using sustainable labelling initiatives like fair trade, eco-rating, and FSC labels, etc. | 2.75 | 3 | |

| 43 | Eliminating plastic materials due to plastic waste, which is difficult and expensive to recycle | 1.75 | 4 | |

| 63 | Sustainable procurement, which uses less water in the production of the product | 2.5 | 3.25 | |

| 66 | Packaging standards that incentivize producers NOT to use GMOs | 2 | 2 | |

| 70 | Eliminating GMO-based food products despite the costs of doing so | 1.25 | 1.75 | |

| 76 | Eliminating unsustainable raw materials for food products, like palm oil, which are cheap | 2.75 | 4 | |

| 78 | Eliminating products, even if they are profitable, that rely on unsustainable mining practices | 1.75 | 3.5 | |

| Mean | 2.30 | 3.15 | ||

| 4. ‘Culture’: People’s mindset culture | 4 | Employee benefits program that supports/encourages sustainable commuting (e.g., EV charging points made available) | 4.25 | 2.75 |

| 5 | Using diversity programs to drive awareness of ESG practices through better reporting, making companies more desirable to work with | 3.75 | 2.75 | |

| 17 | Creating awareness: e.g., the CEO has declared that sustainability aligns with the company vision and “must win battles” | 4.25 | 2.75 | |

| 22 | Renewable initiatives driven by salespeople, via regular monthly brainstormings | 4 | 2.25 | |

| 23 | Valuing ‘fairness’ to stakeholders, including communities, suppliers, etc. | 4 | 2.75 | |

| 24 | Nurturing a collaborative mindset that promotes businesspeople/functions and sustainability people/functions working together | 3.5 | 3.75 | |

| 26 | Creating a sustainability culture | 2.5 | 4 | |

| 32 | Management behaviors leading to responsible choices, such as replacing road transport with rail transport | 2.5 | 3.5 | |

| 33 | Innovation and design mindset that promotes the idea that innovation and sustainability work together | 2.25 | 3.5 | |

| 37 | Incentivizing employees to practice sustainable procurement | 3.5 | 4 | |

| 40 | Incentivizing the use of EVs (electric vehicles) for salespeople | 3.5 | 2.75 | |

| 47 | Creating sustainability policies that go “beyond compliance” | 3 | 3 | |

| 49 | Building sustainability into the corporate mission | 3.75 | 3.25 | |

| 55 | Management behaviors leading to responsible choices, such as increased use of renewable energy | 3.5 | 3.25 | |

| 57 | Investing in safety, both for employees and in our products, to provide safety to customers | 2.25 | 2.25 | |

| 71 | Creating a company culture based on sustainability, by creating and documenting behaviors, training, etc. | 2.5 | 3 | |

| 73 | Fostering a mentality and culture that incentivizes investment and innovation and moves away from being cost-conscious | 1.5 | 3.25 | |

| 77 | Communicating and prioritizing sustainability messages in standard and high-profile communications | 4.5 | 2.5 | |

| 83 | PR and business values based on “being green” | 3.25 | 2.5 | |

| 86 | “Walking the walk” and not just “talking the talk” | 3 | 2.5 | |

| Mean | 3.26 | 3.01 | ||

| 5. ‘Suppliers’: Increasing sustainability by focusing on suppliers. | 9 | Not putting undue economic pressure on our suppliers | 1.75 | 2.75 |

| 12 | Promoting supply chain solutions to manufacture products based on renewable energy | 2.5 | 2.75 | |

| 36 | Certifying not only your suppliers but also that your suppliers’ suppliers are compliant with sustainability practices | 3.25 | 4 | |

| 44 | Certifying supply chains to become sustainable | 3 | 2.75 | |

| 50 | Creating awareness or understanding of cost/benefits or trade-offs of using sustainable procurement approaches | 3.5 | 2.75 | |

| 52 | Sustainable procurement practices that lead to better relationships with farmers, which promote more sustainable practices at the local level | 2.5 | 3.5 | |

| 61 | Supporting suppliers in their target setting and implementation | 2.5 | 3.5 | |

| 69 | Regular assessments and audits of suppliers | 3.5 | 3.75 | |

| 80 | Procurement practices using sustainability certification and traceability | 2.75 | 3 | |

| 81 | Strictly following up on the performance targets of suppliers | 3.75 | 2.25 | |

| 84 | Procurement practices actively seek out local packaging solutions | 3 | 3 | |

| 85 | Eliminating or significantly reducing procurement and outsourcing to LCCs (low-cost countries), which leads to long transport routes and less compliant policies for people and the planet | 2 | 4.25 | |

| Mean | 2.83 | 3.19 | ||

| 6. ‘Circular Manufacturing’: Improving sustainability by creating circular manufacturing processes. | 10 | Remanufacturing in all product lines | 3 | 3.5 |

| 11 | Implementing circularity in our supply chain processes results in more efficient material usage and remanufacturing | 2.75 | 3 | |

| 34 | Eliminating the inefficient processing of returned materials, e.g., burning motherboards for gold, which leads to pollution | 2.25 | 4 | |

| 41 | Recycling and reuse of materials | 3.5 | 4.5 | |

| 51 | Moving back to remanufacturing products due to cost and availability reasons | 3.5 | 4.25 | |

