Energy Density and Nutrient Contents of Selective Chinese New Year Snacks

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample and Sample Preparation

2.2. Reagents for Inductively Coupled Plasma-Mass Spectrometry (ICP-MS)

2.3. Reagents and Standard Solutions for Gas Chromatography-Mass Spectrometry (GC-MS)

2.4. Microwave-Assisted Acid Digestion for ICP-MS Pretreatment

2.5. Lipid Extraction

2.6. Determination of Fatty Acid Profile

2.7. GC-MS Analysis

2.8. ICP-MS Analysis

2.9. Method Validation and Statistical Analysis for Mineral Content Results

2.10. NIR Spectroscopy and Analysis

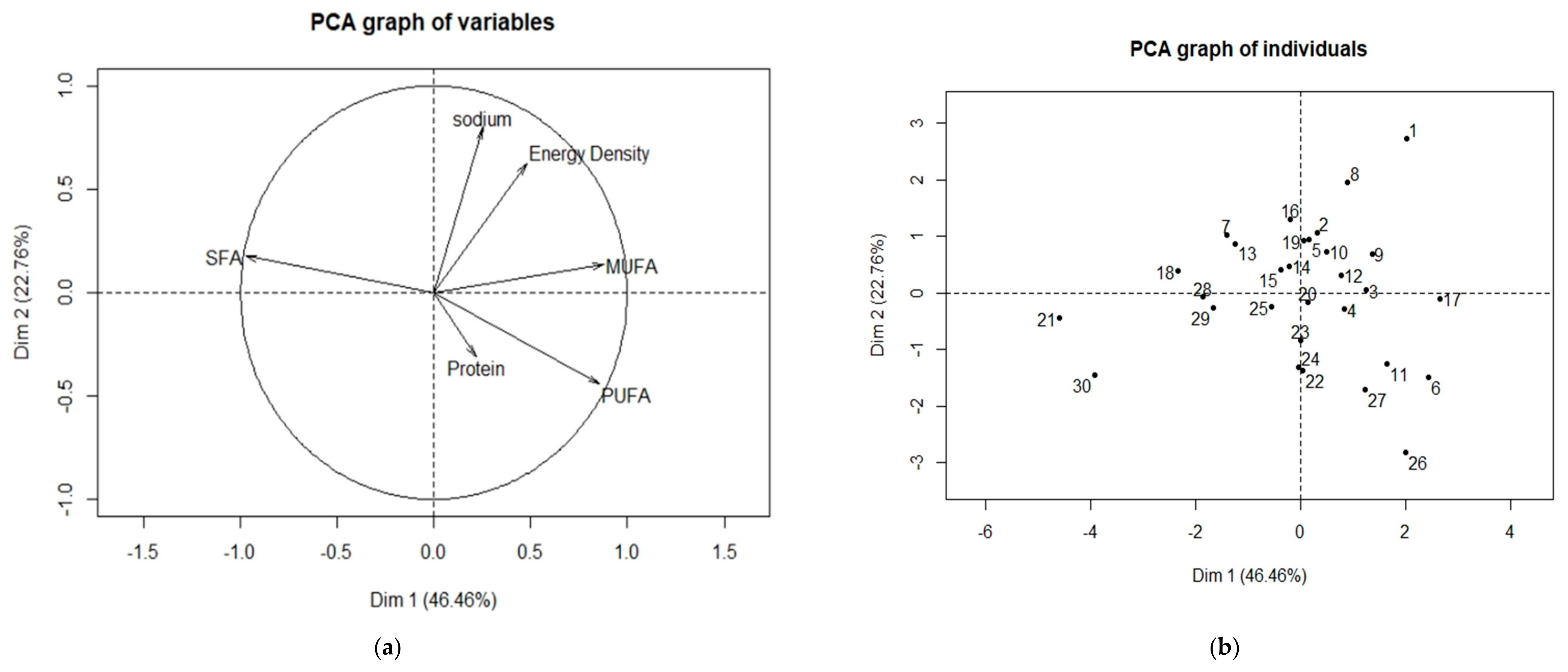

2.11. Principal Component Analysis (PCA)

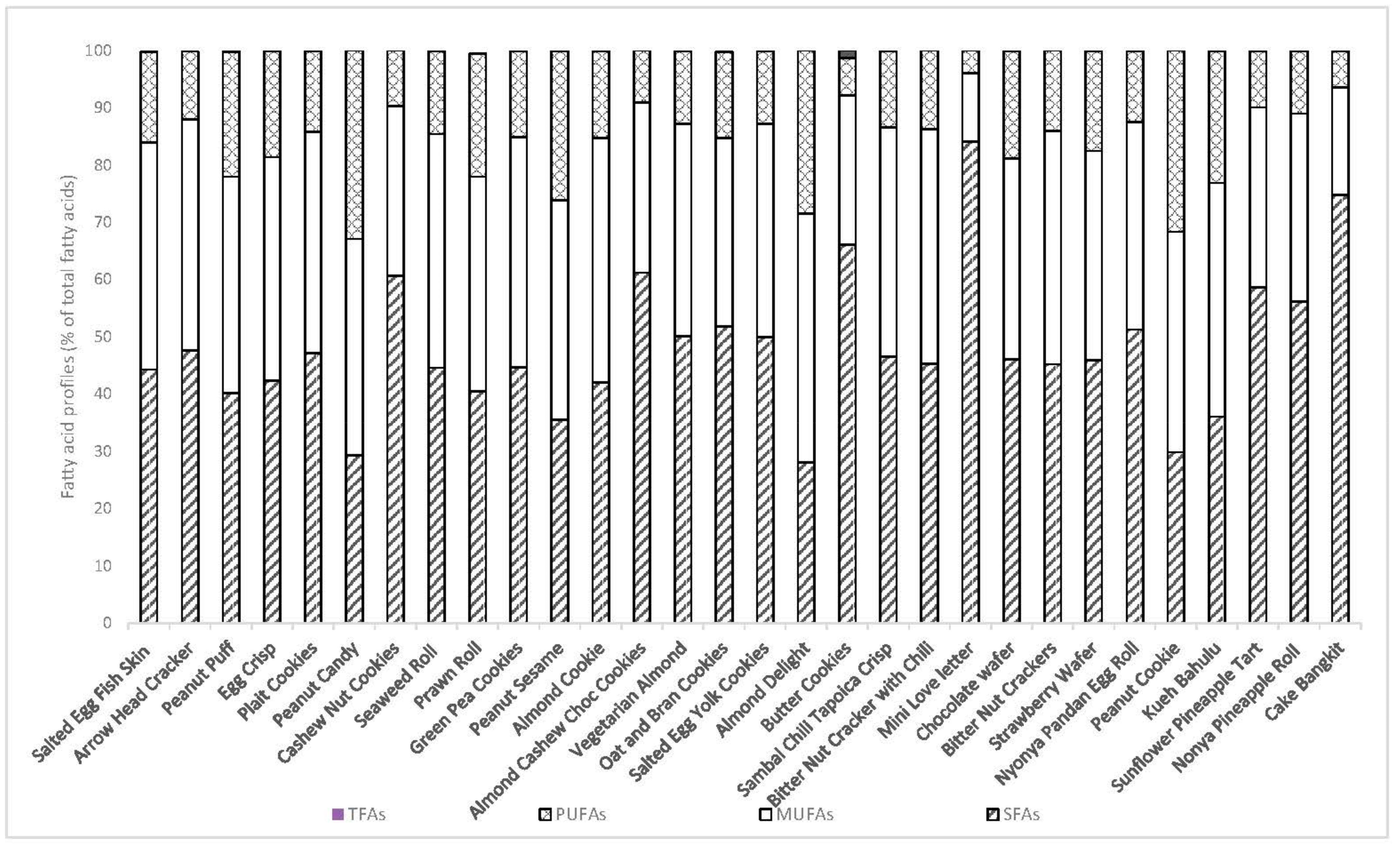

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Health Promotion Board, Singapore. Report of the National Nutrition Survey 2010. Available online: https://www.hpb.gov.sg/docs/default-source/pdf/nns-2010-report.pdf?sfvrsn=18e3f172_2 (accessed on 5 September 2019).

