The Integration of Extended Supply Chain with Sales and Operation Planning: A Conceptual Framework

Abstract

:1. Introduction

2. Concepts and Definitions

3. Review and Discussion

3.1. General Methodology and Selection of the Papers

3.2. S&OP Integration

3.3. SC Integration

3.4. Multi-Criteria Decision in SC

3.4.1. Suppliers’ End

Production Stability

Reduced Lead Time

Reduced Inventory

Forecast Accuracy

Distribution Cost

Cost/Profit Planning

3.4.2. Customers’ End

New Product

Service Level

Quality

Flexibility

On-Time Delivery

Price/Satisfaction

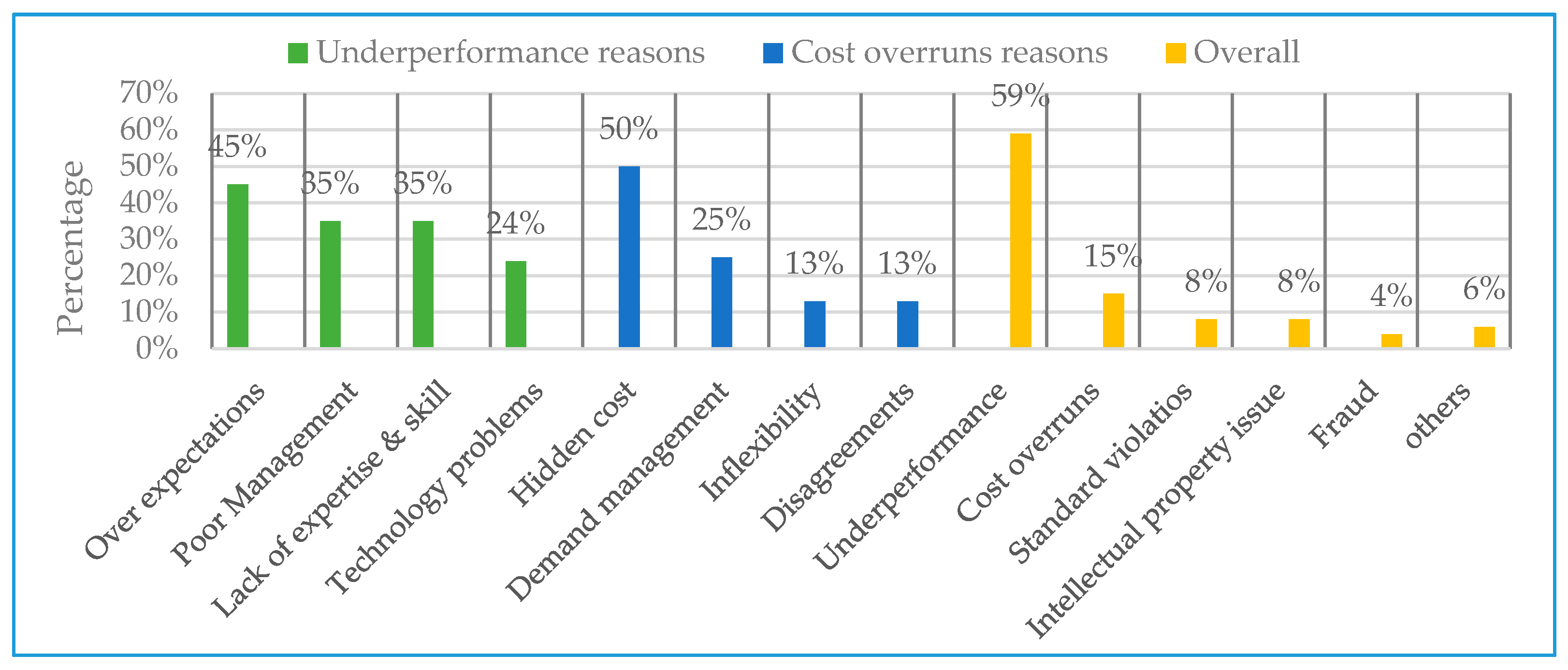

3.5. Key Issues in S&OP and SC Integration

3.6. Enablers of Integration

- (a)

- The firm is connected through the IS resources to all its stakeholders.

- (b)

- The firm gets inputs of all transactions and remains updated over outside information.

- (c)

- The firm employs competent people to conduct efficiently its S&OP process.

- (d)

- The firm is proactive with regard to its system vulnerability and executes all plan accordingly.

