Abstract

While materials count for a considerable amount of construction costs, the way materials are managed seems to be improvised rather than approached methodically. This study investigates the practice of novel techniques used to manage materials in the construction industry. Techniques that have already proven themselves to be efficient ways to manage the production pace within the industry include the pull system, Just-In-Time, Kitting and off-site fabrication. These are explained and assessed in the context of the French construction industry through an exploratory study, supported by a questionnaire completed by contractors. The results reveal that a clear plan to manage materials on-site is lacking among the respondents, creating common inventory problems. This research provides evidence to support the central role played by an efficient management of material flow on-site. It also highlights the obstacles that hinder the adoption of innovative techniques, such as sub-contractor coordination.

1. Introduction

This study begins with the following observations: the realization of a building appears most of the time to be a strenuous process. Construction methods, trades, and processes have much in common (except in terms of security and the use of increasingly frequent tablet/mobile applications). One gets the impression that many problems are managed only after they appear, and that construction managers rely on improvisation more than they should [1].

Considering these observations, several actors are now trying to revolutionize the profession using all the modern means at their disposal [2]. In this process of modernization, we initially think of digital ultra-modern means, including the BIM (Building Information Modeling) [3]. The BIM is a 3D “intelligent” digital projection where each element of the structure is not just a solid image in 3D, but an object with many attributed characteristics (materials, dimensions, etc.).

In addition to the BIM, there are other ways to innovate the construction industry. For instance, techniques from other industries (such as the food industry or the car dealer industry…) could be adopted to optimize the supply chain [4]. In this respect, we could apply techniques such as “Just-in-time”, “Kitting”, and “pull planning” to the construction industry. This work stems from the interest in replicating those techniques in the construction field.

With this idea in mind, we believe it is important to first understand the needs of construction managers in terms of innovative tools for organizing the construction site. Their experience/feedback could be leveraged to draw a guide indicating the effectiveness of the current supply chain in construction while providing perspectives on potential improvements.

Materials Management

Materials Management refers to an optimal way of coordinating, planning, supplying, purchasing and storing construction materials, as well as providing quality control. The purpose of Materials Management is to ensure that the correct products are supplied exactly when they are needed: at the right time, at the right place, with the right quality, and at the right price. It consists of having perfect control over the flow of the products, which will allow an optimal functioning of the supply chain [5].

2. Motivation

This research was initiated following the findings of a recent study from McKinsey [6] that reported potential productivity improvement paths for the construction sector. According to this report, Procurement and Supply Chain Management could generate a potential productivity improvement from 7 to 8%.

Additional studies [7] suggest that the typical problems of construction logistics are as follows: missing or delayed deliveries, no direct unloading of transporters, ineffective management of storage space, installation of wrong and damaged material, and no or insufficient separation of emerging waste. Additionally, material flow is challenging since it involves different trades working in parallel and thus, is subjected to a high potential for optimization [8].

3. Explanation of the Issues at Hand

3.1. Pull System

The concept behind Pull Planning (or Pull System) is to produce only the amount of goods that are expected to be sold while paying attention to avoid any stock-outs or overproduction [9]. In doing so, the demand forecast study needs to be as exact as possible.

Contrary to a Push System in which goods are produced and stocked before the client purchase, the Pull System is entirely dependent on the demand. One good example of a Pull System can be found within the car dealer industry.

Car dealers usually have a minimal number of cars in stock. Thus, when we want to buy a car that is not the “best seller”, chances are low that we find one in the garage at the nearest car dealership. It usually takes a couple of days for the car dealer to contact the automaker to request one.

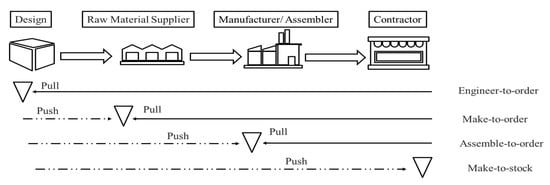

There exist many levels at which Pull Planning could be implemented. Figure 1 presents those levels.

Figure 1.

Supply chain strategies in the construction sector (adapted from: [10]).

- 1-

- The Push System corresponds to the “Make-to-stock” (MTS) system, which consists of producing according to forecasts.

- -

- Pros: the goods are stored and are immediately available for the client (there is no waiting time for the client).

