Implementing Additive Manufacturing in Orthopedic Shoe Supply Chains—Cost and Lead Time Comparison

Abstract

Highlights

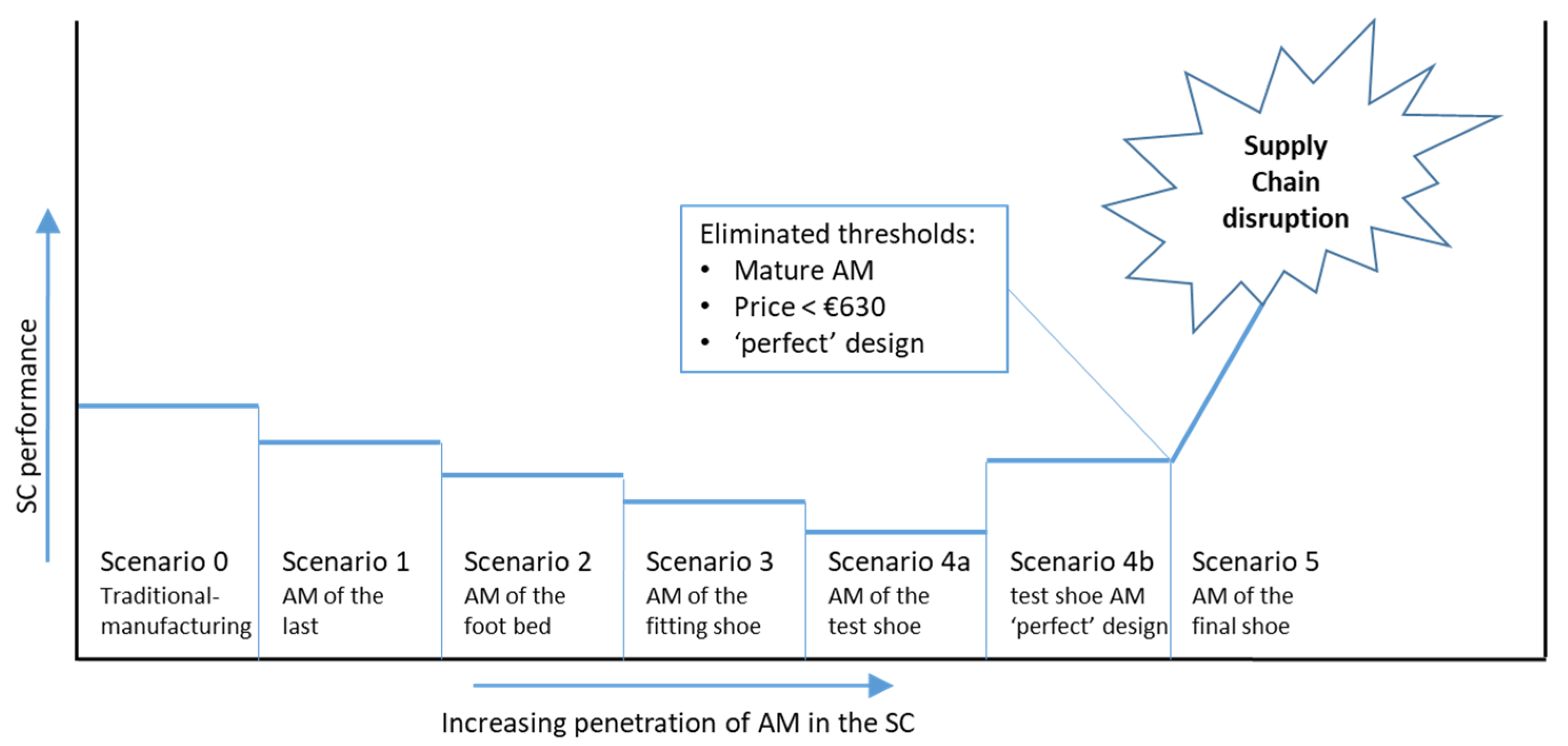

- For current supply chain disruptions, only AM production of entire orthopedic shoes is viable.

- Hybrid solutions, where only components or tools are AM produced, seem not viable.

- Low prices and a perfect digital design are hard requirements for an AM SC.

- Research how traditional craftsmanship can be embedded into digital designs is required.

- Introducing AM may not be sufficient for SC performance improvement in orthopedic shoes.

- More mature and developed AM technologies in future can improve lead time significantly.

Abstract

1. Introduction

- RQ1: How can AM be implemented in the orthopedic shoe supply chain?

- RQ2: How will AM affect the cost and lead time now and in the future?

- RQ3: Which hurdles have to be eliminated for AM to deliver positive SC outcomes?

