Abstract

Background: Endogenous and exogenous factors impact the operational characteristics of supply chains, affecting wholesale warehouses. The survival of a warehouse is often threatened by disruptive events that alter infrastructure and performance. The emergence of COVID-19 exemplified the need for adaptability in retail goods supply chains, emphasizing the necessity for responding to external shocks. Methods: The MARLIN (Method wArehouse ResiLience dIstruptioN) method, founded on theories and models of resilience engineering is introduced. MARLIN is a practical tool designed to identify key areas requiring intervention in response to disruptive events. An empirical test was conducted in an Italian warehouse. Results: The conducted test yielded tangible results, demonstrating the efficacy of the method. It successfully pinpointed areas necessitating intervention and identified Key Performance Indicators (KPIs) associated with disruptions. The study not only underscores the importance of data collection but also highlights the often-overlooked significance of warehouse management. Conclusions: The study establishes MARLIN as a valuable asset for stakeholders involved in disruption management. Its application has proven instrumental in recognizing areas of intervention and identifying KPIs related to disruptions. Ongoing research endeavors to broaden its applicability across diverse supply chain scenarios, aiming to enhance situational awareness and enable proactive risk assessment through what-if analysis.

1. Introduction

The COVID-19 outbreak consistently impacted several economic sectors and at various levels of the value creation network. For example, the agri-food supply chain is regarded as a primary source of products, and as a result, institutions attempted to ensure its regular operation during the epidemic. Despite the constraints, many businesses in these areas were able to maintain operations. Endogenous and exogenous causes, however, had negative impacts such as disruptions and slowdowns. Because the pandemic represents one of the most severe outages in history, practitioners and researchers have been challenged to increase supply chain resilience [1,2,3,4,5]. Globally, 75% of enterprises observed SC interruptions due to transportation limitations in the wholesale distribution phases [6,7], including border restrictions as well as other restrictive policies. The epidemic has affected all sub-segments differently, some more than others [8,9] due to breakages in transportation networks, closures of wholesale markets, financial limitations, market turbulence, a lack of personnel, the closing of distributor retail locations, a lack of heavy vehicles, and the need for labor to load and unload goods from the distribution center to the wholesale market and later points of sale [10,11]. Distribution is an essential component in any sector, relying largely on receiving raw materials from suppliers and guaranteeing the continuation of the flow of commodities from manufacturers to end consumers [12]. Product availability mainly relies on the sales force and transport systems. Government-imposed rigorous regulations have had a significant impact on both [13]. Furthermore, retail market closures have placed further strain on the SC’s last node. Many retailers with physical storefronts have been impacted by social distancing and restricting measures, resulting in a decline in overall sales worldwide, despite an increase in the percentage of e-commerce retail sales [10]. Changes in consumption have also influenced the SC’s usual operation, particularly the marketing and distribution sectors [14], stressing the importance of order timing and price initiatives for wholesale providers in a chaotic situation caused by supply interruptions. A correlation was discovered between the quantity of orders placed with the interrupted supplier and price leadership. This number tends to rise when the non-disrupted supply is the leader. Furthermore, if a disruption occurs before orders are received, the non-disrupted supplier may always demand a higher wholesale price. In the case of a supply interruption, such insights can assist operations managers in appropriately designing ordering and risk mitigation procedures, as well as in the redesign of supply contracts [15]. Because of the interrelationships between different members of the SC, the ramifications of the pandemic proved to be highly crucial [16]. Based on the ideas reported in the literature by [17,18], a pandemic has the potential to cause extremely disruptive occurrences, exhibiting the elements of improvisation, devastation, urgency, complexity, and diffusivity, culminating in so-called ripple effect repercussions [19,20,21]. The urgency of implementing interventions to support the affected social and economic structures, jointly with the otherwise rare chance of observing such an important phenomenon, has drawn the attention of many researchers. However, we can abstract from the specific contingency of the pandemic and its effects to identify methods of focused and rapid response in the face of other disruptive events that are equally difficult to predict and prevent [22]—so-called black swans [23,24,25]. Logically, the most promising approaches to detecting and mitigating disruptions are those of a simulative nature [26,27], but unexpected events are generally difficult to model, before experimenting with their behaviors and characteristics, to validate the simulation models. The warehouse, as well as the supply chain in which it is included, is a complex cyber-socio-technical system in which social and human artifacts are intertwined with technical artifacts that must be seen as a whole. Because of their complexity, these systems have proven to be difficult to manage in the face of a black swan. As a result, modern facility management needs to consider different material resource interests, as well as environmental interests [28]. The discipline of resilience engineering intervenes in this scenario. Resilience engineering seeks to create, in each of its applications, an ever-changing model to capture the extremely dynamic and changing nature of complex socio-technical systems. Companies must operate in highly dynamic situations where essential resources are few and commercial possibilities are frequently unpredictable [29]. However, up to this date, the discipline and its related models and theory have been lightly applied to the scenario of disruption in a warehouse. Specifically, the present study aims to unite the stress and strain model [30,31,32] and the theory of graceful extensibility [31]—shared concepts among resilience engineering theorists—and apply them to a new field of application.

The proposed method measures disruption effects to identify problem areas and intervene to prevent future disruption effects. Specifically, the method focuses on black swan disruptions, known as entirely unpredictable events. From an operations management perspective, the authors will refer to these events as outlier events that are severe in impact and might trigger unexpected problems, cause major visible impacts, and cannot be fixed quickly and easily with a standard response [33]. Furthermore, the approach is tested using a large case study that investigates the pandemic impacts on a wholesaler warehouse of food supplies in Italy. The choice of this Italian warehouse as a case study is notable for two reasons. First, it aligns with our ongoing collaboration with one of the largest and most geographically diverse wholesalers in Italy, encompassing warehouses across the country, including islands and remote areas, providing a comprehensive case study. Second, the choice of this particular case study allows us to address and analyze the effects of disruption in a complex and multifaceted warehouse context involving both automated and digitalized and non-automated warehouses. The research study proposes a novel approach with a twofold purpose that addresses the following research questions:

- How can the consequences of disruptions in a wholesale warehouse be measured?

- How can problem areas be uncovered and addressed to reduce the impact of future disruption?

These research questions reflect research gaps, identified by considering the six-step problematization methodology of [34]: (1) the domain is the disruption effect on wholesale warehouses; (2) the assumption is that the discipline of resilience engineering is nowadays uncommon in warehouse management; (3) the problematization of this last assumption confirms the opportunity to use resilience engineering since it is recognized as a successful paradigm for risky situations [35]; (4) thus, the authors assumed that resilience engineering can add knowledge to researchers and practitioners of warehouse management on how to cope with disruptive events; (5) this problem and the subsequent research questions could strongly benefit several supply chains, often hit by disruptive events (recently, a pandemic and war), thus research questions are interesting for the audience, and (6) the answers to the research questions are not obvious or absurd.

With this research, the authors contribute to the warehouse management literature by proposing a method to manage disruptions in today’s complex cyber socio-technical systems. As mentioned, the MARLIN method relies on the stress and strain model and the theory of graceful extensibility, which are currently being implemented practically [30,36,37,38,39]. Differently, MARLIN merges these two concepts, providing a new practical application to this combination. MARLIN efficiently leverages this visual analogy to identify patterns and potential black swans. On the other hand, the theory of graceful extensibility is a unified way to theorize the adaptive characteristics of complex adaptive systems, of which cyber-socio-technical systems are a subset. Unlike general methods developed by resilience engineering, the MARLIN method is oriented toward viability in the context of warehouse operations. The remainder of the paper is organized as follows.

Section 1 frames the problem of the supply chain and more specifically of the warehouse, assuming the perspective of the recent discipline of resilience engineering, introducing some theories and models underlying the MARLIN method, and providing some literature background information. Section 2 introduces the MARLIN method by detailing the assumptions behind it and the steps involved. Section 3 applies the method to a real-world case study. Section 4 discusses the implications of the research; then, it concludes and outlines the follow-up research.

