1. Introduction

Efficiency in supply chain management (SCM) has become a determining factor for organizations in recent years. This is because this can generate significant competitive advantages when well established, ranging from cost reduction to maintaining good relationships with stakeholders, as highlighted by ref. [

1], highlighting the importance of interfirm resources and skills generated by SCM for competitive advantage. The efficient management of this means optimizing the flow of materials, information, money, and services along the channel, generating performance improvements for all participants in the chain [

2,

3].

Supply chain management is defined as the management of a network of connected organizations from the point of origin (upstream) to the point of consumption (downstream) in the different processes and activities that produce value in the form of products and services for the final consumer [

4]. Therefore, it is important for companies from a strategic point of view, since the maintenance of the interrelationship between processes is indispensable, and the integration between organizations can bring benefits that increase their competitiveness in the face of the market [

5]. This was exposed by [

6], stating “Supply chain management has been presented as an important organizational strategy for obtaining competitive advantages, its objective is to integrate the functional areas of organizations seeking cost reduction, value creation for customers and consequently, competitive advantage over the market”.

In the pandemic scenario caused by COVID-19, the maintenance of supply chains (SC) became a major challenge for organizations, since several restrictive measures between countries and states were imposed, causing the resilience of the supply chain to be put to the test [

7,

8]. This can be defined as a system’s ability to respond to, react to, and to overcome potential risks, vulnerabilities, and disruptions in the flow of goods, services, and/or information [

9,

10]. Moreover, resilience is not only tested in seasonal and unexpected moments, but rather in the face of any adversity that makes the process generally difficult as evidenced [

11,

12], defining supply chain resilience as the ability to weather unexpected disruptions.

Specifically, the Brazilian Amazon region requires greater attention from managers for one of the pillars of the supply chain: logistics. This region of Brazil lacks an adequate infrastructure system, with better roads, ports, and railways, as highlighted in ref. [

13]. Due to its geographical peculiarities, such as the largest hydrographic basin in the world, the abundant presence of forests, and high soil erosion, usually more than one transport modal is used during the route, generating another obstacle to the logistics process. According to a survey prepared by the National Transport Confederation [

14], north of the Brazil region (where most of the Amazon region is inserted) needs to invest R

$ 233.3 billion in transport infrastructure projects, and 353 interventions are needed in national integration projects for current infrastructure problems to be solved, making logistics in the region more feasible and able to drain a large part of Brazilian products. Considering the gaps presented, this research was guided by the following question: “What are the challenges for promoting resilience in supply chain management considering the pandemic period of COVID-19 in the context of companies in the Amazon Region of Brazil?”.

Therefore, this article aimed to analyze the main challenges to the promotion of resilience in the management of supply chains of companies working in the Amazon region during the pandemic period caused by COVID-19, to discuss the elements that were essential for the maintenance of SC, and to evidence them. Regarding the identification of the main challenges for promoting resilience, it is important to highlight that this research was exploratory; therefore, it did not focus on specific cases of a given organization, but aimed to understand, comparatively, the central barriers observed by SC during the COVID-19 pandemic in a broad context.

Starting from the content presented, this article is organized as follows: first, a conceptual review is presented that addresses the definitions that make up the theoretical basis necessary for the article. This is followed by methodological procedures, where research techniques and methods for the development of work are exposed. Subsequently, the results obtained from the study are analyzed, as well as the associated debates relevant to them, and finally, the conclusions of the research are followed by a list of references.

2. Theoretical Framework

In March 2020, the COVID-19 virus was declared by the World Health Organization (OMS) as a global pandemic and has since severely impacted the routine of companies and the world population. According to the studies of [

15], the operations of many organizations were severely affected and disrupted as the outbreak spread, impacting both supply and demand from supply chains. In this sense [

16], it was confirmed that the panorama of the pandemic has broken many SCM.

