Abstract

Background: Warehousing operations, crucial to logistics and supply chain management, often seek innovative technologies to boost efficiency and reduce costs. For instance, AR devices have shown the potential to significantly reduce operational costs by up to 20% in similar industries. Therefore, this paper delves into the pivotal role of smart glasses in revolutionising warehouse effectiveness and efficiency, recognising their transformative potential. However, challenges such as employee resistance and health concerns highlight the need for a balanced trade-off between operational effectiveness and human acceptance. Methods: This study uses scenario and regression analyses to examine data from a German logistics service provider (LSP). Additionally, structured interviews with employees from various LSPs provide valuable insights into human acceptance. Results: The findings reveal that smart glasses convert dead time into value-added time, significantly enhancing the efficiency of order picking processes. Despite the economic benefits, including higher profits and competitive advantages, the lack of employee acceptance due to health concerns still needs to be addressed. Conclusions: After weighing the financial advantages against health impairments, the study recommends implementing smart glass technology in picking processes, given the current state of technical development. This study’s practical implications include guiding LSPs in technology adoption strategies, while theoretically, it adds to the body of knowledge on the human-technology interface in logistics.

1. Introduction

In today’s global supply chains, the demand for speed and agility in logistical processes is imperative, particularly within warehouse operations, where efficiency is a crucial determinant of success []. Order picking is a part of the warehousing logistical processes in a company that has a vital impact on performance in terms of efficiency, quality, cost, and time []. Order picking as an essential part of the material flow is a value-intensive activity with great potential for optimisation []. Recognising this potential for optimisation, pursuing efficiency in this process becomes crucial to reduce operational costs and enhance picking speed []. To do so, new methods, products, and services are required to meet the demands of highly dynamic logistics markets and the increasing complexity of logistics networks. Flexibility, adaptability, and proactivity are becoming increasingly important and can be achieved by incorporating new technologies []. While problem-orientated approaches lead to incremental improvements, technology-orientated approaches can bring more significant changes []. Employees still manually carry out many logistics processes according to the receipt-based pick-by-paper or the receipt-less variant pick-by-scan [].

Securing competitive advantages by improving order picking performance is crucial for a warehouse operation’s competitive positioning. Innovative technologies such as augmented reality (AR) are proving particularly promising for logistics in warehousing. AR can reduce warehouse operations costs while significantly increasing efficiency and productivity [].

Employees must perform information-intensive activities within order picking while keeping their hands free to carry out picking activities. In the form of smart glasses, AR can display context-sensitive information in the user’s field of vision and guide them through work steps []. Smart glasses thus extend current picking scenarios through so-called pick-by-vision systems []. As a result, the employees engaged in transport and logistics operations, equipped with smart glasses, are provided with real-time operational information, such as delivery orders and picking status, without interrupting the actual work process to improve performance [,]. The glasses offer a novel aspect of current picking situations, providing employees with instant operational information without unduly interrupting their work process.

In an experiment, DHL tested two commercial smart glasses, Google Glass and Vuzix® M100, at a warehouse and discovered a 25% boost in efficiency []. Similarly, Boeing investigated using Google Glass to help in wire bundle assembly; they observed a 30% boost in productivity and a favourable response from employees []. In another case study, a head-worn display (HWD) was implemented in two warehouses in Belgium, where one was successful while the other was not. The prime reason was the employees’ involvement in improving the device’s functionality and usage conditions []. Another study reported four cases of implementing AR-enabled vision-picking at DHL, Samsung, Coca-Cola, and Intel. At DHL, productivity and speed increased by 15% and 25%, respectively, while at Samsung, productivity increased by 12–22%. Similarly, at Coca-Cola, performance increased by 6–8%, while at Intel, speed increased by 29% [].

Although the literature focusses on the potential of smart glasses in warehousing, scientific case studies still need to be developed, leading to a gap in understanding their efficiency and effectiveness [,,]. Despite its maturity, the use of AR systems in warehousing, especially in the order picking process, is still an active area of research []. The authors of [] emphasised that there is a need to share selected use cases to resolve any uncertainties in logistics regarding the use of AR-enabled smart glasses. The literature further stressed assessing the impact of smart glasses via well-documented case studies experimenting with various digital technologies and software and rigorous comparisons with existing solutions [,]. Comfort and cleanliness in reusing these glasses across multiple shifts require further testing, posing significant barriers to user acceptance and adoption [].

The gap that this study plans to fill is to determine the productivity benefits of smart glasses over traditional picking methods along with their human acceptance. To fill this identified gap, a research question is posed: Can smart glasses be more effective, efficient, and acceptable than conventional order picking methods for logistics processes? In answering this question, the paper aims to investigate the effects of smart glasses in terms of effectiveness and efficiency increase and acceptance compared to conventional picking methods in a case study in cooperation with a German 3PL service provider, as well as to evaluate the employee acceptance of smart glasses.

The study seeks to understand smart glasses’ potential for transformative capabilities by applying scenario analysis, regression analyses, and structured interviews of employees. The research question is further explained by creating the research objectives, which will be presented in the next section.

2. Literature Review

Picking is one of the core activities of a warehousing operation. As per [], it is the most time-consuming and error-prone activity among all the warehousing tasks. Today, there are multiple ways in which orders are picked in warehouses, namely: pick-by-paper, pick-by-vision, pick-by-light, pick-by-voice, pick-by-gesture, cart-mounted display, and pick-by-scan []. Most warehouses still use paper-based picking approaches. However, any paper-based approach could be faster and more accurate. In addition, picking is often performed by temporary workers, who usually require costly training to ensure efficient and error-free picking []. In this section, we will first discuss the key performance indicators (KPIs) involved in assessing the performance of a picking operation in a warehouse. Subsequently, the role of human touch and smart glasses in pick-by-vision will be discussed. This section will conclude with a discussion of the benefits of AR-enabled picking and the research objectives of this study.

2.1. KPIs in Picking Operation

Efficiency is the improved ratio of (minimum) input to (maximum) output. Logistics’ primary and most important purpose is to connect supply and demand in a demand-orientated and cost-efficient way []. To improve competitiveness, the efficiency of logistics facilities (quantity, speed, and quality with the same resource input) must be increased []. To improve performance, reducing the amount of redundant resources is necessary []. The key performance indicators (KPI) are throughput times, picking performance, and the associated error rates [,].

Throughput Time: Picking time can be defined as the throughput time of the picking process [,]. The throughput time of an order is defined as the sum of the processing, transport, and waiting times at all production stages [], therefore, the sum of dead times, picking times, and travel times across all items [,]. An order picking system’s KPI “picking performance” is relevant to reflect its efficiency []. Usually, the picking performance refers to the number of items regardless of the removal quantity per item []. The performance is always related to a time unit, which is always one hour. Following Equation (1) is formulated to calculate the order picking performance.

Picking Performance: Other variables influencing performance are the availability and utilisation of order pickers. There are empirical values for the availability of human order pickers [] based on the working conditions and the load. In performance comparisons of picking techniques, the number of positions “Pos” is kept constant so that the picking time is multiplied by the same factor each time. The performance is thus directly proportional to the picking time []. Depending on the throughput time and the number of positions, the order picking performance can be determined with Equation (2) below, which is increasingly applied in further processes.

Error Rate: One of the most critical factors in picking is avoiding or reducing errors. Pick errors can directly impact customer relationships and satisfaction, as picking errors are often noticed after delivery. Errors, therefore, result in a negative customer experience, which can affect the customer-supplier relationship and result in financial damage []. According to [,], one error per 1000 items (0.1%) is desirable. The goal of zero error picking is currently not achievable due to human error susceptibility in a non-autonomous picking system. The following Equation (3) is used to calculate the error rate:

Out of the four methods (pick-by-scan, pick-by-voice, pick-by-light, and pick-by-vision), only one picking method is below the desirable error rate of 0.1% (see Table 1), and that is the pick-by-vision method having an average error rate of 0.08%. Although the error rate in order picking today is meagre even with a pick-by-paper approach—experts estimate the rate at 0.35% to 0.45%—every error must be avoided as it usually results in high follow-up costs []. Table 1 establishes pick-by-vision as a candidate to be explored further for wider application due to its potential to reduce error. In a lab test, an optimal set of parameters were extracted for the best performance: the battery is to be positioned on the side of the weight, the storage level of the racks should be high, discrete order mode of picking should be used, a scanner should be used as the confirmation equipment, and there should be a lower number of lines per order.

Table 1.

Overview of Error Rates, compiled from various sources [,,,,,].

2.2. Human Touch in Picking

Human flexibility in order picking is almost impossible to replace, despite many automation concepts. Regardless of increasing requirements such as variable article ranges, decreasing order sizes, and increased flexibility, rationalisation potentials can be tapped if the order picker is optimally supported in their core task, considering both ergonomic and informational aspects, and is relieved of time-consuming and distracting secondary activities []. AR can improve information visualisation if employees in picking systems are equipped with data glasses []. Ref. [] identified a need to document cases where companies have successfully maintained and extended employee interest and participation while implementing smart glasses in picking operations.

2.3. Smart Glasses for Pick-by-Vision

‘Smart glasses’ refers to peripheral devices with integrated small computers worn on or at the head. Things, plants, animals, people, situations, and processes are registered, analysed, and enriched with virtual information []. Mobile devices attached to the user’s body are called wearables []. A wearer of smart glasses, or more broadly, an augmented reality head-worn display HWD (AR HWD), can access various informational types, such as text, graphics, and video. Information can be overlayed onto the real world (augmented vision) or perceptually placed next to real-world objects of interest (conformal augmented reality) so that users do not have to look down to access it, unlike when they access manuals, hand-held devices, or other reference materials []. Typically, the aim is to support real-world action by offering data, assessments, and directions [,]. AR-enabled smart glasses can merge the actual world with virtual data in the user’s field of vision. These AR devices must be distinguished from their virtual reality (VR) equivalents, which have an opaque screen. They do not support the overlay of virtual and physical reality but rather conceal the user’s perspective within the device and protect them from any exterior visual input [].

