Sustainable Supplier Selection Criteria for HVAC Manufacturing Firms: A Multi-Dimensional Perspective Using the Delphi–Fuzzy AHP Method

Abstract

1. Introduction

2. Literature Study

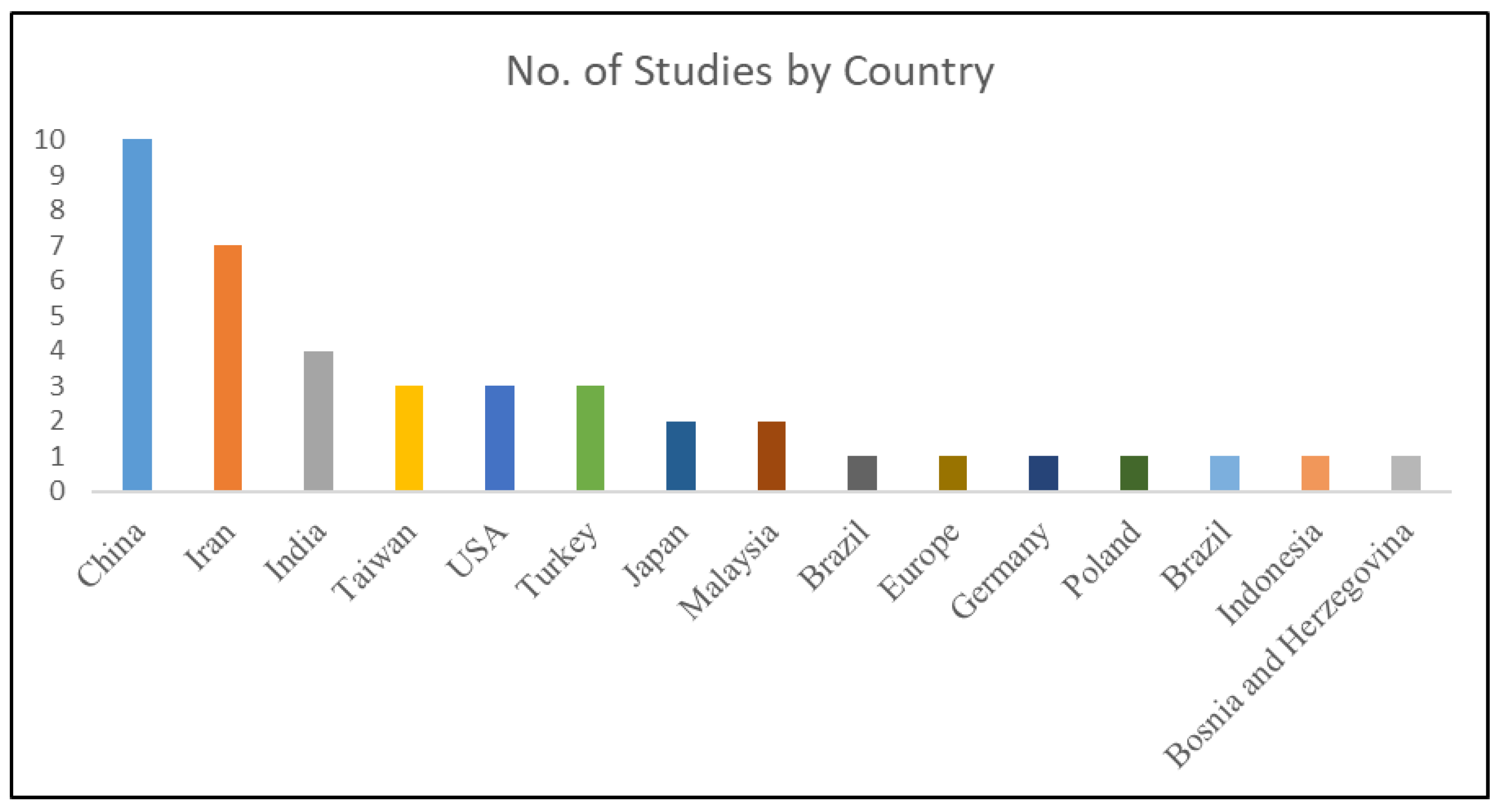

2.1. Literature Search Protocol

2.2. Literature Review

2.3. Research Gap and Novelty

3. Materials and Methods

- Identifying the factors studied for SSS: secondary study (literature review);

- Determination of critical factors for SSS for HVAC firms: Delphi technique study;

- Estimating relative preference weights of the critical factors for SSS: fuzzy AHP technique.