According to the authors of [

17], even with previous efforts of companies seeking to increase the resilience of their supply chains, they were ill-prepared to face large fluctuations in the market. As a result, organizations were pressured to perform significant work to redesign SC, improve resilience, and re-examine supplier relationships to reduce systemic risks [

18]. Given this, the COVID-19 pandemic put supply chain management in the spotlight of organizations.

Supply chain management (SCM) is important because it ensures that organizations can optimize and leverage their business. Its concept is widely debated in the literature. According to [

19], SCM consists of the administration and planning of all areas that make up a production chain, such as raw materials, production, logistics, and purchasing, among others. In [

20], the author argues that this management deals with the administration of the productive flow of organizations that aim to obtain competitive use and gain in profitability. It is also worth mentioning that, according to ref. [

21], the crucial role of supply chain management is to develop the areas of the chain to bring satisfaction efficiently to consumers. Ref. [

22] also highlights how the green supply chain is gaining global acceptance and can bring economic and environmental benefits; in agreement, [

23] enhanced on how the green growth model is constantly expanding, relating the reconstruction of the company’s value chain as a strategic activity in order to improve competitiveness and add value. Thus, in general, the SCM’s main objectives are to deal with uncertainty due to fluctuations in demand, improve market responsiveness, and meet customer demand [

24].

To obtain competitive advantages in supply chain management, organizations are seeking to apply the concept of resilience in their operations. The authors of [

9] defined resilience as the adaptive capacity of a supply chain to resist and know how to deal with unexpected situations, managing to maintain control over the structure and functions of the company so that it can recover to restore or improve its operation.

Corroborating this understanding, ref. [

25] claimed that resilience is evident when the production network can apply measures that enable ensuring customer demand and satisfaction, in addition to meeting the programmed performance. Therefore, individuals and organizations can better deal with ruptures or discontinuities, using the core elements of resilience, i.e., the basic concepts that help develop the capabilities necessary to anticipate, adapt to, respond to, recover from, and learn from ruptures [

26].

Therefore, the analysis of resilience elements is important for good supply chain management. Ref. [

27] highlights that the elements most cited in the academic literature are collaboration, flexibility, redundancy, agility, decision-making, safety, culture, robustness, integration, avoidance, human resources management, sustainability, and logistics capacity.

Thus, depending on the branch in which the organization operates, the elements may have a different degree of importance [

28]. For ref. [

26], leadership, knowledge management, collaboration, and flexibility were the most important elements contributing to the reduction of food waste. On the other hand, ref. [

29] argued that decision-making, human resources, and security were the most critical elements of resilience in the management of supply chains of Brazilian companies in the context of COVID-19.

Another important point to be analyzed in the literature is the main challenges faced in supply chain management in unexpected periods, such as the COVID-19 pandemic. From the point of view of the challenges inherent to economic and industrial problems, ref. [

30] stated that the pandemic affected the national and international scenario in three ways, declining the production of companies, stalling markets, and reducing investments.

Analyzing the challenges related to inflow troubles and production on hold, [

31] reported that many components needed for the assembly of final products had complications reaching their destinations due to the ruptures of supply chains, since they are exported, transferred, or sent to specific locations around the world, directly impacting the production of goods.

Regarding the distribution and allocation of inventory, ref. [

31,

32] pointed out that organizations are going through many difficulties in direct distribution, such as structural changes in distribution centers and warehouses, changes in networks, and distribution and storage capacities, as well as increased online purchases and adaptations.

Another important challenge to be considered is the interruption of supply and demand. Ref. [

15] stated that, in such a turbulent environment, companies facing epidemic outbreaks have a series of doubts related to the time of this interruption, what contingency plans will follow, and what changes will be made, among others.

Ref. [

33] also highlighted the challenge of people management. The author corroborated the importance of human resource management, since they need to seek strategies to develop adaptive training, well-being for employees, management, and team building. As for the challenges associated with the government, many companies faced various measures of reduction, such as mobility and resources, in addition to the closure of savings and uncertainties imposed by the pandemic [

34,

35,

36,

37].

