Conceptualization of Supplier Involvement in Product Development Based on a Systematic Review of 47 Definitions

Abstract

1. Introduction

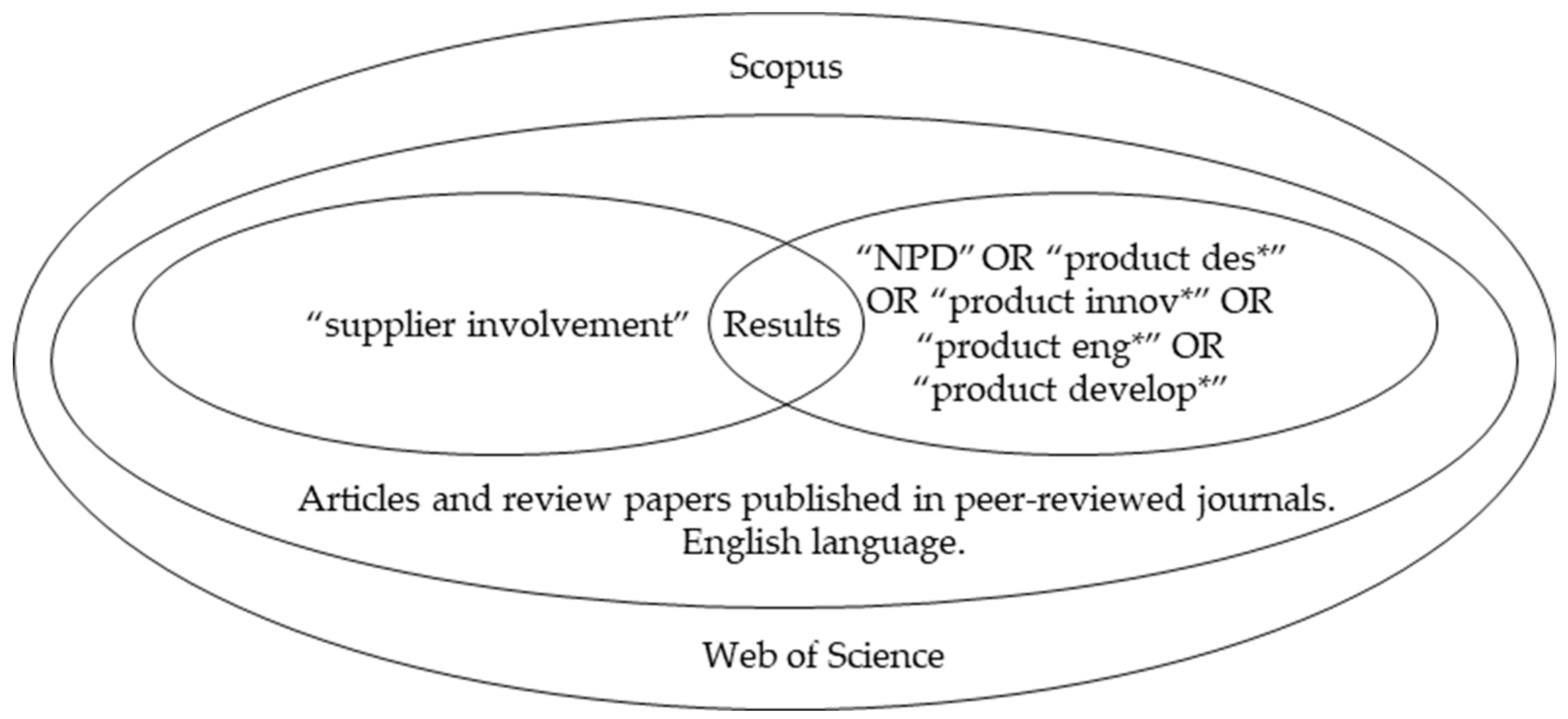

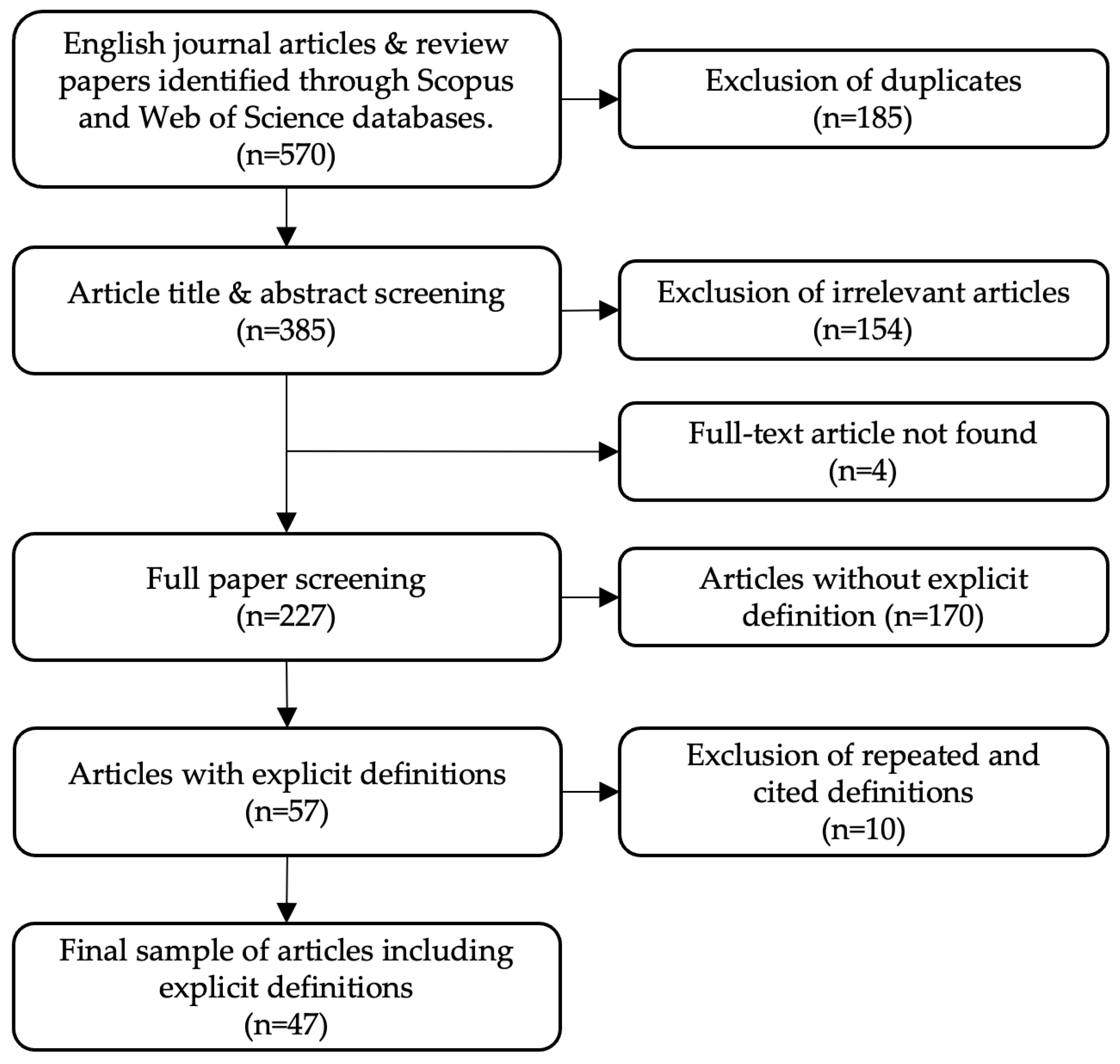

2. Method

2.1. Phase 1: The Systematic Literature Review

2.2. Phase 2: Content Analysis

3. Results of the Literature Review

4. Elements and Dimensions Addressed in the Reviewed Definitions

5. A Conceptual Model of Supplier Involvement in Product Development

6. Future Research Directions

7. Conclusions

7.1. Theoretical Implications

7.2. Managerial Implications

7.3. Limitations

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Journal List

| Journal | Count | References |

|---|---|---|

| Industrial Marketing Management | 4 | [4,36,41,43] |

| Journal of Business Research | 3 | [24,25,56] |

| Journal of Product Innovation Management | 3 | [2,39,40] |

| Journal of Purchasing and Supply Management | 3 | [1,5,33] |

| International Journal of Information Systems and Change Management | 2 | [27,29] |

