Abstract

Background: In an increasingly digitized supply chain landscape, small and medium-sized enterprises (SMEs) face mounting challenges in regard to delivering differentiated and responsive customer experiences. This study investigates the role of Industrial Internet of Things-enabled coopetition networks (IIoT-CNs) in enhancing the customer experience and value cocreation among SMEs. Grounded in Service-Dominant Logic, this research explores how interfirm collaboration and real-time data integration influence key performance indicators (KPIs), including perceived product quality, delivery timeliness, packaging standards, and product performance. Methods: An experimental design involving SMEs in Portugal’s ornamental stone sector contrasts traditional operations with digitally integrated coopetition practices. Results: While individual KPI improvements were not statistically significant, regression analysis revealed a significant positive relationship between IIoT-CN participation and the overall customer experience. The reduced variance in the performance metrics further suggests increased consistency and reliability across the network. Conclusions: These findings highlight IIoT-CNs as a promising model for SME digital transformation, contingent on trust, interoperability, and collaborative governance. This study contributes empirical evidence and practical insights for advancing customer-centric innovation in SME-dominated supply chains.

1. Introduction

In modern supply chains’ dynamic and increasingly digitized landscape, enhancing customer experience has become a vital priority for manufacturing small and medium-sized enterprises (SMEs). As digital technologies reshape customer expectations and competitive dynamics, SMEs, which are often more agile but more resource-constrained than larger firms, face unique pressures to deliver differentiated, seamless, and value-rich experiences, across all touchpoints [1]. The ability to consistently meet or exceed customer expectations is no longer merely an operational concern; it has become a strategic imperative, tied directly to profitability, long-term viability, and competitive positioning [2]. Within this context, exploring innovative organizational strategies that can amplify the customer experience is both timely and necessary.

Problems tatement: SMEs are foundational to the European economy, contributing over 20% of the EU27’s total value added and employing more than 85 million individuals [3]. Historically, manufacturing SMEs have operated within localized markets, either selling directly to customers, thereby fostering strong relational ties, or relying on larger intermediaries for market access [4]. However, the advent of digital supply chains has significantly disrupted these traditional pathways, compelling SMEs to adapt to increasingly globalized environments and more sophisticated customer demands [5]. Despite their economic and social importance, SMEs often struggle to deliver a superior customer experience within these digitally enabled supply networks [6]. Constraints, such as limited financial, technological, and human resources, hinder their ability to scale operations and meet evolving consumer expectations [7]. Simultaneously, the proliferation of digital feedback platforms has heightened transparency and amplified pressure to satisfy and retain customers [8]. Both scholars [9] and policymakers [10] have increasingly emphasized the need for collaborative strategies to boost SME adaptability and competitiveness. One strategic model gaining traction is coopetition, the simultaneous pursuit of cooperation and competition between firms [11]. Coopetition networks aim to harness collective strengths and generate shared value, while allowing firms to retain individual competitive advantages [12]. While effective in regard to ecosystems anchored by dominant firms, such as Microsoft or Amazon [13], this model presents distinct challenges when applied to SME-dominated contexts. These include diminished strategic autonomy, a dependence on central orchestrators, and limited flexibility [14]. Without a coordinating keystone firm, coopetition networks among SMEs often lack cohesion, governance, and long-term viability [15]. Additionally, cultural and structural reluctance among SMEs to engage in inter-organizational collaboration further hinders their ability to adapt and enhance the customer experience. This context foregrounds a question: How can coopetition networks enhance the customer experience and foster value cocreation among SMEs?

Underlying potential solutions: Service-Dominant (S-D) Logic provides a theoretical foundation [16]. Central to S-D Logic is the premise that value is not embedded in products or services, but is cocreated through dynamic and reciprocal interactions between firms and their customers [17]. These interactions are inherently contextual and shaped by individual customer experiences, preferences, and situational factors [16]. For SMEs, adopting a value cocreation mindset enables more personalized engagement, deeper relational bonds, and greater customer loyalty and satisfaction [18]. Advancements in digital technologies, particularly those associated with the Industrial Internet of Things (IIoTs), have further expanded the potential for value cocreation within digital supply chains [19]. The IIoTs facilitates seamless, real-time data exchange across interconnected systems, enabling SMEs to monitor operations, anticipate customer needs, and deliver highly tailored services [20]. By embedding IIoTs capabilities into their operations, SMEs can transition from reactive to proactive service operations, offering more responsive and efficient customer experiences [21]. Emerging evidence suggests that IIoT-driven digital transformation can significantly reshape traditional manufacturing logic, equipping SMEs with tools to deliver scalable and differentiated value propositions [22]. These developments highlight the importance of strategic collaboration and technological enablement as dual levers for improving the customer experience. When leveraged within cooperation networks, they may offer synergistic advantages, enabling SMEs to jointly innovate, cocreate value with customers, and respond effectively to the demands of digital supply chain environments.

Research bjective: This study investigates how IIoT-driven coopetition networks (IIoT-CNs) can enhance the customer experience and foster value cocreation among SMEs operating within digital supply chains. Anchored in S-D Logic, this research positions IIoTs and coopetition as complementary enablers of customer-centric innovation, operational agility, and collaborative service delivery [1]. When integrated with the IIoTs, coopetition networks are positioned to facilitate more dynamic, responsive, and personalized value cocreation processes. These networks are expected to yield measurable improvements in the customer experience by enabling real-time data exchange, resource sharing, and interfirm coordination. To explore this proposition, the study implements an experimental IIoT-CN involving a group of SMEs. Customer perceptions are evaluated through pre- and post-intervention assessments using KPIs, including perceived product quality, delivery timeliness, packaging standards, and product performance. Therefore, this research’s primary objective is to generate empirical insights into the mechanisms by which IIoT-enabled coopetition networks impact customer experience outcomes. By addressing the central research question, this study aims to inform strategic decision making among SME managers, support policy initiatives for digital transformation, and contribute to the broader discourse on sustainable, innovation-driven supply chain ecosystems.

Paper rganization: Section 2 reviews the theoretical foundations of Service-Dominant Logic (S-D Logic), the Industrial Internet of Things (IIoTs), and coopetition, framing their relevance within digitally connected SME ecosystems. Section 3 details the research methodology, including the experimental design, sampling strategy, data collection processes, and analytical techniques. Section 4 defines the key performance indicators (KPIs) used to assess the customer experience. Section 5 presents the empirical findings, combining quantitative KPI results with qualitative insights from the network’s implementation. Section 6 critically discusses the results, addressing the statistical limitations, external validity, and broader implications. Finally, Section 7 concludes the paper by evaluating the research hypothesis and outlining the study’s limitations and recommendations for future research.

2. Literature Review

S-D Logic, first introduced by Vargo and Lusch (2004), redefined the understanding of value creation by shifting from a product-centric paradigm to one that emphasizes value cocreation through dynamic, reciprocal interactions between firms and customers [23]. Within this framework, firms do not deliver value unilaterally, they offer value propositions that customers realize through their contextualized experiences [18]. This reconceptualization positions the customer as a central actor in the value cocreation process.

Recent developments in S-D Logic extend this thinking to service ecosystems, wherein value emerges through interconnected and adaptive relationships among multiple stakeholders [24]. Within these ecosystems, technology assumes a dual role, as an operand resource, a passive tool employed in value creation, and an operant resource, an active agent shaping interactions and outcomes [25].

Among emerging technologies, the IIoTs exemplifies this dual function. While general IoT technologies enable connectivity across consumer devices [19], the IIoTs is distinguished by its focus on industrial environments, where it leverages interconnected sensors, machines, and real-time analytics to improve operational intelligence, enables predictive maintenance, and supports adaptive manufacturing [26]. In the context of coopetition networks, the IIoTs facilitates seamless data sharing, automation, and collaborative problem solving, enhancing firms’ collective capacity to innovate and respond to customer needs [27].

Coopetition, a strategic hybrid of cooperation and competition, aligns closely with S-D Logic principles [28]. It enables SMEs to pool resources, share knowledge, and jointly develop innovations, while maintaining distinct competitive positions [29]. Within service ecosystems, coopetition allows SMEs to integrate specialized capabilities into broader collaborative arrangements that deliver greater customer value [9]. However, SME-driven networks often lack a dominant “keystone” firm to orchestrate the activities, leading to coordination, governance, and sustainability challenges [15]. To address these issues, S-D Logic introduces the concept of shared institutional arrangements, namely informal and formal rules, norms, and practices that facilitate coopetition without a centralized authority [30].