- Misra, A.; Singhal, N.; Sivakumar, B.; Bhagat, N.; Jaiswal, A.; Khurana, L. Nutrition transition in India: Secular trends in dietary intake and their relationship to diet-related non-communicable diseases. J. Diabetes 2011, 3, 278–292. [Google Scholar] [CrossRef] [PubMed]

- You, J.; Imai, K.S.; Gaiha, R. Declining Nutrient Intake in a Growing China: Does Household Heterogeneity Matter? World Dev. 2016, 77, 171–191. [Google Scholar] [CrossRef]

- Mills, S.R.; Wilcox, C.R.; Ibrahim, K.; Roberts, H.C. Can fortified foods and snacks increase the energy and protein intake of hospitalised older patients? A systematic review. J. Hum. Nutr. Diet. 2018, 31, 379–389. [Google Scholar] [CrossRef] [PubMed]

- Mozaffarian, D.; Fahimi, S.; Singh, G.M.; Micha, R.; Khatibzadeh, S.; Engell, R.E.; Lim, S.; Danaei, G.; Ezzati, M.; Powles, J. Global Sodium Consumption and Death from Cardiovascular Causes. N. Engl. J. Med. 2014, 371, 624–634. [Google Scholar] [CrossRef]

- Dahdouh, S.; Grande, F.; Espinosa, S.N.; Vincent, A.; Gibson, R.; Bailey, K.; King, J.; Rittenschober, D.; Charrondière, U.R. Development of the FAO/INFOODS/IZINCG Global Food Composition Database for Phytate. J. Food Compos. Anal. 2019, 78, 42–48. [Google Scholar] [CrossRef]

- Ferguson, E.L.; Watson, L.; Berger, J.; Chea, M.; Chittchang, U.; Fahmida, U.; Khov, K.; Kounnavong, S.; Le, B.M.; Rojroongwasinkul, N.; et al. Realistic Food-Based Approaches Alone May Not Ensure Dietary Adequacy for Women and Young Children in South-East Asia. Matern. Child Health J. 2019, 23, 55–66. [Google Scholar]

- Dias, F.S.L.; Passos, M.E.E.; do Carmo, M.G.T.; Lopes, M.L.M.; Mesquita, V.L.V. Fatty acid profile of biscuits and salty snacks consumed by Brazilian college students. Food Chem. 2015, 171, 351–355. [Google Scholar] [CrossRef]

- Shin, J.-M.; Hwang, Y.-O.; Tu, O.-J.; Jo, H.-B.; Kim, J.-H.; Chae, Y.-Z.; Rhu, K.-H.; Park, S.-K. Comparison of different methods to quantify fat classes in bakery products. Food Chem. 2013, 136, 703–709. [Google Scholar] [CrossRef]

- 5991-5172EN: Automated Sample Preparation for FAME Analysis in Edible Oils Using an Agilent 7696A Sample Prep WorkBench. Available online: https://www.agilent.com/cs/library/applications/5991-5172EN-D2.pdf (accessed on 14 January 2019).

- 5991-4556EN: Application of the Agilent 7900 ICP-MS with Method Automation Function for the Routine Determination of Trace Metallic Components in Food CRMs. Available online: https://www.agilent.com/cs/library/applications/5991-4556EN_AppNote7900_ICP-MS_food_CRMs.pdf (accessed on 1 January 2019).

- Lau, E.; Goh, H.J.; Quek, R.; Lim, S.W.; Henry, J. Rapid estimation of the energy content of composite foods: The application of the Calorie Answer™. Asia Pac. J. Clin. Nutr. 2016, 25, 18–25. [Google Scholar]

- Quek, Y.C.R.; Goh, H.J.; Henry, C.J. Energy Density of Ethnic Cuisines in Singaporean Hawker Centres: A Comparative Study of Chinese, Malay and Indian Foods. Malays. J. Nutr. 2019, 25, 171–184. [Google Scholar] [CrossRef]

- Khodabux, K.; L’Omelette, M.S.S.; Jhaumeer-Laulloo, S.; Ramasami, P.; Rondeau, P. Chemical and near-infrared determination of moisture, fat and protein in tuna fishes. Food Chem. 2007, 102, 669–675. [Google Scholar] [CrossRef]

- Mazurek, S.; Szostak, R.; Kita, A. Application of infrared reflection and Raman spectroscopy for quantitative determination of fat in potato chips. J. Mol. Struct. 2016, 1126, 213–218. [Google Scholar] [CrossRef]

- He, F.J.; MacGregor, G.A. Salt, blood pressure and cardiovascular disease. Curr. Opin. Cardiol. 2007, 22, 298–305. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Guideline: Sodium Intake for Adults and Children. Available online: https://www.who.int/nutrition/publications/guidelines/sodium_intake_printversion.pdf (accessed on 15 February 2019).

