Impact of Additive Manufacturing on the Supply Chain of Aerospace Spare Parts Industry—A Review

Abstract

1. Introduction

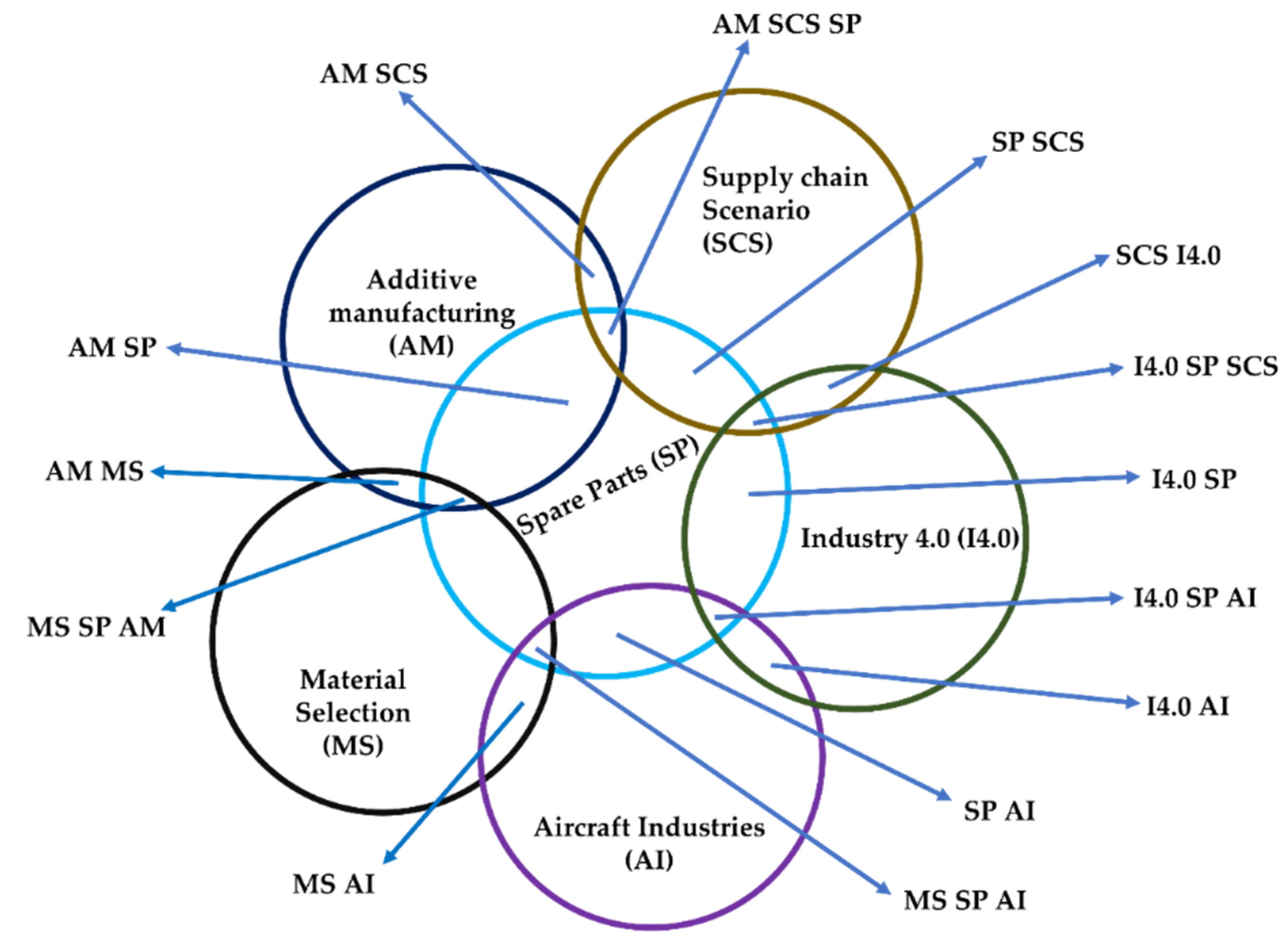

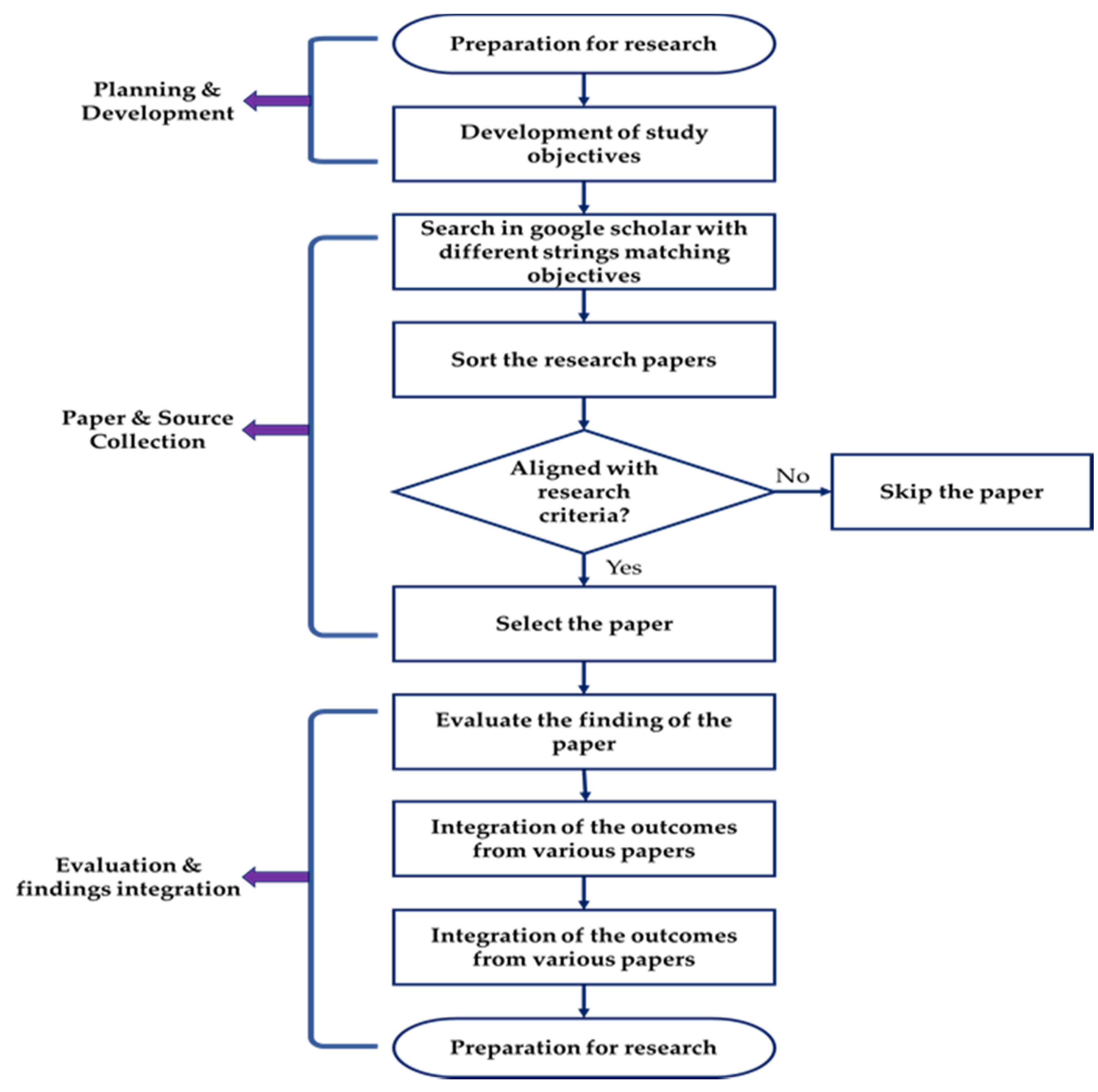

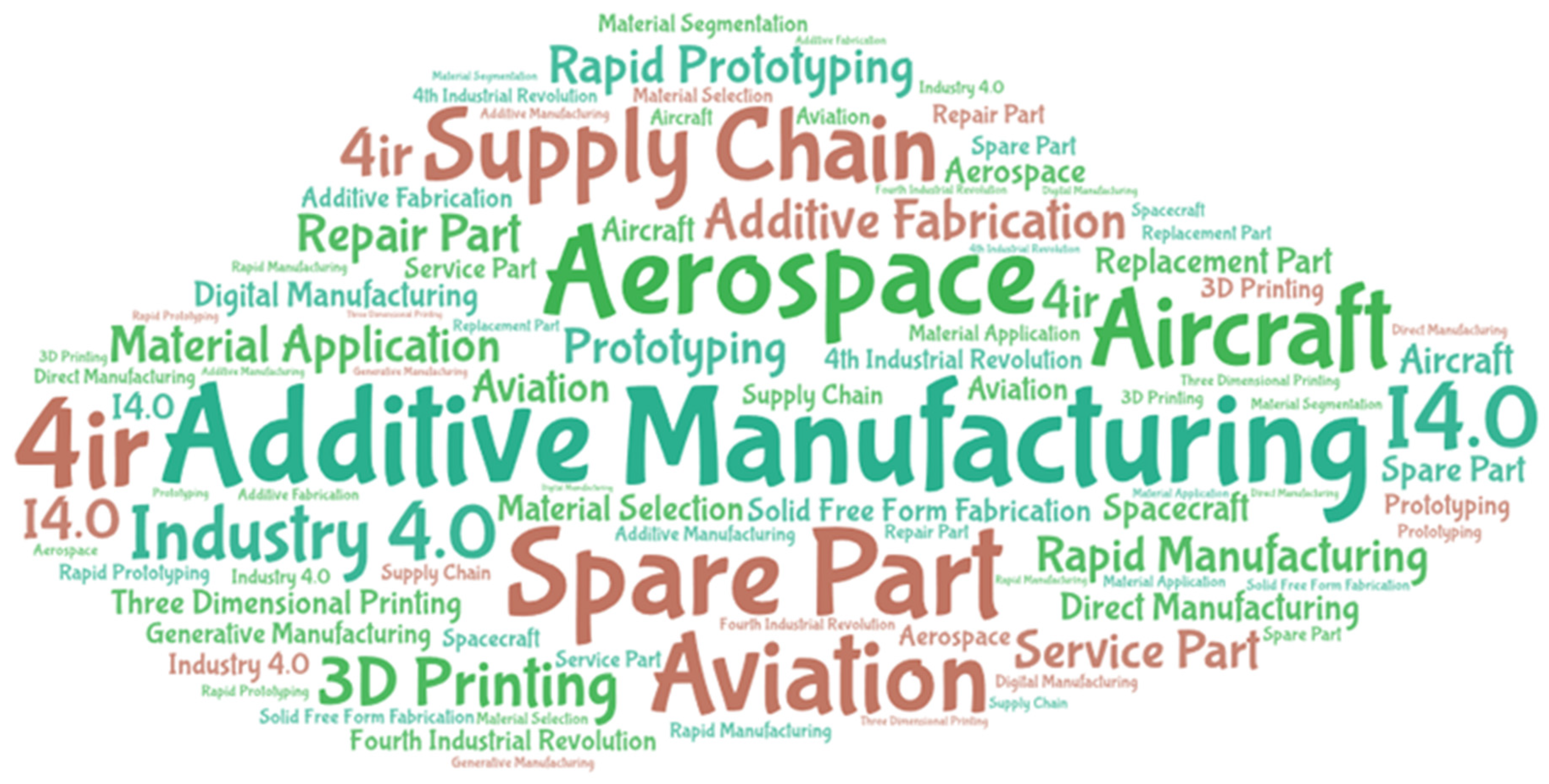

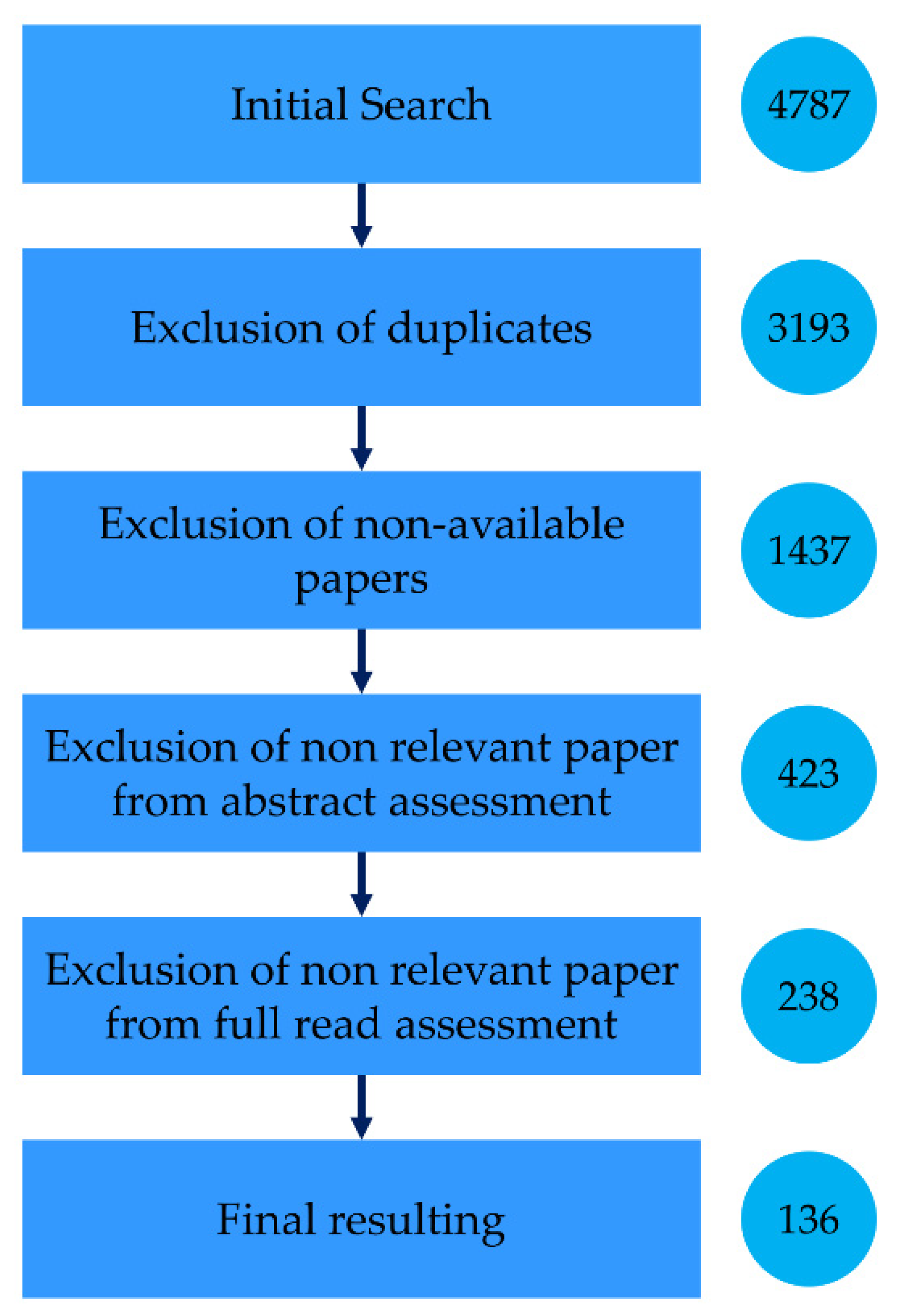

2. Systematic Literature Review (SLR)

3. Additive Manufacturing of Spare Parts

3.1. Current Trends Additive Manufacturing in Aerospace Industry with Example

3.2. Future Perspective

4. Spare Parts with Additive Manufacturing for Aviation Industry

4.1. Quality Assurance and Standardization

4.2. Part Consolidation

4.3. Materials Selection for Spare Parts in Additive Manufacturing

4.4. Material Criteria

5. Supply Chain Scenario

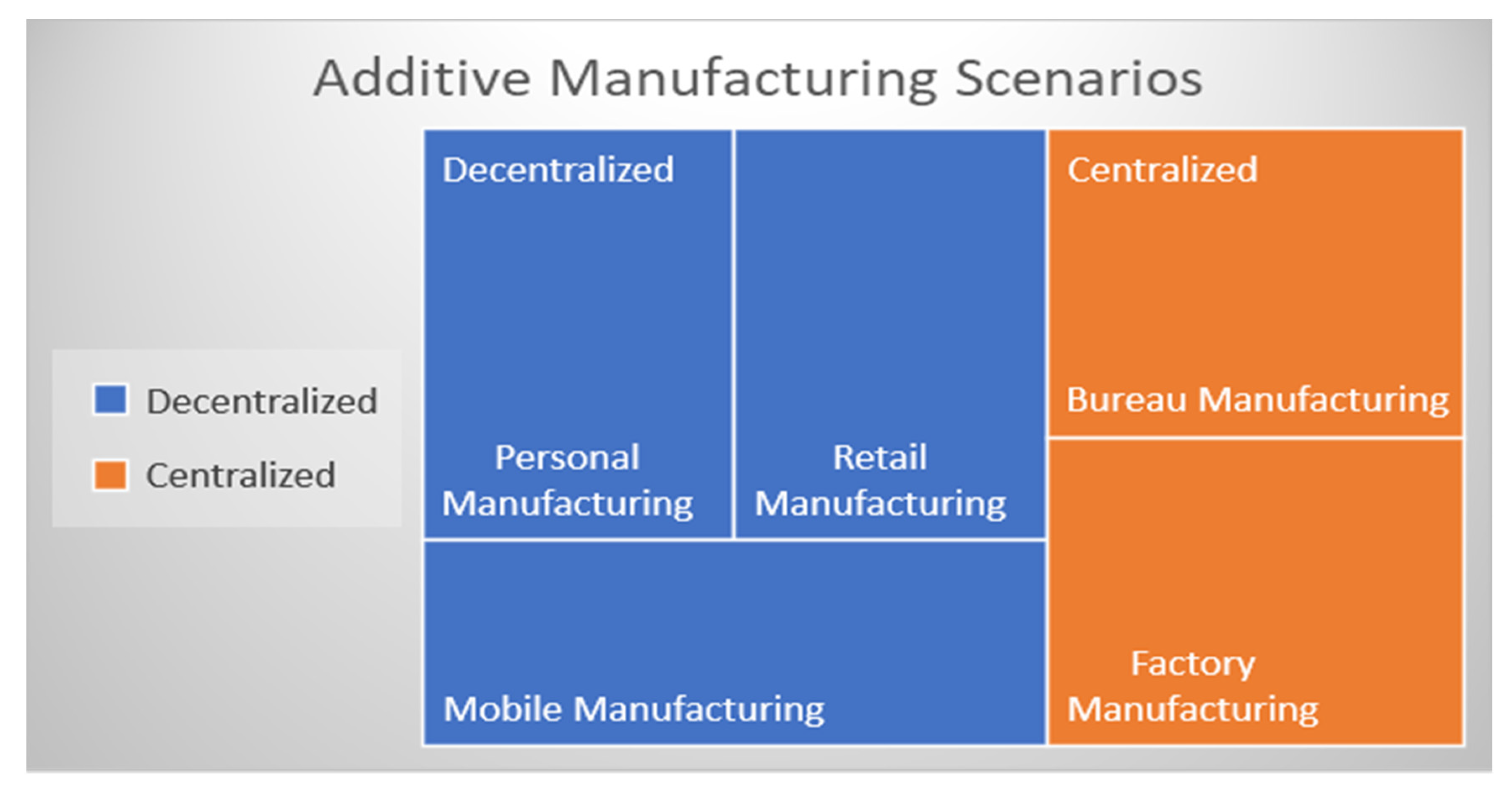

5.1. Spare Parts Manufacturing Scenario

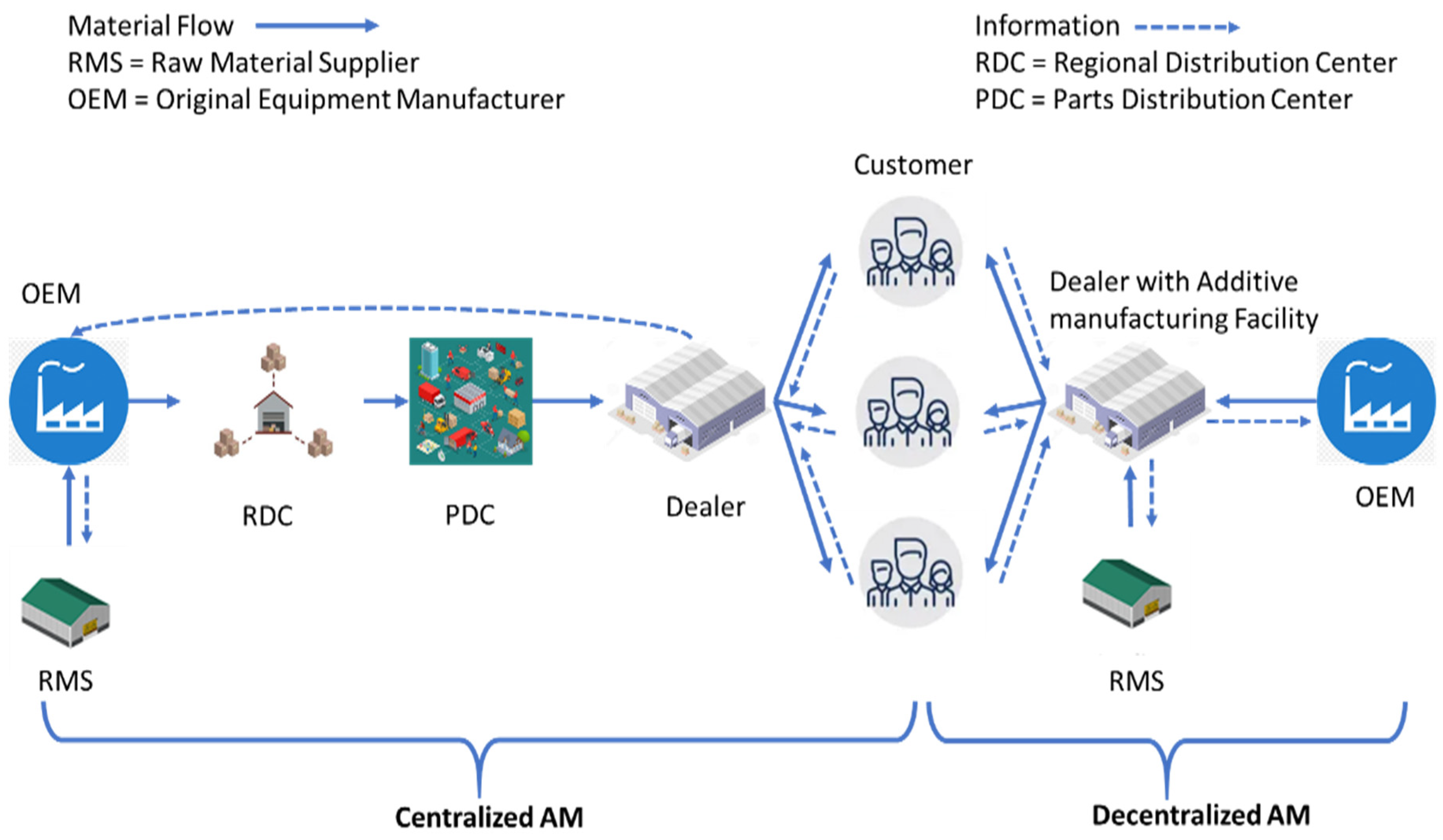

5.2. Centralized vs. Decentralized Supply Chain

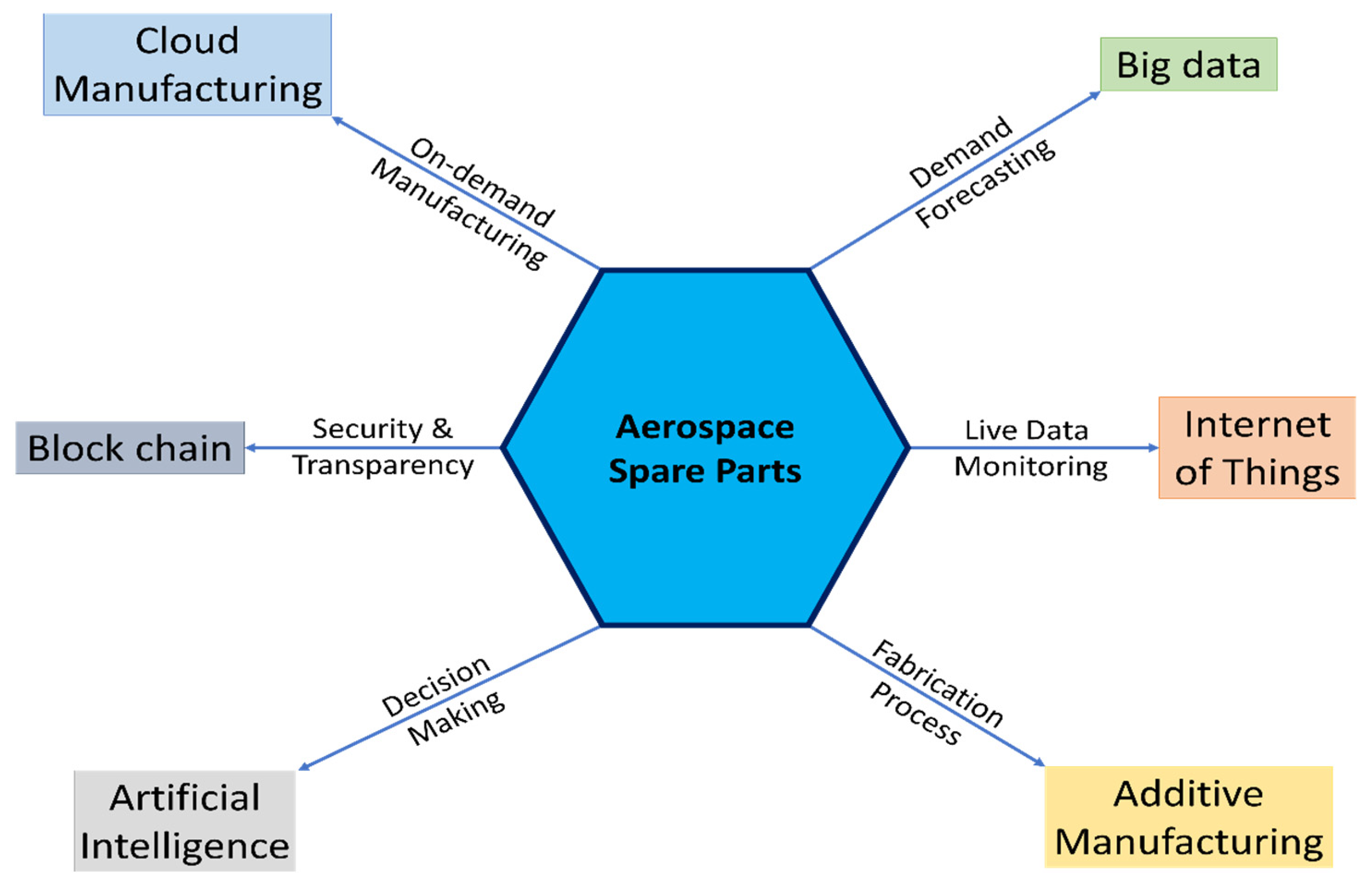

6. Industry 4.0 Context in AM of Spare Parts

7. Managerial and Policy Implications

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wohlers, T.T. Wohlers, T.T. Wohlers Report 2019: 3D Printing and Additive Manufacturing State of the Industry. In Wohlers Associates; ASTM International: Washington, DC, USA; Fort Collins, CO, USA, 2019; p. 369. [Google Scholar]

- Reeves, P.; Tuck, C.; Hague, R. Additive Manufacturing for Mass Customization. In Mass Customization; Springer: Berlin/Heidelberg, Germany, 2011; pp. 275–289. [Google Scholar] [CrossRef]

