Logistics Service Providers and Industry 4.0: A Systematic Literature Review

Abstract

:1. Introduction

2. Systematic Literature Review (SLR) Method

2.1. Systematic Review of the Literature for LSPs and Industry 4.0

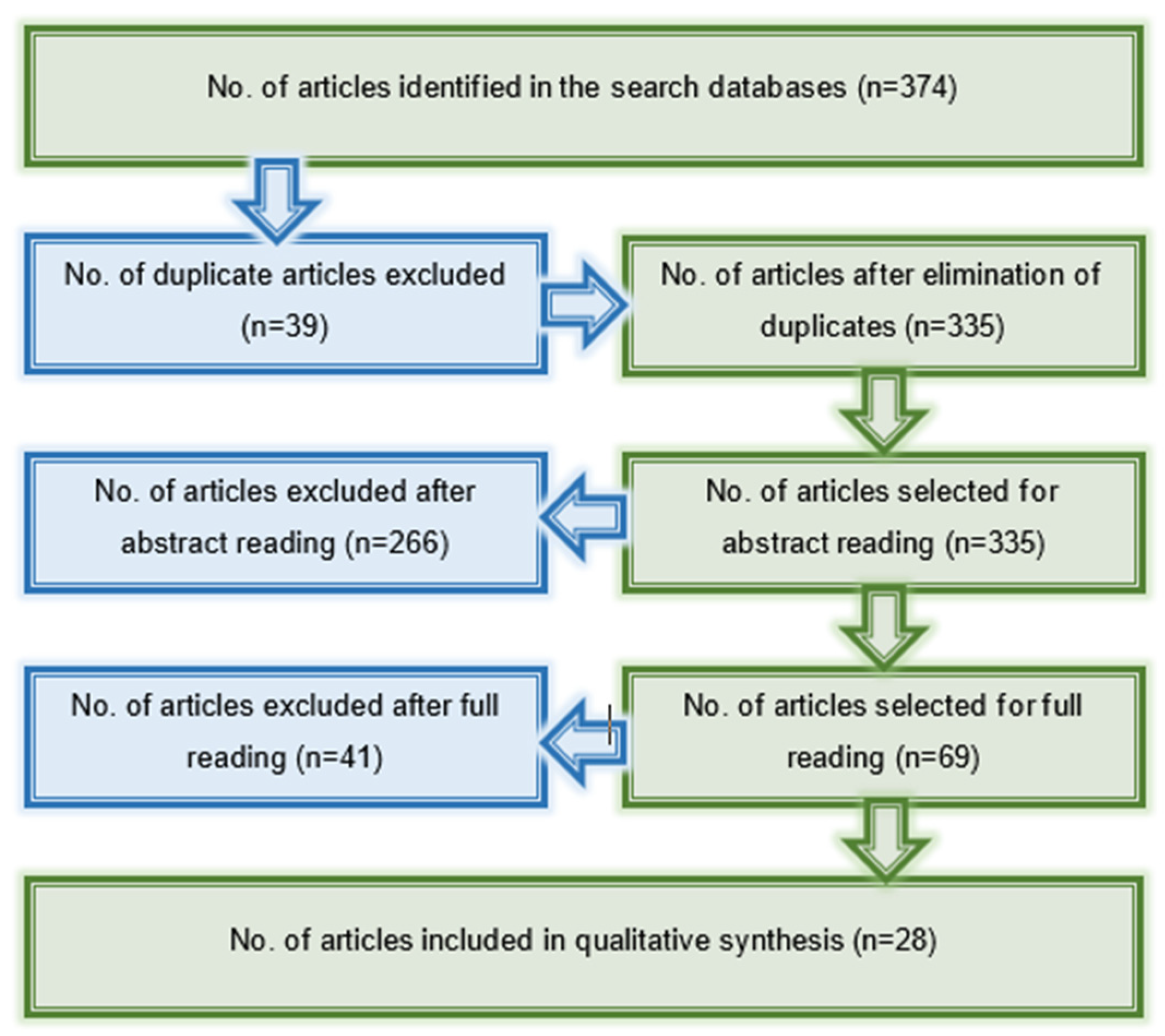

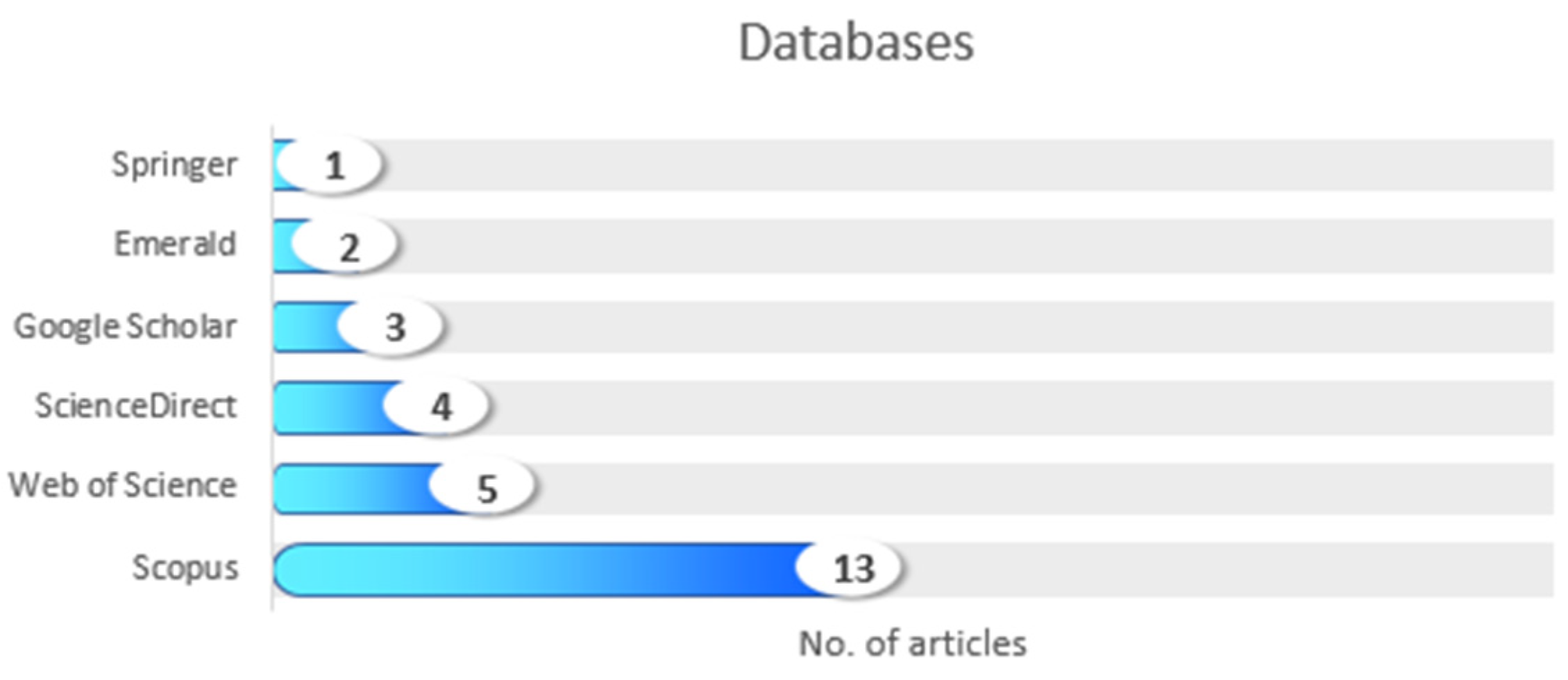

2.1.1. Planning

2.1.2. Processing

3. Results and Discussions

3.1. Conceptual Map for Logistics Service Provider 4.0

3.1.1. Challenges

- Rapid changes in demand: New customer requirements, a greater variety of products and services, high demand combined with an increasingly individualized demand, or uncertain or imprecise demand.

- Complexity of processes: The coordination of several logistics networks, composed of processes between senders, intermediaries, and recipients of different sizes, segments, and geographic location frequently requires customization of services, making it difficult to standardize processes and technological infrastructure.

- Cost reduction: While cost reduction remains the main reason why shippers hire LSPs, the extremely competitive and commoditized environment creates pressure to reduce costs; consequently, LSPs face frequent contract reviews and increasingly tight profit margins.

- Resource management: Failures and mismanagement of resources also cause an increase in logistics costs, due to the waste and idleness generated. Therefore, optimal allocation is the key to maximize the use of logistics resources, be competitive, and reduce costs. However, the lack of reliable information and the dependence on human experience to determine a complex allocation of resources are major impediments.

- Lack of skilled professionals: The lack of workforce skills; shortage of professionals with digital skills, technology skills, and operations knowledge, coupled with low levels of education are all challenges confronting LSPs.

- Technology adoption: Factors such as information technology (IT) experience, top management support, competitive pressure, competitive conditions, requirement and alignment with customers and business partners, security issues, and perceived benefits, are as important to technology adoption as choosing the right technology at the right time—it is the organizational strategy that will drive digital transformation and ensure a successful integration for LSPs.

- Interoperability between systems: The constantly evolving and wide range of digital devices and technologies necessitates greater integration between systems, which must necessarily have the capacity to communicate, integrate with each other in an effective manner, and operate seamlessly regardless of the technology platform and supplier. Interoperability between systems is one of the biggest challenges of Industry 4.0.

- Information security: The large number of connected devices and the high volume of confidential data traffic over the network, often deposited in cloud solutions, mean that data protection and information security are critical issues. Moreover, there is a growing need among customers to obtain information in real-time, anytime and anywhere, placing greater pressure on access security to nullify attempted breaches or unauthorized access and cyber-attacks.

3.1.2. Barriers

- High cost of technologies: Initial investment in advanced IT in the logistics sector is often high. It not only includes the cost of acquiring the technology (purchase or development) but also costs related to its implementation, including transition costs, where these new technologies are integrated into the company, maintenance costs, and costs related to technical support and training.