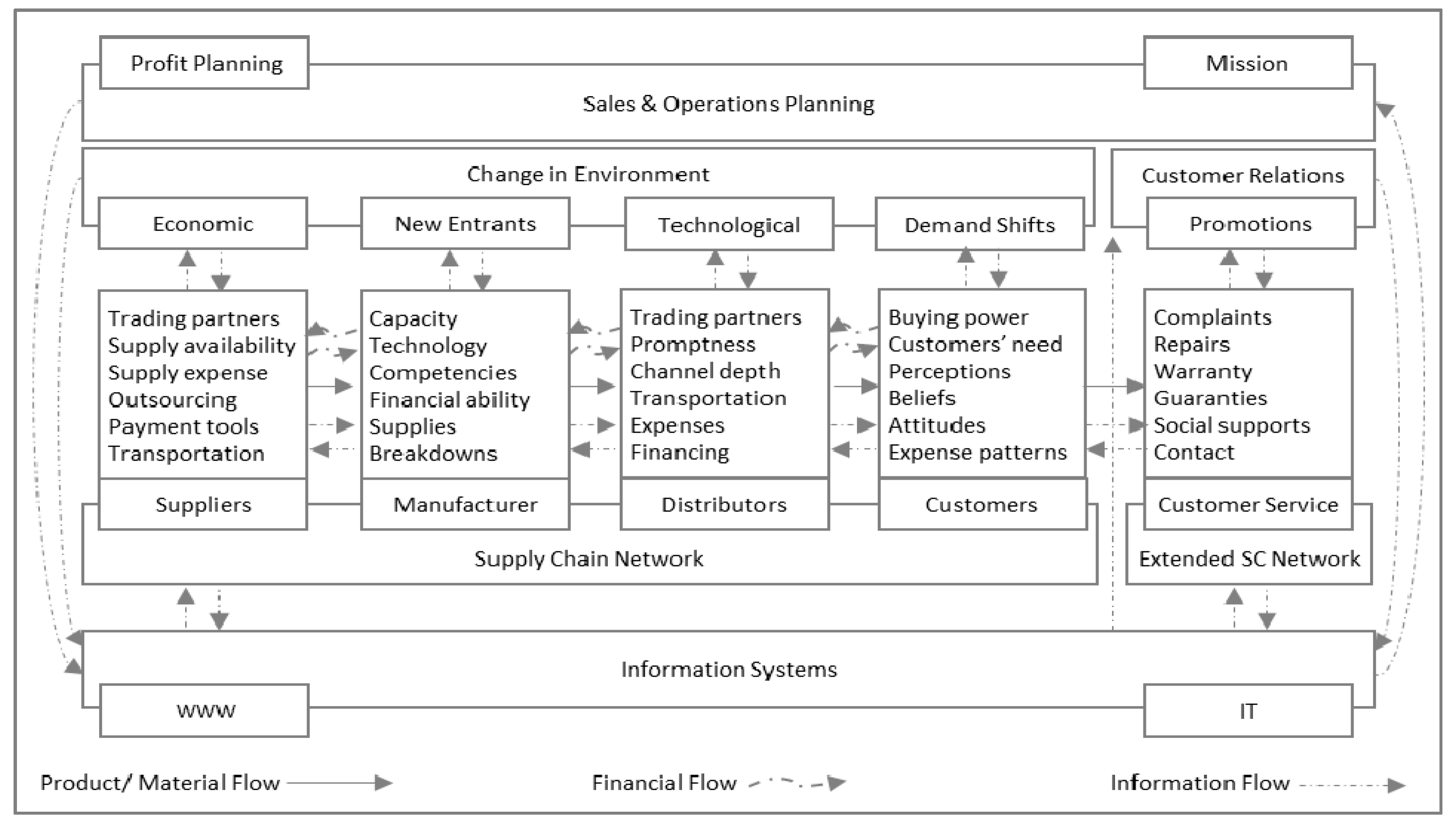

4. Model Building

- (a)

- For better performance, different functional areas of organizations need integration.

- (b)

- With the implementation of S&OP, a better alignment between operational, financial, and marketing plans can be attained.

- (c)

- The integration between customer, supplier, and other key partners in the supply chain network can positively influence the overall performance of the organization.

- (d)

- The S&OP facilitates the integration of operations between business processes and customers.

- (e)

- Different sociotechnical factors impact the level of integration.

- (f)

- IS has been regarded as the key enabler of S&OP and SC integration.

- (g)

- Through an S&OP integrated plan, a company can get better SC performance and therefore can increase its operational excellence.

5. Conclusions, Further Research, and Implications

Conflicts of Interest

References

- Sheldon, D.H. World Class Sales and Operations Planning: A Guide to Successful Implementation and Robust Execution; J. Ross Publishing: Plantation, FL, USA, 2006; ISBN 978-1-932159-53-0. [Google Scholar]

- Angeles, R.; Nath, R. An empirical study of EDI trading partner selection criteria in customer-supplier relationships. Inf. Manag. 2000, 37, 241–255. [Google Scholar] [CrossRef]

- Krajewski, L.J.; Ritzman, L.P. Operation Management: Strategy and Analysis; Pearson: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Oosterhout, V.M. Business Agility and Information Technology in Service Organizations; ERIM Ph.D. Series in Management; Erasmus Research Institute of Management: Rotterdam, The Netherlands, 2010. [Google Scholar]

- Gosain, S.; Malhotra, A.; EL Sawy, O.A. Coordination for flexibility in e-business supply chains. J. Manag. Inf. Syst. 2004, 21, 7–45. [Google Scholar] [CrossRef]

- Overby, E.; Bharadwaj, A.; Sambamurthy, V. Enterprise Agility and the Enabling Role of Information Technology. Eur. J. Inf. Syst. 2006, 152, 120–131. [Google Scholar] [CrossRef]

- Piechule, J. Implementing a sales and operations planning process at Sartomer Company: A grass-roots approach. J. Bus. Forecast. 2008, 27, 13–18. [Google Scholar]

- Ptak, C.; Smith, C. Orlicky's MRP, 3rd ed.; McGraw Hill: New York, NY, USA, 2011; ISBN 978-0-07-175563-4. [Google Scholar]

- Palmatier, G.E. The Need to Lead; Businessexcellence: Palmerston North, New Zealand, 2015; p. 5. Available online: https://www.oliverwight-americas.com/system/files/public/resources/sales-operations-planning-palmatier.pdf (accessed on 7 June 2017).

- Bojei, J.; Alwei, A. The Influence of Relationship Quality on Loyalty in Service Sector. Int. J. Econ. Manag. 2010, 4, 81–100. [Google Scholar]

- Sudarshan, D. Marketing Strategy: Relationships, Offerings, Timing and Resource Allocation; Prentice Hall: Upper Saddle River, NJ, USA, 1995. [Google Scholar]

- Rauyruen, P.; Miller, K.E.; Barrett, N. Relationship Quality as a Predictor of B2B Customer Loyalty. J. Bus. Res. 2007, 60, 21–31. [Google Scholar] [CrossRef]

- Gunaasekaran, A.; Patel, C.; McGaunghey, R.E. A framework for supply chain performance measurement. Int. J. Prod. Econ. 2004, 87, 333–347. [Google Scholar] [CrossRef]

- McCormack, K.; Kasper, K. The extended supply chain: A statistical study. Benchmark. Int. J. 2002, 9, 133–145. [Google Scholar] [CrossRef]

- Junaev, M.; Kumar, D.; Hanaysha, J.R.M. Impact of Relationship Marketing on Customer Loyalty in the Banking Sector. Far East J. Psychol. Bus. 2012, 3, 36–55. [Google Scholar]

- Roland, T.R.; Huang, M. Optimizing Service Productivity. J. Mark. 2012, 76, 47–66. [Google Scholar]

- Köksalan, M.; Wallenius, J.; Zionts, S. Multiple Criteria Decision-making: From Early History to the 21st Century; World Scientific: Singapore, 2011. [Google Scholar]

- Wieland, A.; Wallenburg, C.M. The influence of relational competencies on supply chain resilience: A relational view. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 300–320. [Google Scholar] [CrossRef]

- Beamon, B.M. Designing the green supply chain. Logist. Inf. Manag. 1999, 12, 332–342. [Google Scholar] [CrossRef]

- Yasuyuki, T.; Kentaro, N.; Matous, P. How Do Supply Chain Networks Affect the Resilience of Firms to Natural Disasters. Great East Jpn. Earthq. Reg. Sci. J. 2014, 55, 209–229. [Google Scholar]

- Gunasekaran, A.; Rai, B.K.; Griffin, M. Resilience and competitiveness of small and medium size enterprises: An empirical research. Int. J. Prod. Res. 2011, 49, 5489–5509. [Google Scholar] [CrossRef]