| 56 | Processing and reusing electronic waste | 2 | 4.25 | |

| 59 | Sustainable procurement practices ensure recyclable steel or other recyclable components | 3.25 | 3.5 | |

| Mean | 2.89 | 3.86 | ||

| 7. ‘KPIs’: Improving Sustainability through deployment of performance management and measurement systems, e.g., key performance indicators (KPIs) or other forms of measurement. | 13 | Strictly following up on company performance targets | 3.25 | 3 |

| 25 | Establishing sustainability criteria for decision making in different functions and departments, for example, procurement | 3.5 | 3.5 | |

| 29 | Considering sustainability targets in every target-setting group or department | 3.75 | 3 | |

| 42 | Target setting for sustainability in a top-down way, to all departments, individual ratings, and compensation | 4 | 2.75 | |

| 53 | Having a goal to reduce CO2 significantly in the next decade | 4.5 | 2.75 | |

| 65 | Using KPIs that connect business to sustainability | 3.25 | 3 | |

| 75 | Participating in the Dow Jones Sustainability Index to enforce accountability on companies to meet sustainability KPIs from fund managers | 3 | 3 | |

| 82 | Sustainability goals that impact or correspond broadly to many individual jobs | 2.5 | 2.5 | |

| Mean | 3.47 | 2.94 | ||

| 8. ‘Design’: Improving Sustainability through design processes in product design, new technology, or supply chains. | 16 | Using promising new technologies that are still immature or in the initial phases of development | 1.75 | 2 |

| 20 | Product development practices and processes that support sustainable transport | 2.5 | 3 | |

| 21 | Designing products that use renewable energy | 2.25 | 4 | |

| 35 | Making sustainable products, e.g., battery electric vehicles (BEV) a priority | 2 | 4 | |

| 48 | Reducing the weight of our products by redesigning parts with less weight, so less fuel is consumed | 2.5 | 2.5 | |

| 58 | Deploying additive manufacturing (3D printing), which can drive a sustainable approach by reducing the need for steel | 2.5 | 3 | |

| 67 | Eliminate a centralized manufacturing strategy, which creates more transportation for the distribution of vehicles, parts, and services | 2 | 3.5 | |

| 68 | Prioritizing battery electric vehicle (BEV) products to promote cleaner air, less pollution, and improved health and safety, requiring less energy during use | 2.5 | 3.25 | |

| 72 | Product design processes incentivizing refurbishment or design for disassembly | 2.5 | 3.25 | |

| 79 | Designing products for a long life | 2.25 | 3.75 | |

| Mean | 2.28 | 3.23 | ||

Appendix B

| Cluster No. | Overlapping Statements | Similarities of Each Cluster | Explanations for Specific Statements and Their Association with a Specific Cluster |

| 1 & 2 | 1, 8, 28, 46, 54 | The ‘1. The ‘Supply Chain Waste’ cluster focuses on reducing waste. The ‘Info Tech’ cluster is about increasing sustainability. These are similar concepts. | Statement #46 (‘2. Info Tech’ cluster) emphasizes digitalization. All other statements focus on supply chain-specific practices. |

| 2 & 5 | 2., 9, 12, 61 | The ‘2. Info Tech’ and ‘5. Suppliers’ clusters are both about increasing sustainability and becoming more sustainable. | Statement #2 (‘2. Info Tech’ cluster) focuses on ‘supplying information promptly’, an IT concept. |

| 3 & 8 | 27, 43, 70, 76, 78 | The ‘3. Product Waste’ and ‘8. Design’ clusters both pertain to the sustainability of products. | Statements from cluster #3 (‘3. Product Waste’) pertain to unsustainable elements of products in use rather than in the design phase. |

| 4 & 7 | 23, 37, 82 | The ‘4. Culture’ and KPI clusters both focus on enhancing sustainability through organizational behaviors. | Statement #82 (‘4. Culture’ cluster) is about creating goals, which is part of performance management systems, as opposed to culture. |

| 6 & 8 | 51, 10 | The ‘6. Circular Manufacturing’ and ‘8. Design’ clusters both aim to improve sustainability through enhanced processes. | Statements from cluster (‘6. Circular Manufacturing’) pertain specifically to remanufacturing, a core principle of circular manufacturing. |

| 1 & 2 & 5 | 6, 5, 84, 85 | The ‘1. The ‘Supply Chain Waste’ cluster focuses on reducing waste. The ‘2. Info Tech’ and ‘5. Suppliers’ clusters are both about increasing sustainability and becoming more sustainable, similar concepts. | Statement #6 (‘1. Supply Chain Waste’ cluster) emphasizes increasing sustainability using supply chain standards such as standardized international environmental management systems (EMS) certification, rather than collaborating with suppliers or leveraging IT. |

| 1 & 2 & 6 | 38, 56, 59 | The ‘1. The ‘Supply Chain Waste’ cluster focuses on reducing waste. The ‘2. Info Tech’ and ‘6. Circular Manufacturing’ clusters focus on improving sustainability and becoming more sustainable, which are related concepts. | Statement # 38 emphasizes digital technology, an IT concept, rather than circular manufacturing concepts such as reusing, recycling, or remanufacturing. |