Regarding online shopping challenges, ref. [

38] argued about online shopping habits before and during the pandemic, the main changes, the unfolding of new trends, and how digital strategies can contribute to adaptation to the pandemic situation.

Considering the context presented, it is notoriously important to analyze the challenges faced in the management of supply chains in times of crisis, as is the case of the COVID-19 pandemic, especially in regions with deficient infrastructure such as the Brazilian Amazon region.

Table 1 below summarizes the challenges that were considered in this study for analysis, along with the perception of professionals working in the supply chain management area of companies developing operations in the Brazilian Amazon region.

3. Methodological Procedures

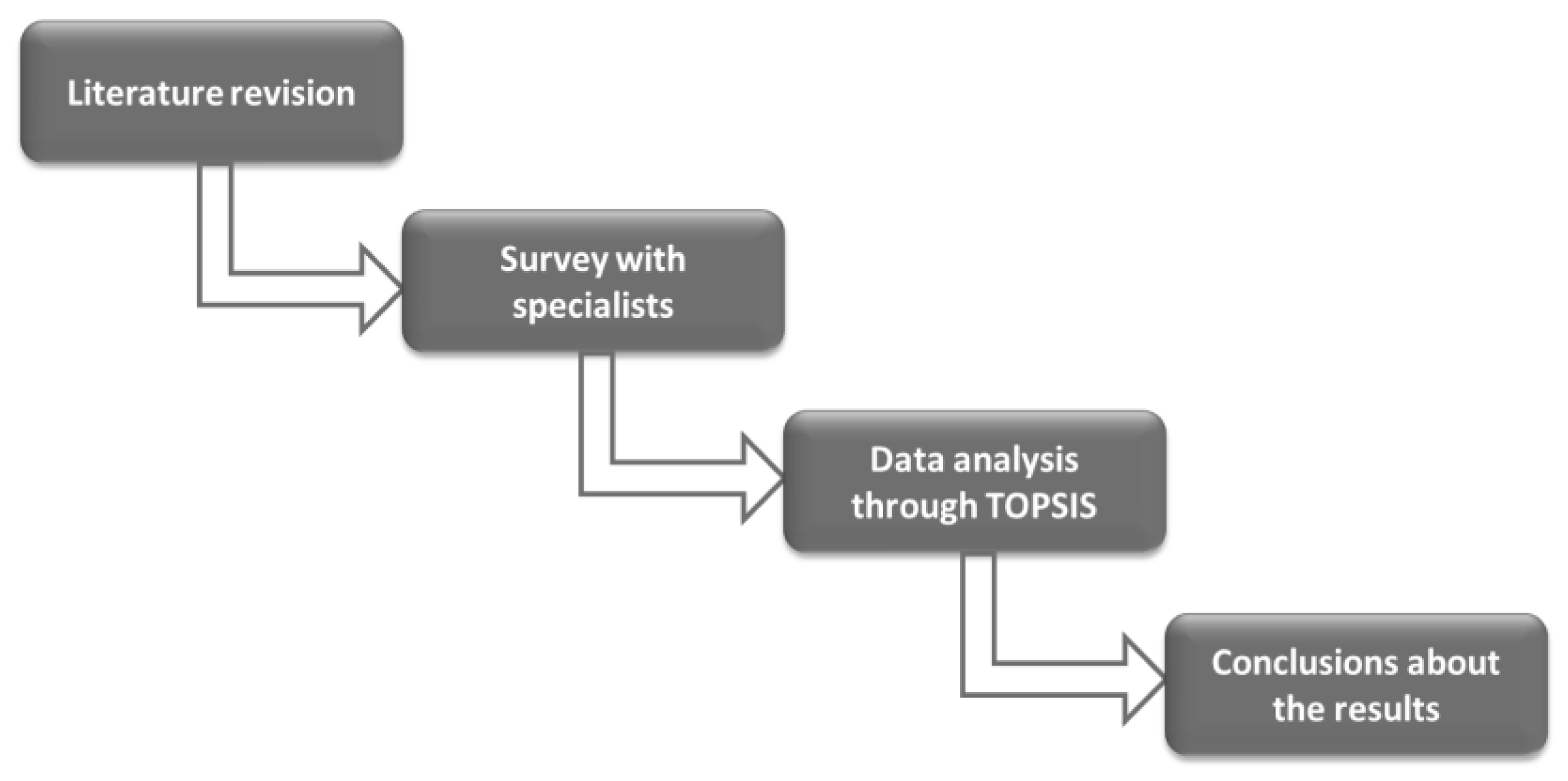

This research was developed through the following steps: (a) a review of the literature on supply chain resilience in the pandemic period; (b) a survey conducted with specialists in the area of SCM who know the particularities of the Amazon region; (c) data analysis utilizing means and comparative ordering via the TOPSIS technique; (d) conclusions drawn on the results obtained. This is shown in

Figure 1.

The literature review was conducted on different scientific bases (Science Direct, Taylor and Francis, Emerald Insight, and Wiley) to find articles that would enable the theoretical foundation in the area of supply chain management during the pandemic period in the Amazon region. The following terms were used: “Supply chain resilience during the COVID-19 pandemic”, “Supply chain in the Amazon”, and “Supply chain challenges”.

The main challenges in supply chain management during the pandemic period observed (see

Table 2) were used in the elaboration of the questionnaire to be applied to the professionals participating in the research. The authors opted for the separation of the ten main challenges into specific evaluation topics and, finally, a general analysis of the respondent about the impact of COVID-19 on SCM in the Amazon region, making the understanding by respondents facilitated.

For each of the listed challenges, the experts pointed out through an evolutionary scale of 0 to 10 how important that challenge was for promoting resilient supply chain management. For a better understanding of how respondents should assign their grades, the meanings of extreme grades 0 and 10 were presented, 0 being the representation that the challenge is irrelevant to the promotion of resilient supply chain management and 10 meaning that the challenge is extremely important for this. This can be seen in