2. Literature Review

3. Methodology

3.1. Case Study

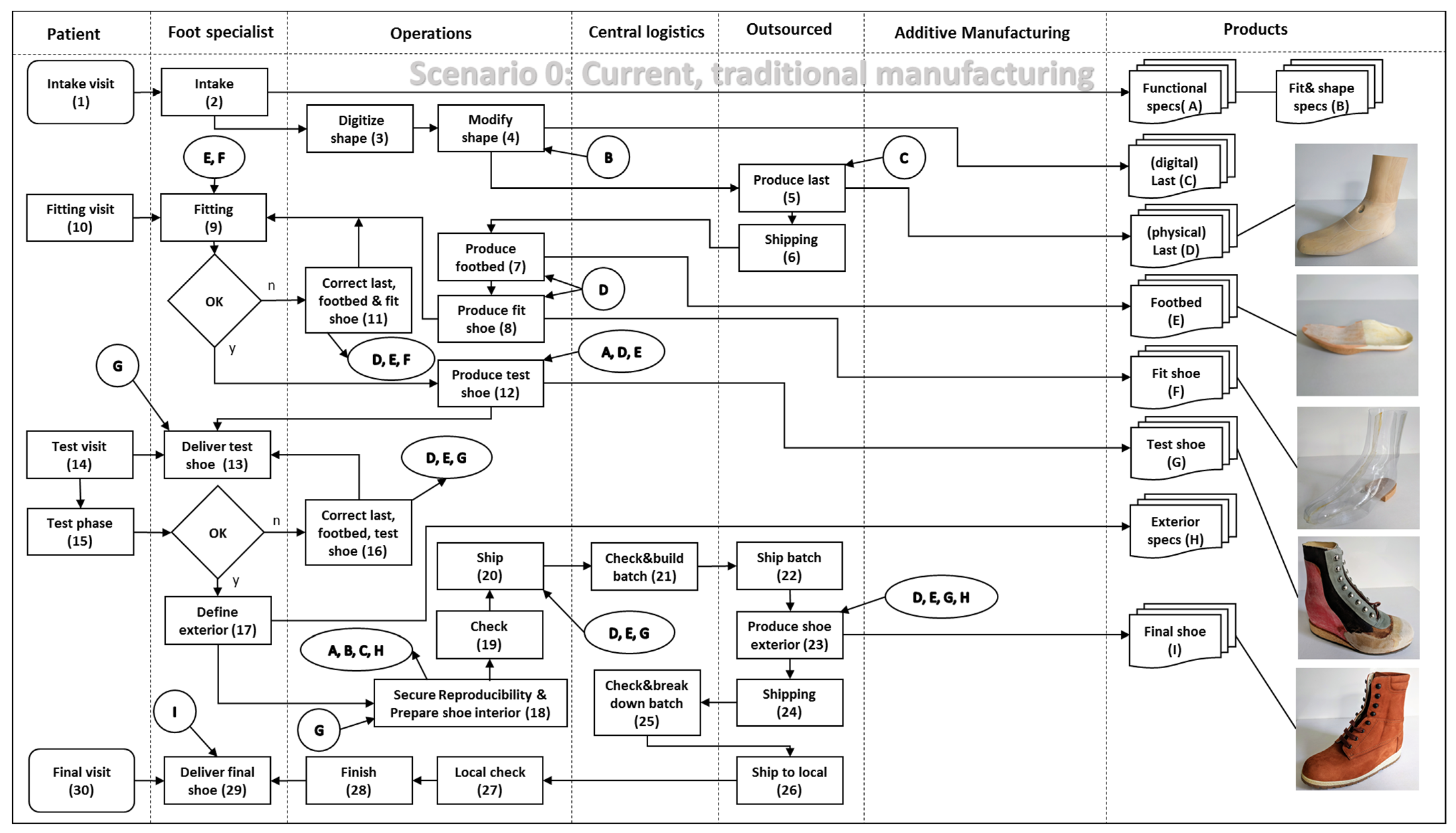

3.2. Scenarios

3.2.1. AM Increasingly Penetrating the SC

3.2.2. The Future Developments in Advancing AM and Digitization

3.3. Calculations

4. Results

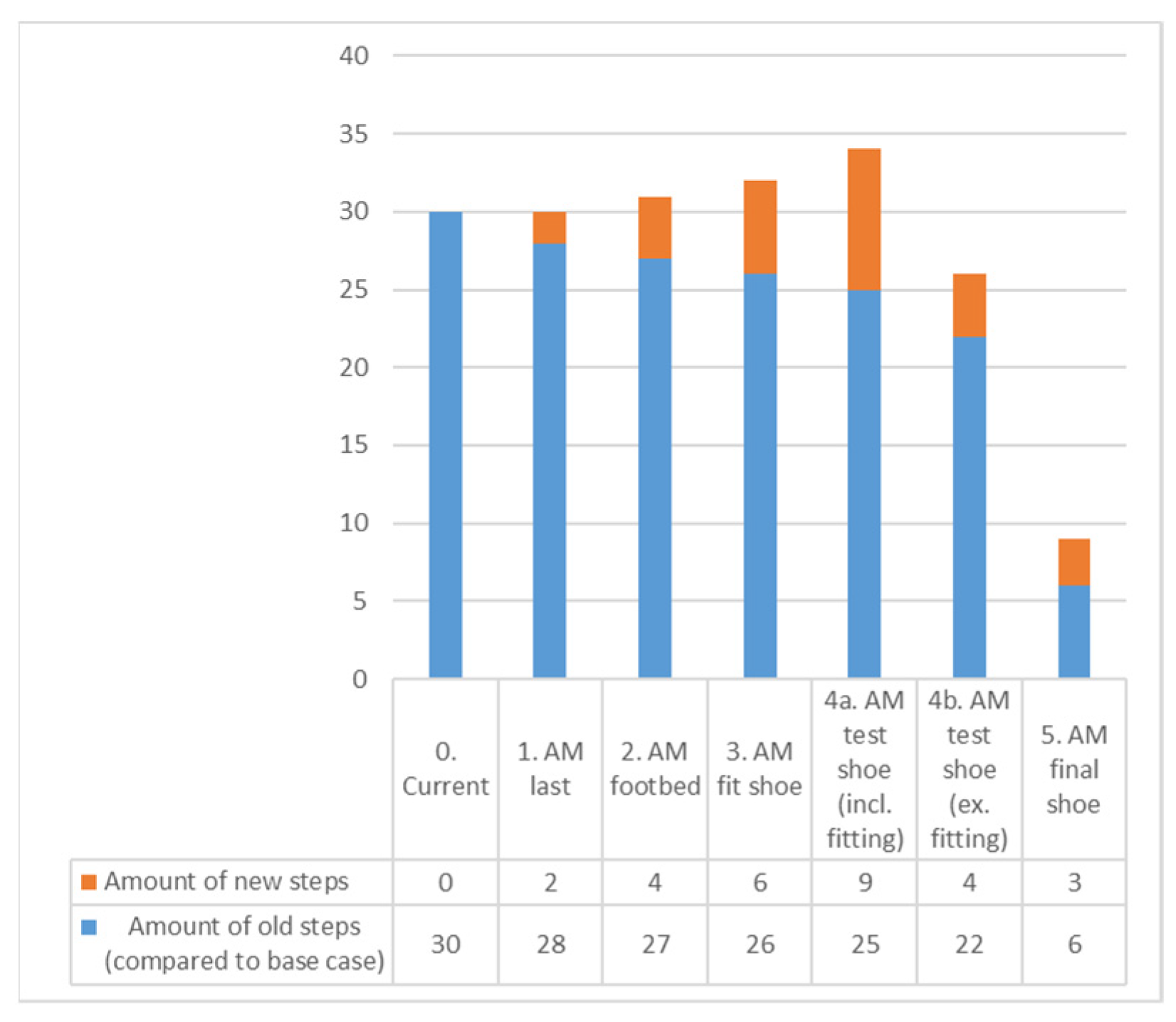

4.1. SC Process Steps Analysis

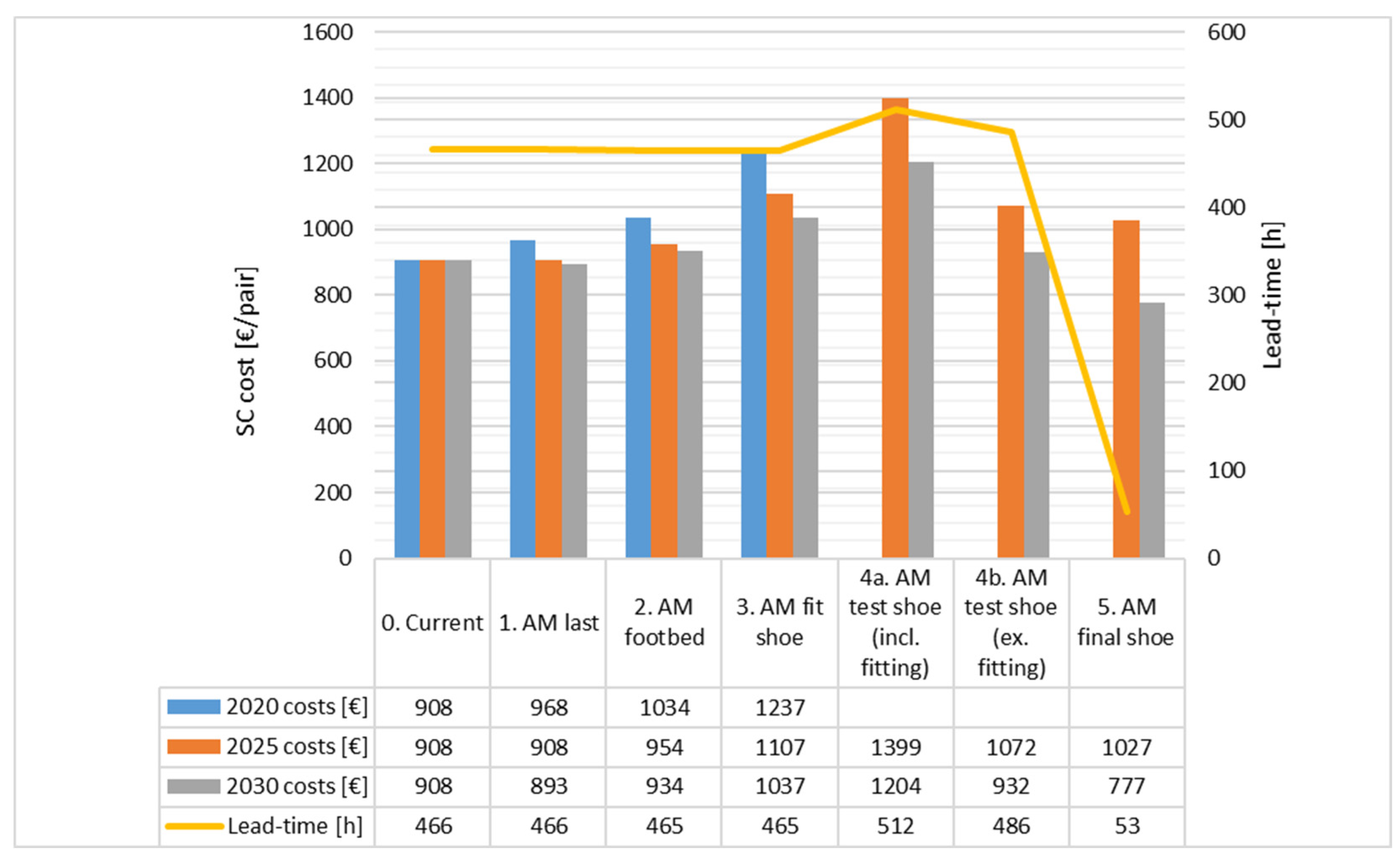

4.2. Cost and Lead Time Analysis

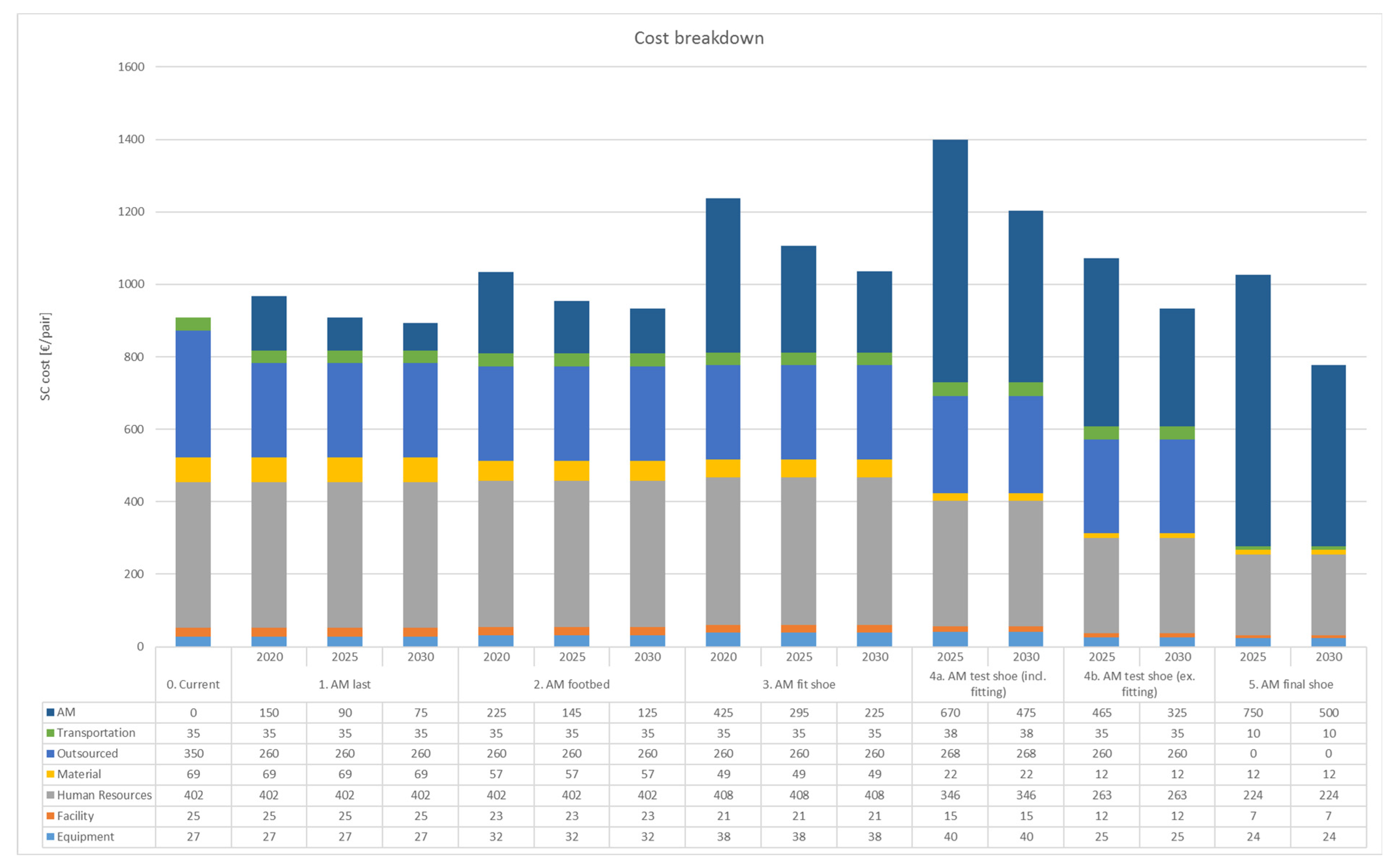

4.3. Cost Components

4.4. Sensitivity Analysis—Costs

4.5. Sensitivity Analysis—Lead Time

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P. Supply Chain Management Strategy, Planning, and Operation, Global Edition, 5th ed.; Pearson: London, UK, 2013. [Google Scholar]

- APICS. Supply Chain Operating Reference (SCOR) Model. 2018. Available online: http://www.apics.org/apics-for-business/frameworks/scor (accessed on 1 April 2024).

- Schwab, K. The Fourth Industrial Revolution; Random House USA Inc.: New York, NY, USA, 2017. [Google Scholar]