- Willett, W.C. Dietary fats and coronary heart disease. J. Intern. Med. 2012, 272, 13–24. [Google Scholar] [CrossRef] [PubMed]

- Hinrichsen, N. Commercially available alternatives to palm oil. Lipid Technol. 2016, 28, 3–4. [Google Scholar] [CrossRef]

- Fernández, P.M.S.J. Fatty Acid Composition of Commercial Spanish Fast Food and Snack Food. J. Food Compost. Anal. 2000, 13, 275–281. [Google Scholar] [CrossRef]

- Kırbaslar, F.G.; Türker, G.; Özsoy-Günes, Z.; Ünal, M.; Dülger, B.; Ertas, E.; Kızılkaya, B. Evaluation of Fatty Acid Composition, Antioxidant and Antimicrobial Activity, Mineral Composition and Calorie Values of Some Nuts and Seeds from Turkey. Rec. Nat. Prod. 2012, 6, 339–349. [Google Scholar]

- Kornsteiner-Krenn, M.; Wagner, K.-H.; Elmadfa, I. Phytosterol Content and Fatty Acid Pattern of Ten Different Nut Types. Int. J. Vitam. Nutr. Res. 2013, 83, 263–270. [Google Scholar] [CrossRef]

- Cherian, G.; Holsonbake, T.B.; Goeger, M.P. Fatty Acid Composition and Egg Components of Specialty Eggs. Poult. Sci. 2002, 81, 30–33. [Google Scholar] [CrossRef]

- Lopes, C.; Aro, A.; Azevedo, A.; Ramos, E.; Barros, H. Intake and Adipose Tissue Composition of Fatty Acids and Risk of Myocardial Infarction in a Male Portuguese Community Sample. J. Am. Diet. Assoc. 2007, 107, 276–286. [Google Scholar] [CrossRef]

- Sales-Campos, H.; de Souza, P.R.; Peghini, B.C.; da Silva, J.S.; Cardoso, C.R. An Overview of the Modulatory Effects of Oleic Acid in Health and Disease. Mini. Rev. Med. Chem. 2013, 13, 201–210. [Google Scholar] [PubMed]

- Ruiz-Lopez, N.; Usher, S.; Sayanova, O.V.; Napier, J.A.; Haslam, R.P. Modifying the lipid content and composition of plant seeds: Engineering the production of LC-PUFA. Appl. Microbiol. Biotechnol. 2015, 99, 143–154. [Google Scholar] [CrossRef] [PubMed]

- Saini, R.K.; Keum, Y.S. Omega-3 and omega-6 polyunsaturated fatty acids: Dietary sources, metabolism, and significance—A review. Life Sci. 2018, 203, 255–267. [Google Scholar] [CrossRef] [PubMed]

- Chajès, V.; Torres-Mejía, G.; Biessy, C.; Ortega-Olvera, C.; Angeles-Llerenas, A.; Ferrari, P.; Lazcano-Ponce, E.; Romieu, I. ω-3 and ω-6 Polyunsaturated Fatty Acid Intakes and the Risk of Breast Cancer in Mexican Women: Impact of Obesity Status. Cancer Epidemiol. Prev. Biomark. 2012, 21, 319–326. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Wang, B.; Pace, R.D.; Oh, J.H. Trans Fatty Acid Content of Selected Foods in an African-American Community. J. Food Sci. 2006, 71, 322–327. [Google Scholar] [CrossRef]

- Costa, N.; Cruz, R.; Graça, P.; Breda, J.; Casal, S. Trans fatty acids in the Portuguese food market. Food Control 2016, 64, 128–134. [Google Scholar] [CrossRef]

- Tardy, A.L.; Morio, B.; Chardigny, J.M.; Malpuech-Brugère, C. Ruminant and industrial sources of trans-fat and cardiovascular and diabetic diseases. Nutr. Res. Rev. 2011, 24, 111–117. [Google Scholar] [CrossRef]

