1. Introduction

The term “sustainability” appeared regarding renewable resources, and the concept first referred to the existence of the ecological conditions necessary to support human life at a specific level of wellness through future generations. Sustainability is a concept that is conducive to economic growth based on social justice and the efficient use of natural resources.

Sartori et al. [

1] define sustainability as a long-term process, as well as an awareness of environmental problems, economic crises, and social inequalities. The field of sustainable development is characterized by a wide range of subjects from different fields and with different frameworks. However, sustainability is characterized as a principle that applies to systems. These systems are open for interaction with society and nature, including industrial systems (transport, manufacturing, energy, etc.), social systems (urbanization, mobility, etc.), and natural systems (air, water, etc.), including flows of information, goods, materials, and others [

1]. The authors state that sustainability involves interaction with dynamic systems that are constantly changing and require proactive measures.

The European Union (EU) launched the Green Deal in 2020 as a set of policy initiatives by the European Commission with the overarching aim of making the EU climate-neutral by 2050 and transforming the EU into a modern, resource-efficient, and competitive economy [

2]. Fit for 55 refers to the EU’s target of reducing greenhouse gas emissions by at least 55% by 2030 [

3]. The introduction of electrified vehicles is currently seen as a major contributor to achieving this goal, but transforming transport systems has never been easy [

4].

To speed up this transition, and in response to the ongoing energy price crisis, the EU is calling on Member States to consider additional measures for both the purchase and use of electric vehicles. The interaction of these plans and directives reinforces their individual objectives, working together to ensure that businesses and Member States move in the same direction and consistently work toward a common goal, considering all factors affecting the road transport sector. To future-proof their operations, businesses should already have clear and implementable transition strategies in place to prepare for and adapt to these upcoming changes to achieve the long-term goal of net-zero emissions. This may include reviewing and analyzing existing supply chains, entering new partnerships, exploring available incentives, etc.

This research aims to answer a research question about the possibility of using simulation modeling as a decision-making tool for companies that should transform their transportation business according to new rules and requirements. Can a flexible and adaptive framework be created for sustainable modeling of a fleet of electric vehicles?

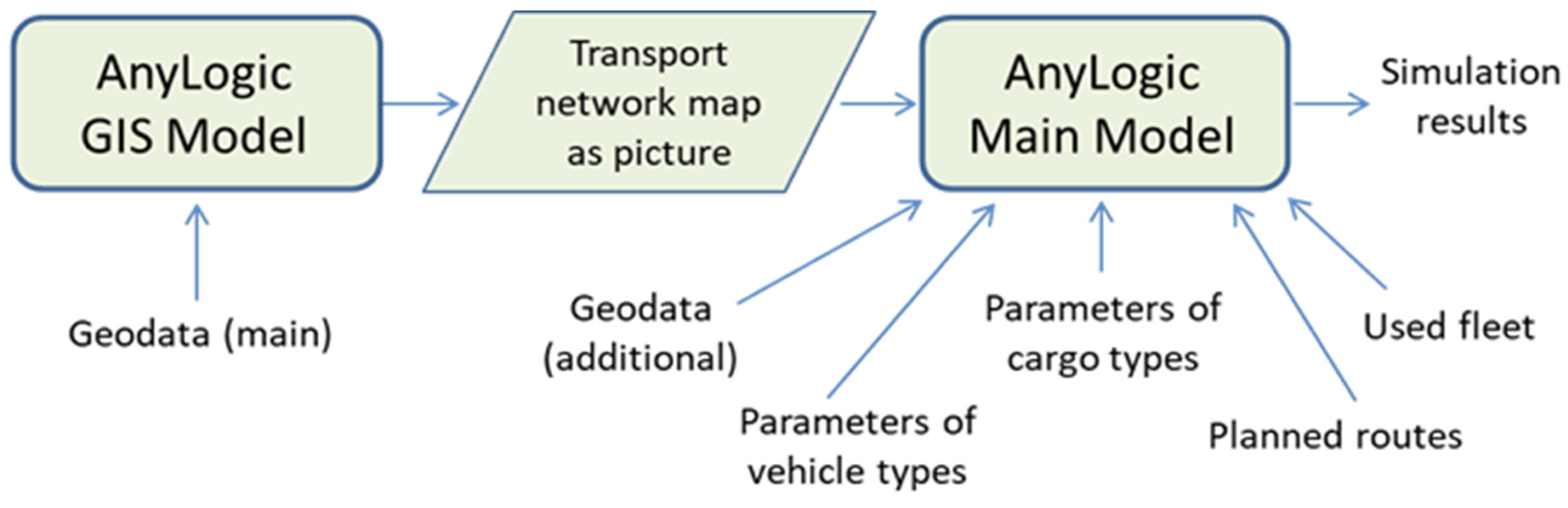

The TraPodSim modeling system was developed by the authors [

5] to solve the practical problems of analyzing options for using electric or diesel trucks for any geographic region, any type of transportation demand, and any fleet of electric or diesel vehicles. The TraPodSim system includes programs executed in the AnyLogic environment for simulating cargo transportation processes and Excel for preparing initial data and analyzing simulation results. The system can form the basis for long-term and sustainable solutions that businesses and society need in this transition to a zero-emission world.

The main novelty of this work lies in the chosen level of process detail, which is displayed using the TraPodSim system. This level can be described as medium (mesoscopic) and clearly differs from the microscopic level, which is characteristic of nearly all examples reviewed in the literature. The comparatively simple methods for describing the simulated scenarios and the omission of most of the random factors influencing the modeled processes result in the ability to obtain a standard set of physical indicators as simulation outputs. These indicators allow the end user to make informed decisions regarding the potential application of electric trucks in their business. The mesoscopic approach used in the TraPodSim system enables the development of specific models almost entirely based on data presented in tabular form, with minimal programming effort. This reduces both the cost and the development time of the project.

In

Section 2, we review related works on the state-of-the-art analysis of using electric trucks for cargo transportation.

Section 3 outlines the concept of the TraPodSim modeling system and its application.

Section 4 describes in detail the characteristics of the TraPodSim modeling system.

Section 5 and

Section 6 present case studies.

Section 7 elaborates on the prospects for building a framework for sustainable modeling of the use of the eTruck fleet. The last section summarizes the conclusions of the research.

2. State-of-the-Art

The review by Wang et al. [

6] notes that the existing literature on the challenges of applying electric commercial vehicles in urban freight transportation reflects four main areas of research: feasibility, adaptations of the logistics concept, adaptations of the vehicle concept, and support from stakeholders. The authors also formulate 15 specific problems that fall within these research areas. It is interesting to note that computer simulation is mentioned exclusively as a method for solving ten of the fifteen problems.