| International Journal of Innovation Management | 2 | [35,45] |

| International Journal of Production Research | 2 | [23,38] |

| Journal of Supply Chain Management | 2 | [10,26] |

| Supply Chain Management: An International Journal | 2 | [47,54] |

| Central European Management Journal | 1 | [60] |

| European Journal of Innovation Management | 1 | [58] |

| Industrial Management & Data Systems | 1 | [37] |

| Information Technology Journal | 1 | [13] |

| International Journal for Quality Research | 1 | [52] |

| International Journal of Innovation and Technology Management | 1 | [48] |

| International Journal of Internet Manufacturing and Services | 1 | [44] |

| International Journal of Management and Enterprise Development | 1 | [42] |

| International Journal of Manufacturing Technology and Management | 1 | [34] |

| International Journal of Market Research | 1 | [49] |

| International Journal of Operations and Production Management | 1 | [28] |

| International Journal of Production Economics | 1 | [51] |

| International Journal of Technology Management | 1 | [22] |

| International Journal of Value Chain Management | 1 | [50] |

| Journal of Business and Industrial Marketing | 1 | [55] |

| Journal of Intelligent Manufacturing | 1 | [46] |

| Journal of Management | 1 | [14] |

| Journal of Manufacturing Technology Management | 1 | [30] |

| Operations and Supply Chain Management | 1 | [12] |

| Operations Management Research | 1 | [57] |

| Production Planning and Control | 1 | [53] |

| Service Industries Journal | 1 | [31] |

| Total Quality Management & Business Excellence | 1 | [59] |

| World Academy of Science, Engineering and Technology | 1 | [32] |

References

- Johnsen, T.E. Supplier involvement in new product development and innovation: Taking stock and looking to the future. J. Purch. Supply Manag. 2009, 15, 187–197. [Google Scholar] [CrossRef]

- Van Echtelt, F.E.A.; Wynstra, F.; Van Weele, A.J.; Duysters, G. Managing supplier involvement in new product development: A multiple-case study. J. Prod. Innov. Manag. 2008, 25, 180–201. [Google Scholar] [CrossRef]

- Lakemond, N.; Berggren, C.; Van Weele, A. Coordinating supplier involvement in product development projects: A differentiated coordination typology. R D Manag. 2006, 36, 55–66. [Google Scholar] [CrossRef]

- Wagner, S.M.; Hoegl, M. Involving suppliers in product development: Insights from R&D directors and project managers. Ind. Mark. Manag. 2006, 35, 936–943. [Google Scholar] [CrossRef]

- Mikkelsen, O.S.; Johnsen, T.E. Purchasing involvement in technologically uncertain new product development projects: Challenges and implications. J. Purch. Supply Manag. 2019, 25, 100496. [Google Scholar] [CrossRef]

- Melander, L.; Rosell, D.; Lakemond, N. In pursuit of control: Involving suppliers of critical technologies in new product development. Supply Chain Manag. 2014, 19, 722–732. [Google Scholar] [CrossRef]

- Rosell, T.D.; Lakemond, N.; Nazli Wasti, S. Integrating knowledge with suppliers at the R&D-manufacturing interface. J. Manuf. Technol. Manag. 2014, 25, 240–257. [Google Scholar] [CrossRef]

- Smals, R.G.M.; Kok, R.A.W.; Smits, A.A.J. Explaining Changes in Supplier Involvement in Complex New Product Development: A Resource Orchestration Perspective. IEEE Trans. Eng. Manag. 2022, 69, 2234–2247. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Suurmond, R.; Wynstra, F.; Dul, J. Unraveling the Dimensions of Supplier Involvement and their Effects on NPD Performance: A Meta-Analysis. J. Supply Chain Manag. 2020, 56, 26–46. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Podsakoff, N.P. Recommendations for Creating Better Concept Definitions in the Organizational, Behavioral, and Social Sciences. Organ. Res. Methods 2016, 19, 159–203. [Google Scholar] [CrossRef]

- Wieteska, G. The impact of supplier involvement in product development on supply chain risks and supply chain resilience. Oper. Supply Chain Manag. 2020, 13, 359–374. [Google Scholar] [CrossRef]

- Ma, W.C.; Zhang, G.Y.; Ding, B.J.; Zhu, G.L. A case study on the impact of supplier involvement on new product development efficiency from knowledge acquisition perspective. Inf. Technol. J. 2013, 12, 3860–3864. [Google Scholar] [CrossRef][Green Version]

- Hoegl, M.; Wagner, S.M. Buyer-supplier collaboration in product development projects. J. Manag. 2005, 31, 530–548. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Xiao, Y.; Watson, M. Guidance on Conducting a Systematic Literature Review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- Takeuchi, H.; Nonaka, I. The new new product development game. Harv. Bus. Rev. 1986, 64, 137–146. [Google Scholar]

- Clark, K.B. Project scope and project performance—The effect of parts strategy and supplier involvement on product development. Manag. Sci. 1989, 35, 1247–1263. [Google Scholar] [CrossRef]

- Miles, M.B.; Huberman, A.M.; Saldaña, J. Qualitative Data Analysis: A Methods Sourcebook, 4th ed.; Sage Publication Inc.: Thousand Oaks, CA, USA, 2020. [Google Scholar]