- -

- Cons: there are sometimes significant storage costs and remaining unsold products.

- 2-

- The first level of the “Pull System” corresponds to the “Assemble-to-order” (ATO) system, which consists of assembling the final product on client demand. Intermediate parts are, however, produced according to forecasts. The car dealer industry follows this system.

- -

- Pros: there is less stock and the possibility of customized products.

- -

- Cons: it requires a fast reaction to the demand and a short final assembly time.

- 3-

- The second level of the Pull System corresponds to the Make-to-order (MTO) system, which consists of starting to produce the whole product (intermediate parts + final assembly) on client demand. This configuration is adapted for customized products such as windows or doors.

- -

- Pros: only raw materials are available in stock.

- -

- Cons: this requires an even faster response time to the client’s demand. The production time needs to be as low as possible.

- 4-

- The last level of the Pull System corresponds to the Engineer-to-order (ETO) system. In the ETO system, the product is designed and produced on client demand. As an example, the production of 3D modules of construction parts (such as bathrooms or kitchens) is an example of an ETO product. If we consider “construction” at the project level, it could be considered as an ETO system since every project is somewhat different (localization, characteristics, engineering, design, stakeholders, etc.).

3.2. Just-In-Time

JIT (Just-In-Time) is a method for organizing and monitoring production. It is well known within the manufacturing sector and aims at reducing inventory and Work In Progress (WIP). This method is mostly used to manage supply and consists of ordering the raw materials only when they are to be used immediately. Accordingly, one purpose of this method is to cut down on intermediate stocks. The Just-In-Time method is based on a Pull System. Thus, good quality coordination between the manufacturer and the client, on one hand, and the manufacturer and the supplier, on the other, is required.

Additionally, for a successful implementation of JIT, the following is required: (1) a relatively precise forecast study of the needs in terms of production; (2) a reliable transportation and delivery network, and (3) a strict management of the demands.

3.3. Kitting

The Kitting is a process within which related but separate parts are gathered, packed, and delivered as one package or unit. In other words, it is a method of supply that consists of packing and delivering together parts that are meant to be assembled together. From a logistic perspective, the Kitting method is expected to make the organization within the site easier and is expected to provide the grounds for the smooth implementation of the Pull System by reducing the quantity of the stocks.

Many studies have investigated the effect of logistics on construction performance [11,12]. For instance, the study of Skjelbred, S. et al. in 2015 compared different approaches to construction site logistics [13]. The research analyzed four case studies where the material supply systems were different. Kitting was among those systems.

3.4. Off-Site Fabrication

This method consists of manufacturing some parts of the final product off-site (for example, walls, stairs, etc.). This technique minimizes the stocks on-site. While off-site fabrication usually refers to modular construction in which entire parts (3D elements) are built off-site and brought afterwards to the site to be directly assembled, it also refers to prefabrication (2D elements).

4. Research Objectives

Current research shows that construction can be considered as a kind of production [14]. Logistics, however, is not considered the primary concern or interest of construction managers [15], especially since the cost of materials constitutes a large proportion of construction costs.

Construction logistics have captivated the interest of several researchers around the world [16,17,18]. While several studies show the limitations of current logistics systems in construction [13], a comprehensive exploratory study on procurement issues has not yet been done in detail. The absence of these studies makes it difficult to rethink current logistics practices in construction. Thus, the purpose of this research is to provide scientific and professional communities with practical insights into how to improve construction logistics.

5. Research Methodology

To meet this objective, we followed an exploratory research method that aims at clarifying a problem that has been defined. A priori, it appears that exploratory research is used to produce knowledge about unknown phenomena. The difference with “descriptive research” is that the latter is used for known phenomena or to deepen the understanding of a given concept. In our case, the exploratory study is backed by a survey that aims at evaluating the awareness of contractors regarding the material management practices cited above. The questionnaire was developed and sent to construction managers and work directors (work directors are one hierarchical level above construction managers: they manage several construction managers). C-levels of construction companies were contacted and approved the survey before sending it to construction managers and work directors.

The questionnaire was divided as follows:

5.1. Population’s Characteristics

The first part of the research consisted of collecting information on people responding to our questionnaire (job title, work experience, nature of the site, size of the building, etc.). To keep the respondent’s privacy and to increase the response rate, the questionnaires were anonymous.