The IIoTs becomes a critical enabler of value cocreation when conceptualized as an operant resource. It supports service innovations such as remote monitoring [31], predictive analytics, and personalized production capabilities that enhance customer satisfaction and operational efficiency [9]. Through the IIoTs, SMEs can generate actionable insights from real-time customer data, develop joint digital innovation platforms, and increase supply chain transparency [32]. This integration transforms linear value chains into collaborative ecosystems, where value is continuously cocreated through digitally mediated engagement [33].

The customer experience is central to S-D Logic, serving as the input and outcome of value cocreation processes [17]. IIoT technologies can improve the customer experience by fostering interfirm collaboration and real-time responsiveness [34]. These networks support a wide range of enhancements, including reduced defect rates, improved product consistency, predictive service delivery, and co-developed solutions that are tailored to customer needs [35]. Integrating IIoT technologies within coopetition frameworks positions SMEs to be able to deliver more reliable, customized, and engaging customer experiences, thereby driving loyalty, advocacy, and long-term competitiveness.

However, the effectiveness of IIoT-CNs hinges on the presence of governance structures that balance collaborative value creation with competitive interests. Shared institutional arrangements, supported by IIoT infrastructure, enable coordination, help manage conflict, and ensure that adaptability is sustained in rapidly evolving market environments [36]. These coordination mechanisms serve as the connective tissue of coopetition networks, supporting mutual trust, distributed decision making, and innovation alignment [30].

Drawing on the S-D Logic perspective, this study formulates the following hypothesis: IIoT-CNs enhance the customer experience by improving product quality, delivery timeliness, packaging standards, and overall service effectiveness.

3. Methodology

This study adopts a quantitative, pretest–posttest experimental case design to investigate how IIoT-enabled coopetition networks influence the customer experience among small and medium-sized enterprises (SMEs). Anchored in the Service-Dominant Logic (S-D Logic) framework, the methodology emphasizes value cocreation as a dynamic outcome shaped by interfirm interactions across supply chain processes, including production, logistics, and customer service (Elo et al., 2024 [9]).

3.1. Research Design

The research design involves two operational phases: (1) Baseline Practices (BL.P), according to which firms operate independently without digital integration or formal cooperation mechanisms; and (2) coopetition practices (CooP.P), according to which the same firms operate within an IIoT-enabled coopetition network, sharing real-time data and collaboratively managing resources and workflows.

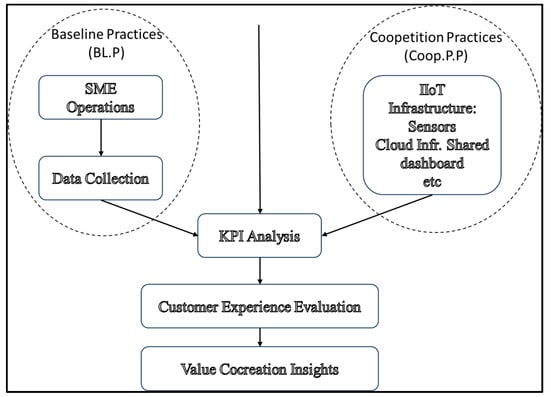

Figure 1 provides a schematic overview of the methodological approach, illustrating the two experimental phases, data sources, IIoT infrastructure, and analysis pipeline.

Figure 1.

Experimental Design and Data Flow Diagram.

This within-subject design allows for causal inference by comparing firm performance and customer outcomes before and after the intervention.

3.2. Sampling and Setting

A convenience sample of SMEs was selected based on two criteria: (1) digital readiness, assessed through preliminary IT audits; and (2) willingness to engage in coopetition, confirmed through formal consent. Participating firms are geographically co-located within a regional industrial cluster, ensuring logistical feasibility and contextual comparability.

3.3. Intervention and IIoT Infrastructure

During the CooP.P phase, an IIoT infrastructure was deployed across the SME network. This included: (1) sensor technologies for tracking production and logistics parameters; (2) cloud-based platforms for interoperable data exchange; (3) cybersecurity protocols to maintain data integrity and trust; and (4) collaborative dashboards to support joint decision making. These systems enabled the SMEs to synchronize their operations, while preserving their strategic autonomy, an essential feature of coopetition.

3.4. Data Collection

Data were collected from two primary sources: (1) System-generated KPIs: Metrics related to delivery timeliness, packaging standards, defect rates, and overall product performance were captured automatically through IIoT platforms during both BL.P and CooP.P phases; and (2) Customer surveys: End customers of the participating SMEs were surveyed before and after the intervention to measure perceived product quality and overall customer experience. The survey instrument was validated through a pretest, including Likert-scale and open-ended items.

3.5. Data Analysis

Paired sample t-tests were used to compare the pre- and post-intervention KPI scores. Changes in customer perceptions were analyzed using descriptive statistics and thematic coding of qualitative responses. The analysis aimed to determine whether IIoT-CNs lead to statistically and substantively significant improvements in the customer experience.

4. Measuring Customer Experience: Key Performance Indicators (KPIs)

The customer experience encompasses the emotions, behaviors, and perceptions shaped by a customer’s interactions across various business touchpoints [37]. Effective management of this experience requires strategic coordination of processes, communication, and service delivery to foster satisfaction and engagement [17]. In industrial contexts, the customer experience is closely tied to operational efficiency, supply chain performance, and service reliability [38].

From an S-D Logic perspective, value is cocreated through ongoing, reciprocal interactions within broader service ecosystems, composed of interdependent actors [16]. These interactions extend beyond transactional events, reflecting collaborative value creation [17]. IoT technologies facilitate continuous feedback, operational transparency, and cross-organizational collaboration, key enablers of value cocreation and enhanced customer satisfaction [39].

To assess customer experience within IIoT-CNs, this study defines a set of KPIs that reflect cocreated value, including: (1) Perceived Product Quality; (2) Delivery Timeliness; (3) Packaging Standards; and (4) Product Performance.

These KPIs offer a structured framework to evaluate how SMEs involved in IIoT-CNs meet customer expectations and cocreate value. Aligned with S-D Logic’s relational and systemic orientation [40], they capture the complexity of the customer experience in digitally connected supply chain ecosystems.

4.1. Evaluating Perceived Product Quality in Regard to Value Cocreation

Perceived product quality plays a central role in shaping the customer experience and is a cornerstone of value cocreation, particularly within IIoT-enabled coopetition networks. Rather than being an objective product attribute, quality is understood through the lens of S-D Logic as something cocreated, emerging from the customer’s contextual interactions and experiences with the product [17]. In this sense, quality is interpreted and validated by the customer.

In digitally integrated environments, SMEs can access real-time customer feedback and respond swiftly to performance gaps. This feedback loop enables continuous refinement of product features and specifications, reinforcing the alignment between the firm’s offerings and customer expectations [6]. As customers engage with products and provide input, they actively shape product value, making perceived quality a dynamic outcome of the cocreation process [41].

To assess this dimension of customer experience, the study adopts a Likert scale-based approach, asking customers to rate the quality of a product on a scale from 1 to 5, where 1 represents “inferior quality” and 5 denotes “excellent quality.” This method transforms subjective perceptions into structured, quantifiable data, offering SMEs actionable insights into how their products are being experienced in practice [42].

The individual ratings are aggregated to measure the perceived product quality (KPIPPQ) (Equation (1)).

RPPQi refers to the perceived product quality rating provided by customer i, and n denotes the total number of responses. This single KPI value reflects customers’ collective judgment and indicates how well the product meets or exceeds expectations.

A KPIPPQ score of 3.0 or above is considered a positive signal of value cocreation, indicating that the product is generally perceived as satisfactory or better. Conversely, a score below 3.0 suggests a gap between customer expectations and product performance, pointing to potential areas for improvement. By monitoring this metric over time, SMEs can use customer input as a strategic asset, driving continuous innovation and deeper engagement within coopetition-based ecosystems.