Table 3 and the questionnaire used in the survey in

Appendix A.

The research questionnaire was developed. Then, the information on the research steps to be developed was sent to the Research Ethics Committee (CEP) for analysis, and approval was obtained for the development of the study. This stage of the analysis by a CEP is important because, in Brazil, research involving people’s opinions needs such authorization.

After approval in the CEP, data collection was initiated with specialists in the supply chain management area in the Amazon region. An invitation was sent via email, and the questionnaire was available to respondents on the Google Forms platform for 2 months. The invitation via e-mail was sent to 52 specialists, and 30 of them answered the questionnaire, thus obtaining a return rate of approximately 58%. The questionnaire was answered by directors (23%), coordinators (20%), managers (37%), and supervisors (20%), whose business branches varied between industry (30%), commerce (30%). and services (40%). Among the respondents, 20% had more than twenty years of experience, 33% had between ten and twenty years of experience, and 47% had less than 10 years of experience.

Once the answers from professionals in the area were obtained, they were analyzed considering the averages given by each of the groups of respondents, considering and grouping according to the specialist’s years of professional experience. Then, the ranking of the analyzed challenges was elaborated through the use of the TOPSIS Multicriteria Technique, according to the guidelines proposed by ref. [

39]. TOPSIS allows for generating a ranking of challenges considering different analysis criteria. Such criteria can assume different weights, denoting varying degrees of importance, and facilitating and supporting decision-making. Considering other applications of the TOPSIS technique in studies with similar objectives, it was defined that the criterion used would be the respondent’s experience time to determine the weights of their answers, and these were a 50% group with more than 20 years, a 30% group between 10 and 20 years, and a 20% group with less than 10 years [

39].

For this study, the seven steps that make up the data processing using Technique TOPSIS were developed. Initially, matrix D was organized with the elements (

xij), (i) being the alternatives and (j) being the criteria to be analyzed. The alternatives corresponded to the ten challenges presented in

Table 1, and the criteria referred to the averages attributed by each group of specialists who participated in the research (see matrix D).