- ISO/ASTM 52900: 2015 (ASTM F2792); Additive Manufacturing—General Principles—Terminology. ISO: Geneva, Switzerland; ASTM: West Conshohocken, PA, USA, 2015.

- Maresch, D.; Gartner, J. Make disruptive technological change happen-The case of additive manufacturing. Technol. Forecast. Soc. Chang. 2018, 155, 119216. [Google Scholar] [CrossRef]

- OECD/EU. Health at a Glance: Europe 2018: State of Health in the EU Cycle; OECD Publishing: Paris, France, 2018. [Google Scholar] [CrossRef]

- RIVM. Public Health Foresight Report 2018—A Healthy Prospect; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2018. Available online: http://www.vtv2018.nl/ (accessed on 1 April 2024).

- Holmström, J.; Holweg, M.; Khajavi, S.H.; Partanen, J. The direct digital manufacturing (r)evolution: Definition of a research agenda. Oper. Manag. Res. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- Verboeket, V.; Krikke, H. The disruptive impact of additive manufacturing on supply chains: A literature study, conceptual framework and research agenda. Comput. Ind. 2019, 111, 91–107. [Google Scholar] [CrossRef]

- Waller, M.A.; Fawcett, S.E. Click Here to Print a Maker Movement Supply Chain: How Invention and Entrepreneurship Will Disrupt Supply Chain Design. J. Bus. Logist. 2014, 35, 99–102. [Google Scholar] [CrossRef]

- Holmström, J.; Holweg, M.; Lawson, B.; Pil, F.K.; Wagner, S.M. The digitalization of operations and supply chain management: Theoretical and methodological implications. J. Oper. Manag. 2019, 65, 728–734. [Google Scholar] [CrossRef]

- Fawcett, S.E.; Waller, M.A. Supply Chain Game Changers—Mega, Nano, and Virtual Trends—And Forces That Impede Supply Chain Design (i.e., Building a Winning Team). J. Bus. Logist. 2014, 35, 157–164. [Google Scholar] [CrossRef]

- Melnyk, S.; Davis, E.; Spekman, R.; Sandor, J. Outcome-Driven Supply Chains. Sloan Manag. Rev. 2010, 33–38. Available online: https://sloanreview.mit.edu/article/outcome-driven-supply-chains/ (accessed on 1 April 2024).