- Distrust of benefits: In addition to the high cost of investment, the indifference in relation to the return also prevents companies from investing in new technologies. Many firms question whether these technologies can really bring competitive advantage and assist in winning new contracts. Organizations are not always convinced of the return on investment, which remains difficult to estimate or doubtful, generating distrust of its benefits.

- Lack of technological know-how: The lack of technological know-how and a digital culture is an obstacle. Logistics providers are generally not seen as innovative companies but strive to acquire technological know-how through collaboration with partners and clients. However, obtaining such knowledge through interaction may not lead to innovation, thus hurting the company’s attempts to establish leadership in innovation or differentiation from the competition. Moreover, without genuine digital transformation, the potential of a technology may not be fully exploited, and any competitive advantage derived might not be sustained.

3.1.3. Threats

3.1.4. People Resources

3.1.5. Technology Resources

3.1.6. Infrastructure Resources

3.1.7. Relationship Resources

3.1.8. Service Resources

3.1.9. Organizational Resources

3.1.10. Performance Requirements

- Efficiency: Processes that deliver high performance rates, reduced costs, failure-free or minimal error rates, and no waste.

- Visibility: Availability and processing of real-time information of events and recorded conditions of processes and equipment.

- Reliability: Reliable and safe processes and services that function properly at an acceptable level of service quality.

- Responsiveness: Appropriate response to changes in the environment and demand, without prejudice to the level of service.

- Assertiveness: Proactivity in the constant reassessment and monitoring of processes and services, with assertive decision-making and solutions.

- Agility: Prompt reaction and the ability to quickly and effectively adapt to constantly changing environments.

- Flexibility: Assume, absorb, and adapt when internal or external changes occur, observing cost, quality, and time constraints.

- Collaboration: Relationship of coordination, cooperation, and communication between internal and external entities in order to achieve common goals.

3.2. Theoretical Foundation of the Conceptual Framework

3.2.1. Challenges

3.2.2. Barriers

3.2.3. Threats

3.2.4. People Resources

3.2.5. Technology Resources

3.2.6. Infrastructure Resources

3.2.7. Relationship Resources

3.2.8. Service Resources

3.2.9. Organizational Resources

4. Conclusions

- What, in shippers’ view, are the necessary elements to create LSPs 4.0?

- What benefits do shippers perceive from LSPs 4.0 in their supply chain?

- How can LSPs 4.0 support customers in deploying Industry 4.0?

- What professional profiles and skills are required to implement LSPs 4.0?

- Which logistics processes should be prioritized to receive investments and achieve technological innovation?

- What are the financial impacts of LSPs 4.0 implementation on LSPs?

- How and which processes should be measured when introducing disruptive technologies?

- What IT infrastructure is needed to deploy LSPs 4.0?

- How should the performance of logistics processes be measured through digital technologies?

- What is the best way for LSPs to acquire disruptive technologies?

- How can LSPs 4.0 measure customer satisfaction?

- What levels of competitive advantage can the transformation to LSPs 4.0 deliver for traditional service providers?

- How can the barriers of high technology cost, lack of know-how, and firm-level misgivings of the benefits, be mitigated?

- How can disruptive technologies support LSPs 4.0 in making logistics processes more sustainable?

- What is the relationship between organizational maturity and the implementation of LSPs 4.0?

- What are the barriers to deploying LSPs 4.0 in small- and medium-sized enterprises?

- How can operational excellence be achieved through LSPs 4.0?

- What is the relationship between performance requirements and value delivery to customers?

- What is the role of lean logistics in a LSPs 4.0 context?

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liao, Y.; Deschamps, F.; de Freitas Rocha, E.; Ramos, L.F.P. Past, Present and Future of Industry 4.0—A Systematic Literature Review and Research Agenda Proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Tang, C.S.; Veelenturf, L.P. The Strategic Role of Logistics in the Industry 4.0 Era. Transp. Res. E Logist. Transp. Rev. 2019, 129, 1–11. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A Systematic Review towards a New Logistics System. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M.; Iranmanesh, M.; Maroufkhani, P.; Morales, M.E. Industry 4.0 Ten Years on: A Bibliometric and Systematic Review of Concepts, Sustainability Value Drivers, and Success Determinants. J. Clean. Prod. 2021, 302, 127052. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The Future of Manufacturing Industry: A Strategic Roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the Art and Future Trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Yavas, V.; Ozkan-Ozen, Y.D. Logistics Centers in the New Industrial Era: A Proposed Framework for Logistics Center 4.0. Transp. Res. E Logist. Transp. Rev. 2020, 135, 101864. [Google Scholar] [CrossRef]

- Tombido, L.L.; Louw, L.; van Eeden, J. A Systematic Review of 3pls’ Entry into Reverse Logistics. South Afr. J. Ind. Eng. 2018, 29, 235–260. [Google Scholar] [CrossRef]

- Kagermann; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0. In Final Report of the Industrie 4.0 WG; Forschungsunion/acatech: Munich Germany, 2013. [Google Scholar]

- Frederico, G.F.; Garza-Reyes, J.A.; Anosike, A.; Kumar, V. Supply Chain 4.0: Concepts, Maturity and Research Agenda. Supply Chain. Manag. 2019, 25, 262–282. [Google Scholar] [CrossRef]