3.1. Secondary Study: Identifying the Factors Studied for the SSSP

3.2. Delphi Technique: Determination of Critical Factors for SSS for HVAC Firms

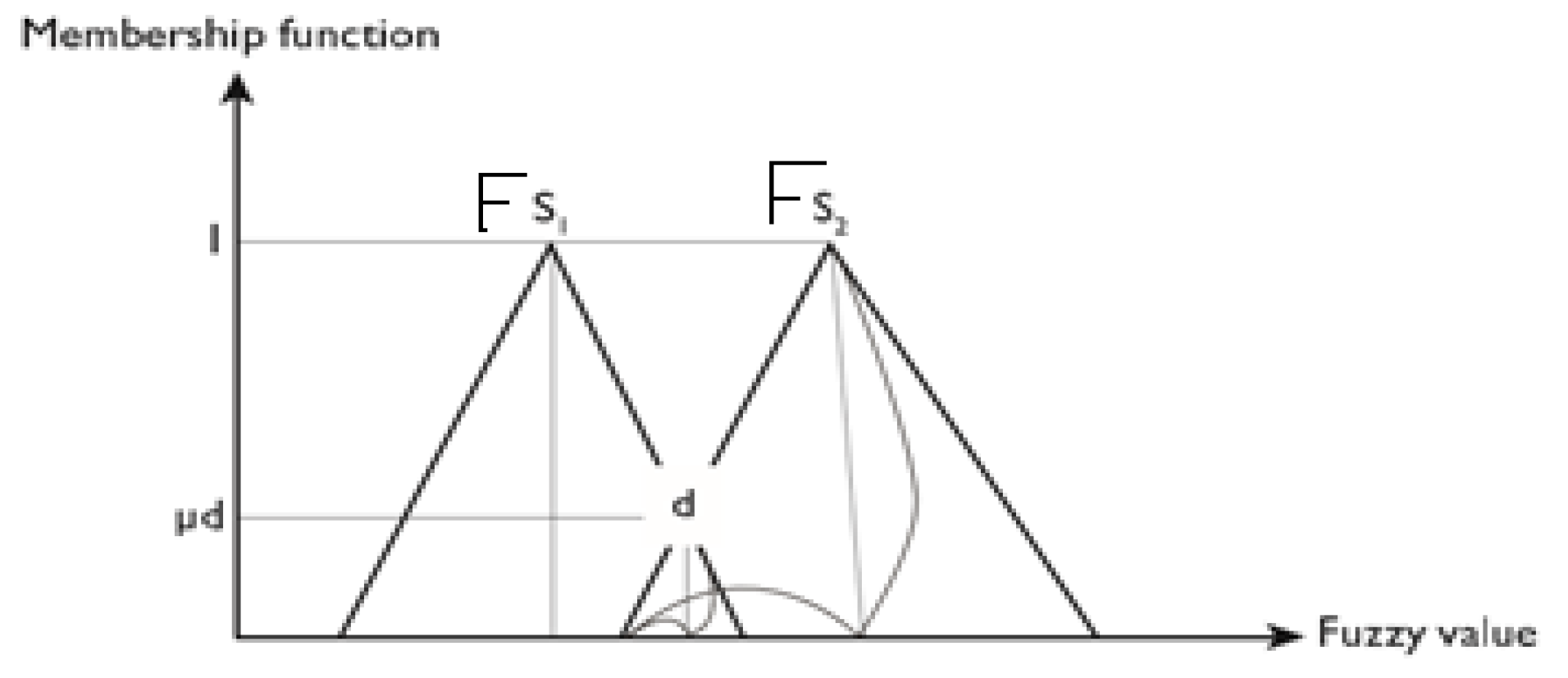

3.3. Fuzzy Analytical Hierarchy Process (AHP)

3.3.1. Calculation of Consistency Index

3.3.2. Global Weight and Ranks of the Sub-Factors

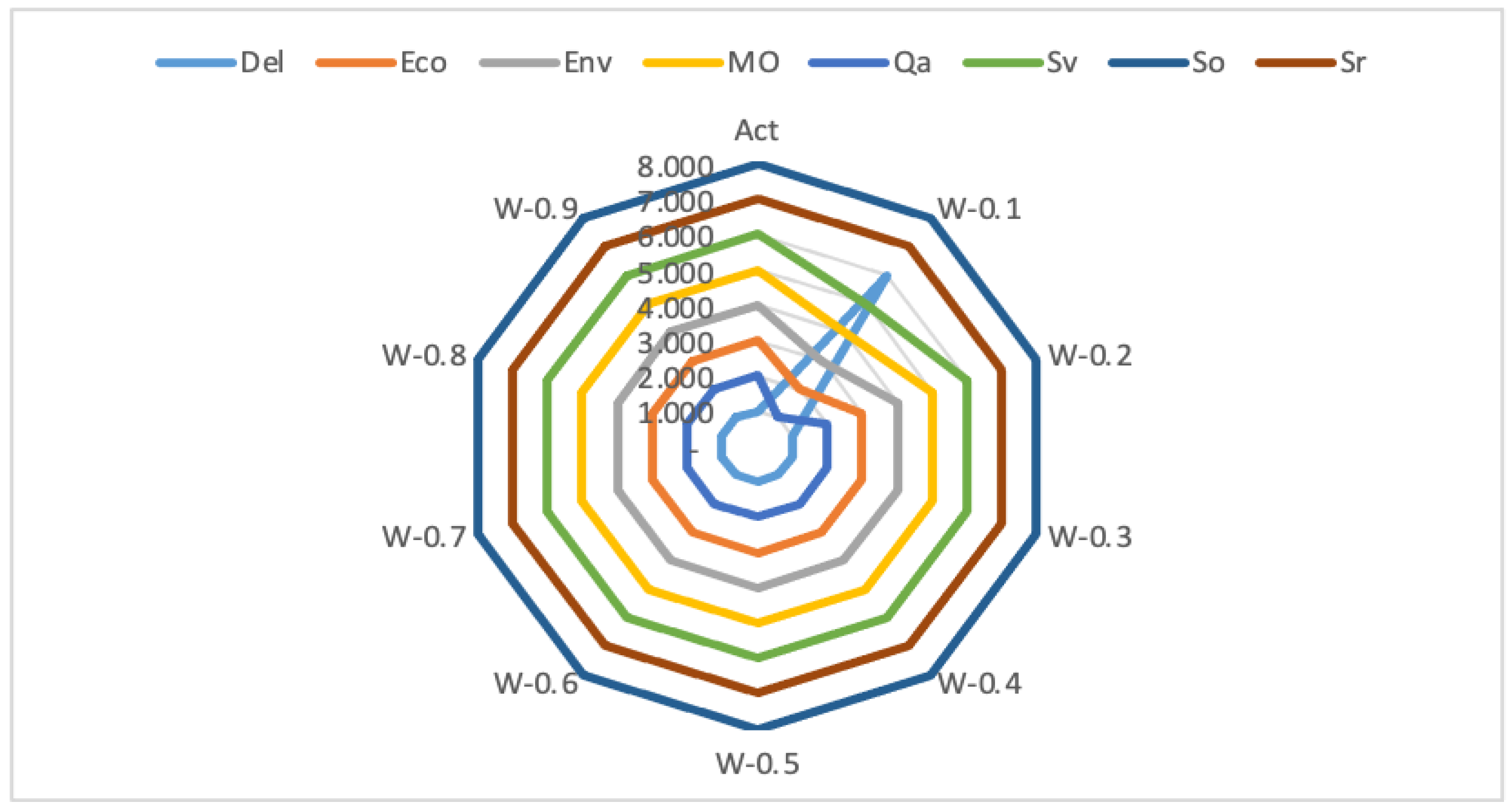

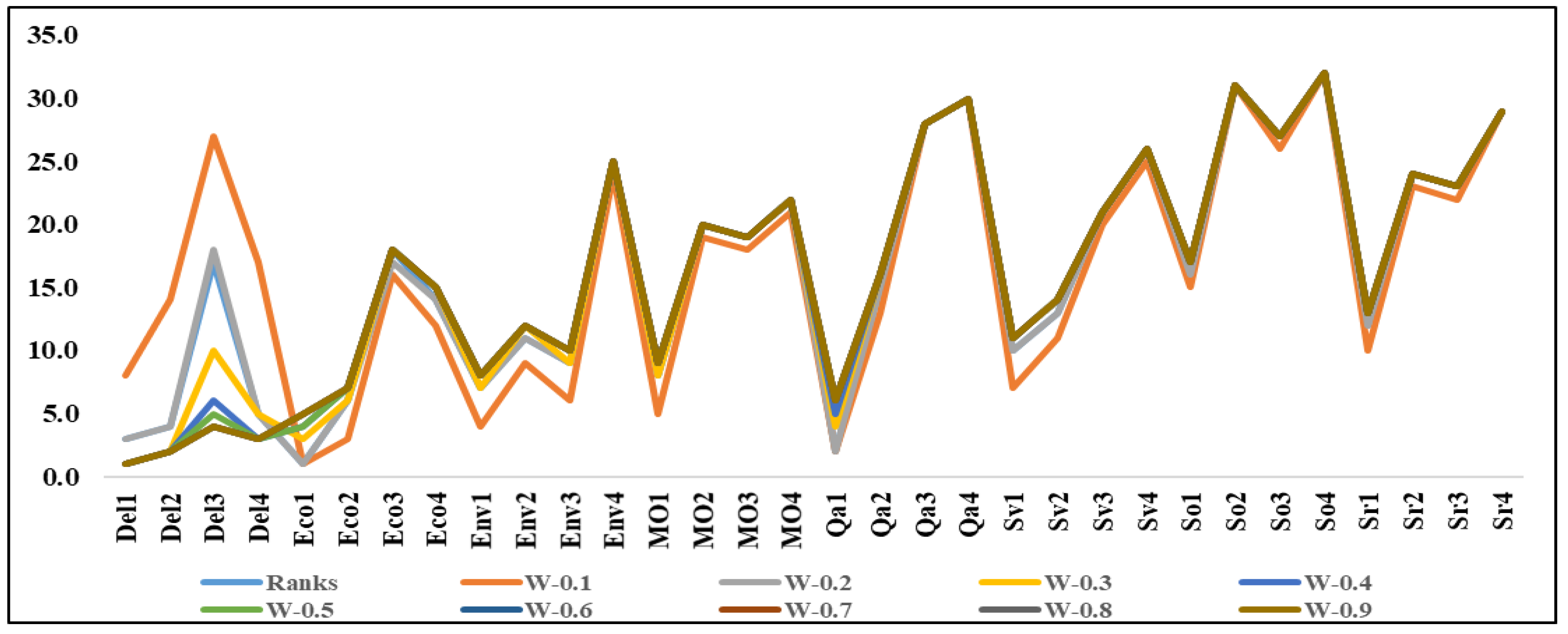

3.3.3. Sensitivity Analysis

4. Results and Discussion

5. Managerial and Practical Implications and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Factors | Mean | Count | COV | Factors | Mean | Count | COV |

|---|---|---|---|---|---|---|---|

| (Quality) | 4.48 | 22 | 0.19 | [Good reputation among industry] | 3.83 | 22 | 0.19 |

| [Ethical issues and legal compliance] | 4.48 | 22 | 0.16 | [Flexibility] | 3.78 | 22 | 0.19 |

| [On-time delivery] | 4.43 | 22 | 0.18 | [Pollution control] | 3.78 | 22 | 0.19 |

| [Long-term cooperation] | 4.39 | 22 | 0.18 | [Design of products to reuse] | 3.78 | 22 | 0.17 |

| [Reliability] | 4.35 | 22 | 0.19 | [Hazardous waste management] | 3.78 | 22 | 0.19 |

| [Mutual trust and easy communication] | 4.26 | 22 | 0.18 | [Staff training] | 3.78 | 22 | 0.18 |

| [Skilled and potential staff] | 4.26 | 22 | 0.18 | [Employee right and welfare] | 3.78 | 22 | 0.18 |

| [Attitude] | 4.26 | 22 | 0.18 | [Customer trade record] | 3.74 | 22 | 0.24 |

| [No error in product type and quantity] | 4.22 | 22 | 0.19 | [Environmental certifications] | 3.74 | 22 | 0.24 |

| [Fast reaction / responsiveness] | 4.22 | 22 | 0.19 | [Recyclable package] | 3.74 | 22 | 0.27 |

| [Financial stability] | 4.22 | 22 | 0.16 | [Designing energy efficient products] | 3.74 | 22 | 0.26 |

| [Technical support] | 4.17 | 22 | 0.17 | [Transportation cost] | 3.70 | 22 | 0.21 |

