Application of Optimization Techniques in the Dairy Supply Chain: A Systematic Review

Abstract

1. Introduction

2. Literature Review

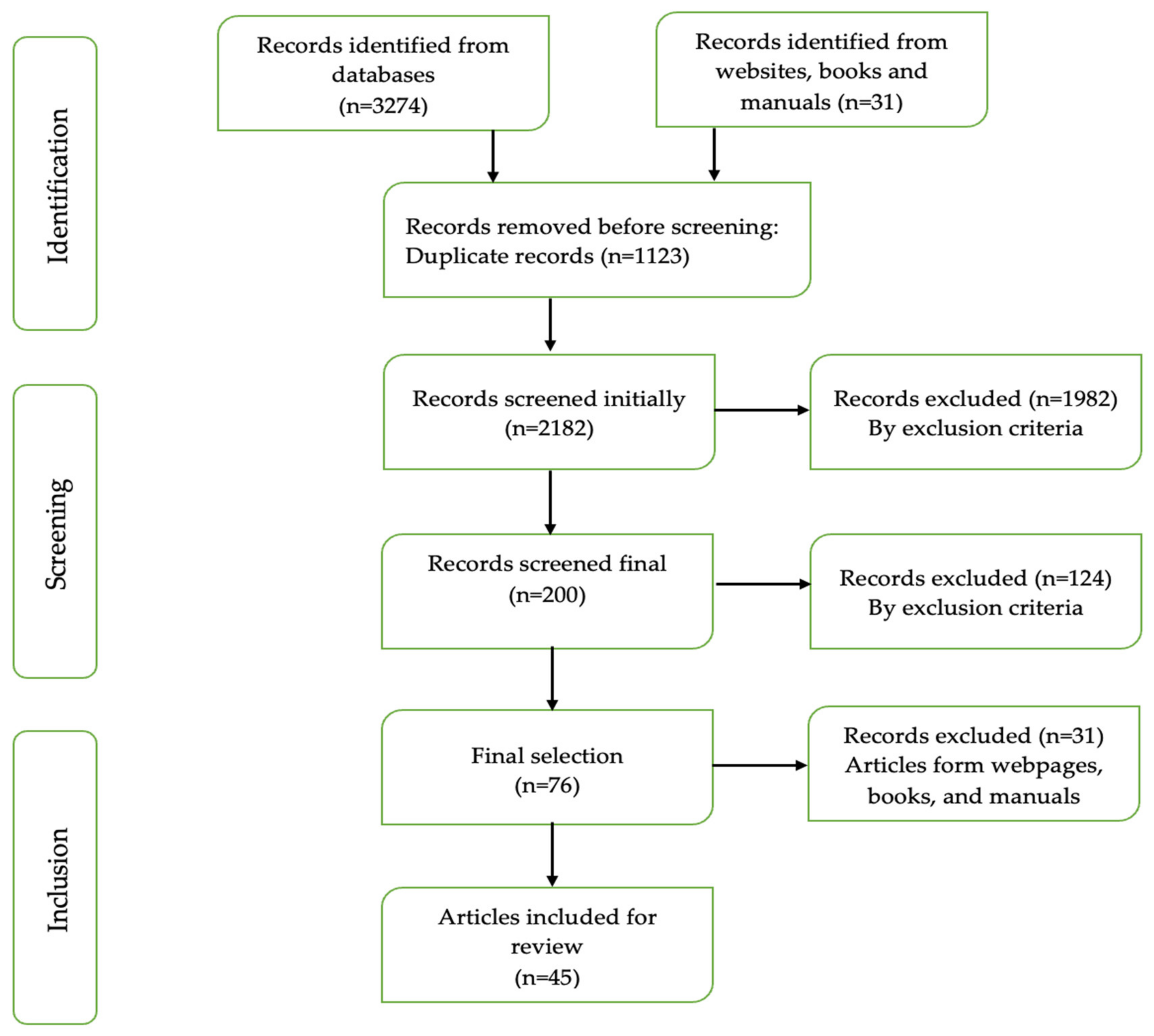

3. Review Methodology

3.1. Review Question

3.2. Search Method

3.3. Data Selection

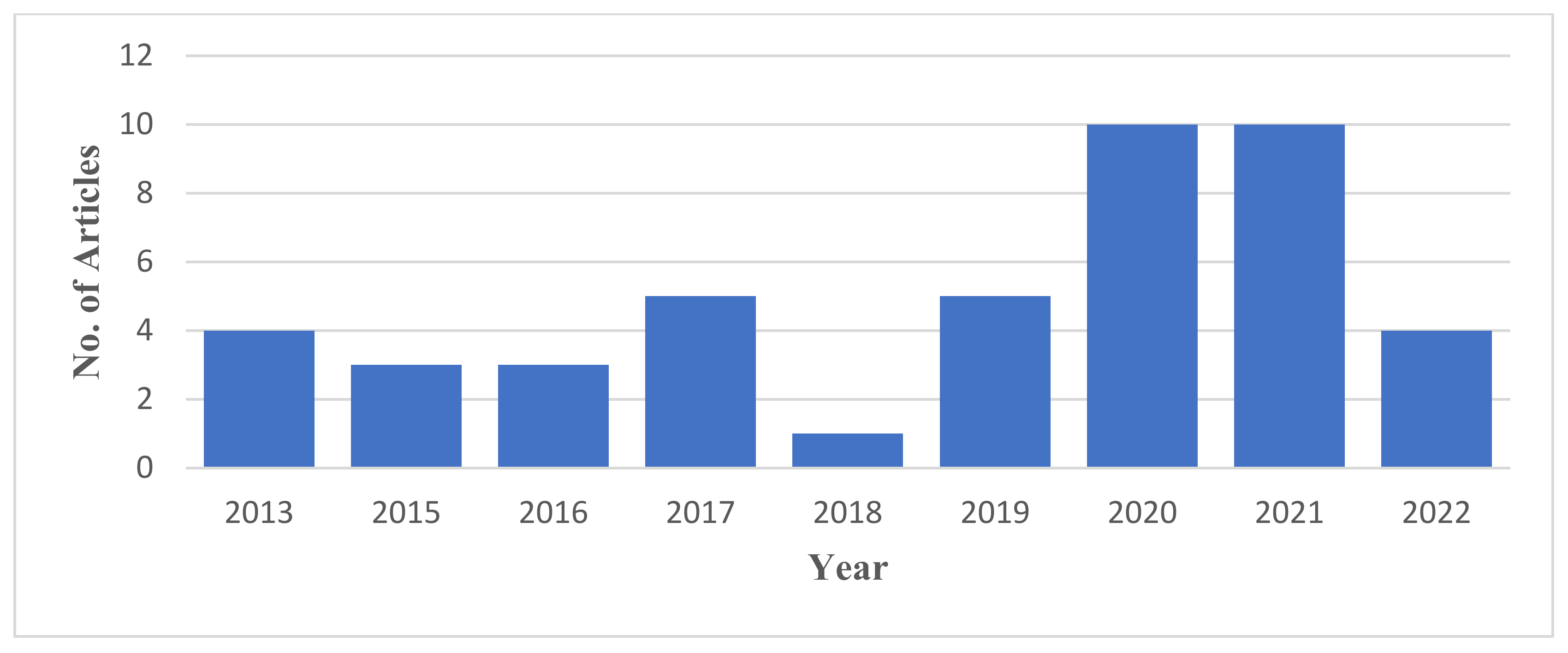

3.4. Statistical Analysis

4. Discussion

4.1. Technological Innovations in the Dairy Supply Chain

4.1.1. Supportive Technologies in the Dairy Supply Chain

- Automatic calf feeders are designed to supply nutrients to calves in exact doses throughout the day, resulting in a healthier and more productive life for the calves. It can control the maturation of the calves. It gives dairy cows the freedom to eat whenever they like [50,53]. Calves’ development and health may be tracked in real-time, which benefits farmers.

- Milk yield recording systems provide information about individual animals. You can see how much milk is produced each time a cow is milked and the daily trends in milk production. Farmers may use this early detection information to discover changes in the animals’ health and food consumption routines [43]. As a result, it aids caregivers in identifying problems that could otherwise go undetected and implementing solutions.

- Automated milking systems reduce the time and effort required to milk cows. Regarding milking, the cows can make their schedule and explore the refuge without human interference [63]. Computer-aided equipment detects the bovine, cleans the udder, softly collects the milk, and ultimately releases the animal after complete milking.

- Rumination activity collars and sensors aid in the early identification of behavioral and activity abnormalities that indicate the onset of any illness or infection. It is possible to follow certain bovine activities, such as the animal’s readiness to breed or enter labor, using devices such as pedometers [31]. This allows the farmer to give timely help.

- Blockchain Technology shows a dairy farm’s ability to produce milk. The technology is an electronic ledger with unique QR codes on the dairy label. These codes may provide information on the cow feed, possible treatment administration, raising procedure, slaughter event, time and place of milk production, processing processes, added ingredients, product release date, etc. [64]. Consumers may scan the tags with their cell phones to follow the whole milk manufacturing process from start to finish. This method attempts to eliminate the market for fake milk products.

- AI Machine learning employs optical and motion sensors to analyze milk quality, fat and protein levels, and the reproductive health of cows. These devices may accurately transmit a cow’s walking, drinking, eating, laying down, or contemplating. Health concerns like mastitis or lameness may be detected 24 h before they become serious [65]. These sensors can detect sick animals, allowing farmers to treat them quickly and prevent disease transmission.

