Abstract

Background: This paper revolves around a meticulous exploration aimed at discerning the impact of total quality management (TQM) and service quality (SQ) practices upon the financial performance (FP) of firms within the container shipping industry. Our pursuit extends further, delving into the intricacies of SQ as a potential mediating factor in the TQM–FP relationship. This distinctive study investigated six TQM practices in conjunction with five SQ factors, analyzing their impact on firm FP. Methods: This study used a quantitative research approach. Data were collected through a structured questionnaire from logistics specialists and experts in the shipping field. Results: The findings were interesting and showed that two TQM practices—managerial leadership and employee involvement—have a significant positive effect on SQ levels, and one SQ dimension, namely responsiveness, has the biggest and most significant effect on the FP of container shipping companies. Furthermore, SQ mediates the relationship between TQM and FP. Conclusions: This study provides a theoretical contribution by developing a conceptual model that elucidates the correlation between TQM practices and the degree of SQ on the FP of container shipping firms. Moreover, this study provides managers with a tool for identifying, prioritizing, and improving key TQM and SQ practices that contribute significantly to financial success.

1. Introduction

Container transport is widely recognized as a highly interconnected global supply chain, mostly owing to the inherent capability of a single container, packed with cargo, to be seamlessly transferred between various modes of transportation [1]. Therefore, container shipping lines play an important role in international trade and global supply networks [2]. In the same vein, the transportation and shipping industries in Jordan are critical components of the country’s infrastructure and have a substantial impact on the country’s level of economic growth [3]. The primary challenge for firms in the container shipping industry is to make a profit through maximizing efficiency, such as obtaining high levels of vessel capacity utilization to improve their financial performance (FP) [4]. On the other hand, firms are required to maintain sustainable client relationships and excellent management of profitable ones [5,6].

Service quality (SQ) is an important factor in sustaining relationships with your clients in the container shipping industry [2,7]. Clients who request containership services have transportation needs that prioritize punctuality, reliability, connectivity, and other criteria over low freight rates [6]. To put it another way, clients that utilize container shipping are more concerned about SQ; thus, quality management procedures must be implemented to meet customer expectations [8,9]. Therefore, the necessity of total quality management (TQM) practices is a major concern for all firms to ensure that customers receive high-quality service and other business outcomes [10,11]. This is applicable to a variety of manufacturing and service industries, as well as to the maritime industry, particularly in container shipping [2]. As a result, quality must be enshrined in every area of an organization’s operations in the shipping industry, ensuring that all tasks are completed correctly the first time and that all obstacles are eliminated along the service process [8].

The study landscape in the field of container shipping businesses has revealed a notable gap in the interaction between SQ, TQM, and their impact on FP. While extensive research has been conducted on the effects of SQ on customer satisfaction and loyalty, as well as TQM’s role in operational efficiency and cost reduction, there is a scarcity of comprehensive studies that bridge these domains to examine their combined effects on the financial health of container shipping firms [2,5,6]. Therefore, incorporating TQM and SQ concepts in the container shipping industry is a little-discussed topic, especially in a developing country such as Jordan, and not much research has been conducted in this field [2,8,9,12].

The significance of this study revolves around investigating the interrelationship between TQM, SQ, and FP. This distinctive study investigated six TQM practices in conjunction with five SQ factors. Consequently, the purpose of this research is to examine how TQM and SQ practices affect companies’ FP in Jordan’s container shipping industry, as well as which TQM and SQ practices shipping firms should prioritize to have an impact on FP. Moreover, the role of SQ as a mediator between TQM and FP is investigated.

In this study, several critical questions were addressed to better understand the dynamics within Jordan’s container shipping industry. First, the researchers sought to determine whether TQM practices exerted a positive influence on SQ, ultimately impacting FP. This inquiry was encapsulated in RQ1. Moving forward, RQ2 focused on identifying which specific TQM practices played a pivotal role in fostering positive and significant improvements in SQ within Jordan’s container shipping industry. Likewise, RQ3 aimed to pinpoint the SQ practices that had a noteworthy positive impact on FP. Finally, the study delved into the mediating role of SQ in the relationship between TQM and FP, encapsulated in RQ4. Through a comprehensive analysis, these questions aimed to shed light on the complex interplay of factors in this industry, offering valuable insights for both academics and practitioners. Thus, this study makes a theoretical contribution by constructing a conceptual model that explains the relationship between TQM practices and the level of SQ on the FP of container shipping businesses. Furthermore, this study offers managers a useful tool for the identification, prioritization, and enhancement of crucial TQM and SQ practices that significantly contribute to achieving financial sustainability.

2. Literature Review

2.1. Total Quality Management (TQM)

TQM is a long-standing management concept that spans all aspects of business and is a widely acknowledged organizational approach for firms looking to succeed both worldwide and domestically [13,14]. It is a representation of how managers have developed their understanding of quality over time. This evolution has been aided by inspection, quality control, and assurance methods [15,16]. As a result, changes in the concept of quality have been linked to the development of the TQM concept [11,17]. As quality lies in the eyes of the observer, there is no consensus on a single definition [18].

TQM has also been addressed in a variety of ways, such as the pursuit of perfection, cultivating a “get it right the first time” mentality, and focusing on customer demands and needs. In the end, this would result in better organizational performance due to improved product and service quality that satisfies customers [14,19]. This makes TQM challenging to adopt, and every industry has unique TQM practices connected to the goods and services they provide [20]. However, TQM mainly aims at protecting the interests of consumers, employees, and stakeholders by focusing on continuous improvement, customer focus, employee empowerment, and top management commitment [14,16].

There are numerous TQM classifications; however, in the context of the shipping industry, this study will use the six dimensions proposed by Thai and Jie [8]. The management leadership dimension (ML) refers to the extent to which top management is held accountable for performance quality as well as the extent to which department heads participate in the quality enhancement process. As for the training dimension (TR), it refers to quality training provided to managers and employees and to promoting training to encourage cooperation and continuous improvement. The customer focus (CF) dimension refers to demonstrating how an organization actively seeks ways to improve its primary service in order to increase customer satisfaction. Furthermore, the supplier quality management (SQM) dimension refers to the extent to which long-term relationships are made available to suppliers, as well as how they are evaluated in terms of quality, cost, and delivery performance. As for the process management (PM) dimension, it indicates how managers monitor and uncover variability in work procedures, as well as the number of procedures with in-process quality measures. Finally, employee involvement (EI) refers to how employee suggestions and innovations are prioritized and how employees are encouraged to find flaws in their work.

2.2. Service Quality (SQ)

Since SQ is made up of a number of customer-pleasing service qualities or dimensions, they are interpreted differently in different business contexts and by different people, so there is no clear indication of what they are [2]. Furthermore, some SQ dimensions which are associated with intense passions and complex experiences are transcendent and cannot be directly viewed or observed [21]. In today’s maritime field, the concept of service quality has far outgrown the limits of carrier or port selection criteria. Quality has a broader scope than simply providing quality services; in a variety of studies on quality in shipping, it includes many other factors [7].