- Ambulkar, S.; Blackhurst, J.; Grawe, S. Firm’s resilience to supply chain disruptions: Scale development and empirical examination. J. Oper. Manag. 2015, 33–34, 111–122. [Google Scholar] [CrossRef]

- Gitman, L.J.; McDaniel, C.D. The Future of Business: The Essentials; South-Western: Mason, OH, USA, 2005; ISBN 0-324-32028-0. [Google Scholar]

- Ling, R.C.; Goddard, W.E. Orchestrating Success: Improve Control of the Business with Sales and Operations Planning; Wiley: Hoboken, NJ, USA, 1992. [Google Scholar]

- Dougherty, J.R.; Gray, C. Sales and Operations Planning—Best Practices: Lessons Learned; Paperback; Trafford Publishing: Bloomington, IN, USA, 2007. [Google Scholar]

- Hamel, G.; Prahalad, C.K. Competing for the Future; Harvard Business School Press: Brighton, MA, USA, 1994. [Google Scholar]

- Pascale, R.; Millemann, M.; Gioja, L. Changing the Way We Change. Harv. Bus. Rev. 1997, 75, 127–139. [Google Scholar]

- Esper, T.L.; Ellinger, A.E.; Stank, T.P.; Flint, D.J.; Moon, M. Demand and supply integration: A conceptual framework of value creation through knowledge management. J. Acad. Mark. Sci. 2010, 38, 5–11. [Google Scholar] [CrossRef]

- Henderson, J.C.; Venkatraman, N. Strategic Allignment: A Process Model for Integrating Information Technology and Business Strategy; CISR WP No. 196; Sloan School, MIT: Cambridge, MA, USA, 1989. [Google Scholar]

- Chen, Y.F.; Drezner, Z.; Ryan, J.K.; Simchi, D.L. Quantifying the Bullwhip Effect in a Simple Supply Chain: The Impact of Forecasting. Lead Times and Information. Manag. Sci. 2000, 46, 436–443. [Google Scholar] [CrossRef]

- Christopher, M. The agile supply chain: Competing in volatile markets. Ind. Mark. Manag. 2000, 29, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Cho, J.K.; Ozment, J.; Sink, H. Logistics capability. Logistics outsourcing and firm performance in an e-commerce market. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 336–359. [Google Scholar]

- Charles, H. International Business Competing in the Global Marketplace, 6th ed.; McGraw-Hill: New York, NY, USA, 2007; p. 168. ISBN 978-0-07-310255-9. [Google Scholar]

- Paul, D. What’s This India Business?: Offshoring, Outsourcing and the Global Services Revolution; Nicholas Brealey International: London, UK, 2004. [Google Scholar]

- Marucheck, A.; Greis, N.; Cai, L. Product safety and security in the global supply chain: Issues, Challenges and research opportunities. J. Oper. Manag. 2011, 29, 707–720. [Google Scholar] [CrossRef] [Green Version]

- Olive, B. Outsourcing Growing, Despite Controversy. Power 2004, 148, 19–20. [Google Scholar]

- Fornell, C.; Rust, R.T.; Dekimpe, M.G. The Effect of Customer Satisfaction on Consumer Spending Growth. J. Mark. Res. 2010, 47, 28–35. [Google Scholar] [CrossRef]

- Andarski, J.C. Leadership and the realization of supply chain collaboration. J. Bus. Logist. 1998, 19, 9–11. [Google Scholar]

- Gong, F.; Kung, D.S.; Zeng, T. The impact of different contract structure on IT investment in logistic outsourcing. Int. J. Prod. Econ. 2018, 195, 158–167. [Google Scholar] [CrossRef]

- Rai, A.; Pavlou, P.A.; Im, G.; Du, S. Interfirm IT capability profiles and communications for cocreating relational value: Evidence from the logistics industry. MIS Q. 2012, 36, 233–262. [Google Scholar]

- Braunscheidel, M.J.; Suresh, N.C. The organizational antecedents of a firm’s supply chain agility for risk mitigation and response. J. Oper. Manag. 2009, 27, 119–140. [Google Scholar] [CrossRef]

- Mackelprang, A.W.; Robinson, J.L.; Bernardes, E.; Webb, G.S. The relationship between strategic supply chain integration and performance: A meta-analytic evaluation and implications for supply chain management research. J. Bus. Logist. 2014, 35, 71–96. [Google Scholar] [CrossRef]

- Schoenherr, T.; Swink, M. Revisiting the arcs of integration: Cross-validations and extensions. J. Oper. Manag. 2012, 30, 99–115. [Google Scholar] [CrossRef]

- Caniato, F.; Cagliano, R.; Kalchschmidt, M.; Golini, R.; Spina, G. Evolutionary patterns in e-business strategy. Int. J. Oper. Prod. Manag. 2009, 29, 921–945. [Google Scholar] [CrossRef]

- Lapide, L. Top-down and bottom-up forecasting in S&OP. J. Bus. Forecast. 2006, 1. Available online: http://mit-ctl.mit.edu/sites/ctl.mit.edu/files/library/public/ article_jbf_top_down_lapide.pdf (accessed on 9 December 2017).

- Affonso, R.; Marcotte, F.; Grabot, B. Sales and operations planning: The supply chain pillar. Prod. Plan. Control 2008, 19, 132–141. [Google Scholar] [CrossRef]

- Stahl, R.A. Executive S&OP: Managing to achieve consensus. Foresight 2010, 19, 34–38. [Google Scholar]

- Burrows, R.P., III. Demand driven S&OP: A sharp departure from the traditional ERP approach. J. Bus. Forecast. 2007, 26, 4–13. [Google Scholar]

- Gallucci, J.A. How to mitigate risk and drive alignment with S&OP. J. Bus. Forecast. 2008, 27, 4–9. [Google Scholar]

- Lapide, L. S&OP: The linchpin planning process. J. Bus. Forecast. 2011, 30, 18–20. [Google Scholar]

- Sinha, D. How to Make the S&OP Process More Robust. J. Bus. Forecast. 2015, 34, 14–17. [Google Scholar]

- Bower, P. Integrated business planning: Is it a hoax or here to stay? J. Bus. Forecast. 2012, 31, 11–17. [Google Scholar]

- Johnson, E.; Margulius, D. Elusive integration: Linking sales and operations planning. Achiev. Supply Chain Excell. Technol. 2005, 7, 2–4. [Google Scholar]