AR offers the possibility of actively supporting work processes in logistics, such as the warehouse picking process, thereby increasing employee efficiency, effectiveness, and satisfaction [,]. Various cases and experiments have been reported in the literature [,,,,,]. The integrated scanning technology, usually in the form of a camera on the frame of the glasses, meets the demand for integrating digitisation measures, such as optimising warehouse management systems []. Different smart glasses and scanners are reported in the literature for pick-by-vision, to name a few: Google Glass, Vuzix® M100 and M300XL, RealWear HMT-1, Samsung Gear S2, and Intel Recon Jet Pro.

Picking is a skill-, rule-, and information-intensive activity, so this technical support for using AR and smart glasses in the pick-by-vision process is one of the most critical success factors []. Using a tracking system to recognise the position and direction of gaze, static data such as text information can be displayed and data that is dynamically positioned in space []. These 3D spatial geometries attractively highlight the picking or storage location or show the optimal path throughout the warehouse []. This always gives the user direct access to information and eliminates the need for disruptive activities to retrieve information that interrupts the work process. Furthermore, when using smart glasses, the user has both hands free through voice-based control [,]. Increased picking performance in the work process is expected through the expansion of the natural environment. This is because of the process guidance along the picking process, which promises cognitive relief for the smart glasses user [].

2.4. Benefits of Paperless Picking

The strict visual guidance of order pickers lets them complete their daily picking tasks in a warehouse environment faster and more error-free than they would be able to do without the support of data glasses []. According to [], smart glasses make it possible to use an ergonomic product that can be worn by the order picker and the cognitive superiority of humans to design logistical processes efficiently. Previous studies in paperless picking suggest that data glasses have great potential as a user-friendly and task-supporting tool with good information display and design quality []. It was also found that the error rate is significantly lower when using pick-by-vision compared to voice-controlled picking support. This is due to the technically determined low error tolerance of data glasses [].

Refs. [,] suggest that paperless picking methods have tremendous advantages. Pick-by-vision leads to reduced search times, clean documentation, increased performance, and reduced errors in the picking process. The use of smart glasses offers the opportunity to actively support work processes in logistics, such as the picking process in the warehouse, thereby increasing efficiency, effectiveness, and employee satisfaction [,]. Especially in throughput time, pick-by-vision can achieve a competitive advantage. The authors of [] have defined the potential of AR smart glasses in logistics and supply chain management around four facets: visualisation, interaction, user convenience, and navigation.

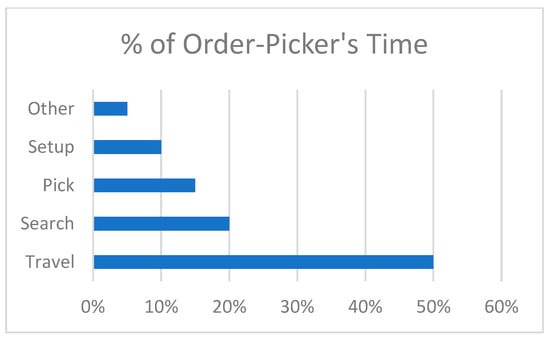

A faster process goes hand in hand with higher productivity, increasing profitability. The faster an order is picked up, the cheaper the product delivery. Other goals are route optimisation, increased picking performance based on short throughput times, and process reliability in the form of little to no error susceptibility. The processing of the order volume should require as little effort as possible and must accordingly be designed as efficiently as possible [,]. In this context, the employee’s movement time plays a significant role at 50%, and the search time is 20% within the picking process (Figure 1) [].

Figure 1.

Order picking time overview [].

2.5. Derivation of the Research Objectives

Order picking takes several items from the warehouse to serve and fulfil several independent customer orders according to customer requirements. The aim is to make this process as practical (e.g., higher speed of picking) and efficient (e.g., reduced operational cost) as possible. This means that the basic operational costs should be reduced, but at the same time, the order picking speed should be increased []. Minimising time for the picking process is necessary for any picking system [,]. By extending the natural environment, increased picking performance in the work process is expected. Pick-by-vision can be used efficiently, primarily for inexperienced employees or high temporary worker rates in a company. The reason for this is, among other things, the guidance along the picking process, which promises cognitive relief for the smart glasses user []. These should be provided to the employee intuitively and ergonomically while aiming for an effective and efficient picking process, i.e., maximising performance while minimising the potential for errors []. The strict visual guidance of order pickers lets them complete their daily picking tasks in a warehouse environment faster and more error-free than they would be able to do without the support of data glasses [].

The following research objective is derived to make the theory tangible and create a possibility of verification.

RO1:

To assess the impact of smart glasses in increasing the effectiveness and efficiency of the picking processes compared to conventional picking methods.

It emphasises exploring the improvement in logistics processes with the use of smart glasses and eventually offers the possibility of a competitive advantage.

Humans will continue to play a crucial role in production and logistics operations due to their adaptability and sensorimotor abilities in an increasingly digitalised world. Thus, ergonomics, flexibility, and occupational safety should be improved []. The goal is to design logistics operations processes so people and machines can operate, interact, and integrate easily [].

Several strategies aim to increase user friendliness and acceptance by deliberately minimising the number of necessary contacts between humans and the system. This allows the user to concentrate more on their task, increasing productivity and reducing the susceptibility to workplace errors. Intelligent devices are designed to be as invisible as possible to the user and to support him in his activity by providing him with the appropriate contextual information [].

For pick-by-vision and the associated process optimisations to result in actual human-added value, it is crucial to consider factors influencing the acceptance and usability of the information system [,,].

To increase user acceptance, it is essential to consider both the physical and psychological strain on the employee []. Ergonomics and mental stress are the most crucial requirements for accepting smart devices []. Employees must be aware of the advantages of wearable technology and incorporate it into their everyday work activities. Wearables should offer quantifiable value, for instance, regarding mobility or weight. Ideally, they should not be noticeable to the employee in the work process but should integrate naturally []. However, ergonomics is not limited to the wearability of smart glasses but also to the ergonomics of the user interface. It is possible that extended use of smart glasses in workplaces can cause visual fatigue and impair attention []. Although AR helps lessen head and neck motions while operating, workers may become distracted or confused by the information [].

In addition to ergonomics, an essential aspect of acceptance is privacy and the associated protection of that privacy []. The challenge is that indoor localisation and task and error tracking are critical to the performance of such a system []. This exposes users to increased surveillance by supervisors [].

The following research objective is derived to make the theory tangible and to create a possibility of assessing acceptability based on various criteria:

RO2:

To assess the employees’ acceptance level of using smart glasses in the picking process without concerns.

3. Methodology

As mentioned in previous sections, this study has one research question and two objectives. A mixed-method study was conducted to achieve the objectives, and the following steps were implemented.

3.1. Research Objective 1

- The following methods were performed to assess the increase in efficiency of smart glasses in picking operations.

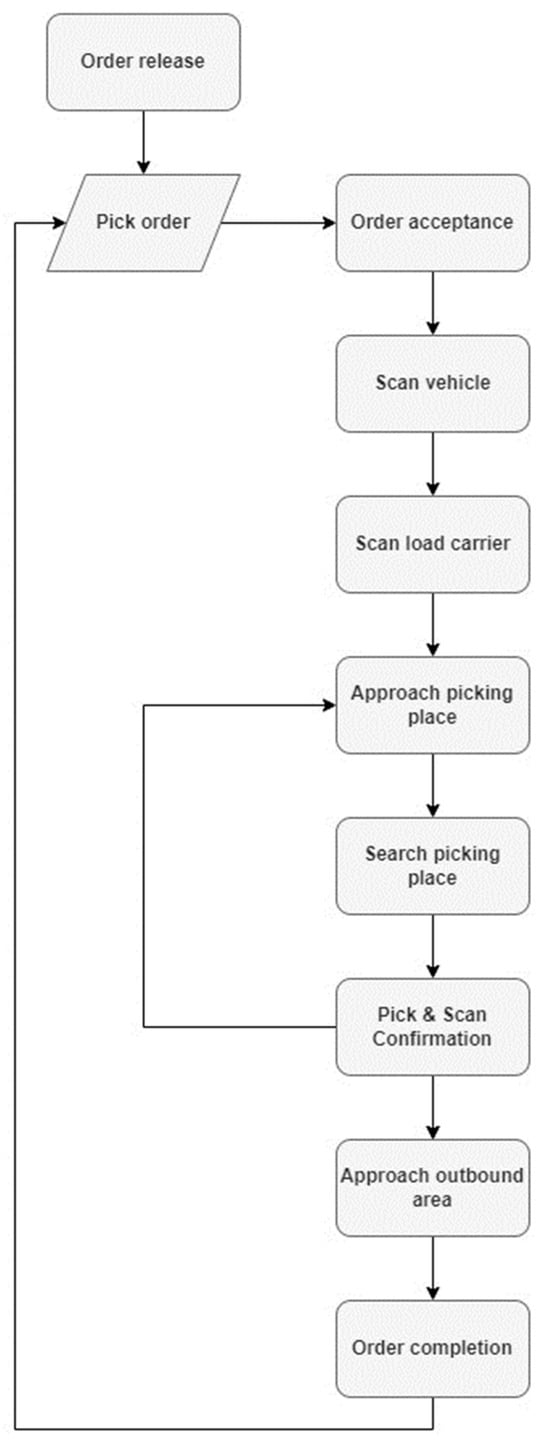

- Two test series (one was in a test environment while the other was in live business operation) were conducted in the year 2022 in the warehousing facilities of the case company, i.e., the German 3PL logistics service provider (LSP). The data on the same picking process with and without using smart glasses was collected for comparison. The process flow within the two tests was defined in advance (Appendix A). During the data collection phase, the employee is accompanied over one week to collect all the data. The same selector performed the picking operation in both test series to reduce external and human influences, such as picking and moving speeds.

- Based on the collected data, a regression analysis was conducted to determine the relationship strength between the dependent variable (throughput time) and the independent variables (setup time, search time, and pick time). Waiting time and travel time were kept constant.