4.2. Evaluating Delivery Timeliness in Regard to Value Cocreation

Among the many elements that shape a customer’s overall experience, delivery timeliness is one of the most immediate and impactful. It directly influences the customer’s perception of reliability and professionalism and is often a key differentiator in highly competitive manufacturing sectors. From the standpoint of value cocreation, timely delivery plays a crucial role; it builds trust, reinforces service consistency, and ensures that the value proposition is fulfilled in terms of content and timing [43].

In digitally integrated coopetition networks enabled by the IIoTs, SMEs can access real-time logistics data, predictive analytics, and interconnected production systems. These capabilities allow firms to coordinate their operations better, reduce lead times, and proactively address disruptions. The result is a more synchronized supply chain in which timely delivery is no longer a matter of chance, but a co-produced outcome shaped through coopetition, shared data, and aligned expectations.

The study uses a five-point Likert scale to assess how customers perceive delivery timeliness within this ecosystem. Customers are invited to rate their experience as follows: 1 for significantly delayed, 2 for delayed, 3 for on time but not ideal, 4 for timely, and 5 for very timely or exceeding expectations. This scale provides a clear and structured means of capturing customer impressions while allowing nuanced differentiation between acceptable and exceptional delivery experiences. These individual ratings are then aggregated into a single performance metric: the Key Performance Indicator for Delivery Timeliness (KPIDT) (Equation (2)).

where RDTi represents the rating given by customer i, and n is the total number of respondents. The resulting score offers a concise summary of how the customer base collectively experiences delivery performance.

4.3. Assessing Packaging Standards in Regard to Value Cocreation

While often overlooked as a purely functional aspect of the product experience, packaging plays a far more significant role than that in shaping customer perceptions. It serves as a physical barrier that protects the product and as a tangible expression of a company’s brand values, attention to detail, and commitment to quality. In regard to value cocreation, packaging represents an important touchpoint where expectations, aesthetics, and functionality converge [44].

Customers frequently interpret packaging as a signal of how much care and consideration has gone into their purchase. Well-designed packaging that balances durability with visual appeal can enhance the unboxing experience, reinforce brand identity, and reflect broader values, such as environmental sustainability. Within IIoT-enabled coopetition networks, packaging quality is not just a downstream concern, but part of an interconnected value chain, where real-time customer feedback can inform iterative improvements and collective innovation.

To assess this dimension, the study employs a five-point Likert scale through which customers rate the quality of the packaging. The scale ranges from 1 (inferior packaging quality) to 5 (excellent packaging quality), with intermediate levels capturing poor, acceptable, and good quality. This structured approach provides a means of converting subjective impressions into standardized data.

The key performance indicator for packaging standards (KPIPS) is calculated as the average of all the customer ratings related to packaging performance (Equation (3)).

where RPSi denotes the packaging performance score given by customer i, and n is the total number of respondents. This calculation produces a representative value, reflecting the overall customer sentiment regarding packaging quality.

A KPIPS score of 3.0 or higher indicates that the packaging meets or exceeds customer expectations regarding functionality, design, or sustainability, key elements in creating value. On the other hand, a score below 3.0 reveals that packaging is perceived as inadequate or misaligned with customer expectations, potentially diminishing the overall customer experience. By paying close attention to this metric, SMEs within coopetition networks can identify opportunities to improve their packaging strategies and, in doing so, contribute meaningfully to a more complete and satisfying customer journey.

4.4. Evaluating Product Performance in Regard to Value Cocreation

For customers, how a product performs in practice is often the most tangible expression of its value. Performance reflects whether a product meets its intended function, operates reliably, and lives up to the user’s expectations, which are crucial factors in shaping the overall customer experience. In regard to value cocreation, product performance is not merely an internal quality benchmark, but a shared outcome resulting from ongoing interactions between the firm and its customers [45].

Within IIoT-enabled coopetition networks, this dimension becomes even more dynamic. SMEs can continuously refine their offerings by leveraging real-time data, shared performance metrics, and coopetition-based problem solving. The IIoTs allows manufacturers to monitor how products are used, identify patterns in performance, and respond proactively, ultimately enhancing the customer experience in alignment with the principles of Service-Dominant Logic [9].

This study uses a five-point Likert scale to assess product performance to capture the customer’s perspective. Customers are asked to rate their experience on a scale, where 1 indicates very poor performance (the product fails to function as intended), 2 reflects poor performance (partially functional but below expectations), 3 represents acceptable performance (adequate but unremarkable), 4 denotes good performance (reliable and user friendly), and 5 signifies excellent performance (consistently exceeds expectations). These individual ratings are then averaged to calculate the KPI for product performance (KPIPP) (Equation (4)).

In this equation, RPPi represents the product performance rating given by customer i, and n is the total number of responses received. The result is a single, interpretable score that captures overall product effectiveness from the user’s perspective. A KPIPP score of 3.0 or higher indicates that the product is fulfilling or surpassing expectations, signalling that value is being successfully cocreated. Conversely, a score below 3.0 suggests a performance shortfall, revealing potential misalignments between the product’s capabilities and customer needs.

By paying close attention to this KPI, SMEs can identify where performance improvements are most needed and ensure that their offerings continue to create meaningful value within cooperative ecosystems. Ultimately, product performance becomes a living measure of customer trust, satisfaction, and engagement, which are essential for sustainable growth in regard to digitally connected supply chains.

4.5. Assessing Innovation Outcomes in Regard to Value Cocreation

Innovation lies at the heart of value cocreation, especially when viewed through the lens of S-D Logic. Rather than being confined to technological novelty or internal process improvements, innovation in this context is understood as a dynamic, relational process that emerges from ongoing interactions between firms, customers, and other stakeholders. It enables organizations to respond to evolving needs, improve service delivery, and enhance the customer experience [46].

Within IIoT-enabled coopetition networks, innovation is not an isolated activity, but a collective outcome. By collaborating through real-time data sharing, SMEs can jointly explore new ways to meet customer expectations, increase operational efficiency, and deliver more personalized, responsive services. This study captures the impact of such competition innovation through a composite metric known as Innovation Outcomes (IOs), which measures how effectively the introduction of the IIoT-CN contributes to improvements in key aspects of the customer experience.

To quantify this impact, Innovation Outcomes are calculated as the percentage change in the average values of selected KPIs, specifically, perceived product quality, delivery timeliness, packaging standards, and product performance, before and after the implementation of the IIoT-CN (Equation (5)).

In this equation, the Average KPIPre-test represents the baseline scores across all the KPIs collected before the SMEs join the network. At the same time, the Average KPIPost-test captures the same indicators after the intervention. The result is expressed as a percentage, providing a clear and comparative view of change over time.

A positive IOs value indicates an improvement, suggesting that the IIoT-CN has contributed meaningfully to enhancing the customer experience and operational metrics. This reflects successful value cocreation, as defined by the S-D Logic framework, wherein innovations are co-developed and validated through real-world use [18]. Conversely, a negative IOs value signals that the implemented changes may not have met expectations, pointing to gaps in execution, alignment, or customer relevance. Such results offer valuable insights into areas that require strategic recalibration or further innovation.

A positive IOs value for SMEs affirms the transformative potential of coopetition and IIoT integration, reinforcing their role as active participants in innovation ecosystems. On the other hand, a negative IOs value serves as an early warning, highlighting the need for further refinement in regard to network collaboration, technological application, or responsiveness to customer feedback.

5. Findings

Unlike conventional IoT systems primarily focused on consumer applications, the IIoTs emphasizes scalability, reliability, and real-time operational intelligence, features that are critical for managing distributed manufacturing processes and supply chain operations [47]. By integrating sensors, actuators, and advanced data analytics platforms, the IIoTs enables firms to make informed decisions [48], respond dynamically to changing conditions, and continuously optimize production and service delivery [25].

In the context of this study, IIoT technologies serve a dual function within the coopetition network: as operand resources, they provide tools for data collection, monitoring, and analysis [49]; as operant resources, they actively mediate and enhance coopetition interactions, innovation processes, and responsiveness to customer needs [50]. Real-time monitoring and cross-firm data sharing facilitate transparency and synchronization across the network, allowing participating SMEs to cocreate value, streamline operations, and deliver more personalized customer experiences. Embedded sensors in equipment, products, and logistics flows generate continuous streams of actionable data that contribute directly to performance refinement and customer satisfaction [51].