- Verboeket, V.; Khajavi, S.; Krikke, H.; Salmi, M.; Holmström, J. Additive Manufacturing for Localized Medical Parts Production: A Case Study. IEEE Access 2021, 9, 25818–25834. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Mills, J.F.; Camek, V. The risks, threats and opportunities of disintermediation: A distributor’s view. Int. J. Phys. Distrib. Logist. Manag. 2004, 34, 714–727. [Google Scholar] [CrossRef]

- Rayna, T.; Striukova, L. From rapid prototyping to home fabrication: How 3D printing is changing business model innovation. Technol. Forecast. Soc. Chang. 2016, 102, 214–224. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of additive manufacturing for end-usable metal parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Gebler, M.; Schoot Uiterkamp, A.J.M.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Heinen, J.J.; Hoberg, K. Assessing the potential of additive manufacturing for the provision of spare parts. J. Oper. Manag. 2019, 65, 810–826. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmstrom, J.; Tuomi, J. Risk reduction in new product launch: A hybrid approach combining direct digital and tool-based manufacturing. Comput. Ind. 2015, 74, 29–42. [Google Scholar] [CrossRef]

- Bogers, M.; Hadar, R.; Bilberg, A. Additive manufacturing for consumer-centric business models: Implications for supply chains in consumer goods manufacturing. Technol. Forecast. Soc. Chang. 2016, 102, 225–239. [Google Scholar] [CrossRef]

- Eyers, D.R.; Potter, A.T. E-commerce channels for additive manufacturing: An exploratory study. J. Manuf. Technol. Manag. 2015, 26, 390–411. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Kothman, I.; Faber, N. How 3D printing technology changes the rules of the game: Insights from the construction sector. J. Manuf. Technol. Manag. 2016, 27, 932–943. [Google Scholar] [CrossRef]

- Wagner, S.M.; Walton, R.O. Additive manufacturing’s impact and future in the aviation industry. Prod. Plan. Control 2016, 27, 1124–1130. [Google Scholar] [CrossRef]

- Emelogu, A.; Marufuzzaman, M.; Thompson, S.M.; Shamsaei, N.; Bian, L. Additive manufacturing of biomedical implants: A feasibility assessment via supply-chain cost analysis. Addit. Manuf. 2016, 11, 97–113. [Google Scholar] [CrossRef]

- Giannatsis, J.; Dedoussis, V. Additive fabrication technologies applied to medicine and health care: A review. Int. J. Adv. Manuf. Technol. 2009, 40, 116–127. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Chung, S.; Im, Y.; Jeong, H.; Jeong, D.; Cho, K.; Lee, S.; Choi, B.; Choi, H. Rapid fabrication of aluminum shoe mold using vacuum sealed casting process. J. Mater. Process. Technol. 2003, 142, 326–333. [Google Scholar] [CrossRef]

- Amza, C.; Zapciu, A.; Popescu, D. 3D-Printed shoe last for bespoke shoe manufacturing. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019. [Google Scholar]

- Meier, M.; Tan, K.H.; Lim, M.K.; Chung, L. Unlocking innovation in the sport industry through additive manufacturing. Bus. Process Manag. J. 2019, 25, 456–475. [Google Scholar] [CrossRef]

- Adidas. Adidas Breaks the Mould with 3D-Printed Performance Footwear. 2015. Available online: https://www.adidas-group.com/en/media/news-archive/press-releases/2015/adidas-breaks-mould-3d-printed-performance-footwear/ (accessed on 1 April 2024).

- Forbes. New Balance to Begin Using 3D-Printed Soles in Latest Sneaker Designs. 2019. Available online: https://www.forbes.com/sites/simonogus/2019/06/30/new-balance-to-begin-using-3d-printed-soles-in-latest-sneaker-designs (accessed on 1 April 2024).

- Dezeen. Nike Unveils “World’s First” Running Shoes with 3D-Printed Uppers. 2018. Available online: https://www.dezeen.com/2018/04/21/nike-unveils-3d-printed-running-shoes-london-marathon/ (accessed on 1 April 2024).

- 3D Printing Industry. Peak Sport Presents Sneakers Using 3D Printing beyond the Midsole. 2019. Available online: https://3dprintingindustry.com/news/peak-sport-presents-sneakers-using-3d-printing-beyond-the-midsole-158472/ (accessed on 1 April 2024).

- Kim, S.; Seong, H.; Her, Y.; Chun, J. A study of the development and improvement of fashion products using a FDM type 3D printer. Fash. Text. 2019, 6, 9. [Google Scholar] [CrossRef]

- Vanderploeg, A.; Lee, S.-E.; Mamp, M. The application of 3D printing technology in the fashion industry. Int. J. Fash. Des. Technol. Educ. 2017, 10, 170–179. [Google Scholar] [CrossRef]

- Salles, A.S.; Gyi, D.E. Delivering personalized insoles to the high street using additive manufacturing. Int. J. Comput. Integr. Manuf. 2013, 26, 386–400. [Google Scholar] [CrossRef]

- Salles, A.S.; Gyi, D.E. An evaluation of personalized insoles developed using additive manufacturing. J. Sports Sci. 2013, 31, 442–450. [Google Scholar] [CrossRef]

- Jordan, J.M. Additive manufacturing (“3D printing”) and the future of organizational design: Some early notes from the field. J. Organ. Des. 2019, 8, 5. [Google Scholar] [CrossRef]

- Nachtigall, T.R.; Tomico, O.; Wakkary, R.; Wensveen, S.; van Dongen, P.; Tentoff van Norten, L. Towards ultra personalized 4D printed shoes. In Proceedings of the Extended Abstracts of the 2018 CHI Conference on Human Factors in Computing Systems, Montreal, QC, Canada, 21–26 April 2018. [Google Scholar]

- Veltink, P.H.; Slycke, P.; Hemssems, J.; Buschman, R.; Bultstra, G.; Hermens, H. Three dimensional inertial sensing of foot movements for automatic tuning of a two-channel implantable drop-foot stimulator. Med. Eng. Phys. 2003, 25, 21–28. [Google Scholar] [CrossRef]