Source: [

39], pp. 24 and 25.

Subsequently, matrix D was normalized using Equation (2) represented below:

Source: [

39], pp. 24 and 25.

resulting in an array named matrix R (Equation (3)) below:

Source: [

39], pp. 24 and 25.

The third step consisted of the weighting of the values of matrix R using Equation (4) below:

Source: [

39], pp. 24 and 25.

obtaining matrix V (Equation (5)):

Source: [

39], pp. 24 and 25.

Subsequently, it was necessary to determine the positive (vj+) and negative (vi-) ideal solutions. They consist of the maximum and minimum values present in the V matrix considering each of the analysis criteria.

In the fifth step, positive and negative Euclidean distances were calculated for each of the alternatives based on Equations (6) and (7) presented below.

Source: [

39], pp. 24 and 25

Finally, with the values of Euclidean distances, the

Ci* was calculated, and then, it was possible to generate the ranking of the 10 challenges analyzed in the research (step 6). It is not a point that

Ci* values must be between 0 and 1. The calculation of the

Ci* indicator was conducted using Equation (8) presented below.

Source: [

39], pp. 24 and 25.

4. Results and Associated Discussions

In this stage, the results of the survey developed with the professionals of the supply chain working in the Amazon region and the discussions of these results are presented with the literature of the area. As detailed in the methodological procedures section, the collected data were treated using the TOPSIS technique. Cronbach’s alpha test was also performed to validate the responses obtained, and this proved satisfactory.

To continue this stage, Cronbach’s alpha coefficient was used, which, according to ref. [

40], is a general formula used to estimate the reliability of an instrument in which the answers have more than two values. The results of this coefficient range from 0 to 1, and it is more reliable when the number is closer to 1. The present questionnaire had a coefficient of 0.7, attesting that the instrument has validity for the research objectives, since, according to ref. [

41], values from 0.7 are acceptable values to indicate a satisfactory internal consistency.

Initially, the mean (

Table 2) of the grades attributed by each professional to each of the objectives considered in this study (

Table 1) was calculated, and then, they were normalized using Equation (1) presented in

Figure 1, resulting in matrix R, presented in

Table 4.

Then, weights were assigned to each of the groups of respondents and professionals; those with more than 20 years of experience received a weight of 0.5, those between 10 and 20 years of experience received 0.3, and professionals with less than 10 years of experience received a weight of 0.2. Then, it was possible to obtain matrix V (

Table 5).

In

Table 6, the ideal positive and negative solutions are presented. It is through them that the calculation of the values in

Table 5 are performed, which correspond to the Euclidean distances of the positive and negative ideal solution. Using Equation (6) previously presented, it is possible to obtain the

Ci* coefficient that was used to generate the ranking of the challenges considered in this study to promote resilience in supply chains in the Amazon region during the pandemic period. This coefficient is also presented in

Table 7.

Finally, by ordering the

Ci* coefficient values, we obtained the comparative ranking of the challenges for the promotion of resilience in SC considered in this study, analyzed by professionals in the supply chain area of companies located in the Amazon region of Brazil.

Table 8 presents the results described:

Checking the first three positions of the challenges observed by managers of companies in the Brazilian Amazon region during the COVID-19 pandemic, it was observed that, through a scale of importance of each challenge, distribution, economic problems, and interruptions in supply and demand stood out as obstacles to promoting resilience in supply chains in the region. Firstly, distribution was the most relevant challenge for these managers during this period of uncertainty caused by COVID-19. The author of [

42] stated that the distribution area represents great potential for supply chain vulnerabilities on a global scale, reinforcing the importance of all links involved with well-established relationships so that, in times of adversity, such as in the pandemic scenario, the distribution operation can function continuously and peacefully.