5.2. Materials Management in Construction

5.2.1. Suppliers

The suppliers are crucial for the implementation of an optimal logistics system. Therefore, it is important to assess their reliability and their reactivity.

Additionally, the surveyed construction managers were asked if they were familiar with the notion of Kitting.

5.2.2. Transport and Delivery

In this section, we investigated whether the construction site had characteristics (due to the nature of the different actors involved in it, or the location) which may have obstructed the implementation of the Kitting and the JIT methods. For instance, a construction site that is located in the heart of Paris will be more challenging to deliver than another construction site located in a less populated region.

5.2.3. On-Site Inventory

Most construction managers recognize that objects are commonly lost and broken on site, and that this can cause serious problems. Additionally, if there is not enough room for storage within the site (if the site is at the heart of a city for instance), many logistic challenges can arise. In this study, we used the managers’ responses to justify the necessity of developing/using new methods for managing the stock within the site.

5.2.4. Prefabrication

Our questionnaire included questions about the managers’ perception of prefabrication. We were interested in knowing if most managers approved of this technique, and most importantly why they did or did not approve of it.

5.2.5. Subcontracting

If a method is to be implemented, the feedback of all actors involved in the process should be considered. In materials management, subcontractors are concerned by the changes we intend to implement. Thus, it is essential for us to anticipate their needs/concerns before initiating any change.

6. Results and Discussion

6.1. Population’s Characteristics

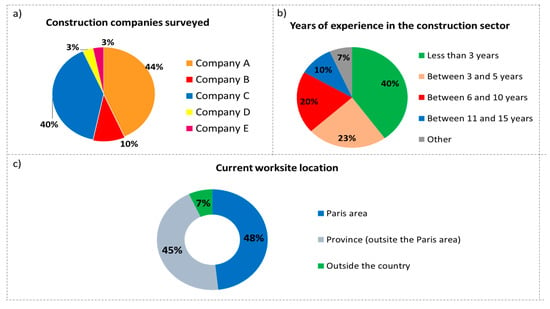

The study concerned a sample of 30 respondents from five different construction companies (Figure 2). We divided the current worksite location into three parts: Paris area, Province (outside the Paris area) and outside France. Figure 3 shows the “Paris Area”. This area is known for very heavy traffic.

Figure 2.

Populations’ characteristics: sample profile.

Figure 3.

“Paris area” surrounded by a red circle. (Adapted from: GoogleMaps).

6.2. Materials Management in Construction

6.2.1. Suppliers

Figure 4a: The definition of “Kitting” was provided to the respondents in case they did not know what the term meant. The suggested definition is:

The Kitting is a process within which related but separate parts are gathered, packed, and delivered as one package or unit. In other words, it is a method of supply that consists of packing and delivering together parts that are meant to be assembled together.

Figure 4.

Questions for contractors related to suppliers’ management.

The results of our survey suggest that almost half of participants were not familiar with the term Kitting. Some respondents recognized that they were using this technique (whether they called it Kitting or not). Some of the respondents, who were familiar with the Kitting concept, asked if such a system was cost effective.

Implementing the Kitting method requires a considerable amount of initial planning, particularly with the suppliers who are supposed to demonstrate their ability to supply goods in packages or Kits. Thus, asking the participants about their suppliers’ responsiveness becomes important to assess the propensity of the suppliers to implement Kitting.

Figure 4b: Few construction managers expressed their disappointment with the quality of their suppliers or with responsiveness. Such findings suggest that the relationship between the construction managers and the suppliers is good on average and that if asked to implement Kitting, the suppliers may be willing to do some additional work to sustain a good relationship.

In general, construction firms have a network of privileged suppliers with whom they sign long-term contracts, called framework agreements. This type of contract represents reciprocal commitment from both sides.

Figure 4c: It makes sense that these privileged suppliers (with framework agreements) would be even more willing to implement Kitting if the virtues of this technique are well founded.

Figure 4d: Construction managers are more satisfied with the contracted suppliers (with framework agreements) than with normal suppliers with whom they do not have partnerships. Thus, the ideal—for implementing Kitting and innovative materials management systems—is to start first with the contracted suppliers who are expected to demonstrate less resistance.