- Dong, G.; Tessier, D.; Zhao, Y.F. Design of Shoe Soles Using Lattice Structures Fabricated by Additive Manufacturing. In Proceedings of the Design Society: International Conference on Engineering Design; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Dorschky, E.; Krüger, D.; Kurfess, N.; Schlarb, H.; Wartzack, S.; Eskofier, B.M.; van den Bogert, A.J. Optimal control simulation predicts effects of midsole materials on energy cost of running. Comput. Methods Biomech. Biomed. Eng. 2019, 22, 869–879. [Google Scholar] [CrossRef] [PubMed]

- Khajavi, S.; Ituarte, I.; Jaribion, A.; An, J.; Chua, C.K.; Holmström, J. Impact of Additive Manufacturing on Supply Chain Complexity. In Proceedings of the Annual Hawaii International Conference on System Sciences, Maui, HI, USA, 7–10 January 2020. [Google Scholar]

- Li, Y.; Jia, G.; Cheng, Y.; Hu, Y. Additive manufacturing technology in spare parts supply chain: A comparative study. Int. J. Prod. Res. 2017, 55, 1498–1515. [Google Scholar] [CrossRef]

- Meisel, N.A.; Williams, C.B.; Ellis, K.P.; Taylor, D. Decision support for additive manufacturing deployment in remote or austere environments. J. Manuf. Technol. Manag. 2016, 27, 898–914. [Google Scholar] [CrossRef]

- Tien, J.M. The Next Industrial Revolution: Integrated Services and Goods. J. Syst. Sci. Syst. Eng. 2012, 21, 257–296. [Google Scholar] [CrossRef]

- Petrick, I.J.; Simpson, T.W. 3D Printing Disrupts Manufacturing. Res. Technol. Manag. 2013, 56, 12. [Google Scholar] [CrossRef]

- Meyer, M.; Glas, A.; Eßig, M. Systematic review of sourcing and 3D printing: Make-or-buy decisions in industrial buyer-supplier relationships. Manag. Rev. Q. 2021, 71, 723–752. [Google Scholar] [CrossRef]

- De la Torre, N.; Espinosa, M.M.; Domínguez, M. Rapid Prototyping in Humanitarian Aid To Manufacture Last Mile Vehicles Spare Parts: An Implementation Plan. Hum. Factors Ergon. Manuf. Serv. Ind. 2016, 26, 533–540. [Google Scholar] [CrossRef]

- Oettmeier, K.; Hofmann, E. Impact of additive manufacturing technology adoption on supply chain management processes and components. J. Manuf. Technol. Manag. 2016, 27, 944–968. [Google Scholar] [CrossRef]

- Barz, A.; Buer, T.; Haasis, H.-D. Quantifying the effects of additive manufacturing on supply networks by means of a facility location-allocation model. Logist. Res. 2016, 9, 13. [Google Scholar] [CrossRef]

- Holmström, J.; Partanen, J.; Tuomi, J.; Walter, M. Rapid manufacturing in the spare parts supply chain: Alternative approaches to capacity deployment. J. Manuf. Technol. Manag. 2010, 21, 687–697. [Google Scholar] [CrossRef]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Holmström, J.; Partanen, J. Digital manufacturing-driven transformations of service supply chains for complex products. Supply Chain Manag. Int. J. 2014, 19, 421–430. [Google Scholar] [CrossRef]

- Hedenstierna, C.P.T.; Disney, S.M.; Eyers, D.R.; Holmström, J.; Syntetos, A.A.; Wang, X. Economies of collaboration in build-to-model operations. J. Oper. Manag. 2019, 65, 753–773. [Google Scholar] [CrossRef]

- Chin, K.-S. Implementation of rapid Prototyping technology—A Hong Kong manufacturing industry’s perspective. Int. J. Adv. Manuf. Technol. 1998, 14, 570–579. [Google Scholar] [CrossRef]

- Chua, C.K.; Lee, C.W.; Hong, K.H. Rapid prototyping in the development of optical pickup unit. Int. J. Adv. Manuf. Technol. 2005, 25, 484–492. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmstrom, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, Y.F. Additive manufacturing-enabled design theory and methodology: A critical review. Int. J. Adv. Manuf. Technol. 2015, 80, 327–342. [Google Scholar] [CrossRef]

- Durach, C.F.; Kurpjuweit, S.; Wagner, S.M. The impact of additive manufacturing on supply chains. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 954–971. [Google Scholar] [CrossRef]

- Dwivedi, G.; Srivastava, S.K.; Srivastava, R.K. Analysis of barriers to implement additive manufacturing technology in the Indian automotive sector. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 972–991. [Google Scholar] [CrossRef]

- Baumers, M.; Holweg, M. On the economics of additive manufacturing: Experimental findings. J. Oper. Manag. 2019, 65, 794–809. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Chekurov, S.; Metsä-Kortelainen, S.; Salmi, M.; Roda, I.; Jussila, A. The perceived value of additively manufactured digital spare parts in industry: An empirical investigation. Int. J. Prod. Econ. 2018, 205, 87–97. [Google Scholar] [CrossRef]

- Kretzschmar, N.; Chekurov, S.; Salmi, M.; Tuomi, J. Evaluating the Readiness Level of Additively Manufactured Digital Spare Parts: An Industrial Perspective. Appl. Sci. 2018, 8, 1837. [Google Scholar] [CrossRef]

- Moore, S.S.; O’Sullivan, K.J.; Verdecchia, F. Shrinking the Supply Chain for Implantable Coronary Stent Devices. Ann. Biomed. Eng. 2016, 44, 497–507. [Google Scholar] [CrossRef] [PubMed]

- Chiu, M.C.; Lin, Y.H. Simulation based method considering design for additive manufacturing and supply chain An empirical study of lamp industry. Ind. Manag. Data Syst. 2016, 116, 322–348. [Google Scholar] [CrossRef]