2. Background

2.1. Complexity of Warehousing Activities, Safety-I and Safety-II

The warehouse, as well as the supply chain in which it is included, can be seen as a cyber-socio-technical system, a kind of Complex Adaptive System (CAS) in which social and human artifacts are inextricably intertwined with technical artifacts (e.g., I.o.T., edge computing, automated guided vehicles, collaborative robots, intelligent tracking systems, warehouse management systems, etc.) so that it is practically impossible to separate them—they must be seen as a whole [40]. These are strongly non-linear, dynamic systems, organized according to a hierarchical structure that repeats itself in a fractal way by incorporating other CASs [41]. Because of their complexity, these systems present so-called emergent features, i.e., features visible only at a certain level of observation of the system (abstraction layer) [42,43]. Notable examples of systems’ emergent phenomena are safety and resilience [44].

Safety, traditionally regarded as a characteristic of a system that frees people, property, and the environment from harm, has been envisioned as an emergent property of a well-functioning system by the contemporary safety science trend known as resilience engineering [45]. The resilience engineering discipline, embracing the legacy of cybernetics, systems theory, and other complexity sciences [46,47,48], aims to design artifacts capable of managing the resilient performance of a system, so that the system is able to proactively adjust itself to perform satisfactorily in the face of, or after, disruptive events [35,49]. Resilience engineering, concerning safety, constitutes a paradigm shift in the Kuhnian sense. This has been historically highlighted by affixing the suffix -II to the resilience engineering view of Safety, precisely to explicitly mark this caesura against the traditional perspective (Safety-I): Safety-II intends to make as many things as possible go well in contrast to Safety-I, which intends to make as few things as possible go wrong [50]. Although the reversed Safety-II view appears, at first sight, to be in complete opposition, it is intended to be an inclusive view of Safety-I [51,52,53]. The former does not contradict the latter but includes it since a system that maximizes successful performance minimizes failures as well. In this sense, the search for resilient performance also implies, as far as possible, the emergence of safety [54].

However, resilience engineering, partly due to its intermingling of only partially overlapping perspectives and themes, and partly due to its intrinsic drive for innovation, has engendered a certain degree of confusion within safety science [55] and, to be fair, has provoked a large fringe of detractors and critics [56,57,58]. Even today, there is a heated debate among safety scholars, which has even led to an internal schism within resilience engineering—also for sociological reasons [58,59]; advocates of the traditional view discredit Safety-II, while proponents of the latter emphasize the fact that it incorporates Safety-I in a full-fledged paradigmatic extension. We will avoid controversy here, although our position is clear. What is certain is that the differences, at least conceptually, have long since been outlined [60]: Safety-I is the approach traditionally adopted in organization management. Its main objective is to discover and reduce errors and incidents to ensure that negative events are avoided. Mostly reactive, it focuses on actions that are wrong, or on human errors, trying to identify the causes behind incidents to prevent their recurrence. It aims for zero errors and incident elimination. Accident investigations are geared towards identifying responsibility. Safety-II aims to understand how people and organizations successfully manage risks and complexity, rather than focusing only on errors. It recognizes that human beings are adaptive and capable resources that play a key role in dealing with complex and unforeseen situations. It is mostly proactive, emphasizing positive actions, skills, and practices that enable people to cope with difficult situations and avoid or mitigate potential incidents. The objective is not to eliminate mistakes, which it considers unrealistic, but rather to learn from them and improve the organization’s adaptability.

For example, FRAM—one of the flagship analytical tools of resilience engineering—has repeatedly been shown to offer insights not attained by traditional methods (e.g., fault tree analysis, HAZOP, bow-tie) [61]. Healthcare, a typical setting seen as particularly complex, provides numerous examples of its application: for example, it was used to reconcile the perspectives of work as done by frontline workers and as imagined by management. It also served to identify several missing processes [62]. Due to this potential to map the complexity of human, technological, and organizational functions, FRAM is often used to identify critical processes that escape linear analysis [35,63,64], to offer social and organizational understandings [65,66,67], and to design leading and lagging Key Performance Indicators [68]. Aviation, maritime, road transportation, and railways sectors have also undergone similar analyses [69,70,71,72,73,74], as well as construction [75,76], and other critical infrastructures [77,78,79].

Logistics and supply chain management have also been touched upon from the perspective of resilience engineering, albeit timidly. Perhaps the most relevant paper is the essay by Weiland and Durach, who clarified between resilience engineering and social-ecological resilience to integrate them for the benefit of supply chains [80]. The intention is to shift the focus from the definition of infrastructure network resilience to organizational resilience, integrating resilience engineering issues. This intent is also expressed by Eltantawy (2015). However, the two essays do not adopt methods or propose any particular tools for practical problem-solving. Adobor and McMullen also reframe supply chain issues by integrating CASs and resilience perspectives. This suggests a shift in perspective, especially in managerial roles. However, it also calls for further research—which the present paper aims to satisfy—about interpreting portions of supply chains as CAS systems and proposing tailored methods [81,82].

The article “Sustainable Design and Management of Industrial Systems—A Human Factors Perspective” explores how socio-technical fields contribute to a human-centric lifecycle management approach for industrial systems, driven by the growing adoption of digitalization. This integration of technology and human factors fosters innovative organizational transformation to promote sustainability. The article presents empirical insights into organizational resilience and offers an example of activity-centered analysis in a logistics process within an outbound warehouse. By combining organizational vectors, the article emphasizes the potential for human-centered design and management to enhance resilience in both production and logistics systems [83].

Beyond these examples, we are not aware, to the extent of our knowledge, that resilience engineering has ever been used to assist in solving warehouse managers’ problems. However, given the actual complexity of these socio-technical environments, we believe that this conceptual approach (also considering the above few academic contributions) might be useful to those professionals not accustomed to this new paradigm who want to consider warehouse management complexity from a resilience engineering standpoint.

This requires three steps in sequence: first , we need to clarify the epistemic assumptions of the discipline, if we accept its assumption of validity; then we need to introduce those specific concepts and models developed by the discipline that are the foundation of the methodology we propose in this article; as a final step, we ought to conceal these models in the implementation of the method, from a perspective of simplex (not simplistic) management of complexity [84,85]—which is also one among other declared purposes of resilience engineering.

2.1.1. The Resilience Engineering Standpoint

We understand a cyber-social-technical system as the broadest possible definition of a contemporary organizational artifact, given the pervasiveness of today’s digital technologies. Warehouses and supply chain segments are no exception. Cyber-socio-technical systems normally manifest resilient performance to pursue the functional purpose for which it was constituted and to continue to exist [86,87].

Resilience engineering proposed an operational definition of resilience as a combination of four pillars of abilities a system must possess to manifest a resilient performance, namely, Responding, Learning, Monitoring, and Anticipating [88,89,90]. Systems deficient in these abilities might exhibit brittleness and be compromised (or even destroyed) by pronounced fluctuations internal to them or present in their environment. Nonetheless, variability (i.e., fluctuations) is the basic mechanism through which systems, most of the time, succeed. In practice, success and failure originate from the same causative mechanism and this exacerbates the unpredictability of behaviors as well as the inapplicability of strictly finalistic methodologies. Taxonomies of causes and events also lose much of the importance given to them by Safety-I methods, since resilience engineering assumes that not only will there always be unknown and unknowable events [91], but above all that a cataloging of the known events is fundamentally meaningless since the same events can produce normal performances (successes) or failures [92]. Resilience engineering, as a discipline, aims to manage the risk of systems that can never be fully described and, indeed, tend to be underspecified. Far from being a Homo Economicus, the worker possesses bounded rationality and incomplete knowledge of the environment, even as he relentlessly adapts to it. Neither will management nor the analyst ever be ontologically able to achieve complete, full knowledge of the work environment [60]. Resilience engineering, by its very nature, is a constructivist discipline that seeks from time to time to create and recreate, in each of its applications, an ever-changing model to capture the extremely dynamic and changing nature of complex socio-technical systems [93]. From this point of view, rather than a classification of risks, the concept of situational awareness is more important and can be more easily related to resilience skills in a proactive sense (unknown knowns, i.e., that which can be known but that we do not yet fully comprehend), reactive sense (known knowns, i.e., that which we believe that we fully understand) and retroactive sense (known unknowns, i.e., that which is uncertain but that we are aware of, for example, a lesson not learned or just forgotten) with anticipation, responsiveness, and the ability to learn, respectively [91]. In this sense, Aven rightly emphasized the concept of the ‘black swan’, which is useful for disseminating certain concepts and is certainly very suggestive but needs to be precisely defined in the scientific study of risk [94,95].