The distinction between “transportation system simulation” and “transportation process simulation” should be clearly understood. In the first case, a large number of “anonymous” vehicles are generated in the model, while in the latter case, the freight demand is specified, and a specific fleet is defined in the simulation to meet all or part of this demand.

The authors of this paper report their first experience in modeling the operation of a specific transportation company using the system dynamics method [

7]. The following examples of simulation modeling applications will be considered to primarily analyze the use of a fleet of electric trucks (eTrucks) in urban freight transport.

In [

8], three scenarios for the shipment of goods from an urban distribution center (UDC) are considered. In the baseline scenario, no electric vehicle is used, and goods are shipped using a conventional 16 m

3 diesel truck. In the second scenario, an electric van with a 4.5 m

3 loading capacity and a range limited to 100 km is used instead of a diesel truck. In the third scenario, an electric truck with the same loading capacity as the diesel truck is used. The simulation model was realized using ARENA software (version 4). As a result of the simulation, it was found that using an electric van increases the number of trips per day, but the entire task can be completed with only one charge at the depot.

Work on modeling a specific fleet of eTrucks using MATSim software (

https://matsim.org/) has been carried out for several years at the Technical University of Berlin. MATSim is an activity-based, extendable, multi-agent simulation framework implemented in Java. It is open-source and can be downloaded from the Internet [

9]. An example of MATSim application is discussed in [

10], where, along with MATSim, the authors apply the

jsprit system to solve the vehicle routing problem (VRP). The object of the study is a system for transporting goods to shops in the food retail industry in the city of Berlin. The demand of 15 retail companies in Berlin, with 17 distribution centers located in and around Berlin, is modeled. These companies serve 1057 food retail shops with 1928 demand requests. The shops’ demand is the demand of an average day. In the modeling process, either current internal combustion engine vehicles (ICEVs) or eTrucks could be used. For each fleet, four types of vehicles were specified, with payloads ranging from 7.5 to 40 tons. The number of vehicles of the different available types was not limited for each carrier. As a result of solving the VRP, 283 ICEVs or 279 eTrucks were used in the model during one workday, of which about 75% are vehicles with a payload of 26 tons. With eTrucks, the simulation shows that 56% of all tours can be completed without recharging during the day, and 90% of tours with one recharge during the day.

In [

11], the results of the study [

10] are taken into account, and based on them, a methodology for the placement of charging infrastructure for eTrucks in a given territory is proposed. One of the specific conclusions of the work is as follows: if 279 eTrucks belonging to 16 different depots share their charging stations, having 71 fast-charging stations with a capacity of 400 kW is sufficient to fulfill 90% of the tours. If 29 additional fast-charging stations are created in the city, then 100% of the tours can be operated by eTrucks. In [

12], an example of estimating the required size of the charging infrastructure for eTrucks used for long-distance transportation is shown. The MATSim package is again used as a modeling tool.

In [

13], the authors apply MATSim and jsprit tools to analyze the feasibility of implementing green vehicles in urban logistics, especially at the last-mile stage of the supply chain in Berlin, Germany. The authors compare simulation results obtained for key transportation, economic, and environmental indicators in three scenarios: (1) diesel vehicles, (2) 100% electric vehicles, and (3) 100% hydrogen vehicles. This study shows that electric and hydrogen vehicles can reduce emissions when delivering goods but cannot reduce traffic volume and transportation costs.

In [

14], the shuttle trips of three different types of vehicles at the Aitik copper mine in northern Sweden are modeled in detail. The purpose of the simulation modeling is to evaluate the feasibility and economics of operating large haul trucks battery-electrically, charging from an electric road system in the form of overhead trolley lines. As a result of the simulation, it is shown that battery-electric is much cheaper than diesel-electric. It is also much cheaper than the diesel-electric mode using an electric road. The simulation model was created and processed using the MATLAB package (version R2020b).

In [

15], a simulation model in Vissim is presented, which allows for the microscopic-level evaluation of energy consumption using electric vehicles. This vehicle movement model serves as a data source for an energy model, which is trained using methods such as linear regression, random forest, gradient boosting, and a neural network. The neural network method is identified as the most effective among them. In the Vissim model, only one roundabout is simulated, and the movement data of each electric vehicle is recorded at a frequency of 1 Hz as they pass through it.

In [

16], a model of the garbage collection process using eTrucks in the city of Hanau (Germany) is described. The model was created by the German company SimPlan using the AnyLogic package. An important feature of the model is that it shows not only numerical simulation results but also animations. The user can see garbage trucks moving through the city streets, the battery level, the charging station (depot), and containers for specific types of garbage. The user can set garbage collection schedules and observe changes in truck movements. In [

17], it is shown how the concept of agent-based modeling and simulation (ABMS) is implemented using the AnyLogic package. The problem of introducing electric trailers into long-distance transportation logistics in the UK is considered. The simulation is performed for a client (called the target operator in the paper) that is the largest motor carrier in the country. A total of 1166 agents are used to model the eTruck fleet. Some of the model inputs are based on real statistics obtained from the customer, but most of the parameters are represented in the model as random variables with theoretical distributions such as the Poisson distribution and the normal distribution. The main objective of the modeling was to estimate the amount of electricity consumed by the eTruck fleet.

From the perspective of a transportation company, a review of the literature reveals the following key features of simulation studies on eTruck fleet operations. Only the MATSim package is specifically designed to address the task of evaluating the efficiency of eTruck fleet usage, but it is a highly specialized and complex software product, with all its usage examples published by experts working in academic institutions. In the other cases presented, the models are the result of detailed simulation studies conducted using one of the general-purpose modeling tools. Hiring specialists proficient in MATSim or commissioning the development of a custom simulation project appears to be an overly expensive approach for assessing the potential of eTruck fleet use at a specific transport company. The system described in this work, TraPodSim, offers a compromise between the complexity and accuracy of the models it creates, making it suitable for use by almost any small or medium-sized enterprise.

4. Case 1: Shuttle Transport Model

This model shows the movement of vehicles along only one circular route connecting two geographical locations. In [

19], a logistic service park (LSP) project is described in the eastern part of Heinenkamp near the city of Wolfsburg in Germany (see

Figure 4).

In

Figure 4, the geographical location is labeled as LSP. It is envisioned that cargo from the LSP site will be transported to the Halle 55 building, which is located within the Volkswagen plant in Wolfsburg. In

Figure 4, this geographical location is labeled as VW Halle 55. In the opposite direction, the same vehicles will transport empty containers. The main part of the route takes motorway A39. The average distance between the route destinations is 14.1 km. The distance from the LSP to VW Halle 55 (12.8 km) differs from the distance from VW Halle 55 to the LSP (15.4 km), as the latter involves a U-turn at the factory site as well as two complicated turns at the entrance and exit of motorway A39.