- Horn, T.J.; Harrysson, O.L.A. Overview of Current Additive Manufacturing Technologies and Selected Applications. Sci. Prog. 2012, 95, 255–282. [Google Scholar] [CrossRef] [PubMed]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace Applications of Laser Additive Manufacturing. Laser Addit. Manuf. Mater. Des. Technol. Appl. 2017, 1, 351–371. [Google Scholar] [CrossRef]

- Zhu, L.; Li, N.; Childs, P.R.N. Light-Weighting in Aerospace Component and System Design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1–27. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Xiao, B. A Market Assessment of Additive Manufacturing Potential for the Aerospace Industry. J. Manuf. Process 2021, 68, 728–738. [Google Scholar] [CrossRef]

- Beyer, C. Strategic Implications of Current Trends in Additive Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2014, 136, 064701. [Google Scholar] [CrossRef]

- Simao, H.; Powell, W. Approximate Dynamic Programming for Management of High/Value Spare Parts. J. Manuf. Technol. Manag. 2009, 20, 147–160. [Google Scholar] [CrossRef]

- Regattieri, A.; Gamberi, M.; Gamberini, R.; Manzini, R. Managing Lumpy Demand for Aircraft Spare Parts. J. Air Transp. Manag. 2005, 11, 426–431. [Google Scholar] [CrossRef]

- Syntetos, A.A.; Babai, M.Z.; Altay, N. On the Demand Distributions of Spare Parts. Int. J. Prod. Res. 2012, 50, 2101–2117. [Google Scholar] [CrossRef]

- Holmström, J.; Partanen, J. Digital Manufacturing-Driven Transformations of Service Supply Chains for Complex Products. Supply Chain Manag. 2014, 19, 421–430. [Google Scholar] [CrossRef]