- Brouwer, I.A.; Wanders, A.J.; Katan, M.B. Effect of Animal and Industrial Trans Fatty Acids on HDL and LDL Cholesterol Levels in Humans–A Quantitative Review. PLoS ONE 2010, 5, e9434. [Google Scholar] [CrossRef]

- Souza, R.J.; Mente, A.; Maroleanu, A.; Cozma, A.I.; Ha, V.; Kishibe, T.; Uleryk, E.; Budylowski, P.; Schünemann, H.; Beyene, J.; et al. Intake of saturated and trans unsaturated fatty acids and risk of all cause mortality, cardiovascular disease, and type 2 diabetes: Systematic review and meta-analysis of observational studies. Br. Med. J. 2015, 351, 3978. [Google Scholar] [CrossRef]

- Singapore Food Agency. Sale of Food Act; Food Regulations, Section 56(1): 67; Chapter 283. Available online: https://www.sfa.gov.sg/docs/default-source/legislation/sale-of-food-act/food_regulations.pdf (accessed on 14 October 2019).

| Snack Item | Energy Density | Protein | Carbohydrate | Fat (Calorie AnswerTM) | Fat (Soxtec) |

|---|---|---|---|---|---|

| (kJ/100 g) | (g/100 g) | (g/100 g) | (g/100 g) | ||

| (g/100 g) | |||||

| Salted Egg Fish Skin | 2743 ± 20 | 42.6 ± 0.8 | 4.5 ± 0.4 | 51.9 ± 1.0 | 48.5 ± 1.0 |

| Arrowhead Cracker | 2582 ± 41 | 0.2 ± 0.0 | 43.5 ± 0.3 | 49.2 ± 1.2 | 36.8 ± 4.8 |

| Peanut Puff | 2466 ± 23 | 12.0 ± 2.5 | 48.3 ± 1.5 | 38.7 ± 1.1 | 40.1 ± 0.7 |

| Egg Crisp | 2364 ± 11 | 13.2 ± 0.6 | 52.0 ± 1.0 | 33.7 ± 0.5 | 29.2 ± 0.3 |

| Peanut Candy | 2332 ± 13 | 19.4 ± 0.7 | 47.3 ± 0.5 | 32.3 ± 0.6 | 32.0 ± 0.8 |

| Cashew Nut Cookies | 2318 ± 18 | 5.8 ± 0.7 | 61.6 ± 0.3 | 31.6 ± 0.9 | 30.9 ± 2.1 |

| Seaweed Roll | 2279 ± 9 | 10.1 ± 1.2 | 59.1 ± 1.7 | 29.7 ± 0.6 | 20.2 ± 1.3 |

| Prawn Roll | 2248 ± 2 | 21.6 ± 0.5 | 49.1 ± 0.5 | 28.3 ± 0.1 | 23.1 ± 0.6 |

| Green Pea Cookies | 2241 ± 42 | 4.3 ± 2.0 | 66.8 ± 0.4 | 28.0 ± 1.9 | 25.9 ± 1.0 |

| Peanut Sesame | 2220 ± 11 | 23.3 ± 0.1 | 48.7 ± 0.4 | 27.0 ± 0.5 | 34.7 ± 0.3 |

| Almond Cookies | 2216 ± 27 | 7.2 ± 2.2 | 65.1 ± 2.6 | 26.8 ± 1.3 | 28.6 ± 1.2 |

| Almond Cashew Chocolate Cookies | 2205 ± 4 | 24.2 ± 1.1 | 48.6 ± 0.9 | 26.2 ± 0.2 | 31.8 ± 0.2 |

| Vegetarian Almond Cookies | 2180 ± 4 | 9.0 ± 0.5 | 65.0 ± 0.7 | 25.0 ± 0.2 | 29.6 ± 0.3 |

| Plait Cookies | 2178 ± 9 | 3.8 ± 1.2 | 62.3 ± 1.3 | 33.0 ± 0.3 | 38.8 ± 0.4 |

| Oat and Bran Cookies | 2169 ± 10 | 12.7 ± 0.8 | 61.8 ± 1.2 | 24.4 ± 0.4 | 25.6 ± 1.0 |