Frameworks for distinguishing aspects of SQ have been developed in the literature. One SQ study proposed that the quality of a service could be sensed both during the service, called functional quality, and after the service was completed, called technical quality. Technical quality relates to what the customer receives or even the quality of the service encounter, whereas functional quality is concerned with how consumers view the service or the quality of the service contact [22,23]. Consequently, the GAP model for SQ was developed as the gap between the expected and perceived scores of service dimensions [24]. Five SQ dimensions are used to score these outcomes: tangibility, responsiveness, reliability, assurance, and empathy. They constitute the SERVQUAL instrument, which is believed to be general and may be used in several circumstances. For example, the SERVQUAL model can be applied within the retail industry to evaluate the SQ offered by retail stores. This evaluation encompasses various aspects, such as the physical aesthetics of the store, the dependability of product availability and pricing, the promptness and effectiveness of staff members, the competence and professionalism of the sales personnel, as well as the extent of personalized attention provided to customers. Furthermore, it can be utilized within the hospitality industry to assess the level of SQ provided by hotels, restaurants, and resorts. Moreover, it is applicable within the shipping and logistics industries to evaluate the efficacy of their services with regards to punctuality of deliveries, state of merchandise upon receipt, promptness in addressing customer queries, and holistic consumer satisfaction. This encompasses ports and terminal operators, wherein the model can evaluate their performance in terms of effective cargo handling, the implementation of safety and security measures, and the provision of customer service at several points of interaction inside the port.

It is also based on customers’ overall SQ judgments [7,21]. Tangibility means that customers will assess a service’s quality based on its outward appearance. They indicate the physical facilities, appearance of employees, machinery, and information system of the firm. Reliability means that companies provide excellent service from the beginning. It also illustrates that firms work hard to keep promises and focus most on outcomes. Empathy indicates that the company treats each customer with care and individual attention in order to show that the company is doing everything necessary to suit his needs. Assurance is employees’ knowledge and courtesy, as well as their ability to express trust and confidence. Responsiveness is the desire of the service provider to support clients, provide timely service, and respond to their requests, concerns, or issues [23,24,25].

SERVQUAL’s efficacy as a method for assessing SQ in shipping has been questioned, as it may not account for the container shipping industry’s unique characteristics [25]. However, Hsu [25] modified the SERVQUAL model items in the context of container terminal service operations to better reflect the nature of the industry. Thus, in this study, the SERVQUAL model modified in the context of container shipping services, which has five SQ dimensions, was used [23,25].

2.3. Financial Performance (FP)

The FP of firms is one of the most important aspects that businesses strive to measure in order to succeed and survive in a competitive market [26]. FP measurement is a crucial aspect of the shipping industry, which involves the transportation of goods and commodities across the world’s oceans [27]. The shipping industry is a complex and highly competitive sector that requires effective financial performance measurements to assess the profitability and efficiency of shipping companies [10]. According to Syriopoulos et al. [28], financial performance measurement is critical in the shipping industry as it enables companies to track their financial performance over time, identify areas for improvement, and make informed decisions about investment and divestment strategies. Common financial performance measures in the shipping industry include revenue growth, profit margin, return on assets, return on equity, return on investment, and market position [26,27,28].

Moreover, some studies have emphasized the importance of incorporating non-financial performance measures in addition to financial performance measures in order to obtain a more complete picture of a company’s performance in the shipping industry [28,29]. This study included both financial and non-financial performance measures, which were represented by measuring FP in addition to TQM and SQ practices. As a result, container shipping companies can obtain a more accurate and holistic view of their overall performance and make better decisions to propel their business forward and improve their financial performance.

2.4. The Nexus between TQM and SQ

TQM is closely connected to aspects of SQ in the container shipping industry. Many studies have showed significant and positive effects of TQM on SQ [8,12,17,30]; however, there have been few studies that show how specific TQM practices significantly impact the level of SQ. The primary goal of TQM is to improve total quality, which is reflected in the process and quality of the service. Moreover, successful TQM implementation will result in higher quality and fewer reworks and cost reductions associated with poor quality [17,30].

In the service industry, TQM and SQ have received a lot of attention. TQM emphasizes continual improvement as a means of delighting and satisfying customers. To put it another way, TQM is linked to SQ because its goal is to make sure that a firm can fulfill its customers’ needs and expectations [20,31]. Moreover, TQM procedures that are implemented correctly can lead to considerable increase in SQ, and consequently increased customer satisfaction [30,31].

2.5. The Nexus between SQ and FP

Since the shipping sector is so important to international trade and transportation, it is crucial that companies in this sector offer top-notch services to stay ahead of the competition. Many studies have recently focused on the relationship between the shipping industry’s FP and SQ [27,32,33]. SQ is used to assess organizational capabilities, which are defined as a customer’s evaluation of a service’s overall quality or excellence, in which customer expectations are compared to customer views of service performance [24].

The effect of SQ on FP in the dry bulk shipping sector was investigated in a study by Gu and Liu [32]. According to the study, there is a link between service quality and financial performance, with better service producing better financial results. Moreover, collaboration and resource sharing among shipping companies to develop new services and enhance SQ help save costs, which in turn improves their FP [33]. According to another study, SQ has a significant direct impact on customer satisfaction and a direct impact on a firm’s FP through customer satisfaction [27].

Therefore, shipping companies should concentrate on enhancing SQ to increase client satisfaction and loyalty, which will enhance FP. These studies’ insights can help shipping companies make better decisions and increase their financial success.

2.6. The Nexus between TQM and FP

TQM is a management concept that is defined as an entire management philosophy that assists organizations in achieving high quality levels in all of their processes and procedures [18,19]. It also ensures the involvement of internal and external suppliers, customers, and employees in monitoring continuous progress [34]. Moreover, TQM is intended to improve, among other things, customer satisfaction, product quality, productivity, waste reduction, cost, time, and inventory levels, and consequently, the financial position of the firm [31]. The association between TQM and FP is well-established in the literature as a result of ongoing investigations into key TQM practices and their impact on FP. Previous studies examining the relationship between TQM and FP revealed a direct positive association [4,31,34]. Relatively few studies found no significant link between TQM practices and FP [35]. However, this study suggests that quality management practices are necessary for container shipping companies to improve the quality of their service to customers and, in turn, the financial performance of the company.

