Abstract

Background: Effective decision-making in supply chain contexts requires understanding how criteria interact to shape rational and transparent decision structures. This study investigates how behavioral aspects influence the structuring of decision-making logic and the interdependencies between key criteria in supply chain contexts. Methods: Using Fuzzy DEMATEL, the research models the interactions between five core criteria —classification, definition, specification, decision, and action feedback—based on inputs from experienced professionals in a global chemical company. The approach enables mapping of causal influences while accounting for subjectivity and uncertainty in expert judgments. Results: The analysis identified specification, definition, and action feedback as causal criteria, with classification and decision being primarily influenced by them. The modeling process supported clearer prioritization and revealed how expert-based interactions can reduce decision biases. Conclusions: This study demonstrates how structuring decision-making logic through causal modeling enhances clarity and reduces subjectivity. The findings contribute to the development of decision support tools applicable across strategic supply chain contexts, offering practical implications for professionals seeking to improve decision transparency and effectiveness.

1. Introduction

Strategic decisions are the foundation of organizations that define their long-term success. They involve establishing goals, allocating resources needed for the company’s growth, deciding about market share, and merging or acquisition agreements. These are complex decisions and require a well-structured decision-making process [1]. Some approaches in decision-making, such as key influencing factors and the impact of model design, play a crucial role. This, in turn, highlights the importance of quantitative models and underscores the need to understand their principles for practical application [2].

Decision-making based on a structured process can minimize decision time, especially if carried out systematically with well-defined factors and a logical sequence. In this way, a significant impact on the decision-making process through the organization is expected [3]. In the context of supply chains, efficient management requires addressing risks, uncertainties, and operational needs. By integrating decision-making approaches, supply chain managers can select the best options based on cost, infrastructure, or other critical factors. This approach provides valuable insights for agile and well-informed decisions [4].

Given these complexities, understanding cognitive limitations and structured frameworks becomes essential for improving decision-making in supply chains. According to decision theory, individuals can express their preferences and are rational in simple approaches. However, human beings often have a limited cognitive capacity to interpret all the information needed for a good decision. The cognitive sources described by [5,6] highlight factors such as the restricted capacity of the human brain, insufficient awareness of all potential solutions, and the influence of emotional and affective factors. In supply chains, ensuring efficiency and maintaining standards are crucial, particularly in contexts that demand high quality and rapid response times. A framework utilizing multi-criteria decision-making methods supports the evaluation of key factors such as cost, logistics efficiency, and infrastructure. This approach further aids in identifying risks, strengthening resilience, and ensuring stability across various operational contexts [7].

Considering these cognitive limitations, decision-making in supply chains becomes even more complex, requiring structured frameworks to enhance efficiency and resilience. Supply chains can be affected by several factors such as political instability, high maintenance costs, and poor infrastructure, which are also important challenges that need to be addressed to strengthen resilience [8]. The supply chain can be expanded into several approaches, including operational, process, demand, social, and environmental dimensions. To develop efficient strategies, ordering is one of the factors that can be incorporated into the decision-making process [9]. For example, an inventory ordering system generates purchase orders based on a specific trigger or set point in the item’s master file record. Moreover, the inventory ordering pattern is one of the factors influencing biases in the decision-making process related to behavior [10,11].

Building upon the need for structured decision-making, ranking methods combined with visual tools support effective assessment in supply chain disruptions. Additionally, evaluating supply chain performance contributes to identifying risks and provides strategies to enhance management and decision-making to prevent disruptions [12]. As decision-making in modern environments is complex and uncertain, a framework that combines advanced methods and behavioral insights supports the evaluation and ranking of alternatives effectively, ensuring adaptability in dynamic situations [13].

However, the manager’s ability to lead with challenges and make rational decisions is considered by many researchers an experience-based skill. Monitoring decision-making practices indicates that senior managers probably have little systematization for managing problems and decisions. Often used, the hit-or-miss method can result in a worse decision [14]. Many bad decisions occur because of approaches based on unwell-defined alternatives, missing information, poor analysis of costs and benefits, or failure to assign appropriate weights. There are often mistakes in the decision-making process, in the rationality of the decision-maker, or in the way the brain reacts to choices [15].

Fundamentally, decision-making involves selecting one from among several possibilities. Decision-making can be a conscious act, with reflection on the options, or an unconscious act, relying on habits and instincts [16]. In addition, decision-making approaches are often mostly qualitative, such as problem identification and definition. Information gathering, in turn, requires choices as well as information synthesis. Therefore, it is assumed that there is a subjective side to most decision-making processes [17].

Many issues of supply chain management could be addressed by decision-making approaches. Applying structured decision-making models to practical problems has proven challenging due to ambiguities in assessment information, although it is fundamental according to decision theory [18]. Multiple-criteria decision-making techniques and decision support systems are effective ways to manage the supply chain to achieve optimal results. Many models help evaluate multiple-criteria decisions [19]. Therefore, some decision-making methods can serve as tools for monitoring cause-and-effect relationships among the supply chain operations. This study’s main research question is to understand how some decision-making techniques could be applied to investigate cause-and-effect relationships. Therefore, this study aims to assess cause-and-effect relationships throughout the supply chain to support decision-making, using the Fuzzy combined with the decision-making trial and evaluation laboratory (DEMATEL), which allows for evaluating the interdependence and feedback between the decision elements.

This paper is divided into four more sections. Section 2 presents the background concepts of decision-making perspectives and decision-making approaches in supply chain management. Section 3 discusses the research methodology, and Section 4 presents the empirical analysis. Finally, Section 5 discusses the results and offers conclusions.

2. Background Concepts

This section addresses the fundamental concepts that form the basis for the analysis. First, different perspectives of decision-making are presented, including the structuring of tangible objects and abstract concepts. Next, decision-making approaches in supply chain management are explored, based on a comprehensive literature review.

2.1. Decision-Making Perspectives

A structure can be adopted for tangible objects or for an abstract concept, and its meaning is always explained based on the context in which it is used. A framework can adopt a specific resolution considering its application and can maintain its capacity for a certain period or maintain its coherence with the environment [20]. Decisions are based on mental frameworks that help simplify them. These structures contribute to maintaining a certain complexity within the dimensions that the mind can manage. No person can make a rational decision without a minimum level of structuring. To understand a decision structure, one can define how limitations are imposed on problems, the definition of reference points that make success or failure, and the measurement standards that can be adopted [21].

Decision-making can be based on a set of alternatives. The process includes simple decisions based on previous experiences or complex decisions that have many factors to be considered. Decision-making without weighing the advantages and disadvantages of the various options in a comprehensive manner is also feasible. In decision-making, many factors are considered that can be admitted as tradeoffs; in other words, decisions can be reached through various possible actions. For this, measures for tangibles and intangibles must be feasible. Intangibles are usually more volatile than tangibles. Additionally, the factors that affect choices for decision-making include the time to make decisions, the effort that a given strategy, the knowledge about the environment, the importance of accurate decisions, justifying the choice to others, and minimizing conflict between the advantages and disadvantages [22,23].