| Salted Egg Yolk Cookies | 2156 ± 9 | 0.1 ± 0.1 | 75.1 ± 0.6 | 23.8 ± 0.5 | 23.9 ± 3.7 |

| Almond Delight | 2149 ± 3 | 14.8 ± 0.1 | 60.7 ± 0.2 | 23.5 ± 0.1 | 26.9 ± 0.9 |

| Butter Cookies | 2109 ± 0 | 13.9 ± 0.6 | 63.4 ± 0.6 | 21.6 ± 0.1 | 24.2 ± 0.3 |

| Sambal Chili Tapioca Crisp | 2028 ± 32 | 0.1 ± 0.0 | 81.1 ± 1.5 | 17.8 ± 1.5 | 15.8 ± 0.5 |

| Bitter Nut Cracker with Chili | 2014 ± 2 | 9.0 ± 1.4 | 72.9 ± 1.3 | 17.1 ± 0.1 | 15.1 ± 2.4 |

| Mini Love Letter | 2011 ± 12 | 22.3 ± 0.1 | 58.6 ± 0.5 | 17.4 ± 0.2 | 16.3 ± 0.2 |

| Chocolate Wafer | 1972 ± 9 | 22.3 ± 0.3 | 62.8 ± 0.1 | 15.1 ± 0.3 | 13.9 ± 0.0 |

| Bitter Nut Crackers | 1969 ± 5 | 10.6 ± 1.2 | 43.0 ± 0.4 | 28.4 ± 0.7 | 26.8 ± 0.1 |

| Strawberry Wafer | 1938 ± 2 | 18.4 ± 0.3 | 67.1 ± 0.4 | 13.5 ± 0.2 | 12.0 ± 0.1 |

| Nyonya Pandan Egg Roll | 1935 ± 11 | 16.6 ± 0.8 | 69.2 ± 1.3 | 13.3 ± 0.5 | 14.6 ± 0.2 |

| Peanut Cookies | 1854 ± 9 | 33.5 ± 0.6 | 56.0 ± 1.0 | 9.5 ± 0.4 | 22.2 ± 0.1 |

| Kueh Bahulu | 1796 ± 18 | 27.3 ± 0.1 | 62.7 ± 1.1 | 7.7 ± 0.1 | 4.3 ± 0.0 |

| Sunflower Pineapple Tart | 1785 ± 86 | 0.1 ± 0.0 | 85.3 ± 7.0 | 9.4 ± 0.8 | 7.1 ± 0.2 |

| Nyonya Pineapple Roll | 1652 ± 60 | 0.1 ± 0.0 | 75.4 ± 3.6 | 10.2 ± 0.6 | 7.4 ± 0.3 |

| Cake Bangkit | 1587 ± 17 | 21.7 ± 0.1 | 51.2 ± 0.7 | 9.7 ± 0.2 | 7.1 ± 0.0 |

| Snack Item | C8:0 | C10:0 | C12:0 | C14:0 | C16:0 | C18:0 | C22:0 | C24:0 | C16:1 | C18:1 | C20:1 | C18:2 | C18:3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Salted Egg | - | - | - | 1.80 ± 0.01 | 32.93 ± 0.00 | 8.06 ± 0.04 | - | - | 1.09 ± 0.01 | 38.10 ± 0.12 | - | 14.63 ± 0.04 | - |

| Fish Skin | |||||||||||||

| Arrowhead | - | - | - | 1.65 ± 0.02 | 37.66 ± 0.05 | 7.33 ± 0.15 | - | - | - | 39.76 ± 0.00 | - | 11.66 ± 0.18 | - |

| Cracker | |||||||||||||

| Peanut Puff | - | - | - | 1.03 ± 0.01 | 29.49 ± 0.02 | 6.22 ± 0.02 | 2.02 ± 0.02 | - | - | 36.82 ± 0.13 | - | 21.68 ± 0.07 | - |

| Egg Crisp | - | - | - | 1.30 ± 0.00 | 32.10 ± 0.09 | 7.83 ±0.02 | - | - | - | 38.24 ± 0.16 | - | 18.13 ± 0.26 | - |

| Plait Cookies | - | - | 1.49 ± 0.04 | 1.90 ± 0.08 | 35.84 ± 0.23 | 7.34 ± 0.21 | - | - | - | 38.11 ± 0.28 | - | 13.82 ± 0.10 | - |