4.1. Preparation of Input Data

The volume of trips specified in the model corresponds to the volume defined in [

19] and is equal to about 135 truck units. The developed simulation model estimates the transportation process performance for this number of trips per day. To verify the simulation model, an analytical spreadsheet model was also developed, which can be used to calculate the variant with any volume of trips. One of the goals of the simulation was to compare the amount of CO

2 emission that would be generated in cases using a fleet of eTrucks or diesel. The eEconic from Mercedes-Benz was chosen as the eTruck to be modeled. Although this eTruck was planned as a dedicated truck for garbage collection, it may have other applications in the future. The Actros 2543, also from Mercedes-Benz, was chosen as the diesel counterpart. The main parameter, which is approximately the same for both trucks, is the loading capacity (tons). For the eEconic, it is 17.8 tons and for the Actros, it is 16.5 tons. Other technical parameters of these trucks are determined with the help of information from Mercedes-Benz [

20,

21]. For the eEconic, the important parameters are battery capacity (336 kWh), average energy consumption (1.2 kWh/km), and charging speed (162.3 kWh/h). A diesel Actros with a tank capacity of 380 L can drive at least 1200 km and run all day without refueling.

The model assumes that eTrucks are additionally charged after each trip on the LSP site. According to the calculations, they will spend 33.8 kWh per trip. It takes 12.6 min to replenish this amount of energy. If the charging time on the LSP side is, for example, 10 min, the eTruck will stay there for an additional 2.6 min. In principle, charging can be organized at both points of the route, and then no additional delay is needed. The travel time in each direction is modeled as a random variable based on real statistical data that refer to different times of the day.

4.2. Simulation Results

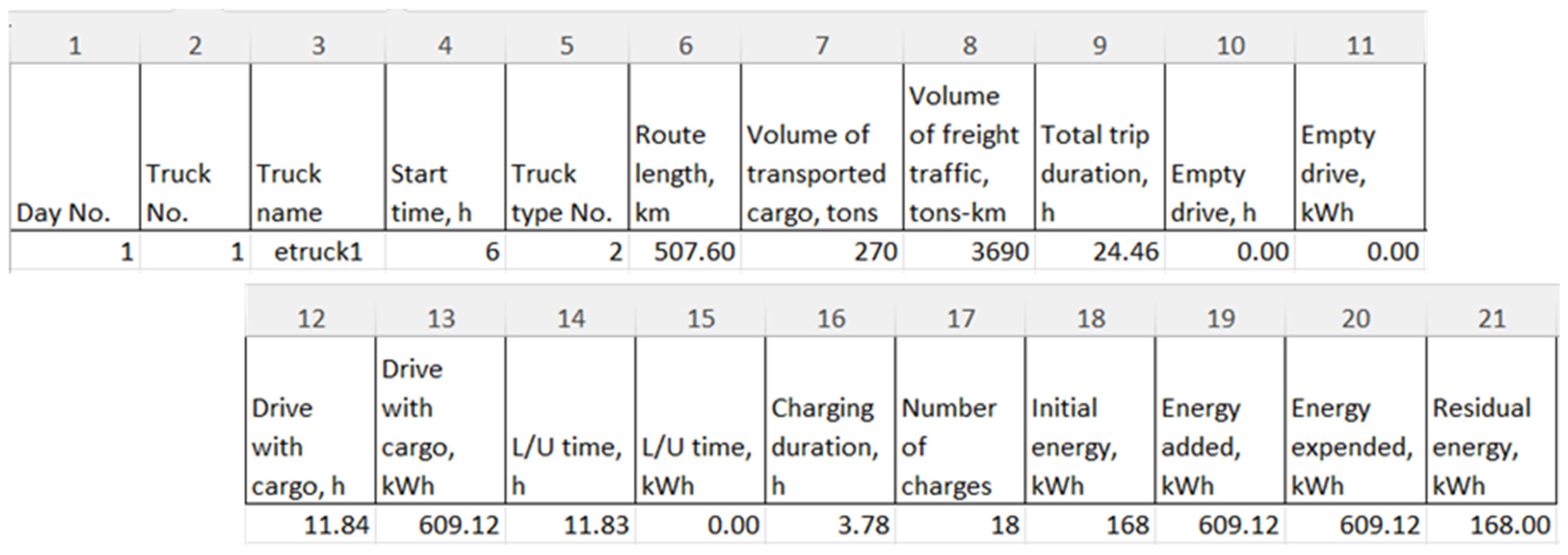

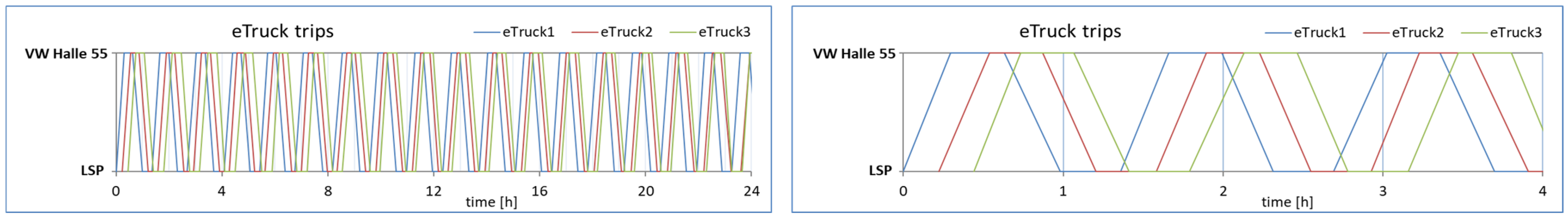

Figure 5 shows movement diagrams for three eTrucks. The model generates such diagrams for any number of trucks occupied during the day, but only three eTrucks are left for their graphical representation. The diagram shows the first 4 h of eTrucks operation so that the differences in travel times can be seen. Although the slope angles of the travel lines are different, due to the very small deviation of the travel times from the mean, this difference is barely noticeable.

The model produces similar movement diagrams for the diesel fleet. In these diagrams, it can be seen that the diesel fleet makes more trips during the day. Diesel trucks spend less time at loading/unloading points, as they do not linger to charge their batteries. The numerical results of the simulation are shown in

Table 1 and

Table 2 in the form of standard outputs from TraPodSim.

The data in the tables indicate that in both cases, 8 trucks can perform 135 trips per day. The number of eTrucks is equal to the limit value because they have completed 136 trips. For the diesel fleet, the number 8 gives a margin in performance, since 8 diesel trucks can perform 144 trips per day. No dispatcher was used in the model, which could have further delayed the trucks to make exactly 135 trips per day. If you want to get, for example, “fuel expended” data for 135 trips, you can use the following formula:

At an emission rate of 0.347 kg/kWh, the eTruck fleet will produce 1678 kg CO2, and at a rate of 2.63 kg/L, the diesel fleet will produce 2661 kg CO2.