- Pedroso, C.B.; da Silva, A.L.; Tate, W.L. Sales and Operations Planning (S&OP): Insights from a multi-case study of Brazilian organizations. Int. J. Prod. Econ. 2016, 182, 213–229. [Google Scholar]

- McCormack, K.; Lockamy, A. The impact of horizontal mechanisms within sales and operations planning processes on supply chain integration and performance: A statistical study. In Proceedings of the 4th Global Conference on Business and Economics, Oxford, UK, 30 November 2005. [Google Scholar]

- Mello, J.; Esper, T. S&OP. forecasting and the knowledge-creating company. Foresight 2007, 20, 23–27. [Google Scholar]

- Bowersox, D.J.; Closs, D.J.; Cooper, M.B. Supply Chain Logistics Management; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Chase, C.W. Putting M arketing back in S&OP. J. Bus. Forecast. 2013, 32, 4–13. [Google Scholar]

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Wisner, J.D.; Tan, K.C. Supply chain management and its impact on purchasing. J. Supply Chain Manag. 2000, 36, 33–42. [Google Scholar] [CrossRef]

- Zhao, X.; Huo, B.; Flynn, B.B.; Yeung, J. The impact of power and relationship commitment on the integration between manufacturers and customers in a supply chain. J. Oper. Manag. 2008, 26, 368–388. [Google Scholar] [CrossRef]

- Lambert, D.M.; Cooper, M.C. Issues in supply chain management. Ind. Mark. Manag. 2000, 29, 65–83. [Google Scholar] [CrossRef]

- Hillebrand, B.; Biemans, W.G. The relationship between internal and external cooperation: Literature review and propositions. J. Bus. Res. 2003, 56, 735–743. [Google Scholar] [CrossRef]

- Marquez, A.C.; Bianchi, C.; Gupta, J.N.D. Operational and financial effectiveness of e-collaboration tools in supply chain integration. Eur. J. Oper. Res. 2004, 159, 348–363. [Google Scholar] [CrossRef]

- Rosenzweig, E.D.; Roth, A.V.; Dean, J.W., Jr. The influence of an integration strategy on competitive capabilities and business performance: An exploratory study of consumer products manufacturers. J. Oper. Manag. 2003, 21, 437–456. [Google Scholar] [CrossRef]

- Vickery, S.K.; Jayaram, J.; Droge, C.; Calantone, R. The effects of an integrative supply chain strategy on customer service and financial performance: An analysis of direct versus indirect relationships. J. Oper. Manag. 2003, 21, 523–539. [Google Scholar] [CrossRef]

- Gimenez, C.; Ventura, E. Logistics-production, logistics-marketing and external integration: Their impact on performance. Int. J. Oper. Prod. Manag. 2005, 25, 20–38. [Google Scholar] [CrossRef]

- Koufteros, X.; Vonderembse, M.; Jayaram, J. Internal and external integration for product development: The contingency effects of uncertainty, equivocality and platform strategy. Decis. Sci. 2005, 36, 97–133. [Google Scholar] [CrossRef]

- Donaldson, L. The Contingency Theory of Organizations; Sage: Thousand Oaks, CA, USA, 2001. [Google Scholar]

- Koufteros, X.A.; Cheng, T.C.E.; Lai, K.H. Black-box and gray box supplier integration in product development: Antecedents, Consequences and the moderating role of firm size. J. Oper. Manag. 2007, 25, 847–870. [Google Scholar] [CrossRef]

- Triantaphyllou, E. Multi-Criteria Decision-making: A Comparative Study; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2000; p. 320. [Google Scholar]

- Madurika, H.K.G.M.; Hemakumara, G.P.T.S. Gis Based Analysis for Suitability Location Finding in the Residential Development Areas of Greater Matara Region. Int. J. Sci. Technol. Res. 2015, 4, 96–105. [Google Scholar]

- Amid, A.; Ghodsypour, S.H.; O’Brien, C. A weighted additive fuzzy multi-objective model for the supplier selection problem under price breaks in a supply chain. Int. J. Prod. Econ. 2009, 121, 323–332. [Google Scholar] [CrossRef]

- Amid, A.; Ghodsypour, S.H.; O’Brien, C. A weighted max–min model for fuzzy multi-objective supplier selection in a supply chain. Int. J. Prod. Econ. 2011, 131, 139–145. [Google Scholar] [CrossRef]

- Kjellsdotter Ivert, L.; Dukovska-Popovska, I.; Kaipia, R.; Fredriksson, A.; Dreyer, H.; Johansson, M.I.; Chabada, L.; Damgaard, C.M.; Tuomikangas, N. Sales and operations planning: Responding to the needs of industrial food producers. Prod. Plan. Control 2014, 26, 280–295. [Google Scholar]

- Godsell, J.; Birtwistle, A.; van Hoek, R. Building the supply chain to enable business alignment: Lessons from British American Tobacco (BAT). Supply Chain Manag. Int. J. 2010, 15, 10–15. [Google Scholar] [CrossRef]

- Mellen, C.; Allen, B.; Prokopets, L. Putting S&OP on the fast track. Supply Chain Manag. Rev. 2010, 14, 40–45. [Google Scholar]

- Chae, B. Developing key performance indicators for supply chain: An industry perspective. Supply Chain Manag. Int. J. 2009, 14, 422–428. [Google Scholar] [CrossRef]

- Singh, M.K. What makes a winning S&OP program. Supply Chain Manag. Rev. 2010, 14, 22–27. [Google Scholar]

- Thome, A.M.T.; Sousa, R.S.; do Carmo, R.S. The impact of sales and operations planning practices on manufacturing operational performance. Int. J. Prod. Res. 2014, 52, 2108–2121. [Google Scholar] [CrossRef]

- Paiva, E.L. Manufacturing and marketing integration from a cumulative capabilities perspective. Int. J. Prod. Econ. 2010, 126, 379–386. [Google Scholar] [CrossRef]

- Olhager, J. The role of the customer order decoupling point in production and supply chain management. Comput. Ind. 2010, 61, 863–868. [Google Scholar] [CrossRef]

- Goh, S.H.; Eldridge, S. New product introduction and supplier integration in sales and operations planning: Evidence from the Asia Pacific region. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 861–886. [Google Scholar] [CrossRef]

- Keal, D.A.; Hebert, P. Benefits to blood banks of a sales and operations planning process. Transfusion 2010, 50, 2785–2787. [Google Scholar] [CrossRef] [PubMed]

- Koh, S.C.; Saad, S.; Arunachalam, S. Competing in the 21st century supply chain through supply chain management and enterprise resource planning integration. Int. J. Phys. Distrib. Logist. Manag. 2006, 36, 455–465. [Google Scholar]