The intuitive decision-making processes can be useful for routine personal matters but are not suitable for complex issues, in which sources of information and opinions are quite diverse [24]. Good decisions arise from a process that may be structured but has clear objectives and can use available means that understand the scope of their actions in the future, follow the rules of the game, and still consider the advantages and disadvantages [25]. Additionally, the use of terms can be common to describe an action that added some value, including rationality, which would be the equivalent of being rational, intelligent, or even successful [26]. It is highlighted that the terms ‘rationality’ and ‘rational choices’ satisfy basic conditions related to consistency and logic [27]. The decision-making process can be structured considering five approaches—classification, definition, specifications, decision, and action and feedback—which were also adopted as criteria in the research and will be described in the following sections.

2.1.1. The Classification

When classifying problems, it is important to determine which situations or events are unique or generic so that the decision-maker can determine the appropriate solutions that require a rule, policy, or principle for each of them. In different situations, it is necessary to adapt the rules to the circumstances of the case [3]. Problems may be social, political, economic, or sustainability-related in nature, and each can be analyzed individually, with their explanations combined to provide a comprehensive understanding. In practice, the challenge lies in whether the problems and their categories are well-defined. In this context, it is essential to consider whether there is interdependence between them [28]. Moreover, classification frameworks, such as closed-loop supply chains and decision-making approaches [29], alongside others like green supply chains [30] and renewable energy [31], which integrate various technologies and processes, can significantly improve efficiency, reduce costs, and minimize environmental impacts, thereby enhancing sustainability.

2.1.2. The Definition

After the previous phase of classifying problems, it is usually easy to define them. The decision-maker needs to be careful to avoid an incorrect definition or the risk of an incomplete definition [3]. For a broader problem definition, it is suggested that it be segmented into smaller subject areas so that experts and different groups can identify the impact of each of the areas on the initial problem. If the process is successful, it is possible to reformulate and evaluate the initial approach and the suggested solutions [32]. One of the most important activities for most decision-makers is managing the process through which they and their organizations define their success scenarios. It stands out that the use of scenarios allows the real problem to be simplified; however, care must be taken not to oversimplify or overlook better options. Just as important as the broad visions, the way in which problems are framed will design the alternatives for their solution [33]. Initially, the problem must be identified and defined in the best possible way. Then, the problem must be broken down into parts suitable for its solution, considering the results that are undesirable and whether there is anything that needs to be corrected [34].

2.1.3. The Specification

Defining specifications is an important component of the decision-making process and involves clear detailing to achieve and meet the minimum objectives [3]. Reaching consensus on which objective is more relevant than another is quite challenging, especially in complex issues where there is a significant possibility of error in making certain concessions. In an environment where there is a lot of information, assistance is needed to achieve the intended objective [24]. The specification may be so detailed and complex that it may be preferable to include relevant objectives, criteria, and alternatives. The procedure should not overwhelm the average person’s ability to reach and participate in the decision-making process with input and understanding of the data generated [28]. Making choices or trade-offs is challenging when making decisions. The effort to make good choices will depend mainly on the number of alternatives defined for the problem and the objectives to be considered. Before determining how to solve the trade-offs, it is necessary to have a broad view considering the alternatives and their impact on each of the defined objectives. Changes may be necessary, such as canceling out one objective, compensating another objective, or selecting dominant alternatives [35].

2.1.4. The Decision

Decision-making involves making judgments that are influenced by feelings and the willingness to explain event data by breaking them down into attributes at varying levels of preference amplitude [23]. Decision-making should begin with what is right, instead of what is sufficient to achieve the final objective. But if there is a poorly defined condition, the decision-maker may not distinguish its aspects [3]. In the decision-making process, there are some gaps that can become barriers, such as the lack of trust in the process, the effective definition of alternatives, and the lack of innovation and flexibility within the organization. Feedback is often an opportunity to develop self-awareness in action and break down barriers [36]. Decision-making is not as easy as rationalists have suggested. Psychologists have suggested that prior to our current problems, human minds had difficulty managing complexities in decision-making. With limited brain capacity, one can only focus on eight aspects at a time [37].

2.1.5. The Action and the Feedback

The decision-making and action processes are intrinsically linked since the decision-maker can reflect on the commitments of a specific decision and its impact on work and its outcomes [3]. Given certain circumstances, many people are afraid to make decisions that are considered difficult. However, difficult choices are linked to implications and consequences that involve a complex approach. Making difficult decisions is often accompanied by anxiety, doubts, mistakes, and other aspects; consequently, it can increase the difficulty of choosing [38]. Objective decision-making models are more valued than human intuition. However, in environments with high volatility, human experience is preferable for updating and extending the model, i.e., adding value through a combined approach [33]. The feedback consists of monitoring information that is part of the decision-making process. These decisions are made by people who organize information for feedback to decision-makers who use the reports and data [3]. Feedback is an efficient way to gain insights and experiences about what happened, its reasons, and positive or negative results. Everyday experience can offer only a limited sample of a potentially complex world. The feedback loop can consider rules, action, results, and interpretations [26]. Feedback on the functioning of a system or on its compliance with its objectives may not occur instantly. Due to the possibility of several events occurring in the interval, when feedback arrives, its results may be distorted and the opportunity to adapt the process is lost [28].

2.2. Decision-Making Approaches in Supply Chain Management

Supply chain management can combine different approaches, such as interpersonal behavior or soft skills, which are related to behavioral that refer to how a person relates to other people and situations. Even with the expansion of information technology in the supply chain and the use of disruptive technologies, it is important to highlight that soft skills are necessary for supply chain collaborators and managers. Research on the adoption of soft skills involving communication, planning, initiative, and negotiation was developed by [39], which reinforces this approach. Traditional business-to-business methodologies often do not consider the dynamics of interpersonal influences on managerial decisions or their impacts on decision-making. Additionally, approaches that integrate interpersonal dynamics in the supply chain, both relational and informational, are incentives, teams, management, and environment [40].

Within supply chain management decision-making processes, the elements of the process are impacted by behavioral factors inherent to the decision, such as rationality. Decision-making can be rational or intuitive, consisting of experiential and emotional components when approaching complex decisions [41]. Precisely, the emotional acuity and constancy of employees to manage parts of the operation produce an effect of order and inventory instability due to failures. Therefore, the relationship between stress and errors results in the intensification of order and inventory discrepancy [42]. Furthermore, the transportation problem for a supply chain network can be addressed by considering scenarios that include stakeholder behavioral factors linked to the evaluation of routes, modes, and industrial products [43].

The application of the theory of planned behavior in the context of insourcing processes collaborates with new behavioral factors in personal decision-making and surrounding forces and alerts supply chain managers about this [44]. Nevertheless, ambiguity affects supply chain decisions that can be performance-related when decision-makers have difficulty assessing partner performance, informational when there are errors of interpretation, relational when there is a lack of understanding of operations and strategies and uncertainties regarding processing time probabilities [45].