To explore the practical application of this framework, this research focuses on a strategically selected industrial setting: the Portuguese ornamental stone processing sector (Pstone-SMEs). This sector was chosen for its economic relevance, export orientation, and technological adaptability, providing a fertile ground for investigating the feasibility and outcomes of IIoT-CNs. Given its responsiveness to global market dynamics and its fragmented but innovation-minded SME base, the sector offers a compelling case for understanding how digital infrastructure and coopetition practices can jointly foster competitiveness, innovation, and customer-centric value creation [52].

Portugal ranks among the world’s leading players in the ornamental stone industry, second in regard to per capita exports and eighth globally. The sector employs over 16,600 workers and exports to more than 116 countries, contributing significantly to regional economies, especially in the country’s interior regions [46]. This industrial and geographical profile strengthens the study’s relevance, particularly in the context of the EU priorities on digitalization and SME development.

Concentrating on Pstone-SMEs, this research aims to evaluate both the technical feasibility and the organizational impact of implementing an IIoT-CN. The experimental design involves deploying an IIoT-enabled network artefact, formalizing interfirm collaboration, and systematically measuring KPIs before and after the intervention. This case study offers valuable insights into how SMEs in traditional manufacturing sectors can leverage digital innovation and coopetition strategies to sustain competitiveness, respond to customer demands, and contribute to the broader digital transformation of industrial ecosystems.

5.1. Transformative Potential of the IIoTs in Regard to Stone Processing SMEs

The Portuguese stone processing industry has long demonstrated a forward-thinking approach to technology adoption. SMEs within this sector, referred to here as OS.PT SMEs, have consistently embraced advanced tools to enhance productivity, optimize operations, and maintain competitiveness in global markets [53]. Among the most impactful innovations in recent years is the IIoTs, which has rapidly gained recognition among practitioners and researchers as a transformative enabler of operational excellence and customer-centered innovation [54].

IIoT technologies facilitate real-time connectivity between production equipment, enterprise systems, and external supply chain partners. By enabling seamless machine-to-machine and machine-to-system communication, the IIoTs empowers SP-SMEs to function as part of digitally integrated ecosystems, wherein dynamic coordination and agile responsiveness to market needs become the norm [55]. Beyond automation, these technologies offer enhanced visibility, adaptability, and precision, which are all essential for meeting rising expectations in regard to product customization, quality, and service excellence in international markets.

These capabilities translate directly into measurable gains in regard to operational efficiency and the customer experience. SMEs are better equipped to forecast demand, reduce waste, streamline workflows, and meet delivery commitments with greater accuracy. The IIoTs is not merely a technological enhancement, it represents a structural redefinition of how value is created, delivered, and experienced in the stone processing industry.

When viewed through the theoretical lens of S-D Logic, the IIoTs extends beyond its physical infrastructure to become a cyber-physical service system that enables context-sensitive value cocreation [56]. As an operant resource, the IIoTs actively shapes interfirm interactions, fosters coopetition innovation, and supports the formation of service ecosystems. Shared capabilities and transparent communication enable SMEs to jointly create value across organizational boundaries.

Furthermore, the IIoTs directly addresses long-standing bottlenecks in SME operations, such as fragmented information flows, resource inefficiencies, and delayed responsiveness, by introducing real-time visibility, coordination, and decision making [27]. This way, the IIoTs empowers SMEs to become more adaptive, resilient, and customer oriented. Its integration into coopetition networks offers a sector-specific innovation model and a scalable, replicable blueprint for digital transformation across other industries, wherein coopetition innovation and service agility are strategic imperatives.

5.2. Implementation of the Experimental IIoT-Driven Network

The success of IIoT-CNs relies not only on the implementation of advanced technologies, but also on the ability of those technologies, and the firms behind them, to function cohesively and coordinatedly. At the center of this challenge lies the concept of interoperability, defined as the multidimensional capability that allows disparate systems [57], devices, and organizations to communicate, collaborate, and cocreate value within an integrated digital environment [58].

Traditionally, interoperability has been treated primarily as a technical issue. However, when viewed through the lens of S-D Logic, interoperability is recognized as a systemic capability extending beyond data connectivity to include cooperation’s institutional and relational dimensions [56]. It involves transmitting information and aligning shared meanings, goals, and operational norms within a service ecosystem [25].

This study adopts the concept of systemic interoperability, which encompasses three interrelated dimensions, technical, semantic, and pragmatic, that must function in concert to ensure the effectiveness of IIoT-enabled coopetition networks [59]. These dimensions, which are outlined as follows, are particularly critical in sectors such as stone processing, where high precision, time-sensitive coordination, and customized service delivery are central to competitive success:

- Technical interoperability forms the foundation. It ensures that machines, platforms, and software systems can exchange data reliably and securely using standardized protocols and interfaces. This includes application programming interfaces (APIs), communication protocols, and robust cybersecurity frameworks that protect the integrity and confidentiality of shared data [60]. Without this baseline layer, real-time coopetition and IIoT integration would be infeasible.

- Semantic interoperability builds on this foundation by ensuring that the exchanged data retain consistent meaning across systems and organizations. This requires standard terminologies, harmonized data models, and standardized formats. By eliminating ambiguity, semantic alignment enables firms to interpret data in a shared context, reducing misunderstandings and improving coordination efficiency [61].

- Pragmatic interoperability addresses the alignment of strategic intent and organizational behaviors. It involves synchronizing participating firms’ expectations, decision rules, and business objectives to ensure that technical and semantic exchanges translate into meaningful, coordinated actions [62]. This dimension is especially critical within coopetition networks, where trust and mutual benefit must be maintained.

Together, these three dimensions form the backbone of a functional IIoT-CN. When integrated effectively, they support continuous information flows, reinforce shared understanding, and enable coopetition innovation across firm boundaries [63]. These mechanisms allow SP-SMEs to adapt to changing demands dynamically, align production efforts, and collectively respond to customer-specific requirements.

For SMEs in the stone processing sector, systemic interoperability facilitates greater agility, deeper integration of processes, and more effective customer engagement. For example, real-time visibility on production schedules, material inventories, or client design specifications enables firms to jointly develop tailored solutions that optimize efficiency and meet unique market demands [64]. This capability enhances the reliability of operations and the quality of service experiences, reinforcing long-term value cocreation.

Ultimately, interoperability in IIoT ecosystems transcends mere machine connectivity. It is about aligning strategic intentions, operational logic, and institutional norms across firms. When these elements are in harmony, SMEs are empowered to form truly integrated, digitally enabled service ecosystems, capable of delivering innovative, responsive, and customer-centric outcomes.

In the rapidly advancing landscape of industrial automation, ensuring secure, scalable, and real-time communication across heterogeneous systems is essential for building resilient and coopetition-based digital networks. One of the most widely recognized enablers of such interoperability is the Open Platform Communications Unified Architecture (OPC UA). This platform-independent communication protocol has become a cornerstone of IIoT integration across complex industrial environments [65].

The OPC UA extends the capabilities of traditional industrial protocols by offering a service-oriented, standardized framework that supports horizontal and vertical integration within IIoT ecosystems [66]. It combines the flexibility of web-based services with robust, built-in security and a unified data modelling architecture. These features make it particularly suitable for sectors that demand high precision, traceability, and cross-system compatibility, such as the stone processing industry. Its adoption has also expanded into broader service ecosystems, where interoperability and real-time responsiveness are essential [67].

Within the scope of this study, the OPC UA is a critical enabler of systemic interoperability with the coopetition IIoT-CN. The OPC UA addresses the foundational requirements of effective interfirm collaboration by facilitating seamless and secure data exchange at multiple organizational and operational levels [65]. Horizontally, it enables real-time communication among machines on the factory floor, such as CNC equipment, allowing for the coordinated adjustment of production parameters and shared process optimization. It supports secure data transfer from shop floor systems to enterprise-level platforms and cloud-based analytics tools, enabling strategic oversight and multi-stakeholder coordination [67].

Its dual functionality positions the OPC UA as the technical backbone of the IIoT-CN and as a strategic facilitator of value cocreation. Its role in enabling collaborative validation is of particular significance, a process through which stakeholders, such as customers, suppliers, regulators, and partner firms, jointly assess and refine the value propositions. By ensuring that communication is secure and semantically aligned, the OPC UA creates an environment where expectations can be transparently shared, decisions can be collectively informed, and performance can be continuously monitored and improved [68].