- Merriam, S.B. Qualitative Research and Case Study Applications in Education; Jossey-Bass: San Francisco, CA, USA, 1998. [Google Scholar]

- Gioia, D.A.; Corley, K.G.; Hamilton, A.L. Seeking Qualitative Rigor in Inductive Research: Notes on the Gioia Methodology. Organ. Res. Methods 2013, 16, 15–31. [Google Scholar] [CrossRef]

- Bidault, F.; Despres, C.; Butler, C. New product development and early supplier involvement (ESI): The drivers of ESI adoption. Int. J. Technol. Manag. 1998, 15, 49–69. [Google Scholar] [CrossRef]

- Dowlatshahi, S.; Contreras, N. The role of designer-buyer-supplier in the maquiladora industry. Int. J. Prod. Res. 1999, 37, 1963–1986. [Google Scholar] [CrossRef]

- LaBahn, D.W.; Krapfel, R. Early supplier involvement in customer new product development: A contingency model of component supplier intentions. J. Bus. Res. 2000, 47, 173–190. [Google Scholar] [CrossRef]

- Walter, A. Relationship-specific factors influencing supplier involvement in customer new product development. J. Bus. Res. 2003, 56, 721–733. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Smith, M.E. Managing supply risk with early supplier involvement: A case study and research propositions. J. Supply Chain Manag. 2005, 41, 44–57. [Google Scholar] [CrossRef]

- Chou, A.Y. Product development flexibility in a changing business environment. Int. J. Inf. Syst. Chang. Manag. 2006, 1, 177–186. [Google Scholar] [CrossRef]

- Carr, A.S.; Kaynak, H.; Hartley, J.L.; Ross, A. Supplier dependence: Impact on supplier’s participation and performance. Int. J. Oper. Prod. Manag. 2008, 28, 899–916. [Google Scholar] [CrossRef]

- Chou, A. The role of knowledge sharing and trust in new product development outsourcing. Int. J. Inf. Syst. Chang. Manag. 2008, 3, 301–313. [Google Scholar] [CrossRef]

- Jiao, Y.Y.; Jun, J.; Jiao, R.J.; Butler, D.L. Operational implications of early supplier involvement in semiconductor manufacturing firms: A case study. J. Manuf. Technol. Manag. 2008, 19, 913–932. [Google Scholar] [CrossRef]

- Chien, S.H.; Chen, J.J. Supplier involvement and customer involvement effect on new product development success in the financial service industry. Serv. Ind. J. 2010, 30, 185–201. [Google Scholar] [CrossRef]

- Eisto, T.; Hölttä, V.; Mahlamäki, K.; Kollanus, J.; Nieminen, M. Early supplier involvement in new product development: A Casting-Network Collaboration Model. World Acad. Sci. Eng. Technol. 2010, 62, 856–866. [Google Scholar]

- Le Dain, M.A.; Calvi, R.; Cheriti, S. Developing an approach for design-or-buy-design decision-making. J. Purch. Supply Manag. 2010, 16, 77–87. [Google Scholar] [CrossRef]

- Wu, S.J.; Ragatz, G.L. The role of integrative capabilities in involving suppliers in New Product Development: A knowledge integration perspective. Int. J. Manuf. Technol. Manag. 2010, 19, 82–101. [Google Scholar] [CrossRef]

- Klioutch, I.; Leker, J. Supplier involvement in customer new product development: New insights from the supplier’s perspective. Int. J. Innov. Manag. 2011, 15, 231–248. [Google Scholar] [CrossRef]

- Ellis, S.C.; Henke, J.W.; Kull, T.J. The effect of buyer behaviors on preferred customer status and access to supplier technological innovation: An empirical study of supplier perceptions. Ind. Mark. Manag. 2012, 41, 1259–1269. [Google Scholar] [CrossRef]

- Feng, T.; Wang, D. Supply chain involvement for better product development performance. Ind. Manag. Data Syst. 2013, 113, 190–206. [Google Scholar] [CrossRef]

- Tavani, S.N.; Sharifi, H.; Soleimanof, S.; Najmi, M. An empirical study of firm’s absorptive capacity dimensions, supplier involvement and new product development performance. Int. J. Prod. Res. 2013, 51, 3385–3403. [Google Scholar] [CrossRef]

- Jean, R.J.B.; Sinkovics, R.R.; Hiebaum, T.P. The effects of supplier involvement and knowledge protection on product innovation in customer-supplier relationships: A study of global automotive suppliers in China. J. Prod. Innov. Manag. 2014, 31, 98–113. [Google Scholar] [CrossRef]