- Bose, I.; Pal, R.; Ye, A. ERP and SCM systems integration: The case of a valve manufacturer in China. Inf. Manag. 2008, 45, 233–241. [Google Scholar] [CrossRef]

- McLaren, T.; Head, M.; Yuan, Y. Supply chain collaboration alternatives: Understanding the expected costs and benefits. Internet Res. Electron. Netw. Appl. Policy 2002, 12, 348–364. [Google Scholar] [CrossRef]

- Hult, G.T.; Ketchen, D.J.; Slater, S.F. Information Processing. Knowledge Development and Strategic Supply Chain Performance. Acad. Manag. J. 2004, 47, 243–253. [Google Scholar] [CrossRef]

- Feng, Y.; Sophie D’Amours, S.; Beauregard, R. The value of sales and operations planning in oriented strand board industry with make-to-order manufacturing system: Cross functional integration under deterministic demand and spot market recourse. Int. J. Prod. Econ. 2008, 115, 189–209. [Google Scholar] [CrossRef]

- Leuschner, R.; Rogers, D.S.; Charveta, F.F. A meta-analysis of supply chain integration and firm performance. J. Supply Chain Manag. 2013, 49, 34–57. [Google Scholar] [CrossRef]

- Bagchi, P.K.; Skjoett-Larsen, T. Supply chain Integration: A European Survey. Int. J. Logist. Manag. 2005, 16, 275–294. [Google Scholar] [CrossRef]

- Boon-Itt, S.; Paul, H. A study of supply chain integration in thai automotive industry: A theoretical framework and measurement. Manag. Res. News 2006, 29, 194–205. [Google Scholar] [CrossRef]

- Quesada, G.; Rachamadugu, R.; Gonzalez, M.; Martinez, J.L. Linking order winning and external supply chain integration strategies. Supply Chain Manag. Int. J. 2008, 13, 296–303. [Google Scholar] [CrossRef]

- Wong, C.Y.; Boon-Itt, S.; Wong, C.W.Y. The contingency effects of environmental uncertainty on the relationship between supply chain integration and operational performance. J. Oper. Manag. 2011, 29, 604–615. [Google Scholar] [CrossRef]

- Hoek, R.I.; Harrison, A.; Christopher, M. Measuring agile capabilities in the supply chain. Int. J. Oper. Prod. Manag. 2001, 21, 126–147. [Google Scholar] [CrossRef]

- De Treville, S.; Shapiro, R.D.; Hameri, A.P. From supply chain to demand chain: The role of lead time reduction in improving demand chain performance. J. Oper. Manag. 2004, 21, 613–627. [Google Scholar] [CrossRef]

- Ouyang, L.Y.; Wu, K.S.; Ho, C.H. An integrated vendor–buyer inventory model with quality improvement and lead time reduction. Int. J. Prod. Econ. 2007, 108, 349–358. [Google Scholar] [CrossRef]

- Tersine, R.J.; Hummingbird, E.A. Lead-time reduction: The search for competitive advantage. Int. J. Oper. Prod. Manag. 1995, 15, 8–18. [Google Scholar] [CrossRef]

- Yao, Y.; Evers, P.T.; Dresner, M.E. Supply chain integration in vendor-managed inventory. Decis. Support Syst. 2007, 43, 663–674. [Google Scholar] [CrossRef]

- Kekre, S.; Mukhopadhyay, T. Impact of electronic data interchange technology on quality improvement and inventory reduction programs: A field study. Int. J. Prod. Econ. 1992, 28, 265–282. [Google Scholar] [CrossRef]

- Yue, X.; Liu, J. Demand forecast sharing in a dual-channel supply chain. Eur. J. Oper. Res. 2006, 174, 646–667. [Google Scholar] [CrossRef]

- Armstrong, G.; Adam, S.; Denize, S.; Kotler, P. Principles of Marketing; Pearson: Sydney, Australia, 2014; pp. 297–394. [Google Scholar]

- Thomas, D.J.; Griffin, P.M. Coordinated supply chain management. Eur. J. Oper. Res. 1996, 94, 1–15. [Google Scholar] [CrossRef]

- Amiri, A. Designing a distribution network in a supply chain system: Formulation and efficient solution procedure. Eur. J. Oper. Res. 2006, 171, 567–576. [Google Scholar] [CrossRef]

- Ishii, K.; Takahashi, K.; Muramatsu, R. Integrated Production. Inventory and Distribution Systems. Int. J. Prod. Res. 1988, 26, 473–482. [Google Scholar]

- Harris, F.W. How Many Parts to Make at Once. Oper. Res. 1990, 38, 947–950. [Google Scholar] [CrossRef]

- Cohen, M.A.; Sanqwon, M. Impact of Production Scale Economies. Manufacturing Complexity and Transportation Costs on Supply Chain Facility Networks. J. Manuf. Oper. Manag. 1990, 3, 269–292. [Google Scholar]

- Cohen, M.A.; Hau, L.L. Resource Deployment Analysis of Global Manufacturing and Distribution Networks. J. Manuf. Oper. Manag. 1989, 2, 81–104. [Google Scholar]

- Yusuf, Y.Y.; Gunasekaran, A.; Adeleye, E.O.; Sivayoganathan, K. Agile supply chain capabilities: Determinants of competitive objectives. Eur. J. Oper. Res. 2004, 159, 379–392. [Google Scholar] [CrossRef]

- Woodruff, R.B. Customer value: The next source for competitive advantage. J. Acad. Mark. Sci. 1997, 25. [Google Scholar] [CrossRef]

- Cui, A.S.; Wu, F. The impact of customer involvement on new product development: Contingent and substitutive effects. J. Prod. Innov. Manag. 2017, 34, 60–80. [Google Scholar] [CrossRef]

- Ernst, H.; Hoyer, W.; Krafft, M.; Soll, J.H. Virtual Co-Creation with Customers in the Early Stages of New Product Development. 2017. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3053800 (accessed on 3 February 2018).