The Bullwhip effect in the supply chain is amplified by the human factor. In inventory management processes, individual choices and decisions can affect the level of inventory, which can be low or high, to the detriment of the feeling of insecurity regarding the available information [46]. Furthermore, there are factors that affect the behavioral coordination of the supply chain in a digitalization scenario. An important causal factor that can effectively solve the problems that affect the behavioral coordination of the supply chain in the digitalization scenario and provide significant implications for decision-makers [47]. Additionally, there is an impact of individual and cultural variations on decision-making. Considering the level of organizational complexity, the consistency premises of decision-makers will potentially be elemental [48].

2.3. Fuzzy DEMATEL

The latest research has been incorporating the Fuzzy DEMATEL method as a fundamental approach to solving the complexities of supply chains. Ref. [49] applied this approach to assess risk factors in the supply chains of emerging industries, revealing hidden challenges beyond the organization. Similarly, Ref. [50] designed a supply chain framework applied to electric vehicles with recycling providers and applying decision-making methods to improve efficiency, transparency, and sustainable practices. In the healthcare sector, Ref. [51] recognized core elements supporting a circular supply chain operation, seeking to reduce material shortages and operational inefficiencies. Managing waste disposal, Ref. [52] applied Fuzzy DEMATEL to explore economic and financial barriers in the reverse supply chain of solar panel waste, identifying pathways for advancing the circular economy.

Further research expands the thematic scope to include urban and industrial supply chains. Ref. [53] emphasized intelligent loading and unloading in urban logistics, while [54] examined the role of digitalization supporting social sustainability through the evaluation of enablers and their interrelationships. In the mining industry, Ref. [55] investigated the primary enablers and challenges to implementing sustainability practices, contributing to policy planning. Ref. [56] explored critical success factors in sustainable packaging supply chains, assessing their effects on economic and environmental performance.

Innovative technologies remain a central focus: Ref. [57] investigated how blockchain contributes to reducing food loss and waste in perishable logistics, and [58] examined generative AI capabilities to support green supply chain management in automotive sector. In the context of all these aspects, the Fuzzy DEMATEL has proven effective in structuring cause-and-effect relationships among complex variables, thereby supporting more informed, sustainable, and system-oriented decision-making in supply chain management. The recurrence of this approach across diverse sectors—including healthcare, mining, packaging, automotive, and urban logistics—demonstrates not only its methodological robustness but also its adaptability to a wide range of sustainability challenges.

These findings provide strong justification for the application of Fuzzy DEMATEL in the present study, reinforcing its suitability for analyzing interdependencies and prioritizing factors within complex supply chain contexts.

In this context, the integration of fuzzy logic with the DEMATEL technique provides a structured approach to dealing with the ambiguity and uncertainty inherent in expert judgments. The method involves the following steps, as proposed by [59].

Step 1: Establish the evaluation criteria and set the fuzzy linguistic scale. Linguistic expressions about the degree of influence are represented mathematically by fuzzy numbers (Table 1).

Table 1.

Linguistic terms and values (Adapted from [59]).

Step 2: Create the directed-relation matrix. The initial fuzzy directed-relation matrix is derived from experts performing pairwise comparisons of criteria (1):

where , which are triangular fuzzy numbers, and on the diagonal is .

Step 3: Defuzzify the matrix. Calculate the area center for triangular numbers by (2):

Step 4: Normalize the fuzzy direct-relation matrix. The normalized fuzzy direct-relation matrix is obtained using (3) and (4):

Step 5: Calculate the fuzzy direct-relation matrix. The fuzzy total-relation matrix is calculated by (5):

If each element of the fuzzy total-relation matrix is expressed as , it is calculated by (6)–(8):

Step 6: Create a causal relation diagram. The sum of rows (R) and columns (C) is calculated by (9) and (10):

Subsequently, the values of R + C and R − C can be derived from C and R, where R + C indicates the overall importance of factor i within the entire system, and R − C denotes the net effects that factor i contributes to the system. Other approaches can be used to evaluate decision-making within supply chain management, such as data envelopment analysis and benefits, opportunities, costs, and risks [60,61,62,63,64,65].

3. Methodology

This section outlines the methodology employed in this study to achieve the research objectives. This comprehensive methodology ensures a robust cause-and-effect analysis in decision-making within supply chain management, providing a solid foundation for the study’s findings and conclusions.

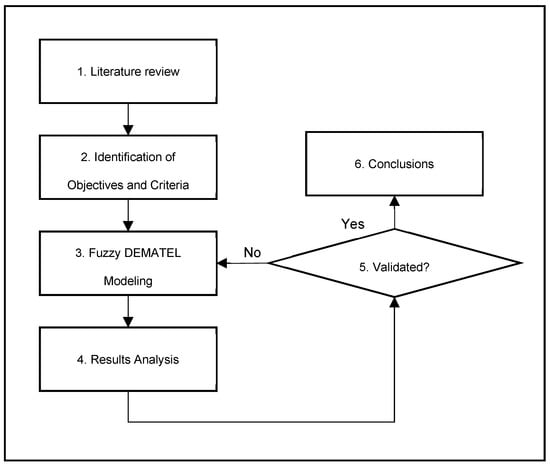

The research framework, aligned with the research objectives, is summarized as follows (Figure 1). In the initial phase, a literature review was conducted to establish foundational concepts about the decision-making process and explore studies on supply chain management. The second step involved defining the objectives and criteria, specifically focusing on decision-making within supply chain management. Subsequently, Fuzzy DEMATEL was employed for modeling purposes to create the diagram of correlation among dimensions and the criteria for understanding the effects in the third step, followed by the evaluation of results in the fourth step. In the fifth step, the obtained results underwent validation by experts and decision-makers who actively contributed to the research.

Figure 1.

The research framework.

Then, these objectives were mathematically formulated. This may have involved creating mathematical models that would represent the problem and the objectives. In the modeling, Fuzzy DEMATEL was considered, as it effectively integrates behavioral considerations and addresses potential biases in the process. In many cases, the judgments and preferences of experts and decision-makers are challenging to represent in exact numbers due to the fuzziness of language. Therefore, Fuzzy DEMATEL emerged as the most suitable approach to handle this complexity.

The eight participants in the identification of objectives and criteria were experienced staff with backgrounds in supply chain management at a leading chemical company, a world-class Fortune 500 company that consistently ranks among the top chemical producers globally. Among them, four were experts serving as consultants and four were decision-makers working as supply chain managers. Operating through thirteen business units globally, it delivers innovative and sustainable solutions. The company’s primary objective is to research, develop, manufacture, and supply products and services to several sectors. The company’s operations span five key global regions: Europe, North America, South America, Asia, and the Pacific. The participants completed the Fuzzy DEMATEL assessment, having the relevant experience needed to provide useful and informed responses.

Therefore, this study was founded on the following key assumptions. First, the decision-making process was characterized by multiple interdependent criteria that exert mutual influence. Additionally, expert judgment was considered a valid and reliable approach for assessing these interactions. Given the inherent uncertainty and subjectivity in expert evaluations, fuzzy logic provided an appropriate framework for managing imprecision. Furthermore, fuzzy DEMATEL was deemed suitable for modeling causal relationships in complex and uncertain environments, allowing for a more nuanced understanding of underlying dependencies.