- Gu, J.; Zhang, G.; Li, K.W. Efficient Aircraft Spare Parts Inventory Management under Demand Uncertainty. J. Air Transp. Manag. 2015, 42, 101–109. [Google Scholar] [CrossRef]

- Gudmundsson, S.V. Thriving on Strategic Alliances: The Competitive Positioning of MTU in the Aircraft Engine Business. SSRN Electron. J. 2014, 7–10. [Google Scholar] [CrossRef]

- Dinis, D.; Barbosa-Póvoa, A.; Teixeira, Â.P. A Supporting Framework for Maintenance Capacity Planning and Scheduling: Development and Application in the Aircraft MRO Industry. Int. J. Prod. Econ. 2019, 218, 1–15. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive Manufacturing in the Spare Parts Supply Chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive Manufacturing and Its Societal Impact: A Literature Review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Chekurov, S.; Salmi, M.; Verboeket, V.; Puttonen, T.; Riipinen, T.; Vaajoki, A. Assessing Industrial Barriers of Additively Manufactured Digital Spare Part Implementation in the Machine-Building Industry: A Cross-Organizational Focus Group Interview Study. J. Manuf. Technol. Manag. 2021, 32, 909–931. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.H.; Rolfe, B.; Gibson, I. Additive Manufacturing a Powerful Tool for the Aerospace Industry. Rapid Prototyp. J. 2022, 28, 87–100. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Cutler, S.; Gao, N. Review: The Impact of Metal Additive Manufacturing on the Aerospace Industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef]