Since Safety-II incorporates Safety-I, the cataloging of the causes of risk may be useful to enable one of the traditional methods. However, managers, or rather blunt-end operators, must consider that focusing on the specificity of causes could lead to losing the holistic vision of the system. Concerning this, Aven concludes in his work that to effectively confront potential black swan events, a comprehensive approach is necessary, combining risk-based strategies, cautionary and precautionary measures (like robustness, resilience, and adaptability), and discourse-based methods. Relying solely on a risk-based approach is rarely sufficient, given the high stakes and significant uncertainties involved. Therefore, it is imperative to devise robust and resilient solutions capable of handling extreme, unforeseen situations. Managing black swan events involves analyzing and adopting appropriate principles and methodologies to prevent their occurrence. This entails identifying potential events and establishing barrier systems to mitigate their impact, which is possible only by unleashing the remaining resilience ability: Monitoring.

While numerous events occur throughout the year, most are inconsequential, underscoring the importance of discerning between routine incidents and extraordinary black swan occurrences. As pointed out by others as well [23,25,96], the critical elements in addressing black swan events are knowledge and uncertainty. The September 11 tragedy serves as a prime example, where some possessed relevant knowledge while others did not. To make progress in this field, it is essential to move beyond existing practices and theories, necessitating the development of novel principles and methods. Another point raised by Aven is that various analyses, including robustness assessments, offer valuable insights and decision-making support. However, caution must be exercised in drawing overly definitive conclusions based solely on these results. We should extend risk-based approaches to encompass black swan risks, requiring a new generation of risk assessment and decision support methodologies, but this can be achieved only by a continuous monitoring framework. Managing activities and minimizing accidents while executing operations as planned necessitates more than just developing procedures and ensuring compliance. Traditional engineering risk analysis alone cannot address the unique challenges posed by black swan risks. Aven recognizes the significance of analysis in acquiring knowledge, but we must also acknowledge the limitations of purely analytical perspectives. A holistic and comprehensive approach is required to account for the unknown and the unforeseen, and this must be achieved through viable methods.

Unfortunately, proven resilience engineering methods, such as FRAM, have the disadvantage that they are difficult to use, require experienced analysts, and, very often, must be complemented by rather complex calculation methods to avoid trivial analyses. The Method for wArehouse ResiLience dIstruptioN (henceforth MARLIN method) is a candidate as a viable method for the continuous (i.e., dynamic) monitoring of parameters of interest that are not predefined, except for the actual state of the warehouse as the focus of the analysis.

2.1.2. The Resilience Engineering Foundational Concepts of MARLIN

MARLIN relies on the “stress and strain” mechanical analogy [30,31,32] and on the “theory of graceful extensibility” [97]. Both are popular constructs among resilience engineers, yet they have never been combined until now.

The Stress and Strain Model of Resilience

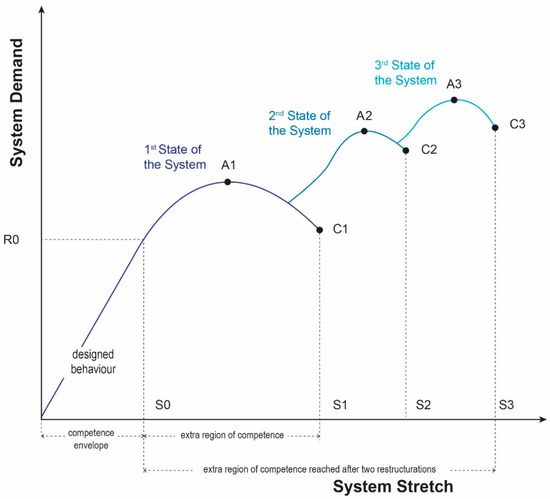

This well-known model, originally conceived by David Woods and John Wreathall [31], sets up an analogy between mechanical and organizational resilience so that the latter can be represented with a plain stress–strain plot. In materials science, the plot portrays the capability of a material to strain when it is stressed. The material, within a given stress value, behaves elastically, i.e., returns to its original dimensions when the load is removed; beyond this value, the material reorganizes its crystalline structure to compensate for the increased level of stress, i.e., the material behavior is inelastic: it does not respond proportionally to the load. In addition, if the material is subjected to even a small further amount of stress, a collapse will be highly likely. Cyber-socio-technical systems actively stretch in the face of the demand variations imposed on them. Under design conditions, similarly to a material behaving within the elastic range, the system distributes its elongations proportionally to demands, yet without structural reorganization. Beyond the design conditions, the system stretches non-proportionally while maintaining a safe and productive performance. It is stretching its so-called envelope competence. As demand increases, the system responds less and less effectively, eventually decompensating. From this position, the system may evolve toward only two distinct states: either it collapses, or it restructures itself to reach a higher level of performance. While for a steel bar, this happens only once, for a cyber-socio-technical system this evolutionary pattern can occur several times. Figure 1 sketches the stretch–demand plot for a generic cyber-socio-technical system [31].

Figure 1.

According to the stress–strain model, organizational resilience is like mechanical resilience. The system, in the face of increased demands, if it exceeds its normal competence envelope (S0), will begin to stretch to accommodate the increased stress. Beyond this point, A1 is possible in only two outcomes: the collapse (C1) or a restructuring corresponding to a new state, more performant. This evolutionary pattern in the figure is repeated another time until a further third state is reached. Adapted from [31].

This capacity for achieving newer stability through change is called allostasis. Allostasis might also lead to unwanted stability states such as collapse. This is when systems misalign the strains to the stresses. The wear and tear associated with chronic overactivity or underactivity is called the allostatic load to which the system is exposed, and recently a way to measure it has been proposed [98]. The allostatic load can be seen as a measure of the degree to which the system can maintain its balance in the presence of environmental changes. This measure is potentially important because it might allow us to better understand the long-term effects of chronic stress and other environmental factors on the system. Examples of applications of stress and strain theory can be found, for instance, in the construction industry [30] or the chemical process industry [99], with a focus on safety issues.

The Theory of Graceful Extensibility

David Woods has theorized, in a unified way, the adaptive characteristics of CAS systems of which cyber-socio-technical systems [97] like warehouses are a subset. Currently, the theory is expressed in the form of ten proto-theorems that are logically consequential and which, among other things, specify and extend some concepts embryonically enucleated in the stress–strain model. In particular, the theory clarifies that sustainable adaptive behavior is the result of systems attempting to cope with pronounced variations under conditions of finite resources as well as distributed and locally bounded rationality. The theory also has the virtue of accounting for particularly significant phenomena among cyber-socio-technical systems. For example, suboptimal behavior at the subsystem level can emerge as optimal at higher abstraction layers, in the so-called “tragedy of the commons” phenomenon. The theory of graceful extensibility describes systems like layered and tangled networks of Units of Adaptive Behaviour (UAB) able to reorganize themselves in structures apt to express the more opportune functions in a given moment and consider the Efficiency-Thoroughness Trade-Offs [100].