5. Case 2: Comparison of Electric and Diesel Truck Utilization on a Real Road Network

The purpose of the simulation is to compare the use of electric and diesel trucks of medium capacity (from 7.5 to 28 tons) for the transportation of goods between cities, with distances ranging from 30 to 50 km. All experiments use the same routes between the main geographical points of the transport network, as well as the same volumes and characteristics of the goods being transported. This approach facilitates the comparison of both primary and secondary indicators obtained from modeling different scenarios.

5.1. Model of the Transportation Process

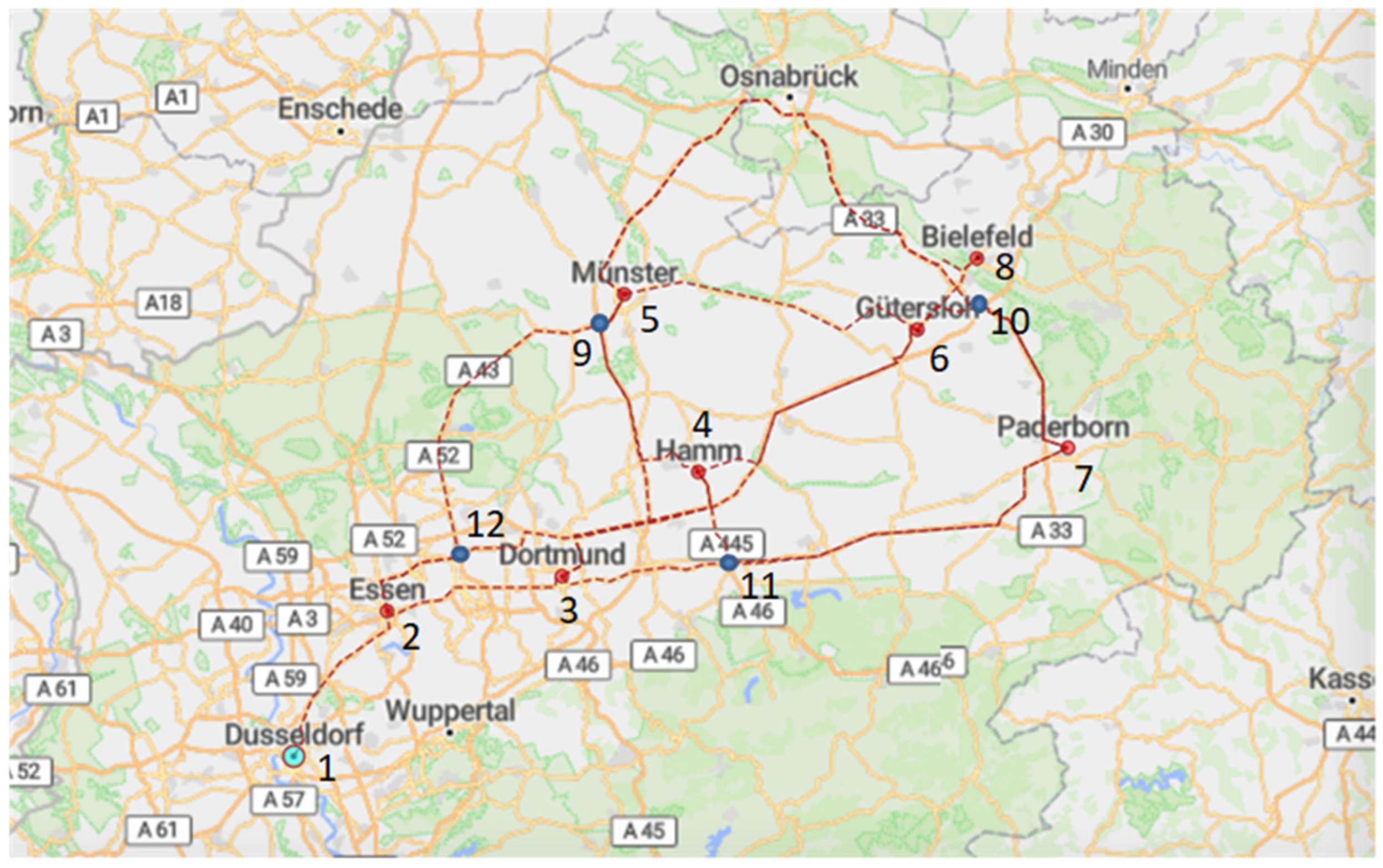

The region in North Rhine-Westphalia (Germany), which consists of eight cities marked on the map by numbers 1 to 8 (

Figure 6), was chosen for the modeling. In Düsseldorf, there is a depot where all trips made during one working day start and end. It is assumed that a load can be transported between any city excluding Düsseldorf. This means that there are L/U points in cities numbered 2 through 8. Cities 1 to 8 are the main points of the transportation network. Numbers 9 to 12 refer to additional points, which may contain high-capacity charging stations or refueling stations for diesel vehicles.

The model uses not only the usual square matrix of distances between main points (1–8) but also a special table with distances between main and additional points (

Table 3). There is a rationale behind this solution. The square distance matrix is created in the AnyLogic GIS Model and remains unchanged while working with the model. The table with distances between the main and additional points of the network is created in the AnyLogic Main Model and can be modified when additional points are created or eliminated during the model experiments.