| 1 & 6 & 8 | 16, 67 | The ‘1. Supply Chain Waste’ cluster is about reducing waste. The ‘6. Circular Manufacturing’ and ‘8. Design’ clusters pertain to improving sustainability, all similar concepts. | Statements #16 (promising new technologies) and #67 (centralized manufacturing), both part of ‘8. Design cluster: Emphasize design principles rather than reducing waste or implementing circular manufacturing. |

| 2 & 3 & 6 | 7 | The ‘3. The Product Waste’ cluster pertains to the sustainability of products. The ‘2. Info Tech’ and ‘6. Circular Manufacturing’ clusters focus on improving sustainability and becoming more sustainable, which are related concepts. | Statement #7 (‘2. Info Tech’ cluster) emphasizes using equipment with sensors, rather than unsustainable elements of products in use or circular manufacturing processes. |

| 3 & 6 & 8 | 30, 34, 39, 51, 63, 66, 68 | The ‘3. Product Waste’, ‘6. Circular Manufacturing’, and ‘8. Design’ clusters focus on reducing waste and increasing sustainability through various aspects of product and process, whether in the design phase or in use. | Statements #34 (material returns) and #51 (remanufacturing) emphasize circular manufacturing processes. Statement #68 ‘8. Design’ cluster) emphasizes the design of new products and technologies (battery electric vehicle (BEV). |

| 1 & 3 & 6 & 8 | 60 | The ‘1. Supply Chain Waste’, 3. Product Waste’, ‘6. Circular Manufacturing’, and ‘8. Design’ clusters all pertain to reducing waste and increasing sustainability through aspects of product, process, and the supply chain itself, whether in the design phase or in use. | Statement #60 (‘1. Supply Chain Waste’ cluster) emphasizes the carbon footprint of the supply chain itself rather than focusing on the product, process, or design elements. |

References

- Ahi, P.; Searcy, C. A Comparative Literature Analysis of Definitions for Green and Sustainable Supply Chain Management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Prasad, D.S.; Pradhan, R.P.; Gaurav, K.; Chatterjee, P.P.; Kaur, I.; Dash, S.; Nayak, S. Analysing the Critical Success Factors for Implementation of Sustainable Supply Chain Management: An Indian Case Study. Decision 2018, 45, 3–25. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, X.; Lim, M.K.; He, Y.; Li, L. Sustainable Recycling Partner Selection Using Fuzzy DEMATEL-AEW-FVIKOR: A Case Study in Small-and-Medium Enterprises (SMEs). J. Clean. Prod. 2018, 196, 489–504. [Google Scholar] [CrossRef]

- Seuring, S.A. Assessing the Rigor of Case Study Research in Supply Chain Management. Supply Chain. Manag. 2008, 13, 128–137. [Google Scholar] [CrossRef]

- Ansari, Z.N.; Kant, R. A State-of-Art Literature Review Reflecting 15 Years of Focus on Sustainable Supply Chain Management. J. Clean. Prod. 2017, 142, 2524–2543. [Google Scholar] [CrossRef]

- Min, H.; Kim, I. Green Supply Chain Research: Past, Present, and Future. Logist. Res. 2012, 4, 39–47. [Google Scholar] [CrossRef]

- Bag, S.; Anand, N. The Importance of Innovation Leadership in Cultivating Sustainable Supply Chain Management and Enhancing Organisation Performance. Int. J. Process Manag. Benchmark. 2016, 6, 469–490. [Google Scholar] [CrossRef]

- D’Eusanio, M.; Zamagni, A.; Petti, L. Social Sustainability and Supply Chain Management: Methods and Tools. J. Clean. Prod. 2019, 235, 178–189. [Google Scholar] [CrossRef]

- Kaufman, F.D.; Ali Ülkü, M. An Interdisciplinary Inquiry into Sustainable Supply Chain Management. In Handbook of Research on Supply Chain Management for Sustainable Development; IGI Global Scientific Publishing: Hershey, PA, USA, 2018; pp. 1–17. [Google Scholar]

- Action Research for Improving Practice. Available online: https://www.academia.edu/14875555/Action_Research_for_Improving_Practice (accessed on 7 July 2025).

- Alvesson, M. Leadership Studies: From Procedure and Abstraction to Reflexivity and Situation. Leadersh. Q. 1996, 7, 455–485. [Google Scholar] [CrossRef]

- Markides, C. In Search of Ambidextrous Professors. Acad. Manag. J. 2007, 50, 762–768. [Google Scholar] [CrossRef]

- Salazar, I.S.M.; Mantilla, C.E.M.; Ramírez, J.P.L.; Zambrano, J.J.A.; Suárez, M.J.T. Validation of a Participant Selection Method within a Mixed Sequential Research Design for Case Studies of Sustainable Supply Chains*. Cuad. Adm. 2023, 36. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Wamba, S.F. World Class Sustainable Supply Chain Management: Critical Review and Further Research Directions. Int. J. Logist. Manag. 2017, 28, 332–362. [Google Scholar] [CrossRef]

- Erkman, S. Industrial Ecology: An Historical View. J. Clean. Prod. 1997, 5, 1–10. [Google Scholar] [CrossRef]