- Neely, E.L. The Risks of Revolution: Ethical Dilemmas in 3D Printing from a US Perspective. Sci. Eng. Ethics 2016, 22, 1285–1297. [Google Scholar] [CrossRef]

- Rogers, H.; Baricz, N.; Pawar, K.S. 3D printing services: Classification, supply chain implications and research agenda. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 886–907. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Tetik, M.; Mohite, A.; Peltokorpi, A.; Li, M.; Weng, Y.; Holmström, J. Additive Manufacturing in the Construction Industry: The Comparative Competitiveness of 3D Concrete Printing. Appl. Sci. 2021, 11, 3865. Available online: https://www.mdpi.com/2076-3417/11/9/3865 (accessed on 1 April 2024). [CrossRef]

- Pérès, F.; Noyes, D. Envisioning e-logistics developments: Making spare parts in situ and on demand: State of the art and guidelines for future developments. Comput. Ind. 2006, 57, 490–503. [Google Scholar] [CrossRef]

- Thiesse, F.; Wirth, M.; Kemper, H.G.; Moisa, M.; Morar, D.; Lasi, H.; Piller, F.; Buxmann, P.; Mortara, L.; Ford, S.; et al. Economic Implications of Additive Manufacturing and the Contribution of MIS. Bus. Inf. Syst. Eng. 2015, 57, 139–148. [Google Scholar] [CrossRef]

- Chen, Z. Research on the Impact of 3D Printing on the International Supply Chain. Adv. Mater. Sci. Eng. 2016, 2016, 4173873. [Google Scholar] [CrossRef]

- Steenhuis, H.-J.; Pretorius, L. Consumer additive manufacturing or 3D printing adoption: An exploratory study. J. Manuf. Technol. Manag. 2016, 27, 990–1012. [Google Scholar] [CrossRef]

- Krikke, H.; Hofenk, D.; Wang, Y. Revealing an invisible giant: A comprehensive survey into return practices within original (closed-loop) supply chains. Resour. Conserv. Recycl. 2013, 73, 239–250. [Google Scholar] [CrossRef]

- Baumers, M.; Tuck, C.; Wildman, R.; Ashcroft, I.; Rosamond, E.; Hague, R. Transparency Built-in Energy Consumption and Cost Estimation for Additive Manufacturing. J. Ind. Ecol. 2013, 17, 418–431. [Google Scholar] [CrossRef]

- Mohr, S.; Khan, O. 3D Printing and Its Disruptive Impacts on Supply Chains of the Future. Technol. Innov. Manag. Rev. 2015, 5, 20–25. [Google Scholar] [CrossRef]

- Rylands, B.; Böhme, T.; Gorkin, R.; Fan, J.; Birtchnell, T. The adoption process and impact of additive manufacturing on manufacturing systems. J. Manuf. Technol. Manag. 2016, 27, 969–989. [Google Scholar] [CrossRef]

- Chekurov, S.; Salmi, M.; Verboeket, V.; Puttonen, T.; Riipinen, T.; Vaajoki, A. Assessing industrial barriers of additively manufactured digital spare part implementation in the machine-building industry: A cross-organizational focus group interview study. J. Manuf. Technol. Manag. 2021, 32, 909–931. [Google Scholar] [CrossRef]

- Weller, C.; Kleer, R.; Piller, F.T. Economic implications of 3D printing: Market structure models in light of additive manufacturing revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- Holmström, J.; Liotta, G.; Chaudhuri, A. Sustainability outcomes through direct digital manufacturing-based operational practices: A design theory approach. J. Clean. Prod. 2017, 167, 951–961. [Google Scholar] [CrossRef]

- Meredith, J. Building operations management theory through case and field research. J. Oper. Manag. 1998, 16, 441–454. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 5th ed.; SAGE: Los Angeles, CA, USA, 2014. [Google Scholar]

- Varum, C.A.; Melo, C. Directions in scenario planning literature—A review of the past decades. Futures 2010, 42, 355–369. [Google Scholar] [CrossRef]

- Cornelius, P.; van de Putte, A.; Romani, M. Three Decades of Scenario Planning in Shell. Calif. Manag. Rev. 2005, 48, 92–109. [Google Scholar] [CrossRef]

- Sodhi, M.S. How to do strategic supply-chain planning. MIT Sloan Manag. Rev. 2003, 45, 69–75. [Google Scholar]

- Jiang, R.; Kleer, R.; Piller, F.T. Predicting the future of additive manufacturing: A Delphi study on economic and societal implications of 3D printing for 2030. Technol. Forecast. Soc. Chang. 2017, 117, 84–97. [Google Scholar] [CrossRef]

- Likert, R.A. Technique for the Measurement of Attitudes. In Archives of Psychology; Woodworth, R.S., Ed.; American Psychological Association: New York, NY, USA, 1932; Volume 140, pp. 54–55. [Google Scholar]

- Waller, M.A.; Fawcett, S.E. Click Here for a Data Scientist: Big Data, Predictive Analytics, and Theory Development in the Era of a Maker Movement Supply Chain. J. Bus. Logist. 2013, 34, 249–252. [Google Scholar] [CrossRef]

- Framinan, J.M.; Perez-Gonzalez, P.; Fernandez-Viagas, V. An overview on the use of operations research in additive manufacturing. Ann. Oper. Res. 2023, 322, 5–40. [Google Scholar] [CrossRef]

- Ritola, I.; Krikke, H.; Caniëls, M.C.J. Learning from Returned Products in a Closed Loop Supply Chain: A Systematic Literature Review. Logistics 2020, 4, 7. Available online: https://www.mdpi.com/2305-6290/4/2/7 (accessed on 1 April 2024). [CrossRef]