- Strandhagen, J.O.; Vallandingham, L.R.; Fragapane, G.; Strandhagen, J.W.; Stangeland, A.B.H.; Sharma, N. Logistics 4.0 and Emerging Sustainable Business Models. Adv. Manuf. 2017, 5, 359–369. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Y.; Liu, Y.; Wang, L.; Wang, X.V. An ‘Internet of Things’ Enabled Dynamic Optimization Method for Smart Vehicles and Logistics Tasks. J. Clean. Prod. 2019, 215, 806–820. [Google Scholar] [CrossRef]

- Pan, S.; Zhong, R.Y.; Qu, T. Smart Product-Service Systems in Interoperable Logistics: Design and Implementation Prospects. Adv. Eng. Inform. 2019, 42, 100996. [Google Scholar] [CrossRef]

- Ardito, L.; Petruzzelli, A.M.; Panniello, U.; Garavelli, A.C. Towards Industry 4.0: Mapping Digital Technologies for Supply Chain Management-Marketing Integration. Bus. Process Manag. J. 2019, 25, 323–346. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2017, 6, 6505–6519. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The Expected Contribution of Industry 4.0 Technologies for Industrial Performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Garay-Rondero, C.L.; Martinez-Flores, J.L.; Smith, N.R.; Caballero Morales, S.O.; Aldrette-Malacara, A. Digital Supply Chain Model in Industry 4.0. J. Manuf. Technol. Manag. 2019, 31, 887–933. [Google Scholar] [CrossRef]

- Frederico, G.F.; Garza-Reyes, J.A.; Kumar, A.; Kumar, V. Performance Measurement for Supply Chains in the Industry 4.0 Era: A Balanced Scorecard Approach. Int. J. Product. Perform. Manag. 2020. ahead of print. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. Impact of Industry 4.0 on Supply Chain Performance. Prod. Plan. Control. 2020, 32, 63–81. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the Current Status as Well as Future Prospects on Logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart Operators in Industry 4.0: A Human-Centered Approach to Enhance Operators’ Capabilities and Competencies within the New Smart Factory Context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Buer, S.V.; Strandhagen, J.O.; Chan, F.T.S. The Link between Industry 4.0 and Lean Manufacturing: Mapping Current Research and Establishing a Research Agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fettermann, D. Implementation of Industry 4.0 and Lean Production in Brazilian Manufacturing Companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the Circular Economy: A Proposed Research Agenda and Original Roadmap for Sustainable Operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as Enabler for a Sustainable Development: A Qualitative Assessment of Its Ecological and Social Potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Melkonyan, A.; Krumme, K.; Gruchmann, T.; Spinler, S.; Schumacher, T.; Bleischwitz, R. Scenario and Strategy Planning for Transformative Supply Chains within a Sustainable Economy. J. Clean. Prod. 2019, 231, 144–160. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, A.; Zavadskas, E.K.; Mangla, S.K.; Garza-Reyes, J.A. Industry 4.0 as an Enabler of Sustainability Diffusion in Supply Chain: An Analysis of Influential Strength of Drivers in an Emerging Economy. Int. J. Prod. Res. 2020, 58, 1505–1521. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the Implications of Digitisation and Automation in the Context of Industry 4.0: A Triangulation Approach and Elements of a Research Agenda for the Construction Industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 Framework: A Systematic Literature Review Identifying the Current Trends and Future Perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Osterrieder, P.; Budde, L.; Friedli, T. The Smart Factory as a Key Construct of Industry 4.0: A Systematic Literature Review. Int. J. Prod. Econ. 2020, 221, 107476. [Google Scholar] [CrossRef]

- van Laarhoven, P.; Berglund, M.; Peters, M. Third-Party Logistics in Europe—Five Years Later. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 425–442. [Google Scholar] [CrossRef]

- Premkumar, P.; Gopinath, S.; Mateen, A. Trends in Third Party Logistics–the Past, the Present & the Future. Int. J. Logist. Res. Appl. 2020, 24, 551–580. [Google Scholar] [CrossRef]

- Zacharia, Z.G.; Sanders, N.R.; Nix, N.W. The Emerging Role of the Third-Party Logistics Provider (3PL) as an Orchestrator. J. Bus. Logist. 2011, 32, 40–54. [Google Scholar] [CrossRef]

- Selviaridis, K.; Spring, M. Third Party Logistics: A Literature Review and Research Agenda. Int. J. Logist. Manag. 2007, 18, 125–150. [Google Scholar] [CrossRef]

- Hofmann, E.; Osterwalder, F. Third-Party Logistics Providers in the Digital Age: Towards a New Competitive Arena? Logistics 2017, 1, 9. [Google Scholar] [CrossRef]

- Chen, I.S.N.; Fung, P.K.O.; Yuen, S.S.M. Dynamic Capabilities of Logistics Service Providers: Antecedents and Performance Implications. Asia Pac. J. Mark. Logist. 2019, 31, 1058–1075. [Google Scholar] [CrossRef]