In

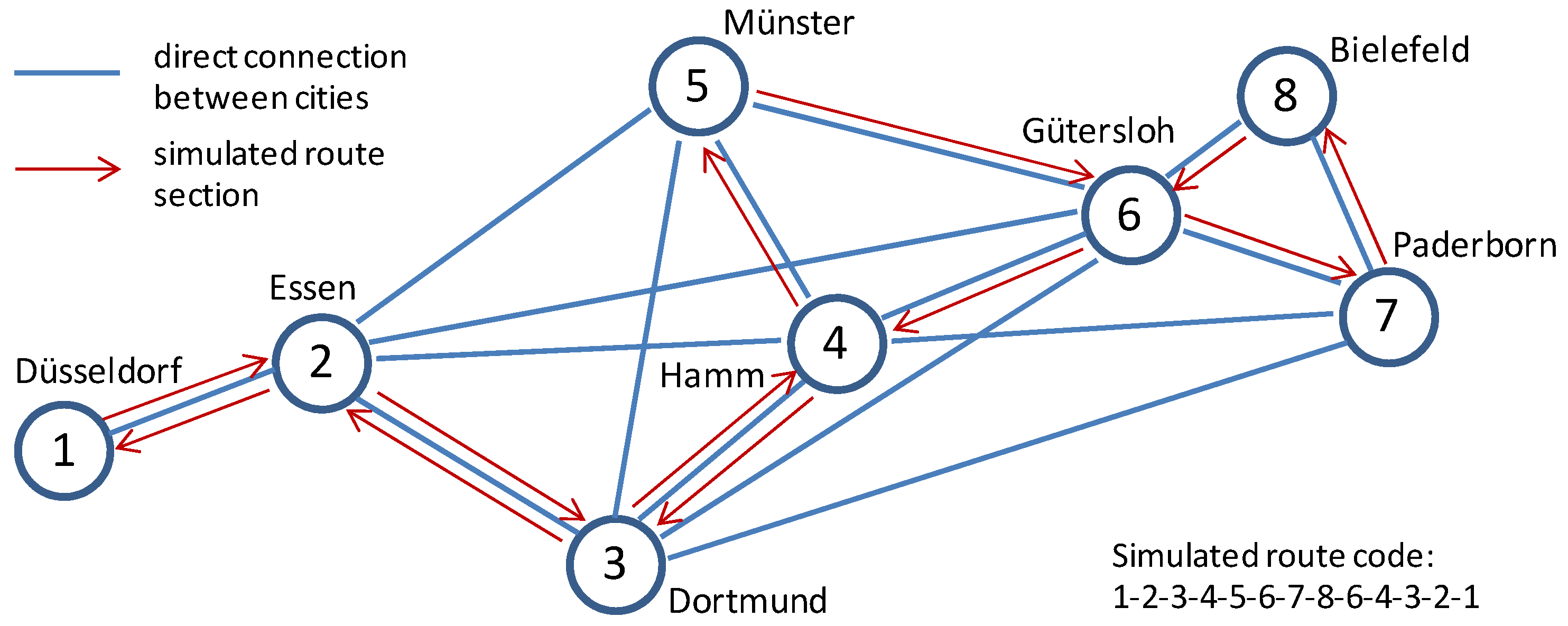

Figure 7, the structure of the transportation network is shown as a graph, where thick lines correspond to direct connections between cities. This means that, for example, it is possible to travel from Dortmund to Münster without visiting Hamm. The arrows indicate the daily route taken by each vehicle leaving Düsseldorf. The code for the main route, which is implemented in all experiments with the model, is 1-2-3-4-5-6-7-8-6-4-3-2-1. Deviations from the route may occur when the vehicle has to stop at one of the additional points 9–12 for battery charging or refueling. The length of the main route is 491.6 km.

Loading/unloading operations are performed at every point except Düsseldorf. At point 2 (Essen), only the loading operation is performed at the beginning of the trip and the unloading operation at the end of the trip. At all other points, both operations are performed. Depending on the payload capacity, each vehicle carries either 8 or 16 tons of cargo on each leg of the route. In the model experiments described below, the average speed of all vehicles was 72 km/h.

5.2. Vehicle and Cargo Parameters

The eActros and eEconic from Mercedes-Benz were chosen as the modeled eTrucks (

Table 4). Although the eEconic has been planned as a dedicated truck for garbage collection, it may have other applications in the future. For both eTrucks, the diesel trucks Actros 1835 and Actros 2543, also from Mercedes-Benz, were chosen as analogues (

Table 5). The main parameter, which is approximately the same for both pairs, is the loading capacity (tons). The number of axles is also the same: two axles (4 × 2) for the eActros and Actros 1835, and three axles (6 × 2) for the eEconic and Actros 2543.

The first three parameters for both groups of trucks can be found in the Mercedes-Benz reference materials [

18,

20,

21,

22]. The value of energy or fuel consumption (empty), i.e., consumption when driving without a load, was determined by a rough calculation using reference data that usually refers to driving with an average load.

The value of the charging speed parameter for eTrucks refers to the linear part of the battery charging graph (from 20 to 80% of capacity), and it was obtained based on the manufacturer’s data: battery capacity 336 kWh and charging time (20–80%) 1 h 15 min. The formula for calculating charging speed is as follows:

In the experiments with the model, when charging the battery at L/U points, the charge level was brought to 50%, and when charging at an external station it was brought to 80%. The refueling time parameter for diesel trucks has a symbolic value because, with a tank capacity of 380 L, trucks can travel at least 1200 km. This means that with a route length of 491.6 km, there is no need for additional refueling.

Any number of cargo types can be described in the model, but in the experiments presented below, only one type of cargo was transported with a fixed weight of one cargo unit equal to 500 kg. In all experiments, a daily transportation plan was set, according to which 32 cargo units, i.e., 16 tons of cargo, had to be removed from each L/U point. This cargo had to be left at the L/U point, which was the next one on the route. It was assumed that trucks with a smaller payload would take on board exactly 16 cargo units, i.e., 8 tons of cargo, and trucks with a larger payload would take on board all 32 cargo units, i.e., 16 tons of cargo. It follows that the daily transportation plan can be fulfilled with two trucks with a smaller payload or one truck with a larger payload.