Particularly relevant to the MARLIN method are:

- The concept of Unit of Adaptive Behaviour (UAB), a unit in the system network capable of autonomous adaptation;

- The adaptive capacity (i.e., the potential to modify the changing demands and the responses that the system can implement to those demands about its goals). The adaptive capacity is divided into a base adaptive capacity (corresponding to the homeostatic adaptation that allows for the ordinary dynamic adaptive behavior) and an extensible adaptive capacity (corresponding to the allostatic adaptation that allows for the extraordinary dynamic adaptive behavior);

- Capacity for Maneuver (CfM), a quantity along which the risk of saturation (i.e., reaching the limit of maneuvering capacity and thus becoming fragile) can be estimated, and by other authors has been traced to so-called slack resources [101];

- The MARLIN method envisions the UABs of the warehouse as areas (also functional) in which surprise phenomena may occur (events that can happen near or outside the limits of the envelope described by the homeostatic functioning of the system, i.e., the disruptions).

Suggested Possible Disruptions to Stretch the Warehouse Performance Envelope

Certainly, for warehouse management experts, the impact of all potential disruptions on the safety and performance of warehouses should be a topic of interest. Yet even a brief query on the Scopus database returns a picture mostly monopolized by the pandemic. Part of the scientific effort has been directed at the rapid identification of mitigation interventions, and the pandemic has offered researchers the rare opportunity to observe and measure the effects of a phenomenon with enormous social, economic, and technological impacts. In the research process, we repeatedly used information taken from the literature [2,102,103]. Consequently, when it was not possible to refer to several types of disruptions, we were left to opportunistically abstract from COVID-19-induced effects on the warehouse system.

The COVID-19 pandemic brought several profound changes to the realm of warehouse management, setting it apart from conventional practices. The pandemic led to social distancing restrictions, limiting the workforce inside warehouses. This restriction translated into rising labor costs due to modified work arrangements, extended working hours, and the necessity to employ additional staff to maintain operations while adhering to health guidelines [104]. Labor shortages were discovered in all stages of production, processing, and marketing, owing to the absenteeism of seasonal foreign labor in the countryside and industry, particularly in highly human-concentrated businesses such as meat processing [105,106,107]. This condition resulted in a shortage of product availability spanning from raw materials to finished items, which was exacerbated by restrictions put on the international commerce of goods in both import and export [106,108]. Warehouses were required to adapt to this sudden increase in demand, necessitating the reevaluation of inventory levels, procurement strategies, and fulfillment processes. To address supply chain disruptions caused by the pandemic, many organizations found themselves needing to store larger inventory volumes than usual. Warehouses were required to manage these increased stock levels efficiently while ensuring the availability of essential goods and minimizing operational disruptions [109].

The pandemic also caused extensive reductions in production levels, as numerous manufacturing enterprises were often forced to pause or temporarily halt production [110,111,112]. Disruptions also impacted maritime, rail, and land transport networks related to food distribution [113,114,115]. On the other hand, labor or transportation scarcity has a negative knock-on impact, because an input in the SC production process is an output of the preceding phase [10,116]. Furthermore, broad government-imposed lockdowns interrupted many citizens’ jobs, resulting in a general fall in consumer income [117,118]. Additionally, the security risk linked with theft and criminality constituted a significant danger to merchants [119,120]. Changes in food consumption and purchasing caused a marked shock on the consumption side [121,122]. Points of sale also faced a decrease in end-product availability [123,124]. End-consumer demand increased in points of sale other than restaurants due to the interruption of HoReCa (Hotellerie Restaurant Café) channels. In addition, there was an increasing tendency towards the need for preservable items and the penalization of highly perishable products [107,125,126], such as consumption frequency change [107,126]. The phenomenon of food insecurity grew from two main perspectives: on the one hand, the perceived lack of necessities in wealthier countries, which resulted in irrational and excessive purchasing [127]; on the other hand, a real food shortage in countries where already before the pandemic the nutritional level of the population was not fair and adequate [10,128,129,130]. The pandemic’s duration may have significant long-term effects on customer purchasing channels, and merchants must adjust to this mutation, for example, by favoring a multi-channel, physical, and online marketing distribution approach [13]. In addition, these multiple challenges encountered during the pandemic underscore the limitations of traditional warehouse management methods and highlight the need for a more resilient and adaptive approach [131]. Indeed, the field of warehouse management has undergone significant changes, driven by the increasing complexity of supply chain operations. This complexity has exposed warehouses to a variety of potential disruptions that can have far-reaching effects on security and performance. Therefore, there has been a growing interest in practical and dynamic solutions to cope with disruptions in today’s complex socio-technical systems [132], providing scope for the introduction of a practical application to enhance the resilience and adaptability of warehouse operations.

2.1.3. Simplexity of the MARLIN Method

Managers of supplies look at the warehouse as a physical facility to optimize supplies based on enterprise needs. A warehouse’s behavior is also clearly dynamic under ordinary conditions, corresponding to homeostatic regulation, even when it does not exceed its normal competence envelope (i.e., its base adaptive capability). The physiological equilibrium of the warehouse is a preferential trajectory—an orbit of dynamic equilibrium—chased by the system during the continuously adjusted operations of the actual work as done [133]. The warehouse, to self-regulate, must possess distributed knowledge that, even with a quota of informative losses, reaches the apical figures of control.

The warehouse manager monitors the state of the warehouse through a dashboard of Key Performance Indicators (KPIs) that summarize the internal status of the warehouse (status variables) [134].

The definition and measurement of performance indicators is a core topic in the literature, even referring to modeling and evaluation of the performance of a stock management system [135,136].

A different viewpoint associated with the warehouse is the external one, which looks at the warehouse as an element of the logistics network. A warehouse (e.g., a distribution center or transit point) is schematically an object that processes material flows through the supply chain it belongs to, and is therefore interested in inputs and outputs of matter, energy, and information. The warehouse manager can evaluate the warehouse’s relationship with the surrounding environment (variable of the environment) through the computation of opportune indicators.

In normal conditions (homeostasis) the warehouse moves in the state space on orbits of quasi-optimality balancing both the necessity of assuring customer services, the one-off leveraging of the suppliers’ agreements, and the one-off withstanding of competitor’s pressure. The system warehouse can sometimes be subject to disruptions (i.e., severe departures from homeostatic equilibrium) originating internally or externally that, directly, or indirectly, influence its state. It is the warehouse’s ability to adapt in the face of disruption that defines it as a CAS, but such information is of no practical use to the manager, who, instead, needs directly plausible aids. The complexity of the systems is often reflected in those models that try to capture it. For these, resilience engineering intends to provide instruments showing only the tightly necessary quota of complexity to render the system viable [137], avoiding the operators’ cognitive overload [138] and tending towards the simple management of complexity [85].

Thus, although MARLIN’s starting assumptions are based on graceful extensibility, the proposed method hides most of its theoretical complexity. At a minimum, the method must relate the internal functioning state of the warehouse with the portion of the environment with which it relates (i.e., at least the nearest supply chain segments), systematically identifying the relationships among the variables involved; that is, it must be able to build the Capacity for Maneuver (CfM) and make the corresponding saturation risk explicit. MARLIN, as we will see in Section 2, assumes that different CfMs can be defined, each of them representative of a unique viewpoint on the warehouse according to the theory of graceful extensibility, which states that: “All adaptive units are local—constrained based on their position relative to the world and relative to other units in the network, therefore there is no best or omniscient location in the network. […] A UAB is responsible for goals relative to its local position in the network […] the view from any point of observation at any point in time simultaneously reveals and obscures properties of the environment—but this limit is overcome by shifting and contrasting over multiple perspectives—or perspective contrast overcomes bounds”.

Each of the CfMs elaborated through the MARLIN method is a function that connects the stretch of the system (the state) with the variation of a variable associated with the demand dictated to the system, tracing the stress–strain model. To summarize, underlying the MARLIN method there is a concept of variation associated with that of the CfM and that of the disruption being nothing more than a large variation pushing the system out of its normal performance envelope. Since the warehouse manager already detects variations in the indicators in use, MARLIN should necessarily investigate the relationship between indicators—in use or to be defined—and the possible disruptions in the warehouse system. Table 1 compares the key features of the theoretical and methodological contributions presented in the background section and summarizes the characteristics of the MARLIN method.