Consumer quality standards have risen in recent years, requiring organizations, both service and manufacturing, to implement TQM principles in order to meet client needs efficiently [36]. A study by Acquah et al. [36] sought to determine the impact of TQM practices on operational performance and how TQM practices interact to influence the operational performance of healthcare institutions. Their findings demonstrated that five of the seven TQM practices evaluated had an impact on operational performance [36]. A study by Niyi et al. [37] looked into the role of innovation speed in mediating the relationship between TQM and the success of small- and medium-sized businesses (SMEs). Their findings revealed that TQM was positively associated with operational performance as well as innovation speed, which has a significant impact on the relationship between TQM and the success of SMEs. The study broadened the understanding of innovation in terms of speed and its measures within TQM, with top management quality practices, employee quality management, customer orientation, process management, and employee knowledge and training being the five basic dimensions of TQM [37]. Moreover, a study by Bhaskar [38] provided an analysis of survey results pertaining to the implementation of TQM methods within manufacturing businesses in India. The primary objective of the study was to examine and ascertain the correlation between the implementation of TQM practices and their subsequent impact on organizational performance (OP). Their research findings indicated that TQM has a notable and statistically significant impact on market orientation (MO) [38]. In a similar vein, the findings of their study indicate that there is a positive and statistically significant relationship between MO and OP. Their study discovered a considerable and beneficial impact of TQM on the OP of manufacturing businesses in India [38]. Another study was conducted to evaluate the impact of TQM on customer satisfaction in the telecommunications industry, specifically focusing on the TQM-SERVQUAL framework [39]. The primary results indicated that the implementation of overall quality management had a notable influence on the level of SQ and customer satisfaction. It was determined that SQ exerts a beneficial impact on customer satisfaction [39]. Furthermore, the significance of SQ as a key factor in TQM for attaining customer satisfaction within the communications sector in Ghana was identified [39]. Finally, a study by Akanmu et al. [40] aimed to examine the mediating effects of organizational excellence on the association between TQM practices and sustainability performance. Their study examined the quality management techniques that are taken into consideration in this study, namely human resources management, service design, information and analysis, benchmarking, and management leadership [40]. The findings indicated that organizational excellence plays a crucial role in mediating the connections between managerial leadership, service design, human resources management, and sustainability [40].

Table 1 presents the summary of the most relevant studies investigating the relationship between TQM and SQ practices and firm performance.

Table 1.

Summary of previous studies.

2.7. Conceptual Framework

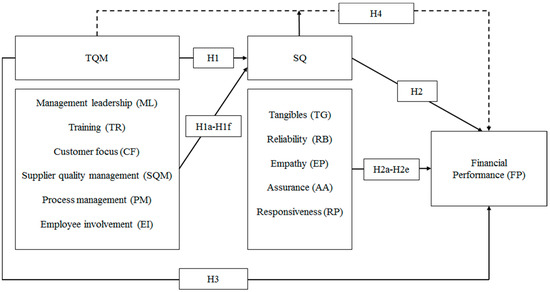

As can be noticed in Table 1, some studies mainly investigated the relationships between TQM and SQ [12,17,30], while other studies focused on the relationship between SQ and FP [27,42] and a few studies explored the association between TQM and FP [8,31,41]. However, to the best of authors’ knowledge, no studies have investigated the three constructs together. As a result, the following conceptual framework has been developed to fill the gap in the literature, as shown in Figure 1.

Figure 1.

Conceptual framework.

H1:

TQM practices positively impact SQ in the container shipping industry in Jordan.

H1a–H1f:

Each TQM practice positively impacts SQ in the container shipping industry in Jordan.

H2:

SQ practices positively impact FP in the container shipping industry in Jordan.

H2a–H2e:

Each SQ practice positively impacts FP in container shipping industry in Jordan.

H3:

TQM practices positively impact FP in the container shipping industry in Jordan.

H4:

SQ mediates the relationship between TQM and FP in the container shipping industry in Jordan.

3. Methodology

3.1. Sampling Process and Data Collection

Jordan’s container shipping industry has experienced significant growth and expansion in recent years. This industry is critical to facilitating international trade and fostering the country’s economic progress. According to the Jordan Maritime Commission (JMC), container throughput in Jordan’s ports has steadily increased in terms of the number of containers handled [43]. Several reasons have contributed to this expansion, including the government’s attempts to improve port infrastructure, the implementation of efficient logistics systems, and the country’s strategic location as a gateway between the Middle East and North America region [43].

Furthermore, Jordan’s strategic location has elevated it to the forefront of the container shipping industry. It has developed as a vital player in the container shipping industry, transforming it into an excellent container shipping center [44]. The country’s well-developed infrastructure, such as its modern ports and effective logistical networks, has aided its performance in this area. Jordan has adopted many government initiatives to attract international investment in the container shipping business, in addition to its strategic position and infrastructure. To attract multinational shipping businesses to operate in Jordan, the government has established free trade zones and provided incentives such as tax cuts and expedited customs procedures [44]. These measures have successfully attracted major international shipping lines to establish a presence in the country, including A.P. Moller-Maersk, CMA CGM, Mediterranean Shipping Co MSC, COSCO Shipping Lines Jordan, Hapag-Lloyd Jordan, Pacific International Lines, Ocean Network Express (ONE), YangMing, Evergreen, Messina Line, and many others [44].

The population under consideration in this study was especially designed to represent Jordan’s container shipping sector, as the primary goal of this study was to gain insights into the viewpoints and experiences of key decision-makers within this sector. To that purpose, a survey was used as the data collection tool, and it was circulated to various firms that play important roles in Jordan’s container shipping scene.

The survey outreach included a varied group of participants, reflecting the industry’s diverse nature. Respondents included container shipping company executives, logistical experts with extensive understanding of supply chain operations, and employees actively involved in the shipping industry. This diverse group of participants enabled a thorough assessment of the sector’s dynamics, integrating perspectives from both strategic decision-makers and those directly involved in day-to-day operations.

A hybrid technique was used for data collection. Some survey responses were gathered through in-person interviews and discussions, allowing for a more in-depth engagement with participants and opportunity for clarification and elaboration on responses. Concurrently, an online survey distribution approach was used to make the survey more accessible and convenient for a larger pool of possible participants.

Furthermore, the study used judgmental sampling techniques as a non-probability sampling strategy. This deliberate choice was made to guarantee that the individuals who had been chosen had the necessary knowledge, skills, and experience in the container shipping company that aligned with the research objectives [45]. This study attempted to collect a highly informed and relevant dataset by selectively selecting participants based on their qualifications, with the goal of yielding important insights into the drivers and dynamics impacting Jordan’s container shipping sector. This approach allowed the research to target individuals who could provide an in-depth understanding of the industry, enhancing the study’s comprehensiveness and capacity to offer valuable recommendations for future improvement and development within Jordan’s container shipping sector [45]. Furthermore, from February to June 2022, 300 questionnaires were distributed, and of the 165 received responses, 136 were valid, providing a valid response rate of 45%. The proposed study model was examined and tested using SPSS.

3.2. Developing the Measurement Instrument

The study employed a quantitative approach, specifically using a survey method, to collect structured and numerical data. This methodology was chosen due to its appropriateness in assessing and examining the connections between TQM practices, aspects of SQ, and the performance of organizations. The use of this methodology facilitated the acquisition of precise, measurable feedback from a large number of respondents, hence enabling the application of statistical techniques to discern trends, associations, and levels of statistical significance. Through the implementation of a survey, this study has the ability to effectively evaluate a wide range of variables. This will establish a robust basis for drawing results and formulating data-driven recommendations regarding the interconnections between TQM, SQ, and FP within the container shipping sector.

TQM and SQ are well-established research concepts; thus, items validated in previous research and used to assess these concepts in all other industries are expected to be applicable to the container shipping industry. In this regard, variables measuring TQM include managerial leadership, employee involvement, customer focus, process management, training, and supplier quality management [8]. The Parasuraman et al. [24] model was utilized in this study as one of many ways for determining SQ. Hence, five SERVQUAL variables were selected to examine the SQ criteria in the current study. Most studies looked at the idea of SQ from a management approach, according to a review of the literature on the link between SQ and quality management. A five-item index was used to assess the five main characteristics of SQ (tangibility, reliability, empathy, assurance, and responsiveness) [24]. The data used in this study were collected through a questionnaire to understand how container shipping companies work and apply TQM and SQ concepts. The questionnaire was structured by first addressing the educational level and current job position of respondents (container shipping firm managers and logistical experts), as the percentage of these answers in each target sample mattered to the study. Then, we posed 23 questions to assess the total quality management dimensions. After that, 19 questions were included to address the SQ dimensions in the firms. Finally, we ended the questionnaire with four questions that focused vividly on the performance of container shipping firms in Jordan, as shown in Table 2. Each one of these practices was assessed using a five-item, five-point Likert scale ranging from strongly disagree to strongly agree.

Table 2.

Constructs and measurement items.

4. Results

4.1. Descriptive Statistics

Descriptive statistics include means, standard deviation, skewness, and kurtosis. This study used means and standard deviation for measuring the central tendency. Moreover, for measuring dispersion, skewness and kurtosis of the data were measured. A value of asymmetry and kurtosis between −2 and +2 are considered acceptable in order to prove normal distribution. Data are considered normal if skewness falls between −2 and +2 and kurtosis falls between −7 and +7. Table 3 shows that skewness and kurtosis fall in the threshold value. Hence, it is proved that the data included in this study are normally distributed.

Table 3.

Descriptive statistics (n = 136).

The results show that the “ML” variable generated the highest mean score (M = 4.29; SD = 0.82). On the other hand, “SQM” generated the lowest mean score (M = 3.81; SD = 0.99).

4.2. Measurement Model

In the first step of PLS-SEM, the measurement model was assessed to examine the indicators’ factor loadings, reliability, and validity. Outer factor loadings were evaluated to show whether the indicators are consistent with their latent constructs. Table 4 shows that outer loadings of all indicators are greater than the threshold value of 0.70. Moreover, a collinearity test was performed to ensure that no collinearity issues exist among the indicators. The recommended value of VIF is less than 5 [46]; Table 4 shows that the VIF of all indicators is less than 5, indicating that there are no collinearity issues.

Table 4.

Collinearity statistics.

In the next step, the reliability of the constructs was evaluated using Cronbach’s alpha, rho_A, and composite reliability. Table 5 shows that Cronbach’s alpha is greater than 0.70 for all constructs. Similarly, rho_A and composite reliability (CR) > 0.7 for all constructs, which indicates that internal consistency is established [47]. After that, convergent validity of the constructs was examined through average variance extracted (AVE), which should be equal or greater than 0.50 [48]. Table 5 indicates all AVE values are above the minimum threshold; hence, convergent validity is established.

Table 5.

Measurement model results.

Discriminant validity was ensured with the criteria given by Fornell and Larcker [48], who proposed that the square root of AVE of each construct should be greater than the correlation between the constructs. Table 6 indicates that the square root of AVE of each construct is greater than their diagonal value, which demonstrates that all constructs are unique and distinct from others.

Table 6.

Discriminant validity.

4.3. Model Fit

Model fit indexes were checked in the SmartPLS 3 tool [49] by using two fit measures, namely the standardized root mean square (SRMR) and normed fit index (NFI). The threshold values for these criteria were SRMR < 0.08 and NFI > 0.90. Table 7 below indicates that the value of SRMR and NFI are consistent with these criteria.

Table 7.

Model fit indexes.

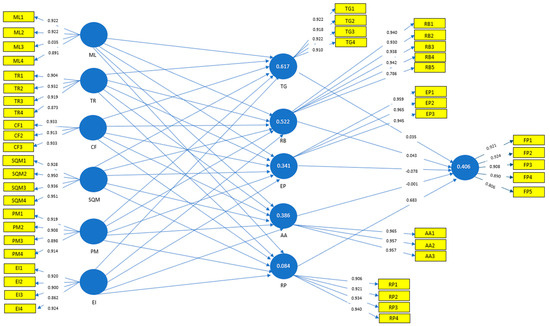

A structural model was assessed to examine the hypotheses proposed in this study, as shown in Figure 2. A bootstrapping procedure was performed on 5000 subsamples [39]. Hypothesis testing was carried out using a bootstrapping technique, with a resample number of 5000 bootstraps [49].

Figure 2.

Structural equation modeling results.

Hypothesis 1 proposed that TQM positively influences SQ. The findings of this study show that TQM positively and significantly affects SQ (β = 0.699, p = 0.000). Hence, H1 is accepted. H2 proposed that SQ positively influences FP. The results reveal that SQ has a positive and significant effect on FP (β = 0.397, p = 0.010). Stepwise regression is a statistical technique employed to ascertain and choose the most pertinent independent variables that account for the variability observed in a dependent variable [46]. In this study, stepwise regression analysis provided empirical evidence supporting the statistical significance of the association between SQ and FP (β = 0.354, p = 0.001). H3 proposed that TQM has a positive and significant impact on FP, but the results showed that TQM has no significant impact on FP. Table 8 summarizes the results of the structural equation modeling.

Table 8.

Structural model results.

4.4. Mediation Effect

H4 proposed that SQ mediates the relationship between TQM and FP. The total and indirect relationships were examined. The results show that SQ significantly mediates the relationship between TQM and FP, as shown in Table 9.

Table 9.

Mediation effect.

4.5. Regression Analysis

Two linear regression tests were used in this study. The first was conducted to explore the predictive influence of TQM practices on the SQ level of container shipping firms, and the second was conducted to explore the predictive influence of SQ dimensions on firm performance. Table 10 shows the coefficients which show how well each of the TQM practices is related to the SQ level of the firms.

Table 10.

Regression coefficients for TQM practices.

The results showed that two TQM practices had a significant effect on SQ level. The first TQM practice that has the biggest impact on SQ level is PM (B = 0.341, T value = 5.051) followed by EI (B = 0.332, T-value = 4.001). Table 11 shows the coefficients which show how well each of the SQ dimensions is related to firm performance.

Table 11.

Regression coefficients for SQ dimensions.

The result shows an interesting finding. The SQ dimension RP has the biggest impact on the FP of container shipping firms (B = 0.567, T-value = 8.152).

5. Discussion

This study investigated the associations between TQM, SQ, and FP among container shipping organizations. Data analysis revealed that TQM practices have a considerable and beneficial impact on service quality. Our findings were in line with those of Lam et al. [30] and Pattanayak et al. [12]. Because both frameworks focus greatly on customer satisfaction, both investigations validated the substantial positive connection between TQM and SQ. Furthermore, our research was in line with Lasrado and Nyadzayo [17] since TQM methods were found to significantly improve company SQ. Furthermore, research by [50] supports our finding that TQM is favorably and substantially related to SQ. TQM-enabled businesses are better equipped to satisfy their customers’ demands and expectations by offering improved SQ. Furthermore, our findings supported the positive relationship between SQ and FP. This finding is consistent with Yuen and Thai [23], who found that SQ practices are positively and substantially associated with company performance [51]. Moreover, Thai’s [52] research on SQ in shipping enterprises is used as a tool to help a company attain high performance, as SQ components have been shown to boost firm performance considerably. Gu and Liu [32] and Lebdaoui and Chetioui [42] recently conducted research that corroborated our findings that SQ is positively and strongly related to company performance.

Moreover, the results of this study showed that there is no significant relationship between TQM and FP. Some possible reasons behind this result are that our sample size was not large; however, the p-value in the test is not far from the significance level of 0.05. Hence, the association between these two factors was positive and not far from being significant. This is not consistent with Abbas and Kumari [41], who found that TQM is positively associated with company performance in their empirical study. Management leadership scored the highest among TQM variables, and it ranks as one of the most significant variables. In terms of management leadership, it appears that the most essential challenges for container shipping firms are focusing on top management defining objectives for quality performance and evaluating top management’s performance in terms of quality, which are comparable to those found by Thai and Jie [8]. Employee involvement was then emphasized as a key practice that included workers in quality management activities such as focusing on the creation of value for customers and fostering cross-functional communication. It also focused on whether employees are encouraged to discover defects in their work and the efficacy of cross-functional teams in resolving quality concerns. Customer focus was the third-ranked TQM dimension; its main issues concern the use of customer satisfaction surveys in determining customer requirements and the amount of effort put into enhancing primary services to ensure more satisfaction is produced by the organization, because it may assist shipping companies in becoming more attached to their customers and boosting customer retention. As a result, communication may be seen as a crucial component of TQM customer focus. Process management ranked fourth among TQM practices. This dimension indicated which service disruptions can be prevented by having a strong attitude. Furthermore, it focused on the implementation of quality measures into container shipping firms’ operations, as well as the continual monitoring and identification of business procedure variation by supervisors and managers. Next, training concentrated on providing quality training to supervisors and managers throughout the organization, encouraging the team to participate in the training, and providing a training plan to employees across the entire organization. Finally, supplier quality management came in sixth place among TQM practices. The quality of the supplier rating system was the emphasis of this dimension. Furthermore, its long-term focus was on providing relationships to suppliers and the extent to which suppliers are evaluated based on quality, delivery performance, and pricing.

Moreover, an interesting finding of this study was found that SQ mediates the relationship between TQM and FP. The findings of the regression test showed that two TQM practices, process management (B = 0.341, T-value = 5.051) and employee involvement (B = 0.332, T-value = 4.001), have the greatest impact on SQ levels. In addition, the SQ responsiveness dimension (B = 0.567, T-value = 8.152) had the biggest effect on the FP of container shipping companies. When it comes to SQ dimensions, responsiveness, which is a significant practice in SQ, scored the highest score. The most significant responsiveness practices indicated how the organizations adjust their operations to meet customer needs. Furthermore, responsiveness focused on responding quickly to customer concerns and providing timely information on export containers to facilitate loading. Another important dimension in SQ that followed responsiveness was tangibility; this dimension concentrated more on the availability of adequate container storage space, the intensity of shipping schedules, and the convenience of using a container tracking system. Empathy ranked third among SQ dimensions. It focused more on handling damaged cargo problems with sincerity and managing cargo damage professionally by operators. As for the fourth SQ dimension, reliability highlighted issues regarding the safety of cargo and charge accuracy based on dynamic information. The fifth dimension in SQ was assurance. Despite the fact that assurance received the lowest score, its importance to the entire SQ concept should not go unnoticed. This dimension concentrated more on responding to inquiries from customers in a proactive manner and providing dynamic information about container numbers in a strategic approach.

It is worth noting that the TQM–SQ–FP relationship in the container shipping industry can be greatly impacted by external factors, such as changes in the global economy and regulatory frameworks. The demand for shipping services and price structures can be influenced by economic fluctuations, which in turn can have an impact on the feasibility of investing in TQM practices. Regulatory adjustments may necessitate adaptations to ensure compliance, which might possibly redirect resources away from TQM operations. The ability to effectively respond to these external factors requires the adoption of flexible strategies in adjusting TQM practices, dimensions of SQ, and ultimately, the performance of the organization to sustain competitiveness and resilience in the continuously changing shipping industry.

6. Theoretical and Practical Implications

This study makes a theoretical contribution by developing a conceptual model that illustrates the relationship between TQM practices and the level of SQ, as well as the influence of SQ practices on the FP of container shipping firms. Additionally, this study highlights the mediating impact of SQ on the association between TQM practices and the FP of firms.

This study provides various benefits to practitioners and managers in the shipping sector. First, container shipping firms should emphasize the incorporation of quality metrics into their operations, as well as the ongoing observation and detection of business procedure variations by supervisors and management since process management practices have been proven to have a significant positive impact on SQ. Second, by getting employees involved in quality management initiatives, container shipping managers may be inspired to identify and prioritize areas for improvement. As a result, staff will be more committed to their goals since they are involved in them and will make better judgments using their extensive process expertise. Third, this study’s findings propose solutions to focus on their clients in order to boost customer satisfaction. For instance, since customers determine the quality of your service, knowing what your customers want or need will help you better identify how to put the appropriate people, materials, and processes in place to meet and surpass their expectations. It was found that responsiveness enhances the performance of companies. This study could help container shipping companies concentrate on the proper implementation of this SQ factor through supporting aspects of a liner shipping service like improving claim speed, quickly adapting operating procedures to meet customer needs, providing export container information to meet loading operation requirements, and ensure the prompt correction of operational errors. Managers will also be able to influence the component of customer satisfaction that results from the execution of supporting activities which are normally offered before and after a transportation service. Prior to a shipping service, for instance, the interaction between shippers and frontline staff may lead to satisfaction. Additionally, the wide range of service offerings by container shipping companies enables greater levels of customization to clients and hence improves their level of satisfaction. Moreover, the connection between SDG 8, which pertains to the promotion of decent work and economic growth, and the concepts of TQM, SQ, and FP within firms lies in the fact that SDG 8′s focus on fostering decent work and economic growth can be achieved by implementing efficient TQM practices [53,54]. This, in turn, results in the enhancement of SQ and ultimately leads to improved FP for firms. Firms can enhance TQM conditions by placing emphasis on employee well-being, labor standards, and sustainable economic growth. This approach has the potential to improve the SQ and FP of firms.

The potential benefits of incorporating TQM and SQ dimensions into container shipping businesses include the enhancement of operational excellence and the elevation of customer satisfaction. In order to initiate this transformative process, organizations should commence by cultivating robust managerial leadership that demonstrates a distinct dedication to TQM concepts. The establishment of a specialized TQM leadership team can offer essential direction and foresight. In addition, it is recommended that companies foster employee engagement across various organizational hierarchies through the establishment of cross-functional teams that actively cooperate in the processes of problem-solving and decision-making. The provision of consistent training in quality tools and techniques will equip personnel with the necessary skills to effectively implement significant changes. It is imperative to prioritize a customer focus, placing significant importance on gathering frequent client feedback in order to comprehend their expectations and modify services accordingly. Furthermore, it is imperative for organizations to formulate effective process management strategies, which involve the systematic mapping and optimization of container shipping operations. Additionally, the implementation of key performance indicators is crucial in order to monitor and enhance overall performance. In addition, the implementation of efficient supplier quality management practices plays a crucial role in guaranteeing the dependability of input materials and services, thereby cultivating a mutual dedication to excellence between the organization and its suppliers.

It is of utmost importance to integrate the five fundamental attributes of SQ, namely tangibility, reliability, empathy, assurance, and responsiveness. To enhance tangibility, it is recommended to ensure the proper maintenance of facilities and the implementation of user-friendly online services. Ensuring the dependability of schedules and services is of paramount significance, hence requiring the supply of precise timetables and efficient contingency strategies to address any disruptions. In order to ensure effective customer interactions, it is imperative that empathy serves as the foundation. This entails the presence of well-trained personnel who engage in active listening and provide responses that demonstrate a genuine understanding of the customer’s perspective. Assurance can be achieved by exhibiting competence and transparency in service terms and communication. Finally, responsiveness can be accomplished by implementing effective communication channels for client inquiries and adopting a proactive approach to meeting their demands. Container shipping companies should include these ideas in ongoing procedures, utilizing performance indicators and feedback mechanisms to consistently enhance their operations. Engaging people at every level fosters a pervasive culture of quality and service excellence throughout the firm, encouraging long-term success.

The generalizability of the results obtained in this study is limited to the container shipping industry, specifically in Jordan, which is classified as a developing country. Therefore, it is necessary to use caution when generalizing these findings to different sectors in diverse contexts. However, these results can provide significant insights for other developing countries that face comparable challenges, although there may be variations influenced by specific local characteristics. This study could potentially serve as a beneficial resource for individuals aiming to enhance operational practices and service quality within comparable settings, hence aiding in the adjustment to specific local intricacies. This study has the potential to provide valuable insights for developed countries, provided that appropriate measures are taken. Although the primary focus of the research lies within the container shipping industry of a developing country, several findings pertaining to TQM and SQ may have relevance in developed countries as well. Nevertheless, it is imperative for developed countries to acknowledge that the distinctive problems and dynamics inherent to their specific circumstances may result in discrepancies in the efficacy and relevance of these findings. Hence, it is imperative to thoroughly evaluate and modify this study’s suggestions in order to ensure their compatibility with the distinct requirements and conditions of developed countries.

7. Conclusions

Although several studies on the impact of TQM on FP and the impact of SQ on FP have been identified, few of them studied the relationships between the three constructs taken together, and few studies were conducted in the context of the container shipping industry. This study fills in the gaps left by previous studies. The findings of this study were intriguing. Two TQM practices, namely process management and employee involvement, were found to have a significant positive effect on SQ in container shipping companies in Jordan. Moreover, one dimension of SQ, namely responsiveness, had a significant positive impact on FP. Since relationships among TQM, SQ, and FP in the container shipping industry are complex, it would be a challenging task for researchers, practitioners, and industry professionals to understand those dimensions. From a managerial perspective, this study provides recommendations to shipping managers on how to properly use SQ and TQM practices to maximize their FP.

This study presents a conceptual model that demonstrates the relationship between TQM practices and the level of SQ and the influence of SQ practices on the FP of container shipping firms. It emphasizes the mediating role of SQ in the association between TQM practices and the FP of firms. This study suggests that container shipping firms should incorporate quality metrics into their operations and monitor business procedure variations to improve SQ. Employee involvement in quality management initiatives can inspire managers to identify and prioritize areas for improvement, leading to increased commitment and better judgment. This study also suggests focusing on customer satisfaction to improve service quality. Responsiveness enhances company performance, and this can be achieved through supporting aspects of liner shipping services, such as enhancing claim speed, adapting operating procedures, providing export container information, and promptly correcting of operational errors. Managers can also influence customer satisfaction through the execution of supporting activities, such as interaction between shippers and frontline staff. This study also highlights the connection between SDG 8, which promotes decent work and economic growth, and TQM, SQ, and FP within firms. Therefore, the integration of TQM and SQ into container shipping businesses can enhance operational excellence and customer satisfaction. Container shipping firms should develop strong managerial leadership, foster employee engagement, provide quality training, prioritize customer focus, and implement effective process management strategies. Key performance indicators and supplier quality management practices are also crucial. Integrating the five fundamental attributes of SQ (tangibility, reliability, empathy, assurance, and responsiveness) is essential. Ensuring the maintenance of facilities, providing user-friendly online services, and ensuring the dependability of schedules and services are essential. Empathy, competence, transparency, and responsiveness are also crucial. These ideas should be integrated into ongoing procedures, using performance indicators and feedback mechanisms to consistently improve operations.

There are a few limitations to this study. To begin, our research was confined to the container transportation sector, which is mostly a B2B activity. In this study, the majority of customers were corporate entities rather than individual customers. As a result, further study of other industries and other contexts, such as B2C, should be conducted to cross-validate the results. Any future research that seeks to generalize the service industry can employ a larger sample. Future research that builds on this study and investigates the relationship between TQM practices, SQ dimensions, and their impact on company performance can help us gain a better understanding of these essential business factors. Many future studies could look into the impact of TQM practices and SQ aspects on company performance in specific industries like healthcare, manufacturing, retail, or technology. The association may be influenced by industry-specific factors including the size of the firm. Furthermore, future research can undertake longitudinal studies to see how the relationship between TQM, SQ, and company performance changes over time. This can aid in determining the long-term viability and impact of TQM practices. In addition, further studies can look into how cultural differences affect the implementation and outcomes of TQM practices and SQ in firms operating in a variety of global markets, as well as how emerging technologies like artificial intelligence, IoT, and blockchain affect TQM practices and SQ in firms, and how these innovations can drive or hinder firm performance. Besides, future studies might look into the role of staff engagement, motivation, and satisfaction in TQM adoption, as well as their impact on SQ and company performance. Studies may also consider how staff well-being might be a motivator for TQM success, in addition to differences in managerial positions and backgrounds. Finally, this study recommends that the impact of the sub-dimensions of TQM and SQ on firm performance be investigated further.

Author Contributions

Conceptualization, L.J. and M.M.; methodology, L.J. and M.M.; software, L.J.; validation, L.J. and M.M.; formal analysis, L.J.; investigation, M.M.; resources, L.J. and M.M.; data curation, L.J.; writing—original draft preparation, L.J. and M.M.; writing—review and editing, L.J. and M.M.; visualization, M.M.; supervision, L.J.; project administration, L.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Song, D. A Literature Review, Container Shipping Supply Chain: Planning Problems and Research Opportunities. Logistics 2021, 5, 41. [Google Scholar] [CrossRef]

- Chao, S.-L.; Yu, M.-M.; Sun, Y.-H. Ascertaining the effects of service quality on customer loyalty in the context of ocean freight forwarders: An integration of structural equation modeling and network data envelopment analysis. Res. Transp. Bus. Manag. 2023, 47, 100955. [Google Scholar] [CrossRef]

- Hamed, M. Logistics Performance and Freight Sector in Jordan. Eur. J. Sci. Res. 2019, 152, 516–527. Available online: https://www.researchgate.net/publication/332862010_Logistics_Performance_and_Freight_Sector_in_Jordan (accessed on 3 May 2023).

- Veselinović, L.; Kulenović, M.; Turulja, L.; Činjarević, M. The interplay of entrepreneurial orientation, total quality management, and financial performance. Total Qual. Manag. Bus. Excell. 2021, 32, 1732–1750. [Google Scholar] [CrossRef]

- Balci, G.; Cetin, I.B. Market segmentation in container shipping services: A qualitative study. Manag. Res. Rev. 2017, 40, 1100–1116. [Google Scholar] [CrossRef]

- Hu, J.-L.; Yang, S.-Y.; Lin, F.-L.; Tsai, I.-C. Efficiency and input congestion of major marine transport companies in the world. Res. Transp. Bus. Manag. 2023, 46, 100831. [Google Scholar] [CrossRef]

- Le, D.N.; Nguyen, H.T.; Truong, P.H. Port logistics service quality and customer satisfaction: Empirical evidence from Vietnam. Asian J. Shipp. Logist. 2019, 36, 89–103. [Google Scholar] [CrossRef]

- Thai, V.; Jie, F. The impact of total quality management and supply chain integration on firm performance of container shipping companies in Singapore. Asia Pac. J. Mark. Logist. 2018, 30, 605–626. [Google Scholar] [CrossRef]

- Sarinten, S.; Pujaningsih, P.; Islami, B.; Andiansyah, M. Quality Management in Indonesia Maritime Education: Is it well implemented? J. Innov. Educ. Cult. Res. 2022, 3, 582–589. [Google Scholar] [CrossRef]

- Ha, M.H.; Yang, Z.; Heo, M.W. A new hybrid decision making framework for prioritising port performance improvement strategies. Asian J. Shipp. Logist. 2017, 33, 105–116. [Google Scholar] [CrossRef]

- Jum’a, L.; Basheer, M.E. Analysis of Warehouse Value-Added Services Using Pareto as a Quality Tool: A Case Study of Third-Party Logistics Service Provider. Adm. Sci. 2023, 13, 51. [Google Scholar] [CrossRef]

- Pattanayak, D.; Koilakuntla, M.; Punyatoya, P. Investigating the influence of TQM, service quality and market orientation on customer satisfaction and loyalty in the Indian banking sector. Int. J. Qual. Reliab. Manag. 2017, 34, 362–377. [Google Scholar] [CrossRef]

- Bouranta, N.; Psomas, E.; Suárez-Barraza, M.F.; Jaca, C. The key factors of total quality management in the service sector: A cross-cultural study. Benchmarking Int. J. 2019, 26, 893–921. [Google Scholar] [CrossRef]

- Jum’a, L.; Alkalha, Z.; Al Mandil, K.; Alaraj, M. Exploring the influence of lean manufacturing and total quality management practices on environmental sustainability: The moderating role of quality culture. Int. J. Lean Six Sigma 2023. Ahead-of-print. [Google Scholar] [CrossRef]

- Sweis, R.J.; Saleh, F.I.M.; Dahiyat, S.E.; Sweis, N.J.; Saleh, R.A.; Diab, H. Benchmarking of TQM practices in INGOs: A literature review. Benchmarking Int. J. 2016, 23, 236–261. [Google Scholar] [CrossRef]

- Shang, K.-C.; Huang, S.T.; Buchari, E.; Lirn, T.-C.; Della, R.H. Integration of safety quality function deployment in ferry services: Empirical study of Indonesia. Res. Transp. Bus. Manag. 2023, 47, 100938. [Google Scholar] [CrossRef]

- Lasrado, F.; Nyadzayo, M. Improving service quality: Examining the drivers and outcomes of TQM internalization in organizations. Int. J. Qual. Reliab. Manag. 2019, 37, 393–410. [Google Scholar] [CrossRef]

- Van Kemenade, E.; Hardjono, T.W. Twenty-first century Total Quality Management: The Emergence Paradigm. TQM J. 2019, 31, 150–166. [Google Scholar] [CrossRef]

- Magd, H.; Negi, S.; Ansari, M.S.A. Effective TQM Implementation in the Service Industry: A Proposed Framework. Qual. Innov. Prosper. 2021, 25, 95–129. [Google Scholar] [CrossRef]

- Talapatra, S.; Uddin, M.K. Prioritizing the barriers of TQM implementation from the perspective of garment sector in developing countries. Benchmarking Int. J. 2019, 26, 2205–2224. [Google Scholar] [CrossRef]

- Sayareh, J.; Iranshahi, S.; Golfakhrabadi, N. Service Quality Evaluation and Ranking of Container Terminal Operators. Asian J. Shipp. Logist. 2016, 32, 203–212. [Google Scholar] [CrossRef]

- Gronroos, C. Strategic Management and Marketing in the Service Sector; Marketing Science Institute: Cambridge, MA, USA, 2008. [Google Scholar]

- Yuen, K.F.; Thai, V.V. Service quality and customer satisfaction in liner shipping. Int. J. Qual. Serv. Sci. 2015, 7, 170–183. [Google Scholar] [CrossRef]

- Parasuraman, A.; Zeithaml, V.A.; Berry, L.L. SERVQUAL: A multiple-item scale for measuring consumer perceptions of service quality. J. Retail. 1988, 64, 12–40. [Google Scholar]

- Hsu, W.K. Improving the service operations of container terminals. Int. J. Logist. Manag. 2013, 24, 101–116. [Google Scholar] [CrossRef]

- Jum’a, L.; Zimon, D.; Ikram, M. A Relationship Between Supply Chain Practices, Environmental Sustainability and Financial Performance: Evidence from Manufacturing Companies in Jordan. Sustainability 2021, 13, 2152. [Google Scholar] [CrossRef]

- Yuen, K.F.; Thai, V.V.; Wong, Y.D.; Wang, X. Interaction impacts of corporate social responsibility and service quality on shipping firms’ performance. Transp. Res. Part A Policy Pract. 2018, 113, 397–409. [Google Scholar] [CrossRef]

- Syriopoulos, T.; Tsatsaronis, M.; Gorila, M. Shang. The global cruise industry: Financial performance evaluation. Res. Transp. Bus. Manag. 2022, 45, 100558. [Google Scholar] [CrossRef]

- Parola, F.; Satta, G.; Panayides, P.M. Corporate strategies and profitability of maritime logistics firms. Marit. Econ. Logist. 2015, 17, 52–78. [Google Scholar] [CrossRef]

- Lam, S.; Lee, V.; Ooi, K.; Phusavat, K. A structural equation model of TQM, market orientation and service quality. Manag. Serv. Qual. Int. J. 2012, 22, 281–309. [Google Scholar] [CrossRef]

- Alaghbari, M.A.; Al-Dubai, M.M.; Arishi, N.A. The Relationship between Total Quality Management and Organizational Performance. Inf. Sci. Lett. 2022, 11, 199–207. [Google Scholar] [CrossRef]

- Gu, B.; Liu, J. Determinants of dry bulk shipping freight rates: Considering Chinese manufacturing industry and economic policy uncertainty. Transp. Policy 2022, 129, 66–77. [Google Scholar] [CrossRef]

- Tongzon, J.L.; Nguyen, H.-O. Effects of port-shipping logistics integration on technical and allocative efficiency. Asian J. Shipp. Logist. 2021, 37, 109–116. [Google Scholar] [CrossRef]

- Al-Dhaafri, H.S.; Alosani, M.S. Impact of total quality management, organisational excellence and entrepreneurial orientation on organisational performance: Empirical evidence from the public sector in UAE. Benchmarking Int. J. 2020, 27, 2497–2519. [Google Scholar] [CrossRef]

- Khalfallah, M.; Lakhal, L. The impact of lean manufacturing practices on operational and financial performance: The mediating role of agile manufacturing. Int. J. Qual. Reliab. Manag. 2020, 38, 147–168. [Google Scholar] [CrossRef]

- Acquah, I.S.K.; Quaicoe, J.; Arhin, M. How to invest in total quality management practices for enhanced operational performance: Findings from PLS-SEM and fsQCA. TQM J. 2023, 35, 1830–1859. [Google Scholar] [CrossRef]

- Niyi Anifowose, O.; Ghasemi, M.; Olaleye, B.R. Total quality management and small and medium-sized enterprises’(SMEs) performance: Mediating role of innovation speed. Sustainability 2022, 14, 8719. [Google Scholar] [CrossRef]

- Bhaskar, H.L. Establishing a link among total quality management, market orientation and organizational performance: An empirical investigation. TQM J. 2020, 32, 1507–1524. [Google Scholar] [CrossRef]

- Owusu-Kyei, M.; Kong, Y.; Owusu Akomeah, M.; Owusu Afriyie, S. Assessing the Influence of Total Quality Management on Customer Satisfaction in the Telecom Industry: A TQM–SERVQUAL Perspective. Businesses 2023, 3, 251–271. [Google Scholar] [CrossRef]

- Akanmu, M.D.; Hassan, M.G.; Ibrahim Alshuaibi, M.S.; Ibrahim Alshuaibi, A.S.; Mohamad, B.; Othman, A. The mediating role of organizational excellence between quality management practices and sustainable performance. Total Qual. Manag. Bus. Excell. 2023, 34, 1217–1242. [Google Scholar] [CrossRef]

- Abbas, J.; Kumari, K. Examining the relationship between total quality management and knowledge management and their impact on organizational performance: A dimensional analysis. J. Econ. Adm. Sci. 2021, 39, 426–451. [Google Scholar] [CrossRef]

- Lebdaoui, H.; Chetioui, Y. CRM, service quality and organizational performance in the banking industry: A comparative study of conventional and Islamic banks. Int. J. Bank Mark. 2020, 38, 1081–1106. [Google Scholar] [CrossRef]

- Jordan Maritime Commission. Annual Report—Jordan Maritime Commission. 2023. Available online: https://jma.gov.jo/en/about-jmc/annual-report/ (accessed on 11 October 2023).

- Aqaba Container Terminal. News & Operational Updates—Aqaba Container Terminal. 2022. Available online: https://www.act.com.jo/en/news-room/latest-news (accessed on 11 October 2023).

- Sekaran, U.; Bougie, R. Research Methods for Business: A Skill Building Approach, 8th ed.; Wiley: Hoboken, NJ, USA, 2020. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.Y.J.; Anderson, R.E. Multivariate Data Analysis, 8th ed.; Cengage: Boston, MA, USA, 2019. [Google Scholar]

- Gefen, D.; Straub, D.; Boudreau, M.C. Structural equation modeling and regression: Guidelines for research practice. Commun. Assoc. Inf. Syst. 2000, 4, 7. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Structural Equation Models with Unobservable Variables and Measurement Error: Algebra and Statistics. J. Mark. Res. 1981, 18, 382–388. [Google Scholar] [CrossRef]

- Ringle, C.M.; Wende, S.; Becker, J.M. SmartPLS 3. Bönningstedt: SmartPLS. 2015. Available online: http://www.smartpls.com (accessed on 4 June 2023).

- Ooi, K.; Lin, B.; Tan, B.; Yee-Loong Chong, A. Are TQM practices supporting customer satisfaction and service quality? J. Serv. Mark. 2011, 25, 410–419. [Google Scholar] [CrossRef]

- Jum′a, L. The effect of value-added activities of key suppliers on the performance of manufacturing firms. Pol. J. Manag. Stud. 2020, 22, 231–246. [Google Scholar] [CrossRef]

- Thai, V.V. Service quality in maritime transport: Conceptual model and empirical evidence. Asia Pac. J. Mark. Logist. 2008, 20, 493–518. [Google Scholar] [CrossRef]

- United Nations. Goal 8 Department of Economic and Social Affairs. 2023. Available online: https://sdgs.un.org/goals/goal8 (accessed on 3 June 2023).

- Yosef, F.A.; Jum’a, L.; Alatoom, M. Identifying and Categorizing Sustainable Supply Chain Practices Based on Triple Bottom Line Dimensions: Evaluation of Practice Implementation in the Cement Industry. Sustainability 2023, 15, 7323. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).