Based on these assumptions, the analysis of results of different possible solutions to the identified problem considered the cause-and-effect factors relationships. This was right solution that best met the defined objectives. Additionally, the conclusions contribute to a complete answer to this problem in decision-making approaches in supply chain management, specially in sensitive scenarios [66,67,68,69,70].

4. Empirical Analysis

The objective of this approach was to assess cause-and-effect relationships to support decision-making within supply chain management. A discussion between decision-makers and experts played a pivotal role in the modeling process. Conducted in a single, focused, in-person session, this activity facilitated direct interaction and collaborative engagement. The decision-making process was explained at the beginning of the session, and with the guidance of experts, the concepts were translated for decision-makers. This interaction contributed to refining the process and selecting the criteria. Additionally, the integration of Fuzzy logic with DEMATEL contributed to mitigating behavioral biases in judgments by providing a systematic framework to handle uncertainty and subjectivity, ensuring more balanced and objective evaluations.

Based on their discussion, the experts suggested the criteria classification (C1), definition (C2), specifications (C3), decision (C4), and action and feedback (C5), as listed in Table 2, drawing from the relevant literature (Section 2.1) to better reflect the specific challenges faced by the company. All these criteria relate to decision-making in supply chain contexts: Classification allows for structuring the problem dimensions clearly before analysis, definition facilitates the elimination of ambiguities, ensuring that all involved share a common interpretation of the concepts, specifications define parameters for more well-founded decisions, decision represents the critical phase where interdependencies between criteria directly impact the choice, action and feedback ensure that decisions are executed and refined as needed.

Table 2.

The key criteria for assessing cause-and-effect relationships.

The adoption of these five criteria is guided by a structured decision-making framework in supply chain management, where decisions advance from problem classification and framing to the implementation and continuous monitoring of actions. This systematic approach aligns with established decision-making methods in the context of sustainable supply chains and provides a foundation for applying the Fuzzy DEMATEL method. Furthermore, the rationale for the adoption of these criteria is supported by previous research in the field such as [71], which divides the decision-making process into levels. The selection of criteria defined by [72] aligns with established decision-making methodologies in sustainable supply chain management, integrating structured decision contexts with sustainability considerations. Ref. [73] further emphasize that decision-making is fundamental to complex processes and highlight methodological advancements that continue to shape structured decision contexts in supply chain management.

This collaborative effort aimed to align theoretical foundations and practical insights, ensuring the criteria were comprehensive and contextually relevant. Behavioral aspects, such as the experts’ preferences and perceptions, influenced the criteria selection process, highlighting the importance of integrating diverse viewpoints. Additionally, potential subjective challenges, including differing interpretations of criteria and their interrelationships, were carefully managed through iterative dialog and consensus-building.

The Fuzzy DEMATEL was applied following the steps described in the previous section (Section 2.3), using the criteria (Table 2) in addition to the linguistic terms and values (Table 1). During the judgments phase, a focused discussion among experts and decision-makers was conducted within the same session. The interaction played a critical role in helping the decision-makers better structure their decision problems by leveraging the expertise and insights of the specialists. The experts facilitated the process by clarifying the criteria, addressing potential ambiguities, and guiding the decision-makers in articulating their preferences and perceptions more systematically.

Despite this collaborative environment, individual judgments from each participant were independently collected using an Excel spreadsheet to allow the preservation of unique perspectives and mitigate potential biases. These individual judgments were subsequently aggregated using the arithmetic mean as presented in Table 3, Table 4 and Table 5. This process underscores the importance of expert guidance in structuring decision problems while ensuring that the behavioral nuances and diverse viewpoints of participants are adequately captured and integrated.

Table 3.

Aggregated judgments matrix for l.

Table 4.

Aggregated judgments matrix for m.

Table 5.

Aggregated judgments matrix for u.

To process the evaluations collected during this session, the analysis employed fuzzy triangular numbers, which are defined as follows: The values l (lower), m (middle), and u (upper) correspond to the minimum, average, and maximum limits of the evaluations provided by experts regarding the degree of influence between criteria. These fuzzy triangular numbers capture uncertainty and subjectivity in responses, reflecting variations in individual perceptions of participants.

The value l represents the lowest possible influence between criteria, m indicates a moderate or most common evaluation among experts, and u corresponds to the upper limit of the maximum perceived influence. This approach ensures that differences in participants’ interpretations are considered in the analysis process

To assess the reliability of expert judgments, the average difference between the upper (u) and lower (l) bounds of the aggregated fuzzy comparisons was calculated. This value represents the degree of uncertainty in expert consensus. According to [74,75], such dispersion measures are suitable for evaluating the consistency and reliability of fuzzy DEMATEL results. Afterwards, the remaining steps were carried out with defuzzification (Table 6), which formed the basis for calculating the row and column values for dimensions (Table 7).

Table 6.

Defuzzification of aggregated relation matrix Z.

Table 7.

Row and column sums of the total-relation matrix.

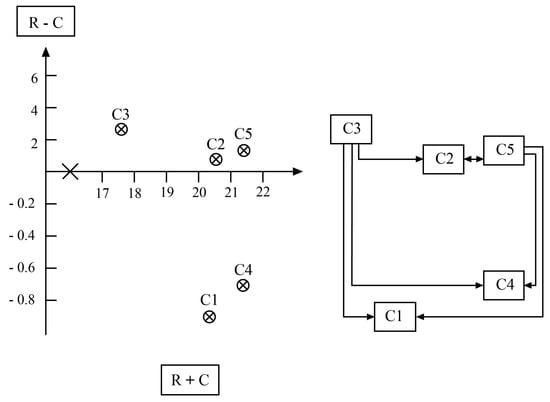

In Table 7, the centrality (higher R + C values) indicates that C4 (decision) with a value of 21.345 and C5 (action and feedback) with a value of 21.352 are the most central, playing an essential role in the system, both as influencers and as influenced. Cause criteria (R − C > 0) indicate that C2 (definition) with 0.840, C3 (specifications) with 2.535, and C5 (action and feedback) with 1.243 are more influential in the system and act as “causal” factors. Effect criteria (R − C < 0) indicate that C1 (classification) with −0.844 and C4 (decision) with −0.727 are more impacted by other criteria, and act as “effect” factors.

In Figure 2, the cause-and-effect relationship can be observed among criteria. C3 (specifications), C5 (action and feedback), and C2 (definition) are the causal factors, while C1 (classification) and C4 (decision) are the impacted factors.

Figure 2.

Cause-and-effect diagram among criteria.

This relationship (Figure 2) indicates the causal factors that drive changes within the system. These include specifications related to parameters and requirements for each criterion, actions and feedback based on evaluation of the criteria, and definitions regarding what each criterion means and its role in the decision process drive changes within the system, influencing the classification of different criteria relevant to decision-making and decision-making processes. Understanding these dynamics is crucial for managers to identify leverage points and implement strategies that can support decision-making within supply chain management. The results were presented to experts and decision-makers who, through consensus, acknowledged the importance of each criterion and validated their relevance.