Table 1.

Comparison of scope and key features of the theoretical and methodological contributions presented in the background section.

3. Methods

According to the literature detailed in the previous paragraphs, the negative impacts of the pandemic on the SCs have often been addressed by academics. Such disruptive events have damaged all levels and sectors of the SC, causing ripple effects throughout the system. Nevertheless, exhaustive research on the wholesale warehouse sector has not been conducted so far.

The MARLIN method seeks to help SC stakeholders identify areas of greatest concern and develop solutions to reduce the consequences of future disruptions. The method has a dynamic and adaptive structure. This must be understood in all its parts and readapted to the context in which it applies. In particular, the method launches practitioners into reflection, guiding them to measure their system, study it, and find action points such as the importance of collecting data and the ability to analyze them.

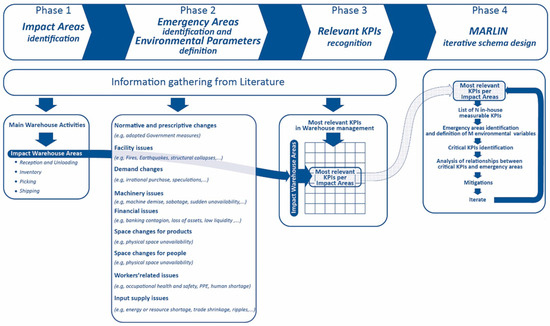

3.1. Building Steps of the MARLIN Method

The research process (Figure 2) began with an analysis of the major impact areas—namely the UABs most easily identifiable—within a large retail warehouse (Phase One). In the following phase two, the emergency areas (i.e., the areas where emerging phenomena are referable to the hypothesized disruption). The most significant elements and signs of a disruption, as well as the requirements and limits that influenced warehouse management during the disturbances, were discovered through a study of the literature. To objectively examine the condition of the system, all important performance metrics linked to warehouse management were gathered in phase three (both state and environment variables). Finally, during phase 4, the authors developed the iterative procedures required to apply the MARLIN approach uniformly to any distribution center for a consumer goods warehouse, which were then conducted for validation purposes.

Figure 2.

The research process put in place to build the Method wArehouse ResiLience dIstruptioN, a.k.a. MARLIN.

3.1.1. Phase One: Identifying Impact Areas

In developing the technique, the classification of activities offered by Frazelle [141] and the description of a basic warehouse structure [142], were used to define the primary activities and regions of a distribution center (DC). Receiving, putting away, storing, picking, and shipping (Figure 3) are all examples of warehouse activities that may be connected to distinct warehouse regions [141,143]. These areas have adaptive autonomy in the sense of graceful extensibility theory, and are therefore the starting UABs considered in the method. This assumption allows for the areas of the warehouse to be tailored to the examined areas in the DC and the functional relationships that are present. If successive refinements are needed, it might become necessary to decompose more deeply the functional network that realizes the warehouse. In this case, UABs belonging to a lower abstraction layer should be specified.

Figure 3.

Basic UABs considered in MARLIN, i.e., impact areas.

- Reception and Unloading Area: in this area the receiving activities are carried out; Receiving involves allocating vehicles to docks as well as organizing and carrying out unloading tasks. This zone is accessible to goods delivery trucks, trailers, and containers. Specifically, a warehouse’s loading and unloading facilities enable more agile and faster handling of unit loads, but they must be large enough to allow for simple loading and unloading while guaranteeing total safety. The utilization of this zone must adhere to a precise timetable for trucks to remain mobile;

- Inventory area: here, the put-away activities are carried out. The process of storing a purchased commodity or item in a warehouse is known as put away. These are the procedures that operators execute to store items unloaded from supplier trucks in the right warehouse locations, which include material handling as well as quantitative and qualitative product control. Following the completion of the control, the products will be sorted and put in the storage area;

- Picking area: in this area, the order picking activities are conducted. These activities entail the process of putting together an order. It is a major and labor-intensive operation in warehouses, and it is performed in the picking area. The goods are prepared here for transport to the shipping area;

- Shipping area: in this area, the shipping activities are conducted. Specifically, the processes of scheduling and allocating trucks to order docks, packaging after picking, and truck loading are realized. The packing areas are used for repackaging or pallet racking of goods according to predetermined unit loads.

3.1.2. Phase Two: Identifying Emergency Areas and Environmental Variables

When disruptive events occur, the identification of emergency areas becomes increasingly important. Emergency areas embody factors and elements that, directly or indirectly, suffer disruption consequences. Therefore, quantitative and/or qualitative monitoring of these areas allow us to understand anomalous trends, chain effects and, in general, to understand the impact of a disruption. For this reason, one or more KPIs, representative of environmental variables, should be defined for each emergency area. These KPIs make explicit the purpose and the object of monitoring. This lets us keep under control every relevant performance of each emergency area. The emergency areas can be correlated since the variation of a KPI of a specific area could also generate effects on other areas’ KPIs. Obviously, for each disruptive event, specific emergency areas must be defined, which can emerge from context analysis, field surveys, past experiences, literature reviews, and more.

For example, as explored in Section 3, the pandemic has significantly impacted the end consumer demand, generating chain effects on the entire supply chain. Against this backdrop, wholesale warehouses were required to modify the space required for finished goods. In addition, government restrictions have imposed a minimum interpersonal distance between workers to minimize contagiousness. Thus, wholesale warehouses were required to modify the space required for people. A further emergency area appears in the number of workers available since the pandemic generated absenteeism phenomena due to illness, or fears, as well as restrictions on people’s movement. Lastly, several factors, such as transportation restrictions, have negatively impacted the input supply—a further emergency area for the case study presented. Therefore, applying the method’s rationale, Figure 2 shows an example of the emergency area definition process. These are defined by the events illustrated, and previously discussed, namely: normative and prescriptive changes, facility issues, demand changes, machinery issues, financial issues, space changes for products, space changes for people, worker’s related issues, and input supply issues.

In general, the method, in the face of M distortion-related contingency areas, proposes M indicators that depend on actual operating conditions. They represent the so-called environmental variables. Given the context subsequently analyzed, the following emerging areas were identified: Demand, Space, Number of People, and Input Supply. The following Key Performance Indicators (KPIs) were defined for the first three areas: Variation in Product Demand, Area Utilization Coefficient, Volumetric Utilization Coefficient, Space Required for People, Absenteeism Rate, and Number of Personal Protective Equipment (PPE) available for workers. Finally, accounting for the Input Supply area, KPIs for service performance have been defined, including both the Delivery Time (i.e., Requested Readiness, Planned Readiness, Total Perceived Readiness, Planned Punctuality, Actual Punctuality, and Total Perceived Punctuality) and Delivery Characteristics (i.e., Completeness and Accuracy).

3.1.3. Phase Three: Identifying a Set of N Actual System-Specific State Variables

To support the management areas’ decisions and create a benchmarking process within the reference sector, it is crucial to analyze and monitor warehouse performance. This is due to the strategic role that a DC plays alongside the SC and the substantial increase in the complexity of the logistics network.

To establish a company’s strategy and evaluate its management effectiveness, it is normally required to introduce and define a set of KPIs that monitor progress and performance levels for meeting corporate objectives. Because deployment is a multi-part process with numerous players and activities, it is vital to control and manage the whole scope of the scheduled operations, as well as all aspects that directly or indirectly impact the plant’s performance levels. These elements might be internal, based on the equipment, layout, or staff engaged, or external, based on the SC actors [144]. Companies establish, measure, and monitor KPIs to assess their performance as well as to gain cost savings and boost DC efficiency [145].