- Paul, H.S. Sales Process Engineering: An Emerging Quality Application. Qual. Prog. 1998, 31, 59–63. [Google Scholar]

- Hossain, M.Z. Building Sustainable Relationships through Customer Support Service in Telecommunication Industry. Glob. J. Manag. Bus. Res. 2017, 17, 43–55. [Google Scholar]

- Frimpong, J.M.; Owusu-Bio, M.K.; Annan, C. Maximizing Customer Service through Logistics Service Support in the Automobile Industry in Ghana. World Acad. Sci. Eng. Technol. Int. J. Ind. Manuf. Eng. 2017, 11, 1171–1175. [Google Scholar]

- Kiran, K.; Diljit, S. Antecedents of customer loyalty: Does service quality suffice? Malays. J. Libr. Inf. Sci. 2017, 16, 95–113. [Google Scholar]

- Konstantas, D.; Ioannidis, S.; Kouikoglou, V.S.; Grigoroudis, E. Linking product quality and customer behavior for performance analysis and optimization of make-to-order manufacturing systems. Int. J. Adv. Manuf. Technol. 2017, 95, 1–10. [Google Scholar] [CrossRef]

- Corbett, L.M. Delivery windows-a new view on improving manufacturing flexibility and on-time delivery performance. Prod. Inventory Manag. J. 1992, 33, 74–79. [Google Scholar]

- Maldonado-Guzman, G.; Pinzón-Castro, S.Y.; Valdez-Bocanegra, H.G. Logistics Flexibility and Customer Satisfaction in Spain’s Furniture Industry. Int. Bus. Res. 2017, 10, 161. [Google Scholar] [CrossRef]

- Fayezi, S.; Zutshi, A.; O’Loughlin, A. Understanding and development of supply chain agility and flexibility: A structured literature review. Int. J. Manag. Rev. 2017, 19, 379–407. [Google Scholar] [CrossRef]

- Kumar, A.; Dash, M.K. Using fuzzy Delphi and generalized fuzzy TOPSIS to evaluate technological service flexibility dimensions of internet malls. Glob. J. Flex. Syst. Manag. 2017, 18, 153–161. [Google Scholar] [CrossRef]

- Grimson, J.A.; Pyke, D.F. Sales and operations planning: An exploratory study and framework. Int. J. Logist. Manag. 2007, 18, 322–346. [Google Scholar] [CrossRef]

- Kjellsdotter Ivert, L.; Jonsson, P. The potential benefits of advanced planning and scheduling systems in sales and operations planning. Ind. Manag. Data Syst. 2010, 110, 659–681. [Google Scholar] [CrossRef]

- Farris, P.W.; Neil, T.B.; Phillip, E.P.; David, J.R. Marketing Metrics: The Definitive Guide to Measuring Marketing Performance; Pearson Education Inc.: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Woodham, O.P.; Williams, J.A.; McNeil, K.R. Toward Understanding the Impact of Attributes on Satisfaction in Different Price Tiers. J. Consum. Satisf. Dissatisf. Complain. Behav. 2017, 29, 91–117. [Google Scholar]

- Rai, A.; Patnayakuni, R.; Patnayakuni, N. Firm Performance Impacts of Digitally-enabled Supply Chain Integration Capabilities. MIS Q. 2006, 30, 225–246. [Google Scholar] [CrossRef]

- Lin, H.F. The impact of socialization mechanisms and technological innovation capabilities on partnership quality and supply chain integration. Inf. Syst. e-Bus. Manag. 2014, 12, 285–306. [Google Scholar] [CrossRef]

- Plank, R.E.; Hooker, R. Sales and operations planning: Using the internet and internet-based tools to further supply chain integration. J. Res. Interact. Mark. 2014, 8, 18–36. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Ngai, E.W.T. Information systems in supply chain integration and management. Eur. J. Oper. Res. 2004, 159, 269–295. [Google Scholar] [CrossRef]

- Iyer, K.N.; Germain, R.; Claycomb, V.A. B2B e-commerce supply chain integration and performance: A contingency fit perspective on the role of environment. Inf. Manag. 2009, 46, 313–322. [Google Scholar] [CrossRef]

- Li, G.; Yang, H.; Sun, L.; Sohal, A.S. The impact of IT implementation on supply chain integration and performance. Int. J. Prod. Econ. 2009, 120, 125–138. [Google Scholar] [CrossRef]

- Cagliano, R.; Caniato, F.; Spina, G. E-business strategy: How companies are shaping their supply chain through the Internet. Int. J. Oper. Prod. Manag. 2003, 23, 1142–1162. [Google Scholar] [CrossRef]

- Projogo, D.; Olhager, J. Supply chain integration and performance: The effects of long-term relationships. information technology and sharing and logistics integration. Int. J. Prod. Econ. 2012, 135, 514–522. [Google Scholar] [CrossRef]

- Frohlich, M.T.; Westbrook, R. Arcs of integration: An international study of supply chain strategies. J. Oper. Manag. 2001, 19, 185–200. [Google Scholar] [CrossRef]

- Simatupang, T.M.; Wright, A.C.; Sridharan, R. The knowledge of coordination for supply chain integration. Bus. Process Manag. J. 2002, 8, 289–308. [Google Scholar] [CrossRef]

- Kim, S.W. The effect of supply chain integration on the alignment between corporate competitive capability and supply chain operational capability. Int. J. Oper. Prod. Manag. 2006, 26, 1084–1107. [Google Scholar]

- Butler, D. Business Planning for New Ventures: A Guide for Start-Ups and New Innovations; Routledge: Abingdon, UK, 2014. [Google Scholar]

- Rahman, A.; Chattopadhyay, G. Long Term Warranty and After Sales Service: Concept, Policies and Cost Models; Springer: Berlin, Germany, 2015. [Google Scholar]

- Khriyenko, O. Customer Feedback System Evolution towards Semantically-Enhanced Systems; Institute for Systems and Technologies of Information, Control and Communication: Lisbon, Portugal, 2015; pp. 518–524. [Google Scholar]

- Handfield, R.B.; Nichols, E.L. Supply Chain Redesign: Transforming Supply Chains into Integrated Value Systems; FT Press: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Burrows, R.P. The Market-Driven Supply Chain: A Revolutionary Model for Sales and Operations Planning in the New On-Demand Economy; American Management Association: New York, NY, USA, 2012. [Google Scholar]

- Hines, T. Supply Chain Strategies: Customer-Driven and Customer-Focused; Routledge: Abingdon, UK, 2004. [Google Scholar]

- Aronow, S. The Gartner Supply Chain Top 25. Gartner Inc., 2017. Available online: https://www.gartner.com/technology/supply-chain/top25.jsp (accessed on 17 March 2018).