- Ten scenarios were created using the collected data and historical data on order picking from the case company for 2021. These scenarios were thoroughly evaluated to generalise the possible increase in efficiency considering the number of picking locations and the number of picks per picking location.

- The following method was performed to assess the increase in the effectiveness of smart glasses.

- A cost–benefit analysis (CBA) was performed to identify the savings the pick-by-vision approach can achieve. This analysis used the data collected in the test series and developed scenarios.

3.2. Research Objective 2

- This objective was achieved using a structured interview-based survey, the details of which are presented as follows:

- An interview guide was prepared with 13 questions (10 closed-ended statements and one open-ended question). These questions were divided into the three essential attributes around human acceptance: ‘ergonomics’ (four statements), ‘mental’ (three statements), and ‘privacy & social’ (three statements). The ten closed-ended statements followed a seven-point Likert-type scale from ‘not true at all’ to ‘true exactly’, with a ‘neutral’ in the centre, and were considered quantitative data []. The answer that reflected 100% acceptance is assigned a seven, while all the answers are then assigned values in descending order.

- The only open-ended question was about possible concerns regarding the technology. To analyse this question, the first-order codes were developed using direct responses, and similar responses were categorised into six concerns as the second-order code.

- The interview questions were tested and validated as part of a pilot test where ten employees of the case company were interviewed, and each gave individual feedback. The interviews took 10–15 min per interviewee. The phrasing was improved as an outcome of the pilot.

- The inclusion criteria required that the respondents be those who use smart glasses technology daily or have worked with them in the last year.

- To assess the broader acceptance of smart glasses, 86 respondents were included. They were employees from different companies in the LSP sector. The sample data were divided into 37% women and 63% men. The interviews were conducted face-to-face.

The diversity of the mixed-method approach allowed for rich data collection, which had the advantage of building a comprehensive view through enhanced triangulation. These data collection and analysis methods were chosen to achieve the research objectives effectively and objectively.

4. Findings and Discussion

The aim is to achieve the two research objectives in two steps: RO1 is achieved using the tests performed, regression analysis, scenario analysis, and cost–benefit analysis (CBA), while RO2 is realised by analysing the data collected through structured interviews.

4.1. RO1: To Assess the Impact of Smart Glasses in Increasing the Effectiveness and Efficiency of the Picking Processes Compared to Conventional Picking Methods

RO1 is achieved in two parts: (a) first, the ‘efficiency’ part by two test series, regression analysis, and scenario analysis, and (b) second, the ‘effectiveness’ part via CBA.

4.1.1. Assessing the ‘Efficiency’ of Smart Glasses

To make a scientifically relevant statement about achieving RO1, two different series of tests were carried out. The first series of tests are based on a test environment outside the daily business, while the second one is conducted during the live daily business. The average pick quantity per day based on historical data for the period January–July 2022 is 10,754 picks per day. The average order size based on the total of all orders in 2021 is five pick positions with three picks each. According to this, a picking activity must be carried out 15 times per order.

Within the pick-by-vision method, the company does not use the option of visual guidance in route optimisation through the warehouse but a direct location display in the employee’s field of vision. The smart glasses provide visual information about the storage location of the material to be picked, the order size, and the respective pick quantity of the item. To reduce a possible source of error, the order picker confirms the location in advance. Afterwards, the order picker is provided with the order’s picking information. The scan confirmation is performed via a scanner integrated into the system, which maintains the advantage of “hands-free” order picking compared to the pick-by-scan method with a hand-held scanner.

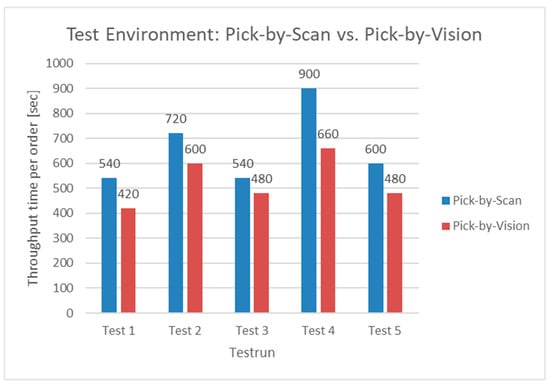

Test series 1—pick-by-scan vs. pick-by-vision in the test environment: Five picking processes were carried out using the conventional pick-by-scan and pick-by-vision methods. Accordingly, the exact picking locations were stored in the order for each test run and then picked using the pick-by-scan and pick-by-vision methods. The measurement period for the throughput time of a complete order with the respective predefined pick quantity starts with the order acceptance. It ends with providing the wholly picked order in the goods issue zone. This trial series aims to obtain a basic comparison of the technologies based on throughput time. Due to the standardisation, it is then possible to make a statement about a potential increase (or decrease) in efficiency.

Figure 2 visualises the throughput times of pick-by-scan and pick-by-vision for the respective test series. It can be seen that the pick-by-vision method has a significantly shorter throughput time in each test series compared to the conventional pick-by-scan method. The average time per pick, including search times, picking times, travel times, etc., amounts to 39.76 s with the conventional pick-by-scan method. The pick-by-vision method can be quantified here with an average of 31.81 s per pick. On average, the pick-by-vision method is 7.95 s faster per pick than the conventional pick-by-scan method, corresponding to a 25% increase in efficiency.

Figure 2.

Test environment: comparison of pick-by-scan and pick-by-vision.

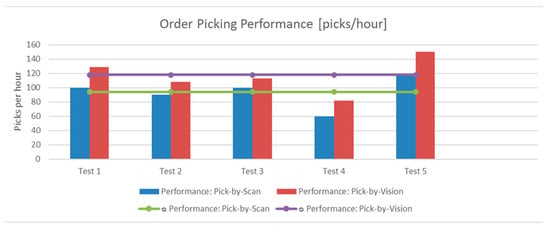

The system’s performance can be evaluated based on the throughput times obtained in the test environment and the respective pick quantity (Figure 3). The average order picking performance within the test environment of the pick-by-scan method is 95.42 picks per hour per employee. The pick-by-vision method achieves an average performance of 117.92 picks per hour per employee. The difference in the performance of the two systems amounts to 23.58%. Based on a population of 7.48 h per shift, 713.75 picks per shift can be achieved mathematically per order picker with the conventional pick-by-scan method. The pick-by-vision method achieves 882.04 picks per shift.

Figure 3.

Order-picking performance per employee (test environment).

Test series 2—pick-by-scan vs. pick-by-vision in day-to-day operations: The study is conducted on a sample basis and is intended to represent the population of all orders in the case company. A sample’s reliability, size, and representativeness play a significant role in meaningful results [,]. The measurement basis of the trial series is based on a total of 10 orders with a total of 105 items and 256 picks of the pick-by-scan method and 12 orders with 108 items and 367 picks of the pick-by-vision method. One position is equivalent to one picking location.

The two test series assist in achieving RO1 by concluding that a smart glasses-enabled pick-by-vision approach increases the effectiveness and efficiency of the picking processes compared to conventional picking methods.

Regression Analysis: The collected data are examined for normality using the Kolmogorov–Smirnov test before further analysis. The test assumes in its null hypothesis that the tested variable is normally distributed. The test is suitable for smaller samples (n < 30) []. The critical value for the maximum difference for a sample size (n = 22) at a significance level of alpha 0.05 [,]. The values in Table 2 show that the null hypothesis, “a normal distribution exists”, cannot be rejected.

Table 2.

Kolmogorov-Smirnov test.

The next step is identifying the relationship between the dependent and independent variables through a regression analysis []. The dependent variable is the throughput time of the picking process. The independent variables directly influencing the throughput time are setup, travel, search, and picking times. Table 3 illustrates the results from the regression analysis. Multiple R is 0.9873, indicating a robust linear relationship [] between the predictor (independent variables) and the response (dependent: throughput time) variables. The quality of the relationships can be inferred from the R-square of 0.9747, meaning that the variations in the dependent variable almost wholly explain the variation in the throughput time. According to [], 0.05 is a reliable F-value significance level, and the regression table confirms its value at 0.025.

Table 3.

Results of the regression analysis.

Regarding the coefficients, if all other predictor variables remain constant, each coefficient is viewed as the average increase in the response variable for each unit increase in a particular predictor variable [,]. Looking at the coefficients, it becomes clear that the travel time (1.1605) has the greatest positive correlation with the throughput time and influences it significantly. However, because the value is above 1, a certain inaccuracy is present due to multicollinearity. The dependent variables of travel time (p = 0.0000206), search time (p = 0.04511), and picking time (p = 0.000000137) correlate with the dependent variable of throughput time and are statistically significant as the p-values are less than 0.05 []. The variable “setup-time” (p = 0.8878 > 0.05) seems to have no significant influence on the throughput time of the process, and this is due to its smaller percentage of time in the overall picking process.

The regression analysis further helps explain RO1, concluding that optimising the independent variables can change the throughput time and increase efficiency. In continuation, these same variables were influenced heavily by the pick-by-vision approach, thus achieving higher efficiency.

Scenario Analysis: The data sets aggregated to a mean value, and the respective standard deviation of the test series can be seen in Table 4. This data set serves as a basis for further analyses. Based on the collected data and determined time elements in combination with the historical data records from 2021, scenarios were created in which different orders with different picking positions were estimated. In each case, the pick quantity is multiplied by the pick position by a factor of 3 (average pick quantity per pick position in 2021). The data sets of the scenarios can be found in Appendix B. The specific scenario for five picking positions with three picks each can be taken from Table 5, where the efficiency is improved by 10% for the pick-by-vision method.

Table 4.

Results of the quantitative data collection.

Table 5.

Cost–benefit calculation.