| [Production capacity] | 4.09 | 22 | 0.19 | [Development of culture and technology] | 3.70 | 22 | 0.21 |

| [Service and after-sales service] | 4.09 | 22 | 0.18 | [Utilizing eco-friendly and recyclable raw materials] | 3.70 | 22 | 0.24 |

| [Information disclosure] | 4.04 | 22 | 0.19 | [Green R&D and innovation] | 3.70 | 22 | 0.24 |

| [Performance history] | 4.04 | 22 | 0.19 | [Internal R&D and scientific expertise] | 3.65 | 22 | 0.21 |

| [Cost] | 4.00 | 22 | 0.16 | [Automation] | 3.57 | 22 | 0.25 |

| [Company background] | 4.00 | 22 | 0.19 | [Integration and partnership] | 3.57 | 22 | 0.20 |

| [Long durability (life)] | 4.00 | 22 | 0.16 | [Trained human resources] | 3.57 | 22 | 0.28 |

| [Low rejection / return rate] | 4.00 | 22 | 0.17 | [Designing products so that they are easily reusable and recyclable] | 3.57 | 22 | 0.30 |

| [Product development] | 4.00 | 22 | 0.19 | [Geographical location] | 3.52 | 22 | 0.22 |

| [Warranty/Insurance] | 3.96 | 22 | 0.19 | [Environmental and social responsibility] | 3.52 | 22 | 0.22 |

| [Developing supplier’s capabilities] | 3.96 | 22 | 0.19 | [Ability to collocate to buyers manufacturing side] | 3.52 | 22 | 0.24 |

| [Enhanced value to customers] | 3.96 | 22 | 0.19 | [Green operational efficiencies] | 3.52 | 22 | 0.22 |

| [Financial status of the company] | 3.91 | 22 | 0.17 | [Environmental management systems] | 3.43 | 22 | 0.30 |

| [Meeting minimum standards and requirements] | 3.91 | 22 | 0.19 | [Creating job opportunities] | 3.43 | 22 | 0.31 |

| [ISO certified] | 3.91 | 22 | 0.18 | [Carbon reduction initiatives] | 3.43 | 22 | 0.30 |

| [Provide sample before first ordering] | 3.91 | 22 | 0.18 | [Production cost] | 3.39 | 22 | 0.25 |

| [Confidence in a durable product] | 3.91 | 22 | 0.17 | [Reverse logistics] | 3.39 | 22 | 0.30 |

| [Reduced consumption of materials and energy through better design of products] | 3.91 | 22 | 0.16 | [CSR] | 3.39 | 22 | 0.29 |

| [Good communication system] | 3.87 | 22 | 0.18 | [Environmental cost] | 3.35 | 22 | 0.25 |

| [Good supplier relationship management (SRM)] | 3.87 | 22 | 0.18 | [N2 environmental commitment of the firm] | 3.30 | 22 | 0.32 |

| [Customer-friendly and environmental adoptability] | 3.87 | 22 | 0.17 | [Green operational practices] | 3.30 | 22 | 0.28 |

| [Product shelf life] | 3.87 | 22 | 0.16 | [Selecting supplier based on environmental criteria] | 3.30 | 22 | 0.31 |

| [Process integration] | 3.83 | 22 | 0.15 | [Green transportation] | 3.26 | 22 | 0.23 |

| [Strategic organization structure] | 3.83 | 22 | 0.19 | [Pressuring suppliers for green initiatives at their end] | 3.22 | 22 | 0.31 |

| [R&D investments] | 3.17 | 22 | 0.35 |

References

- Gligor, D. Birds of a feather: The impact of race on the supplier selection and evaluation process. Int. J. Prod. Econ. 2020, 230, 107802. [Google Scholar] [CrossRef]

- Nair, A.; Jayaram, J.; Das, A. Strategic purchasing participation, supplier selection, supplier evaluation and purchasing performance. Int. J. Prod. Res. 2015, 53, 6263–6278. [Google Scholar] [CrossRef]

- Gao, H.; Ju, Y.; Gonzalez, E.D.S.; Zhang, W. Green supplier selection in electronics manufacturing: An approach based on consensus decision making. J. Clean. Prod. 2020, 245, 118781. [Google Scholar] [CrossRef]

- Konys, A. Methods supporting supplier selection processes—Knowledge-based approach. Procedia Comput. Sci. 2019, 159, 1629–1641. [Google Scholar] [CrossRef]

- Ahmadi, H.B.; Lo, H.-W.; Gupta, H.; Kusi-Sarpong, S.; Liou, J.J. An integrated model for selecting suppliers on the basis of sustainability innovation. J. Clean. Prod. 2020, 277, 123261. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Gupta, H.; Sarkis, J. A supply chain sustainability innovation framework and evaluation methodology. Int. J. Prod. Res. 2018, 57, 1990–2008. [Google Scholar] [CrossRef]

- Jones, J.; de Zubielqui, G.C. Doing well by doing good: A study of university-industry interactions, innovationess and firm performance in sustainability-oriented Australian SMEs. Technol. Forecast. Soc. Chang. 2017, 123, 262–270. [Google Scholar] [CrossRef]

- Shao, Y.; Barnes, D.; Wu, C. External R&D Supplier Evaluation and Selection: A Three-Stage Integrated Funnel Model. IEEE Trans. Eng. Manag. 2024, 71, 4101–4115. [Google Scholar] [CrossRef]

- Schramm, V.B.; Cabral, L.P.B.; Schramm, F. Approaches for supporting sustainable supplier selection—A literature review. J. Clean. Prod. 2020, 273, 123089. [Google Scholar] [CrossRef]

- Mina, H.; Kannan, D.; Gholami-Zanjani, S.M.; Biuki, M. Transition towards circular supplier selection in petrochemical industry: A hybrid approach to achieve sustainable development goals. J. Clean. Prod. 2020, 286, 125273. [Google Scholar] [CrossRef]

- Saputro, T.E.; Rosiani, T.Y.; Mubin, A.; Dewi, S.K.; Baroto, T. Green supplier selection under supply risks using novel integrated fuzzy multi-criteria decision-making techniques. J. Clean. Prod. 2024, 449, 141788. [Google Scholar] [CrossRef]

- Ecer, F.; Torkayesh, A.E. A Stratified Fuzzy Decision-Making Approach for Sustainable Circular Supplier Selection. IEEE Trans. Eng. Manag. 2022, 71, 1130–1144. [Google Scholar] [CrossRef]

- Bruck, B.; Iori, M.; Magni, C.A.; Pretolani, D.; Vezzali, D. Supplier selection for global service providers: A decision support system. Inf. Syst. Oper. Res. 2024, 1–28. [Google Scholar] [CrossRef]

- Aditi; Kannan, D.; Darbari, J.D.; Jha, P.C. Sustainable supplier selection model with a trade-off between supplier development and supplier switching. Ann. Oper. Res. 2022, 331, 351–392. [Google Scholar] [CrossRef]

- Mishra, A.R.; Rani, P.; Pamucar, D.; Saha, A. An integrated Pythagorean fuzzy fairly operator-based MARCOS method for solving the sustainable circular supplier selection problem. Ann. Oper. Res. 2023, 1–42. [Google Scholar] [CrossRef]

- Sreenivasan, A.; Shah, B.; Suresh, M. Modeling of factors affecting supplier selection on start-ups during frequent pandemic episodes like COVID-19. Benchmarking Int. J. 2022, 30, 2891–2920. [Google Scholar] [CrossRef]

- Meena, P.L.; Katiyar, R.; Kumar, G. Supplier performance and selection from sustainable supply chain performance perspective. Int. J. Prod. Perform. Manag. 2022, 72, 2420–2445. [Google Scholar] [CrossRef]

- Ghosh, S.; Mandal, M.C.; Ray, A. Strategic sourcing model for green supply chain management: An insight into automobile manufacturing units in India. Benchmarking Int. J. 2021, 29, 3097–3132. [Google Scholar] [CrossRef]

- Alikhani, R.; Torabi, S.A.; Altay, N. Strategic supplier selection under sustainability and risk criteria. Int. J. Prod. Econ. 2019, 208, 69–82. [Google Scholar] [CrossRef]

- Quarshie, A.M.; Salmi, A.; Leuschner, R. Sustainability and corporate social responsibility in supply chains: The state of research in supply chain management and business ethics journals. J. Purch. Supply Manag. 2016, 22, 82–97. [Google Scholar] [CrossRef]