4.1.2. Supportive Technologies Implemented in Different Phases of the Dairy Supply Chain

Herd Management Software

Farm Management Software

Food Safety Software

Supplier Management Software

| Processes | Techniques | Application | Reference |

|---|---|---|---|

| Livestock Management | Smart Monitoring, Smartphone application, RFID, ANN, Clustering, Deep Learning | Grassland monitoring, animal welfare, livestock production, and decision-making based on accurate data and evidence | [32,42,43,50,51,52,53] |

| Procurement and Transportation | Simulation, IoT Blockchain, ANN, Genetic Algorithm | Quality and safety management, Route planning, Cost optimization | [10,12,33,55] |

| Planning and Production | ML such as Bayesian network clustering, genetic algorithm, Forecasting, ANN, Decision tree, Regression, SVM | Cost and profit Optimization in the production system to reduce setup time and better demand sensing | [20,22,49] |

| Inventory Management | Smart Phone application, genetic algorithm | To predict daily demand and deal with inventory-related problems | [17,19,24,28] |

| Dairy management | Simulation, Data analytics, robust and heuristic optimization | To achieve sustainability goals, to manage the data better | [9,21,26,36] |

| Distribution | Blockchain, robust optimization, regression, clustering | To predict future demand | [18,25,41,59,61] |

| Entire supply chain | Simulation, Cost optimization, Environmental impacts, Transportation optimization | To maintain transparency and visibility | [13,23,29,30,31,60] |

4.2. Strategic Outcomes

4.3. Future Research Directions

- Integrated supply chain optimization;

- Real-time optimization for the routing problem;

- Real-time optimization for waste management in the supply chain;

- Real-time monitoring for information flow in the supply chain;

- Integrated optimization system based on AI and ML for the entire supply chain;

- Development of integrated frameworks for complete supply chain optimization;

- Implementation of optimizations models based on ML algorithms;

- The challenges and benefits of implementing optimization techniques can be explored;

- Factors affecting the adoption of digital techniques for DSC can be an area of research in future;

- Blockchain and IoT sensor-based real-time optimization in DSC.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| No. | Title |

|---|---|

| 1 | Dynamic dairy facility location and supply chain planning under traffic congestion and demand uncertainty: A case study of Tehran |

| 2 | Integrated production scheduling and distribution planning in dairy supply chain by hybrid modelling |

| 3 | RFID and perishable inventory management with shelf-space and freshness dependent demand |

| 4 | Strategies to characterize fungal lipases for applications in medicine and dairy industry |

| 5 | Decision Support System, Based on the Paradigm of the Petri Nets, for the Design and Operation of a Dairy Plant |

| 6 | Multi-bucket optimization for integrated planning and scheduling in the perishable dairy supply chain |

| 7 | Quantitative models for supply chain management within dairy industry: A review and discussion |

| 8 | A food traceability framework for dairy and other low-margin products |

| 9 | Possibilistic programming approach for production and distribution problem in milk supply chain |

| 10 | Recent advances in spray drying relevant to the dairy industry: A comprehensive critical review |

| 11 | Implementation of Artificial Intelligence Policy in the Field of Livestock and Dairy Farm |

| 12 | Integrated production and distribution scheduling with a perishable product |

| 13 | Order Picking Process in Warehouse: Case Study of Dairy Industry in Croatia |

| 14 | Planning and scheduling of the make-and-pack dairy production under lifetime uncertainty |

| 15 | The effect of Sales and Operations Planning (S&OP) on supply chain’s total performance: A case study in an Iranian dairy company |

| 16 | A comprehensive model of demand prediction based on hybrid artificial intelligence and metaheuristic algorithms: A case study in dairy industry |

| 17 | A bi-objective multi-echelon supply chain model with Pareto optimal points evaluation for perishable products under uncertainty |

| 18 | An integrated two-layer network model for designing a resilient, green, closed loop supply chain of perishable products under disruption |

| 19 | Heuristic method for robust optimization model for green closed-loop supply chain network design of perishable goods |

| 20 | Optimal Production Scheduling in the Dairy Industries |

| 21 | Proposing a new model for location—Routing problem of perishable raw material suppliers with using meta-heuristic algorithms |

| 22 | A stochastic approach for integrated production and distribution planning in dairy supply chains |

| 23 | An intelligent Edge-IoT platform for monitoring livestock and crops in a dairy farming scenario |

| 24 | Artificial intelligence applied to a robotic dairy farm to model milk productivity and quality based on cow data and daily environmental parameters |

| 25 | Energy cost assessment of a dairy industry wastewater treatment plant |

| 26 | IoT for Development of Smart Dairy Farming |

| 27 | Machine learning based fog computing assisted data-driven approach for early lameness detection in dairy cattle |

| 28 | Optimization of Sampling for Monitoring Chemicals in the Food Supply Chain Using a Risk-Based Approach: The Case of Aflatoxins and Dioxins in the Dutch Dairy Chain |

| 29 | Robust design and planning for a multi-mode multi-product supply network: A dairy industry case study |

| 30 | The design and planning of an integrated supply chain for perishable products under uncertainties: A case study in milk industry |

| 31 | Towards combining data prediction and internet of things to manage milk production on dairy cows |

| 32 | A comparison of analytical test methods in dairy processing |

| 33 | A robust multi-objective optimization model for inventory and production management with environmental and social consideration: A real case of dairy industry |

| 34 | Biometric physiological responses from dairy cows measured by visible remote sensing are good predictors of milk productivity and quality through artificial intelligence |

| 35 | Future of dairy farming from the Dairy Brain perspective: Data integration, analytics, and applications |