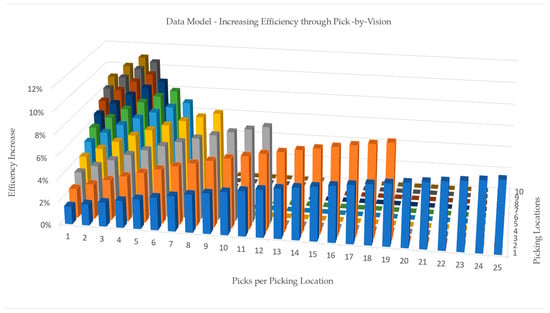

It must be noted that the shorter the paths in the warehouse and the more frequent the picking, the more the pick-by-vision process can contribute to an increase in efficiency. To transfer the experiences and results from the actual measurements to other warehouses and their specific situations, the structure of the warehouse processes must be compared. As a contribution of this work, the results should assess the efficiency increase potential of the pick-by-vision method by a structured comparison based on a diagram (Figure 4) and thus support an economic decision.

Figure 4.

Simulation model—increasing efficiency through pick-by-vision.

To make a reliable statement, specifications are made supported by literature sources; for example, the travel time in the warehouse is fixed at an average share of 50%, according to []. In special warehouse situations, deviating constellations must be taken into account accordingly. A 5% labour share for waiting times and other inefficiencies is also fixed according to the model of []. Based on the case company’s data, 45 orders per employee per day were determined, which may differ in other companies. However, this does not affect the trend statement regarding the increase in efficiency when extracting the number of picks per warehouse location or the number of warehouse locations approached per order.

The three-dimensional data model (Figure 4) shows all possible combinations or scenarios feasible in a warehouse worker’s standard daily working time based on the set parameters (scenario-based data model in Appendix B). Based on the indicators from the literature reviewed and the test series, the data model is based on the formula derived below (Equation (4)). The formula refers to one employee, the number of orders per day per employee and their working time per day. The number of picking stations and picks is also measured per order.

This subsequently results in the following Equation (4):

The central statement is that the more picks are completed, the more efficient the process becomes. This also clearly shows again which factor the pick-by-vision method optimises most intensively. Not so prominent is the finding that an increase in the number of items in an order leads to increased efficiency. In the scenario-based model, this is solely because travel time in the warehouse is fixed at 50%. If the model is transferred to an actual warehouse situation, this supposed deviation does not apply.

4.1.2. Assessing the ‘Effectiveness’ of Smart Glasses

Cost–Benefit Analysis (CBA): The finding that the pick-by-vision approach leads to significant increases in efficiency seems insufficient as a basis for decision-making since the acquisition of the system requires a considerable investment of 8500 € per pair of glasses plus annual operating costs of 500 €, as per the case company’s data. To determine whether this investment is worth the related increase in efficiency, it is necessary to determine (a) where the specific warehouse is located in the scenario-based data model (Appendix C) in terms of the number of pick locations and the number of picks per order, and (b) how many shifts per day are operational in the warehouse. However, this would presuppose several employees sharing the glasses, raising ergonomic and hygienic concerns, which purely depend on human acceptance.

The CBA in Table 6 illustrates two scenarios, starting with the lowest savings through the data model and the highest possible savings. Depending on efficiency, different daily hours can be gained, resulting in different financial savings. Based on a balance sheet depreciation over eight years, 2699.68 € to 3423.13 € per year per workplace can be saved. This corresponds to a profit generated per workplace over 8 years of 21,597.45 € to 27,385.04 €. With 20 workplaces, according to the data model, an annual profit of at least 431,948.93 € can be assumed. This conclusion manifests the effectiveness of using smart glasses for the picking process.

Table 6.

Simulation results (5 picking positions, 15 picks).

4.1.3. Discussion of the Empirical Results

The test series clearly showed that smart glasses can increase order picking efficiency. Using regression analysis, the correlations between throughput time and the independent variables of setup time, picking time, and search time can be statistically proved.

The information shown on the display of the smart glasses guides the employee through the entire picking order. The internal system guides him directly to the storage location, and the visual display shows the article and pick number. Finally, the picking process is confirmed and completed with the scanner integrated into the smart glasses. With AR, the user’s normal field of vision is extended by helpful, virtually generated information. Pick-by-vision thus clearly combines the advantages of pick-by-voice and pick-by-light.

Barcodes must be scanned at various work steps to ensure traceability and achieve transparency in order picking for, on the one hand, the customer, and on the other hand, internal control. When carrying out manual activities, the hand-held scanner must generally be put aside within the pick-by-scan method to carry out the activities with both hands. Afterwards, the hand-held scanner must be picked up again to confirm the respective work step with a barcode on the system side. Due to the integrated scanning system in the pick-by-vision method, the advantage of “hands-free” working plays a significant role and ensures more efficient work processes.

Eliminating the required picking times for the use of the hand-held scanner and the respective putting away of the hand-held scanner to fulfil the picking order increases the effect linearly. A scanner integrated into the system eliminates dead time and optimises time elements such as setup, search, and picking times. In practical tests, the setup time was reduced by 7%, the search time by 89%, and the picking time by 18%. Pick-by-vision makes it possible to transform non-value-added times into value-added times. This ensures an increase in efficiency in the order picking system and simultaneously provides the opportunity to process one’s order volume better, thus achieving a competitive advantage. The virtual data preparation also creates a high degree of flexibility for the employees. To avoid system failures, complete WLAN coverage in the warehouse environment is a mandatory prerequisite to avoid waiting times due to a lack of connectivity. External battery packs are also required, as the smart glasses’ battery life is insufficient to cover an entire work shift.

An increase in efficiency using smart glasses technology can be demonstrated using the designed scenario-based data model through a combination of literature and the results of the test series as well as the regression analysis. This result of a 25% increase in efficiency is in line with previous studies by [,]. However, to what extent do the employees accept this technology? To take this crucial additional aspect into account, in addition to the demonstrated increase in efficiency and realisation of RO1, RO2 must also be attained.

4.2. RO2: To Assess the Employees’ Acceptance Level of Using Smart Glasses in the Picking Process Without Concerns

4.2.1. Assessing the ‘Employee Acceptance Level’ of Using Smart Glasses

Interviews were conducted to explore human acceptance of smart glasses in order picking. Wearables should offer measurable value, for instance, regarding mobility or weight. Ideally, they should be imperceptible to the employee in the work process and integrate naturally []. However, ergonomics is not limited to the wearability of smart glasses but also to the ergonomics of the user interface. In addition to ergonomics, privacy protection and psychological stress [] also play a significant role.

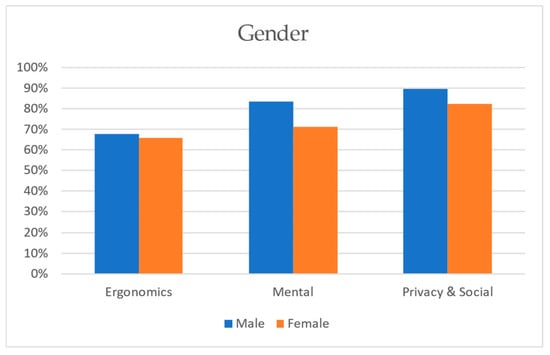

The general acceptance level of the sample is 77.56%. Within the category “ergonomics”, the acceptance is 67.07%, the category “mental” comes to an acceptance of 78.74%, and “Privacy & Social” comes to 86.88%. Within the three categories, women generally accept smart glasses less than men (Figure 5). The difference between female and male acceptance in the mean value amounts to 6.98%.

Figure 5.

Acceptance of smart glasses—gender-wise preferences.

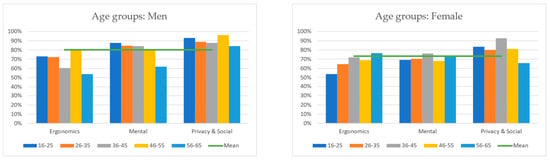

To obtain a more detailed insight into the human acceptance of smart glasses, the sample was divided according to five predefined age groups and analysed in combination with gender. In addition, the gender-dependent mean value was inserted (Figure 6). Within the category “ergonomics”, a contrasting tendency within the age groups is noticeable. A higher level of acceptance can be identified among the male participants in the interview than the female participants. Among men, the acceptance level decreases with increasing age. An outlier is the age group 46–55 years, which surprisingly shows the highest acceptance. Among women, the acceptance of smart glasses increases with age. For both men and women, acceptance in ergonomics is significantly below the average acceptance level of the sample, almost across all age groups. It becomes clear that the main problem of both genders and across almost all age groups lies within the category “ergonomics”. Women experience more problems, such as disorientation, due to the change between the real and virtual worlds.

Figure 6.

Acceptance of smart glasses—gender-wise and age-wise preferences.

4.2.2. Discussion of the Interview Results

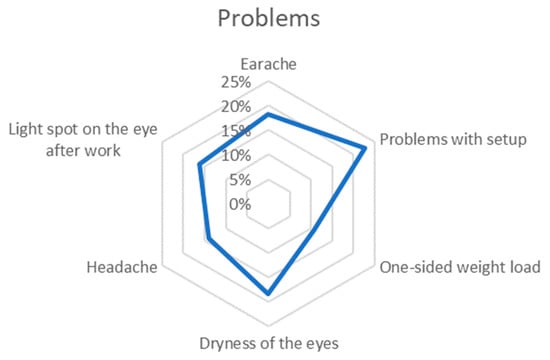

The core problem of the low human acceptance of smart glasses is ergonomics. The fact that the interviews were conducted directly with the employees made it possible to unearth the reasons for a firm rejection of the technology. By asking the ‘why’ question, various causes of rejection were identified (Figure 7). To interpret the graph correctly, it should be noted that the percentage refers to the sum of the problems mentioned and their frequency and is not related to the number of participants.

Figure 7.

Causes of the rejection of smart glasses.

The main reasons for the lack of acceptance of smart glasses are physical, as wearing discomfort plays a vital role in the acceptance of smart glasses. The main ergonomic problem is the setup of the smart glasses. For all test persons, the smart glasses require an external power supply, in which the interface to the warehouse management system (WMS) is also integrated. On the one hand, this additional device adds weight; on the other hand, a cable connection is required, which the employees perceive as annoying. In addition, when order picking is performed with a vehicle, a problem often arises when the cable becomes caught on the vehicle.