This capability is critical in highly regulated and quality-sensitive sectors, such as stone processing. The OPC UA supports alignment in regard to critical parameters, such as production standards, customer specifications, and compliance requirements, while safeguarding operational independence and intellectual property. Real-time data sharing and the co-development of performance criteria reinforce trust among network participants. It strengthens the customer’s role as a cocreator of value, in line with S-D Logic principles [69].

Ultimately, the integration of the OPC UA transforms the IIoT-CN into a robust, agile, and customer-centric ecosystem. It enables SP-SMEs to align their technical infrastructure with strategic intent, enhance responsiveness, and participate in continuous value cocreation. These SMEs achieve technical interoperability by embedding the OPC UA into their digital architecture and unlock new pathways for sustainable innovation, service personalization, and enhanced customer experiences across the coopetition value network.

Implementing an experimental IIoT-CN among Pstone-SMEs represents a crucial milestone in integrating digital innovation and coopetition value creation strategies. Building on prior research that demonstrated the potential of IIoT technologies to digitally connect SMEs with global cyber markets [70], this initiative transitions from conceptual exploration to practical execution. Anchored in the principles of S-D Logic, the project adopts a coopetitive, systems-oriented framework, designed to promote innovation, strengthen cooperation, and improve the performance across a network of independent yet interconnected firms (Tiukhova et al., 2024 [71]).

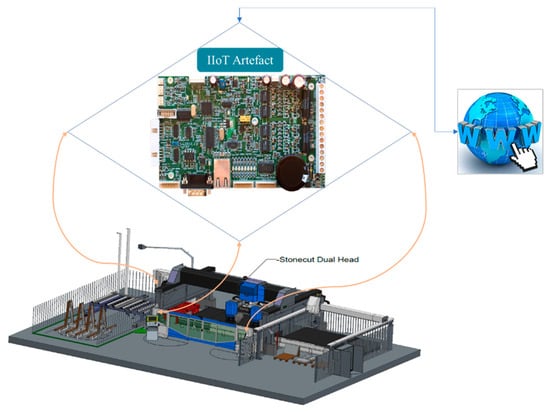

The participating SMEs jointly funded the experimental network, reflecting a shared commitment to digital transformation and mutual value cocreation [46]. At its core is a bespoke IIoT-enabled network artefact, purpose built to meet the operational and strategic needs of Pstone-SMEs (Figure 2). This artefact is engineered to optimize resource use, enable secure interfirm communication, and preserve individual participants’ autonomy, embodying the S-D Logic view that value emerges through context-specific interactions rather than isolated transactions.

Figure 2.

The architecture of the IIoT-enabled network artefact.

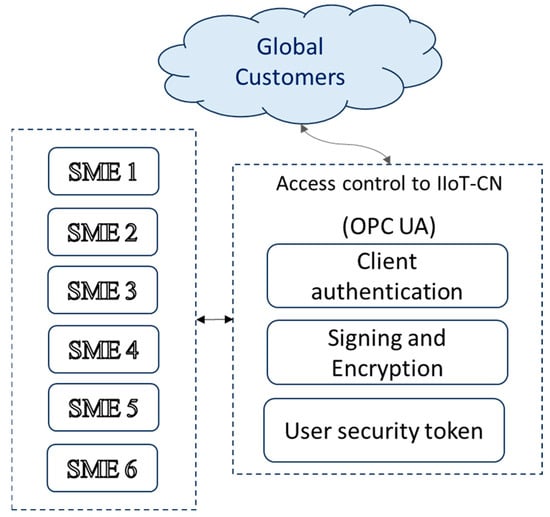

One of the defining features of the IIoT-enabled network artefact is its flexible participation model, which allows SMEs to join or exit the network without long-term contractual obligations. This structure protects firms’ competitive independence, while encouraging voluntary cooperation, a critical attribute in sectors where interfirm trust must be earned and sustained over time. As shown in Figure 3, access to the network is managed via encrypted, protocol-based communication channels using the OPC UA, which ensures secure and confidential data exchange between the parties.

Figure 3.

Integration of IIoT in regard to the coopetition network access control through the OPC UA protocol.

The system architecture also supports the shared use of strategic resources, including inventory, machinery, and technical expertise. Furthermore, it is fully compatible with Building Information Modelling (BIM) platforms, enabling effective coopetition with external stakeholders, such as architects, engineers, and contractors. This cross-sector interoperability reinforces the network’s position within a broader digital value chain [72].

By digitally linking the shop floors of multiple firms, the experimental network redefines the logic of competition. Rather than perceiving one another as adversaries, participating SMEs operate as cocreators of value, leveraging complementary capabilities to develop more responsive services and exceed customer expectations. The coopetition model fosters innovation through shared processes, open knowledge exchange, and a collective commitment to continuous improvement.

The experimental network involved a diverse cohort of SMEs, selected for their range of production capacities, digital maturity levels, and strategic priorities. The implementation process encompassed three key steps: (1) the installation of the IIoT-enabled network artefact; (2) the establishment of interoperability mechanisms; and (3) the activation of real-time, secure communication between the participants. Throughout the pilot, the operational indicators and customer-facing KPIs were closely monitored to assess the network’s influence on value cocreation and the customer experience.

Ultimately, this experimental network initiative represents more than a technological intervention, it signifies a transformational step forward for the sector. By embedding IIoT technologies into coopetition-based industrial frameworks, the project demonstrates how SMEs can evolve toward more agile, transparent, and customer-centric operation models. The implementation also underscores the scalability and replicability of the coopetition network model, providing a blueprint for digital transformation in other sectors seeking to balance technological innovation with strategic flexibility.

5.3. Participants and Data Collection

The successful deployment of the experimental IIoT-CN was predicated on the strategic selection of the participating firms. Six Pstone-SMEs were chosen based on a structured set of inclusion criteria to ensure technical readiness, operational flexibility, and a collaborative mindset, essential for functioning within a digitally connected, interoperability-driven ecosystem. The selection criteria are as follows:

- Digital readiness: This is assessed according to the adoption of technologies, such as automated machinery, digital inventory systems, and data connectivity infrastructure. High digital maturity is essential for leveraging IIoT-CN capabilities, such as real-time monitoring and adaptive coordination.

- Willingness to collaborate: This is measured according to a firm’s strategic openness to resource and data sharing within a competitive model. Preference was given to SMEs with prior experience in industry clusters, joint innovation projects, or collaborative supply chain initiatives.

- Operational scalability: Firms needed to demonstrate the ability to scale production or reallocate resources in response to shared network demands, ensuring responsiveness without compromising delivery performance.

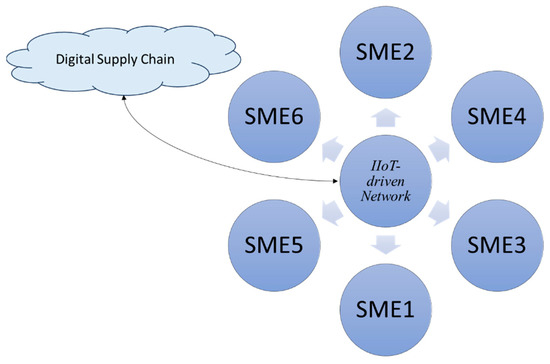

These criteria resulted in the selection of a strategically aligned experimental group of SMEs capable of sustaining real-time digital communication, secure data exchange, and synchronized production workflows. The six selected firms represented a diversity of technological capabilities and coopetition experiences and were embedded into a network that was designed to evaluate whether digitally enabled coopetition enhances the customer experience through value cocreation (Figure 4).

Figure 4.

Experimental IIoT-driven coopetition network among the SMEs.

5.4. Establishing a Control Group

A control group was incorporated into the study to address the influence of external market or operational variables and isolate the effect of IIoT-CN participation. The control group comprised five demographically and operationally similar SMEs, operating under traditional, non-integrated practices. These firms were matched with the experimental group based on their size, product offerings, regional location, and customer segments. Like the experimental firms, they also participated in customer satisfaction surveys and performance monitoring across the same periods, allowing for baseline comparisons and eliminating attribution bias.