Each warehouse, once the areas have been defined, establishes the performance it wants to monitor. Along with this, a data collection process must be activated. These assumptions create different groups of monitored KPIs in each warehouse. This process, like the MARLIN method, is dynamic. Each warehouse periodically gathers the management team, defines the KPIs, and prepares the data collection systems. This dynamism is necessary in today’s warehouse environment. Depending on the products handled, warehouse coverage area, or disruptions, different situations emerge that require monitoring. The ability to measure KPIs is also an important issue today. While increasing digitalization is making warehouses highly automated, this logic does not always lead to the presence of a system for collecting and analyzing warehouse data [146]. Coupled with this, there are still numerous warehouses that are not yet very digitalized, so a continuous review of the available data is necessary.

Several academics have investigated warehouse performance evaluation in various ways [136,147]. Each study focuses on a certain set of objectives, KPIs, and warehousing systems. The authors determined through a literature analysis the most widely monitored KPIs. In particular, articles and manuals from Operations Management and Logistics were analyzed to identify measurable KPIs in a consumer goods warehouse. The list should not be considered exhaustive, but as an evolving element that can be integrated in each specific case providing a starting point for the MARLIN application. The found KPIs were then categorized by applying Frazelle’s model to the warehouse indicators of interest. Frazelle’s model has been selected since it not only measures warehouse performance (e.g., quality, cost, time, and productivity dimensions) but also associates them with warehouse activities. Therefore, this study focuses on warehouse KPIs monitoring an initial list of 32 KPIs within the UABs identified: Reception and Unloading, Inventory, Picking, and Shipping. The identified warehouse KPIs selected are shown in Table 2.

Table 2.

Warehouse KPIs. Color differentiates the various impact areas.

The N × M variables identified in the previous steps may not all be available in the real warehouse, nor it is viable to mandate the collection of impractical data. As a result, only the subset of data accessible in work as done will be filtered. As a result of the previous step, some relationships between the state and environmental variables will have been formed; these in principle represent the relationships identified between the variables related to the stresses to which the system is subjected, and the variables related to the degree of stretch in the system. Each of these relationships will define a distinct dimension of CfM for the warehouse. In principle, during the performance, it will be possible to estimate which CfM dimensions will behave elastically and which others will gracefully extend the competence envelope. The CfM dimensions are expected to be different. Theoretically, if necessary, some mitigation interventions could be identified by identifying suitable control variables. However, it may engender unwanted emerging behaviors. Further monitoring and analysis are then necessary.

3.1.4. Phase Four: Method Application

The method can be applied iteratively. In the systematic application of the MARLIN method, new disruptions are periodically evaluated, and any cross-effects between the variables are monitored. A sufficient period of application should provide sufficient data to increase the reliability of the assessment of the risk of saturation and therefore of the brittleness of the warehouse. The iterative and dynamic nature of the model allows for the selection, calculation, and evaluation of emergency areas, environmental variables, KPIs, and their relationships at each iteration. If in one iteration there is a disruption, this will likely be reported in the KPI values, interventions will be identified, and the KPI values will be reassessed at the next iteration. Clearly, at the end of the disruption we may again find off-target KPIs that will result in us withdrawing emergency corrective actions. Other corrective actions and interventions, on the other hand, might remain.

4. Results

The research approach used is deductive. The deduction started from the conceptualization of the MARLIN method through the analysis of resilience engineering, warehouse, and cyber-socio technical systems concepts. Subsequently, a qualitative exploratory case study was conducted [163]. Indeed, the literature frequently cites the case study strategy as an intensive study of a single case or a small number of cases that draw on observational data from a bounded object or process [164,165]. The case study will be bounded according to the research questions of the research and lead the study to a specific unit of analysis as detailed by [166,167]. This first application to a real case scenario is not intended to be exhaustive or a validation of the method. It is to be considered as an exploration of the method to understand its potential and limitations. The following paragraphs underline the steps needed for the application of the MARLIN method.

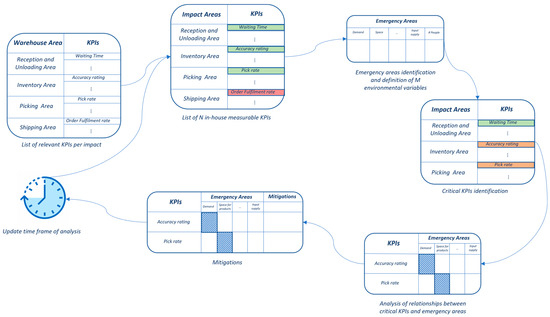

4.1. How to Apply the MARLIN Method

The method shown in Figure 4 is applied in six steps:

Figure 4.

MARLIN iterative process.

- (1)

- Identification of N measurable KPIs;

- (2)

- Emergency areas identification and definition of M environmental variables;

- (3)

- Critical KPIs identification;

- (4)

- Evaluation of relationships between N critical KPIs and M environmental variables;

- (5)

- Identification of intervention measures;

- (6)

- Qualitative investigation of relationships between measures and other KPIs;

- (7)

- Analysis time frame update

In the next part, we will quickly outline each stage before presenting an application to a real case scenario.

- Stage 1: Identification of N measurable KPIs

In this stage, the team must analyze which of the N real system-specific state variables (Warehouse KPIs) accessible for warehouse management can be monitored. Specifically, the team discusses which KPIs are measurable in their DC to date. This first stage requires an initial analysis of the system and its functional relations. At this stage, they assess which data are available and which are being collected. This allows them to understand the measurable KPIs. It is vital to understand which data are available and usable for the goals of the analysis at this phase. At this stage in the dynamic process of the method, the team is required to evaluate the expected target values for each KPI. Following black swan events, it may be necessary to readjust the thresholds for each KPI.

- Stage 2: Emergency areas identification and definition of M environmental variables

In this stage, the team must determine emergency areas that are directly or indirectly impacted by the specific disruption. Furthermore, the team must discuss and describe M environmental aspects that will aid in regulating every relevant performance of each emergency zone.

- Stage 3: Critical KPIs identification

In this Stage, the team calculates the KPIs chosen in Stage 1. Once processed, the team compares the KPIs with the organization’s target values, thus identifying critical KPIs

- Stage 4: Evaluation of relationships between N critical KPIs and M environmental variables

It is beneficial to detect any relationships between vital KPIs and environmental factors to prevent disruptive consequences. It is proposed that the nature of each found connection be specified: how are the two dimensions related? Is there a positive or negative correlation?

- Stage 5: Identification of intervention measures

In this stage, the team identifies the intervention measures to be implemented to mitigate disruption effects.

- Stage 6: Qualitative investigation of relationships between intervention measures and other KPIs

In this step, it is required to verify whether a chosen intervention could negatively affect other KPIs.

- Stage 7: Analysis time frame update

Once the interventions are defined, a time frame for repeating the analysis and monitoring the KPIs against the interventions is established.

4.2. Method Application in the Real Case Scenario

Case study data were collected in a DC located in central Italy and owned by one of the main companies in the sector. The DC manages the logistic flows of over 800 suppliers and 500 customers, and the goods taken into analysis are 17,000. The area occupied by the warehouse can be divided into three distinct zones:

- (1)

- Reception and Unloading Area;

- (2)

- Inventory and Picking Area;

- (3)

- Order preparation and Shipping Area.

While the method can result in extensive analyses, an abridged example is summarized in these paragraphs following the aforementioned steps of analysis.