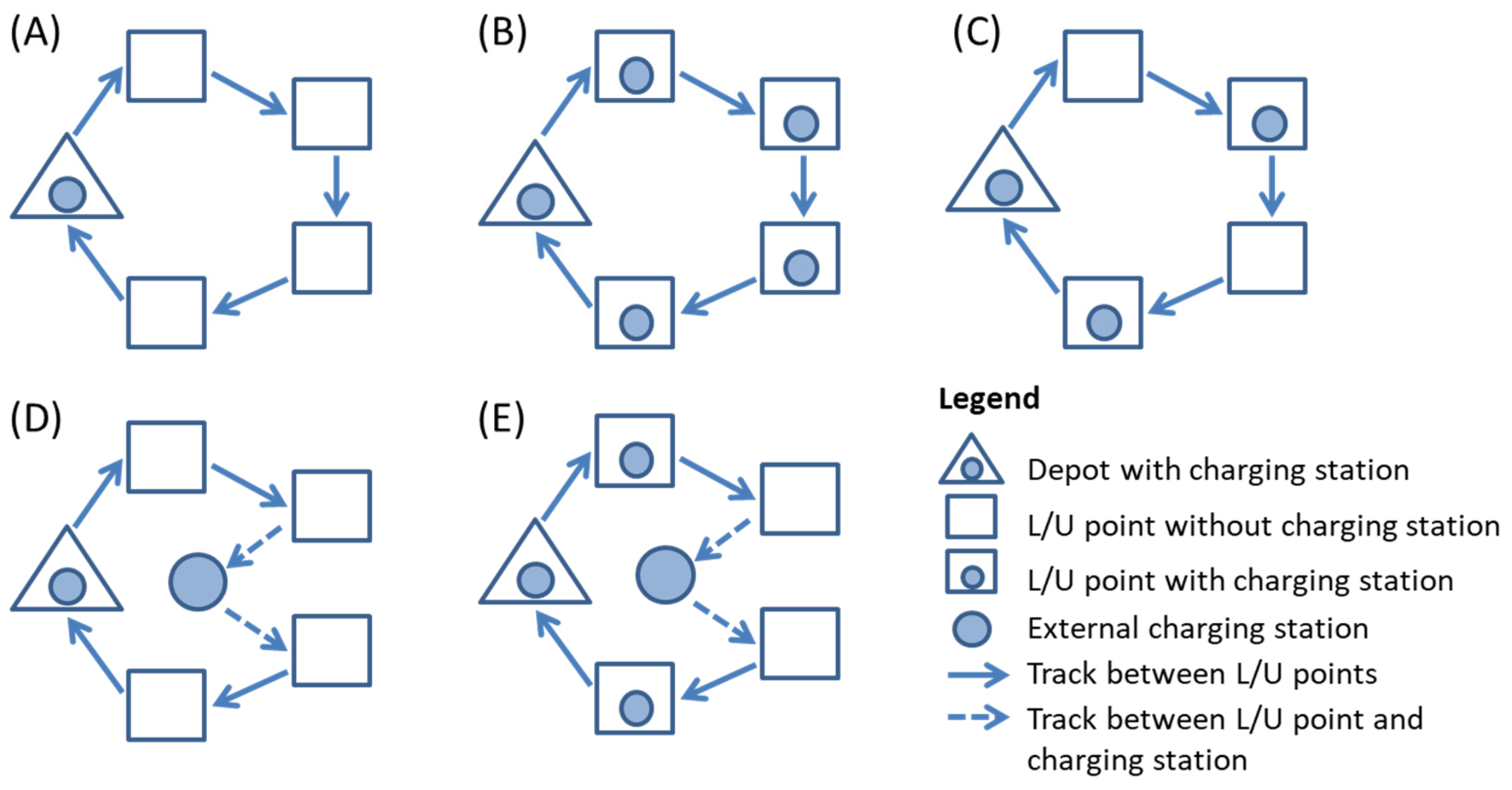

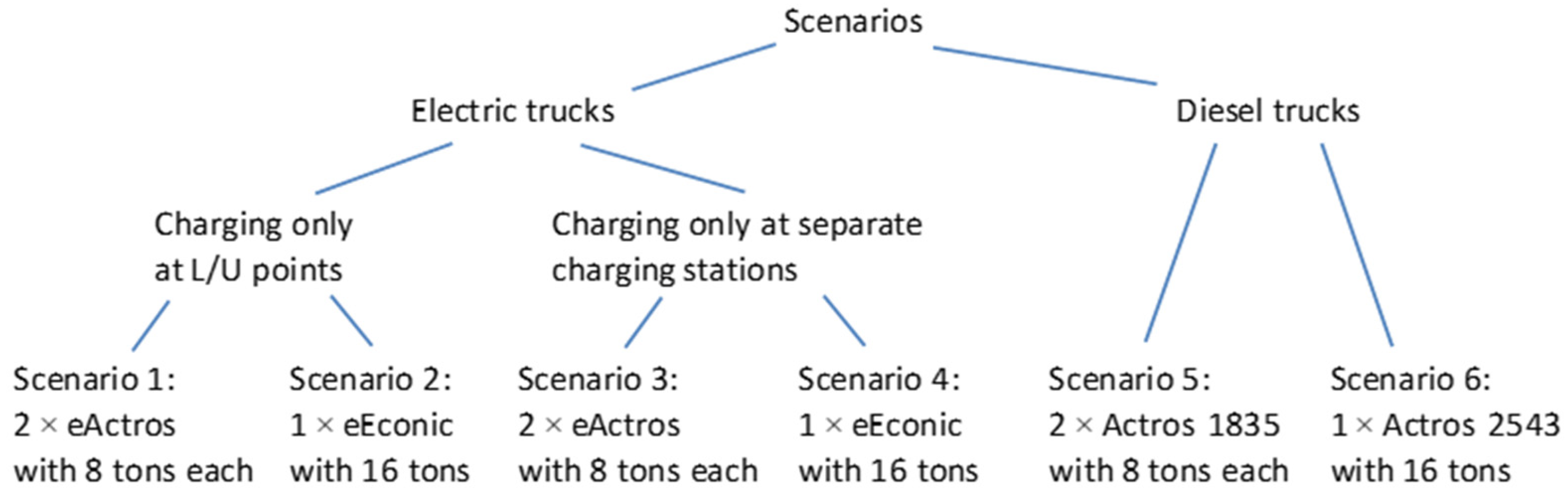

5.3. Description of the Modeled Scenarios

Figure 8 shows the scheme of formation of six cargo transportation scenarios, the simulation results of which can be compared with each other. In the eTrucks transportation simulation, two variants of charging station locations were used, which are labeled Case b and Case d in

Figure 1. These variants correspond to the two charging implementation methods shown in

Figure 8.