5.5. Evaluation Structure

The impact of IIoT-CN participation was assessed through a two-phase comparative design, as follows:

- The Baseline Period (BL.P): April–June 2024, during which experimental and control group SMEs operated independently, using traditional workflows and internal systems;

- The Coopetition Period (CooP.P): July–August 2024, only the experimental group transitioned to the IIoT-CN model, while the control group continued operating under conventional practices.

During the BL.P, all the firms relied solely on their internal resources to fulfil customer orders. The customer experience data collected during this phase established a standard benchmark. During the CooP.P, the experimental group leveraged IIoT tools, such as OPC UA-secured communication, shared resource visibility, and BIM-integrated stakeholder coordination, to implement synchronized, value-driven workflows.

Key features of IIoT-CN implementation included: (1) live resource sharing, namely real-time visibility on inventory and machine availability across firms; (2) cross-firm innovation, namely collaborative development of customized solutions by integrating complementary competencies; (3) secure coopetition, namely encrypted communications that safeguarded proprietary data, while enabling collaboration; and (4) BIM integration, namely streamlined project alignment with external stakeholders, improving coordination and delivery precision.

5.6. Customer Feedback and KPI Measurement

The customer experience was assessed through structured surveys administered approximately two weeks after product delivery. The respondents evaluated four key performance indicators (KPIs): perceived product quality, delivery timeliness, packaging standards, and product performance. These KPIs were measured in regard to both the experimental and control groups to isolate the effects of IIoT-CN implementation.

Table 1 presents the experimental group’s average KPI scores across two operational phases: the Baseline Practices period, during which firms operated independently, and the coopetition practices period, during which firms collaborated through the IIoT-CN. The Innovation Outcomes (IOs) reflect the net improvements in each KPI resulting from the coopetition model.

Table 1.

Comparative analysis of average KPI scores and resulting Innovation Osutcomes (IOs).

The results, validated against the control group, confirm that the IIoT-CN contributed to measurable improvements in the customer experience. The most significant gains were observed in regard to product quality and delivery timeliness, while more modest packaging and product performance enhancements suggest increased alignment and consistency across the networked operations.

5.7. Analyzing Perceived Product Quality (KPIPPQ)

The analysis of the KPIPPQ indicates a modest improvement following the implementation of the IIoT-CN. During the Baseline Practices period, the average customer rating for product quality was 3.08. This increased to 3.32 during the coopetition practices period, suggesting a favorable shift in customer perception as a result of digitally enabled collaboration.

In addition to the increase in the mean score, a reduction in variance was observed, from 2.0099 under the BL.P to 1.5643 during the CooP.P, indicating consistency in the perceived quality. This reduced dispersion suggests more uniform quality delivery across the network, which is particularly valuable in sectors like stone processing, where quality can vary due to material and operational factors.

However, the statistical tests revealed that the observed improvements did not meet conventional significance thresholds. A paired t-test yielded a one-tailed p-value of 0.1373 and a two-tailed p-value of 0.2745, above the α = 0.05 level. The corresponding t-statistic of −1.1029 also fell below the critical values for both tests (1.6711 for one tailed, 2.0010 for two tailed). These results suggest that, while the trend is positive, the changes in the KPIPPQ cannot be conclusively attributed to the IIoT-CN operations based on this dataset alone.

Despite the lack of statistical significance, the directional improvement and reduced variability in the customer ratings offer important operational insights. They point to the potential of coopetition practices, when digitally supported, to enhance consistency and set the stage for more significant gains over time. These early indicators reflect the beginning of a service stabilization process within the IIoT-CN, in interoperability and shared standards gradually reduce fluctuations in output quality.

In this light, the findings underscore the value of interpreting early stage results within the broader context of service ecosystem development. While short-term improvements may not be statistically robust, they provide a foundation for enhancing long-term performance. Continued coopetition engagement, iterative refinement, and data-driven feedback loops are likely to amplify these initial gains.

In summary, although the improvement in perceived product quality was not statistically significant, the results suggest a promising trend toward greater consistency and alignment with customer expectations. These findings reinforce the importance of coopetition networks in building resilient and customer-centric supply networks among SMEs.

5.8. Analyzing Delivery Timeliness (KPIDT)

Delivery timeliness is critical to customer satisfaction, particularly in industrial supply chains, where on-time performance affects project continuity and stakeholder trust.

During the BL.P period, the average delivery timeliness score was 3.15, which is adequate, but indicative of improvement potential. This rose to 3.51 during the CooP.P, reflecting a positive trend following the adoption of a digitally connected, collaboratively structured operating model. Furthermore, the variance in the customer ratings decreased from 1.9263 during the BL.P to 1.4447 during the CooP.P, suggesting increased consistency in meeting delivery expectations.

However, this improvement, while directionally favorable, did not meet the conventional threshold for statistical significance. The one-tailed t-test yielded a p-value of 0.0615, and the two-tailed test produced a p-value of 0.1230, both above the α = 0.05 significance level. The t-statistic of −1.5648 also fell short of the critical values (1.6711 for one tailed, 2.0010 for two tailed), indicating that the observed gains, while promising, cannot be conclusively attributed to the IIoT-CN based on statistical evidence alone.

These results suggest that external variables, operational noise, or the relatively small sample size may have limited the ability to detect significant differences. Nonetheless, the observed increase in the mean score, combined with the reduced variance, reflects an encouraging pattern of operational improvement and service reliability.

Strategically, these trends indicate that the IIoT-CN may support more agile and coordinated delivery execution through real-time inventory visibility, shared production schedules, and improved inter-organizational communication. Even without statistically significant results, the directional gains support the feasibility of coopetition-driven logistics improvements.

To achieve more conclusive results, future research should consider extended observation periods, broader implementation across a larger sample, and the integration of predictive logistics tools. Such steps could help capture the full impact of IIoT-driven coordination on delivery timeliness.

In conclusion, while the improvement in the KPIDT was not statistically significant, the findings suggest early operational benefits from digitally enabled coopetition. These results provide a foundation for iterative refinement and indicate the potential of IIoT-CNs to enhance responsiveness and reliability in SME supply networks over time.

5.9. Analyzing Packaging Standards (KPIPS)

Packaging is vital in shaping the customer experience, by combining functional protection, aesthetic appeal, and sustainability. It influences brand perception and is particularly relevant in sectors where product presentation reinforces customer trust and satisfaction.

During the BL.P period, the average customer rating for packaging stood at 3.20. This increased marginally to 3.21 during the CooP.P, indicating virtually no change in perceived packaging quality. However, the variance in scores dropped considerably, from 2.0949 during the BL.P to 1.1800 during the CooP.P. This reduction suggests enhanced uniformity in packaging outcomes across the network, even if the overall customer perceptions remained static.

Despite this improvement in consistency, the change in the average scores did not achieve statistical significance. The one-tailed t-test produced a p-value of 0.4894; the two-tailed p-value was 0.9787, far exceeding the conventional α = 0.05 threshold. The corresponding t-statistic of −0.0268 also fell well short of the critical values (1.6711 for one tailed, 2.0010 for two tailed). These results confirm that the observed changes in packaging standards cannot be confidently attributed to the IIoT-CN intervention based on the current data.

Nonetheless, the substantial reduction in score variability suggests a meaningful operational development. The more consistent delivery of packaging standards may reflect improved coordination, shared quality benchmarks, or streamlined material sourcing practices within the network. Such stability is a valuable outcome, particularly in markets where customers value predictability in regard to product presentation and the unboxing experience.

Moreover, the negligible change in the mean scores highlights an area for strategic attention. While the coopetition model supports standardization, it has yet to catalyze significant packaging design, functionality, or sustainability improvements. This presents a clear opportunity for innovation. As customer expectations increasingly favor eco-friendly materials and user-centric packaging, SMEs within coopetition networks are well-positioned to co-develop advanced packaging solutions through joint supplier relationships, shared R&D investments, or co-designed packaging systems.

In summary, although the transition to the CooP.P did not result in a statistically significant improvement in perceived packaging quality, the observed reduction in performance variability points to greater consistency and reliability. Moving forward, network participants can build on this operational foundation by pursuing collaborative innovations that align with evolving customer expectations and sustainability imperatives.