- Sauerwein, M.; Doubrovski, E.; Balkenende, R.; Bakker, C. Exploring the potential of additive manufacturing for product design in a circular economy. J. Clean. Prod. 2019, 226, 1138–1149. [Google Scholar] [CrossRef]

- Friesike, S.; Flath, C.M.; Wirth, M.; Thiesse, F. Creativity and productivity in product design for additive manufacturing: Mechanisms and platform outcomes of remixing. J. Oper. Manag. 2019, 65, 735–752. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Pereira, G.M.; Borchardt, M.; Da Silva, R.I.; Viegas, C.V. A SCOR-based model for supply chain performance measurement: Application in the footwear industry. Int. J. Prod. Res. 2015, 53, 4917–4926. [Google Scholar] [CrossRef]

- Mandolla, C.; Petruzzelli, A.M.; Percoco, G.; Urbinati, A. Building a digital twin for additive manufacturing through the exploitation of blockchain: A case analysis of the aircraft industry. Comput. Ind. 2019, 109, 134–152. [Google Scholar] [CrossRef]

| Digital Encapsulation Enabled Pathways | |||

|---|---|---|---|

| Proposition | Independence (from Complex Production Systems) | Redistribution (of Tasks in the SC) | Interactivity (with Other SC Partners, Incl. Suppliers) |

| p1: Plan | - | shorter, simpler SC | - |

| p2: Source | reduced suppliers | changed need for suppliers | strong relations with suppliers |

| p3: Make | reduced equipment and buildings | - | - |

| p4: Deliver | shift to digital storage | reduced material handling and transportation | - |

| p5: Return | reduced raw materials | - | - |

| p6: Enable | less personnel | knowledge shift/changing jobs | enabling IT systems |

| Name | Description | Supplementary |

|---|---|---|

| 1. AM of the last | AM production replaces traditional manufacturing of the last | Figure S1 |

| 2. AM of the footbed | AM production replaces traditional manufacturing of the last and the footbed | Figure S2 |

| 3. AM of the fitting shoe | AM production replaces traditional manufacturing of the last, the footbed and the fitting shoe | Figure S3 |

| 4a. AM of the test shoe (including fitting process) | AM production replaces traditional manufacturing of the last, the footbed, the fitting, and the test shoe. The ‘fitting iterations’ continue to take place | Figure S4 |

| 4b. AM of the test shoe (excluding fitting process) | AM production replaces traditional manufacturing of the last, the footbed and the test shoe. The ‘fitting iterations (fitting shoe)’ are eliminated | Figure S5 |

| 5. AM of the final shoe | AM production of the complete final shoe; traditional manufacturing of the last, the footbed, the fitting, test, and the final shoe are eliminated | Figure S6 |

| Scenario | 2020 | 2025 | 2030 |

|---|---|---|---|

| 1. AM last | <60% | <100% | <120% |

| 2. AM foot bed | <44% | <68% | <79% |

| 3. AM fitting shoe | <22% | <32% | <43% |

| 4a. AM test shoe (including fitting) | N/A | <26% | <37% |

| 4b. AM test shoe (excluding fitting) | N/A | <64% | <92% |

| 5. AM final shoe | N/A | <84% | <126% |

| Scenario | Lead Time [h] | Major Contributor | Alternative |

|---|---|---|---|

| 0. Current (traditional) manufacturing | 466 | Circa 360 h outsourced manufacturing (east Asia) of outer shell | Reduced to circa 120 h when nearshored manufacturing of outer shell |

| 1. AM last | 466 | ||

| 2. AM foot bed | 466 | ||

| 3. AM fitting shoe | 465 | ||

| 4a. AM test shoe (including fitting) | 465 | ||

| 4b. AM test shoe (excluding fitting) | 512 | ||

| 5. AM final shoe | 53 | Circa 24 h AM of shoe + circa 24 h shipping | Reduced to circa 24 h when insourced |

| Digital Encapsulation Enabled Pathways | |||||

|---|---|---|---|---|---|

| Life Cycle Stage | SCOR Element | Independence | Redistribution | Interactivity | Resilience (New) |

| Design | Plan | Perfect design (case study) | Buyer-supplier relations (case study) | Co-creation (literature study) | (Not in case/literature study) |

| Source (new) | Universal /standardized materials (case study) | Insource/outsource decision (case study) | Supplier base (case study) | (Not in case/literature study) | |

| Manufacturing | Make | More location options (literature study) | (Not in case/literature study) | (Not in case/literature study) | On-demand availability (case study) |

| Delivery | Deliver | More transportation options (literature study) | Last-mile shortens (case study) | Share user knowledge (case study) | Hard to reach locations (literature study) |

| Return (new) | (Not in case/literature study) | (Not in case/literature study) | (Not in case/literature study) | Lower footprints (case study) | |

| Enable (new) | (Not in case/literature study) | New knowledge and skills/analytical tools for design support (case study) | IT platforms (literature study) | (Not in case/literature study) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verboeket, V.; Krikke, H.; Salmi, M. Implementing Additive Manufacturing in Orthopedic Shoe Supply Chains—Cost and Lead Time Comparison. Logistics 2024, 8, 49. https://doi.org/10.3390/logistics8020049

Verboeket V, Krikke H, Salmi M. Implementing Additive Manufacturing in Orthopedic Shoe Supply Chains—Cost and Lead Time Comparison. Logistics. 2024; 8(2):49. https://doi.org/10.3390/logistics8020049

Chicago/Turabian StyleVerboeket, Victor, Harold Krikke, and Mika Salmi. 2024. "Implementing Additive Manufacturing in Orthopedic Shoe Supply Chains—Cost and Lead Time Comparison" Logistics 8, no. 2: 49. https://doi.org/10.3390/logistics8020049

APA StyleVerboeket, V., Krikke, H., & Salmi, M. (2024). Implementing Additive Manufacturing in Orthopedic Shoe Supply Chains—Cost and Lead Time Comparison. Logistics, 8(2), 49. https://doi.org/10.3390/logistics8020049