- Bhushan, A.; Zanwar, A.; Jain, N.; Rao, P.H. Technological Integration and Sustainable Initiatives to bring in Efficiency in Supply Chain in Indian Multi-Brand Retail. J. Supply Chain Manag. Syst. 2017, 6, 51–60. [Google Scholar]

- Piya, S.; Shamsuzzoha, A.; Khadem, M.; Al-kindi, M. Supply Chain Complexity Drivers and Solution Methods. Int. J. Supply Chain Manag. 2017, 6, 43–50. [Google Scholar]

- D’Amours, S.; Rönnqvist, M.; Weintraub, A. Using operational research for supply chain planning in the forest products industry. Inf. Syst. Oper. Res. 2008, 46, 265–281. [Google Scholar] [CrossRef]

- Simatupang, T.M.; Sridharan, R. A benchmarking scheme for supply chain collaboration. Benchmark. Int. J. 2004, 11, 9–30. [Google Scholar] [CrossRef]

- Panayides, P.M.; Venus Lun, Y.H. The impact of trust on innovativeness and supply chain performance. Int. J. Prod. Econ. 2009, 122, 35–46. [Google Scholar] [CrossRef]

- Monczka, R.M.; Handfield, R.B.; Giunipero, L.C.; Patterson, J.L. Purchasing and Supply Chain Management, 6th ed.; Greenwood Avenue North: Shoreline, WA, USA, 2015. [Google Scholar]

- Li, S. An Integrated Model for Supply Chain Management Practice, Performance and Competitive Advantage. In Manufacturing Management; The University of Toledo: Toledo, OH, USA, 2002. [Google Scholar]

| Name of the Journal | No. of Articles |

|---|---|

| Academy of Management Journal | 1 |

| Business Process Management Journal | 1 |

| Computers in Industry | 1 |

| European Journal of Operational Research | 1 |

| Information and Management | 3 |

| Information Systems and e-Business Management | 1 |

| International Journal of Operations and Production Management | 2 |

| International Journal of Physical Distribution and Logistics Management | 2 |

| International Journal of Production Economics | 4 |

| International Journal of Production Research | 1 |

| Internet Research: Electronic Networking Applications and Policy | 1 |

| Journal of Operations Management | 2 |

| Journal of Research in Interactive Marketing | 1 |

| Journal of Supply Chain Management | 1 |

| Management Research News | 1 |

| MIS Quarterly | 1 |

| Production Planning and Control | 1 |

| Supply Chain Management Review | 2 |

| Supply Chain Management: An International Journal | 3 |

| The International Journal of Logistics Management | 1 |

| Transfusion | 1 |

| Total | 31 |

| Author(s) | Year | Method | Multi-Criteria Decision Sets | Ref. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Suppliers’ End | Customers’ End | ||||||||||||||

| Production Stability | Reduced Lead Time | Reduced Inventory | Forecast Accuracy | Distribution Cost | Cost/Profit | New Product | Service Level | Quality | Flexibility | On-Time Delivery | Price/Satisfaction | ||||

| S&OP | |||||||||||||||

| Ivert et al. | 2014 | Survey | √ | √ | √ | [75] | |||||||||

| Godsell et al. | 2010 | Case Study | √ | √ | √ | [76] | |||||||||

| Mellen et al. | 2010 | Longitude Study | √ | √ | √ | √ | √ | [77] | |||||||

| Chae | 2009 | Review | √ | √ | √ | √ | [78] | ||||||||

| Singh | 2010 | Review | √ | √ | √ | [79] | |||||||||

| Thome et al. | 2014 | Survey | √ | √ | √ | [80] | |||||||||

| Paiva | 2010 | Survey | √ | √ | [81] | ||||||||||

| Olhager | 2010 | Case Study | √ | √ | [82] | ||||||||||

| Goh and Eldridge | 2015 | Case Study | √ | √ | √ | [83] | |||||||||

| Keal and Hebert | 2010 | Survey | √ | √ | √ | √ | [84] | ||||||||

| SCM | |||||||||||||||

| Koh et al. | 2006 | Case Study and Interview | √ | √ | √ | [85] | |||||||||

| Bose et al. | 2008 | Case Study | √ | √ | √ | [86] | |||||||||

| McLearn et al. | 2002 | Literature Review | √ | √ | √ | √ | √ | √ | [87] | ||||||

| Hult et al. | 2004 | Questionnaire Survey | √ | √ | √ | √ | √ | [88] | |||||||

| Feng et al. | 2008 | Experimental | √ | √ | √ | [89] | |||||||||

| Leuschner et al. | 2013 | Survey | √ | √ | √ | √ | √ | [90] | |||||||

| Bagchi and S-Larsen | 2005 | Survey | √ | √ | √ | [91] | |||||||||

| Boon-Itt and Paul | 2006 | Survey | √ | √ | √ | √ | √ | [92] | |||||||

| Quesada et al. | 2008 | Survey | √ | √ | √ | √ | [93] | ||||||||

| Wong et al. | 2011 | Questionnaire Survey | √ | √ | √ | √ | √ | [94] | |||||||

| Author(s) | Year | Method | Enablers | Key Variables | Key Entities | IS Example | Ref. |

|---|---|---|---|---|---|---|---|

| Koh et al. | 2006 | Case study and Interview | IT | Financial control Supply planning Demand planning | Supply chain partners | Enterprise Resource Planning (ERP) | [85] |

| Bose et al. | 2008 | Case study | IT | Information flow Physical operations | Supply chain partners, Environment | ERP | [86] |

| McLearn et al. | 2002 | Literature review | ICT | Market intelligence Information flow Physical operations | Supply chain partners, Other partners | Electronic Data Interchange (EDI), Business to Business (B2B), Business to Customer (B2C), ERP | [87] |

| Rai et al. | 2006 | Questionnaire survey | IT | IT infrastructure SC processes Demand predictability Firm size Operational excellence | Supply chain partners Customers Competitors | Web-enabled SC | [126] |

| Lin | 2014 | Field survey | Socialization | Partnership quality Communication quality Trust and commitment | Supply chain partners | e-Business | [127] |

| Plank and Hooker | 2014 | Literature review | IS | Customers’ replay Interactive marketing | Partners in the supply chain | B2B, B2C | [128] |

| Gunasekaran and Ngai | 2004 | Literature survey | ICT | Competitors Customers Technology and Marketing | Supply chain partners | EDI, B2B, Web | [129] |

| Iyer et al. | 2009 | Review | IS | Financial, market and operational performance Product turbulence Demand unpredictability | Supply chain partners Business environment | B2B | [130] |

| Li et al. | 2009 | Questionnaire survey | IT | IT implementation Supply chain performance | Supply chain partners | Information Technology (IT) Tools | [131] |

| Cagliano et al. | 2003 | Survey | IT | Competitive Strategy Supply and Demand integration | Supply chain partners | Internet-Tools | [132] |