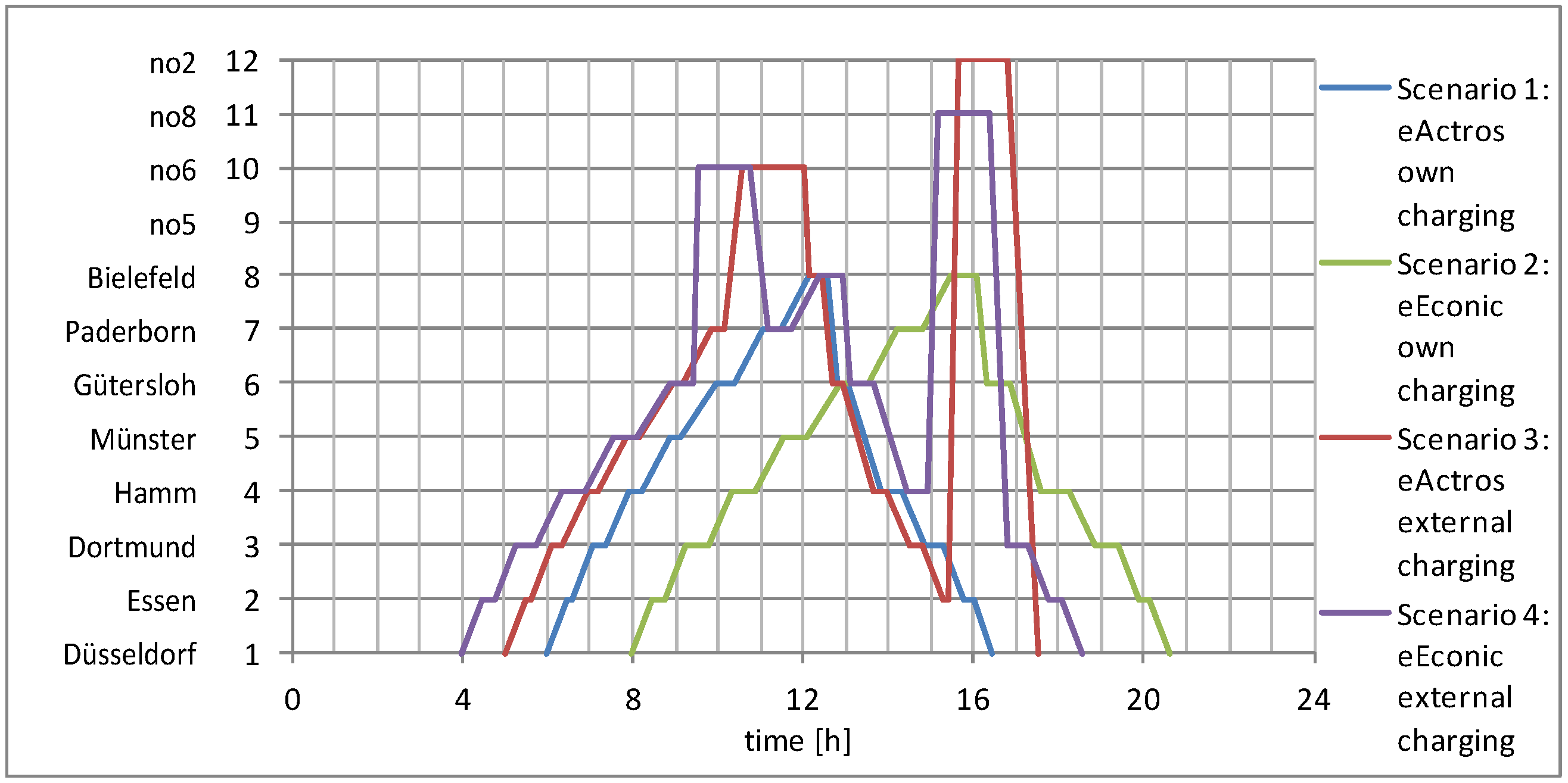

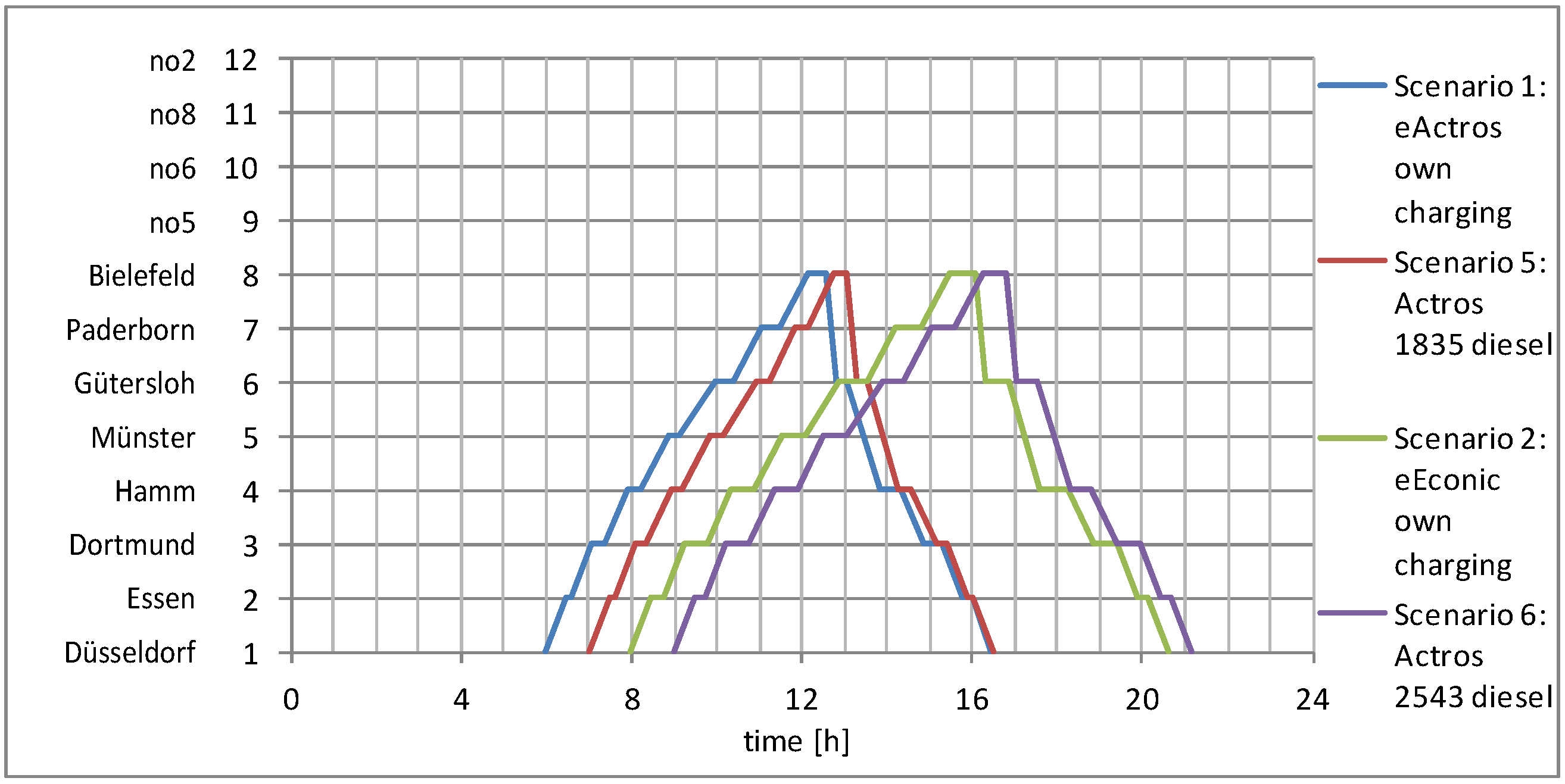

5.4. Scenario Modeling Results

Figure 9 shows the motion diagrams of eTrucks corresponding to scenarios 1–4. Although two eActros trucks are used in scenarios 1 and 3, they both travel along the same routes, so this trip is shown once in the diagram. The start time of each trip is chosen so that the route is visible on the diagram. The routes for scenarios 1 and 2 can also be seen in

Figure 10. In

Figure 9, scenarios 3 and 4 assume the use of external charging stations, which are labeled with numbers 9–12 on the route map (

Figure 6). In modeling scenario 3, each eActros used charging stations numbered 10 and 12. When modeling scenario 4, one eEconic used the charging stations with numbers 10 and 11. In

Figure 9 and

Figure 10, it is possible to visually estimate the execution time of each route operation and its duration as a whole, but the exact time values can be seen in the tables presented below with the numerical results of the simulation.