5.10. Analyzing Product Performance (KPIPP)

Product performance is a fundamental dimension of the customer experience, reflecting the extent to which a product fulfils its intended function and aligns with user expectations. In this study, the implementation of the IIoT-CN corresponded with a modest improvement in the KPIPP, suggesting early progress toward delivering more dependable and user-centric outcomes.

During the BL.P phase, the average customer rating for product performance was 3.02, indicative of a neutral to moderately satisfactory experience. The mean increased to 3.24 during the CooP.P, pointing to a positive shift in customer perceptions. Concurrently, the variance in performance ratings declined from 1.9828 to 1.4703, signalling improved consistency in the product outcomes during the cooperation phase.

Despite these favorable trends, the changes did not reach statistical significance. The one-tailed p-value was 0.1572, and the two-tailed p-value was 0.3145, above the standard threshold (α = 0.05). The associated t-statistic of −1.0145 was also below the critical values for significance (1.6711 for one tailed, 2.0010 for two tailed). These results indicate that the improvement in product performance, while directionally positive, cannot be attributed with statistical confidence to the IIoT-CN intervention.

However, the reduction in variance is a meaningful operational signal. A tighter distribution in terms of the product performance scores suggests enhanced process control and repeatability, which are critical attributes for building customer trust and minimizing dissatisfaction. This stability may reflect the early benefits of shared expertise, standardized procedures, and collaborative quality assurance introduced by the coopetition framework.

Strategically, these results highlight the potential of the IIoT-CN to foster long-term gains in terms of product reliability and performance. The digital infrastructure and collaborative model provide a foundation for further refinement through real-time product monitoring, continuous feedback loops, and data-driven quality improvements. These mechanisms can help SMEs align product outcomes with customer expectations and dynamic market requirements.

In summary, while the observed increase in the KPIPP was not statistically significant, the positive trend and reduced variability suggest that the coopetition model fosters greater consistency in regard to product quality. Realizing significant improvements will likely require deeper integration of IIoT tools, sustained interfirm collaboration, and targeted innovation efforts. These early results offer a foundation for scaling continuous improvement initiatives and transforming product performance into a sustainable competitive advantage.

6. Discussion and Hypothesis Evaluation

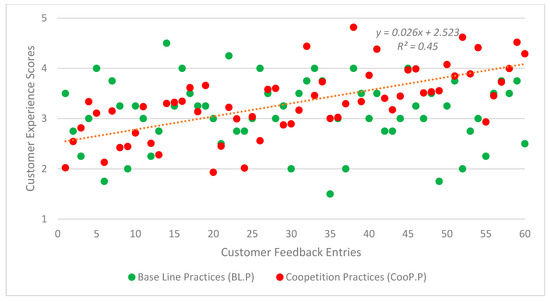

The transition from the BL.P to the CooP.P yielded measurable, though modest, improvements across all four customer experience KPIs. As shown in Figure 5, the positive slope in the average KPI trend line (0.026) suggests a gradual upward trajectory in regard to performance. The coefficient of determination (R2 = 0.45) implies that approximately 45% of the variance in the KPI outcomes may be associated with the coopetition intervention. However, the absence of consistently significant p-values across individual KPIs limits the strength of causal claims and highlights the need for a cautious interpretation.

Figure 5.

Trend analysis of average KPI improvements from Baseline Practices to coopetition practices.

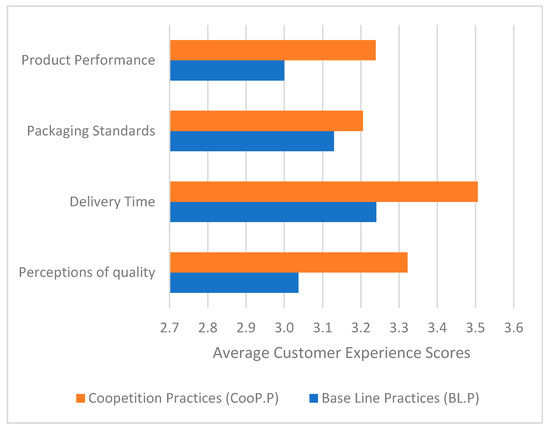

Figure 6 illustrates the average KPI scores across both operational phases. The perceived product quality increased from 3.04 to 3.32 (+9.21%), and the delivery timeliness improved from 3.24 to 3.51 (+8.33%), suggesting enhanced service perception and logistical coordination under the IIoT-CN framework. More modest gains were observed in regard to the packaging standards (3.13 to 3.21, +2.56%) and product performance (3.00 to 3.24, +8.00%), pointing to consistency and functional reliability improvements.

Figure 6.

Comparative analysis of average KPI scores between BL.P and CooP.P.

To evaluate the hypothesis, a linear regression model was employed to assess the relationship between coopetition practices and KPI performance. The model produced a multiple R of 0.2937, with an R2 of 0.0863 and an adjusted R2 of 0.0705. These values suggest a weak to moderate association, with coopetition practices explaining a modest share of the performance variance. However, the ANOVA results (F-statistic = 5.4766, p = 0.0227) and the regression coefficient for the CooP.P (β = 0.2935, 95% CI = 0.0425 to 0.5445) were statistically significant, supporting the hypothesis that digitally enabled coopetition positively affects customer-facing outcomes.

6.1. Addressing Statistical Significance and Potential Confounding Factors

Although the analysis demonstrated positive trends across all the KPIs, none of the individual improvements reached statistical significance at the 95% confidence level. This limitation is likely due to the relatively small sample size and the natural variability in performance across the participating SMEs, reducing the paired t-tests’ statistical power. Furthermore, the observed changes may have been influenced by uncontrolled operational or market dynamics, such as seasonal demand shifts, heterogeneous customer expectations, or firm-specific practices, introducing potential confounding effects.

To mitigate these concerns, a control group of SMEs operating under traditional practices was included in the study, providing a comparative benchmark, during the same evaluation period. While the experimental group demonstrated more pronounced directional improvements, the control group’s KPI scores remained relatively stable. This contrast supports the interpretation that the observed performance gains are partially attributable to the IIoT-CN implementation. However, due to the absence of random assignment, the potential for selection bias or unmeasured firm-level variables remains.

Several potential confounding factors may have influenced the outcomes: (1) seasonal fluctuations affecting production schedules and delivery performance; (2) differences in customer profiles and expectations across market segments; (3) variations in internal process maturity and technological readiness among the SMEs; and (4) learning curve effects as firms adapted to new tools and workflows during the transition to coopetition practices; among others.

6.2. Qualitative Insights

To complement the quantitative results, qualitative data were gathered through interviews and workshops with SME managers involved in the IIoT-CN. These insights reveal both challenges and emerging benefits during implementation.

Key challenges included technical difficulties in integrating legacy systems with IIoT platforms, cybersecurity concerns, and inconsistent digital readiness. Organizational barriers, such as limited trust, reluctance to share data, and cultural resistance to collaboration, also hindered early adoption.

Emerging benefits involved improved visibility into partner operations, a faster response to disruptions, and increased alignment with customer project timelines. Firms with prior collaboration experience adapted more quickly and reported more substantial gains in terms of coordination and reliability.

Overall, the qualitative findings highlight that IIoT-CN success depends not only on technology, but also on trust, shared standards, and change readiness. These relational and organizational factors help explain the modest KPI improvements shown here and suggest priorities for scaling the model in regard to future implementations.

6.3. External Validity and Broader Applicability

This study centers on SMEs within the ornamental stone sector, characterized by moderate-to-high digital maturity and a relatively cohesive supply chain. While the findings offer promising insights into the potential of IIoT-enabled coopetition, their broader applicability should be interpreted cautiously. Industries with more fragmented supply chains, lower levels of digital adoption, or limited system interoperability may face greater challenges in replicating the IIoT-CN model.

Nonetheless, the IIoT-CN framework’s core principles, real-time data exchange, collaborative scheduling, and shared resource optimization, are conceptually transferable to other contexts. These mechanisms are particularly relevant in sectors where the customer experience is tightly coupled with operational coordination, such as custom manufacturing, logistics, construction, and service-intensive supply chains.