6.2.2. Transport and Delivery

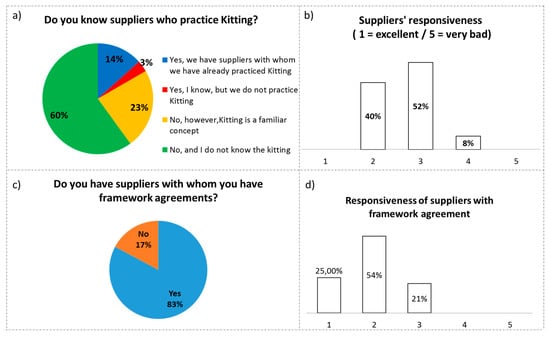

The application of Pull systems depends on the premise that delivery delay risks are mitigated. Thus, it is important to assess the frequency of delays.

Figure 5a: The responses suggest that delays in delivery are common within the surveyed sites. More specifically, around half the participants stated that they got used to delays. This indicates the necessity of further investigations into recurrent delays, so as to bring about viable solutions.

Figure 5.

Questions for contractors related to transport and delivery.

Figure 5b: Most sites located in the Paris region suffer from difficulties related to the delivery. It seems that this difficulty is characteristic of the Paris region in which heavy traffic, lack of space, and other logistical problems are predominant. We hypothesize that the high rate of delays in delivery found in Figure 5a is correlated with the site location: sites located in Paris are more susceptible to high rates of delay because of accessibility challenges.

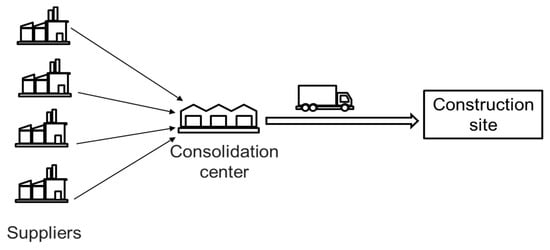

Figure 5c: We noticed that delays were less common outside the Paris region. Since Kitting heavily depends on the ability of the supplier to avoid delays, it is fair to presume that caution should be taken in implementing Kitting in congested locations. The Kitting system relies on the reduction of the number of deliveries as shown in Figure 6, thus reducing work delay risks.

Figure 6.

Kitting system based on a consolidation center before final delivery to the worksite.

Figure 5d: Of 3/4 of the surveyed people, other stakeholders than the suppliers intervened in the delivery process. It is important then to further investigate this proposition in future research projects.

6.2.3. On-Site Inventory

The implementation of the techniques mentioned earlier (Kitting and Just-In-Time) is contingent on one’s ability to minimize intermediate stocks.

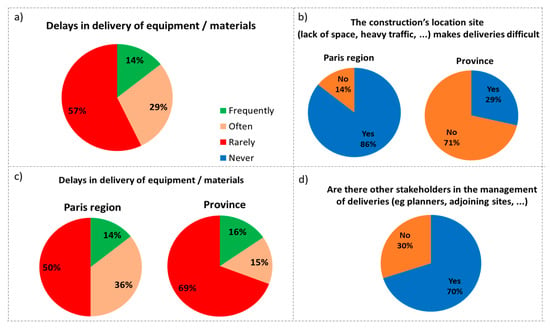

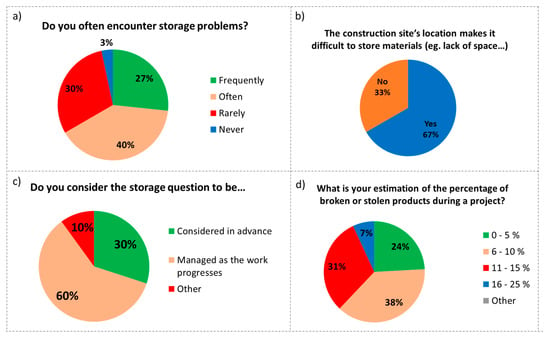

Figure 7a: The answers to this question demonstrate the need for new methods for organizing storage facilities within the site. Indeed, about 67% of the participants declared that they encountered storage problems on a regular basis.

Figure 7.

Questions for contractors related to on-site inventory.

Figure 7b: two-thirds of the participants suggested that the constructions site’s location made it difficult to store materials. This finding strengthens the premise that the storage issue is important and should be managed.

Figure 7c: Managing the stock is among the many tasks that a construction manager is supposed to handle. According to the survey answers, only 30% of the participants believed that the issue of storage was settled during the planning phase. The rest of the participants managed their stock throughout the whole construction period.