- Khajavi, S.M.; Holmström, J.; Partanen, J. Additive Manufacturing in the Spare Parts Supply Chain: Hub Configuration and Technology Maturity. Rapid Prototyp. J. 2018, 24, 1178–1192. [Google Scholar] [CrossRef]

- de Souza, R.; Tan, A.W.K.; Othman, H.; Garg, M. A Proposed Framework for Managing Service Parts in Automotive and Aerospace Industries. Benchmarking 2011, 18, 769–782. [Google Scholar] [CrossRef]

- Frandsen, C.S.; Nielsen, M.M.; Chaudhuri, A.; Jayaram, J.; Govindan, K. In Search for Classification and Selection of Spare Parts Suitable for Additive Manufacturing: A Literature Review. Int. J. Prod. Res. 2019, 58, 970–996. [Google Scholar] [CrossRef]

- Ceruti, A.; Marzocca, P.; Liverani, A.; Bil, C. Maintenance in Aeronautics in an Industry 4.0 Context: The Role of Augmented Reality and Additive Manufacturing. J. Comput. Des. Eng. 2019, 6, 516–526. [Google Scholar] [CrossRef]

- Kalender, M.; Kilic, S.E.; Ersoy, S.; Bozkurt, Y.; Salman, S. Additive Manufacturing and 3D Printer Technology in Aerospace Industry. In Proceedings of the 2019 9th International Conference on Recent Advances in Space Technologies (RAST), Istanbul, Turkey, 11–14 June 2019; pp. 689–695. [Google Scholar] [CrossRef]

- Li, Y.; Jia, G.; Cheng, Y.; Hu, Y. Additive Manufacturing Technology in Spare Parts Supply Chain: A Comparative Study. Int. J. Prod. Res. 2017, 55, 1498–1515. [Google Scholar] [CrossRef]

- Caesarendra, W.; Pappachan, B.K.; Wijaya, T.; Lee, D.; Tjahjowidodo, T.; Then, D.; Manyar, O.M. An AWS Machine Learning-Based Indirect Monitoring Method for Deburring in Aerospace Industries Towards Industry 4.0. Appl. Sci. 2018, 8, 2165. [Google Scholar] [CrossRef]