- Webster, J.; Watson, R.T. Analysing the Past to Prepare for the Future: Writing a Literature Review. MIS Q. 2002, 26, 2005–2008. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Papert, M.; Pflaum, A. Development of an Ecosystem Model for the Realization of Internet of Things (IoT) Services in Supply Chain Management. Electron. Mark. 2017, 27, 175–189. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Trappey, C.v.; Fan, C.Y.; Hsu, A.P.T.; Li, X.K.; Lee, I.J.Y. IoT Patent Roadmap for Smart Logistic Service Provision in the Context of Industry 4.0. J. Chin. Inst. Eng. Trans. Chin. Inst. Eng. Ser. A 2017, 40, 593–602. [Google Scholar] [CrossRef]

- Delfmann, W.; ten Hompel, M.; Kersten, W.; Schmidt, T.; Stölzle, W. Logistics as a Science: Central Research Questions in the Era of the Fourth Industrial Revolution. Logist. Res. 2018, 11, 1–13. [Google Scholar]

- Karia, N. Knowledge Resources, Technology Resources and Competitive Advantage of Logistics Service Providers. Knowl. Manag. Res. Pract. 2018, 16, 414–426. [Google Scholar] [CrossRef]

- Sevinç, A.; Gür, Ş.; Eren, T. Analysis of the Difficulties of SMEs in Industry 4.0 Applications by Analytical Hierarchy Process and Analytical Network Process. Processes 2018, 6, 264. [Google Scholar] [CrossRef]

- Barczak, A.; Dembińska, I.; Marzantowicz, Ł. Analysis of the Risk Impact of Implementing Digital Innovations for Logistics Management. Processes 2019, 7, 815. [Google Scholar] [CrossRef]

- Fernández-Caramés, T.M.; Blanco-Novoa, O.; Froiz-Míguez, I.; Fraga-Lamas, P. Towards an Autonomous Industry 4.0 Warehouse: A UAV and Blockchain-Based System for Inventory and Traceability Applications in Big Data-Driven Supply Chain Management. Sensors 2019, 19, 2394. [Google Scholar] [CrossRef]

- Mathauer, M.; Hofmann, E. Technology Adoption by Logistics Service Providers. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 416–434. [Google Scholar] [CrossRef]

- Mostafa, N.; Hamdy, W.; Alawady, H. Impacts of Internet of Things on Supply Chains: A Framework for Warehousing. Soc. Sci. 2019, 8, 84. [Google Scholar] [CrossRef]

- Aida Abdul Rahman, N.; Muda, J.; Fakhrulnizam Mohammad, M.; Fauzi Ahmad, M.; Abdul Rahim, S. Digitalization and Leap Frogging Strategy Among the Supply Chain Member: Facing GIG Economy and Why Should Logistics Players Care? ExcelingTech: London, UK, 2019; Volume 8. Available online: http://excelingtech.co.uk/ (accessed on 1 June 2020).

- Sundarakani, B.; Lai, Y.S.; Goh, M.; de Souza, R. Studying the Sustainability of Third Party Logistics Growth Using System Dynamics. J. Model. Manag. 2019, 14, 872–895. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Pursuing Supply Chain Sustainable Development Goals through the Adoption of Green Practices and Enabling Technologies: A Cross-Country Analysis of LSPs. Technol. Forecast Soc. Chang. 2020, 153, 119920. [Google Scholar] [CrossRef]

- Cichosz, M.; Wallenburg, C.M.; Knemeyer, A.M. Digital Transformation at Logistics Service Providers: Barriers, Success Factors and Leading Practices. Int. J. Logist. Manag. 2020, 31, 209–238. [Google Scholar] [CrossRef]

- Ding, Y.; Jin, M.; Li, S.; Feng, D. Smart Logistics Based on the Internet of Things Technology: An Overview. Int. J. Logist. Res. Appl. 2021, 24, 323–345. [Google Scholar] [CrossRef]

- Leung, K.H.; Lee, C.K.M.; Choy, K.L. An Integrated Online Pick-to-Sort Order Batching Approach for Managing Frequent Arrivals of B2B e-Commerce Orders under Both Fixed and Variable Time-Window Batching. Adv. Eng. Inform. 2020, 45, 101125. [Google Scholar] [CrossRef]

- Tiwong, S.; Ramingwong, S.; Tippayawong, K.Y. On LSP Lifecycle Model to Re-Design Logistics Service: Case Studies of Thai LSPs. Sustainability 2020, 12, 2394. [Google Scholar] [CrossRef]

- Wu, W.; Cheung, C.; Lo, S.Y.; Zhong, R.Y.; Huang, G.Q. An Iot-Enabled Real-Time Logistics System for a Third Party Company: A Case Study. In Procedia Manufacturing; Elsevier: Amsterdam, The Netherlands, 2020; Volume 49, pp. 16–23. [Google Scholar] [CrossRef]

- Yadav, D.K.; Pant, M.; Seth, N. Analysing Enablers of Knowledge Management in Improving Logistics Capabilities of Indian Organisations: A TISM Approach. J. Knowl. Manag. 2020, 24, 1559–1584. [Google Scholar] [CrossRef]