- Menguc, B.; Auh, S.; Yannopoulos, P. Customer and supplier involvement in design: The moderating role of incremental and radical innovation capability. J. Prod. Innov. Manag. 2014, 31, 313–328. [Google Scholar] [CrossRef]

- Luzzini, D.; Amann, M.; Caniato, F.; Essig, M.; Ronchi, S. The path of innovation: Purchasing and supplier involvement into new product development. Ind. Mark. Manag. 2015, 47, 109–120. [Google Scholar] [CrossRef]

- Niskanen, T.; Hänninen, K.; Kujala, J. Supplier involvement in rapid development. Int. J. Manag. Enterp. Dev. 2015, 14, 273–287. [Google Scholar] [CrossRef]

- Laursen, L.N.; Andersen, P.H. Supplier involvement in NPD: A quasi-experiment at Unilever. Ind. Mark. Manag. 2016, 58, 162–171. [Google Scholar] [CrossRef]

- Liu, B.; Cai, D.; Zhang, Z. Antecedents and performance consequences of external involvement in new product development. Int. J. Internet Manuf. Serv. 2017, 4, 170–194. [Google Scholar] [CrossRef]

- Rauniar, R.; Rawski, G.; Hudson, D. Antecedents and consequences of IPPD effectiveness. Int. J. Innov. Manag. 2017, 21, 1750059. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, L.H.; Gao, J. Supplier collaboration and speed-to-market of new products: The mediating and moderating effects. J. Intell. Manuf. 2017, 28, 805–818. [Google Scholar] [CrossRef]

- Cheng, C.C.J.; Krumwiede, D. Enhancing the performance of supplier involvement in new product development: The enabling roles of social media and firm capabilities. Supply Chain Manag. 2018, 23, 171–187. [Google Scholar] [CrossRef]

- Moon, H.; Johnson, J.L.; Mariadoss, B.J.; Cullen, J.B. Supplier and Customer Involvement in New Product Development Stages: Implications for New Product Innovation Outcomes. Int. J. Innov. Technol. Manag. 2018, 15, 1850004. [Google Scholar] [CrossRef]

- Li, Y.; Li, G.; Zhang, Y.; Xu, J.P. Can firm innovativeness affect performance? The role of external involvement. Int. J. Mark. Res. 2021, 63, 514–534. [Google Scholar] [CrossRef]

- Silva, L.F.; Moreira, A.C. Involving suppliers in collaborative new product development: Comparing large and small firms. Int. J. Value Chain Manag. 2021, 12, 1–27. [Google Scholar] [CrossRef]

- Wang, Y.; Modi, S.B.; Schoenherr, T. Leveraging sustainable design practices through supplier involvement in new product development: The role of the suppliers’ environmental management capability. Int. J. Prod. Econ. 2021, 232, 107919. [Google Scholar] [CrossRef]

- Kędzia, G.; Staniec, I. The impact of supplier involvement in product development on supply chain resilience: The mediating role of communication. Int. J. Qual. Res. 2022, 16, 973–1000. [Google Scholar] [CrossRef]

- Moradlou, H.; Roscoe, S.; Ghadge, A. Buyer–supplier collaboration during emerging technology development. Prod. Plan. Control 2022, 33, 159–174. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, T.; Chen, J.L.; Chen, Q.J. Does supplier involvement enhance financial performance? The encapsulation effects of product modularity and smartness. Supply Chain Manag. Int. J. 2022, 27, 144–161. [Google Scholar] [CrossRef]

- Flankegård, F.; Johansson, G.; Granlund, A. Critical factors for involvement in customers’ product development: An SME perspective. J. Bus. Ind. Mark. 2023, 38, 143–153. [Google Scholar] [CrossRef]

- Oh, J.; In, J. Supplier involvement and supplier performance in new product development: Moderating effects of supplier salesperson behaviors. J. Bus. Res. 2023, 161, 113816. [Google Scholar] [CrossRef]

- Wang, X.; Um, K.H.; Wang, S.; Kang, M. The mediating role of key supplier adaptability and involvement in the relationship between supplier relationship management and NPD project success. Oper. Manag. Res. 2023, 16, 794–807. [Google Scholar] [CrossRef]

- Zhang, C.; Li, S. Different forms of supplier involvement, knowledge orchestration capability, technological uncertainty and new product development performance: A test of three-way interaction. Eur. J. Innov. Manag. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Benhayoun, L.; Le-Dain, M.A.; Schiele, H.; Personnier, H. How to prevent ruining new product development projects with suppliers? A failure factors’ perspective. Total Qual. Manag. Bus. Excell. 2024, 35, 670–686. [Google Scholar] [CrossRef]