- Zijm, H.; Knofius, N.; van der Heijden, M. Additive Manufacturing and Its Impact on the Supply Chain; Springer International Publishing: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Liu, P.; Huang, S.H.; Mokasdar, A.; Zhou, H.; Hou, L. The Impact of Additive Manufacturing in the Aircraft Spare Parts Supply Chain: Supply Chain Operation Reference (Scor) Model Based Analysis. Prod. Plan. Control 2014, 25, 1169–1181. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Kilibarda, M.; Andrejić, M.; Popović, V. Research in Logistics Service Quality: A Systematic Literature Review. Transport 2020, 35, 224–235. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review* Introduction: The Need for an Evidence- Informed Approach. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P. Modelling of Additive Manufacturing Processes: A Review and Classification. Manuf. Rev. 2018, 5, 2. [Google Scholar] [CrossRef]

- Babu, S.S.; Love, L.; Dehoff, R.; Peter, W.; Watkins, T.R.; Pannala, S. Additive Manufacturing of Materials: Opportunities and Challenges. MRS Bull. 2015, 40, 1154–1161. [Google Scholar] [CrossRef]

- Beamon, B.M. Supply Chain Design and Analysis: Models and Methods. Int. J. Prod. Econ. 1998, 55, 281–294. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput. Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Diegel, O.; Singamneni, S.; Reay, S.; Withell, A. Tools for Sustainable Product Design: Additive Manufacturing. J. Sustain. Dev. 2010, 3, 68. [Google Scholar] [CrossRef]

- Sharratt, B.M. Non-Destructive Techniques and Technologies for Qualification of Additive Manufactured Parts and Processes: A Literature Review; Sharratt Research and Consulting Inc.: Victoria, Australia, 2015. [Google Scholar]

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making Sense of 3-D Printing: Creating a Map of Additive Manufacturing Products and Services. Addit. Manuf. 2014, 1–4, 64–76. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Biamino, S.; Lombardi, M.; Atzeni, E.; Salmi, A.; Minetola, P.; Iuliano, L.; Fino, P. Overview on Additive Manufacturing Technologies. Proc. IEEE 2017, 105, 593–612. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. Trans. ASME 2015, 137, 014001. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of Additive Manufacturing for End-Usable Metal Parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Hopkinson, N.; Dickens, P. Analysis of Rapid Manufacturing—Using Layer Manufacturing Processes for Production. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2003, 217, 31–40. [Google Scholar] [CrossRef]

- Upadhyay, M.; Sivarupan, T.; El Mansori, M. 3D Printing for Rapid Sand Casting—A Review. J. Manuf. Process 2017, 29, 211–220. [Google Scholar] [CrossRef]

- Levy, G.N.; Schindel, R.; Kruth, J.P. Rapid Manufacturing and Rapid Tooling with Layer Manufacturing (Lm) Technologies, State of the Art and Future Perspectives. CIRP Ann. 2003, 52, 589–609. [Google Scholar] [CrossRef]

- Berman, B. 3-D Printing: The New Industrial Revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F.H.S. The Additive Manufacturing (AM) of Titanium Alloys. Met. Powder Rep. 2017, 72, 96–106. [Google Scholar] [CrossRef]

- Zuniga, J.M.; Carson, A.M.; Peck, J.M.; Kalina, T.; Srivastava, R.M.; Peck, K. The Development of a Low-Cost Three-Dimensional Printed Shoulder, Arm, and Hand Prostheses for Children. Prosthet. Orthot. Int. 2017, 41, 205–209. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and Applications of 3D Printing for Novel Materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Zhang, Y.; Bose, S. Recent Developments in Metal Additive Manufacturing. Curr. Opin. Chem. Eng. 2020, 28, 96–104. [Google Scholar] [CrossRef]

- Kwon, J.Y.; Kim, N. Performance of Wearables and the Effect of User Behavior in Additive Manufacturing Process. Fash. Text. 2021, 8, 1–38. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- The FAA Cleared the First 3D Printed Part to Fly in a Commercial Jet Engine from GE|GE News. Available online: https://www.ge.com/news/reports/the-faa-cleared-the-first-3d-printed-part-to-fly-2 (accessed on 28 February 2022).

- New Manufacturing Milestone: 30,000 Additive Fuel Nozzles|GE Additive. Available online: https://www.ge.com/additive/stories/new-manufacturing-milestone-30000-additive-fuel-nozzles (accessed on 10 January 2022).

- Bryan, W. Future Rocket Engines May Include Large-Scale 3D Printing. 2020. Available online: https://www.pioneeringminds.com/future-rocket-engines-may-include-large-scale-3d-printing/ (accessed on 10 January 2022).

- NASA Using 3D Laser Printing to Create Complex Rocket Parts. Available online: https://newatlas.com/3d-printing-rockets-nasa-sls/24909/ (accessed on 11 January 2022).

- Boeing: Additive Manufacturing Insight. Available online: https://www.boeing.com/features/innovation-quarterly/2019_q4/btj-additive-manufacturing.page (accessed on 25 February 2022).

- Pioneering Bionic 3D Printing|Airbus. Available online: https://www.airbus.com/en/newsroom/news/2016-03-pioneering-bionic-3d-printing. (accessed on 23 April 2022).

- Press Releases|Rolls-Royce-3-D Printed Parts and New Materials Help Rolls-Royce to Engine Test Success. Available online: https://www.rolls-royce.com/media/press-releases/2018/11-10-2018-3-d-printed-parts-and-new-materials-help-rolls-royce-to-engine-test-success.aspx (accessed on 13 January 2022).

- World’s First Jet-Powered, 3D Printed UAV Tops 150 MPH|Stratasys. Available online: https://www.stratasys.com/explore/blog/2015/aurora-uav-3d-printing (accessed on 17 January 2022).

- Lee, K.-O.; Lim, B.; Kim, D.-J.; Hong, M.; Lee, K. Technology Trends in Additively Manufactured Small Rocket Engines for Launcher Applications. J. Korean Soc. Propuls. Eng. 2020, 24, 73–82. [Google Scholar] [CrossRef]

- Seedhouse, E. Preparing for Crew: Dragon V2. In SpaceX’s Dragon America s Next Generation Spacecra; Springer: Cham, Switzerland, 2016; pp. 127–143. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of Additive Manufacturing Technologies and Applications in the Aerospace Industry. Addit. Manuf. Aerosp. Ind. 2019, 7–31. [Google Scholar] [CrossRef]

- Committee F42 on Additive Manufacturing Technologies. Available online: https://www.astm.org/get-involved/technical-committees/committee-f42 (accessed on 16 January 2022).

- The I/O Buffer Information Specification (IBIS) Open Forum Releases the IBIS Version 7.1 Specification. Available online: https://www.sae.org/news/2018/06/sae-international-issues-first-aerospace-additive-manufacturing-technical-standards (accessed on 16 January 2022).

- Singamneni, S.; LV, Y.; Hewitt, A.; Chalk, R.; Thomas, W.; Jordison, D. Additive Manufacturing for the Aircraft Industry: A Review. J. Aeronaut. Aerosp. Eng. 2019, 8, 1–13. [Google Scholar] [CrossRef]

- Hrabe, N.W.; Barbosa, N.; Daniewicz, S.; Shamsaei, N. Findings from the NIST/ASTM Workshop on Mechanical Behavior of Additive Manufacturing Components; National Institute of Standards and Technology: Boulder, CO, USA, 2016. [Google Scholar] [CrossRef]

- SAE Standards Works. Available online: https://www.sae.org/works/committeeHome.do?comtID=TEAAMSAM (accessed on 16 January 2022).

- FAA. In Joint Federal Aviation Administration–Air Force Workshop on Qualification/Certification of Additively Manufactured Parts; Tech Report, United States, (DOT/FAA/TC-16/15); Department of Transportation. Federal Aviation Administration. William J. Hughes Technical Center: Atlantic City, NJ, USA, 2016; p. 227.

- Shapiro, A.A.; Borgonia, J.P.; Chen, Q.N.; Dillon, R.P.; McEnerney, B.; Polit-Casillas, R.; Soloway, L. Additive Manufacturing for Aerospace Flight Applications. J. Spacecr. Rocket. 2016, 53, 952–959. [Google Scholar] [CrossRef]

- Saadat, M. Challenges in the Assembly of Large Aerospace Components. Integr. Syst. Des. Technol. 2011, 37–46. [Google Scholar] [CrossRef]

- Duda, T.; Raghavan, L.V. 3D Metal Printing Technology. IFAC-PapersOnLine 2016, 49, 103–110. [Google Scholar] [CrossRef]

- 3D Opportunity in Aerospace and Defense: Additive Manufacturing Takes Flight|Deloitte Insights. Available online: https://www2.deloitte.com/us/en/insights/focus/3d-opportunity/additive-manufacturing-3d-opportunity-in-aerospace.html (accessed on 9 January 2022).

- An Epiphany of Disruption: GE Additive Chief Explains How 3D Printing Will Upend Manufacturing|GE News. Available online: https://www.ge.com/news/reports/epiphany-disruption-ge-additive-chief-explains-3d-printing-will-upend-manufacturing (accessed on 9 January 2022).

- Zhu, J.H.; Zhang, W.H.; Xia, L. Topology Optimization in Aircraft and Aerospace Structures Design. Arch. Comput. Methods Eng. 2015, 23, 595–622. [Google Scholar] [CrossRef]

- Ghadge, A.; Karantoni, G.; Chaudhuri, A.; Srinivasan, A. Impact of Additive Manufacturing on Aircraft Supply Chain Performance: A System Dynamics Approach. J. Manuf. Technol. Manag. 2018, 29, 846–865. [Google Scholar] [CrossRef]

- Sasson, A.; Johnson, J.C. The 3D Printing Order: Variability, Supercenters and Supply Chain Reconfigurations. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 82–94. [Google Scholar] [CrossRef]

- Knofius, N.; Van Der Heijden, M.C.; Zijm, W.H.M. Selecting Parts for Additive Manufacturing in Service Logistics. J. Manuf. Technol. Manag. 2016, 27, 915–931. [Google Scholar] [CrossRef]

- Kretzschmar, N.; Chekurov, S.; Salmi, M.; Tuomi, J. Evaluating the Readiness Level of Additively Manufactured Digital Spare Parts: An Industrial Perspective. Appl. Sci. 2018, 8, 1837. [Google Scholar] [CrossRef]

- Lowas, A.F.; Ciarallo, F.W. Reliability and Operations: Keys to Lumpy Aircraft Spare Parts Demands. J. Air Transp. Manag. 2016, 50, 30–40. [Google Scholar] [CrossRef]

- Basten, R.J.I.; van Houtum, G.J. System-Oriented Inventory Models for Spare Parts. Surv. Oper. Res. Manag. Sci. 2014, 19, 34–55. [Google Scholar] [CrossRef]

- Additive Manufacturing Reduces Tooling Cost and Lead Time to Produce Composite Aerospace Parts-Global Print Monitor. Available online: http://globalprintmonitor.de/en/3d/3d-printing-news/aerospace/17617-additive-manufacturing-reduces-tooling-cost-and-lead-time-to-produce-composite-aerospace-parts (accessed on 19 January 2022).

- America Makes Announces Project Call Awardees-America Makes. Available online: https://www.americamakes.us/america-makes-announces-mamls-ph3-project-call-awardees/ (accessed on 18 January 2022).

- Bhattacharya, A.; Sarkar, B.; Mukherjee, S.K. Distance-Based Consensus Method for ABC Analysis. Int. J. Prod. Res. 2007, 45, 3405–3420. [Google Scholar] [CrossRef]

- Shneiderman, B. Human-Centered Artificial Intelligence: Reliable, Safe & Trustworthy. Int. J. Hum.-Comput. Interact. 2020, 36, 495–504. [Google Scholar] [CrossRef]

- Wischmeyer, T.; Rademacher, T. Regulating Artificial Intelligence; Springer: Cham, Switzerland, 2019; pp. 1–388. [Google Scholar] [CrossRef]

- Dirican, C. The Impacts of Robotics, Artificial Intelligence on Business and Economics. Procedia-Soc. Behav. Sci. 2015, 195, 564–573. [Google Scholar] [CrossRef]

- Lindermann, C.; Jahnke, U.; Moi, M.; Koch, R. Analyzing Product Lifecycle Costs for a Better Understanding of Cost Drivers in Additive Manufacturing. 2012. Available online: https://repositories.lib.utexas.edu/handle/2152/88402 (accessed on 10 January 2022). [CrossRef]

- Chekurov, S.; Metsä-Kortelainen, S.; Salmi, M.; Roda, I.; Jussila, A. The Perceived Value of Additively Manufactured Digital Spare Parts in Industry: An Empirical Investigation. Int. J. Prod. Econ. 2018, 205, 87–97. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D Printing with Polymers: Challenges among Expanding Options and Opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Zaman, U.K.U.; Rivette, M.; Siadat, A.; Mousavi, S.M. Integrated Product-Process Design: Material and Manufacturing Process Selection for Additive Manufacturing Using Multi-Criteria Decision Making. Robot. Comput. Integr. Manuf. 2018, 51, 169–180. [Google Scholar] [CrossRef]

- Molenaers, A.; Baets, H.; Pintelon, L.; Waeyenbergh, G. Criticality Classification of Spare Parts: A Case Study. Int. J. Prod. Econ. 2012, 140, 570–578. [Google Scholar] [CrossRef]

- Huiskonen, J. Maintenance Spare Parts Logistics: Special Characteristics and Strategic Choices. Int. J. Prod. Econ. 2001, 71, 125–133. [Google Scholar] [CrossRef]

- Lolli, F.; Ishizaka, A.; Gamberini, R. New AHP-Based Approaches for Multi-Criteria Inventory Classification. Int. J. Prod. Econ. 2014, 156, 62–74. [Google Scholar] [CrossRef]

- Sarmah, S.P.; Moharana, U.C. Multi-Criteria Classification of Spare Parts Inventories-A Web Based Approach. J. Qual. Maint. Eng. 2015, 21, 456–477. [Google Scholar] [CrossRef]

- Bourell, D.L.; Leu, M.C.; Rosen, D.W. Roadmap for Additive Manufacturing: Identifying the Future of Freeform Processing; The University of Texas at Austin: Austin, TX, USA, 2009. [Google Scholar]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for Additive Manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Wu, X.; Liang, J.; Mei, J.; Mitchell, C.; Goodwin, P.S.; Voice, W. Microstructures of Laser-Deposited Ti–6Al–4V. Mater. Des. 2004, 25, 137–144. [Google Scholar] [CrossRef]

- The Blade Runners: This Factory Is 3D Printing Turbine Parts for the World’s Largest Jet Engine|GE News. Available online: https://www.ge.com/news/reports/future-manufacturing-take-look-inside-factory-3d-printing-jet-engine-parts (accessed on 15 January 2022).

- Titanium Aluminide-MTU Aero Engines Develops New Turbine Blade Material-MTU Aero Engines. Available online: https://www.mtu.de/newsroom/press/press-archive/press-archive-detail/titanium-aluminide-mtu-aero-engines-develops-new-turbine-blade-material/ (accessed on 15 January 2022).

- Froes, R.B.F. Additive Manufacturing for the Aerospace Industry, 1st ed.; Froes, R.B.F., Ed.; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- NASA 3D Printing Case Study|Stratasys. Available online: https://www.stratasys.co.in/resources/search/case-studies/nasa (accessed on 17 January 2022).

- Watson, J.K.; Taminger, K.M.B. A Decision-Support Model for Selecting Additive Manufacturing versus Subtractive Manufacturing Based on Energy Consumption. J. Clean. Prod. 2018, 176, 1316–1322. [Google Scholar] [CrossRef]

- Allen, J. An Investigation into the Comparative Costs of Additive Manufacture vs. Machine from Solid for Aero Engine Parts. 2006. Available online: https://www.sto.nato.int/publications/STO%20Meeting%20Proceedings/RTO-MP-AVT-139/MP-AVT-139-17.pdf (accessed on 10 January 2022).

- Weller, C.; Kleer, R.; Piller, F.T. Economic Implications of 3D Printing: Market Structure Models in Light of Additive Manufacturing Revisited. Int. J. Prod. Econ. 2015, 164, 43–56. [Google Scholar] [CrossRef]

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The Cost of Additive Manufacturing: Machine Productivity, Economies of Scale and Technology-Push. Technol. Forecast. Soc. Change 2016, 102, 193–201. [Google Scholar] [CrossRef]

- Rawal, S. Materials and Structures Technology Insertion into Spacecraft Systems: Successes and Challenges. Acta Astronaut. 2018, 146, 151–160. [Google Scholar] [CrossRef]

- Wimpenny, D.I.; Pandey, P.M.; Kumar, L.J. Advances in 3D Printing & Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2016; pp. 1–186. [Google Scholar] [CrossRef]

- Thomas, D. Costs, Benefits, and Adoption of Additive Manufacturing: A Supply Chain Perspective. Int. J. Adv. Manuf. Technol. 2016, 85, 1857–1876. [Google Scholar] [CrossRef]

- Durão, L.F.C.S.; Christ, A.; Zancul, E.; Anderl, R.; Schützer, K. Additive Manufacturing Scenarios for Distributed Production of Spare Parts. Int. J. Adv. Manuf. Technol. 2017, 93, 869–880. [Google Scholar] [CrossRef]

- Rinaldi, M.; Caterino, M.; Manco, P.; Fera, M.; Macchiaroli, R. The Impact of Additive Manufacturing on Supply Chain Design: A Simulation Study. Procedia Comput. Sci. 2021, 180, 446–455. [Google Scholar] [CrossRef]

- Eggenberger, T.; Oettmeier, K.; Hofmann, E. Additive Manufacturing in Automotive Spare Parts Supply Chains—A Conceptual Scenario Analysis of Possible Effects. In Proceedings of the Industrializing Additive Manufacturing-Proceedings of Additive Manufacturing in Products and Applications-AMPA2017, ETH, Zürich, Switzerland, 13–15 September 2017; Springer: Cham, Switzerland, 2018; pp. 223–237. [Google Scholar] [CrossRef]

- Ryan, M.J.; Eyers, D.R. Digital Manufacturing for Spare Parts: Scenarios for the Automotive Supply Chain. In Proceedings of the Third Summit of ACMA Centre for Technology, Pune, India, 8–9 December 2017. [Google Scholar]

- Verna, E.; Maisano, D.A. A Benchmark Analysis of the Quality of Distributed Additive Manufacturing Centers. Int. J. Qual. Reliab. Manag. 2022. [Google Scholar] [CrossRef]

- Queipo, N.V.; Haftka, R.T.; Shyy, W.; Goel, T.; Vaidyanathan, R.; Tucker, P.K. Surrogate-Based Analysis and Optimization. Prog. Aerosp. Sci. 2005, 41, 1–28. [Google Scholar] [CrossRef]

- Behfard, S.; Van Der Heijden, M.C.; Al Hanbali, A.; Zijm, W.H.M. Last Time Buy and Repair Decisions for Spare Parts. Eur. J. Oper. Res. 2015, 244, 498–510. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- McLearen, L.J. Additive Manufacturing in the Marine Corps. Available online: https://calhoun.nps.edu/handle/10945/45903 (accessed on 24 March 2022).

- Bahrin, M.A.K.; Othman, M.F.; Azli, N.H.N.; Talib, M.F. Industry 4.0: A Review on Industrial Automation and Robotic. J. Teknol. 2016, 78, 137–143. [Google Scholar] [CrossRef]

- Almada-Lobo, F. The Industry 4.0 Revolution and the Future of Manufacturing Execution Systems (MES). J. Innov. Manag. 2015, 3, 16–21. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0-A Glimpse. In Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 20, pp. 233–238. [Google Scholar] [CrossRef]

- Büchi, G.; Cugno, M.; Castagnoli, R. Smart Factory Performance and Industry 4.0. Technol. Forecast. Soc. Change 2020, 150, 119790. [Google Scholar] [CrossRef]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, Investments, and Challenges for Enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Fisher, O.; Watson, N.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Cloud Manufacturing as a Sustainable Process Manufacturing Route. J. Manuf. Syst. 2018, 47, 53–68. [Google Scholar] [CrossRef]

- Simeone, A.; Caggiano, A.; Zeng, Y. Smart Cloud Manufacturing Platform for Resource Efficiency Improvement of Additive Manufacturing Services. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2020; Volume 88, pp. 387–392. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Wamba, S.F.; Papadopoulos, T. The Impact of Big Data on World-Class Sustainable Manufacturing. Int. J. Adv. Manuf. Technol. 2016, 84, 631–645. [Google Scholar] [CrossRef]

- Lu, Y.; Choi, S.; Witherell, P. Towards an Integrated Data Schema Design for Additive Manufacturing: Conceptual Modeling. In Proceedings of the ASME Design Engineering Technical Conference, Boston, MA, USA, 2–5 August 2015; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2015; Volume 1A-2015. [Google Scholar] [CrossRef]

- Majeed, A.; Lv, J.; Peng, T. A Framework for Big Data Driven Process Analysis and Optimization for Additive Manufacturing. Rapid Prototyp. J. 2019, 25, 308–321. [Google Scholar] [CrossRef]

- Amirkolaii, K.N.; Baboli, A.; Shahzad, M.K.; Tonadre, R. Demand Forecasting for Irregular Demands in Business Aircraft Spare Parts Supply Chains by Using Artificial Intelligence (AI). IFAC-PapersOnLine 2017, 50, 15221–15226. [Google Scholar] [CrossRef]

- Lin, J.; Zheng, M.; Chen, J.; He, K.; Pan, E. Smart Spare Part Inventory Management System with Sensor Data Updating. In Proceedings of the 2019 IEEE International Conference on Industrial Cyber Physical Systems (ICPS), Taipei, Taiwan, 6–9 May 2019; pp. 597–602. [Google Scholar] [CrossRef]

- Ho, G.T.S.; Tang, Y.M.; Tsang, K.Y.; Tang, V.; Chau, K.Y. A Blockchain-Based System to Enhance Aircraft Parts Traceability and Trackability for Inventory Management. Expert Syst. Appl. 2021, 179, 115101. [Google Scholar] [CrossRef]

- Haddara, M.; Elragal, A. The Readiness of ERP Systems for the Factory of the Future. Procedia Comput. Sci. 2015, 64, 721–728. [Google Scholar] [CrossRef]

- Strandhagen, J.W.; Buer, S.V.; Semini, M.; Alfnes, E.; Strandhagen, J.O. Sustainability Challenges and How Industry 4.0 Technologies Can Address Them: A Case Study of a Shipbuilding Supply Chain. Prod. Plan. Control 2020, 1–16. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Hasan, S.; Rashid, A.A.; Rahman, M.A. A Cyber-Physical System (CPS) for Automating Additive Manufacturing Process with Industry 4.0. In Proceedings of the International Conference on Mechanical, Industrial and Energy Engineering, Khulna, Bangladesh, 19–21 December 2020. [Google Scholar]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal Additive Manufacturing in the Commercial Aviation Industry: A Review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- Togwe, T.; Eveleigh, T.J.; Tanju, B. An Additive Manufacturing Spare Parts Inventory Model for an Aviation Use Case. EMJ-Eng. Manag. J. 2019, 31, 69–80. [Google Scholar] [CrossRef]

| Author name | Supply Chain | Additive Manufacturing | Industry 4.0 | Spare Parts | Material Selection | Aircraft Industry |

|---|---|---|---|---|---|---|

| (Khajavi et al., 2014) [17] | ✓ | ✓ | ✓ | |||

| (Frandsen et al., 2019) [21] | ✓ | ✓ | ✓ | |||

| (Ceruti et al., 2019) [22] | ✓ | ✓ | ✓ | |||

| (Kalender et al., 2019) [23] | ✓ | ✓ | ✓ | |||

| (Li et al., 2017) [24] | ✓ | ✓ | ✓ | |||

| (Caesarendra et al., 2018) [25] | ✓ | ✓ | ||||

| (Zijm et al., 2019) [26] | ✓ | ✓ | ✓ | |||

| (P. Liu et al., 2014) [27] | ✓ | ✓ | ✓ | ✓ | ||

| (Chekurov et al., 2021) [19] | ✓ | ✓ | ✓ | ✓ | ||

| (Mehrpouya et al., 2019) [28] | ✓ | ✓ | ✓ | |||

| (Yusuf et al., 2019) [29] | ✓ | ✓ | ✓ | |||

| (H. Khajavi et al., 2018) [30] | ✓ | ✓ | ✓ | ✓ | ||

| (de Souza et al., 2011) [31] | ✓ | ✓ | ✓ | |||

| This Paper | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Criteria | Description |

|---|---|

| Contribution | Importance observed in the review area |

| Relation to the research | Must align with research questions |

| Source | Journal, Review, Official Website, Proceedings |

| Timeline | 2005–2022 |

| Search Engine | Google Scholar |

| Language | English |

| Subject Area | Word String Used |

|---|---|

| Supply chain | ‘Supply chains’ OR ‘supply chain’ |

| Additive manufacturing | ‘Additive manufacturing’ OR ‘3D printing’ OR ‘Three-dimensional printing’ OR ‘Direct manufacturing’ OR ‘Digital manufacturing’ OR ‘Rapid prototyping’ OR ‘Rapid manufacturing’ OR ‘Additive fabrication’ OR ‘Solid free form fabrication’ OR ‘Generative manufacturing’ |