The application of Fuzzy DEMATEL has demonstrated significant impacts on the effectiveness of decision-making within the supply chain management of the analyzed company. To illustrate this impact, consider a concrete example related to optimizing supplier selection, one of the challenges faced by the organization. Before the implementation of the method, the company made decisions based on individual perceptions and transaction histories, resulting in a non-systematic evaluation of the critical factors influencing supplier selection. The application of Fuzzy DEMATEL allowed for mapping cause-and-effect relationships among criteria such as material quality, delivery time, supplier reliability, and cost. This led to a more precise prioritization of the elements that truly impacted supply chain performance.

Based on this analysis, the company identified that supplier reliability (specifications—C3) and delivery time (action and Feedback—C5) were the most influential factors in decision-making. As a result, it revised its internal procedures, placing greater emphasis on these criteria when selecting new strategic partners. This application illustrates how a systematic procedure for assessing cause-and-effect relationships supports decision-making within supply chain management. The collaborative interaction between experts and decision-makers throughout the process ensured that critical insights were effectively shared and incorporated, leading to more robust and informed decisions. The experts’ structured interaction was designed to mitigate potential biases, such as anchoring or overconfidence, by fostering a systematic and interactive discussion of criteria and preferences.

In addition to improving the criteria assessment structure, the application of the Fuzzy DEMATEL method made the decision-making process more agile and systematic, according to the research participants. The approach provided greater clarity in identifying critical factors, allowing managers to make decisions in a more structured and well-founded manner. Another benefit observed was the reduction in biases in the assessment, especially subjective influences, such as the overvaluation of historical suppliers. The method ensured that choices were based on a logical and objective model, minimizing the interference of intuitive factors that could distort the decision. These improvements demonstrate how the proposed approach contributes to more efficient and well-structured decision-making.

5. Discussion and Conclusions

This section synthesizes the findings of the research, connecting them to theoretical and practical implications while acknowledging its limitations and suggesting future directions for exploration. By analyzing the structured approach to decision-making, this research offers valuable insights into the dynamics cause-and-effect relationships within supply chain management. This research advances on the integration of behavioral considerations in multicriteria decision-making by systematically involving experts and decision-makers to refine decisions problem and mitigate biases through structured interactions.

5.1. Decision-Making Scenarios in Supply Chain Management

In the outsourcing scenario in supply chain management, the decision to outsource certain production processes or services in the supply chain requires a detailed analysis of the criteria influencing this choice, such as cost, quality, flexibility, and supplier reliability. Strategic decisions in global supply chains are inherently complex, encompassing multiple factors like international cost structures, environmental considerations, and service-level expectations. Outsourcing decisions, for instance, necessitate analyzing crucial elements such as information availability, partner location, and the delicate balance between production flexibility and inventory policies [76]. The research developed by [50] highlights the application of decision-making methods in electric vehicle supply chains, where recycling providers play a crucial role. In this context, applying Fuzzy DEMATEL can significantly contribute to identifying the most influential factors in selecting outsourced partners, allowing for a precise mapping of cause-and-effect relationships among criteria such as supplier financial stability, innovation capacity, and environmental impact.

In transportation, decision-making is an essential element for supply chain efficiency, influenced by variables such as costs, delivery times, infrastructure availability, and sustainability. Similarly, advances in packaging materials are reshaping supply chains towards greater sustainability, particularly through returnable transport packaging. Multi-objective closed-loop supply chain models are being developed to optimize these systems, focusing on maximizing economic returns and minimizing environmental impact (carbon emissions) [77]. The research developed by [53] addresses the optimization of smart loading and unloading processes in urban logistics, highlighting the need for strategic transportation decisions. Using Fuzzy DEMATEL can enable a structured analysis of interdependencies among factors such as transportation modes, delivery policies, environmental impact, and local regulations, providing more precise recommendations for optimizing logistical flows.

Location-allocation decisions in supply chain management, which involve choosing the ideal location for storage, production, or distribution facilities, represent a critical challenge. They involve variables such as operating costs, market proximity, infrastructure availability, and sustainability. This complexity extends to location-allocation decisions in supply chain design, which often face high levels of uncertainty, especially in emerging sectors like biofuel production. Recent research underscores the importance of optimizing both operational costs and environmental impact when planning facility locations and material flows; by incorporating robust modeling techniques, studies demonstrate how strategic investments and efficient logistics management can improve resilience and cost-effectiveness [78]. Ref. [55] discuss challenges in the mining industry related to efficient resource distribution and the implementation of sustainable practices. Fuzzy DEMATEL can be used to identify and prioritize factors impacting the choice of logistics center locations, analyzing relationships among operating costs, supplier access, workforce availability, and environmental impact, ensuring a more well-founded decision aligned with the organization’s strategic objectives.

5.2. Theoretical Implications

A structured approach to decision-making can significantly reduce the decision time compared to a step-by-step process. By understanding the structure of a decision, one can define how limitations could be imposed on problems. Better decisions arise from a structured process, with the analysis considering key criteria identified from the literature in the decision-making process. These criteria include classification, the definition, specifications, decision, action, and feedback.

In its development, the steps detailed in the Methodology section were followed, applying Fuzzy DEMATEL based on linguistic terms and values, using the key criteria to create a diagram of correlation among the criteria for understanding their effects. The assessment involved judgments made by the experts and decision-makers from the studied company in a collaborative session. This collaboration, where the experts supported the decision-makers in better structuring the problem, ensured that both theoretical foundations and practical insights were aligned, with behavioral aspects influencing the criteria selection process.

In the cause-and-effect criteria diagram, at least three of them were identified as causal factors, meaning they influence other criteria, namely specifications, definition, action, and feedback. Considering the detailed and complex nature of the specification, it might be better to include relevant goals, criteria, and alternatives. Defining a crucial task for many decision-makers involves overseeing how they and their organizations outline their success plans. The process of decision-making, taking action, and providing feedback are closely connected because the decision-maker can consider the commitments tied to a particular decision and their effects on work and results.

Conversely, the criteria that are impacted, meaning they are influenced by other criteria, were also identified: decision and classification. Making decisions should begin by considering what is correct rather than what is merely enough to reach the end goal. This process involves making choices influenced by emotions and the readiness to interpret event data. When categorizing issues, it is crucial to identify whether situations or events are unique or common, allowing the decision-maker to find the most suitable solutions.

The research question was addressed through a procedure that enabled the evaluation of cause-and-effect approaches in decision-making within supply chain management. These findings contribute to the existing literature on decision-making by demonstrating how cause-and-effect relationships in decision-making processes can be effectively assessed within the context of supply chain management. Moreover, these insights further underscore the importance of integrating behavioral considerations in decision support systems, offering practical implications for supply chain management professionals aiming to enhance decision-making effectiveness.

5.3. Managerial Implications

The study expands our understanding of decision-making processes. It provides insights into how cause-and-effect relationships among key criteria operate within the context of supply chain management. From a managerial perspective, adopting a structured process acknowledges that decision-making involves selecting one option from among several possibilities.