Figure 7d: The answers to this question prove that the problem of broken/stolen products is relatively serious. The problem of storage is correlated with the number of broken/stolen objects according to the data; having a minimum intermediate stock (security stock) as a buffer may partially mitigate this problem.

6.2.4. Prefabrication

The benefits of prefabrication have already been established [19]: this technique allows for the manufacturing of parts in a safe environment (without any risk of bad weather for instance), to minimize the stock within the site, to better manage/recycle the waste, and more importantly to minimize the workload (and the Work-In-Progress: WIP) within the site. Indeed, the only tasks left for the worker on site are to receive and to assemble the prefabricated parts.

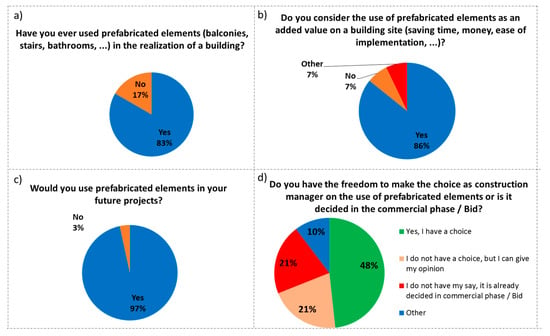

Figure 8a: The figure shows that prefabrication is common within the profession.

Figure 8.

Questions for contractors related to prefabrication.

The following question sheds light on the managers’ satisfaction with this method.

Figure 8b: The results show that construction managers are widely in favor of prefabrication. According to those surveyed, the quality of prefabricated items is most often irreproachable. Few managers seem to disapprove of prefabricated materials, but still mention that some economies of scale can be possible using this technique if the number of prefabricated items is important.

Figure 8c: Almost the entire surveyed population was in favor of the use of prefabrication in the future.

Figure 8d: The use of prefabrication was widely praised by the construction managers, however, not all of them seemed to have a say in the decision to use them or not. This result is particularly important to investigate in future research, so as to determine a clear map of the decision-making process related to the use of such a system.

6.2.5. Subcontracting

The main contractor relies on subcontracting for different reasons: lack of expertise in a certain construction trade (exterior carpentry, floor tile, etc.), not enough time to manage a certain trade in detail, or in some cases, for cost and quality reasons. The selected subcontractor is responsible for achieving the subcontracted work under the main contractor’s supervision.

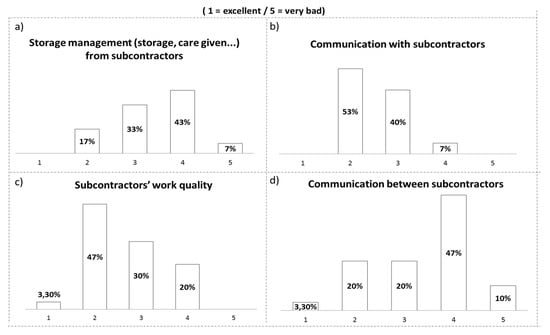

Figure 9a: Those surveyed felt that storage management from subcontractors was not good on average. This finding strengthens the idea that the storage issue is an important one and should be managed with high priority.

Figure 9.

Questions for contractors related to subcontracting practice.

Figure 9b: The quality of communication with subcontractors seemed decent overall, indicating that mutual collaboration is possible to solve the problem of storage.

Figure 9c: On average, the quality of subcontractors’ work is perceived as correct.

Figure 9d: If the quality of communication between the construction manager and the subcontractors is perceived as good, that among subcontractors is assessed as bad. This finding brings challenges to our attempt to implement Kitting. Indeed, Kitting requires a sustainable collaboration among the subcontractors who are supposed to work on the delivered kits (or packages) at the same time.

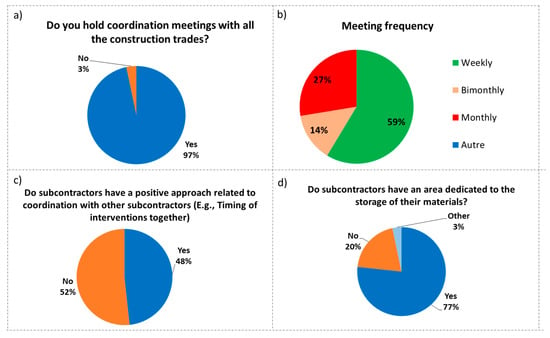

Figure 10a: With few exceptions, coordination meetings involving all the interested actors were regularly held within the site. It is important to sustain this habit especially when communication among the subcontractors is perceived as bad. Coordination meetings provide subcontractors with more opportunities to interact. On the other hand, the efficiency of those coordination meetings is questionable due to the results in Figure 9c.