Many employees complain about the one-sided weight load of the smart glasses resulting from the additional accumulator integrated into the glasses’ frame. Subsequently, this leads to earaches and headaches after an 8 h shift. Focussing on the same spot (display) and restricting head movement lead to fatigue, headaches, and stress []. In addition, it is often mentioned that while working with smart glasses, the eye behind the screen dries out quickly. A light spot is often perceived in the eye after taking off the smart glasses. This phenomenon also occurs in eye health studies concerning smart glasses, where vision and visual field sensitivity are reduced [,]. However, sickness cannot be proven in the interviews conducted. Nevertheless, health impairments, especially regarding the eye, are a decisive factor in the human acceptance and use of smart glasses.

Due to the multitude of health problems resulting from smart glasses and an acceptance level of 77.56%, RO2 is realised with a conclusion that smart glasses do not experience high acceptance by employees and cannot be used in the picking process without concerns. These results comply with the findings of [,].

5. Conclusions

This research investigates the question: Can smart glasses be more effective and efficient than conventional order picking methods for logistics processes? To respond to this research question, two research objectives were defined in the study. These objectives were divided into ‘efficiency’, ‘economic viability or profitability’, and ‘human acceptance’.

5.1. Efficiency

Both the series of trials within a test environment and the series of trials within daily operations show a significant increase in efficiency. Reducing the throughput time of a picking order using pick-by-vision technology increases the picking system’s performance. Using smart glasses has resulted in a 23.3% increase in performance within the test environment. Evaluating the data from the daily business amounts to a 10% increase in performance.

The performance increase is due to a significant shortening of elementary process steps within order picking. The setup time is reduced by 7%, the search time by 89%, and the picking time by 18%. Accordingly, dead times due to the use of the hand-held scanner, such as reaching for the hand-held scanner or similar activities, are converted into value-adding times. A linear influence of the throughput time, primarily through the time elements search time and picking time, results in a more significant scale effect in pick-heavy environments. As a result of a statistical investigation through a regression analysis, a dependency of the throughput time on the variables “travel time”, “search time”, and “picking time” can be established, which further helped in the realisation of RO1.

5.2. Profitability

To strengthen competitiveness, the efficiency of logistics facilities must be increased. An increase in efficiency is based on increased quantity, speed, and quality with the same use of resources. The study finds that smart glasses strengthen competitiveness by increasing the possible processing volume. In addition, the throughput time is reduced, which means increased speed. Finally, the study finds that using smart glasses reduces the error rate, which leads to an increase in quality. Regarding CBA in the concrete example, the investment made to purchase the smart glasses leads to a cost savings of at least 2699.68 € per year and workplace according to the scenario-based data model. The increase in performance in the day-to-day business of 10% offers the possibility of achieving a competitive advantage, which further assisted in attaining RO1.

5.3. Human Acceptance

The study found that smart glasses achieved an acceptance level of 77.56% in the interview. The result is more favourable here, as it is strongly influenced by the “privacy & social” category. For men, the acceptance level decreases with increasing age. For women, the acceptance of smart glasses increases with age. The main concern for both genders is primarily in the category “ergonomics”, with an acceptance level of 67%.

The main reasons for not accepting smart glasses are physical aspects such as restricted vision or wearing comfort. Although the work facilitation through pick-by-vision contributes to increased efficiency, wearing comfort plays a vital role in accepting smart glasses. The main ergonomic problem is the setup of the smart glasses. Many employees complain about the one-sided weight load of the smart glasses, which leads to long-term earaches and headaches. Furthermore, many employees complain about the lack of comfort of the glasses, leading to physical problems such as ear pain, fatigue, or tension after an 8 h shift. In addition, the eye behind the lens dries out quickly. A light spot is often perceived in the eye after taking off the smart glasses. Health impairments, especially regarding the eye, are a decisive factor in the human acceptance and use of smart glasses.

Due to the many health problems resulting from smart glasses and an acceptance level of 77.56%, an alternative version of RO2: “Smart glasses experience a high acceptance by employees and can be used in the picking process without further concerns” must be rejected.

5.4. Contributions and Outlook

This work’s theoretical contribution is the documentation of a detailed scientific case study highlighting the increase in picking effectiveness and efficiency due to smart glasses, as mandated by [,,]. Moreover, this study thoroughly compares pick-by-vision with conventional pick-by-scan methods, highlighted as a gap by [,].

With the pick-by-vision solution for order picking, an innovative hybrid technology was brought to market that incorporates people and their abilities into a warehouse environment that is becoming more digital []. With their cognitive abilities and flexibility, they are gaining a firm place in Industry 4.0 and thus remain an essential factor in successfully implementing intralogistics, even in this networked world. Smart glasses make a significant contribution to the digitalisation of logistics work processes.

However, giving a fundamental action recommendation is difficult for the following reasons: There is an increase in efficiency and the associated economic added value versus the employees’ lack of acceptance and health impairments. Smart glasses and hands-free order picking are target-orientated concepts that make order picking more effective and efficient; however, ergonomic adjustments are needed to reduce health impairments.

The basic idea of changing order picking so that existing dead times are transformed into value-creating times is decisive to remain competitive in the long term and increase competitiveness. To strengthen competitiveness, the efficiency of the logistics facilities must, therefore, be increased in terms of quantity, speed, and quality with the same use of resources. Currently, the use of smart glasses in order picking requires a trade-off between efficiency and human acceptance. Human acceptance could be increased through motivation, consultation, and monetary incentives such as offering profit sharing to the order pickers in the generated added value and involving employees in improving the design and functionality of smart glasses []. They further suggested encouraging employees with high technology affinity to become champions for creating awareness regarding this new technology []. However, it would be better to eliminate the criticisms of the technology by exploring further development. Considering both economic advantages and health impairments, implementing the smart glasses technology within order picking processes can be recommended at the current state of technical development.

It is recommended that practitioners prioritise the collaboration between ergonomic specialists and technology developers to improve the smart glasses’ comfort and design. This partnership may result in more user-friendly designs that make it more pleasant for employees to utilise them for extended periods []. Additionally, it is recommended that organisations consider continuous improvement activities, utilising smart glasses to boost competitiveness and optimise logistics procedures. Moreover, supply chain decision-makers should develop practical and technical guidelines and procedures for smoothly implementing this technology in their warehouses. The study’s findings regarding the beneficial effects on profitability and efficiency point to the possibility of a broader application in logistics operations.

5.5. Limitations and Further Research

The quantitative data collection of the picking process times in only one company is a limitation of the work. An increase in the sample size, considering multiple companies, can provide further insights into the influence of smart glasses on the order picking process. A representative statement is nevertheless possible. However, an increase in the sample size would provide a better overall picture of the population of all logistics companies with smart glasses in use. Additionally, it is essential to mention that AR technology and smart glasses paired with industrial environments are still in the early stages of development. On the one hand, the glasses must still be sufficiently robust in many situations. On the other hand, technologies such as WLAN and Bluetooth need to be more stable due to interactions, bearing structures, and environmental influences.

For further investigations, an expansion of the study on human acceptance of smart glasses is recommended via a suitable theoretical lens of TAM, UTAUT2, and technology diffusion theory, in addition to an increase in the sample size. It may be possible to include company doctors in the study to objectify the subjectivity of the statements. Future studies should examine the use of smart glasses at real workplaces with the employees working there to derive recommendations for action for the use of smart glasses at the workplace and estimate long-term effects on efficiency and health through the use. Scholars are urged to carry out comprehensive studies on the health risks related to smart glasses, with a particular emphasis on ergonomic issues. These investigations can offer insightful information on possible improvements to the design or substitutions.

Author Contributions

Conceptualization, M.E.; Methodology, M.E. and M.A.; Validation, M.A. and D.M.Z.I.; Analysis, M.E.; Supervision, D.M.Z.I.; Review and editing, R.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The researchers could not obtain written consent from the participants to make the data for this research available for further research.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Figure A1.

Order picking process.

Appendix B. Order Picking Scenarios

| Picking Positions: 1 | Pick-by-Scan (PbS) | Pick-by-Vision (PbV) | Difference PbS vs. PbV | Efficiency Increase |

| Picking quantity: 3 | [sec] | [sec] | [sec] | [%] |

| Setup Time per Order | 30.5 | 28.42 | −2.08 | 7% |

| Travel Time per Pick Location | 23.05 | 23.05 | 0 | 0% |

| Search Time per Pick Location | 5.75 | 3.05 | −2.71 | 89% |

| Picking Time per Pick | 23.04 | 19.56 | −3.48 | 18% |

| Outbound Travel Time per Order | 40.77 | 40.77 | 0 | 0% |

| Waiting Time per Order | 34.27 | 34.27 | 0 | 0% |

| Throughput time | 157.38 | 149.11 | −8.27 | 6% |

| Picking positions: 2 | Pick-by-Scan (PbS) | Pick-by-Vision (PbV) | Difference PbS vs. PbV | Efficiency increase |

| Picking quantity: 6 | [sec] | [sec] | [sec] | [%] |

| Setup Time per Order | 30.5 | 28.42 | −2.08 | 7% |

| Travel Time per Pick Location | 46.09 | 46.09 | 0 | 0% |

| Search Time per Pick Location | 11.50 | 6.09 | −5.41 | 89% |

| Picking Time per Pick | 46.08 | 39.12 | −6.96 | 18% |

| Outbound Travel Time per Order | 40.77 | 40.77 | 0 | 0% |

| Waiting Time per Order | 34.27 | 34.27 | 0 | 0% |

| Throughput time | 209.22 | 194.77 | −14.46 | 7% |

| Picking positions: 3 | Pick-by-Scan (PbS) | Pick-by-Vision (PbV) | Difference PbS vs. PbV | Efficiency increase |