Initially, the results of this research indicate that companies, regardless of the stage they are in the business life cycle, must be able to develop their decision-making processes related to cause-and-effect relationships among key criteria. Aligning business objectives with supply chain strategies is a common practice in strategic management, aimed at ensuring coherence between operational decisions and organizational goals. Rather than positioning business objectives as a competitive advantage per se, this alignment helps establish clearer priorities, improves internal coordination, and supports long-term performance within dynamic supply chain environments [79]. The implementation of Fuzzy DEMATEL provides a clear framework for decision-making, enabling managers to systematically evaluate interactions between criteria. This process reduces uncertainties and enhances decision-makers’ confidence by offering a transparent view of cause-and-effect relationships. Additionally, by better structuring criteria prioritization, the approach contributes to faster and more strategically aligned decisions. Collaboration between experts and decision-makers also strengthens organizational culture by encouraging more well-founded and less subjective practices.

5.4. Limitations and Future Research Directions

This research was conducted with a group of eight experts from a company in the chemical sector, which may limit the representativeness of the results for other industrial segments. Although the criteria and approaches discussed may be applicable to different sectors, we recognize that directly extrapolating the findings to all industries should be carried out with caution, and additional studies with more diverse samples would be necessary to validate this applicability. While the sample was based on experts from the chemical industry, the fundamental principles of the approach used, such as cause-and-effect analysis through Fuzzy DEMATEL, are widely recognized in decision-making processes. Previous studies indicate that this method has been applied in various sectors, including manufacturing, logistics, and services [54,55,56]. Therefore, the findings of this study can serve as a foundation for future applications in other business contexts.

Future research should consider including a diverse range of industries to apply this procedure. Furthermore, exploring the combination of other decision-making methods, such as the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS), could provide more comprehensive insights. TOPSIS positions alternatives relative to ideal and anti-ideal reference points, making it a valuable tool for comparative analysis.

Moreover, future research could investigate the long-term impact of choice criteria and the benefits, opportunities, costs, and risks arising from the decision-making process in supply chain management. Researchers could also examine the applicability of these methods in different geographical regions to determine their effectiveness in decision-making process in supply chain management.

Author Contributions

Conceptualization, C.L.T., A.F.D.S. and J.E.H.B.; methodology, C.L.T., A.F.D.S. and J.E.H.B.; software, C.L.T.; validation, C.L.T., A.F.D.S. and J.E.H.B.; formal analysis, C.L.T., A.F.D.S. and J.E.H.B.; investigation, C.L.T., A.F.D.S. and J.E.H.B.; resources, C.L.T., A.F.D.S. and J.E.H.B.; data curation, C.L.T., A.F.D.S. and J.E.H.B.; writing—original draft preparation, C.L.T.; writing—review and editing, C.L.T., A.F.D.S. and J.E.H.B.; visualization, C.L.T., A.F.D.S. and J.E.H.B.; supervision, C.L.T.; project administration, C.L.T.; funding acquisition, C.L.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All the necessary data are cited in the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gupta, A. How CEO’s Decide: Unveiling the Decision-Making Process of Business Leaders; Notion Press: Chennai, India, 2024. [Google Scholar]

- Shariati, A.; L’Hermitte, C.; Trent, N.M. Decision-making insights on the prepositioning of relief items: A systematic review. J. Humanit. Logist. Supply Chain Manag. 2025. ahead-of-print. [Google Scholar] [CrossRef]

- Drucker, P.F. The effective decision. In Havard Business Review on Decision Making; HBSP: Boston, MA, USA, 2001. [Google Scholar]

- Haseli, G.; Yazdani, M.; Shaayesteh, M.T.; Hajiaghaei-Keshteli, M. Logistic hub location problem under fuzzy Extended Z-numbers to consider the uncertainty and reliable group decision-making. Appl. Soft Comput. 2025, 171, 112751. [Google Scholar] [CrossRef]

- Simon, H. Models of Bounded Rationality; MIT Press: Cambridge, MA, USA, 1982; Volume 2. [Google Scholar]

- Kaufman, B.E. Emotional arousal as a source of bounded rationality. J. Econ. Behav. Organ. 1999, 38, 135–144. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, A.; Zhou, Y.; Zheng, S. Research on fresh supply chain risk evaluation of community group purchase based on hybrid multi-attribute decision-making method. Eng. Appl. Artif. Intell. 2025, 143, 110065. [Google Scholar] [CrossRef]

- Kayouh, N.; Dkhissi, B. Evaluating Supply Chain Risks in The Moroccan Automotive Industry: A Multi-Criteria Decision-Making Approach. Manag. Syst. Prod. Eng. 2025, 33, 123–135. [Google Scholar] [CrossRef]

- Pandey, S.; Singh, R.K.; Gunasekaran, A. Supply chain risks in Industry 4.0 environment: Review and analysis framework. Prod. Plan. Control 2023, 34, 1275–1302. [Google Scholar] [CrossRef]

- Gatewood, A.K.; Drake, M.J. ASCM Supply Chain Dictionary, 18th ed.; ASCM: Chicago, IL, USA, 2024. [Google Scholar]

- Yamini, S.; Gajanand, M.S. Inventory decision-making biases: A review and suggestions for future research. Benchmarking Int. J. 2022, 29, 1889–1912. [Google Scholar] [CrossRef]

- Khan, J.; Ishizaka, A.; Kheybari, S. Risk assessment of perishable products supply chains amidst COVID-19 through multi-criteria visualization. IMA J. Manag. Math. 2025, 36, 299–322. [Google Scholar] [CrossRef]

- Ruan, C.; Gong, S.; Chen, X. Multi-criteria group decision-making with extended ELECTRE III method and regret theory based on probabilistic interval-valued intuitionistic hesitant fuzzy information. Complex Intell. Syst. 2025, 11, 92. [Google Scholar] [CrossRef]

- Stryker, P. Can You Analize This Problem? HBSP: Boston, MA, USA, 2001. [Google Scholar]

- Hammond, J.S.; Keeney, R.L.; Raiffa, H. The Hidden Traps in Decision Making; HBSP: Boston, MA, USA, 2001. [Google Scholar]

- Brewster, D.N. The Psychology of Decision Making: Understanding Mind Roles in Making Choices’s; Independently Publ.: New York, NY, USA, 2024. [Google Scholar]

- Danielson, M.; Ekenberg, L. Real-Life Decision-Making; CRC Press: Boca Raton, FL, USA, 2024. [Google Scholar]

- Mondal, A.; Roy, S.K. Behavioural three-way decision making with Fermatean fuzzy Mahalanobis distance: Application to the supply chain management problems. Appl. Soft Comput. 2024, 151, 111182. [Google Scholar] [CrossRef]

- Mubarik, M.S.; Khan, S.A. Multi-Criteria Decision-Making Methods in Digital Supply Chain. In The Theory, Methods and Application of Managing Digital Supply Chains; Emerald Publishing Limited: Leeds, UK, 2024; pp. 145–161. [Google Scholar]

- Saaty, T.L. The Neural Network Process (NNP): Generalization of the AHP and ANP to Continuos Case of Neural Firing; RWS Pubs: Pittsburg, PA, USA, 2015. [Google Scholar]

- Russo, J.E.; Schoemaker, P.J.H. Decision Traps; Saraiva: São Paulo, Brazil, 1993. [Google Scholar]

- Goodwin, P.; Wright, G. Decision Analysis for Management Judgment; John Wiley & Sons: West Sussex, UK, 2014. [Google Scholar]