Figure 10 shows traffic diagrams for both eTrucks and diesel trucks. Scenarios 1 and 2 are selected for the eTrucks without external charging stations so that the routes of all trips are the same. The diagrams clearly show that the Actros 1835 diesel truck is almost 1 h faster than the competitor, while the Actros 2543 diesel truck is only 0.5 h faster. This is because the large load increases the loading/unloading time, during which the eTruck almost recharges the battery to 50% of its capacity and, therefore, needs only a little extra time to complete this recharging.

The numerical results of the simulation are shown in

Table 6 in the form of standard output from the TraPodSim modeling system. For scenarios 1, 3, and 5, the numbers shown are the sum of the results of trips made by the same trucks. The volume of freight traffic will always be 6768.89 tons × km if the truck does not make a trip with freight to the charging station. In scenario 3, both eActros trucks did make such trips, but they used alternative roads to reach the charging stations, resulting in a total “Drive with Cargo” trip a couple of kilometers shorter. The same effect is observed in scenario 4, where the eEconic made two trips to charging stations with cargo on board, so the volume of freight traffic decreased slightly.

If “Total Trip Duration” and “Energy” or “Fuel Expended” are considered the main physical indicators of the transportation process, the best scenarios are 2 and 4 for eTrucks and scenario 6 for diesel trucks. When comparing scenario 1 (charging only at L/U points) with scenario 3 (charging only at separate charging stations), it can be seen that the values for “Energy” or “Fuel Expended” are almost the same, but the value for “Total Trip Duration” increases by 4 h with scenario 3. The general conclusion is also obvious: one truck with a larger payload in all scenarios studied shows better results than two trucks with half the payload.

There are many regulations and calculators on the Internet for the calculation of CO

2 emissions. For example, the calculator [

23] offers the following data:

The price per kWh at a high-capacity charging station in Germany was 79 Ct/kWh at the beginning of December 2022, and the price per liter of diesel fuel was 1.85 EUR/L. Based on these data,

Table 7 is compiled, which shows that the lowest CO

2 emissions are expected in scenarios 2 and 4 (charging only at L/U points, 1 × eEconic), and the least costly is scenario 6 (1 × Actros 2543).

The data in the tables indicate that in both cases, 8 trucks can perform 135 trips per day. The number of eTrucks is equal to the limit value because they have completed 136 trips. For diesel trucks, the number 8 gives a margin in performance, since 8 diesel trucks can perform 144 trips per day. No dispatcher was used in the model, which could have further delayed the trucks to make exactly 135 trips per day. If you want to get, for example, “fuel expended” data for 135 trips, you can use the following formula:

At an emission rate of 0.347 kg/kWh, the eTruck fleet will produce 1678 kg CO2, and at a rate of 2.63 kg/L, the diesel fleet will produce 2661 kg CO2.

6. Perspectives on Building a Framework for Sustainable Modeling of eTruck Fleet Utilization

The traditional view of a simulation project is that it is a one-off activity within which individual steps may be repeated but which has a clearly defined beginning and end [

24]. Even with this view of a simulation project, it is assumed that there are two parties involved in its execution: the simulation experts and the customer-side experts, which are referred to as subject-matter experts in [

25]. The notion of real-time simulation [

26] refers to purely technical systems where the relationship between customer and performer is not considered. About 10 years ago, the concept of Modeling and Simulation as a Service (MSaaS) was defined and formally adopted within NATO [

27]. In the civilian domain, this concept is defined as the provision of modeling and simulation services by a cloud service provider, with the underlying infrastructure, platform, and software details hidden from the user [

26]. The focus here is on the development of large-scale projects by multiple participating organizations, whose efforts are combined based on cloud technologies [

28].

For the problem of modeling the utilization of an electric or diesel truck fleet considered in this paper, it is not possible to obtain a long-term and sustainable solution by performing a conventional simulation project where the project’s end is clearly defined. It is important to consider that numerous fleet conditions will change over time. A carrier may experience changes in its mix of regular customers or even in the geography of the region where it predominantly operates. Over time, new types of eTrucks will emerge, and there will be changes in the prices of trucks, electricity, and diesel fuel. New types of fuel will likely emerge. There may be times when a carrier will want to increase or decrease the size of its fleet. Such dynamics in fleet conditions may cause the modeling results to lose their value within a year or even a few months. If the customer accepts the initial modeling results with confidence, it is natural for them to want to repeat such experiments after some time, when significant changes in fleet operating conditions have occurred.

In fact, we are talking about a long-term form of work with the customer, which falls under the definition of MSaaS, although it does not necessarily involve the use of cloud computing. The model developer must store all generations of the respective customer’s model and make changes to the model database when new data are received from the customer. As noted above concerning TraPodSim, the model experiments agreed upon with the customer must be performed by the model developer.

For a dynamic database reflecting the real working conditions of the truck fleet, it is possible to apply the concept of digital twins. It should be noted that the simulation model itself cannot be referred to by this term, as it contains data not only from the real world but also entered by the user and generated by the model itself. The possible relationship between the notions of digital twin and simulation has been very intensively discussed over the last few years, and the outcome of these discussions can be seen in the reviews of [

29,

30].

To summarize, a sustainable solution to the problem of modeling fleet operations can be achieved through regular, long-term cooperation between the model developer and the customer. The model’s database should be regularly updated using digital twin technologies.

7. Conclusions

The peculiarity of the described modeling examples is the use of real data as model input parameters, which include the following:

An important decision is whether to use other model input parameters as deterministic or random variables. When using deterministic data for daily transportation conditions (route, cargo volume, and average speed), it is relatively easy to identify significant differences between the main indicators of the processes defined by the corresponding scenarios. Even in such experiments, elements of randomness automatically appear in scenarios where the eTruck must choose an external charging station, as the time and location of this event are not known in advance. With the stochastic approach, some input parameters will be described by random variables. The adequacy of the modeling results will increase, but they will also become random variables, complicating their interpretation for users who lack experience with confidence intervals and histograms. This fact further confirms the necessity of constant participation of the model developers in the simulation project.

The main result of this work is the confirmation of the TraPodSim modeling system’s capability to solve practical problems in analyzing electric or diesel truck application options. These problems can be addressed for any geographical region, type of transportation demand, or fleet of electric or diesel trucks. The user can compare charging station locations at L/U points and other geographical locations. CO2 emissions and economic indicators can be annualized if the model user has sufficient information about the business process in which the transportation occurs.

The TraPodSim system is a versatile but highly sophisticated non-commercial product [

5]. This means that any new simulation task can be only realized as quickly and accurately as possible by the developers of the TraPodSim system, who are prepared to provide this service to interested users. Thus, a sustainable solution to the task of simulating fleet operations requires long-term cooperation between the model developer and the customer.