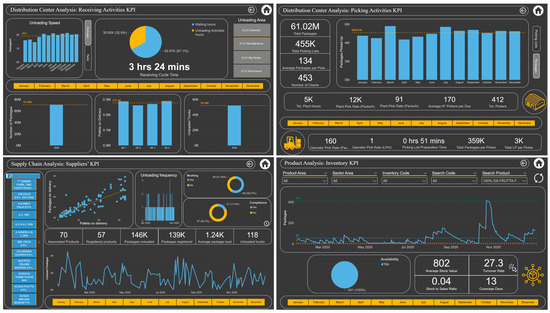

- Step 1: Selection of N measurable KPIs

At this stage, the team questioned which KPIs were measurable on the day the method was applied. In the DC under investigation, it was possible to monitor 17 KPIs. The KPIs selected were: waiting time, discharge time, receiving time, unloading speed, compliant orders rate, average stock, average stock value, turnover rate, coverage ratio, stock-to-sales ratio, stock out, handling, distribution center uptime, pick list preparation, picker activity time, global pick rate, pick rate per operator. The reason for this selection is that the reference DC did not manage the shipping area internally and it did not have sufficiently advanced systems to monitor the data of each performance (e.g., perfect order rate). In this step, the team also defined acceptable threshold values for each KPI. Figure 5 shows the dashboards used to monitor the KPIs of the DC. The PowerBI dashboard was developed in the context of a project aimed at digitalizing the warehouse operations of the DC and was then used to collect and analyze data while monitoring various Key Performance Indicators (KPIs) related to warehouse operations. The Power BI dashboard played a pivotal role in this data-driven approach, facilitating real-time insights and aiding us in adapting to the disruptions caused by the pandemic.

Figure 5.

Dashboards used to monitor the KPIs of the DC.

- Step 2: Identify emergency areas and define M environmental variables

The DC under review has been affected by a pandemic disruption due to the COVID-19 virus in the months from March 2020 to date. Governmental restrictions and requirements are elements that may have had a direct or indirect impact on warehouse management. Most of the countries affected by the pandemic focused on internal transportation services, high-speed rail, maritime traffic, the closure of shopping malls, stores, bars, and discos, the postponement of studies in schools and universities, the reduction of employment rates in some government-determined jobs, and the suspension of certain international and domestic commercial activities, tourist activities, religious rituals, and high-speed rail as their main policy decisions [168]. The following list summarizes the most important limitations placed on the case study at the federal level [169]:

- The suspension of company activities, including places where consumers can go to buy necessities;

- The suspension of retail activities in the neighborhood and medium- and large-scale distribution, save from those related to food and initial necessities;

- Canteens and continuous catering on a contractual basis, which provides a minimum one-meter safety distance, are exempt from the suspension of catering services (including bars, pubs, restaurants, ice cream parlors, and pastry shops);

- A license to operate for home delivery services by packaging and transport health and hygiene standards;

- A license to operate that ensures a one-meter interpersonal safety distance for food and beverage enterprises located in service and refueling areas beside the road and highway network, as well as inside railway, airport, lake, and hospital stations.

To identify the emergency areas described below, the team considered these governmental restrictions. Furthermore, a narrative review was conducted on the effects of the COVID-19 pandemic on SCs, to select those aspects that most directly affected DCs like the case study. In addition to this, the identified areas were also shared with the DC team through in-depth interviews, observations, and consultations. These allowed us to make useful choices to provide a holistic understanding of the warehouse disruption scenarios we analyzed. Once the emergency areas were settled, indicators capturing key aspects of these areas were formulated, resulting in 14 environmental variables to monitor (i.e., Variation in Product Demand, Area Utilization Coefficient, Volumetric Utilization Coefficient, Space Required for People, Absenteeism Rate, Number of Personal Protective Equipment (PPE) available for workers, Requested Readiness, Planned Readiness, Total Perceived Readiness, Planned Punctuality, Actual Punctuality, Total Perceived Punctuality, Completeness and Accuracy). These indicators do not provide an exhaustive assessment of the emergency areas identified, rather they serve as examples of a possible way to quantify the effect of changes in such areas.

4.2.1. Demand

Since panic buying resulted in unrestrained purchases of some product categories, the pandemic altered end-user demand in terms of quantity [127,169,170]. Demand shifts in terms of product kinds; a rising trend in the demand for preservable items and the penalization of highly perishable products [112], replacing them with those that have a longer shelf life occurs [125,169,171]. Additionally, the closing of commercial enterprises like pubs and restaurants caused the final demand intended for HoReCa channels to shift to alternative sales and distribution channels, including supermarkets, home delivery, and Internet channels [172]. Within a short period, the majority of overall food costs, which had previously been distributed among several channels of distribution, switched fully to retail, having a considerable impact on all merchants [173,174]. As a result, the demand at the wholesale warehouses changed.

where Qpi represents the volume of i-th product pi required by the end consumer, while tj is the considered j-th point in time (e.g., year, month, week, day); that is, follows that if:

To this end, meaningful variation thresholds must be established, as well as time horizons to be compared. For example, the demand level could be analyzed compared to the previous year, the previous month, the previous week, and so on, depending on the type of product (e.g., seasonal product) and the type of information to be obtained.

4.2.2. Space

- Required space for products

The pandemic forced wholesale warehouses to act immediately to ensure faster pickup of commodities in frequent demand and additional room for goods with larger volume demand. The effects of the pandemic indicate a shift in consumption patterns due to a decline in the demand for exporting goods and an increase in the demand for local goods [169,175,176]. Additionally, items having a longer shelf life predominately replaced preservable and extremely perishable items [107,125,169]. Additionally, there was unrestrained purchasing of several goods categories, such as essential food items [107,125]. This necessitated rearranging the items in a warehouse in terms of their spatial configuration and the space set aside for specific items. In this scenario, it becomes critical to constantly monitor warehouse space occupancy. A study of the literature identified two useful measures to manage warehouse space: Surface Utilization Coefficient; and Volumetric Surface Coefficient [157].

- Required space for people

Work activities must continue uninterrupted to preserve social isolation, as is also evident from governmental regulations [177]. Many businesses with physical storefronts, especially wholesalers, have been impacted by social exclusion and restrictive practices, which have decreased the overall number of workers [10]. In a non-emergency situation, Space Utilization refers to the number of people in a workplace during a given period. It can be defined as a building’s occupancy divided by its capacity. This gives a percentage of how much of the space is used versus how much is available. In a pandemic scenario, the capacity will change according to measures that recommend 2m of physical distance between workers. Therefore, it is possible to generalize by defining Space utilization as that #Workers such that:

4.2.3. Number of People

- Number of available workers (unskilled and skilled jobs)

Worker absenteeism in the industry and among skilled laborers (such as in transportation tasks requiring expert driving, in port and international trade operations, and in production-supporting activities like quality checks, veterinary care, livestock feed supply, and equipment maintenance services) has increased [107,178,179]. This phenomenon can be linked to both illness and the challenge of getting to work due to transportation constraints, such as border closures and other restraints [6,7,168,177] which led to labor issues for wholesalers. Therefore, it is possible to keep track of this phenomenon by monitoring the Absenteeism rate, described below. Obviously, the lower the value of this indicator, the better.

- Amount of Personal Protective Equipment (PPEs) available for workers

Work activities that are not suspended needed to ensure the presence of PPEs such as masks and gloves [177]. All forms of PPE must be: correctly fitted and frequently adjusted; consistently and properly worn as required; routinely examined, maintained, and replaced, as necessary; and safely removed, cleaned, and stored or disposed of to avoid contamination of self, others, or the environment. Companies, including wholesalers, were compelled to limit the number of workers protected if PPE was not available or compatible. For all these reasons, we can generalize by defining the following measure:

4.2.4. Input Supply

Resources and inputs were scarce, both in terms of physical manufacturing inputs and human resources [180,181]. This resulted in increased expenses for manufacturers, such as increases in transportation and ingredient prices [182,183,184] as well as a shortage of product availability spanning from raw materials to finished items, hampered further by restrictions imposed on international commerce of commodities in both import and export [185,186]. The availability of inputs was also connected to the general lowering of production levels, which were often forcefully paused or temporarily halted in many manufacturing facilities [110,112].

On the other hand, labor or transportation scarcity has a negative knock-on impact, because an input in the SC production process is an output of the preceding phase [10]. As a result, wholesalers, for example, encountered both a lack of sale items and packing supplies.