- Noura, M.; Atiquzzaman, M.; Gaedke, M. Interoperability in Internet of Things: Taxonomies and Open Challenges. Mob. Netw. Appl. 2019, 24, 796–809. [Google Scholar] [CrossRef]

- Wagner, S.M. Innovation Management in the German Transportation Industry. J. Bus. Logist. 2008, 29, 215–231. [Google Scholar] [CrossRef]

- Strandhagen, J.W.; Alfnes, E.; Strandhagen, J.O.; Vallandingham, L.R. The Fit of Industry 4.0 Applications in Manufacturing Logistics: A Multiple Case Study. Adv. Manuf. 2017, 5, 344–358. [Google Scholar] [CrossRef]

- Nica, E.; Stan, C.I.; Luțan Petre, A.G.; Oașa Geambazi, R.-Ș. Internet of Things-based Real-Time Production Logistics, Sustainable Industrial Value Creation, and Artificial Intelligence-driven Big Data Analytics in Cyber-Physical Smart Manufacturing Systems. Econ. Gestão E Merc. Financ. 2021, 16, 52–62. [Google Scholar] [CrossRef]

- Andronie, M.; Lăzăroiu, G.; Iatagan, M.; Uță, C.; Ștefănescu, R.; Cocoșatu, M. Artificial Intelligence-Based Decision-Making Algorithms, Internet of Things Sensing Networks, and Deep Learning-Assisted Smart Process Management in Cyber-Physical Production Systems. Electronics 2021, 10, 2497. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Andronie, M.; Iatagan, M.; Geamănu, M.; Ștefănescu, R.; Dijmărescu, I. Deep Learning-Assisted Smart Process Planning, Robotic Wireless Sensor Networks, and Geospatial Big Data Management Algorithms in the Internet of Manufacturing Things. ISPRS Int. J. Geo-Inf. 2022, 11, 277. [Google Scholar] [CrossRef]

| Stages | Results |

|---|---|

| Planning | Databases: Web of Science, Scopus, ScienceDirect, Emerald, Springer, Wiley, SAGE, and Google Scholar. Search terms: “the fourth industrial revolution” OR “the 4th industrial revolution” OR “Industry 4.0” AND 3PL OR 4PL OR LSP OR “logistics services providers” OR “third-party logistics” OR “fourth-party logistics”. Research period: 2011 to Oct 2020Number of articles found: 374 |

| Processing | Search performed based on criteria in the planning stage Screening: application of the exclusion method, reading of articles based on the theme of this research. Content that addressed concepts, capabilities, technologies, barriers, and success factors. Extraction: structuring of the concept matrix by authors x dimensions. |

| Reporting | Establishment of the dimensions identified in the reading and analysis of the articles. Application of the concept matrix, specification of the dimensions and sub-dimensions most cited by the authors. |

| No. | Author | Title | Database | Periodical |

|---|---|---|---|---|

| 1 | [21] | Industry 4.0 and the current status as well as future prospects on logistics | Science Direct | Computers in Industry |

| 2 | [40] | Development of an Ecosystem Model for the realization of Internet of Things (IoT) services in supply chain management | Springer | Electronic Markets |

| 3 | [11] | Logistics 4.0 and emerging sustainable business models | Scopus | Advances in Manufacturing |

| 4 | [41] | IoT patent roadmap for smart logistic service provision in the context of Industry 4.0 | Scopus | Journal of the Chinese Institute of Engineers |

| 5 | [42] | Logistics as a science—central research questions in the era of the fourth industrial revolution: Invited paper based on the position paper of the scientific advisory board of bundesvereinigung logistik (BVL) [1] | Scopus | Logistics Research |

| 6 | [43] | Knowledge resources, technology resources and competitive advantage of logistics service providers | Web of Science | Knowledge Management Research and Practice |

| 7 | [44] | Analysis of the difficulties of SMEs in Industry 4.0 applications by analytical hierarchy process and analytical network process | Scopus | Processes |

| 8 | [8] | A Systematic Review of 3PLS’ entry into reverse logistics | Web of Science | South African Journal of Industrial Engineering |

| 9 | [45] | Analysis of the risk impact of implementing digital innovations for logistics management | Scopus | Processes |

| 10 | [37] | Dynamic capabilities of logistics service providers: antecedents and performance implications | Emerald | Asia Pacific Journal of Marketing and Logistics |

| 11 | [46] | Towards an autonomous Industry 4.0 warehouse: A UAV and blockchain-based system for inventory and traceability applications in big data-driven supply chain management | Web of Science | Sensors |

| 12 | [12] | An ‘Internet of Things’ enabled dynamic optimization method for smart vehicles and logistics tasks | Scopus | Journal of Cleaner Production |

| 13 | [47] | Technology adoption by logistics service providers | Scopus | International Journal of Physical Distribution and Logistics Management |

| 14 | [27] | Scenario and strategy planning for transformative supply chains within a sustainable economy | Scopus | Journal of Cleaner Production |

| 15 | [48] | Impacts of Internet of Things on supply chains: A framework for warehousing | Google Scholar | Social Sciences |