| Prajogo and Olhager | 2012 | Questionnaire survey | IT | Information flow Material flow Supplier relationship Operational performance | Supply chain partners | IT Tools | [133] |

| Frohlich and Westbrook | 2001 | Questionnaire survey | IT | Supply chain strategies Operational performance Supplier-customer integration | Manufacturer Supplier Customer | EDI | [134] |

| Simatupang et al. | 2002 | Review | IS | Logistics sync Collective learning Market globalization Technological breakthrough | Supply chain partners | IT Tools | [135] |

| Kim | 2006 | Questionnaire Survey | Capabilities | Interactive relationship Integrations Performances | Internal and external SC entities | Nation-wide information network | [136] |

| Issues | Factors | Starting Annotations ⁺ and Findings ‡ | Ref. |

|---|---|---|---|

| Integration | Supplier–customer integration Supply–Demand integration Internal and external integration | Integration level of supplier impacts the S&OP’s success ‡ Functional areas of organizations need integration ⁺ S&OP implementation provides better SC performance ‡ Integration of SC with ERP systems enhances performance ⁺ Integration need between customer, supplier, and other partners ⁺ Integrated plan positively related to firm’s performances ‡ IT provides higher order of supplier integration ‡ Sociotechnical factors influence SC integration ⁺ S&OP integrates operations between businesses and customers ‡ The level of customer–supplier integration highly depends on IT ‡ Higher supplier–customer integration gives higher performance ‡ | [80] [81] [83] [85] [86] [87] [126] [127] [128] [132] [134] |

| Performance | Financial performance Market performance Manufacturing performance Operational excellence Operational performance | S&OP facilitates stable production performance ‡ Manufacturing performance vitally depends upon S&OP ‡ Firms can get better SC performance through S&OP ‡ Integrated plan enhances financial, operational, and market performance ‡ IT integration increases firm’s operational excellence and financial gains ‡ | [75] [80] [83] [85] [86] [126] |

| Communication | Communication quality Collective learning | Collective learning is a mode for coordination in SC ‡ Communication quality significantly impacts SC integration ‡ | [127] [135] |

| Competition | Competitive Strategy Competitors | Increasing competitions simulates collaboration in supply chain ⁺ Competitive capability needs to align with SC capability ⁺ | [135] [136] |

| Customer | Customers’ demand Customers’ preferences Customers’ replay Customers’ satisfaction | New product and customer service level is critical for S&OP ‡ Customer service is a vital metrics for SC performance ‡ Market dynamics impacts S&OP and manufacturing performance ‡ A robust S&OP process can lead to high customer satisfaction ‡ | [75] [78] [80] [84] |

| Demand | Demand planning Demand predictability Demand unpredictability Product turbulence | Fast-track S&OP initiatives make easier the demand forecasting ‡ Forecast accuracy is one of the vital factors for S&OP’s success ‡ IT-enabled SC integration provides improved demand planning ‡ Product turbulence and demand unpredictability negatively impact firm’s operational, market, and financial performance ‡ It is critically significant to manage demand uncertainty actively ‡ | [77] [79] [126] [130] |

| Information and Knowledge | Information flow Information sharing Knowledge coordination | Information sharing is a mode for coordination in SC ‡ Information sharing highly influences logistics coordination ‡ Knowledge coordination positively impact SC performance ‡ Knowledge sharing impacts SC integration ‡ | [127] [133] [135] |

| Information Systems | IT implementation IT infrastructure IT Tools | ERP helps for SC integration ‡ IT tools helps SCM collaboration ‡ Digital platform plays a critical role in SC ⁺ Sophisticated software are used in S&OP to B2B and B2C process integration ‡ IT largely supports the integration of SCM ‡ SC integration highly depends upon IT implementation ‡ IT Tools capable of logistics coordination ‡ | [86] [87] [126] [128] [129] [131] [132] [133] |

| Changes | Market globalization Technological breakthrough | S&OP is much vital in change process ‡ Country’s development status needs to be considered in S&OP ‡ S&OP can significantly assist in the change process through the organization ‡ Companies are changing their operation strategies to increase flexibility and responsiveness ⁺ Economy is becoming increasingly globalized and competitive ⁺ Market globalization, product diversity, and technological breakthroughs stimulate independent firms to cooperate in a supply chain ⁺ | [76] [80] [84] [129] [131] [135] |

| Logistics | Logistics sync Material flow Physical operations | S&OP implementation helps decrease the inventory level ‡ Logistics integration highly depends upon IT integration ‡ Material flow between SC partners enhance their operational performance ‡ Logistics sync a mode for coordination in SC ‡ | [83] [133] [135] |

| Market and Marketing | Interactive marketing Interactive relationship Market intelligence | Firms need to be strategically aligned to market requirements ⁺ Combined SCM increases market intelligence ‡ Interactive marketing tools are uniquely important B2B marketing ‡ | [82] [87] [128] |

| Partnership | Partnership quality | Strategic partnership is evolving ⁺ Digital platform plays a critical role in partnership ⁺ Sociotechnical factors influence SC integration ⁺ Partnership quality mediates the relationship within SC integration ‡ | [87] [126] [127] |

| Supply chain | Supply planning Supplier relationship Supply chain partners Supply chain performance Supply chain strategies | Supply uncertainty influences production performance ‡ S&OP integration with supply partners impacts production ‡ Firms are increasingly depending on strategies (CODP) to do better Supply chain integration increases SC performance ⁺ | [75] [80] [82] [133] |

| Others | Firm’s size Environment Business environment Joint planning Trust and commitment | The size of the firm impacts S&OP process and productions ‡ Integration of SCM and ERP systems results in green environment ‡ SCM need to focus on joint planning ⁺ SC integration enables trust and commitment among partners ‡ | [80] [86] [87] [127] |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rokonuzzaman, M. The Integration of Extended Supply Chain with Sales and Operation Planning: A Conceptual Framework. Logistics 2018, 2, 8. https://doi.org/10.3390/logistics2020008

Rokonuzzaman M. The Integration of Extended Supply Chain with Sales and Operation Planning: A Conceptual Framework. Logistics. 2018; 2(2):8. https://doi.org/10.3390/logistics2020008

Chicago/Turabian StyleRokonuzzaman, Md. 2018. "The Integration of Extended Supply Chain with Sales and Operation Planning: A Conceptual Framework" Logistics 2, no. 2: 8. https://doi.org/10.3390/logistics2020008

APA StyleRokonuzzaman, M. (2018). The Integration of Extended Supply Chain with Sales and Operation Planning: A Conceptual Framework. Logistics, 2(2), 8. https://doi.org/10.3390/logistics2020008