- McDaniel, T.; Vastag, G. 2022 Annual Conference of the Decision Sciences Institute Proceedings—Decision Sciences Institute. In Applying Group Concept Mapping to Determine Leading Management Practices Enhancing Sustainability in Industrial Supply Chains; The Decision Sciences Institute: Houston, TX, USA, 2022; pp. 180–195. [Google Scholar]

- Lu, Y.; Jenkins, A.; Ferrier, R.C.; Bailey, M.; Gordon, I.J.; Song, S.; Huang, J.; Jia, S.; Zhang, F.; Liu, X.; et al. Addressing China’s Grand Challenge of Achieving Food Security While Ensuring Environmental Sustainability. Sci. Adv. 2015, 1, e1400039. [Google Scholar] [CrossRef]

- Mitra, S.; Datta, P.P. Adoption of Green Supply Chain Management Practices and Their Impact on Performance: An Exploratory Study of Indian Manufacturing Firms. Int. J. Prod. Res. 2014, 52, 2085–2107. [Google Scholar] [CrossRef]

- Souhli, K.A.; El Hilaly, J.; Ennadi, A. Green and Sustainable Supply Chain Management (GSCM and SSCM): A Comparative Literature Analysis of Definitions and the Identification of the Relationship between Environmental and Economic Pillars in GSCM. Int. J. Sci. Res. (IJSR) 2020, 9, 811–819. [Google Scholar]

- Mutingi, M.; Mutingi, M. Developing Green Supply Chain Management Strategies: A Taxonomic Approach. J. Ind. Eng. Manag. 2013, 6, 525–546. [Google Scholar] [CrossRef][Green Version]

- Dobers, P.; Wolff, R. Competing with ‘Soft’ Issues—From Managing the Environment to Sustainable Business Strategies. Bus. Strategy Environ. 2000, 9, 143–150. [Google Scholar] [CrossRef]

- Rahimifard, S.; Clegg, A.J. Aspects of Sustainable Design and Manufacture. Int. J. Prod. Res. 2007, 45, 4013–4019. [Google Scholar] [CrossRef]

- Saha, M.; Darnton, G. Green Companies or Green Con-Panies: Are Companies Really Green, or Are They Pretending to Be? Bus. Soc. Rev. 2005, 110, 117–157. [Google Scholar] [CrossRef]

- Butlin, J. Our Common Future. By World Commission on Environment and Development. (London, Oxford University Press, 1987, pp.383 £5.95.). J. Int. Dev. 1989, 1, 284–287. [Google Scholar] [CrossRef]

- Elkington, J. Partnerships from Cannibals with Forks: The Triple Bottom Line of 21st-Century Business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Forrester, J.W. Industrial Dynamics A Major Breakthrough for Decision Makers. Harv. Bus. Rev. 1958, 36, 37–66. Available online: https://www.scirp.org/reference/referencespapers?referenceid=1121949 (accessed on 7 July 2025).

- Full Text of “Financial Times, 1982, UK, English”. Available online: https://archive.org/stream/FinancialTimes1982UKEnglish/Jun%2004%201982%2C%20Financial%20Times%2C%20%2328790%2C%20UK%20%28en%29_djvu.txt (accessed on 7 July 2025).

- When Will Supply Chain Management Grow Up? Available online: https://www.strategy-business.com/article/03304 (accessed on 7 July 2025).

- Solari, F.; Lysova, N.; Romagnoli, G.; Montanari, R.; Bottani, E. Insights from 20 Years (2004–2023) of Supply Chain Disruption Research: Trends and Future Directions Based on a Bibliometric Analysis. Sustainability 2024, 16, 7530. [Google Scholar] [CrossRef]

- Sinoimeri, D.; Teta, J. Systematic Literature Review of Supply Chain Management. Proc. Int. Conf. Bus. Manag. Econ. 2024, 1, 16–21. [Google Scholar] [CrossRef]

- Hopp, W.J. Supply Chain Science; Waveland Press: Lake Zurich, IL, USA, 2011. [Google Scholar]

- New, S.J. The Scope of Supply Chain Management Research. Supply Chain. Manag. 1997, 2, 15–22. [Google Scholar] [CrossRef]

- Sarkis, J. A Strategic Decision Framework for Green Supply Chain Management. J. Clean. Prod. 2003, 11, 397–409. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Saini, N.; Malik, K.; Sharma, S. Transformation of Supply Chain Management to Green Supply Chain Management: Certain Investigations for Research and Applications. Clean. Mater. 2023, 7, 100172. [Google Scholar] [CrossRef]

- de Oliveira, U.R.; Espindola, L.S.; da Silva, I.R.; da Silva, I.N.; Rocha, H.M. A Systematic Literature Review on Green Supply Chain Management: Research Implications and Future Perspectives. J. Clean. Prod. 2018, 187, 537–561. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green Supply-Chain Management: A State-of-the-Art Literature Review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Extending Green Practices across the Supply Chain: The Impact of Upstream and Downstream Integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- Sarkis, J. A Boundaries and Flows Perspective of Green Supply Chain Management. Supply Chain Manag. 2012, 17, 202–216. [Google Scholar] [CrossRef]