- Saaty, T.L. Principia Mathematica Decernendi: Mathematical Principles of Decision Making; RWS Pubs: Pittsburg, PA, USA, 2010. [Google Scholar]

- Saaty, T.L. Decision Making for Leaders: The Analytic Hierarchy Process for Decisions in a Complex World; RWS Pubs: Pittsburg, PA, USA, 2012. [Google Scholar]

- Lumpert, R.J. Robust Decision Making (RDM). In Decision Making Under Deep Uncertainty: From Theory to Practice; Marchau, V.A.W.J., Walker, W.E., Bloemen, P.J.T.M., Popper, S.W., Eds.; Springer: Cham, Switzerland, 2019. [Google Scholar]

- March, J.G. A Primer on Decision Making: How Decisions Happen; The Free Press: New York, NY, USA, 1994. [Google Scholar]

- Tversky, A.; Kahneman, D. The framing of decisions and the psychology of choice. Science 1981, 211, 453–458. [Google Scholar] [CrossRef] [PubMed]

- Saaty, T.L.; Kearns, K.P. Analytical Planning: The Organization of Systems; RWS Pubs: Pittsburg, PA, USA, 2013. [Google Scholar]

- Cao, X.; Xiao, B.; Wen, H. Closed-loop supply chain decision making considering product design strategy under patent protection. RAIRO-Oper. Res. 2025, 59, 279–310. [Google Scholar] [CrossRef]

- Su, Q.; Zhang, Z.; Li, F.; Zhang, W. Decision-Making for Quality Visibility in Green Supply Chain Based on Blockchain Technology. Int. Game Theory Rev. 2025, 2440018. [Google Scholar] [CrossRef]

- Zhang, Y.; Bin, D. Optimizing economic and environmental sustainability in biomass-based energy supply chains: A multi-criteria decision-making approach. Energy 2025, 316, 134208. [Google Scholar] [CrossRef]

- Saaty, T.L. Fundamentals of Decision Making and Priority Theory with the Analytic Hierarchy Process; RWS Pubs: Pittsburg, PA, USA, 2013. [Google Scholar]

- Russo, J.E.; Schoemaker, P.J.H. Winning Decisions; Campus: Rio de Janeiro, Brazil, 2002. [Google Scholar]

- Gomes, L.F.A.M.; Gomes, C.F.S.; Almeida, A.T. Tomada de Decisão Gerencial: Enfoque Multicritério; Atlas: São Paulo, Brazil, 2009. [Google Scholar]

- Hammond, J.S.; Keeney, R.L.; Raiffa, H. Even Swaps: A Rational Method for Making Trade-Offs; HBSP: Boston, MA, USA, 2001. [Google Scholar]

- Argyris, C. Interpessoal barriers to decision making. In Havard Business Review on Decision Making; HBSP: Boston, MA, USA, 2001. [Google Scholar]

- Etzioni, A. Humble decision-making. In Havard Business Review on Decision Making; HBSP: Boston, MA, USA, 2001. [Google Scholar]

- Hammond, J.S.; Keeney, R.L.; Raiffa, H. Smart Choices: A Practical Guide to Making Better Decisions; HBSP: Boston, MA, USA, 1999. [Google Scholar]

- Bak, O.J.C.; Midgley, J. The adoption of soft skills in supply chain and understanding their current role in supply chain management skills agenda: A UK perspective. Benchmarking Int. J. 2019, 26, 063–1079. [Google Scholar] [CrossRef]

- Bitsch, L.; Hanf, J.H. The perfect match: Interpersonal relationships and their impact on chain management. Int. Food Agribus. Manag. Rev. 2022, 25, 489–508. [Google Scholar] [CrossRef]

- Boffelli, A.; Golini, R.; Orzes, G.; Dotti, S. Open the box: A behavioural perspective on the reshoring decision-making and implementation process. J. Purch. Supply Manag. 2020, 26, 100623. [Google Scholar] [CrossRef]

- Bruccoleri, M.; Cannella, S.; La Porta, G. Inventory record inaccuracy in supply chains: The role of workers’ behavior. Int. J. Phys. Distrib. Logist. Manag. 2014, 44, 796–819. [Google Scholar] [CrossRef]

- De, A.; Mogale, D.G.; Zhang, M.; Pratap, S.; Kumar, S.K.; Huang, G.Q. Multi-period multi-echelon inventory transportation problem considering stakeholders behavioural tendencies. Int. J. Prod. Econ. 2020, 225, 107566. [Google Scholar] [CrossRef]

- Foerstl, K.; Franke, H.; Cataldo, Z. What drives managers to insource production? Evidence from a behavioural experiment. J. Purch. Supply Manag. 2021, 27, 100715. [Google Scholar] [CrossRef]

- Gunessee, S.; Subramanian, N. Ambiguity and its coping mechanisms in supply chains lessons from the COVID-19 pandemic and natural disasters. Int. J. Oper. Prod. Manag. 2020, 40, 1201–1223. [Google Scholar] [CrossRef]

- Khan, M.H.; Ahmed, S.; Hussain, D. Analysis of bullwhip effect: A behavioral approach. Supply Chain Forum Int. J. 2019, 20, 310–331. [Google Scholar] [CrossRef]

- Kumar, P.; Mangla, S.K.; Kazancoglu, Y.; Emrouznejad, A. A decision framework for incorporating the coordination and behavioural issues in sustainable supply chains in digital economy. Ann. Oper. Res. 2023, 326, 721–749. [Google Scholar] [CrossRef]

- Li, X.; Chen, L.G.; Chen, J. Individual and cultural differences in newsvendor decision making. Int. J. Oper. Prod. Manag. 2019, 39, 164–186. [Google Scholar] [CrossRef]

- Huang, Z.; Shi, Y.; Liang, D. Risk Identification and Prioritization in China’s New Energy Vehicle Supply Chain: An Integrated Tanimoto Similarity and Fuzzy-DEMATEL Approach. IEEE Trans. Eng. Manag. 2025, 72, 1434–1439. [Google Scholar] [CrossRef]

- Rohit, K.; Verma, A.; Dhairiyasamy, R.; Gabiriel, D. A continuous supply chain management approach using SPJS-Fuzzy DEMATEL and LPWBN for automotive electric vehicles in India. Sustain. Futures 2025, 9, 100518. [Google Scholar] [CrossRef]

- Agrawal, D.; Gupta, S.; Dusad, C.; Meena, M.L.; Dangayach, G.S.; Jagtap, S. Identifying enablers for a circular healthcare supply chain: An integrated fuzzy DEMATEL-MMDE approach with hesitant information. Clean. Eng. Technol. 2025, 24, 100882. [Google Scholar] [CrossRef]

- Yadav, D.; Saraf, A.K. Analysis of numerous economic and financial barriers using the fuzzy DEMATEL method in the reverse supply chain to implement PV waste handling. Environ. Prog. Sustain. Energy 2025, 44, e14578. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, M.; Su, M. Critical Success Factors for Enhancing Intelligent Loading and Unloading in Urban Supply Chains: A Comprehensive Approach Based on Fuzzy DEMATEL-AISM-MICMAC. Systems 2025, 13, 230. [Google Scholar] [CrossRef]