- Guarnieri, P.; Trojan, F. Decision making on supplier selection based on social, ethical, and environmental criteria: A study in the textile industry. Resour. Conserv. Recycl. 2018, 141, 347–361. [Google Scholar] [CrossRef]

- Vaezi, A.; Rabbani, E.; Yazdian, S.A. Blockchain-integrated sustainable supplier selection and order allocation: A hybrid BWM-MULTIMOORA and bi-objective programming approach. J. Clean. Prod. 2024, 444, 141216. [Google Scholar] [CrossRef]

- Shang, Z.; Yang, X.; Barnes, D.; Wu, C. Supplier selection in sustainable supply chains: Using the integrated BWM, fuzzy Shannon entropy, and fuzzy MULTIMOORA methods. Expert Syst. Appl. 2022, 195, 116567. [Google Scholar] [CrossRef]

- Liu, C.; Rani, P.; Pachori, K. Sustainable circular supplier selection and evaluation in the manufacturing sector using Pythagorean fuzzy EDAS approach. J. Enterp. Inf. Manag. 2021, 35, 1040–1066. [Google Scholar] [CrossRef]

- Unal, Y.; Temur, G.T. Sustainable supplier selection by using spherical fuzzy AHP. J. Intell. Fuzzy Syst. 2021, 42, 593–603. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Deng, X.; Javed, S.A.; Zhang, N. Sustainable Supplier Selection in Megaprojects: Grey Ordinal Priority Approach. Bus. Strat. Environ. 2020, 30, 318–339. [Google Scholar] [CrossRef]

- del Río, P.; Peñasco, C.; Romero-Jordán, D. What drives eco-innovators? A critical review of the empirical literature based on econometric methods. J. Clean. Prod. 2016, 112, 2158–2170. [Google Scholar] [CrossRef]

- Wong, J.-T. Dynamic procurement risk management with supplier portfolio selection and order allocation under green market segmentation. J. Clean. Prod. 2019, 253, 119835. [Google Scholar] [CrossRef]

- Kara, K.; Acar, A.Z.; Polat, M.; Önden, I.; Yalçın, G.C. Developing a hybrid methodology for green-based supplier selection: Application in the automotive industry. Expert Syst. Appl. 2024, 249, 123668. [Google Scholar] [CrossRef]

- Koc, K.; Ekmekcioğlu, Ö.; Işık, Z. Developing a probabilistic decision-making model for reinforced sustainable supplier selection. Int. J. Prod. Econ. 2023, 259, 108820. [Google Scholar] [CrossRef]

- Münch, C.; Benz, L.A.; Hartmann, E. Exploring the circular economy paradigm: A natural resource-based view on supplier selection criteria. J. Purch. Supply Manag. 2022, 28, 100793. [Google Scholar] [CrossRef]

- He, Q.-R.; Chen, P.-K. Developing a green supplier evaluation system for the Chinese semiconductor manufacturing industry based on supplier willingness. Oper. Manag. Res. 2022, 16, 227–244. [Google Scholar] [CrossRef]

- Rajesh, R.; Aljabhan, B. A Novel Grey Stratified Decision-Making (GSDM) Model for Social Sustainability-Based Supplier Selection. IEEE Trans. Comput. Soc. Syst. 2022, 11, 531–545. [Google Scholar] [CrossRef]

- Koufteros, X.; Vickery, S.K.; Dröge, C. The Effects of Strategic Supplier Selection on Buyer Competitive Performance in Matched Domains: Does Supplier Integration Mediate the Relationships? J. Supply Chain Manag. 2012, 48, 93–115. [Google Scholar] [CrossRef]

- Wetzstein, A.; Hartmann, E.; Benton, W.C., Jr.; Hohenstein, N.-O. A systematic assessment of supplier selection literature—State-of-the-art and future scope. Int. J. Prod. Econ. 2016, 182, 304–323. [Google Scholar] [CrossRef]

- Zimmer, K.; Fröhling, M.; Schultmann, F. Sustainable supplier management—A review of models supporting sustainable supplier selection, monitoring and development. Int. J. Prod. Res. 2015, 54, 1412–1442. [Google Scholar] [CrossRef]

- Song, W.; Xu, Z.; Liu, H.-C. Developing sustainable supplier selection criteria for solar air-conditioner manufacturer: An integrated approach. Renew. Sustain. Energy Rev. 2017, 79, 1461–1471. [Google Scholar] [CrossRef]

- Mostofi, A.; Kumar, S.; Jain, V.; Chandra, C.; Momeni, M.A. The Interactive Weighting Method Concerning Consistency, Inadequacy, Complementary and Supplementary Properties of Criteria. IEEE Trans. Eng. Manag. 2020, 69, 2014–2025. [Google Scholar] [CrossRef]

- Kannan, D.; Govindan, K.; Rajendran, S. Fuzzy axiomatic design approach based green supplier selection: A case study from Singapore. J. Clean. Prod. 2015, 96, 194–208. [Google Scholar] [CrossRef]

- Freeman, J.; Chen, T. Green supplier selection using an AHP-Entropy-TOPSIS framework. Supply Chain Manag. Int. J. 2015, 20, 327–340. [Google Scholar] [CrossRef]

- Baskaran, V.; Nachiappan, S.; Rahman, S. Indian textile suppliers sustainability evaluation using the grey approach. Int. J. Prod. Econ. 2012, 135, 647–658. [Google Scholar] [CrossRef]

- Xu, L.; Kumar, D.T.; Shankar, K.M.; Kannan, D.; Chen, G. Analyzing criteria and sub-criteria for the corporate social responsibility-based supplier selection process using AHP. Int. J. Adv. Manuf. Technol. 2013, 68, 907–916. [Google Scholar] [CrossRef]

- Igarashi, M.; de Boer, L.; Fet, A.M. What is required for greener supplier selection? A literature review and conceptual model development. J. Purch. Supply Manag. 2013, 19, 247–263. [Google Scholar] [CrossRef]

- Shen, L.; Olfat, L.; Govindan, K.; Khodaverdi, R.; Diabat, A. A fuzzy multi criteria approach for evaluating green supplier’s performance in green supply chain with linguistic preferences. Resour. Conserv. Recycl. 2013, 74, 170–179. [Google Scholar] [CrossRef]

- Stević, Ž.; Pamucar, D.; Puška, A.; Chatterjee, P. Sustainable supplier selection in healthcare industries using a new MCDM method: Measurement of alternatives and ranking according to COmpromise solution (MARCOS). Comput. Ind. Eng. 2020, 140, 106231. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2016, 140, 1686–1698. [Google Scholar] [CrossRef]

- Wu, C.; Lin, Y.; Barnes, D. An integrated decision-making approach for sustainable supplier selection in the chemical industry. Expert Syst. Appl. 2021, 184, 115553. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Zolfani, S.H. Integrated QFD-MCDM framework for green supplier selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Almasi, M.; Khoshfetrat, S.; Galankashi, M.R. Sustainable Supplier Selection and Order Allocation under Risk and Inflation Condition. IEEE Trans. Eng. Manag. 2019, 68, 823–837. [Google Scholar] [CrossRef]

- Li, H.; Wang, F.; Zhang, C.; Wang, L.; An, X.; Dong, G. Sustainable supplier selection for water environment treatment public-private partnership projects. J. Clean. Prod. 2021, 324, 129218. [Google Scholar] [CrossRef]

- Chauhan, A.S.; Badhotiya, G.K.; Soni, G.; Kumari, P. Investigating interdependencies of sustainable supplier selection criteria: An appraisal using ISM. J. Glob. Oper. Strat. Sourc. 2020, 13, 195–210. [Google Scholar] [CrossRef]

- Ali, H.; Zhang, J.; Liu, S.; Shoaib, M. An integrated decision-making approach for global supplier selection and order allocation to create an environment-friendly supply chain. Kybernetes 2022, 52, 2649–2671. [Google Scholar] [CrossRef]

- Tong, L.Z.; Wang, J.; Pu, Z. Sustainable supplier selection for SMEs based on an extended PROMETHEE Ⅱ approach. J. Clean. Prod. 2021, 330, 129830. [Google Scholar] [CrossRef]

- Nasr, A.K.; Tavana, M.; Alavi, B.; Mina, H. A novel fuzzy multi-objective circular supplier selection and order allocation model for sustainable closed-loop supply chains. J. Clean. Prod. 2020, 287, 124994. [Google Scholar] [CrossRef]

- Javad, M.O.M.; Darvishi, M.; Javad, A.O.M. Green supplier selection for the steel industry using BWM and fuzzy TOPSIS: A case study of Khouzestan steel company. Sustain. Futures 2020, 2, 100012. [Google Scholar] [CrossRef]