- Linton, J.D.; Klassen, R.; Jayaraman, V. Sustainable Supply Chains: An Introduction. J. Oper. Manag. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Adel, H.M. Mapping and Assessing Green Entrepreneurial Performance: Evidence from a Vertically Integrated Organic Beverages Supply Chain. J. Entrep. Innov. Emerg. Econ. 2021, 7, 78–98. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.H. An Organizational Theoretic Review of Green Supply Chain Management Literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Balkumar, K.; Gedam, V.V.; Himateja, M.; Anbuudayasankar, S.P.; Narassima, M.S.; Ganesh, K.; Dwarakanath, M.; Pazhani, S. Prevalence and Future Trend in Green Supply Chain Management (GSCM): A Systematic Literature Review. Benchmarking 2024, 31, 2002–2033. [Google Scholar] [CrossRef]

- Pollard, J.; Osmani, M.; Grubnic, S.; Díaz, A.I.; Grobe, K.; Kaba, A.; Ünlüer, Ö.; Panchal, R. Implementing a Circular Economy Business Model Canvas in the Electrical and Electronic Manufacturing Sector: A Case Study Approach. Sustain. Prod. Consum. 2023, 36, 17–31. [Google Scholar] [CrossRef]

- Tellnes, L.G.F.; Pedersen, A.O.; Pamies, R.; Hauge, B.G.; Kjøniksen, A.L. Implementing Life Cycle Thinking and Climate Change Indicators in Small and Medium Size Enterprises. Sustain. Prod. Consum. 2024, 51, 278–291. [Google Scholar] [CrossRef]

- Dormeier, C.; Mindt, N.; Niemeyer, J.F.; Asghari, R.; Mennenga, M. Review and Framework for the Engineering of Business Models for Sustainability: A System of Systems Perspective. Sustain. Prod. Consum. 2024, 51, 1–22. [Google Scholar] [CrossRef]

- Cheng, X.; Long, R.; Zhang, L.; Li, W. Unpacking the Experienced Utility of Sustainable Lifestyle Guiding Policies: A New Structure and Model. Sustain. Prod. Consum. 2021, 27, 486–495. [Google Scholar] [CrossRef]

- Lubowiecki-Vikuk, A.; Dąbrowska, A.; Machnik, A. Responsible Consumer and Lifestyle: Sustainability Insights. Sustain. Prod. Consum. 2021, 25, 91–101. [Google Scholar] [CrossRef]

- Hallstedt, S.I.; Villamil, C.; Lövdahl, J.; Nylander, J.W. Sustainability Fingerprint—Guiding Companies in Anticipating the Sustainability Direction in Early Design. Sustain. Prod. Consum. 2023, 37, 424–442. [Google Scholar] [CrossRef]

- Wu, R.; Tao, J.; Yu, S. Enhancing Sustainability in Manufacturing: A Methodology for Quantitative Assessment and Improvement of Life-Cycle Design Conflict Managing Capabilities. Sustain. Prod. Consum. 2024, 48, 339–361. [Google Scholar] [CrossRef]

- Sarancic, D.; Pigosso, D.C.A.; McAloone, T.C. Evaluation and Instantiation of a Generic Process Model for Early-Stage Sustainable Product-Service System Design within Three Manufacturing Companies. J. Clean. Prod. 2024, 458, 142543. [Google Scholar] [CrossRef]

- Zhang, J.; Trautman, D.; Liu, Y.; Bi, C.; Chen, W.; Ou, L.; Goebel, R. Achieving the Rewards of Smart Agriculture. Agronomy 2024, 14, 452. [Google Scholar] [CrossRef]

- Saxena, L.K.; Jain, P.K.; Sharma, A.K. Tactical Supply Chain Planning for Tyre Remanufacturing Considering Carbon Tax Policy. Int. J. Adv. Manuf. Technol. 2018, 97, 1505–1528. [Google Scholar] [CrossRef]

- Amicarelli, V.; Rana, R.L.; Lombardi, M.; Fellner, J.; Tricase, C.; Bux, C. Material Flow Analysis and Carbon Footprint of Water-Packaging Waste Management. Environ. Impact Assess. Rev. 2024, 106. [Google Scholar] [CrossRef]

- Zarei-Kordshouli, F.; Paydar, M.M.; Nayeri, S. Designing a Dairy Supply Chain Network Considering Sustainability and Resilience: A Multistage Decision-Making Framework. Clean. Technol. Environ. Policy 2023, 25, 2903–2927. [Google Scholar] [CrossRef]

- Junaid, M.; Du, J.; Mubarik, M.S.; Shahzad, F. Creating a Sustainable Future through Industry 4.0 Technologies: Untying the Role of Circular Economy Practices and Supply Chain Visibility. Bus. Strategy Environ. 2024, 33, 5753–5775. [Google Scholar] [CrossRef]

- Piyathanavong, V.; Olapiriyakul, S.; Garza-Reyes, J.A.; Kumar, V.; Huynh, V.N.; Karnjana, J. Implementing Industry 4.0 and Circular Economy through the Developmental Culture Perspective—Driving a Competitive Advantage in the Manufacturing Industry. Bus. Strategy Environ. 2024, 33, 9059–9074. [Google Scholar] [CrossRef]

- Wojtaszczyk, K.; Różańska-Bińczyk, I.; Syper-Jędrzejak, M. Human Resource Management: A Link between Sustainable Development and Sustainable Lifestyles. Traditional and Systematic Review. Sustain. Dev. 2024, 32, 5567–5580. [Google Scholar] [CrossRef]