| 16 | [13] | Smart product-service systems in interoperable logistics: Design and implementation prospects | Scopus | Advanced Engineering Informatics |

| 17 | [49] | Digitalization and leap frogging strategy among the supply chain member: Facing GIG economy and why should logistics players care? | Scopus | International Journal of Supply Chain Management |

| 18 | [50] | Studying the sustainability of third-party logistics growth using system dynamics | Web of Science | Journal of Modelling in Management |

| 19 | [2] | The strategic role of logistics in the Industry 4.0 era | Science Direct | Transportation Research Part E: Logistics and Transportation Review |

| 20 | [51] | Pursuing supply chain sustainable development goals through the adoption of green practices and enabling technologies: A cross-country analysis of LSPs | Science Direct | Technological Forecasting and Social Change |

| 21 | [52] | Digital transformation at logistics service providers: barriers, success factors and leading practices | Scopus | International Journal of Logistics Management |

| 22 | [53] | Smart logistics based on the Internet of Things technology: an overview | Scopus | International Journal of Logistics Research and Applications |

| 23 | [54] | An integrated online pick-to-sort order batching approach for managing frequent arrivals of B2B e-commerce orders under both fixed and variable time-window batching | Science Direct | Advanced Engineering Informatics |

| 24 | [55] | On LSP lifecycle model to re-design logistics service: Case studies of Thai LSPs | Web of Science | Sustainability |

| 25 | [3] | Logistics 4.0: a systematic review towards a new logistics system | Google Scholar | International Journal of Production Research |

| 26 | [56] | An IoT-enabled real-time logistics system for a third-party company: a case study | Google Scholar | Procedia Manufacturing |

| 27 | [57] | Analyzing enablers of knowledge management in improving logistics capabilities of Indian organizations: a TISM approach | Emerald | Journal of Knowledge Management |

| 28 | [7] | Logistics centers in the new industrial era: A proposed framework for logistics center 4.0 | Scopus | Transportation Research Part E: Logistics and Transportation Review |

| Author(s) | Staff | Technology | Infra Structure | Relationship | Services | Organizational | Challenges | Barriers | Threats | Performance Requirements |

|---|---|---|---|---|---|---|---|---|---|---|

| [21] | X | X | X | X | ||||||

| [40] | X | X | X | X | X | |||||

| [11] | X | X | X | X | X | |||||

| [41] | X | X | X | |||||||

| [42] | X | X | X | X | X | X | X | |||

| [43] | X | X | X | X | ||||||

| [44] | X | X | X | X | X | |||||

| [8] | X | X | X | X | ||||||

| [45] | X | X | X | X | ||||||

| [37] | X | X | X | X | X | X | X | |||

| [46] | X | X | X | X | ||||||

| [12] | X | X | X | X | X | X | ||||

| [47] | X | X | X | X | X | X | X | X | X | |

| [27] | X | X | X | |||||||

| [48] | X | X | X | X | X | X | ||||

| [13] | X | X | X | X | X | X | X | X | ||

| [49] | X | X | X | X | ||||||

| [50] | X | X | X | X | X | X | X | |||

| [2] | X | X | X | X | ||||||

| [51] | X | X | X | |||||||

| [52] | X | X | X | X | X | X | X | X | X | X |

| [53] | X | X | X | X | X | X | ||||

| [54] | X | X | X | X | X | X | X | X | X | |

| [55] | X | X | X | X | ||||||

| [3] | X | X | X | X | X | X | ||||

| [56] | X | X | X | X | ||||||

| [57] | X | X | X | X | X | X | X | |||

| [7] | X | X | X | X | X | X | ||||

| No. of items considered | 9 | 28 | 5 | 11 | 13 | 20 | 22 | 10 | 10 | 26 |

| Author(s) | IoT | IoS | RFID | WSN | CPS | Cloud Computing | BigData | Blockchain | 3D Printing | Drones | Augmented Reality | Autonomous Entities | Social Media |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [21] | X | X | X | X | X | X | X | X | X | X | |||

| [40] | X | X | |||||||||||

| [11] | X | X | X | X | X | X | X | X | X | ||||

| [41] | X | X | X | X | X | X | |||||||

| [42] | X | X | |||||||||||

| [43] | X | ||||||||||||

| [44] | X | X | |||||||||||

| [8] | X | X | |||||||||||

| [45] | X | X | X | X | X | X | X | ||||||

| [37] | X | X | X | X | |||||||||

| [46] | X | X | X | X | X | X | X | X | X | ||||

| [12] | X | X | |||||||||||

| [47] | |||||||||||||

| [27] | X | X | X | X | X | ||||||||

| [48] | X | X | X | X | X | ||||||||

| [13] | X | X | X | ||||||||||

| [49] | X | X | X | X | X | ||||||||

| [50] | X | X | |||||||||||

| [2] | X | X | X | X | |||||||||

| [51] | X | X | |||||||||||

| [52] | X | X | |||||||||||

| [53] | X | X | X | X | X | X | |||||||

| [54] | X | ||||||||||||

| [55] | X | X | X | X | X | ||||||||

| [3] | X | X | X | X | X | X | X | X | X | X | X | ||

| [56] | X | X | X | X | |||||||||

| [57] | X | X | X | X | |||||||||

| [7] | X | X | X | X | X | X | X | ||||||

| No. of items considered | 22 | 3 | 13 | 3 | 8 | 14 | 14 | 13 | 7 | 8 | 5 | 9 | 3 |