Regarding the economic problems that managers went through, the second main challenge found in the ranking, according to ref. [

43], was that COVID-19 seriously affected the global economy, as issues related to labor immobility, reduced productivity of companies, declines in exports, and all the market uncertainties involved directly impacted supply chains. Furthermore, in the third position, the challenges related to interruptions in supply and demand brought major obstacles to decision-makers, as stated by ref. [

44], the COVID-19 crisis affected companies around the world, impacting the supply of goods in addition to forcing the closure of many businesses. Adding to this, the author stated that this period of uncertainty changed the style of purchases of consumers, totally modifying the existing market demands. Ref. [

45] stated that, to mitigate the effects of supply interruption, companies should adopt the advance of manufacturing at the company level, reducing the impact of supplier failure, and ref. [

46] corroborated and complemented this, stating that the company should seek to adopt the modularity of its products and processes so that, in cases of supply interruption, they are not so affected.

On the other hand, analyzing the last three placed in the ranking, the challenges of people management, stock allocation, and online shopping, according to the opinions of the professionals participating in this research, when analyzing the degree of importance of these among all the mentioned challenges comparatively, they obtained the lowest coefficients. However, the fact that even these challenges are in the last positions does not mean that they are not important to be analyzed in a scenario that aims to promote resilience in supply chains in the Brazilian Amazon region. In this way, according to ref. [

42], disruptions in the supply chain due to worker illness, self-isolation, or movement restrictions directly affect labor shortages in various sectors, reinforcing the need for proactive measures to deal with these vulnerabilities and introducing the management of these people regarding their health and safety in workspaces.

It is also worth noting that, according to ref. [

47], small companies are more severely affected than large corporations in a pandemic scenario, mainly due to the number of their resources when compared to the more developed ones; therefore, it directly implies the allocation of stock of these companies, with some losing and others gaining market share. Finally, the challenge with the lowest impact among those mentioned is related to online shopping; according to ref. [

48], digital media are of great importance for the organization and development of more assertive and close communication with the customer. In addition, they enable organizations to be better positioned to engage in social media and be transparent with their different stakeholders.

5. Conclusions

Given the results achieved, it was concluded that the objectives of the research carried out were achieved, since it was possible to identify and rank, in the opinion of professionals in the supply chain area, which are the main challenges responsible for promoting resilience in supply chains during the COVID-19 pandemic in companies operating in the Amazon region, namely distribution, economic problems, and interruptions in supply and demand.

It is important to highlight the impact of the results presented in both theory and practice regarding supply chain management, specifically in its maintenance. From a theoretical point of view and because it is exploratory research, the results can serve as a basis for researchers in the area who aim to understand and expand the debates on this topic through future research. From a practical point of view, the results can help supply chain managers in the Amazon region who work directly in its maintenance and aim to maintain its resilience, since they already have the main challenges for the proper functioning of the supply chains identified and ranked. Therefore, as presented, it is important to highlight the importance of the resilience of supply chains to ensure the health of companies, especially in the most difficult periods such as the COVID-19 pandemic. Both researchers and managers involved in the area of supply chain management, through the results presented here, can define actions to make supply chains increasingly resilient in the face of challenges such as the one faced during the pandemic period.

It is important to emphasize that the results achieved in this study can be used as a basis by chain managers to define resilient strategies in the face of unexpected intercurrences caused by unforeseen periods such as the COVID-19 pandemic. Such strategies contribute to the development and maintenance of supply chain activities located in regions characterized by limitations of infrastructure and technological resources, as is the case of the Amazon region. Therefore, focusing on solving problems in the movement of inputs, materials, and finished products along the supply chain, facing the challenges of reducing jobs linked to activities in the production chain and guaranteeing supply in line with demand consist of priority actions to the development and sustainability of regions with such limitations.

As limitations of the present research, it is highlighted that, as it was an exploratory study, its results cannot be generalized to other contexts of which the sample used is not part, since the reality of the answers to the questionnaire was experienced in the Brazilian Amazon region, i.e., there is a regional limitation. To be able to develop future studies from this, it is suggested to: (a) choose a defined geographic region/location; (b) survey the main topics/important challenges in the locality; and (c) use the definition of a professional profile for the application of the questionnaire.