- Zimon, D.; Tyan, J.; Sroufe, R. Implementing Sustainable Supply Chain Management: Reactive, Cooperative, and Dynamic Models. Sustainability 2019, 11, 7227. [Google Scholar] [CrossRef]

- Shekarian, E.; Ijadi, B.; Zare, A.; Majava, J. Sustainable Supply Chain Management: A Comprehensive Systematic Review of Industrial Practices. Sustainability 2022, 14, 7892. [Google Scholar] [CrossRef]

- Kähkönen, A.K.; Lintukangas, K.; Hallikas, J. Sustainable Supply Management Practices: Making a Difference in a Firm’s Sustainability Performance. Supply Chain Manag. 2018, 23, 518–530. [Google Scholar] [CrossRef]

- Berg, S.; Cloutier, L.M.; Bröring, S. Collective Stakeholder Representations and Perceptions of Drivers of Novel Biomass-Based Value Chains. J. Clean. Prod. 2018, 200, 231–241. [Google Scholar] [CrossRef]

- Rondinelli, D.; Vastag, G. Panacea, Common Sense, or Just a Label? The Value of ISO 14001 Environmental Management Systems. Eur. Manag. J. 2000, 18, 499–510. [Google Scholar] [CrossRef]

- Trochim, W.M.; McLinden, D. Introduction to a Special Issue on Concept Mapping. Eval. Program Plan. 2017, 60, 166–175. [Google Scholar] [CrossRef]

- Ladinig, T.B.; Vastag, G. Mapping Quality Linkages Based on Tacit Knowledge. Int. J. Prod. Econ. 2021, 233. [Google Scholar] [CrossRef]

- Vastag, G.; Jenei, Á. Mapping Improvement Options of Government Services: Illustration of ‘Concept-Mapping’. Hung. Stat. Rev. 2019, 2, 24–39. [Google Scholar] [CrossRef]

- Mollenkopf, D.; Stolze, H.; Tate, W.L.; Ueltschy, M. Green, Lean, and Global Supply Chains. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 14–41. [Google Scholar] [CrossRef]

- Kane, M.; Trochim, W.M. Concept Mapping for Planning and Evaluation; Sage Publications, Inc.: Thousand Oaks, CA, USA, 2007. [Google Scholar]

- Trochim, W.M.K.; Linton, R. Conceptualization for Planning and Evaluation. Eval. Program Plan. 1986, 9, 289–308. [Google Scholar] [CrossRef]

- Trochim, W.M.K. Outcome Pattern Matching and Program Theory. Eval. Program Plan. 1989, 12, 355–366. [Google Scholar] [CrossRef]

- Trochim, W.M.K. Concept Mapping: Soft Science or Hard Art? Eval. Program Plan. 1989, 12, 87–110. [Google Scholar] [CrossRef]

- Trochim, W.M.K. An Introduction to Concept Mapping for Planning and Evaluation. Eval. Program Plan. 1989, 12, 1–16. [Google Scholar] [CrossRef]

- Trochim, W.M.K.; Cook, J.A.; Setze, R.J. Using Concept Mapping to Develop a Conceptual Framework of Staff’s Views of a Supported Employment Program for Individuals with Severe Mental Illness. J. Consult. Clin. Psychol. 1994, 62, 766–775. [Google Scholar] [CrossRef] [PubMed]

- Cook, T.D.; Campbell, D.T.; Day, A. Quasi-Experimentation: Design & Analysis Issues for Field Settings; Houghton Mifflin: Boston, UK, 1979. [Google Scholar]

- Guba, E.G.; Lincoln, Y.S. Effective Evaluation: Improving the Usefulness of Evaluation Results through Responsive and Naturalistic Approaches; Jossey-Bass: Hoboken, NJ, USA, 1981. [Google Scholar]

- Dumont, J. Validity of Multidimensional Scaling in the Context of Structured Conceptualization. Eval. Program Plan. 1989, 12, 81–86. [Google Scholar] [CrossRef]

- Silva, C.; Vaz, P.; Ferreira, L.M. The Impact of Lean Manufacturing on Environmental and Social Sustainability: A Study Using a Concept Mapping Approach. IFAC Proc. Vol. 2013, 46, 306–310. [Google Scholar] [CrossRef]

- Rondinelli, D.A.; Vastag, G. Private Investment and Environmental Protection: Alcoa-Köfém’s Strategy in Hungary. Eur. Manag. J. 1998, 16, 422–430. [Google Scholar] [CrossRef]

- Rosenberg, S.; Kim, M.P. The Method of Sorting as a Data-Gathering Procedure in Multivariate Research. Multivar. Behav. Res. 1975, 10, 489–502. [Google Scholar] [CrossRef]

- Weller, S.C.; Romney, A.K. Systematic Data Collection; Sage Publications: Thousand Oaks, CA, USA, 1988. [Google Scholar]

- Kruskal, J.; Wish, M. Multidimensional Scaling; Sage: Thousand Oaks, CA, USA, 1978. [Google Scholar]

- Klassen, R.D.; McLaughlin, C.P. The Impact of Environmental Management on Firm Performance. Manag. Sci. 1996, 42, 1199–1214. [Google Scholar] [CrossRef]