| 36 | Implementation of technical and technological progress in dairy production |

| 37 | IoT-based Dairy Supply Chain—An Ontological Approach |

| 38 | Milk reception in a time-efficient manner: A case from the dairy processing plant |

| 39 | Multi-Product Multi Echelon Measurements of Perishable Supply Chain: Fuzzy Non-Linear Programming Approach |

| 40 | Robustness within the optimal economic poly generation system for a dairy industry |

| 41 | Sustainable closed-loop supply chain for dairy industry with robust and heuristic optimization |

| 42 | Environmental friendly route design for a milk collection problem: The case of an Indian dairy |

| 43 | Optimization of resource flows across the whole supply chain. Application to a case study in the dairy industry |

| 44 | Over 20 years of machine learning applications on dairy farms: A comprehensive mapping study |

| 45 | The role of livestock feed fertilization as an improvement of sustainability in the dairy sector |

References

- Akanksha, E.; Debnath, A.; Dey, B. Extensive Review of Cloud Based Internet of Things Architecture and Current Trends. In Proceedings of the 6th International Conference on Inventive Computation Technologies (ICICT), Coimbatore, India, 20–22 January 2021. [Google Scholar] [CrossRef]

- Davis, C.G.; Hahn, W. Assessing the Status of the Global Dairy Trade. Int. Food Agribus. Manag. Rev. 2016, 19. Available online: https://www.ifama.org/resources/Documents/v19ib/0_EdIntro.pdf (accessed on 16 May 2022).

- Houhou, R.; Bocklitz, T. Trends in artificial intelligence, machine learning, and chemometrics applied to chemical data. Anal. Sci. Adv. 2021, 2, 128–141. [Google Scholar] [CrossRef]

- Dwivedi, S. Economic Survey Says per Capita Milk Availability Increased to 427 Grams/Day. Krishi Jagran, 1 February 2022. Available online: https://krishijagran.com/agriculture-world/economic-survey-says-per-capita-milk-availability-increased-to-427-gramsday/ (accessed on 17 May 2022).

- Angad Singh Punia, Dairy. Invest India. Available online: https://www.investindia.gov.in/sector/food-processing/dairy (accessed on 17 May 2022).

- Mor, R.S.; Bhardwaj, A.; Singh, S.; Khan, S.A.R. Modelling the distribution performance in dairy industry: A predictive analysis. Logforum 2021, 17, 425–440. [Google Scholar] [CrossRef]

- Indian Brand Equity Foundation. Indian Food Processing. Ministry of Food Processing Industries (MoFPI). December 2020. Available online: https://www.ibef.org/industry/indian-food-industry.aspx (accessed on 17 May 2022).

- Ramírez-Faz, J.; Fernández-Ahumada, L.M.; Fernández-Ahumada, E.; López-Luque, R. Monitoring of temperature in retail refrigerated cabinets applying iot over open-source hardware and software. Sensors 2020, 20, 846. [Google Scholar] [CrossRef]

- Georgiadis, G.P.; Kopanos, G.M.; Karkaris, A.; Ksafopoulos, H.; Georgiadis, M.C. Optimal Production Scheduling in the Dairy Industries. Ind. Eng. Chem. Res. 2019, 58, 6537–6550. [Google Scholar] [CrossRef]

- Khademi, H. A comprehensive model of demand prediction based on hybrid artificial intelligence and metaheuristic algorithms: A case study in dairy industry. J. Ind. Syst. Eng. 2018, 11, 190–203. Available online: http://www.jise.ir/article_76524.html (accessed on 16 May 2022).

- Jukan, A.; Carpio, F.; Masip, X.; Ferrer, A.J.; Kemper, N.; Stetina, B.U. Fog-to-Cloud Computing for Farming: Low-Cost Technologies, Data Exchange, and Animal Welfare. Computer 2019, 52, 41–51. [Google Scholar] [CrossRef]

- Fuentes, S.; Viejo, C.G.; Cullen, B.; Tongson, E.; Chauhan, S.S.; Dunshea, F.R. Artificial intelligence applied to a robotic dairy farm to model milk productivity and quality based on cow data and daily environmental parameters. Sensors 2020, 20, 2975. [Google Scholar] [CrossRef]

- Shine, P.; Murphy, M.D. Over 20 years of machine learning applications on dairy farms: A comprehensive mapping study. Sensors 2022, 22, 52. [Google Scholar] [CrossRef]

- Jouzdani, J.; Govindan, K. On the sustainable perishable food supply chain network design: A dairy products case to achieve sustainable development goals. J. Clean. Prod. 2021, 278, 123060. [Google Scholar] [CrossRef]

- Jachimczyk, B.; Tkaczyk, R.; Piotrowski, T.; Johansson, S.; Kulesza, W.J. IoT-based dairy supply chain—An ontological approach. Elektron. Elektrotechn. 2021, 27, 71–83. [Google Scholar] [CrossRef]

- Correia, V.H.L.; de Abreu, R.P.; Carvalho, M. Robustness within the optimal economic polygeneration system for a dairy industry. J. Clean. Prod. 2021, 314, 127976. [Google Scholar] [CrossRef]

- Jouzdani, J.; Sadjadi, S.J.; Fathian, M. Dynamic dairy facility location and supply chain planning under traffic congestion and demand uncertainty: A case study of Tehran. Appl. Math. Model. 2013, 37, 8467–8483. [Google Scholar] [CrossRef]

- Bilgen, B.; Çelebi, Y. Integrated production scheduling and distribution planning in dairy supply chain by hybrid modelling. Ann. Oper. Res. 2013, 211, 55–82. [Google Scholar] [CrossRef]

- Piramuthu, S.; Zhou, W. RFID and perishable inventory management with shelf-space and freshness dependent demand. Int. J. Prod. Econ. 2013, 144, 635–640. [Google Scholar] [CrossRef]

- Gopinath, S.C.B.; Anbu, P.; Lakshmipriya, T.; Hilda, A. Strategies to characterize fungal lipases for applications in medicine and dairy industry. Biomed. Res. Int. 2013, 2013, 154549. [Google Scholar] [CrossRef]

- Latorre-Biel, J.I.; Jiménez-Macías, E.; Blanco-Fernández, J.; Martínez-Cámara, E.; Sáenz-Díez, J.C.; Pérez-Parte, M. Decision Support System, Based on the Paradigm of the Petri Nets, for the Design and Operation of a Dairy Plant. Int. J. Food Eng. 2015, 11, 767–776. [Google Scholar] [CrossRef]

- Sel, C.; Bilgen, B.; Bloemhof-Ruwaard, J.M.; van der Vorst, J.G.A.J. Multi-bucket optimization for integrated planning and scheduling in the perishable dairy supply chain. Comput. Chem. Eng. 2015, 77, 59–73. [Google Scholar] [CrossRef]

- Touil, A.; Echchtabii, A.; Charkaoui, A. Possibilistic programming approach for production and distribution problem in milk supply chain. In Proceedings of the 2016 3rd International Conference on Logistics Operations Management (GOL), Fez, Morocco, 23–25 May 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Habazin, J.; Glasnović, A.; Bajor, I. Order picking process in warehouse: Case study of dairy industry in Croatia. Promet-Traffic Transp. 2017, 29, 57–65. [Google Scholar] [CrossRef]

- Devapriya, P.; Ferrell, W.; Geismar, N. Integrated production and distribution scheduling with a perishable product. Eur. J. Oper. Res. 2017, 259, 906–916. [Google Scholar] [CrossRef]

- Yavari, M.; Geraeli, M. Heuristic method for robust optimization model for green closed-loop supply chain network design of perishable goods. J. Clean. Prod. 2019, 226, 282–305. [Google Scholar] [CrossRef]

- Yaghoubi, A.; Akrami, F. Proposing a new model for location—Routing problem of perishable raw material suppliers with using meta-heuristic algorithms. Heliyon 2019, 5, e03020. [Google Scholar] [CrossRef]

- Dutta, P.; Shrivastava, H. The design and planning of an integrated supply chain for perishable products under uncertainties: A case study in milk industry. J. Model. Manag. 2020, 15, 1301–1337. [Google Scholar] [CrossRef]

- Sel, Ç.; Bilgen, B. Quantitative models for supply chain management within dairy industry: A review and discussion. Eur. J. Ind. Eng. 2015, 9, 561–594. [Google Scholar] [CrossRef]

- Li, H.; Zhang, B.; Zhang, L.; Xue, Y.; He, M.; Ren, C. A food traceability framework for dairy and other low-margin products. IBM J. Res. Dev. 2016, 60, 10:1–10:8. [Google Scholar] [CrossRef]

- Schuck, P.; Jeantet, R.; Bhandari, B.; Chen, X.D.; Perrone, T.; de Carvalho, A.F.; Fenelon, M.; Kelly, P. Recent advances in spray drying relevant to the dairy industry: A comprehensive critical review. Dry. Technol. 2016, 34, 1773–1790. [Google Scholar] [CrossRef]

- Chimakurthi, V.N.S.S. Implementation of Artificial Intelligence Policy in the Field of Livestock and Dairy Farm. Am. J. Trade Policy 2019, 6, 113–118. Available online: https://ideas.repec.org/a/ris/ajotap/0051.html (accessed on 16 May 2022). [CrossRef]

- Sel, Ç.; Bilgen, B.; Bloemhof-Ruwaard, J. Planning and scheduling of the make-and-pack dairy production under lifetime uncertainty. Appl. Math. Model. 2017, 51, 129–144. [Google Scholar] [CrossRef]

- Nemati, Y.; Madhoshi, M.; Ghadikolaei, A.S. The effect of Sales and Operations Planning (S&OP) on supply chain’s total performance: A case study in an Iranian dairy company. Comput. Chem. Eng. 2017, 104, 323–338. [Google Scholar] [CrossRef]

- Gitinavard, H.; Shirazi, M.A.; Ghodsypour, S. A bi-objective multi-echelon supply chain model with Pareto optimal points evaluation for perishable products under uncertainty. Sci. Iran. 2019, 26, 2952–2970. [Google Scholar] [CrossRef]

- Yavari, M.; Zaker, H. An integrated two-layer network model for designing a resilient green-closed loop supply chain of perishable products under disruption. J. Clean. Prod. 2019, 230, 198–218. [Google Scholar] [CrossRef]

- Guarnaschelli, A.; Salomone, H.E.; Méndez, C.A. A stochastic approach for integrated production and distribution planning in dairy supply chains. Comput. Chem. Eng. 2020, 140, 106966. [Google Scholar] [CrossRef]

- Alonso, R.S.; Sittón-Candanedo, I.; García, Ó.; Prieto, J.; Rodríguez-González, S. An intelligent Edge-IoT platform for monitoring livestock and crops in a dairy farming scenario. Ad Hoc Netw. 2020, 98, 102047. [Google Scholar] [CrossRef]

- Mor, R.S.; Bhardwaj, A.; Singh, S. A structured-literature-review of the supply chain practices in dairy industry. J. Oper. Supply Chain. Manag. 2018, 11, 14–25. [Google Scholar] [CrossRef]

- Yapicioğlu, P. Energy Cost Estimation for a Dairy Wastewater Treatment Plant in Terms of Organic Load. Acad. Perspect. Procedia 2019, 2, 859–864. [Google Scholar] [CrossRef][Green Version]

- Jouzdani, J.; Fathian, M.; Makui, A.; Heydari, M. Robust design and planning for a multi-mode multi-product supply network: A dairy industry case study. Oper. Res. 2020, 20, 1811–1840. [Google Scholar] [CrossRef]

- Akbar, M.O.; Khan, M.S.S.; Ali, M.J.; Hussain, A.; Qaiser, G.; Pasha, M.; Pasha, U.; Missen, M.S.; Akhtar, N. IoT for Development of Smart Dairy Farming. J. Food Qual. 2020, 2020, 4242805. [Google Scholar] [CrossRef]

- Taneja, M.; Byabazaire, J.; Jalodia, N.; Davy, A.; Olariu, C.; Malone, P. Machine learning based fog computing assisted data-driven approach for early lameness detection in dairy cattle. Comput. Electron. Agric. 2020, 171, 105286. [Google Scholar] [CrossRef]

- Feil, A.A.; Schreiber, D.; Haetinger, C.; Haberkamp, M.; Kist, J.I.; Rempel, C.; Maehler, A.E.; Gomes, M.C.; Da Silva, G.R. Sustainability in the dairy industry: A systematic literature review. Environ. Sci. Pollut. Res. 2020, 27, 33527–33542. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015 statement. Syst. Rev. 2015, 4, 1. [Google Scholar] [CrossRef]

- Durach, C.F.; Kembro, J.; Wieland, A. A New Paradigm for Systematic Literature Reviews in Supply Chain Management. J. Supply Chain. Manag. 2017, 53, 67–85. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Sharma, S.; Gahlawat, V.K.; Rahul, K.; Mor, R.S.; Malik, M. Sustainable Innovations in the Food Industry through Artificial Intelligence and Big Data Analytics. Logistics 2021, 5, 66. [Google Scholar] [CrossRef]

- Wang, Z.; van der Fels-Klerx, H.J.; Lansink, A.G.J.M.O. Optimization of Sampling for Monitoring Chemicals in the Food Supply Chain Using a Risk-Based Approach: The Case of Aflatoxins and Dioxins in the Dutch Dairy Chain. Risk Anal. 2020, 40, 2539–2560. [Google Scholar] [CrossRef]

- Righi, R.d.; Goldschmidt, G.; Kunst, R.; Deon, C.; da Costa, C.A. Towards combining data prediction and internet of things to manage milk production on dairy cows. Comput. Electron. Agric. 2020, 169, 105156. [Google Scholar] [CrossRef]

- Burke, N.; Zacharski, K.; Adley, C.C.; Southern, M. A comparison of analytical test methods in dairy processing. Food Control 2021, 121, 107637. [Google Scholar] [CrossRef]

- Shafiee, F.; Kazemi, A.; Jafarnejad Chaghooshi, A.; Sazvar, Z.; Amoozad Mahdiraji, H. A robust multi-objective optimization model for inventory and production management with environmental and social consideration: A real case of dairy industry. J. Clean. Prod. 2021, 294, 126230. [Google Scholar] [CrossRef]

- Fuentes, S.; Viejo, C.G.; Tongson, E.; Lipovetzky, N.; Dunshea, F.R. Biometric physiological responses from dairy cows measured by visible remote sensing are good predictors of milk productivity and quality through artificial intelligence. Sensors 2021, 21, 6844. [Google Scholar] [CrossRef]

- Cabrera, V.E.; Fadul-Pacheco, L. Future of dairy farming from the Dairy Brain perspective: Data integration, analytics, and applications. Int. Dairy J. 2021, 121, 105069. [Google Scholar] [CrossRef]

- Gaworski, M. Implementation of technical and technological progress in dairy production. Processes 2021, 9, 2103. [Google Scholar] [CrossRef]

- Zacharski, K.A.; Burke, N.; Adley, C.C.; Hogan, P.; Ryan, A.; Southern, M. Milk reception in a time-efficient manner: A case from the dairy processing plant. Food Control 2021, 124, 107939. [Google Scholar] [CrossRef]

- Ali, S.S.; Barman, H.; Kaur, R.; Tomaskova, H.; Roy, S.K. Multi-product multi echelon measurements of perishable supply chain: Fuzzy non-linear programming approach. Mathematics 2021, 9, 2093. [Google Scholar] [CrossRef]

- Gholizadeh, H.; Jahani, H.; Abareshi, A.; Goh, M. Sustainable closed-loop supply chain for dairy industry with robust and heuristic optimization. Comput. Ind. Eng. 2021, 157, 107324. [Google Scholar] [CrossRef]

- Jabir, E.; Panicker, V.; Sridharan, R. Environmental friendly route design for a milk collection problem: The case of an Indian dairy. Int. J. Prod. Res. 2022, 60, 912–941. [Google Scholar] [CrossRef]

- Cóccola, M.E.; Basán, N.; Méndez, C.A.; Dondo, R.G. Optimization of resource flows across the whole supply chain. Application to a case study in the dairy industry. Comput. Chem. Eng. 2022, 158, 107632. [Google Scholar] [CrossRef]

- Quintero-Herrera, S.; Zwolinski, P.; Evrard, D.; Cano-Gómez, J.J.; Botello-Álvarez, J.E.; Rivas-García, P. The role of livestock feed fertilization as an improvement of sustainability in the dairy sector. Sustain. Prod. Consum. 2022, 31, 448–458. [Google Scholar] [CrossRef]

- Brar, G.S.; Saini, G. Milk Run Logistics: Literature Review and Directions Gurinder; Newswood Ltd.: Hong Kong, China, 2011; Volume 1, Available online: http://www.iaeng.org/publication/WCE2011/WCE2011_pp797-801.pdf (accessed on 16 May 2022).

- Tang, Y.; Dananjayan, S.; Hou, C.; Guo, Q.; Luo, S.; He, Y. A survey on the 5G network and its impact on agriculture: Challenges and opportunities. Comput. Electron. Agric. 2021, 180, 105895. [Google Scholar] [CrossRef]

- Poongodi, T.; Rathee, A.; Indrakumari, R.; Suresh, P. IoT Sensing Capabilities: Sensor Deployment and Node Discovery, Wearable Sensors, Wireless Body Area Network (WBAN), Data Acquisition. In Principles of Internet of Things (IoT) Ecosystem: Insight Paradigm; Peng, S.-L., Pal, S., Huang, L., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 127–151. [Google Scholar] [CrossRef]

- Witten, I.H.; Holmes, G.; McQueen, R.J.; Smith, L.A.; Cunningham, S.J. Practical Machine Learning and Its Application to Problems in Agriculture; Department of Computer Science, University of Waikato: Hamilton, New Zealand, 1993; Available online: https://hdl.handle.net/10289/9915 (accessed on 16 May 2022).

- Amiri, S.; Aghamirzaei, M.; Mostashari, P.; Sarbazi, M.; Tizchang, S.; Madahi, H. The impact of biotechnology on dairy industry. In Microbial Biotechnology in Food and Health; Elsevier: Amsterdam, The Netherlands, 2021; pp. 53–79. [Google Scholar] [CrossRef]

- Yildirim-Elikoglu, S.; Erdem, Y.K. Interactions between milk proteins and polyphenols: Binding mechanisms, related changes, and the future trends in the dairy industry. Food Rev. Int. 2018, 34, 665–697. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mishra, P.; Ruiz-García, L. Food traceability: New trends and recent advances. A review. Food Control 2015, 57, 393–401. [Google Scholar] [CrossRef]

- Malihi, E.; Aghdasi, M. A decision framework for optimisation of business processes aligned with business goals. Int. J. Bus. Inf. Syst. 2013, 15, 22–42. [Google Scholar] [CrossRef]

- Lu, S.; Xu, C.; Zhong, R.Y.; Wang, L. A RFID-enabled positioning system in automated guided vehicle for smart factories. J. Manuf. Syst. 2017, 44, 179–190. [Google Scholar] [CrossRef]

- Bibi, F.; Guillaume, C.; Gontard, N.; Sorli, B. A review: RFID technology having sensing aptitudes for food industry and their contribution to tracking and monitoring of food products. Trends Food Sci. Technol. 2017, 62, 91–103. [Google Scholar] [CrossRef]

- Astill, J.; Dara, R.A.; Campbell, M.; Farber, J.M.; Fraser, E.D.; Sharif, S.; Yada, R.Y. Transparency in food supply chains: A review of enabling technology solutions. Trends Food Sci. Technol. 2019, 91, 240–247. [Google Scholar] [CrossRef]

- Provenance. Blockchain: The Solution for Transparency in Product Supply Chains. 21 November 2015. Available online: https://www.provenance.org/whitepaper (accessed on 8 January 2022).

- Praveen, U.; Farnaz, G.; Hatim, G. Inventory management and cost reduction of supply chain processes using AI based time-series forecasting and ANN modeling. Procedia Manuf. 2019, 38, 256–263. [Google Scholar] [CrossRef]

- Butler, M.; Herlihy, P.; Keenan, P.B. Integrating information technology and operational research in the management of milk collection. J. Food Eng. 2005, 70, 341–349. [Google Scholar] [CrossRef]

- Anjomshoae, A.; Banomyong, R.; Mohammed, F.; Kunz, N. A systematic review of humanitarian supply chains performance measurement literature from 2007 to 2021. Int. J. Disaster Risk Reduct. 2022, 72, 102852. [Google Scholar] [CrossRef]

| Inclusion Criteria | Exclusion Criteria |

|---|---|

| Articles published from 2013–2022 | Articles published before 2013 and after 2022 |

| Published in the English language | Published in a non-English language |

| Articles focused on Optimization Techniques based on Artificial Intelligence, Machine Learning, and Dairy supply chain | Articles that are not relevant to review questions |

| Articles related to food science | Articles related to non-food domains |

| Full-text articles only | Articles that are not available in full-text form |

| Peer-reviewed research and review articles | Conference proceedings, thesis, poster abstracts, and short communications are excluded |

| Reference | Area | Technique Used | ||||

|---|---|---|---|---|---|---|

| Production | Processing | Inventory | Distribution | Mathematical Modelling | AI/ML/IoT | |

| [9] | ✓ | ✓ | ||||

| [10] | ✓ | ✓ | ✓ | |||

| [12] | ✓ | ✓ | ||||

| [13] | ✓ | ✓ | ||||

| [15] | ✓ | ✓ | ✓ | ✓ | ✓ | |

| [16] | ✓ | ✓ | ||||

| [17] | ✓ | ✓ | ✓ | |||

| [18] | ✓ | ✓ | ✓ | ✓ | ||

| [19] | ✓ | ✓ | ||||

| [20] | ✓ | ✓ | ||||

| [21] | ✓ | ✓ | ✓ | ✓ | ✓ | |

| [22] | ✓ | ✓ | ✓ | |||

| [23] | ✓ | ✓ | ✓ | ✓ | ✓ | |

| [24] | ✓ | ✓ | ||||

| [25] | ✓ | |||||

| [26] | ✓ | ✓ | ✓ | ✓ | ||

| [27] | ✓ | ✓ | ||||

| [28] | ✓ | ✓ | ||||

| [29] | ✓ | ✓ | ||||

| [30] | ✓ | ✓ | ✓ | ✓ | ✓ | |

| [31] | ✓ | |||||

| [32] | ✓ | ✓ | ||||

| [33] | ✓ | ✓ | ✓ | |||

| [34] | ✓ | ✓ | ||||

| [35] | ✓ | ✓ | ||||

| [36] | ✓ | ✓ | ✓ | |||

| [37] | ✓ | ✓ | ✓ | |||

| [38] | ✓ | ✓ | ||||

| [40] | ✓ | ✓ | ||||

| [41] | ✓ | ✓ | ||||

| [42] | ✓ | ✓ | ||||

| [43] | ✓ | ✓ | ||||

| [49] | ✓ | ✓ | ✓ | |||

| [50] | ✓ | ✓ | ||||

| [51] | ||||||

| [52] | ✓ | ✓ | ✓ | ✓ | ||

| [53] | ✓ | ✓ | ||||

| [54] | ✓ | ✓ | ||||

| [55] | ✓ | |||||

| [56] | ✓ | |||||

| [57] | ✓ | ✓ | ✓ | ✓ | ✓ | |

| [58] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| [59] | ✓ | ✓ | ||||

| [60] | ✓ | ✓ | ✓ | ✓ | ✓ | |

| [61] | ✓ | ✓ | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malik, M.; Gahlawat, V.K.; Mor, R.S.; Dahiya, V.; Yadav, M. Application of Optimization Techniques in the Dairy Supply Chain: A Systematic Review. Logistics 2022, 6, 74. https://doi.org/10.3390/logistics6040074

Malik M, Gahlawat VK, Mor RS, Dahiya V, Yadav M. Application of Optimization Techniques in the Dairy Supply Chain: A Systematic Review. Logistics. 2022; 6(4):74. https://doi.org/10.3390/logistics6040074

Chicago/Turabian StyleMalik, Mohit, Vijay Kumar Gahlawat, Rahul S Mor, Vijay Dahiya, and Mukheshwar Yadav. 2022. "Application of Optimization Techniques in the Dairy Supply Chain: A Systematic Review" Logistics 6, no. 4: 74. https://doi.org/10.3390/logistics6040074

APA StyleMalik, M., Gahlawat, V. K., Mor, R. S., Dahiya, V., & Yadav, M. (2022). Application of Optimization Techniques in the Dairy Supply Chain: A Systematic Review. Logistics, 6(4), 74. https://doi.org/10.3390/logistics6040074