To enhance external validity, future research should extend the application of the IIoT-CN model to: (1) low-tech or digitally lagging SMEs, to assess the required infrastructure adaptations and onboarding strategies; (2) service-based and hybrid industries, wherein coordination and responsiveness are key drivers of customer satisfaction; and (3) cross-border and multicultural networks, to evaluate how coopetition dynamics evolve in more complex regulatory and cultural environments.

While this study provides initial empirical support for the hypothesis that IIoT-enabled coopetition can enhance the customer experience, its conclusions remain context bound. The directionality of the KPI trends, reductions in performance variability, and statistically significant regression results suggest meaningful potential. However, future work must address the challenges of scalability, digital readiness, and sector-specific constraints. Strengthening causal inference and expanding the diversity of the implementation contexts will be essential to fully realizing the strategic value of IIoT-CNs across broader industrial ecosystems.

7. Conclusions

This study examined whether IIoT-enabled coopetition networks (IIoT-CNs) enhance the customer experience in SME contexts, by improving perceived product quality, delivery timeliness, packaging standards, and product performance. Although none of the individual KPI improvements reached statistical significance at the 95% confidence level, the overall trends were positive. The regression analysis identified a statistically significant relationship between coopetition practices and aggregated KPI performance, while reduced performance variability pointed to increased consistency, an essential component of customer satisfaction.

Qualitative insights from the participating SMEs further supported the hypothesis, highlighting early operational benefits, such as improved process visibility, enhanced coordination, and collaborative responsiveness. These findings suggest that IIoT-CNs may serve as effective enablers of service improvements by fostering real-time communication and resource integration across firm boundaries.

In conclusion, the results offer preliminary empirical support for the hypothesis that IIoT-driven coopetition can improve the customer experience in digitally mature SME networks. However, these findings remain context specific. Broader validation will require addressing the challenges related to scalability, varying levels of digital readiness, and sectoral diversity. Strengthening causal inference and testing the model in different industrial environments will be crucial to establishing the broader applicability and strategic impact of IIoT-CNs.

Limitations: The study is limited in several respects. First, the sample was restricted to a specific industrial cluster (ornamental stone SMEs), with moderate-to-high digital maturity, which limits its external validity. Second, the short evaluation period may not have captured the long-term effects or allowed enough time for complete adaptation to the coopetition model. Third, although a control group was included, the absence of random assignment introduces potential selection bias. Additionally, the individual KPI results lacked statistical significance, and performance improvements may have been influenced by external factors, such as seasonal fluctuations, customer variability, or learning curve effects.

Recommendations for future research: To strengthen evidence on the impact of IIoT-CNs, future studies should: (1) expand to other sectors and regions, including low-tech or service-oriented SMEs, to assess scalability and adaptability; (2) extend the evaluation period to capture long-term performance changes and organizational learning; (3) incorporate randomized or quasi-experimental designs to improve causal inference; (4) integrate richer qualitative methods, such as structured interviews or case studies, to deepen the understanding of the implementation dynamics and value cocreation; and (5) address organizational and cultural readiness, exploring how trust building, governance, and interoperability influence coopetition success.

By addressing these areas, future research can offer more definitive insights into the transformative potential of digitally connected SME networks in diverse industrial ecosystems.

Author Contributions

Conceptualization, A.a.d.S. and A.J.M.C.; methodology, A.a.d.S.; software, A.a.d.S. and A.J.M.C.; validation, A.a.d.S. and A.J.M.C.; formal analysis, A.a.d.S. and A.J.M.C.; investigation, A.a.d.S. and A.J.M.C.; resources, A.a.d.S. and A.J.M.C.; data curation, A.a.d.S. and A.J.M.C.; writing—original draft preparation, A.a.d.S. and A.J.M.C.; writing—review and editing, A.a.d.S.; visualization, A.a.d.S.; supervision, A.J.M.C.; project administration, A.J.M.C.; funding acquisition, A.a.d.S. and A.J.M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The authors declare that all the original contributions presented in this study are included in the article. Any further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that there are no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| BIM | Building Information Modelling |

| BL.P | Baseline Practices |

| CooP.P | Coopetition practices |

| IIoTs | Industrial Internet of Things |

| IIoT-CN | Industrial Internet of Things Coopetition Network |

| IOs | Innovation Outcomes |

| KPI | Key Performance Indicator |

| KPIDT | Key Performance Indicator Delivery Timeliness |

| KPIPP | Key Performance Indicator Product Performance |

| KPIPPQ | Key Performance Indicator Perceived Product Quality |

| KPIPS | Key Performance Indicator Packaging Standards |

| OPC UA | Open Platform Communications Unified Architecture |

| S-D Logic | Service-Dominant Logic |

| SMEs | Small and medium-sized enterprises |

References

- Al-Rimawi, T.; Nadler, M. Leveraging Smart City Technologies for Enhanced Real Estate Development: An Integrative Review. Smart Cities 2025, 8, 10. [Google Scholar] [CrossRef]

- Lu, X.; Taghipour, A. A Review of Supply Chain Digitalization and Emerging Research Paradigms. Logistics 2025, 9, 47. [Google Scholar] [CrossRef]

- Di Bella, L.; Katsinis, A.; Lagüera-González, J.; Odenthal, L.; Hell, M.; Lozar, B. Annual Report on European SMEs 2022/2023; Publications Office of the European Union: Luxembourg, 2023; Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC134336 (accessed on 25 January 2025).

- Draghi, M. The Future of European Competitiveness: A Competitiveness Strategy for Europe; European Commission: Bruxels, Brussels, 2024; Available online: https://commission.europa.eu/topics/strengthening-european-competitiveness/eu-competitiveness-looking-ahead_en#paragraph_47059 (accessed on 25 January 2025).

- Dai, J.; Jin, Y.H.; Cantor, D.E.; Elking, I.; Guntuka, L. An experimental investigation of environmental knowledge sharing in a supply chain coopetition situation. Int. J. Oper. Prod. Manag. 2025, 45, 628–650. [Google Scholar] [CrossRef]

- El Makkaoui, R.; Bahoussa, A. Nature of Customer Experience in the Sharing Economy. Hong Kong J. Soc. Sci. 2023. [Google Scholar] [CrossRef]

- Štěrbová, M.; Stojanovski, V.; Weiss, G.; Šálka, J. Innovating in a traditional sector: Innovation in forest harvesting in Slovakia and Macedonia. For. Policy Econ. 2019, 106, 101960. [Google Scholar] [CrossRef]

- Muller, P.; Devnani, S.; Ladher, R.; Cannings, J.; Murphy, E.; Robin, N.; Ramos Illán, S.; Aranda, F.; Gorgels, S.; Priem, M.; et al. Annual Report on European SMEs 2020/2021—Digitalisation of SMEs—Background Document; Publications Office: Luxembourg, 2021; Available online: https://op.europa.eu/en/publication-detail/-/publication/849659ce-dadf-11eb-895a-01aa75ed71a1 (accessed on 25 January 2025).

- Elo, J.; Lumivalo, J.; Tuunanen, T.; Vargo, S.L. Enabling Value Co-Creation in Partner Collaboration Ecosystems: An Institutional Work Perspective. In Proceedings of the 57th Hawaii International Conference on System Sciences, Honolulu, HI, USA, 3–6 January 2024; Available online: https://www.sdlogic.net/pdf/post2018/24_0031.pdf (accessed on 1 January 2025).

- von der Leyen, U. A Competitiveness Compass for the EU; European Commission: Bruxels, Brussels, 2025; Available online: https://commission.europa.eu/document/download/10017eb1-4722-4333-add2-e0ed18105a34_en (accessed on 1 January 2025).

- Crick, J.M.; Crick, D.; Ferrigno, G. Coopetition and the marketing/entrepreneurship interface in an international arena. Int. J. Entrep. Behav. Res. 2025, 31, 414–455. [Google Scholar] [CrossRef]

- Mwesiumo, D.; Harun, M.; Hogset, H. Unravelling the black box between coopetition and firms’ sustainability performance. Ind. Mark. Manag. 2023, 114, 110–124. [Google Scholar] [CrossRef]

- Estrada, I.; Dong, J. Learning from experience? Technological investments and the impact of coopetition experience on firm profitability. Long Range Plann. 2020, 53, 101866. [Google Scholar] [CrossRef]