- Trochim, W.M.k. Pattern Matching, Validity, and Conceptualization in Program Evaluation. Eval. Rev. 1985, 9, 575–604. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Examining the effects of green supply chain management practices and their mediations on performance improvements. IJPR 2012, 50, 1377–1394. [Google Scholar]

- Liu, J.; Feng, Y.; Zhu, Q.; Sarkis, J. Green Supply Chain Management and the Circular Economy: Reviewing Theory for Advancement of Both Fields. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 794–817. [Google Scholar] [CrossRef]

- Bennekrouf, M.; Aggoune-Mtalaa, W.; Sari, Z. A Generic Model for Network Design Including Remanufacturing Activities. Supply Chain Forum 2013, 14, 4–17. [Google Scholar] [CrossRef]

- Dabees, A.; Barakat, M.; Elbarky, S.S.; Lisec, A. A Framework for Adopting a Sustainable Reverse Logistics Service Quality for Reverse Logistics Service Providers: A Systematic Literature Review. Sustainability 2023, 15, 1755. [Google Scholar] [CrossRef]

- Govindan, K.; Kaliyan, M.; Kannan, D.; Haq, A.N. Barriers Analysis for Green Supply Chain Management Implementation in Indian Industries Using Analytic Hierarchy Process. Int. J. Prod. Econ. 2014, 147 Pt B, 555–568. [Google Scholar] [CrossRef]

- Kuo, Y.L.; Perrings, C. Wasting Time? Recycling Incentives in Urban Taiwan and Japan. Environ. Resour. Econ. 2010, 47, 423–437. [Google Scholar] [CrossRef]

- Nazir, S.; Zhaolei, L.; Mehmood, S.; Nazir, Z. Impact of Green Supply Chain Management Practices on the Environmental Performance of Manufacturing Firms Considering Institutional Pressure as a Moderator. Sustainability 2024, 16, 2278. [Google Scholar] [CrossRef]

- Sheu, J.B. Buyer Behavior in Quality-Dominated Multi-Sourcing Recyclable-Material Procurement of Green Supply Chains. Prod. Oper. Manag. 2016, 25, 477–497. [Google Scholar] [CrossRef]

- Dai, J.; Cantor, D.E.; Montabon, F.L. How Environmental Management Competitive Pressure Affects a Focal Firm’s Environmental Innovation Activities: A Green Supply Chain Perspective. J. Bus. Logist. 2015, 36, 242–259. [Google Scholar] [CrossRef]

- Chin, T.A.; Tat, H.H.; Sulaiman, Z.; Muhamad Zainon, S.N.L. Green Supply Chain Management Practices and Sustainability Performance. Adv. Sci. Lett. 2015, 21, 1359–1362. [Google Scholar] [CrossRef]

- Kannan, D.; De Sousa Jabbour, A.B.L.; Jabbour, C.J.C. Selecting Green Suppliers Based on GSCM Practices: Using Fuzzy TOPSIS Applied to a Brazilian Electronics Company. Eur. J. Oper. Res. 2014, 233, 432–447. [Google Scholar] [CrossRef]

- Dai, J.; Xie, L.; Chu, Z. Developing Sustainable Supply Chain Management: The Interplay of Institutional Pressures and Sustainability Capabilities. Sustain. Prod. Consum. 2021, 28, 254–268. [Google Scholar] [CrossRef]

- Brandenburg, M.; Rebs, T. Sustainable Supply Chain Management: A Modelling Perspective. Ann. Oper. Res. 2015, 229, 213–252. [Google Scholar] [CrossRef]

- Li, J.; Zhong, D. Comparing the Impact of Green Supplier Selection and Integration on Environmental Performance: An Analysis of the Moderating Role of Government Support. Sustainability 2024, 16, 7228. [Google Scholar] [CrossRef]

- Tseng, M.L.; Chiu, A.S.F.; Tan, R.R.; Siriban-Manalang, A.B. Sustainable Consumption and Production for Asia: Sustainability through Green Design and Practice. J. Clean. Prod. 2013, 40, 1–5. [Google Scholar] [CrossRef]

- Stroumpoulis, A.; Kopanaki, E.; Chountalas, P.T. Enhancing Sustainable Supply Chain Management through Digital Transformation: A Comparative Case Study Analysis. Sustainability 2024, 16, 6778. [Google Scholar] [CrossRef]

- Jabbour, A.B.; Jabbour, C.; Govindan, K.; Kannan, D.; Arantes, A.F. Mixed Methodology to Analyze the Relationship between Maturity of Environmental Management and the Adoption of Green Supply Chain Management in Brazil. Resour. Conserv. Recycl. 2014, 92, 255–267. [Google Scholar] [CrossRef]

- Gao, H.; Al Mamun, A.; Masukujjaman, M.; Yang, Q. Exploring the Nexus of Green Human Resource Management, Leadership and Organizational Culture on Workplace pro-Environmental Behavior. Humanit. Soc. Sci. Commun. 2025, 12, 1–17. [Google Scholar] [CrossRef]