- Ecer, F.; Pamucar, D. Sustainable supplier selection: A novel integrated fuzzy best worst method (F-BWM) and fuzzy CoCoSo with Bonferroni (CoCoSo’B) multi-criteria model. J. Clean. Prod. 2020, 266, 121981. [Google Scholar] [CrossRef]

- Jain, N.; Singh, A. Sustainable supplier selection under must-be criteria through Fuzzy inference system. J. Clean. Prod. 2019, 248, 119275. [Google Scholar] [CrossRef]

- Irie, H.; Kinoshita, Y.; Yamada, T. Design problem of economic carbon recovery and reduction by integrated supplier and disassembly part selections. Procedia Manuf. 2020, 43, 306–313. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Mardani, A.; Dashtian, Z.; Soltani, M.; Weber, G.-W. A novel hybrid method using fuzzy decision making and multi-objective programming for sustainable-reliable supplier selection in two-echelon supply chain design. J. Clean. Prod. 2019, 250, 119517. [Google Scholar] [CrossRef]

- Negash, Y.T.; Kartika, J.; Tseng, M.-L.; Tan, K. A novel approach to measure product quality in sustainable supplier selection. J. Clean. Prod. 2020, 252, 119838. [Google Scholar] [CrossRef]

- Govindan, K.; Mina, H.; Esmaeili, A.; Gholami-Zanjani, S.M. An Integrated Hybrid Approach for Circular supplier selection and Closed loop Supply Chain Network Design under Uncertainty. J. Clean. Prod. 2019, 242, 118317. [Google Scholar] [CrossRef]

- Hasan, M.; Jiang, D.; Ullah, A.S.; Alam, N.E. Resilient supplier selection in logistics 4.0 with heterogeneous information. Expert Syst. Appl. 2019, 139, 112799. [Google Scholar] [CrossRef]

- Günay, E.E.; Kremer, G.E.O.; Park, K. Effect of supplier selection regulations on new product design. Procedia Manuf. 2019, 39, 1337–1345. [Google Scholar] [CrossRef]

- Taherdoost, H.; Brard, A. Analyzing the Process of Supplier Selection Criteria and Methods. Procedia Manuf. 2019, 32, 1024–1034. [Google Scholar] [CrossRef]

- Liu, A.; Xiao, Y.; Lu, H.; Tsai, S.-B.; Song, W. A fuzzy three-stage multi-attribute decision-making approach based on customer needs for sustainable supplier selection. J. Clean. Prod. 2019, 239, 118043. [Google Scholar] [CrossRef]

- Fu, Y.K. An integrated approach to catering supplier selection using AHP-ARAS-MCGP methodology. J. Air Transp. Manag. 2019, 75, 164–169. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Zolfani, S.H. An integrated optimization model for selection of sustainable suppliers based on customers’ expectations. Oper. Res. Perspect. 2019, 6, 100113. [Google Scholar] [CrossRef]

- Wu, Y.; Ke, Y.; Xu, C.; Li, L. An integrated decision-making model for sustainable photovoltaic module supplier selection based on combined weight and cumulative prospect theory. Energy 2019, 181, 1235–1251. [Google Scholar] [CrossRef]

- Kaya, R.; Yet, B. Building Bayesian networks based on DEMATEL for multiple criteria decision problems: A supplier selection case study. Expert Syst. Appl. 2019, 134, 234–248. [Google Scholar] [CrossRef]

- Yu, C.; Shao, Y.; Wang, K.; Zhang, L. A group decision making sustainable supplier selection approach using extended TOPSIS under interval-valued Pythagorean fuzzy environment. Expert Syst. Appl. 2018, 121, 1–17. [Google Scholar] [CrossRef]

- Hu, S.; Dong, Z.S. Supplier selection and pre-positioning strategy in humanitarian relief. Omega 2019, 83, 287–298. [Google Scholar] [CrossRef]

- Kellner, F.; Utz, S. Sustainability in supplier selection and order allocation: Combining integer variables with Markowitz portfolio theory. J. Clean. Prod. 2019, 214, 462–474. [Google Scholar] [CrossRef]

- Lu, Z.; Sun, X.; Wang, Y.; Xu, C. Green supplier selection in straw biomass industry based on cloud model and possibility degree. J. Clean. Prod. 2018, 209, 995–1005. [Google Scholar] [CrossRef]

- Manello, A.; Calabrese, G. The influence of reputation on supplier selection: An empirical study of the European automotive industry. J. Purch. Supply Manag. 2019, 25, 69–77. [Google Scholar] [CrossRef]

- Sim, H.K.; Omar, M.K.; Chee, W.C.; Gan, N.T. A Survey on Supplier Selection Criteria in the Manufacturing Industry in Malaysia. In Proceedings of the 11th Asia Pacific Industrial Engineering and Management Systems Conference, Melaka, Malaysia, 2–5 December 2010. [Google Scholar]

- Luthra, S.; Garg, D.; Haleem, A. The impacts of critical success factors for implementing green supply chain management towards sustainability: An empirical investigation of Indian automobile industry. J. Clean. Prod. 2016, 121, 142–158. [Google Scholar] [CrossRef]

- Gandhi, S.; Mangla, S.K.; Kumar, P.; Kumar, D. A combined approach using AHP and DEMATEL for evaluating success factors in implementation of green supply chain management in Indian manufacturing industries. Int. J. Logist. Res. Appl. 2016, 19, 537–561. [Google Scholar] [CrossRef]

- Srivastava, V.; Gupta, A.K. Price sensitivity, government green interventions, and green product availability triggers intention toward buying green products. Bus. Strategy Environ. 2022, 32, 802–819. [Google Scholar] [CrossRef]

- Kumar, G.A. Framing a model for green buying behavior of Indian consumers: From the lenses of the theory of planned behavior. J. Clean. Prod. 2021, 295, 126487. [Google Scholar] [CrossRef]

- Azadi, M.; Jafarian, M.; Saen, R.F.; Mirhedayatian, S.M. A new fuzzy DEA model for evaluation of efficiency and effectiveness of suppliers in sustainable supply chain management context. Comput. Oper. Res. 2015, 54, 274–285. [Google Scholar] [CrossRef]

- Rahimianzarif, E.; Moradi, M. Designing Integrated Management Criteria of Creative Ideation Based on Fuzzy Delphi Analytical Hierarchy Process. Int. J. Fuzzy Syst. 2018, 13, 669158. [Google Scholar] [CrossRef]

- Saaty, T.L. What is the Analytic Hierarchy Process? In Mathematical Models for Decision Support; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar] [CrossRef]

- De FSM Russo, R.; Camanho, R. Criteria in AHP: A systematic review of the literature. Procedia Comput. Sci. 2015, 55, 1123–1132. [Google Scholar] [CrossRef]

- Buckley, J.J. Fuzzy hierarchical analysis. Fuzzy Sets Syst. 1985, 17, 233–247. [Google Scholar] [CrossRef]

- Saaty, T.L. A Scaling Method for Priorities in Hierarchical Structures. J. Math. Psychol. 1977, 15, 234–281. [Google Scholar] [CrossRef]

- Yedla, S.; Shrestha, R.M. Application of analytic hierarchy process to prioritise urban transport options—Comparative analysis of group aggregation methods. World Rev. Sci. Technol. Sustain. Dev. 2012, 9, 15–33. [Google Scholar] [CrossRef]

- Aczél, J.; Saaty, T.L. Procedures for synthesizing ratio judgments. J. Math. Psychol. 1983, 27, 93–102. [Google Scholar] [CrossRef]

- Pauer, F.; Schmidt, K.; Babac, A.; Damm, K.; Frank, M.; von der Schulenburg, J.-M.G. Comparison of different approaches applied in Analytic Hierarchy Process—An example of information needs of patients with rare diseases. BMC Med. Inform. Decis. Mak. 2016, 16, 117. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Jafarian, A. A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 2013, 47, 345–354. [Google Scholar] [CrossRef]

- Prakash, C.; Barua, M. A combined MCDM approach for evaluation and selection of third-party reverse logistics partner for Indian electronics industry. Sustain. Prod. Consum. 2016, 7, 66–78. [Google Scholar] [CrossRef]

- Bangwal, D.; Tiwari, P. Workplace environment, employee satisfaction and intent to stay. Int. J. Contemp. Hosp. Manag. 2019, 31, 268–284. [Google Scholar] [CrossRef]

- Larsen, L.; Adams, J.; Deal, B.; Kweon, B.S.; Tyler, E. Plants in the workplace the effects of plant density on productivity, attitudes, and perceptions. Environ. Behav. 1998, 30, 261–281. [Google Scholar] [CrossRef]