- Kędzia, G. The ambiguous impact of supplier involvement in product development on supplier relationship resilience and company performance. Cent. Eur. Manag. J. 2024, 32, 233–261. [Google Scholar] [CrossRef]

- Flankegard, F.; Granlund, A.; Johansson, G. Supplier involvement in product development: Challenges and mitigating mechanisms from a supplier perspective. J. Eng. Technol. Manag. 2021, 60, 101628. [Google Scholar] [CrossRef]

- Song, M.; De Jong, A.; Anthony Di Benedetto, C.; Lisa Zhao, Y. Enhancing Supplier’s Involvement in Startup’s Innovation through Equity Offering and Trust Building. Int. J. Innov. Manag. 2019, 23, 1950013. [Google Scholar] [CrossRef]

- Yeniyurt, S.; Henke, J.W., Jr.; Yalcinkaya, G. A longitudinal analysis of supplier involvement in buyers’ new product development: Working relations, inter-dependence, co-innovation, and performance outcomes. J. Acad. Mark. Sci. 2014, 42, 291–308. [Google Scholar] [CrossRef]

- Petersen, K.J.; Handfield, R.B.; Ragatz, G.L. Supplier integration into new product development: Coordinating product, process and supply chain design. J. Oper. Manag. 2005, 23, 371–388. [Google Scholar] [CrossRef]

- Eggers, J.E.; Hofman, E.; Schiele, H.; Holschbach, E. Identifying the ‘right’ supplier for module developments—A cross-industrial case analysis. Int. J. Innov. Manag. 2017, 21, 1750026. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.-H. Engineering Design: A Systematic Approach, 3rd ed.; Springer-Verlag: London, UK, 2007; p. 617. [Google Scholar]

- Le Dain, M.A.; Calvi, R.; Cheriti, S. Measuring supplier performance in collaborative design: Proposition of a framework. R. D. Manag. 2011, 41, 61–79. [Google Scholar] [CrossRef]

- Handfield, R.B.; Ragatz, G.L.; Petersen, K.J.; Monczka, R.M. Involving suppliers in new product development. Calif. Manag. Rev. 1999, 42, 59–82. [Google Scholar] [CrossRef]

- Fujimoto, T. The Evolution of a Manufacturing System at Toyota; Oxford University Press Inc.: New York, NY, USA, 1999. [Google Scholar]

- Lawrence, P.R.; Lorsch, J.W. Organization and the Environment: Managing Differentiation and Integration; Harvard Business School Press: Boston, MA, USA, 1986. [Google Scholar]

- Sjoerdsma, M.; van Weele, A.J. Managing supplier relationships in a new product development context. J. Purch. Supply Manag. 2015, 21, 192–203. [Google Scholar] [CrossRef]

- Parker, D.B.; Zsidisin, G.A.; Ragatz, G.L. Timing and extent of supplier integration in new product development: A contingency approach. J. Supply Chain Manag. 2008, 44, 71–83. [Google Scholar] [CrossRef]

- Yan, T.T.; Dooley, K. Buyer-supplier collaboration quality in new product development projects. J. Supply Chain Manag. 2014, 50, 59–83. [Google Scholar] [CrossRef]

| Reference | Definition |

|---|---|

| [22] (p. 49) | “a form of vertical co-operation in which manufacturers involve suppliers at an early stage in the product development/innovation process, generally at the level of concept and design” |

| [23] (p. 1967) | “the early involvement of preferred suppliers in the buyer’s design and development process with regard to part/product development, a product’s cost and time to market, material development and selection, and supplier relationships” |

| [24] (p. 174) | “cooperation between component suppliers and original equipment manufacturers beginning at the product conceptualization stage” |

| [25] (p. 723) | “the extent a supplier contributes to NPD of a focal customer from the idea stage to the prototype testing stage” |

| [14] (p. 531) | “the extent to which a buyer organization shares responsibility with a supplier organization for the development and design of the subsystems (or components) of a new product” |

| [26] (p. 45) | “a form of collaboration in which purchasing firms involve suppliers at an early stage in the life cycle of a product, generally at the time of product concept or design” |

| [27] (p. 182) | “the extent of suppliers’ direct involvement in the product development activities. The extent of supplier involvement can be determined by the frequency of design-related communications between the suppliers and NPD team […] *, and the extent to which suppliers have their influence in the decision-making of product design” |

| [4] (p. 937) | “the combination of the buyer’s and supplier’s R&D resources and the exploitation of joint capabilities through strategic integration of the buyer–supplier relationship” |

| [28] (p. 903) | “entails involving suppliers in the product development phases for the buying firms’ new products and/or in redesigning the existing products of the buying firm” |