Figure 10.

Questions for contractors related to subcontractors’ coordination.

Figure 10b: Most of the coordination meetings were held on a weekly basis. Construction managers argued that the frequency of those meetings should be adapted to correspond with the pace of work.

Figure 10c: This figure strengthens the statement that communication among the subcontractors requires improvement. Even more, it suggests that subcontractors do not use a positive approach to collaborate with their peers (according to the construction managers). One of the proposed solutions in literature is the use of the “Last Planner System®” (LPS) introduced by [1]. The Last Planner System® is based on principles of leaning production to minimize the waste in a system through assignment-level planning or detailed look-ahead scheduling [20]. It is comprised of four elements: a master plan, a phase plan, a look ahead plan, and a weekly work plan [21]. The use of LPS coupled with Kitting could be a solution to the lack of communication between subcontractors. In their research, Shokri, S. et al. suggested work on process interfaces (including subcontractors’ management) to optimize the flow of construction [22].

Figure 10d: In general, subcontractors have their own private space within the site to store their items. Thus, it seems useful to sensitize and to make them involved in the overall management of the stock on site.

7. Conclusions

The responses highlighted the problem of on-site inventory. Inventory problems are common and are illustrated by the common occurrence of broken/stolen products and by unused products. Construction managers therefore deplore having to manage this issue as work progresses on-site when those problems should be addressed and well managed upstream. These problems are more common in the Paris region because of the difficulties imposed by the location, but they are also very present in the province (outside the Paris region in France). Despite a dedicated storage area, construction managers overwhelmingly consider their subcontractors to be poorly managing their stocks.

The establishment of well-designed materials management techniques could help to overcome these storage problems.

Suppliers’ responsiveness, and those with whom framework agreements have been signed are well graded according to the survey. Therefore, this type of supplier is more appropriate for the establishment of a JIT (Just-In-Time) system for materials management. Kitting is a concept still unknown to most contractors, which means materials management techniques are not the priority of construction companies. On the other hand, the use of efficient techniques has been very well received as demonstrated by the use of prefabricated elements. With communication with subcontractors being rather good, the French construction industry is in a favorable context to explain and bring new approaches to various construction stakeholders to adopt novel techniques.

However, the application of Kitting could be jeopardized in particular because of the many delays in the delivery of materials. In addition, poor communication between contractors is an obstacle to the necessary coordination in a Kitting system. Finally, the idea to diminish stocks by setting up a “predefined kits delivery time” may increase costs.

This exploratory research identified a set of research items that need more investigation:

- -

- The current challenges of on-site inventory management of construction sites.

- -

- The link between the use of prefabrication and delays.

- -

- The identification of cost allocations related to the Kitting system.

- -

- The investigation of the decision-making process related to the use of materials management systems during design and construction phases.

- -

- The link between the subcontracting practice in construction and delays.

- -

- The creation of the matrix of delay frequency and severity as a function of product typologies in construction.

Acknowledgments

The authors kindly thank M. Thibaut SIMONEK for his contribution. The authors also thank the companies interviewed for their involvement. Our special recognition to the editor and the two anonymous reviewers who helped us to improve our paper significantly with their valuable comments and feedback.

Author Contributions

The authors contributed equally to this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ballard, G. The Last Planner System of Production Control. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2000. [Google Scholar]

- Bock, T. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- Jung, Y.; Joo, M. Building information modelling (BIM) framework for practical implementation. Autom. Constr. 2011, 20, 126–133. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Technical Report; CIFE: Stanford, CA, USA, 1992; pp. 37–62. [Google Scholar]

- Augiseau, V.; Barles, S. Studying construction materials flows and stock: A review. Resour. Conserv. Recycl. 2017, 123, 153–164. [Google Scholar] [CrossRef]

- Barbosa, F.; Woetzel, J.; Mischke, J.; Ribeirinho, M.J.; Sridhar, M.; Parsons, M.; Bertram, N.; Brown, S. Reinventing Construction: A Route to Higher Productivity, 2017. Available online: https://www.mckinsey.com/~/media/McKinsey/Industries/Capital%20Projects%20and%20Infrastructure/Our%20Insights/Reinventing%20construction%20through%20a%20productivity%20revolution/MGI-Reinventing-construction-A-route-to-higher-productivity-Full-report.ashx (accessed on 5 March 2018).