| Author(s) | Efficiency | Visibility | Reliability | Responsiveness | Assertiveness | Agility | Flexibility | Collaboration |

|---|---|---|---|---|---|---|---|---|

| [21] | X | X | X | X | X | |||

| [40] | X | |||||||

| [11] | X | X | X | X | ||||

| [41] | X | X | X | X | X | |||

| [42] | X | X | X | X | X | X | ||

| [43] | X | X | X | X | ||||

| [44] | X | |||||||

| [8] | X | X | ||||||

| [45] | ||||||||

| [37] | X | X | X | X | ||||

| [46] | X | X | X | |||||

| [12] | X | X | X | X | X | X | ||

| [47] | X | |||||||

| [27] | X | X | ||||||

| [48] | X | X | X | X | X | X | ||

| [13] | X | X | X | X | ||||

| [49] | X | X | X | |||||

| [50] | ||||||||

| [2] | X | X | ||||||

| [51] | X | |||||||

| [52] | X | X | X | X | X | X | ||

| [53] | X | X | X | X | X | X | X | X |

| [54] | X | X | X | X | X | X | X | |

| [55] | X | X | X | X | ||||

| [3] | X | X | X | X | ||||

| [56] | X | X | X | X | ||||

| [57] | X | X | X | X | ||||

| [7] | X | X | X | X | X | X | ||

| No. of items considered | 19 | 10 | 8 | 15 | 9 | 15 | 12 | 15 |

| Author(s) | Sustainability | Digitalization | Differentiation | Leadership | Agile Management |

|---|---|---|---|---|---|

| [21] | |||||

| [40] | X | ||||

| [11] | X | ||||

| [41] | |||||

| [42] | X | ||||

| [43] | X | X | |||

| [44] | X | ||||

| [8] | X | X | X | ||

| [45] | X | X | |||

| [37] | X | ||||

| [46] | |||||

| [12] | X | X | |||

| [47] | X | ||||

| [27] | X | X | X | ||

| [48] | X | ||||

| [13] | X | ||||

| [49] | X | X | |||

| [50] | X | ||||

| [2] | |||||

| [51] | X | ||||

| [52] | X | X | X | X | |

| [53] | X | X | |||

| [54] | X | ||||

| [55] | X | ||||

| [3] | X | X | |||

| [56] | X | ||||

| [57] | X | ||||

| [7] | X | X | X | ||

| No. of items considered | 8 | 7 | 16 | 3 | 5 |

| Author(s) | Quick Changes in Demand | Process Complexity | Cost Reduction | ResourceManagement | Shortage of Skilled Labor | Technology Adoption | System Interoperability | Information Security |

| [21] | X | X | X | |||||

| [40] | ||||||||

| [11] | X | |||||||

| [41] | X | X | ||||||

| [42] | ||||||||

| [43] | X | |||||||

| [44] | X | |||||||

| [8] | X | |||||||

| [45] | ||||||||

| [37] | X | X | ||||||

| [46] | X | X | X | X | ||||

| [12] | X | X | X | |||||

| [47] | X | X | X | |||||

| [27] | X | |||||||

| [48] | X | X | X | |||||

| [13] | X | X | X | X | ||||

| [49] | X | X | ||||||

| [50] | X | X | ||||||

| [2] | X | X | ||||||

| [51] | ||||||||

| [52] | X | X | X | X | X | |||

| [53] | X | X | X | X | ||||

| [54] | X | X | X | |||||

| [55] | ||||||||

| [3] | X | X | X | X | X | |||

| [56] | X | X | ||||||

| [57] | X | |||||||

| [7] | X | |||||||

| No. of items considered | 9 | 4 | 12 | 7 | 7 | 4 | 5 | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva, R.M.; Frederico, G.F.; Garza-Reyes, J.A. Logistics Service Providers and Industry 4.0: A Systematic Literature Review. Logistics 2023, 7, 11. https://doi.org/10.3390/logistics7010011

da Silva RM, Frederico GF, Garza-Reyes JA. Logistics Service Providers and Industry 4.0: A Systematic Literature Review. Logistics. 2023; 7(1):11. https://doi.org/10.3390/logistics7010011

Chicago/Turabian Styleda Silva, Ricardo Moreira, Guilherme Francisco Frederico, and Jose Arturo Garza-Reyes. 2023. "Logistics Service Providers and Industry 4.0: A Systematic Literature Review" Logistics 7, no. 1: 11. https://doi.org/10.3390/logistics7010011

APA Styleda Silva, R. M., Frederico, G. F., & Garza-Reyes, J. A. (2023). Logistics Service Providers and Industry 4.0: A Systematic Literature Review. Logistics, 7(1), 11. https://doi.org/10.3390/logistics7010011