| [29] (p. 307) | “the extent to which supplier involves in new product development activities and decision-making” |

| [30] (p. 914) | “Partnerships are forged with suppliers to take advantage of their technological expertise in design and manufacturing” |

| [2] (p. 182) | “the resources (capabilities, investments, information, knowledge, ideas) that suppliers provide, the tasks they carry out and the responsibilities they assume regarding the development of a part, process or service for the benefit of a buyer’s current or future product development projects” |

| [1] (p. 187) | “fundamentally it concerns the integration of the capabilities that suppliers can contribute to NPD projects […], the tasks they are able to carry out on behalf of the customer, and the reponsibilities they assume for the development of a part, process or service” |

| [31] (p. 191) | “Appropriate responsibility given to supplier during the NPD process and improve NPD success by sharing cost and technology information and innovation capability” |

| [32] (p. 856) | “occurs when a customer involves its supplier at the early phase into NPD process” |

| [33] (p. 78) | “a form of vertical cooperation in which manufacturers involve suppliers at an early stage in the NPD process” |

| [34] (p. 84) | “the combination of the purchasing firm’s and the supplier’s R&D resources and the exploitation of joint capabilities through the strategic relationship” |

| [35] (p. 235) | “the supplier resources, tasks and responsibilities provided at all NPD stages of a focal customer, from the idea stage to the prototype building and pilot testing stage” |

| [36] (p. 1261) | “a buyer’s decision to involve a supplier “from the outset and through successive stages” of its new product development process” |

| [37] (p. 193) | “involving major supplier in the product development process to achieve improved NPD performance” |

| [13] (p. 3860) | “suppliers providing firms with resources and taking the relevant responsibilities” |

| [38] (p. 3388) | “the utilisation of joint capabilities stemming from the strategic integration of buyer–supplier relationship and combination of buyer’s and supplier’s R&D” |

| [39] (p. 102) | “the extent to which a supplier is involved in codesigning and new product development processes with their customers in exchange relationships” |

| [40] (p. 315) | “supplier input in the design phase of new product development that results in better information, technology, and efficiency” |

| [41] (p. 112) | “the integration of suppliers’ capabilities into NPD projects […], the tasks they are able to carry out on behalf of the customer, and the responsibilities they assume for the development of a part, process or service” |

| [42] (p. 275) | “the resources provided by suppliers—for instance, capabilities, information and knowledge—as well as the tasks suppliers carry out and their responsibilities in the development of a part, process or service for the buying company’s current or upcoming product development projects” |

| [43] (p. 163) | “the responsibility suppliers assume, the activities they perform and the resources they supply, all of which are influenced by the task they are asked to carry out” |

| [44] (p. 173) | “the extent to which manufacturers incorporate their suppliers into product development and continuous improvement programs” |

| [45] (p. 1750059-13) | “the extent to which design and development related responsibilities of the subsystems (or components) of a new product are shared with suppliers” |

| [46] (p. 806) | “the dependence of manufactures on suppliers for engineering work to reduce the former’s internal engineering efforts” |

| [47] (p. 172) | “the extent to which a supplier is involved in its manufacturers’ NPD process by providing knowledge resources and participating in decision-making during the development of new products” |

| [48] (p. 1850004-4) | “the relative degree of participation that suppliers have in a firm’s NPD process. Supplier involvement in NPD is the integration of capabilities, investments, information, knowledge that suppliers provide” |

| [5] (p. 2) | “the integration of the capabilities that suppliers can contribute to NPD projects […], the tasks they are able to carry out on behalf of the customer, and the responsibilities they assume for the development of a part, process or service” |

| [10] (p. 33) | “The (amount of) participation of suppliers in their customer’s innovation projects” |

| [12] (p. 360) | “it is ‘a process of managing the involvement of suppliers in the development of (new) products/services/processes/technologies for the chosen category’” |

| [49] (p. 521) | “the strategic joint collaboration between the supplier and manufacturer in planning and product development” |

| [50] (p. 3) | “the incorporation of technologies, technical information, ideas and the development of tasks in order to enhance the performance of new products” |

| [51] (p. 3) | “the extent to which activities are conducted jointly with the supplier during the five stages (i.e., from the idea generation stage to the prototype development stage) of an NPD project aimed at developing an environmentally friendly product. |

| [52] (p. 976) | “a situation in which a customer integrates a supplier within their R&D area, especially in designing new products or redesigning the customer’s existing products […]. This practice entails giving the supplier some responsibility in the NPD process” |