| Picking quantity: 9 | [sec] | [sec] | [sec] | [%] |

| Setup Time per Order | 30.5 | 28.42 | −2.08 | 7% |

| Travel Time per Pick Location | 69.14 | 69.14 | 0 | 0% |

| Search Time per Pick Location | 17.26 | 9.14 | −8.12 | 89% |

| Picking Time per Pick | 69.12 | 58.68 | −10.44 | 18% |

| Outbound Travel Time per Order | 40.77 | 40.77 | 0 | 0% |

| Waiting Time per Order | 34.27 | 34.27 | 0 | 0% |

| Throughput time | 261.06 | 240.42 | −20.64 | 9% |

| Picking positions: 4 | Pick-by-Scan (PbS) | Pick-by-Vision (PbV) | Difference PbS vs. PbV | Efficiency increase |

| Picking quantity: 12 | [sec] | [sec] | [sec] | [%] |

| Setup Time per Order | 30.5 | 28.42 | −2.08 | 7% |

| Travel Time per Pick Location | 92.19 | 92.19 | 0 | 0% |

| Search Time per Pick Location | 23.01 | 12.19 | −10.82 | 89% |

| Picking Time per Pick | 92.16 | 78.24 | −13.92 | 18% |

| Outbound Travel Time per Order | 40.77 | 40.77 | 0 | 0% |

| Waiting Time per Order | 34.27 | 34.27 | 0 | 0% |

| Throughput time | 312.90 | 286.07 | −26.83 | 9% |

| Picking positions: 5 | Pick-by-Scan (PbS) | Pick-by-Vision (PbV) | Difference PbS vs. PbV | Efficiency increase |

| Picking quantity: 15 | [sec] | [sec] | [sec] | [%] |

| Setup Time per Order | 30.5 | 28.42 | −2.08 | 7% |

| Travel Time per Pick Location | 115.23 | 115.23 | 0 | 0% |

| Search Time per Pick Location | 28.76 | 18.28 | −13.53 | 89% |

| Picking Time per Pick | 115.20 | 117.36 | −17.40 | 18% |

| Outbound Travel Time per Order | 40.77 | 40.77 | 0 | 0% |

| Waiting Time per Order | 34.27 | 34.27 | 0 | 0% |

| Throughput time | 364.74 | 333.73 | −33.01 | 10% |

| Picking positions: 6 | Pick-by-Scan (PbS) | Pick-by-Vision (PbV) | Difference PbS vs. PbV | Efficiency increase |

| Picking quantity: 18 | [sec] | [sec] | [sec] | [%] |

| Setup Time per Order | 30.5 | 28.42 | −2.08 | 7% |

| Travel Time per Pick Location | 138.28 | 138.28 | 0 | 0% |

| Search Time per Pick Location | 34.51 | 18.28 | −16.24 | 89% |

| Picking Time per Pick | 138.24 | 117.36 | −20.88 | 18% |

| Outbound Travel Time per Order | 40.77 | 40.77 | 0 | 0% |

| Waiting Time per Order | 34.27 | 34.27 | 0 | 0% |

| Throughput time | 416.58 | 377.38 | −39.20 | 10% |

| Picking positions: 7 | Pick-by-Scan (PbS) | Pick-by-Vision (PbV) | Difference PbS vs. PbV | Efficiency increase |

| Picking quantity: 21 | [sec] | [sec] | [sec] | [%] |

| Setup Time per Order | 30.5 | 28.42 | −2.08 | 7% |

| Travel Time per Pick Location | 161.33 | 161.33 | 0 | 0% |

| Search Time per Pick Location | 40.27 | 21.32 | −18.94 | 89% |

| Picking Time per Pick | 161.28 | 136.92 | −24.36 | 18% |

| Outbound Travel Time per Order | 40.77 | 40.77 | 0 | 0% |

| Waiting Time per Order | 34.27 | 34.27 | 0 | 0% |

| Throughput time | 468.42 | 423.03 | −45.39 | 11% |

| Picking positions: 8 | Pick-by-Scan (PbS) | Pick-by-Vision (PbV) | Difference PbS vs. PbV | Efficiency increase |

| Picking quantity: 24 | [sec] | [sec] | [sec] | [%] |

| Setup Time per Order | 30.5 | 28.42 | −2.08 | 7% |

| Travel Time per Pick Location | 184.38 | 184.38 | 0 | 0% |

| Search Time per Pick Location | 46.02 | 24.37 | −21.65 | 89% |

| Picking Time per Pick | 184.32 | 156.48 | −27.84 | 18% |

| Outbound Travel Time per Order | 40.77 | 40.77 | 0 | 0% |

| Waiting Time per Order | 34.27 | 34.27 | 0 | 0% |

| Throughput time | 520.26 | 468.69 | −51.57 | 11% |

Appendix C. Scenario-Based Data Model—Increasing Efficiency Through Pick-by-Vision

| Number of Picks per Pick Location | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

| Pick Locations | ||||||||||||||||||||||||||

| Throughput time (PBS) in sec | 1 | 16,787.51 | 17,133.11 | 17,478.71 | 17,824.31 | 18,169.91 | 18,515.51 | 18,861.11 | 19,206.71 | 19,552.31 | 19,897.91 | 20,243.51 | 20,589.11 | 20,934.71 | 21,280.31 | 21,625.91 | 21,971.51 | 22,317.11 | 22,662.71 | 23,008.31 | 23,353.91 | 23,699.51 | 24,045.11 | 24,390.71 | 24,736.31 | 25,081.91 |

| Throughput time PBV in sec | 16,519.78 | 16,813.18 | 17,106.58 | 17,399.98 | 17,693.38 | 17,986.78 | 18,280.18 | 18,573.58 | 18,866.98 | 19,160.38 | 19,453.78 | 19,747.18 | 20,040.58 | 20,333.98 | 20,627.38 | 20,920.78 | 21,214.18 | 21,507.58 | 21,800.98 | 22,094.38 | 22,387.78 | 22,681.18 | 22,974.58 | 23,267.98 | 23,561.38 | |

| Difference in % | 1.6% | 1.9% | 2.2% | 2.4% | 2.7% | 2.9% | 3.2% | 3.4% | 3.6% | 3.8% | 4.1% | 4.3% | 4.5% | 4.7% | 4.8% | 5.0% | 5.2% | 5.4% | 5.5% | 5.7% | 5.9% | 6.0% | 6.2% | 6.3% | 6.5% | |

| Throughput time (PBS) in sec | 2 | 17,391.96 | 18,083.16 | 18,774.36 | 19,465.56 | 20,156.76 | 20,847.96 | 21,539.16 | 22,230.36 | 22,921.56 | 23,612.76 | 24,303.96 | 24,995.16 | 25,686.36 | 26,377.56 | 27,068.76 | 27,759.96 | 28,451.16 | 29,142.36 | 29,833.56 | 30,524.76 | 31,215.96 | 31,907.16 | 32,598.36 | 33,289.56 | 33,980.76 |

| Throughput time PBV in sec | 16,950.27 | 17,537.07 | 18,123.87 | 18,710.67 | 19,297.47 | 19,884.27 | 20,471.07 | 21,057.87 | 21,644.67 | 22,231.47 | 22,818.27 | 23,405.07 | 23,991.87 | 24,578.67 | 25,165.47 | 25,752.27 | 26,339.07 | 26,925.87 | 27,512.67 | 28,099.47 | 28,686.27 | 29,273.07 | 29,859.87 | 30,446.67 | 31,033.47 | |

| Difference in % | 2.6% | 3.1% | 3.6% | 4.0% | 4.5% | 4.8% | 5.2% | 5.6% | 5.9% | 6.2% | 6.5% | 6.8% | 7.1% | 7.3% | 7.6% | 7.8% | 8.0% | 8.2% | 8.4% | 8.6% | 8.8% | 9.0% | 9.2% | 9.3% | 9.5% | |

| Throughput time (PBS) in sec | 3 | 17,996.42 | 19,033.22 | 20,070.02 | 21,106.82 | 22,143.62 | 23,180.42 | 24,217.22 | 25,254.02 | 26,290.82 | 27,327.62 | 28,364.42 | 29,401.22 | 30,438.02 | 31,474.82 | 32,511.62 | 33,548.42 | 34,585.22 | 35,622.02 | 36,658.82 | 37,695.62 | 38,732.42 | 39,769.22 | 40,806.02 | 41,842.82 | 42,879.62 |

| Throughput time PBV in sec | 17,380.75 | 18,260.95 | 19,141.15 | 20,021.35 | 20,901.55 | 21,781.75 | 22,661.95 | 23,542.15 | 24,422.35 | 25,302.55 | 26,182.75 | 27,062.95 | 27,943.15 | 28,823.35 | 29,703.55 | 30,583.75 | 31,463.95 | 32,344.15 | 33,224.35 | 34,104.55 | 34,984.75 | 35,864.95 | 36,745.15 | 37,625.35 | 38,505.55 | |

| Difference in % | 3.5% | 4.2% | 4.9% | 5.4% | 5.9% | 6.4% | 6.9% | 7.3% | 7.7% | 8.0% | 8.3% | 8.6% | 8.9% | 9.2% | 9.5% | 9.7% | 9.9% | 10.1% | 10.3% | 10.5% | 10.7% | 10.9% | 11.1% | 11.2% | 11.4% | |

| Throughput time (PBS) in sec | 4 | 18,600.88 | 19,983.28 | 21,365.68 | 22,748.08 | 24,130.48 | 25,512.88 | 26,895.28 | 28,277.68 | 29,660.08 | 31,042.48 | 32,424.88 | 33,807.28 | 35,189.68 | 36,572.08 | 37,954.48 | 39,336.88 | 40,719.28 | 42,101.68 | 43,484.08 | 44,866.48 | 46,248.88 | 47,631.28 | 49,013.68 | 50,396.08 | 51,778.48 |

| Throughput time PBV in sec | 17,811.23 | 18,984.83 | 20,158.43 | 21,332.03 | 22,505.63 | 23,679.23 | 24,852.83 | 26,026.43 | 27,200.03 | 28,373.63 | 29,547.23 | 30,720.83 | 31,894.43 | 33,068.03 | 34,241.63 | 35,415.23 | 36,588.83 | 37,762.43 | 38,936.03 | 40,109.63 | 41,283.23 | 42,456.83 | 43,630.43 | 44,804.03 | 45,977.63 | |