- Vanalle, R.M.; Ganga, G.M.D.; Godinho Filho, M.; Lucato, W.C. Green Supply Chain Management: An Investigation of Pressures, Practices, and Performance within the Brazilian Automotive Supply Chain. J. Clean. Prod. 2017, 151, 250–259. [Google Scholar] [CrossRef]

- King, A.A.; Lenox, M.J. Lean and Green? An Empirical Examination of the Relationship between Lean Production and Environmental Performance. Prod. Oper. Manag. 2001, 10, 244–256. [Google Scholar] [CrossRef]

- Woo, C.; Kim, M.G.; Chung, Y.; Rho, J.J. Suppliers’ Communication Capability and External Green Integration for Green and Financial Performance in Korean Construction Industry. J. Clean. Prod. 2016, 112, 483–493. [Google Scholar] [CrossRef]

- Shahriari, M.; Pilevari, N.; Gholami, Z. The Effect of Information Systems on the Supply Chain Sustainability Using DEMATEL Method. Commun. Adv. Comput. Sci. Appl. 2016, 2016, 47–56. [Google Scholar] [CrossRef]

- Kumar, A.; Shrivastav, S.K.; Shrivastava, A.K.; Panigrahi, R.R.; Mardani, A.; Cavallaro, F. Sustainable Supply Chain Management, Performance Measurement, and Management: A Review. Sustainability 2023, 15, 5290. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, J.; Lee, P.K.C.; Cheng, T.C.E. How to Enhance the Effects of the Green Supply Chain Management Strategy in the Organization: A Diffusion Process Perspective. Transp. Res. E Logist. Transp. Rev. 2023, 175, 103148. [Google Scholar] [CrossRef]

| Number | Industry | Yrs. Exp. | Supply Chain Segment | Managerial Level | Educ./Cert. Level | Market Focus |

|---|---|---|---|---|---|---|

| 1 | Metals and mining | 18 | Primary Processing | Head of Supply Chain Planning | LSS Black Belt | Western Europe |

| 2 | Metals and mining | 21 | Procurement | Procurement Director | EMBA | Latin America |

| 3 | Cons. Electronics | 37 | Procurement | Global Strategic Commodity Mgr. | BA, LSS | North America |

| 4 | Pkg. Cons. Food and Bev. | 28 | Sales and Distribution | CFO, Partner, Board member | CPA, CMA | North America |

| 5 | Auto. and Vehicle Mfg. | 24 | Value-added Mfg. | Global Mfg. Excellence Leader | MSc Eng. | Western Europe |

| 6 | Auto. and Vehicle Mfg. | 26 | Value added Mfg. | Co-founder, Owner | ACDMM, LSS Master Black Belt | Asia |

| 7 | Pkg. Cons. Food and Bev. | 22 | Raw Matl. Extraction | Vice President | MBA | Eastern Europe |

| 8 | Cons. Electronics | 27 | Sales & Distribution | Managing Director, Chief Sales Officer | MBA | Eastern Europe |

| Step 1: Preparation and Design | Step 2: Brainstorming | Step 3: Sorting and Rating | Step 4: Analysis | Step 5 Interpretation |

|---|---|---|---|---|

|

|

|

|

|

| Raw Material Extraction | Procurement | Primary Processing | Sales and Distribution | Value-Added Manufacturing | Logistics | ||

|---|---|---|---|---|---|---|---|

| Ease of Implementation (EoI) | Average | 2.97 | 2.82 | 3.05 | 3.03 | 3.01 | 2.68 |

| Total | 113.00 | 84.50 | 119.00 | 119.00 | 141.25 | 45.50 | |

| Impact (I) | Average | 3.01 | 3.19 | 3.21 | 3.21 | 3.18 | 3.53 |

| Total | 114.50 | 95.75 | 125.25 | 126.00 | 149.50 | 60.00 | |

| Total number of solution statements | 38 | 38 | 30 | 39 | 41 | 17 | |

| Cluster represented | 1, 2, 3, 4, 7, 8 | 1, 2, 3, 4, 7, 8 | 1, 2, 3, 4, 5, 6, 7 | 1, 2, 3, 4, 6, 7, 8 | 1, 2, 3, 4, 6, 7 | 1, 2, 4, 6, 8 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

McDaniel, T.; Süle, E.; Vastag, G. Achieving Sustainable Supply Chains: Applying Group Concept Mapping to Prioritize and Implement Sustainable Management Practices. Logistics 2025, 9, 99. https://doi.org/10.3390/logistics9030099

McDaniel T, Süle E, Vastag G. Achieving Sustainable Supply Chains: Applying Group Concept Mapping to Prioritize and Implement Sustainable Management Practices. Logistics. 2025; 9(3):99. https://doi.org/10.3390/logistics9030099

Chicago/Turabian StyleMcDaniel, Thompson, Edit Süle, and Gyula Vastag. 2025. "Achieving Sustainable Supply Chains: Applying Group Concept Mapping to Prioritize and Implement Sustainable Management Practices" Logistics 9, no. 3: 99. https://doi.org/10.3390/logistics9030099

APA StyleMcDaniel, T., Süle, E., & Vastag, G. (2025). Achieving Sustainable Supply Chains: Applying Group Concept Mapping to Prioritize and Implement Sustainable Management Practices. Logistics, 9(3), 99. https://doi.org/10.3390/logistics9030099