| [53] (p. 161) | “the integration of the capabilities that suppliers can contribute to new product development projects, the tasks they are able to carry out on behalf of the customer and the responsibility they assume for the development of a part, process or service” |

| [54] (p. 145) | “the extent to which suppliers are directly involved in the focal firm’s new product development, coordinates interfirm activities related to the product, process and supply chain design” |

| [55] (p. 143) | “the integration of the supplier’s resources and capabilities, as well as the tasks and responsibilities it assumes for developing a component on behalf of the customer” |

| [56] (p. 1) | “a supplier’s participation in the early stages of the buyer’s new product development (NPD) to contribute to the buyer’s NPD success” |

| [57] (p. 799) | “the responsibility suppliers assume, the activities they perform, and the resources they supply, all of which are influenced by the task they are asked to carry out” |

| [58] (p. 5) | “the extent a supplier is involved in the NPD process with its buyers” |

| [59] (p. 671) | “the resources (capabilities, investments, knowledge, etc.) that suppliers can provide and the responsibilities they hold regarding the design and development of an NPD” |

| [60] (p. 236) | “the supplier’s participation in various stages of product development based on a partnership, extensive communication and the long-term perspective of cooperation” |

| Elements and References to Definitions | Dimensions | WH-Questions |

|---|---|---|

| Improve NPD success [31]; improved NPD performance [37]; better information [40]; better technology [40]; better efficiency [40]; reduce engineering efforts [46]; enhance performance of new products [50]; NPD success [56]. | Product development performance | Why? |

| Resources [2,4,34,35,37,42,43,47,55,57,59]; capabilities [1,2,4,5,34,38,41,42,48,53,55,59]; investments [2,48,59]; information [2,42,48,50]; knowledge [2,42,47,48,59]; ideas [2,50]; technologies [50]; technological expertise [30]. | Leveraging resources and capabilities | |

| Sub-system [14,45]; component [14,45,55]; product [14,23,27,28,45,47,49,50,51,52,54]; part [1,2,5,23,41,42,53]; process [1,2,5,41,42,49,51,53,54]; service [1,2,5,41,42,49,53]; technology [12]. | Entity of development | What? |

| Development [1,2,14,23,41,42,44,45,47,49,51,53,55,59]; design [14,45,52,59]; activities [27,43,51,54,57]; re-design [28,52]; codesign [39]; continuous improvement [44]; engineering work [46]; planning [49]. | Type of development | |

| All NPD stages [35]; various stages [60]; idea stage [25,35,51]; outset of new product development process [35]; early stage [22,26,32,33,56]; product conceptualization stage [24]; level of concept and design [22,26]; design phase [40]; prototype testing [25]; pilot testing stage [35]; prototype development [51]. | Moment of involvement | When? |

| Task [1,2,5,35,41,42,43,50,53,55,57]; responsibility [1,2,5,14,31,35,37,41,42,43,45,52,53,55,57,59]. | Division of tasks and responsibilities | How? |

| Cooperation [22,24,33,60]; integration [1,5,41,48,53,55]; utilization [38]; sharing [31]; combination [4]; incorporation [50]; collaboration [26,49]; partnership [30,60]; influence [27], involve [22,23,26,28,32,33,58]; involvement in product development activities [27], participating in decision-making [47]; participating in product development [10,48,56,60]; jointly activities [51]; coordinating activities [54]; communication [27,60]; sharing information [31]. | Integration |

| Interrogative Words | Questions |

|---|---|

| Why |

|

| What |

|

| When |

|

| How |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flankegård, F.; Johansson, G.; Granlund, A.; Johansson, P.E. Conceptualization of Supplier Involvement in Product Development Based on a Systematic Review of 47 Definitions. Logistics 2024, 8, 94. https://doi.org/10.3390/logistics8040094

Flankegård F, Johansson G, Granlund A, Johansson PE. Conceptualization of Supplier Involvement in Product Development Based on a Systematic Review of 47 Definitions. Logistics. 2024; 8(4):94. https://doi.org/10.3390/logistics8040094

Chicago/Turabian StyleFlankegård, Filip, Glenn Johansson, Anna Granlund, and Peter E. Johansson. 2024. "Conceptualization of Supplier Involvement in Product Development Based on a Systematic Review of 47 Definitions" Logistics 8, no. 4: 94. https://doi.org/10.3390/logistics8040094

APA StyleFlankegård, F., Johansson, G., Granlund, A., & Johansson, P. E. (2024). Conceptualization of Supplier Involvement in Product Development Based on a Systematic Review of 47 Definitions. Logistics, 8(4), 94. https://doi.org/10.3390/logistics8040094