| Peanut | - | - | - | - | 15.94 ± 0.04 | 5.69 ± 0.05 | 5.08 ± 0.04 | 2.38 ± 0.05 | - | 35.98 ± 0.10 | 1.57 ± 0.02 | 32.77 ± 0.04 | - |

| Candy | |||||||||||||

| Cashew Nut | 1.25 ± 0.03 | 1.89 ± 0.04 | 9.89 ± 0.03 | 7.92 ± 0.08 | 27.37 ± 0.20 | 10.43 ± 0.05 | - | - | - | 28.06 ± 0.08 | - | 9.19 ± 0.03 | - |

| Cookies | |||||||||||||

| Seaweed | - | - | - | 1.66 ± 0.04 | 34.86 ± 0.21 | 7.03 ± 0.14 | - | - | - | 40.21 ± 0.11 | - | 14.16 ± 0.06 | - |

| Roll | |||||||||||||

| Prawn Roll | - | - | 3.06 ± 0.01 | 2.35 ± 0.04 | 27.93 ± 0.09 | 6.00 ± 0.16 | - | - | - | 36.81 ± 0.09 | - | 16.51 ± 0.09 | 5.01 ± 0.00 |

| Green Pea | - | - | - | 1.37 ± 0.00 | 35.83 ± 0.02 | 6.70 ± 0.01 | - | - | - | 39.67 ± 0.11 | - | 14.61 ± 0.08 | - |

| Cookies | |||||||||||||

| Peanut | - | - | - | - | 24.63 ± 0.07 | 6.44 ± 0.12 | 2.27 ± 0.08 | 1.05 ± 0.06 | - | 37.33 ± 0.24 | - | 25.81 ± 0.04 | - |

| Sesame | |||||||||||||

| Almond | - | - | - | 1.36 ± 0.06 | 33.49 ± 0.13 | 6.59 ± 0.21 | - | - | - | 41.87 ± 0.13 | - | 15.05 ± 0.05 | - |

| Cookies | |||||||||||||

| Almond | 1.17 ± 0.01 | 2.19 ± 0.01 | 11.20 ± 0.04 | 10.45 ± 0.01 | 20.05 ± 0.02 | 13.20 ± 0.01 | - | - | 1.29 ± 0.00 | 27.58 ± 0.01 | - | 8.64 ± 0.11 | - |

| Cashew | |||||||||||||

| Chocolate | |||||||||||||

| Cookies | |||||||||||||

| Vegetarian | - | - | - | 1.31 ± 0.02 | 41.80 ± 0.49 | 6.60 ± 0.07 | - | - | - | 36.67 ± 0.19 | - | 12.59 ± 0.58 | - |

| Almond | |||||||||||||

| cookies | |||||||||||||

| Oat and Bran | - | - | 8.20 ± 0.04 | 4.73 ± 0.03 | 27.75 ± 0.04 | 8.91 ± 0.04 | - | - | - | 32.22 ± 0.01 | - | 14.36 ± 0.02 | - |

| Cookies | |||||||||||||

| Salted Egg | - | - | 3.60 ± 0.04 | 2.60 ± 0.03 | 35.85 ± 0.24 | 7.12 ± 0.04 | - | - | - | 36.45 ± 0.04 | - | 12.38 ± 0.38 | - |

| Yolk | |||||||||||||

| Cookies | |||||||||||||

| Almond | - | - | 1.26 ± 0.04 | 3.15 ± 0.03 | 16.05 ± 0.05 | 5.41 ± 0.06 | - | - | - | 42.24 ± 0.14 | - | 27.69 ± 0.09 | - |

| Delight | |||||||||||||

| Butter | 1.44 ± 0.02 | 2.49 ± 0.03 | 10.44 ± 0.00 | 10.13 ± 0.03 | 27.96 ± 0.09 | 10.93 ± 0.04 | - | - | 1.11 ± 0.03 | 24.15 ± 0.13 | - | 6.06 ± 0.06 | - |

| Cookies | |||||||||||||

| Sambal Chili | - | - | - | 1.56 ± 0.03 | 36.90 ± 0.09 | 7.16 ± 0.20 | - | - | - | 39.50 ± 0.06 | - | 12.79 ± 0.13 | - |

| