Optimization of the Residual Biomass Supply Chain: Process Characterization and Cost Analysis

Abstract

1. Introduction

- Understanding the inherent complexities of the residual biomass supply chain and identifying efficient and sustainable optimization strategies.

- Emphasizing the use of optimization techniques, such as linear programming, genetic algorithms, and tabu search, and their potential to enhance the efficiency and sustainability of this logistical process.

- Applying these tools to minimize operational costs in an integrated manner.

- Examining the various constraints and challenges that may emerge in this context, such as biomass quality and availability, environmental conditions, legal and policy constraints, and stakeholder needs.

- Providing a comprehensive understanding of this subject, which can inform and guide future decisions and practices in the field of residual biomass collection and recovery.

2. Organization of the Work

- Section 1, the Introduction, provides an overview of the topic and sets the context for the subsequent discussions. It outlines the importance of understanding and optimizing the logistics of residual biomass collection, and the potential benefits that can be derived from such efforts. The introduction also highlights the research gap that this article aims to address.

- Section 2, Organization of the Work, outlines the structure of the article and provides a roadmap for the reader. It describes the sequence of topics that will be discussed and explains how each section contributes to the overall objective of the article.

- Section 3, Literature Review, presents analysis of previous works related to the subject of this research and outlines the contributions of this manuscript comparatively with the existing literature.

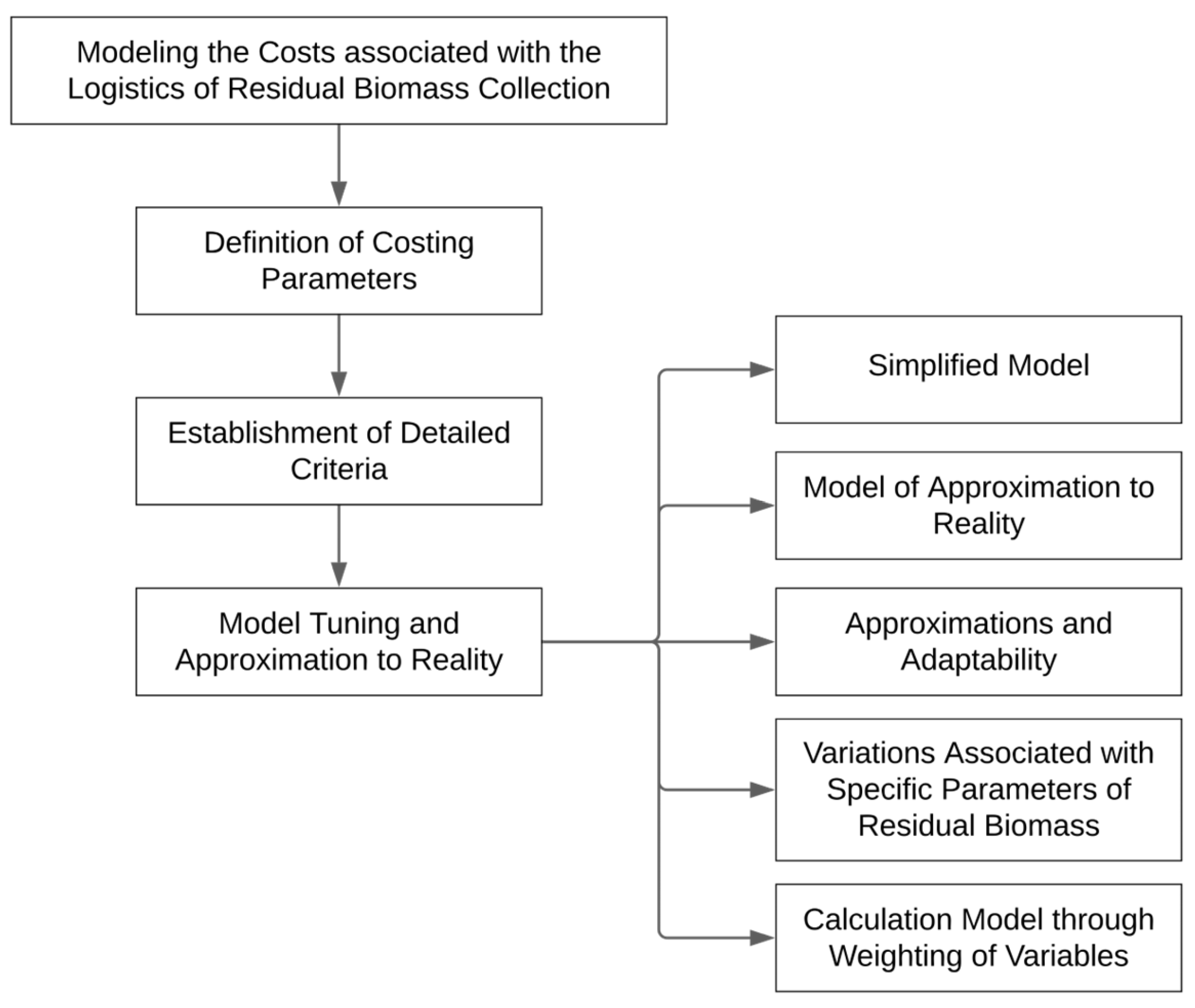

- Section 4, Modeling the Costs Associated with the Logistics of Residual Biomass Collection, is organized as presented in Figure 1. It begins with the Definition of Costing Parameters, where the various factors that contribute to the cost of logistics are identified and defined. This is followed by the Establishment of Detailed Criteria, where these parameters are further refined and categorized. The section then moves on to Model Tuning and Approximation to Reality, which is further divided into five subsections. The Simplified Model provides a basic understanding of the cost structure, while the Model of Approximation to Reality introduces more complexity and realism. The Approximations and Adaptability subsection discusses the flexibility of the model and its ability to adapt to different scenarios. The Variations Associated with Specific Parameters of Residual Biomass subsection examines how changes in the characteristics of the biomass can affect the costs. Finally, the Calculation Model through Weighting of Variables presents a method for quantifying the costs based on the defined parameters and criteria.

- Section 5, Optimization Models for the Collection Process, presents different models for optimizing the logistics of residual biomass collection. It starts with a Linear Approach for the Characterization of the Supply Chain, which provides a simplified model for understanding the logistics process. This is followed by Complex Models, which introduce more sophisticated methods for optimizing the collection process.

- Section 6, Conclusions, summarizes the key findings of the article. It highlights the implications of the cost models and optimization methods discussed in the previous sections and suggests directions for future research. This section also reiterates the importance of understanding and optimizing the logistics of residual biomass collection, and the potential benefits that can be derived from such efforts.

3. Literature Review

4. Modeling the Costs Associated with the Logistics of Residual Biomass Collection

4.1. Definition of Costing Parameters

- Cutting cost (Cc): may include labor cost, equipment cost, and equipment maintenance cost, and can also be influenced by factors such as the type of biomass and site conditions.

- Cleaning cost (Cl): the cost associated with preparing the biomass for transportation. This may include debris removal, biomass separation from other materials, and the selection of distinct parts that constitute this biomass, such as the separation of husks.

- Recollection cost (Cr): the cost of collecting the biomass and preparing it for transportation, which may include biomass compaction (baling) and loading it onto transport vehicles or using more traditional methods (now making a comeback), such as modern animal traction.

- Loading cost (Cca): the cost of loading the biomass onto the transport vehicle, which can vary depending on the type of vehicle used and the amount of biomass that needs to be loaded.

- Transportation cost (Ct): the cost of moving the biomass from the cutting site to the final processing site, which may include the cost of fuel, vehicle wear and tear, and time spent in transportation.

4.2. Establishment of Detailed Criteria

- Biomass acquisition cost (Ca): the cost of acquiring biomass and may depend on a variety of factors, including the type of biomass and its location and spatial distribution.

- Waste management cost (Cd): the cost associated with managing any waste produced during the process of cutting, cleaning, reloading, loading, and transporting biomass.

- Insurance coverage cost (Ci): the cost of insuring the process, including equipment insurance and insurance for liability, environmental and work accidents, among others.

- Permit/license cost (Cp): the cost associated with obtaining the necessary permits and licenses to carry out the process.

- Indirect cost (Cin): a general cost that may include things such as administration, supervision, facility maintenance, and so on.

- Unloading cost (Cde): the cost of unloading biomass at the intermediate location.

- Shredding cost (Cdt): the cost of shredding biomass at the intermediate location.

- Reloading cost (Crc): the cost of reloading biomass onto the transport vehicle after shredding.

- Additional transportation cost (Cta): the cost of transporting biomass from the intermediate location to the final processing location.

4.3. Model Tuning and Approximation to Reality

4.3.1. Simplified Model

- Cutting cost (Cc): this cost can be influenced by factors such as labor cost (Cmo); labor productivity (Pmo), which may depend on workers’ education and experience; equipment cost (Pe), which may vary depending on the type and quality of the equipment; maintenance cost (Me); equipment lifespan (Le); and site conditions, which can affect cutting speed.

- Cleaning cost (Cl): this cost can be influenced by factors similar to those of the cutting cost, such as labor productivity and equipment cost. It may also depend on the type of biomass and site conditions, among other factors.

- Reharvesting cost (Cr): this cost can be influenced by factors such as biomass size and shape, labor productivity, and equipment cost. For example, reharvesting larger biomass pieces may be more expensive than reharvesting smaller pieces, as it requires more effort from the equipment, resulting in increased fuel consumption.

- Loading cost (Cca): this cost may depend on the type of vehicle used for transportation, the quantity of biomass that needs to be loaded, and labor productivity.

- Transportation cost (Ct): this cost may depend on factors such as the distance to the final processing location (Dpf), the type of vehicle used, fuel cost (Ccomb), and the time required for travel (Tdesl).

4.3.2. Model of Approximation to Reality

- Cutting cost (Cc): this cost can be represented as the sum of labor cost, equipment cost, and equipment maintenance cost. It can be assumed that the labor cost depends on the hourly rate (H) and the time required to cut the biomass (Tc). The equipment cost can be the price of the equipment (Pe) divided by its useful life (Le), and the equipment maintenance cost (Me) can be considered as a percentage of the equipment cost. Therefore, the formula can be presented as follows:

- Cleaning cost (Cl): this cost can be represented similarly to the cutting cost, assuming that the time required for cleaning is Tl and the cleaning equipment has its own acquisition value (Pl), lifespan (Ll), and maintenance cost (Ml), as presented in the following equation:

- Reharvesting cost (Cr): this cost can be influenced by the dimension and shape of the available biomass (Sb) if the amount of time required for recharging varies depending on the size of the pieces to be collected and processed. The recharging equipment has its own acquisition cost (Pr), useful life (Lr), and maintenance cost (Mr):

- Loading cost (Cca): this cost can be influenced by the biomass quantity (Qb) available if the time required for loading increases with the biomass quantity. The loading equipment also has its own acquisition value (Pca), useful life (Lca), and maintenance cost (Mca).

- Transportation cost (Ct): this cost may depend on the distance to the final processing location (D), the fuel cost per kilometer (F), and the transit time (Tt). The vehicle has its own acquisition cost (Pv), useful life (Lv), and maintenance cost (Mv):

4.3.3. Approximations and Adaptability

- Biomass acquisition cost (Ca): this cost may depend on the price per unit of biomass (Pb) and the quantity of biomass acquired (Qb).

- Cost associated with waste management (Cd): this cost may depend on the quantity of waste produced (Qr), which can be a proportion of the acquired biomass quantity and the cost per unit of waste to be managed (Pr):

- Insurance cost (Ci): this cost can correspond to a fixed rate or may depend on the value of the insured assets (Va) and the insurance rate (I):

- Cost associated with obtaining permits/licenses (Cp): this cost may depend on the number of permits or licenses required (Np) and the cost per permit or license (Pp):

- Indirect costs (Cin): this is a general cost that may include items such as administration, supervision, and facility maintenance. It can be difficult to model mathematically, but it can be considered as a percentage (α) of the total direct cost (Cdirect), which is the sum of cutting, cleaning, reloading, loading, and transportation costs.

- Unloading cost (Cde): this cost may depend on the quantity of biomass to be unloaded (Qde), the time required for unloading (Tde), and the labor cost (H). Additionally, there may be an equipment cost associated with unloading.

- Shredding cost (Cdt): this cost may depend on the dimensions and shape of the biomass (Sdt), the time required for shredding (Tdt), and the labor cost (H). Additionally, there may be an equipment cost associated with shredding.

- Reharvesting cost (Crc): this cost may be similar to the loading cost, but it may depend on the quantity (volume) of biomass after shredding (Qrc), the time required for recharging (Trc), and the labor cost (H). Additionally, there may be equipment costs associated with recharging.

- Additional transportation cost (Cta): this cost may depend on the additional distance to the final processing location (Da), the cost of fuel per kilometer (F), and the time for the additional displacement (Tta). The vehicle has its own acquisition cost (Pv), useful life (Lv), and maintenance cost (Mv).

4.3.4. Variations Associated with Specific Parameters of Residual Biomass

- Moisture: biomass with high moisture content may be less valuable because moisture reduces its calorific value and increases transportation costs (as the water is also being transported). Therefore, a depreciation factor for moisture (dH) can be introduced, which decreases the price of biomass as moisture content increases.

- Inert percentage: biomass with a high percentage of inert materials may be less valuable because inert materials do not contribute to the energy value and can even cause damage to processing equipment, in addition to significantly contributing to the amount of ash produced if thermochemical conversion is the valorization pathway. Therefore, a depreciation factor for inert materials (dI) can be introduced, which decreases the price of biomass as the percentage of inert materials increases.

- Spatial dispersion: biomass that is more scattered may be less valuable because it becomes more expensive to collect and transport. Therefore, a depreciation factor for spatial dispersion (dD) can be introduced, which decreases the price of biomass as spatial dispersion increases.

- If H ≤ H1, then dH = 0 (there is no depreciation).

- If H1< H ≤ H2, then (linear depreciation with slope a).

- If H > H2, then (linear depreciation with slope b and a displacement to ensure the function is continuous).

4.3.5. Calculation Model through Weighting of Variables

- Measurement errors: if the data used to calculate individual costs (Cc, Cl, …) are measurements, they may contain measurement errors.

- Parameter variation: the model parameters (e.g., weights w1, w2, …) can vary over time and/or space, or across different biomass supply systems.

- Cost variation: individual costs (Cc, Cl, …) can vary over time and/or space, or across different biomass supply systems.

- Model simplifications: the model may incorporate various simplifications (e.g., assuming costs are additive and that the effects of different variables are independent). These simplifications may not be exact, leading to errors in the estimation of total cost.

- Error propagation: if there is an estimation of the error associated with each individual cost (e.g., due to measurement errors), one can utilize the theory of error propagation to calculate the margin of error in the total cost.

- Sensitivity analysis: if there is an understanding of how the model parameters (the weights w1, w2, …) can vary, a sensitivity analysis can be conducted to observe how the variation in these parameters affects the total cost.

- Simulation: if there is a probabilistic model of the biomass supply system (e.g., if the variation in costs and parameters has been modeled as random variables), simulation techniques such as the Monte Carlo method can be used to estimate the margin of error.

- Experience and industry knowledge: weights can be determined based on practical experience and industry knowledge. For example, if it is known that transportation costs are significantly higher than other operational costs, a higher weight can be assigned to transportation costs.

- Expert consultation: experts familiar with biomass production and transportation can be consulted. They can provide valuable insights into which costs are generally more significant.

- Economic analysis: an economic analysis can be conducted to determine the relative importance of each cost. For instance, evaluating how changes in each cost affect the total production cost or operational profitability.

- Sensitivity analysis: sensitivity analysis can be used to determine the impact of changes in each variable on the total cost. Variables that have the greatest impact on the total cost when changed can be assigned higher weights.

- Historical data analysis: if historical data on biomass production and transportation costs are available, statistical analyses can be used to determine which costs have had the greatest impact on the total cost over time.

- Optimization: in some cases, weights can be determined using optimization techniques. For example, defining an objective function (such as minimizing total cost or maximizing profit) and using optimization techniques to find the weights that optimize that function.

5. Optimization Models for the Collection Process

5.1. Linear Approach for the Characterization of the Supply Chain

- Flexibility: LP allows for the inclusion of a variety of operational constraints, such as capacity limits, demand requirements, and time constraints.

- Computational efficiency: there already exist efficient algorithms (such as the simplex method) for solving LP problems.

- Interpretability: the solutions to an LP problem are easy to interpret. The optimal solution indicates the collection and transportation strategy that minimizes total costs, and the shadow prices (or reduced marginal costs) associated with constraints provide information about the method of minimizing those constraints.

- Sensitivity and scenario analysis: LP allows for sensitivity analysis to understand the impact of changes in model parameters (e.g., transportation costs, biomass availability) on the optimized solution. It also enables scenario analysis to explore alternative strategies under different assumptions or future conditions.

- The amount of biomass collected at each location must not exceed the available quantity (for all i).

- The total amount of biomass collected must meet the processing facility’s (demand) needs ( for all i).

- The biomass quantities to be collected cannot be negative ( for all i).

- for all , where D is the search at the processing location;

- for all i, where qi is the quantity available at location i;

- for all i, where C is the vehicle’s carrying capacity;

- for all i, ensuring that the collected quantity cannot be negative.

- for all , where D is the demand at the processing location;

- for all i, where qi is the quantity available at location i;

- for all i, where C is the vehicle’s carrying capacity and y is a binary variable (0 or 1);

- for all i, ensuring that the collected quantity cannot be negative;

- y is a binary variable.

5.2. Complex Models

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nunes, L.J.; Casau, M.; Dias, M.F.; Matias, J.; Teixeira, L.C. Agroforest woody residual biomass-to-energy supply chain analysis: Feasible and sustainable renewable resource exploitation for an alternative to fossil fuels. Results Eng. 2023, 17, 101010. [Google Scholar] [CrossRef]

- Lozano, F.J.; Lozano, R. Assessing the potential sustainability benefits of agricultural residues: Biomass conversion to syngas for energy generation or to chemicals production. J. Clean. Prod. 2018, 172, 4162–4169. [Google Scholar] [CrossRef]

- Nanda, S.; Berruti, F. Municipal solid waste management and landfilling technologies: A review. Environ. Chem. Lett. 2021, 19, 1433–1456. [Google Scholar] [CrossRef]

- Parikka, M. Global biomass fuel resources. Biomass Bioenergy 2004, 27, 613–620. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Perpina, C.; Alfonso, D.; Pérez-Navarro, A.; Penalvo, E.; Vargas, C.; Cárdenas, R. Methodology based on Geographic Information Systems for biomass logistics and transport optimisation. Renew. Energy 2009, 34, 555–565. [Google Scholar] [CrossRef]

- Leitão, A. Bioeconomy: The challenge in the management of natural resources in the 21st century. Open J. Soc. Sci. 2016, 4, 26–42. [Google Scholar] [CrossRef]

- Chidozie, B.C.; Ramos, A.L.; Ferreira, J.V.; Ferreira, L.P. Residual Agroforestry Biomass Supply Chain Simulation Insights and Directions: A Systematic Literature Review. Sustainability 2023, 15, 9992. [Google Scholar] [CrossRef]

- Searcy, E.; Flynn, P.; Ghafoori, E.; Kumar, A. The relative cost of biomass energy transport. Appl. Biochem. Biotechnol. 2007, 137, 639–652. [Google Scholar] [PubMed]

- Mahmudi, H.; Flynn, P.C. Rail vs truck transport of biomass. In Proceedings of the Twenty-Seventh Symposium on Biotechnology for Fuels and Chemicals; Springer Science & Business Media: New York, NY, USA, 2006; pp. 88–103. [Google Scholar]

- Ranjbari, M.; Esfandabadi, Z.S.; Ferraris, A.; Quatraro, F.; Rehan, M.; Nizami, A.-S.; Gupta, V.K.; Lam, S.S.; Aghbashlo, M.; Tabatabaei, M. Biofuel supply chain management in the circular economy transition: An inclusive knowledge map of the field. Chemosphere 2022, 296, 133968. [Google Scholar] [CrossRef]

- Casau, M.; Dias, M.F.; Matias, J.C.; Nunes, L.J. Residual biomass: A comprehensive review on the importance, uses and potential in a circular bioeconomy approach. Resources 2022, 11, 35. [Google Scholar] [CrossRef]

- Huang, Y.; Kang, J.; Liu, L.; Zhong, X.; Lin, J.; Xie, S.; Meng, C.; Zeng, Y.; Shah, N.; Brandon, N. A hierarchical coupled optimization approach for dynamic simulation of building thermal environment and integrated planning of energy systems with supply and demand synergy. Energy Convers. Manag. 2022, 258, 115497. [Google Scholar] [CrossRef]

- Albashabsheh, N.T.; Stamm, J.L.H. Optimization of lignocellulosic biomass-to-biofuel supply chains with densification: Literature review. Biomass Bioenergy 2021, 144, 105888. [Google Scholar] [CrossRef]

- Shabani, N.; Akhtari, S.; Sowlati, T. Value chain optimization of forest biomass for bioenergy production: A review. Renew. Sustain. Energy Rev. 2013, 23, 299–311. [Google Scholar] [CrossRef]

- Nunes, L.; Causer, T.; Ciolkosz, D. Biomass for energy: A review on supply chain management models. Renew. Sustain. Energy Rev. 2020, 120, 109658. [Google Scholar] [CrossRef]

- Rentizelas, A.A.; Tolis, A.J.; Tatsiopoulos, I.P. Logistics issues of biomass: The storage problem and the multi-biomass supply chain. Renew. Sustain. Energy Rev. 2009, 13, 887–894. [Google Scholar] [CrossRef]

- Daugherty, P.J.; Fried, J.S. Jointly optimizing selection of fuel treatments and siting of forest biomass-based energy production facilities for landscape-scale fire hazard reduction. INFOR Inf. Syst. Oper. Res. 2007, 45, 17–30. [Google Scholar] [CrossRef]

- Ba, B.H.; Prins, C.; Prodhon, C. Models for optimization and performance evaluation of biomass supply chains: An Operations Research perspective. Renew. Energy 2016, 87, 977–989. [Google Scholar] [CrossRef]

- Shahsavani, I.; Goli, A. A systematic literature review of circular supply chain network design: Application of optimization models. Environ. Dev. Sustain. 2023, 1–32. [Google Scholar] [CrossRef]

- Lotfi, R.; Safavi, S.; Gharehbaghi, A.; Ghaboulian Zare, S.; Hazrati, R.; Weber, G.-W. Viable supply chain network design by considering blockchain technology and cryptocurrency. Math. Probl. Eng. 2021, 2021, 7347389. [Google Scholar] [CrossRef]

- Del Rosario, E.; Vitoriano, B.; Weber, G.-W. OR for sustainable development. Cent. Eur. J. Oper. Res. 2020, 28, 1179–1186. [Google Scholar] [CrossRef]

- Shokouhifar, M.; Ranjbarimesan, M. Multivariate time-series blood donation/demand forecasting for resilient supply chain management during COVID-19 pandemic. Clean. Logist. Supply Chain 2022, 5, 100078. [Google Scholar] [CrossRef]

- Shokouhifar, M.; Sohrabi, M.; Rabbani, M.; Molana, S.M.H.; Werner, F. Sustainable Phosphorus Fertilizer Supply Chain Management to Improve Crop Yield and P Use Efficiency Using an Ensemble Heuristic–Metaheuristic Optimization Algorithm. Agronomy 2023, 13, 565. [Google Scholar] [CrossRef]

- Salehi, S.; Mehrjerdi, Y.Z.; Sadegheih, A.; Hosseini-Nasab, H. Designing a resilient and sustainable biomass supply chain network through the optimization approach under uncertainty and the disruption. J. Clean. Prod. 2022, 359, 131741. [Google Scholar] [CrossRef]

- Meyer, A.; Schneider, P. Cradle-to-Cradle for Sustainable Development: From Ecodesign to Circular Economy. In Encyclopedia of Sustainability in Higher Education; Springer: Berlin/Heidelberg, Germany, 2019; pp. 321–330. [Google Scholar]

- Ho, D.P.; Ngo, H.H.; Guo, W. A mini review on renewable sources for biofuel. Bioresour. Technol. 2014, 169, 742–749. [Google Scholar] [CrossRef]

- Wee, H.-M.; Yang, W.-H.; Chou, C.-W.; Padilan, M.V. Renewable energy supply chains, performance, application barriers, and strategies for further development. Renew. Sustain. Energy Rev. 2012, 16, 5451–5465. [Google Scholar] [CrossRef]

- Dale, V.H.; Kline, K.L.; Buford, M.A.; Volk, T.A.; Smith, C.T.; Stupak, I. Incorporating bioenergy into sustainable landscape designs. Renew. Sustain. Energy Rev. 2016, 56, 1158–1171. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking Int. J. 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Allen, J.; Browne, M.; Hunter, A.; Boyd, J.; Palmer, H. Logistics management and costs of biomass fuel supply. Int. J. Phys. Distrib. Logist. Manag. 1998, 28, 463–477. [Google Scholar] [CrossRef]

- Guzmán-Bello, H.; López-Díaz, I.; Aybar-Mejía, M.; de Frias, J.A. A Review of Trends in the Energy Use of Biomass: The Case of the Dominican Republic. Sustainability 2022, 14, 3868. [Google Scholar] [CrossRef]

- Misni, F.; Lee, L.S. A review on strategic, tactical and operational decision planning in reverse logistics of green supply chain network design. J. Comput. Commun. 2017, 5, 83–104. [Google Scholar] [CrossRef]

- Shabani, N.; Sowlati, T. A mixed integer non-linear programming model for tactical value chain optimization of a wood biomass power plant. Appl. Energy 2013, 104, 353–361. [Google Scholar] [CrossRef]

- Boston, K.; Bettinger, P. Combining tabu search and genetic algorithm heuristic techniques to solve spatial harvest scheduling problems. For. Sci. 2002, 48, 35–46. [Google Scholar]

- Zhang, F.; Johnson, D.M.; Johnson, M.A. Development of a simulation model of biomass supply chain for biofuel production. Renew. Energy 2012, 44, 380–391. [Google Scholar] [CrossRef]

- Bello, O.; Holzmann, J.; Yaqoob, T.; Teodoriu, C. Application of artificial intelligence methods in drilling system design and operations: A review of the state of the art. J. Artif. Intell. Soft Comput. Res. 2015, 5, 121–139. [Google Scholar] [CrossRef]

- Batidzirai, B.; van der Hilst, F.; Meerman, H.; Junginger, M.H.; Faaij, A.P. Optimization potential of biomass supply chains with torrefaction technology. Biofuels Bioprod. Biorefin. 2014, 8, 253–282. [Google Scholar] [CrossRef]

- Nunes, L.J.; Matias, J.C.; Loureiro, L.M.; Sá, L.C.; Silva, H.F.; Rodrigues, A.M.; Causer, T.P.; DeVallance, D.B.; Ciolkosz, D.E. Evaluation of the potential of agricultural waste recovery: Energy densification as a factor for residual biomass logistics optimization. Appl. Sci. 2020, 11, 20. [Google Scholar] [CrossRef]

- Atashbar, N.Z.; Labadie, N.; Prins, C. Modeling and optimization of biomass supply chains: A review and a critical look. IFAC-Pap. 2016, 49, 604–615. [Google Scholar] [CrossRef]

- Sun, O.; Fan, N. A review on optimization methods for biomass supply chain: Models and algorithms, sustainable issues, and challenges and opportunities. Process Integr. Optim. Sustain. 2020, 4, 203–226. [Google Scholar] [CrossRef]

- Lo, S.L.Y.; How, B.S.; Leong, W.D.; Teng, S.Y.; Rhamdhani, M.A.; Sunarso, J. Techno-economic analysis for biomass supply chain: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 135, 110164. [Google Scholar] [CrossRef]

- Jauhar, S.K.; Pant, M. Genetic algorithms in supply chain management: A critical analysis of the literature. Sādhanā 2016, 41, 993–1017. [Google Scholar] [CrossRef]

- Min, H. Genetic algorithm for supply chain modelling: Basic concepts and applications. Int. J. Serv. Oper. Manag. 2015, 22, 143–164. [Google Scholar] [CrossRef]

- Sang, B. Application of genetic algorithm and BP neural network in supply chain finance under information sharing. J. Comput. Appl. Math. 2021, 384, 113170. [Google Scholar] [CrossRef]

- Radhakrishnan, P.; Prasad, V.; Gopalan, M. Inventory optimization in supply chain management using genetic algorithm. Int. J. Comput. Sci. Netw. Secur. 2009, 9, 33–40. [Google Scholar]

- Cambero, C.; Sowlati, T. Assessment and optimization of forest biomass supply chains from economic, social and environmental perspectives—A review of literature. Renew. Sustain. Energy Rev. 2014, 36, 62–73. [Google Scholar] [CrossRef]

- Pinho, T.M.; Coelho, J.P.; Veiga, G.; Moreira, A.P.; Boaventura-Cunha, J. Soft computing optimization for the biomass supply chain operational planning. In Proceedings of the 2018 13th APCA International Conference on Automatic Control and Soft Computing (CONTROLO), Ponta Delgada, Portugal, 4–6 June 2018; pp. 259–264. [Google Scholar]

- Castillo-Villar, K.K. Metaheuristic algorithms applied to bioenergy supply chain problems: Theory, review, challenges, and future. Energies 2014, 7, 7640–7672. [Google Scholar] [CrossRef]

- De Meyer, A.; Cattrysse, D.; Rasinmäki, J.; Van Orshoven, J. Methods to optimise the design and management of biomass-for-bioenergy supply chains: A review. Renew. Sustain. Energy Rev. 2014, 31, 657–670. [Google Scholar] [CrossRef]

- Sarker, B.R.; Wu, B.; Paudel, K.P. Modeling and optimization of a supply chain of renewable biomass and biogas: Processing plant location. Appl. Energy 2019, 239, 343–355. [Google Scholar] [CrossRef]

- Cao, J.X.; Zhang, Z.; Zhou, Y. A location-routing problem for biomass supply chains. Comput. Ind. Eng. 2021, 152, 107017. [Google Scholar] [CrossRef]

- Edwards, G.; Sørensen, C.G.; Bochtis, D.D.; Munkholm, L.J. Optimised schedules for sequential agricultural operations using a Tabu Search method. Comput. Electron. Agric. 2015, 117, 102–113. [Google Scholar] [CrossRef]

- An, H.; Wilhelm, W.E.; Searcy, S.W. Biofuel and petroleum-based fuel supply chain research: A literature review. Biomass Bioenergy 2011, 35, 3763–3774. [Google Scholar]

- Sharma, B.; Ingalls, R.G.; Jones, C.L.; Khanchi, A. Biomass supply chain design and analysis: Basis, overview, modeling, challenges, and future. Renew. Sustain. Energy Rev. 2013, 24, 608–627. [Google Scholar] [CrossRef]

- Durmaz, Y.G.; Bilgen, B. Multi-objective optimization of sustainable biomass supply chain network design. Appl. Energy 2020, 272, 115259. [Google Scholar] [CrossRef]

- Galik, C.S.; Benedum, M.E.; Kauffman, M.; Becker, D.R. Opportunities and barriers to forest biomass energy: A case study of four US states. Biomass Bioenergy 2021, 148, 106035. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Schuler, J.; Hartley, D.; Volk, T.; Eisenbies, M. Optimization of harvest and logistics for multiple lignocellulosic biomass feedstocks in the northeastern United States. Energy 2020, 197, 117260. [Google Scholar] [CrossRef]

- Gómez-Marín, N.; Bridgwater, A. Mapping bioenergy stakeholders: A systematic and scientometric review of capabilities and expertise in bioenergy research in the United Kingdom. Renew. Sustain. Energy Rev. 2021, 137, 110496. [Google Scholar] [CrossRef]

- Hibbard, M.; Lurie, S. The new natural resource economy: Environment and economy in transitional rural communities. Soc. Nat. Resour. 2013, 26, 827–844. [Google Scholar] [CrossRef]

- Soltanian, S.; Aghbashlo, M.; Almasi, F.; Hosseinzadeh-Bandbafha, H.; Nizami, A.-S.; Ok, Y.S.; Lam, S.S.; Tabatabaei, M. A critical review of the effects of pretreatment methods on the exergetic aspects of lignocellulosic biofuels. Energy Convers. Manag. 2020, 212, 112792. [Google Scholar] [CrossRef]

- Ilic, D.; Williams, K.; Farnish, R.; Webb, E.; Liu, G. On the challenges facing the handling of solid biomass feedstocks. Biofuels Bioprod. Biorefin. 2018, 12, 187–202. [Google Scholar] [CrossRef]

- Ubeda, S.; Arcelus, F.J.; Faulin, J. Green logistics at Eroski: A case study. Int. J. Prod. Econ. 2011, 131, 44–51. [Google Scholar] [CrossRef]

- Mafakheri, F.; Nasiri, F. Modeling of biomass-to-energy supply chain operations: Applications, challenges and research directions. Energy Policy 2014, 67, 116–126. [Google Scholar] [CrossRef]

- Hess, J.R.; Wright, C.T.; Kenney, K.L. Cellulosic biomass feedstocks and logistics for ethanol production. Biofuels Bioprod. Biorefin. Innov. Sustain. Econ. 2007, 1, 181–190. [Google Scholar] [CrossRef]

- Daneshmandi, M.; Sahebi, H.; Ashayeri, J. The incorporated environmental policies and regulations into bioenergy supply chain management: A literature review. Sci. Total Environ. 2022, 820, 153202. [Google Scholar] [CrossRef] [PubMed]

- Thompson, I.; Mackey, B.; McNulty, S.; Mosseler, A. Forest resilience, biodiversity, and climate change. In Proceedings of the A Synthesis of the Biodiversity/Resilience/Stability Relationship in Forest Ecosystems; Technical Series. Secretariat of the Convention on Biological Diversity: Montreal, QC, Canada, 2009; pp. 1–67. [Google Scholar]

| % Humidity (H) | Depreciation Rate (dH) |

|---|---|

| 0 | 0.00 |

| 10 | 0.00 |

| 20 | 0.05 |

| 30 | 0.10 |

| 40 | 0.15 |

| 50 | 0.25 |

| 60 | 0.35 |

| 70 | 0.45 |

| 80 | 0.55 |

| 90 | 0.65 |

| 100 | 1.00 |

| A | B | C | D | E | |

|---|---|---|---|---|---|

| A | 0 | 10 | 15 | 20 | 25 |

| B | 10 | 0 | 5 | 15 | 20 |

| C | 15 | 5 | 0 | 10 | 15 |

| D | 20 | 15 | 10 | 0 | 5 |

| E | 25 | 20 | 15 | 5 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nunes, L.J.R.; Silva, S. Optimization of the Residual Biomass Supply Chain: Process Characterization and Cost Analysis. Logistics 2023, 7, 48. https://doi.org/10.3390/logistics7030048

Nunes LJR, Silva S. Optimization of the Residual Biomass Supply Chain: Process Characterization and Cost Analysis. Logistics. 2023; 7(3):48. https://doi.org/10.3390/logistics7030048

Chicago/Turabian StyleNunes, Leonel J. R., and Sandra Silva. 2023. "Optimization of the Residual Biomass Supply Chain: Process Characterization and Cost Analysis" Logistics 7, no. 3: 48. https://doi.org/10.3390/logistics7030048

APA StyleNunes, L. J. R., & Silva, S. (2023). Optimization of the Residual Biomass Supply Chain: Process Characterization and Cost Analysis. Logistics, 7(3), 48. https://doi.org/10.3390/logistics7030048