| Difference in % | 4.4% | 5.3% | 6.0% | 6.6% | 7.2% | 7.7% | 8.2% | 8.6% | 9.0% | 9.4% | 9.7% | 10.0% | 10.3% | 10.6% | 10.8% | 11.1% | 11.3% | 11.5% | 11.7% | 11.9% | 12.0% | 12.2% | 12.3% | 12.5% | 12.6% | |

| Throughput time (PBS) in sec | 5 | 19,205.34 | 20,933.34 | 22,661.34 | 24,389.34 | 26,117.34 | 27,845.34 | 29,573.34 | 31,301.34 | 33,029.34 | 34,757.34 | 36,485.34 | 38,213.34 | 39,941.34 | 41,669.34 | 43,397.34 | 45,125.34 | 46,853.34 | 48,581.34 | 50,309.34 | 52,037.34 | 53,765.34 | 55,493.34 | 57,221.34 | 58,949.34 | 60,677.34 |

| Throughput time PBV in sec | 18,241.72 | 19,708.72 | 21,175.72 | 22,642.72 | 24,109.72 | 25,576.72 | 27,043.72 | 28,510.72 | 29,977.72 | 31,444.72 | 32,911.72 | 34,378.72 | 35,845.72 | 37,312.72 | 38,779.72 | 40,246.72 | 41,713.72 | 43,180.72 | 44,647.72 | 46,114.72 | 47,581.72 | 49,048.72 | 50,515.72 | 51,982.72 | 53,449.72 | |

| Difference in % | 5.3% | 6.2% | 7.0% | 7.7% | 8.3% | 8.9% | 9.4% | 9.8% | 10.2% | 10.5% | 10.9% | 11.2% | 11.4% | 11.7% | 11.9% | 12.1% | 12.3% | 12.5% | 12.7% | 12.8% | 13.0% | 13.1% | 13.3% | 13.4% | 13.5% | |

| Throughput time (PBS) in sec | 6 | 19,809.79 | 21,883.39 | 23,956.99 | 26,030.59 | 28,104.19 | 30,177.79 | 32,251.39 | 34,324.99 | 36,398.59 | 38,472.19 | 40,545.79 | 42,619.39 | 44,692.99 | 46,766.59 | 48,840.19 | 50,913.79 | 52,987.39 | 55,060.99 | 57,134.59 | 59,208.19 | 61,281.79 | 63,355.39 | 65,428.99 | 67,502.59 | 69,576.19 |

| Throughput time PBV in sec | 18,672.20 | 20,432.60 | 22,193.00 | 23,953.40 | 25,713.80 | 27,474.20 | 29,234.60 | 30,995.00 | 32,755.40 | 34,515.80 | 36,276.20 | 38,036.60 | 39,797.00 | 41,557.40 | 43,317.80 | 45,078.20 | 46,838.60 | 48,599.00 | 50,359.40 | 52,119.80 | 53,880.20 | 55,640.60 | 57,401.00 | 59,161.40 | 60,921.80 | |

| Difference in % | 6.1% | 7.1% | 7.9% | 8.7% | 9.3% | 9.8% | 10.3% | 10.7% | 11.1% | 11.5% | 11.8% | 12.0% | 12.3% | 12.5% | 12.7% | 12.9% | 13.1% | 13.3% | 13.5% | 13.6% | 13.7% | 13.9% | 14.0% | 14.1% | 14.2% | |

| Throughput time (PBS) in sec | 7 | 20,414.25 | 22,833.45 | 25,252.65 | 27,671.85 | 30,091.05 | 32,510.25 | 34,929.45 | 37,348.65 | 39,767.85 | 42,187.05 | 44,606.25 | 47,025.45 | 49,444.65 | 51,863.85 | 54,283.05 | 56,702.25 | 59,121.45 | 61,540.65 | 63,959.85 | 66,379.05 | 68,798.25 | 71,217.45 | 73,636.65 | 76,055.85 | 78,475.05 |

| Throughput time PBV in sec | 19,102.68 | 21,156.48 | 23,210.28 | 25,264.08 | 27,317.88 | 29,371.68 | 31,425.48 | 33,479.28 | 35,533.08 | 37,586.88 | 39,640.68 | 41,694.48 | 43,748.28 | 45,802.08 | 47,855.88 | 49,909.68 | 51,963.48 | 54,017.28 | 56,071.08 | 58,124.88 | 60,178.68 | 62,232.48 | 64,286.28 | 66,340.08 | 68,393.88 | |

| Difference in % | 6.9% | 7.9% | 8.8% | 9.5% | 10.2% | 10.7% | 11.2% | 11.6% | 11.9% | 12.2% | 12.5% | 12.8% | 13.0% | 13.2% | 13.4% | 13.6% | 13.8% | 13.9% | 14.1% | 14.2% | 14.3% | 14.4% | 14.5% | 14.6% | 14.7% | |

| Throughput time (PBS) in sec | 8 | 21,018.71 | 23,783.51 | 26,548.31 | 29,313.11 | 32,077.91 | 34,842.71 | 37,607.51 | 40,372.31 | 43,137.11 | 45,901.91 | 48,666.71 | 51,431.51 | 54,196.31 | 56,961.11 | 59,725.91 | 62,490.71 | 65,255.51 | 68,020.31 | 70,785.11 | 73,549.91 | 76,314.71 | 79,079.51 | 81,844.31 | 84,609.11 | 87,373.91 |

| Throughput time PBV in sec | 19,533.17 | 21,880.37 | 24,227.57 | 26,574.77 | 28,921.97 | 31,269.17 | 33,616.37 | 35,963.57 | 38,310.77 | 40,657.97 | 43,005.17 | 45,352.37 | 47,699.57 | 50,046.77 | 52,393.97 | 54,741.17 | 57,088.37 | 59,435.57 | 61,782.77 | 64,129.97 | 66,477.17 | 68,824.37 | 71,171.57 | 73,518.77 | 75,865.97 | |

| Difference in % | 7.6% | 8.7% | 9.6% | 10.3% | 10.9% | 11.4% | 11.9% | 12.3% | 12.6% | 12.9% | 13.2% | 13.4% | 13.6% | 13.8% | 14.0% | 14.2% | 14.3% | 14.4% | 14.6% | 14.7% | 14.8% | 14.9% | 15.0% | 15.1% | 15.2% | |

| Throughput time (PBS) in sec | 9 | 21,623.16 | 24,733.56 | 27,843.96 | 30,954.36 | 34,064.76 | 37,175.16 | 40,285.56 | 43,395.96 | 46,506.36 | 49,616.76 | 52,727.16 | 55,837.56 | 58,947.96 | 62,058.36 | 65,168.76 | 68,279.16 | 71,389.56 | 74,499.96 | 77,610.36 | 80,720.76 | 83,831.16 | 86,941.56 | 90,051.96 | 93,162.36 | 96,272.76 |

| Throughput time PBV in sec | 19,963.65 | 22,604.25 | 25,244.85 | 27,885.45 | 30,526.05 | 33,166.65 | 35,807.25 | 38,447.85 | 41,088.45 | 43,729.05 | 46,369.65 | 49,010.25 | 51,650.85 | 54,291.45 | 56,932.05 | 59,572.65 | 62,213.25 | 64,853.85 | 67,494.45 | 70,135.05 | 72,775.65 | 75,416.25 | 78,056.85 | 80,697.45 | 83,338.05 | |

| Difference in % | 8.3% | 9.4% | 10.3% | 11.0% | 11.6% | 12.1% | 12.5% | 12.9% | 13.2% | 13.5% | 13.7% | 13.9% | 14.1% | 14.3% | 14.5% | 14.6% | 14.7% | 14.9% | 15.0% | 15.1% | 15.2% | 15.3% | 15.4% | 15.4% | 15.5% | |

| Throughput time (PBS) in sec | 10 | 22,227.62 | 25,683.62 | 29,139.62 | 32,595.62 | 36,051.62 | 39,507.62 | 42,963.62 | 46,419.62 | 49,875.62 | 53,331.62 | 56,787.62 | 60,243.62 | 63,699.62 | 67,155.62 | 70,611.62 | 74,067.62 | 77,523.62 | 80,979.62 | 84,435.62 | 87,891.62 | 91,347.62 | 94,803.62 | 98,259.62 | 101,715.62 | 105,171.62 |

| Throughput time PBV in sec | 20,394.13 | 23,328.13 | 26,262.13 | 29,196.13 | 32,130.13 | 35,064.13 | 37,998.13 | 40,932.13 | 43,866.13 | 46,800.13 | 49,734.13 | 52,668.13 | 55,602.13 | 58,536.13 | 61,470.13 | 64,404.13 | 67,338.13 | 70,272.13 | 73,206.13 | 76,140.13 | 79,074.13 | 82,008.13 | 84,942.13 | 87,876.13 | 90,810.13 | |

| Difference in % | 9.0% | 10.1% | 11.0% | 11.6% | 12.2% | 12.7% | 13.1% | 13.4% | 13.7% | 14.0% | 14.2% | 14.4% | 14.6% | 14.7% | 14.9% | 15.0% | 15.1% | 15.2% | 15.3% | 15.4% | 15.5% | 15.6% | 15.7% | 15.7% | 15.8% | |

| Notes: Working hours per day, 7.48; Working time in sec, 26,928; Working days per year, 230. Literature values: Travel time, 50%; Other, 5%; Orders per employee/day, 45. | ||||||||||||||||||||||||||

References

- Ten Hompel, M.; Schmidt, T. Warehouse Management, 4th ed.; Springer: Berlin, Germany, 2010. [Google Scholar]

- Elbert, R.; Franzke, T.; Glock, C.; Grosse, E. The effects of human behavior on the efficiency of routing policies in order picking. Comput. Ind. Eng. 2017, 111, 537–551. [Google Scholar] [CrossRef]

- Ten Hompel, M.; Schmidt, T.; Dregger, J. Materialflusssysteme: Förder- und Lagertechnik, 4th ed.; Springer: Berlin, Germany, 2018. [Google Scholar]

- Petersen, C. An evaluation of order picking routeing policies. Int. J. Oper. Prod. Manag. 1997, 11, 1098–1111. [Google Scholar] [CrossRef]

- Lu, W.; McFarlane, D.; Giannikas, V.; Zhang, Q. An algorithm for dynamic order-picking in warehouse operations. Eur. J. Oper. Res. 2016, 248, 107–122. [Google Scholar] [CrossRef]

- Uckelmann, D. A Definition Approach to Smart Logistics. In Next Generation Teletraffic and Wired/Wireless Advanced Networking; Balandin, S., Moltchanov, D., Koucheryavy, Y., Eds.; Springer: Heidelberg, Germany, 2008; pp. 273–284. [Google Scholar]

- TUP-Redaktion. Kommissionierung–Definition und Kommissioniermethoden. 2013. Available online: https://logistikknowhow.com/kommissionierung/kommissionierung-grundlagen/ (accessed on 8 June 2022).