- Turan, I.; Chegut, A.; Fink, D.; Reinhart, C. The value of daylight in office spaces. Build. Environ. 2019, 168, 106503. [Google Scholar] [CrossRef]

- Veitch, J.A.; Gifford, R. Choice, perceived control, and performance decrements in the physical environment. J. Environ. Psychol. 1996, 16, 269–276. [Google Scholar] [CrossRef]

- Wu, C.; Zou, H.; Barnes, D. A supply risk perspective integrated sustainable supplier selection model in the intuitionistic fuzzy environment. Soft Comput. 2023, 27, 15133–15151. [Google Scholar] [CrossRef] [PubMed]

- Lücker, F.; Seifert, R.W.; Biçer, I. Roles of inventory and reserve capacity in mitigating supply chain disruption risk. Int. J. Prod. Res. 2018, 57, 1238–1249. [Google Scholar] [CrossRef]

| Reference | Country | Sector | Area of Application | Technique |

|---|---|---|---|---|

| [11] | Indonesia | Manufacturing | Racket | Fuzzy AHP and CoCoSo |

| [13] | Brazil | Services | FM services | Fuzzy AHP |

| [33] | India | Manufacturing | Electronics | Grey stratified decision-making (GSDM) model |

| [14] | - | Manufacturing | - | BWM-MARCOS |

| [52] | China | Manufacturing | Automobile | FAHP-FTOPSIS |

| [23] | China | Manufacturing | Forklift truck manufacturer | Fuzzy MULTIMOORA |

| [53] | China | Manufacturing | SMEs | PLTS-PROMETHEE II |

| [12] | Turkey | Manufacturing | Textile | Stratification theory |

| [24] | China | manufacturing | Sustainable supply chain management | PF-EDAS |

| [47] | China | Chemical industry | Petrochemical companies | FGRA, FMEA, EWM, and DEMATEL |

| [50] | China | Water environment treatment | PPP projects | Shapley-AHP-TOPSIS-IVIFS |

| [54] | Iran | Manufacturing | Garment Industry | Fuzzy BWM |

| [10] | Iran | Petroleum | Petrochemical Industry | TOPSIS and MCDM |

| [45] | Bosnia and Herzegovina | Healthcare | Polyclinic | MARCOS |

| [55] | Iran | Manufacturing | Steel industry | BWM, Fuzzy TOPSIS |

| [56] | Turkey | Production | - | Fuzzy BWM and Fuzzy CoCoSo |

| [57] | India | Manufacturing | Steel industry | FIS and Fuzzy Kano |

| [1] | USA | Race | Race | Descriptive analysis |

| [28] | Taiwan | Environment | Global climate change | Fuzzy goal programming |

| [58] | Japan | Environment | CO2 emissions | Mathematical modeling |

| [3] | China | Manufacturing | Electronic manufacturing | Mathematical modeling |

| [59] | Iran | Logistics | Warehouse | FANP and DEMATEL and Fuzzy TOPSIS |

| [60] | Taiwan | Manufacturing | Personal computers | Statistical analysis, Monte Carlo simulation, MCB, Bonferroni |

| [61] | Iran | Manufacturing | Distribution chain of automotive parts | FANP and FDEMATEL |

| [62] | Japan | Manufacturing | Semiconductor | Fuzzy MADM TOPSIS |

| [4] | Poland | - | - | Mathematical modeling |

| [63] | USA | Manufacturing | Production | Mathematical modeling |

| [64] | Malaysia | - | - | MCDM |

| [65] | China | Electric Vehicle | New energy vehicle | Fuzzy MCDM |

| [66] | Taiwan | Airlines | catering | AHP-ARAS-MCGP |

| [67] | India | Manufacturing | Home appliance | Fuzzy TOPSIS |

| [68] | China | Manufacturing | Photovoltaic module | Fuzzy AHP |

| [69] | Turkey | Manufacturing | Automobile | MCDM |

| [19] | Iran | Supermarket | Supermarket | Fuzzy |

| [70] | China | Home Appliance | Decision-making process | Fuzzy TOPSIS |

| [71] | USA | Natural Disasters | Supply structure post-natural disaster | Stochastic programming model |

| [72] | Germany | Manufacturing | Automobile | Mathematical modeling |

| [73] | China | Power plant | Straw biomass industry | MCDM Fuzzy AHP |

| [21] | Brazil | Manufacturing | Textile | AHP |

| [74] | Europe | Manufacturing | Automobile | - |

| [46] | India | Manufacturing | Automobile | AHP-VIKOR |

| [48] | Iran | Dairy Company | Dairy product | QFD-DEMATEL-COPRAS |

| [40] | China | Manufacturing | Electronics machinery | AHP-Entropy/TOPSIS |

| [75] | Malaysia | Manufacturing | Manufacturing industry | Survey |

| Designation | Numbers | Experience | Numbers |

|---|---|---|---|

| AM/M/SM | 10 | (Exp <10 yrs.) | 7 |

| CM/DGM/AGM/GM | 9 | (Exp: 10–15 yrs.) | 10 |

| Director/MD/ | 4 | (Exp >15 yrs.) | 6 |

| Major Factor | Sub-Factor | Citations |

|---|---|---|

| Delivery (Del) | On-time delivery (Del1) | [24,40,45,47,53] |

| No error in product type and quantity (Del2) | [23,75] | |

| The product received in good condition (Del3) | [47,75] | |

| Order lead time (Del4) | [10,46,53] | |

| Economic (Eco) | Reliability (Eco1) | [45,63] |

| Service and after-sales service (Eco2) | [53,54] | |

| Performance history (Eco3) | [75] | |

| Cost (Eco4) | [12,23,24,40,45,46,47,53,63] | |

| Environmental (Env) | Enhanced value to customers (Env1) | [55] |

| Customer-friendly and environmental adaptability (Env2) | [23,53,64] | |

| Pollution control (Env3) | [24,45,47,56] | |

| Environmental certifications (Env4) | [40,45,54] | |

| Management and organization (Mo) | Skilled and potential staff (MO1) | [75] |

| The financial status of the company (MO2) | [24] | |

| Strategic organization structure (MO3) | [50] | |

| Good reputation among the industry (MO4) | [23,45,50] | |

| Quality (Qa) | Long durability (life) (Qa1) | [75] |

| Low rejection/return rate (Qa2) | [40,75] | |

| Meeting minimum standards and requirements (Qa3) | [53] | |

| ISO certified (Qa4) | [75] | |

| Services (Sv) | Fast reaction/responsiveness (Sv1) | [75] |

| Technical support (Sv2) | [75] | |

| Warranty/Insurance (Sv3) | [75] | |

| Ability to collocate to buyer’s manufacturing side (Sv4) | [75] | |

| Social (So) | Ethical issues and legal compliance (So1) | [64] |

| Mutual trust and easy communication (So2) | [63] | |

| Information disclosure (So3) | [12,45,46,56] | |

| Staff training (So4) | [24,45,56] | |

| Supplier relationship (Sr) | Long-term cooperation (Sr1) | [23,75] |

| Attitude (Sr2) | [63] | |

| Flexibility (Sr3) | [23,24,46,70] | |

| Customer trade record (Sr4) | [75] |

| 1 | 1,1,1 | ||

| 3 | 2,3,4 | 0.33 | 0.25,0.33,0.5 |

| 5 | 4,5,6 | 0.2 | 0.167,0.2,0.25 |

| 7 | 6,7,8 | 0.14 | 0.125,0.143,0.167 |

| 9 | 9,9,9 | 0.11 | 0.11,0.11,0.11 |

| 2 | 1,2,3 | 0.5 | 0.33,0.5,1 |

| 4 | 3,4,5 | 0.25 | 0.2,0.25,0.33 |

| 6 | 5,6,7 | 0.17 | 0.143,0.167,0.2 |

| 8 | 7,8,9 | 0.13 | 0.11,0.125,0.143 |

| Company | Respondent Expertise | Mgt Position | Year of Experience |

|---|---|---|---|

| AC manufacturing—A | Supply Chain | GM, SCM | 15 |

| Commodity | Commodity Manager | 8 | |

| AC manufacturing—B | Materials Handling | AGM Materials | 13 |

| Sourcing | Manager Sourcing | 10 | |

| HVAC OEM—C | Strategic Sourcing | Head Strategic Sourcing | 14 |

| Marketing | Head Marketing | 15 | |

| Sourcing | Senior Manager Sourcing | 12 |

| Del | Eco | Env | MO | Qa | Sv | So | Sr | |

|---|---|---|---|---|---|---|---|---|

| Del | 1,1,1 | 0.33,0.5,1 | 0.2,0.25,0.33 | 0.25,0.33,0.5 | 1,2,3 | 0.33,0.5,1 | 0.25,0.33,0.5 | 0.25,0.33,0.5 |