| Spare parts | ‘Spare part’ OR ‘Service part’ OR ‘Repair part’ OR ‘Replacement part’ |

| Industry 4.0 | ‘Industry 4.0′ OR ‘I4.0′ or ‘4IR’ OR ‘Fourth Industrial Revolution’ OR ‘4th Industrial Revolution’ |

| Material Selection | ‘Material selection’ OR ‘Material application’ or ‘Material segmentation’ |

| Aircraft industry | ‘Aircraft industry’ OR ‘Aerospace industry’ or ‘Aircraft’ OR ‘Aerospace application’ OR ‘Spacecraft’ OR ‘Aviation industry’ OR ‘Aviation’ |

| Core Subject Area | Short Form of Core Subject Area | No of Papers (Abstract, Title, Keywords) |

|---|---|---|

| Spare parts AND Supply chain | SP SC | 2050 |

| Industry 4.0 AND Supply Chain | I4.0 SC | 538 |

| Spare parts AND Industry 4.0 | SP I4.0 | 1 |

| Aerospace industry AND Industry 4.0 | AI I4.0 | 30 |

| Aerospace Industry AND Spare parts | AI SP | 1710 |

| Material Selection AND Aerospace Industry | MS AI | 34 |

| Additive Manufacturing AND Material Selection | AM MS | 13 |

| Additive Manufacturing AND Spare parts | AM SP | 103 |

| Additive Manufacturing AND supply chain | AM SC | 299 |

| Additive Manufacturing AND Supply Chain AND Spare parts | AM SC SP | 3 |

| Industry 4.0 AND Spare parts AND supply chain | I4.0 SP SC | 1 |

| Industry 4.0 AND Spare parts AND Aerospace Industry | I4.0 SP AI | 5 |

| Material Selection AND Spare parts AND Aerospace Industry | MS SP AI | 1 |

| Material Selection AND Spare parts AND Additive Manufacturing | MS SP AM | 1 |

| Total | 4789 | |

| Attributes | Explanation | References | |

|---|---|---|---|

| Advantages | Flexible design | AM process can overcome the limitations of not producing complex shapes in the conventional process. The parts do not need further fabrication or operator to produce complex parts. | [3,37,38,39,40,41,42,43,44,45,46,47] |

| Low cost | Because of AM, rapid prototyping is easier based on time and monetary budgets. Compared to CM, a CNC milling setup is much cheaper with AM. | [37,47,48,49] | |

| Customized products | As AM does not have limitations over shapes, it can produce customized products massively. | [3,38,41,43,47] | |

| Efficient use of materials | 3D printing means methodically adding materials until a part is created. Since AM starts laying down a base layer of material and then adds subsequent layers until the part is ready, the overall waste is minimal. Additionally, consolidating parts for manufacturing can save energy and manufacturing costs. | [42,44,47,48,50] | |

| Increased part reliability | As newer materials, such as polymers, metals, and composites become available for the AM, replacing parts with improved materials gets easier to improve the parts’ performances. | [51,52] | |

| Reduction in on-hand inventory | Unlike the traditional manufacturing that sticks to a warehouse packed with premade parts, AM needs a virtual inventory that saves warehouse space, personnel, and obsolete parts. | [37,40,42,53] | |

| Small production runs often prove faster and less expensive | Almost nothing beats AM for speed and economy for a handful of products. It will be faster to print those. Gathering design files, printers, and materials are all we will need. | [44] | |

| Disadvantages | Not preferred for mass production | The process of AM is slow, and it allows mass customization, and thus till now, it is not being able to be used for mass production. | [3,37,40,45,47,48] |

| Size limitation | Industries are slow to adopt AM and consider it a niche process even in 2021, probably because 3D printing is not an efficient method of producing a considerable quantity of parts. | [42,43,53] | |

| Low range of material | Unlike CM, AM have fewer materials to be used. | [44,47,53] |

| Spare Parts Selection Parameters | Description | Author Reference |

|---|---|---|

| Part size, Build volume | AM machines have limitations of build volume as well as part size which depends on the resolution of the machine. | [79,89,90] |

| Supplier availability, demand pattern, lead time, predictability of delivery time | Normally AM is a time-consuming process rather than the machining process depending on the process parameters and part quality. Therefore, high resolution products can take large fabrication time rather than machining process, which may result in large lead time and delivery time need to be predicted to supply the spare parts in time | [90] |

| Appropriate material | Different materials have different mechanical properties, and their application may vary depending on their characteristics. | [91] |

| Appropriate material, Dimensional accuracy | The formability of complex shapes can affect the product dimension. Hence, proper material needs to be employed depending on material properties. | [92] |

| Post-production shrinkage; Appropriate material, water, and temperature resistance | The AM fabrication process is conducted in an ambient temperature depending on the material. After producing the parts, it tends to have shrinkage and resulting change in the product dimensions. As accuracy and tolerance is a big factor for aviation spare parts, so the shrinkage, dimensional accuracy and temperature resistance need to be considered for the fabrication process | [3] |

| Stiffness to weight ratio, Appropriate material, support material, strength to weight ratio | The part mechanical properties like stiffness to weight ratio, and strength to weight ratio need to be considered for better performance under a loading environment. The mechanical properties also depend on the product material and support material to sustain under loading. | [93] |

| Layer thickness, Build speed | Optimized layer thickness, and printing speed needed for better part quality and material consumption. | [94] |

| Supplier availability, demand pattern, lead time, responsiveness, downtime cost, maintenance type | The spare parts need to be easy to change or repair. Otherwise, it will increase downtime in the maintenance work. | [5,95] |

| Supplier availability, demand pattern, lead time, Annual consumption value | The annual consumption of materials and spare parts plays a vital role in the MRO’s yearly revenue. | [21,96,97] |

| AM machine Technology | ||||||||

|---|---|---|---|---|---|---|---|---|

| Current Technology | Future Technology | |||||||

| SoA-SP [30] | SoA-MP [30] | SoA-2013 [17] | ReqTecDM [17,30] | |||||

| Attribute | Centralized | Decentralized | Centralized | Decentralized | Centralized | Decentralized | Centralized | Decentralized |

| Material Cost | Same | Same | Same | Same | Same | Same | Same | Same |

| Spare parts transportation cost | High | Nil | High | Nil | High | Nil | High | Nil |

| Inventory carrying cost | High | Low | High | Low | High | Low | High | Low |

| Aircraft downtime cost | Low | High | Low | High | High | Low | High | Low |

| Annual cost of initial inventory production | High | Low | High | Low | High | Low | High | Low |

| Inventory obsolescence cost | High | Low | High | Low | High | Low | High | Low |

| Initial investment in AM machines, depreciation cost | Low | High | Low | High | Low | High | Low | High |

| Personnel cost | Low | High | Low | High | Low | High | Low | High |

| Total Cost | Lower | Higher | Lower | Higher | Lower | Higher | Higher | Lower |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Debnath, B.; Shakur, M.S.; Tanjum, F.; Rahman, M.A.; Adnan, Z.H. Impact of Additive Manufacturing on the Supply Chain of Aerospace Spare Parts Industry—A Review. Logistics 2022, 6, 28. https://doi.org/10.3390/logistics6020028

Debnath B, Shakur MS, Tanjum F, Rahman MA, Adnan ZH. Impact of Additive Manufacturing on the Supply Chain of Aerospace Spare Parts Industry—A Review. Logistics. 2022; 6(2):28. https://doi.org/10.3390/logistics6020028

Chicago/Turabian StyleDebnath, Binoy, Md Shihab Shakur, Fahmida Tanjum, M. Azizur Rahman, and Ziaul Haq Adnan. 2022. "Impact of Additive Manufacturing on the Supply Chain of Aerospace Spare Parts Industry—A Review" Logistics 6, no. 2: 28. https://doi.org/10.3390/logistics6020028

APA StyleDebnath, B., Shakur, M. S., Tanjum, F., Rahman, M. A., & Adnan, Z. H. (2022). Impact of Additive Manufacturing on the Supply Chain of Aerospace Spare Parts Industry—A Review. Logistics, 6(2), 28. https://doi.org/10.3390/logistics6020028