- Glockner, H.; Jannek, K.; Mahn, J.; Theis, B. Augmented Reality in Logistics-Changing the Way We See Logistics—A DHL Perspective; DHL Trend Research: Troisdorf, Germany, 2019. [Google Scholar]

- Niemöller, C.; Metzger, D.; Fellmann, M.; Özcan, D.; Thomas, O. Shaping the future of mobile service support systems-ex-ante evaluation of smart glasses in technical customer service processes. In Informatik 2016; Gesellschaft für Informatik e.V.: Bonn, Germany, 2016; pp. 753–767. [Google Scholar]

- Bechtle. SAP: Smarte Brillen optimieren Lagerlogistik. it&t Business 2016, 3, 27–28. [Google Scholar]

- Ernst, C.-P. The Drivers of Wearable Device Usage, 1st ed.; Springer International: Mainz, Germany, 2016. [Google Scholar]

- Kim, S.; Nussbaum, M.; Gabbard, J. Augmented reality “smart glasses” in the workplace: Industry perspectives and challenges for worker safety and health. IIE Trans. Occup. Ergon. Hum. Factors 2016, 4, 253–258. [Google Scholar] [CrossRef]

- Tita, B. Smart Glasses Get New Look on Factory Floor. 2015. Available online: https://www.wsj.com/articles/smart-glasses-get-new-look-on-factory-floor-1433301177 (accessed on 21 April 2022).

- Bal, M.; Vermeerbergen, L.; Benders, J. Putting head-worn displays to use for order picking: A most-similar comparative case study. Int. J. Logist. Manag. 2023, 34, 1475–1499. [Google Scholar] [CrossRef]

- Husár, J.; Knapčíková, L. Possibilities of using augmented reality in Warehouse Management: A study. Acta Logist. 2021, 8, 133–139. [Google Scholar] [CrossRef]

- Al-Maroof, R.; Alfaisal, A.; Salloum, S. Google glass adoption in the educational environment: A case study in the Gulf area. Educ. Inf. Technol. 2021, 26, 2477–2500. [Google Scholar] [CrossRef]

- Syberfeldt, A.; Danielsson, O.; Gustavsson, P. Augmented reality smart glasses in the smart factory: Product evaluation guidelines and review of available products. IEEE Access 2017, 5, 9118–9130. [Google Scholar] [CrossRef]

- Mecalux. Komissionieren mit Datenbrille: Eine neue Technologie für die Auftragszusammenstellung. 2022. Available online: https://www.mecalux.de/blog/kommissionieren-mit-datenbrille (accessed on 21 April 2022).

- Liu, M.; Ma, J.; Lin, L. Intelligent assembly system for mechanical products and key technology based on internet of things. J. Intell. Manuf. 2017, 28, 271–299. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.; Leong, G.; Treiblmaier, H. Potentials and challenges of augmented reality smart glasses in logistics and supply chain management: A systematic literature review. Int. J. Prod. Res. 2021, 59, 3747–3776. [Google Scholar] [CrossRef]

- Jumahat, S.; Sidhu, M.; Shah, S. A review on the positive implications of augmented reality pick-by-vision in warehouse management systems. Acta Logist. 2023, 10, 1–10. [Google Scholar] [CrossRef]

- Smith, E.; Strawderman, L.; Chander, H.; Smith, B. A comfort analysis of using smart glasses during “picking” and “putting” tasks. Int. J. Ind. Ergon. 2021, 83, 103–133. [Google Scholar] [CrossRef]

- Thomas, O.; Ickerott, I.; Berkemeier, L.; Werning, S.; Zobel, B.; Vogel, J.; Kaiser, C.; Mollen-Ungru, T.; Neumann, T. Glasshouse-Smart Glasses zur Unterstützung von Logistikdienstleistungen. In Smart Glasses-Augmented Reality zur Unterstützung von Logistikdienstleistungen; Thomas, O., Ickerott, I., Eds.; Springer: Osnabrück, Germany, 2020; pp. 2–18. [Google Scholar]

- Clausen, U.; Baudach, J.; Diekmann, D.; Goedicke, I.; Miodrag, Z.; Tesch, C.; Voll, R.; Winter, K.; Wohlgemuth, S. Efficiency in Logistics Facilities. In Efficiency and Logistics; Clausen, U., ten Hompel, M., Klumpp, M., Eds.; Springer: Dortmund, Germany, 2013; pp. 55–63. [Google Scholar]

- Banton, C. Efficiency. 2020. Available online: https://www.investopedia.com/terms/e/efficiency.asp (accessed on 22 April 2022).

- Clausen, U.; Hompel, M.; Klumpp, M. Efficiency and Logistics, 1st ed.; Springer: Wiesbaden, Germany, 2013. [Google Scholar]

- Statista. Definition Sekundärdaten. Available online: https://de.statista.com/statistik/lexikon/definition/120/sekundaerdaten/ (accessed on 23 April 2022).

- Chopra, S.; Meindl, P. Supply Chain Management -Strategy, Planning, and Operation-, 6th ed.; Pearson: New York, NY, USA, 2016. [Google Scholar]

- Günthner, W.A.; Blomeyer, N.; Reif, R.; Schedlbauer, M. Pick-by-Vision: Augmented Reality unterstützte Kommissionierung; fml–Lehrstuhl für Fördertechnik Materialfluss Logistik: Munich, Germany, 2009. [Google Scholar]

- Richards, G. Warehouse Management, 2nd ed.; Kogan Page: London, UK, 2014. [Google Scholar]

- Arnold, D.; Furmans, K. Materialfluss in Logistiksystemen, 7th ed.; Springer: Berlin, Germany, 2019. [Google Scholar]

- van Gils, T.; Ramaekers, K.; Caris, A.; de Koster, R. Designing efficient order picking systems by combining planning problems: State-of-the-art classification and review. Eur. J. Oper. Res. 2018, 267, 1–15. [Google Scholar] [CrossRef]

- Gudehus, T. Logistik: Grundlagen, Strategien, Anwendungen, 4th ed.; Springer: Berlin, Germany, 2010. [Google Scholar]

- Günthner, W.A.; Rammelmeier, T. Vermeidung von Kommissionierfehlern mit Pick-by-Vision; fml–Lehrstuhl für Fördertechnik Materialfluss Logistik: Munich, Germany, 2012. [Google Scholar]

- Schwerdtfeger, B. Pick-by-Vision: Bringing HMD-Based Augmented Reality into the Warehouse; Technische Universität München: Munich, Germany, 2009. [Google Scholar]

- Lolling, A. Analyse der Menschlichen Zuverlässigkeit; Shaker Verlag: Dortmund, Germany, 2003. [Google Scholar]

- Reif, R. Entwicklung und Evaluierung eines Augmented Reality Unterstützten Kommissioniersystems; Technischen Universität: München, Germany, 2009. [Google Scholar]

- Guo, A.; Starner, T.; Raghu, S.; Xie, X.; Ismail, S.; Luo, X.; Simoneau, J.; Gilliland, S.; Baumann, H.; Southern, C.; et al. A Comparison of Order Picking Assisted by Head-Up Display (HUD), Cart-Mounted Display (CMD), Light, and Paper Pick List. In Proceedings of the 2014 ACM International Symposium on Wearable Computers, Seattle, WA, USA, 13–17 September 2014; pp. 71–78. [Google Scholar]

- Göpfert, I.; Kersting, R. Organisation und Forschungsdesigns der Zukunftsforschung. In Logistik der Zukunft-Logistics for the Future; Göpfert, I., Ed.; Springer: Wiesbaden, Germany, 2017; pp. 7–27. [Google Scholar]

- Reif, R.; Günthner, W. Pick-by-vision: Augmented reality supported order picking. Vis. Comput. 2009, 25, 461–467. [Google Scholar] [CrossRef]

- Bendel, O. Gabler Wirtschaftslexikon. Available online: https://wirtschaftslexikon.gabler.de/definition/datenbrille-54021/version-384621 (accessed on 28 May 2022).

- Rauschnabel, P.; Ro, Y. Augmented reality smart glasses: An investigation of technology acceptance drivers. Int. J. Technol. Mark. 2016, 11, 123–148. [Google Scholar] [CrossRef]

- Sesay, A.; Steffen, J. Wearables as Augmentation Means: Conceptual Definition, Pathways, and Research Framework. Int. Conf. Syst. Sci. 2020, 53, 4559–4568. [Google Scholar]

- Nwazor, N.; Horsfall, O. Wearable Computing Technologies and their Applications. Glob. Sci. J. 2022, 10, 2392–2402. [Google Scholar]

- Hein, D.; Jodoin, J.; Rauschnabel, P.; Ivens, B. Are Wearables Good or Bad for Society? An Exploration of Societal Benefits, Risks and Consequences of Augmented Reality Smart Glasses; University of Bamberg: Bamberg, Germany, 2017. [Google Scholar]