- Lange, S.; Schilling, D. Reasons for an Optimized Construction Logistics. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, At Perth, Australia, 29–31 July 2015; IGLC 2015 Organizing Committee: Perth, Australia, 2015; pp. 733–742. [Google Scholar]

- Safa, M.; Shahi, A.; Haas, C.T.; Hipel, K.W. Supplier selection process in an integrated construction materials management model. Autom. Constr. 2014, 48, 64–73. [Google Scholar] [CrossRef]

- Galbraith, L.; Miller, W.A.; Greene, T.J. Pull system performance measures: A review of approaches for system design and control. Prod. Plan. Control 1991, 2, 24–35. [Google Scholar] [CrossRef]

- Hoekstra, S.; Romme, J. Integral Logistic Structures: Developing Customer-Oriented Goods Flow; Industrial Press Inc.: Norwalk, CT, USA, 1992. [Google Scholar]

- Albaloushi, H.; Skitmore, M. Supply Chain Management in The UAE Construction Industry. Int. J. Constr. Manag. 2008, 8, 53–71. [Google Scholar] [CrossRef]

- Rameezdeen, R.; Chileshe, N.; Hosseini, M.R.; Lehmann, S. A qualitative examination of major barriers in implementation of reverse logistics within the South Australian construction sector. Int. J. Constr. Manag. 2016, 16, 185–196. [Google Scholar] [CrossRef]

- Skjelbred, S.; Fossheim, M.E.; Drevland, F. Comparing Different Approaches to Site Organization and Logistics: Multiple Case Studies. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, At Perth, Australia, 29–31 July 2015; pp. 13–22. [Google Scholar]

- Koskela, L.; Rooke, J. The TFV theory of production: New developments. In Proceedings of the 15th Conference of the International Group for Lean Construction, Lansing, MI, USA, 18–20 July 2007; pp. 2–12. [Google Scholar]

- Dakhli, Z.; Lafhaj, Z. Efficient logistics enabled by smart solutions in tunneling. Undergr. Space 2017, 2, 227–233. [Google Scholar] [CrossRef]

- Bataglin, F.S.; Viana, D.D.; Formoso, C.T.; Bulhões, I.R. Application of Bim for Supporting Decisionmaking Related to Logistics in Prefabricated Building Systems. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 9–12 July 2017; pp. 71–78. [Google Scholar]

- Mossman, A. More than materials: Managing what’s needed to create value in construction. In Proceedings of the 2nd European Conference on Construction Logistics, Dortmund, UK, 8 May 2008; pp. 1–13. [Google Scholar]

- Sundquist, V.; Gadde, L.E.; Hulthén, K. Reorganizing construction logistics for improved performance. Constr. Manag. Econ. 2018, 36, 49–65. [Google Scholar] [CrossRef]

- Goulding, J.S.; Rahimian, F.P.; Arif, M.; Sharp, M.D. New offsite production and business models in construction: Priorities for the future research agenda. Archit. Eng. Des. Manag. 2014, 11, 163–184. [Google Scholar] [CrossRef]

- Issa, U.H. Implementation of lean construction techniques for minimizing the risks effect on project construction time. Alex. Eng. J. 2013, 52, 697–704. [Google Scholar] [CrossRef]

- Ballard, G.; Howell, G. Implementing Lean Construction: Stabilizing Work Flow; Lean Construction Institute: Arlington, VA, USA, 1994; pp. 101–110. [Google Scholar]

- Shokri, S.; Safa, M.; Haas, C.T.; Haas, R.C.G.; Maloney, K.; MacGillivray, S. Interface Management Model for Mega Capital Projects. In Proceedings of the Construction Research Congress 2012, West Lafayette, Indiana, 21–23 May 2012; ASCE Library: Reston, VA, USA, 2012; pp. 447–456. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).