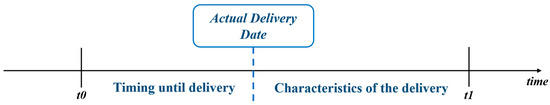

To monitor suppliers’ performance, and consequently promptly identify anomalous trends, service performance can be defined which, once calculated, needs to be compared with acceptance thresholds internally established by individual companies. Among such performances, the ones that retained meaning for the analyzed event are summarized as follows. Namely, the focus of service performances on different aspects of receiving the delivery is taken as a temporal boundary (Figure 6). The performance measured before the Actual Delivery Date pertains to the temporal domain, and these aim to monitor readiness- and punctuality-related aspects. Those after the delivery date pertain to the characteristics of the received delivery. Furthermore, a timeframe for monitoring such performance needs to be fixed ([t1–t0] in Figure 6). The shorter the time frame, the more effective and timelier the monitoring is, even if it is more labor-intensive and expensive, and vice versa.

Figure 6.

The conceptual focus of the two service performance groups for a given product’s delivery in a fixed timeframe [t1–t0], considering the Actual Delivery Data, i.e., the moment of order receipt, as a temporal boundary.

Generally, the readiness-related performances reflect the ability of the supplier to provide the warehouse in an acceptable time, while the punctuality-related ones are the ability of the supplier to minimize the number and entity of delayed orders delivered. When the order is delivered, its features require analysis to assess whether the order was delivered as requested. The performances are further detailed below.

- 1.

- Service performances (Timing until delivery)

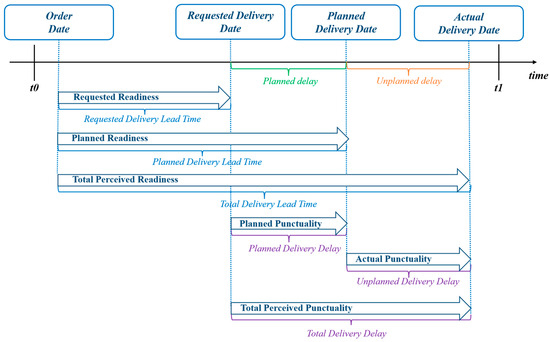

- Requested Readiness: it measures the delay between the emission of the order date and the requested delivery date. The customer wishes the product to be delivered when requested or at an acceptable time. Once an acceptable requested readiness value is defined, it can be monitored by comparing the average requested readiness time for each product with a reference standard. Consequently, the number of non-standard orders for each product should also be monitored. It is advisable to define a warning threshold, indicating too many orders that fail to satisfy the expected performance.

- Planned Readiness: it measures the delay between the emission of the order date and the planned delivery date. The customer wishes the planned delivery date to be not too far away from the requested one or within an acceptable timeframe. Once an acceptable planned readiness value is defined, it can be monitored by comparing the average planned readiness time for each product with a reference standard. Consequently, the number of non-standard orders for each product should also be monitored. It is advisable to define a warning threshold, indicating too many orders that fail to satisfy the expected performance.

- Total Perceived Readiness: it measures the total readiness as perceived by the customer, between the emission of the order date and the actual delivery date. Once an acceptable total readiness value is defined, it can be monitored by comparing the average total readiness time for each product with a reference standard. Consequently, the number of non-standard orders for each product should also be monitored. It is advisable to define a warning threshold, indicating too many orders that fail to satisfy the expected performance.

- Planned Punctuality: it measures the delay between the requested delivery date and the planned delivery date. It represents the planned delay, generated by the mismatch between the customer’s expectations and the supplier’s feasibility, and known to both the customer and supplier. Once an acceptable planned punctuality value is defined and agreed upon, it can be monitored by comparing the average planned punctuality time for each product with a reference standard. Consequently, the number of non-standard orders for each product should also be monitored. It is advisable to define a warning threshold, indicating too many orders that fail to satisfy the expected performance.

- Actual Punctuality: it measures the delay between the planned delivery date and the actual delivery date. It represents the unplanned delay, generated by unexpected supplier delays. Since it is unknown to the customer, it significantly affects the quality of service. On the other hand, the supplier also lacks prior knowledge of it and may find it difficult to implement corrective measures. Bringing it back to a null value, it is desirable. As a preventive measure, a possible unplanned delay can be predicted and communicated based on historical data. Once an acceptable unplanned punctuality value is defined and agreed upon, it can be monitored by comparing the average actual punctuality time for each product with a reference standard. Consequently, the number of non-standard orders for each product should also be monitored. It is advisable to define a warning threshold, indicating too many orders that fail to satisfy the expected performance.

- Total Perceived Punctuality: it measures the total punctuality as perceived by the customer, between the requested delivery date and the actual delivery date. It includes both the planned and the unplanned delay. Once an acceptable total punctuality value is defined and agreed upon, it can be monitored by comparing the average total punctuality time for each product with a reference standard. Consequently, the number of non-standard orders for each product should also be monitored. It is advisable to define a warning threshold, indicating too many orders that fail to satisfy the expected performance.

These indicators should be monitored on each product since ad hoc thresholds should be defined concerning them, complying with product and supplier features. The timing until delivery performance is summarized in Figure 7.

Figure 7.

Illustration of service performance before the order receipt, i.e., the Actual Delivery Date, for a given product’s delivery into a fixed timeframe [t1–t0], considering the four main dates agreed between supplier and customer.

- 2.

- Service performance (characteristics of delivery)

- Completeness: it measures the ability to fulfill the order with all the units requested. An error is defined as receiving one or more products less (or more) than that ordered. Thus, it reflects the ability of the supplier to deliver exactly the quantity of product required, which can be monitored by the number of non-complete orders for each product.

- Accuracy: it measures how accurately the order is delivered, to prevent mistakes in the order fulfillment. An error is defined as receiving a product other than what was ordered. Thus, it reflects the ability of the supplier to deliver exactly the type of product requested, which can be monitored by the number of non-accurate orders for each product.

- Step 3: Critical KPIs identification

For the first timeframe, KPIs were determined. The research takes data from one month of interruption into account: a snapshot of the warehouse after the first month of national closure (9 March–9 April 2020). Seventeen KPIs were computed and compared to the organization’s threshold levels. Waiting time, stock-out index, handling index, and pick rate per operator were identified as key metrics.

- Step 4: Analysis of relationships between n critical KPIs and M environmental variables

The MARLIN method was applied by the warehouse logistics team on one of the critical KPIs: operator pick rate. The number of operators was reduced during the first month of the lockdown (due to quarantines and constraints on the number of persons per m2), and product demand grew, worsening pick rate figures. As a result, for this KPI, we identified three associated emergency areas: demand, people, and space. Specifically, the operator pick rate was negatively correlated with the environmental parameters: Variation in Product Demand and Space Utilization; and positively correlated with: #Number of available workers.

- Step 5: Intervention measures identification

Levers to act on the pick rate value were found after discussions with the warehouse logistics team. The decision was reached to raise the overall number of operators and the DC’s working hours. This allowed operators to be distributed throughout numerous shifts, reducing the number of employees per m2.

- Step 6: Qualitative evaluation of relationships between intervention measures and other KPIs

This stage was dedicated to determining whether the chosen actions had a negative impact on other KPIs within the team. During this time period, the team discovered no unfavorable connections between intervention levers and KPIs.

- Step 7: Update the time frame of the analysis

Following the completion of the analysis, the organization adopted intervention measures and established a new period for repeating the evaluation. Surprisingly, the group conducted the investigation one month after the initial lockdown ended (11 June–11 July 2020), showing an increase in operator pick rate. Longer hours and less congestion in the aisles by workers made operations run more smoothly and boosted the pick rate.

5. Discussion

With this research, the authors contribute to the warehouse management literature by proposing a method to manage disruptions in today’s complex cyber socio-technical systems. The MARLIN methods suggest several takeaways which can be described by dividing them into theoretical and managerial implications.

5.1. Theoretical Implications