| Eco | 1,2,3 | 1,1,1 | 0.25,0.33,0.5 | 0.25,0.33,0.5 | 1,1,1 | 0.33,0.5,1 | 0.2,0.25,0.33 | 0.33,0.5,1 |

| Env | 3,4,5 | 2,3,4 | 1,1,1 | 0.33,0.5,1 | 1,1,1 | 0.25,0.33,0.5 | 0.2,0.25,0.33 | 0.33,0.5,1 |

| MO | 2,3,4 | 2,3,4 | 1,2,3 | 1,1,1 | 1,1,1 | 0.33,0.5,1 | 0.33,0.5,1 | 1,1,1 |

| Qa | 0.33,0.5,1 | 1,1,1 | 1,1,1 | 1,1,1 | 1,1,1 | 0.25,0.33,0.5 | 0.167,0.2,0.25 | 0.2,0.25,0.33 |

| Sv | 1,2,3 | 1,2,3 | 2,3,4 | 1,2,3 | 2,3,4 | 1,1,1 | 0.2,0.25,0.33 | 0.33,0.5,1 |

| So | 2,3,4 | 3,4,5 | 3,4,5 | 1,2,3 | 4,5,6 | 3,4,5 | 1,1,1 | 1,1,1 |

| Sr | 2,3,4 | 1,2,3 | 1,2,3 | 1,1,1 | 3,4,5 | 1,2,3 | 1,1,1 | 1,1,1 |

| GM Lower | 1.30 | 1.19 | 0.86 | 0.62 | 1.49 | 0.54 | 0.32 | 0.45 |

| GM Middle | 1.96 | 1.71 | 1.19 | 0.83 | 1.82 | 0.76 | 0.39 | 0.56 |

| GM Upper | 2.71 | 2.28 | 1.53 | 1.11 | 2.09 | 1.18 | 0.51 | 0.80 |

| Fuzzy Wt Lower | 0.11 | 0.10 | 0.07 | 0.05 | 0.12 | 0.04 | 0.03 | 0.04 |

| Fuzzy Wt Middle | 0.21 | 0.19 | 0.13 | 0.09 | 0.20 | 0.08 | 0.04 | 0.06 |

| Fuzzy Wt Upper | 0.40 | 0.34 | 0.23 | 0.16 | 0.31 | 0.17 | 0.08 | 0.12 |

| Overall Wt | 0.24 | 0.21 | 0.14 | 0.10 | 0.21 | 0.10 | 0.05 | 0.07 |

| Normalized Wt | 0.214 | 0.184 | 0.127 | 0.091 | 0.187 | 0.090 | 0.043 | 0.065 |

| Rank | 1 | 3 | 4 | 5 | 2 | 6 | 8 | 7 |

| Economic Factors | Management and Organization Factors | Delivery Factors | Environment Factors | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Eco1 | Eco2 | Eco3 | Eco4 | MO1 | MO2 | MO3 | MO4 | Del1 | Del2 | Del3 | Del4 | Env1 | Env2 | Env3 | Env4 |

| 0.506 | 0.231 | 0.123 | 0.14 | 0.417 | 0.201 | 0.21 | 0.171 | 0.376 | 0.287 | 0.108 | 0.228 | 0.323 | 0.323 | 0.198 | 0.156 |

| 1 | 2 | 4 | 3 | 1 | 3 | 2 | 4 | 1 | 2 | 4 | 3 | 1 | 2 | 3 | 4 |

| Quality factors | Social factors | Service factors | Supplier relationship factors | ||||||||||||

| Qa1 | Qa2 | Qa3 | Qa4 | So1 | So2 | So3 | So4 | Sv1 | Sv2 | Sv3 | Sv4 | Sr1 | Sr2 | Sr3 | Sr4 |

| 0.451 | 0.285 | 0.173 | 0.092 | 0.579 | 0.122 | 0.22 | 0.079 | 0.403 | 0.288 | 0.177 | 0.132 | 0.433 | 0.232 | 0.233 | 0.103 |

| 1 | 2 | 3 | 4 | 1 | 3 | 2 | 4 | 1 | 2 | 3 | 4 | 1 | 3 | 2 | 4 |

| N | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|

| RI | 0.52 | 0.89 | 1.11 | 1.25 | 1.35 | 1.4 |

| Sub-Factors | Eco | MO | Del | Env | Qa | So | Sv | Sr |

|---|---|---|---|---|---|---|---|---|

| CR value | 0.074 | 0.095 | 0.097 | 0.092 | 0.096 | 0.02 | 0.092 | 0.085 |

| Major Factors | Sub-factors | Local Wts | Global Wts | Overall Rank |

|---|---|---|---|---|

| Economic (0.184) | Reliability | 0.5064 | 0.0934 | 1 |

| Service and after-sales service | 0.2314 | 0.0427 | 7 | |

| Performance history | 0.1225 | 0.0226 | 19 | |

| cost | 0.1397 | 0.0258 | 15 | |

| Management and organization (0.091) | Skilled and potential staff | 0.4174 | 0.0378 | 10 |

| Financial stability | 0.2010 | 0.0182 | 22 | |

| Production capacity | 0.2104 | 0.0190 | 21 | |

| Company background | 0.1712 | 0.0155 | 25 | |

| Delivery (0.214) | On-time delivery | 0.3764 | 0.0806 | 3 |

| No error in product type and quantity | 0.2873 | 0.0615 | 4 | |

| Order lead time | 0.1078 | 0.0231 | 18 | |

| Delivery reliability | 0.2285 | 0.0489 | 6 | |

| Environment (0.127) | Enhanced value to customers | 0.3230 | 0.0409 | 8 |

| Customer-friendly and environmental adaptability | 0.3226 | 0.0409 | 9 | |

| Process integration | 0.1983 | 0.0251 | 16 | |

| Pollution control | 0.1561 | 0.0198 | 20 | |

| Quality (0.187) | Long durability (life) | 0.4512 | 0.0844 | 2 |

| Low rejection/return rate | 0.2846 | 0.0533 | 5 | |

| Meeting minimum standards and requirements | 0.1726 | 0.0323 | 12 | |

| ISO certified | 0.0916 | 0.0171 | 23 | |

| Social (0.043) | Ethical issues and legal compliance | 0.5786 | 0.0248 | 17 |

| Mutual trust and easy communication | 0.1219 | 0.0052 | 31 | |

| Information disclosure | 0.2202 | 0.0094 | 29 | |

| Staff training | 0.0793 | 0.0034 | 32 | |

| Services (0.09) | Fast reaction/responsiveness | 0.4034 | 0.0361 | 11 |

| Technical support | 0.2880 | 0.0258 | 14 | |

| Warranty/Insurance | 0.1768 | 0.0158 | 24 | |

| Ability to collocate to buyer’s manufacturing side | 0.1317 | 0.0118 | 28 | |

| Supplier relationship (0.065) | Long-term cooperation | 0.4329 | 0.0279 | 13 |

| Attitude | 0.2317 | 0.0149 | 27 | |

| Good communication system | 0.2329 | 0.0150 | 26 | |

| Good supplier relationship management (SRM) | 0.1025 | 0.0066 | 30 |

| Major Factor | N. Wt (0.214) | W-0.1 | W-0.2 | W-0.3 | W-0.4 | W-0.5 | W-0.6 | W-0.7 | W-0.8 | W-0.9 |

|---|---|---|---|---|---|---|---|---|---|---|

| Del | 0.214 | 0.1000 | 0.2000 | 0.3000 | 0.4000 | 0.5000 | 0.6000 | 0.7000 | 0.8000 | 0.9000 |

| Eco | 0.184 | 0.2113 | 0.1878 | 0.1644 | 0.1409 | 0.1174 | 0.0939 | 0.0704 | 0.0470 | 0.0235 |

| Env | 0.127 | 0.1452 | 0.1290 | 0.1129 | 0.0968 | 0.0807 | 0.0645 | 0.0484 | 0.0323 | 0.0161 |

| MO | 0.091 | 0.1037 | 0.0922 | 0.0806 | 0.0691 | 0.0576 | 0.0461 | 0.0346 | 0.0230 | 0.0115 |

| Qa | 0.187 | 0.2143 | 0.1905 | 0.1667 | 0.1429 | 0.1191 | 0.0953 | 0.0714 | 0.0476 | 0.0238 |

| Sv | 0.090 | 0.1026 | 0.0912 | 0.0798 | 0.0684 | 0.0570 | 0.0456 | 0.0342 | 0.0228 | 0.0114 |

| So | 0.043 | 0.0490 | 0.0436 | 0.0381 | 0.0327 | 0.0272 | 0.0218 | 0.0163 | 0.0109 | 0.0054 |

| Sr | 0.065 | 0.0739 | 0.0657 | 0.0575 | 0.0493 | 0.0411 | 0.0328 | 0.0246 | 0.0164 | 0.0082 |

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Factors | G Wts | W-0.1 | W-0.2 | W-0.3 | W-0.4 | W-0.5 | W-0.6 | W-0.7 | W-0.8 | W-0.9 |

|---|---|---|---|---|---|---|---|---|---|---|

| Del1 | 0.0806 | 0.0376 | 0.0753 | 0.1129 | 0.1506 | 0.1882 | 0.2258 | 0.2635 | 0.3011 | 0.3388 |

| Del2 | 0.0615 | 0.0287 | 0.0575 | 0.0862 | 0.1149 | 0.1436 | 0.1724 | 0.2011 | 0.2298 | 0.2585 |

| Del3 | 0.0231 | 0.0108 | 0.0216 | 0.0324 | 0.0431 | 0.0539 | 0.0647 | 0.0755 | 0.0863 | 0.0971 |

| Del4 | 0.0489 | 0.0228 | 0.0457 | 0.0685 | 0.0914 | 0.1142 | 0.1371 | 0.1599 | 0.1828 | 0.2056 |

| Eco1 | 0.0934 | 0.1070 | 0.0951 | 0.0832 | 0.0713 | 0.0594 | 0.0476 | 0.0357 | 0.0238 | 0.0119 |

| Eco2 | 0.0427 | 0.0489 | 0.0435 | 0.0380 | 0.0326 | 0.0272 | 0.0217 | 0.0163 | 0.0109 | 0.0054 |

| Eco3 | 0.0226 | 0.0259 | 0.0230 | 0.0201 | 0.0173 | 0.0144 | 0.0115 | 0.0086 | 0.0058 | 0.0029 |

| Eco4 | 0.0258 | 0.0295 | 0.0262 | 0.0230 | 0.0197 | 0.0164 | 0.0131 | 0.0098 | 0.0066 | 0.0033 |

| Env1 | 0.0409 | 0.0469 | 0.0417 | 0.0365 | 0.0313 | 0.0260 | 0.0208 | 0.0156 | 0.0104 | 0.0052 |

| Env2 | 0.0409 | 0.0468 | 0.0416 | 0.0364 | 0.0312 | 0.0260 | 0.0208 | 0.0156 | 0.0104 | 0.0052 |

| Env3 | 0.0251 | 0.0288 | 0.0256 | 0.0224 | 0.0192 | 0.0160 | 0.0128 | 0.0096 | 0.0064 | 0.0032 |

| Env4 | 0.0198 | 0.0227 | 0.0201 | 0.0176 | 0.0151 | 0.0126 | 0.0101 | 0.0076 | 0.0050 | 0.0025 |

| MO1 | 0.0378 | 0.0433 | 0.0385 | 0.0337 | 0.0289 | 0.0240 | 0.0192 | 0.0144 | 0.0096 | 0.0048 |

| MO2 | 0.0182 | 0.0208 | 0.0185 | 0.0162 | 0.0139 | 0.0116 | 0.0093 | 0.0069 | 0.0046 | 0.0023 |

| MO3 | 0.0190 | 0.0218 | 0.0194 | 0.0170 | 0.0145 | 0.0121 | 0.0097 | 0.0073 | 0.0048 | 0.0024 |

| MO4 | 0.0155 | 0.0178 | 0.0158 | 0.0138 | 0.0118 | 0.0099 | 0.0079 | 0.0059 | 0.0039 | 0.0020 |

| Qa1 | 0.0844 | 0.0967 | 0.0860 | 0.0752 | 0.0645 | 0.0537 | 0.0430 | 0.0322 | 0.0215 | 0.0107 |

| Qa2 | 0.0533 | 0.0610 | 0.0542 | 0.0474 | 0.0407 | 0.0339 | 0.0271 | 0.0203 | 0.0136 | 0.0068 |

| Qa3 | 0.0323 | 0.0370 | 0.0329 | 0.0288 | 0.0247 | 0.0206 | 0.0164 | 0.0123 | 0.0082 | 0.0041 |

| Qa4 | 0.0171 | 0.0196 | 0.0175 | 0.0153 | 0.0131 | 0.0109 | 0.0087 | 0.0065 | 0.0044 | 0.0022 |

| Sv1 | 0.0361 | 0.0414 | 0.0368 | 0.0322 | 0.0276 | 0.0230 | 0.0184 | 0.0138 | 0.0092 | 0.0046 |

| Sv2 | 0.0258 | 0.0295 | 0.0263 | 0.0230 | 0.0197 | 0.0164 | 0.0131 | 0.0098 | 0.0066 | 0.0033 |

| Sv3 | 0.0158 | 0.0181 | 0.0161 | 0.0141 | 0.0121 | 0.0101 | 0.0081 | 0.0060 | 0.0040 | 0.0020 |

| Sv4 | 0.0118 | 0.0135 | 0.0120 | 0.0105 | 0.0090 | 0.0075 | 0.0060 | 0.0045 | 0.0030 | 0.0015 |

| So1 | 0.0248 | 0.0284 | 0.0252 | 0.0221 | 0.0189 | 0.0158 | 0.0126 | 0.0095 | 0.0063 | 0.0032 |

| So2 | 0.0052 | 0.0060 | 0.0053 | 0.0046 | 0.0040 | 0.0033 | 0.0027 | 0.0020 | 0.0013 | 0.0007 |

| So3 | 0.0094 | 0.0108 | 0.0096 | 0.0084 | 0.0072 | 0.0060 | 0.0048 | 0.0036 | 0.0024 | 0.0012 |

| So4 | 0.0034 | 0.0039 | 0.0035 | 0.0030 | 0.0026 | 0.0022 | 0.0017 | 0.0013 | 0.0009 | 0.0004 |

| Sr1 | 0.0279 | 0.0320 | 0.0284 | 0.0249 | 0.0213 | 0.0178 | 0.0142 | 0.0107 | 0.0071 | 0.0036 |

| Sr2 | 0.0149 | 0.0171 | 0.0152 | 0.0133 | 0.0114 | 0.0095 | 0.0076 | 0.0057 | 0.0038 | 0.0019 |

| Sr3 | 0.0150 | 0.0172 | 0.0153 | 0.0134 | 0.0115 | 0.0096 | 0.0076 | 0.0057 | 0.0038 | 0.0019 |

| Sr4 | 0.0066 | 0.0076 | 0.0067 | 0.0059 | 0.0051 | 0.0042 | 0.0034 | 0.0025 | 0.0017 | 0.0008 |

| W-0.1 | W-0.2 | W-0.3 | W-0.4 | W-0.5 | W-0.6 | W-0.7 | W-0.8 | W-0.9 | Average | |

|---|---|---|---|---|---|---|---|---|---|---|

| G-wts | 0.907 | 1 | 0.986 | 0.964 | 0.959 | 0.952 | 0.952 | 0.952 | 0.952 | 0.9582222 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gupta, A.K.; Shaikh, I. Sustainable Supplier Selection Criteria for HVAC Manufacturing Firms: A Multi-Dimensional Perspective Using the Delphi–Fuzzy AHP Method. Logistics 2024, 8, 103. https://doi.org/10.3390/logistics8040103

Gupta AK, Shaikh I. Sustainable Supplier Selection Criteria for HVAC Manufacturing Firms: A Multi-Dimensional Perspective Using the Delphi–Fuzzy AHP Method. Logistics. 2024; 8(4):103. https://doi.org/10.3390/logistics8040103

Chicago/Turabian StyleGupta, Amit Kumar, and Imlak Shaikh. 2024. "Sustainable Supplier Selection Criteria for HVAC Manufacturing Firms: A Multi-Dimensional Perspective Using the Delphi–Fuzzy AHP Method" Logistics 8, no. 4: 103. https://doi.org/10.3390/logistics8040103

APA StyleGupta, A. K., & Shaikh, I. (2024). Sustainable Supplier Selection Criteria for HVAC Manufacturing Firms: A Multi-Dimensional Perspective Using the Delphi–Fuzzy AHP Method. Logistics, 8(4), 103. https://doi.org/10.3390/logistics8040103