- Öztürk, C. Digitalization as a catalyst for social sustainability in supply chains: An ISM-fuzzy MICMAC and DEMATEL approach. Environ. Dev. Sustain. 2025, 1–61. [Google Scholar] [CrossRef]

- Paul, A.; Mahapatra, S.S. An integrated fuzzy-AHP and fuzzy-DEMATEL approach for analyzing sustainable supply chain factors in the mining industry. Supply Chain Analyt. 2025, 10, 100113. [Google Scholar] [CrossRef]

- Gaur, G.K.; Madaan, J.; Chan, F.T.; Chungcharoen, E. Critical success factors for improving economic and environmental performance of packaging supply chain system. Flex. Serv. Manuf. J. 2025, 1–71. [Google Scholar] [CrossRef]

- Kashyap, A.; Shukla, O.J.; Soni, G.; Ramtiyal, B. Blockchain-Driven Circular Economy Practices in Perishable Supply Chain for Mitigating Food Loss and Waste. J. Syst. Sci. Syst. Eng. 2025, 1–27. [Google Scholar] [CrossRef]

- Kurrahman, T.; Tsai, F.M.; Lim, M.K.; Sethanan, K.; Tseng, M.L. Generative AI capabilities for green supply chain management improvement: Extended dynamic capabilities view. Int. J. Logist. Res. Appl. 2025, 1–28. [Google Scholar] [CrossRef]

- Chen-Yi, H.; Ke-Ting, C.; Gwo-Hshiung, T. FMCDM with Fuzzy DEMATEL Approach for Customers’ Choice Behavior Model. Int. J. Fuzzy Syst. 2007, 9, 236–246. [Google Scholar]

- Kumar, A.; Mukherjee, K.; Adlakha, A. Dynamic performance assessment of a supply chain process: A case from pharmaceutical supply chain in India. Bus. Process Manag. J. 2015, 21, 743–770. [Google Scholar] [CrossRef]

- Testoni, P.S.; Tramarico, C.L.; Rodríguez, E.C.A.; Marins, F.A.S. Analytic hierarchy process applied in the prioritization of third-party logistics providers in banking services. Production 2024, 34, e20230108. [Google Scholar] [CrossRef]

- Castro, J.I.D.; Muniz, J., Jr.; Bernardes, E.; Tramarico, C.L. Logistics projects based on radio frequency identification: Multi-criteria assessment of Brazilian aircraft industry. Pesq. Oper. 2021, 41, e244928. [Google Scholar] [CrossRef]

- Silva, A.M.; Tramarico, C.L. Multi-criteria analysis of big data and big data analytics on supply chain management. Int. J. Integr. Supply Manag. 2022, 15, 280–303. [Google Scholar] [CrossRef]

- Ortiz-Barrios, M.; Miranda-De la Hoz, C.; López-Meza, P.; Petrillo, A.; De Felice, F. A case of food supply chain management with AHP, DEMATEL, and TOPSIS. J. Multi-Criteria Decis. Anal. 2020, 27, 104–128. [Google Scholar] [CrossRef]

- Tramarico, C.L.; Karpak, B.; Salomon, V.A.P.; Silveira, C.A.M.D.; Marins, F.A.S. Multi-criteria analysis of professional education on supply chain management. Production 2019, 29, e20180087. [Google Scholar] [CrossRef]

- Tramarico, C.L. Systematic Mapping Analysis on Sustainable Supply Chain Management. In Proceedings of the 2nd South American International Conference on Industrial Engineering and Operations Management, Sao Paulo, Brazil, 5–8 April 2021; pp. 279–289. [Google Scholar]

- Tramarico, C.L. Managing lead time variability in the activity ingredient supply chain: A game theory-based risk response framework. Pesq. Oper. 2024, 44, e283830. [Google Scholar] [CrossRef]

- Tramarico, C.L. A multi-criteria assessment of readiness for disruptive technology implementation in supply chain management: A risk response framework perspective. Pesq. Oper. 2024, 44, e282884. [Google Scholar] [CrossRef]

- Tramarico, C.L.; Palominos, P.; Salomon, V.A.P. Enhancing circular supply chain implementation: Multi-criteria analysis with the Analytic Hierarchy Process. In AI, Analytics and Strategic Decision Making; Ujwary-Gil, A., Florek-Paszkowska, A., Eds.; Routledge: Abingdon, UK, 2025; Available online: https://www.routledge.com/AI-Analytics-and-Strategic-Decision-Making/Ujwary-Gil-Florek-Paszkowska/p/book/9781032831107 (accessed on 12 May 2025).

- Tramarico, C.L. Circular supply chain: Addressing critical success factors through multi-criteria analysis. In Proceedings of the Industrial Engineering and Operations Management: IJCIEOM 2024, Salvador, Brazil, 26–28 June 2024; Springer Proceedings in Mathematics & Statistics. Gonçalves dos Reis, J.C., Mendonça Freires, F.G., Vieira Junior, M., Garcia Barbastefano, R., Oliveira Sant’Anna, Â.M., Eds.; Springer: Cham, Switzerland, 2025; Volume 483. [Google Scholar]

- Attadjei, D.D.; Madhwal, Y.; Panfilov, P.B. A decision phases of a supply chain management: A proposed decision support system to boost organizational decision making. Int. J. Eng. Technol. (UAE) 2018, 7, 157–159. [Google Scholar] [CrossRef]

- Alexander, A.; Walker, H.; Naim, M. Decision theory in sustainable supply chain management: A literature review. Supply Chain Manag. 2014, 19, 504–522. [Google Scholar] [CrossRef]

- Chai, J.; Ngai, E.W. Decision-making techniques in supplier selection: Recent accomplishments and what lies ahead. Expert Syst. Appl. 2020, 140, 112903. [Google Scholar] [CrossRef]

- Shieh, J.I.; Wu, H.H. Measures of consistency for DEMATEL method. Commun. Stat. Simul. Comput. 2016, 45, 781–790. [Google Scholar] [CrossRef]

- Tzeng, G.H.; Huang, J.J. Multiple Attribute Decision Making: Methods and Applications; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Guchhait, R.; Sarkar, B. A decision-making problem for product outsourcing with flexible production under a global supply chain management. Int. J. Prod. Econ. 2024, 272, 109230. [Google Scholar] [CrossRef]

- Sarkar, B.; Tayyab, M.; Kim, N.; Habib, M.S. Optimal production delivery policies for supplier and manufacturer in a constrained closed-loop supply chain for returnable transport packaging through metaheuristic approach. Comput. Ind. Eng. 2019, 135, 987–1003. [Google Scholar] [CrossRef]

- Habib, M.S.; Asghar, O.; Hussain, A.; Imran, M.; Mughal, M.P.; Sarkar, B. A robust possibilistic programming approach toward animal fat-based biodiesel supply chain network design under uncertain environment. J. Clean. Prod. 2021, 278, 122403. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P. Supply Chain Management: Strategy, Planning, and Operation; Prentice Hall: São Paulo, Brazil, 2003. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).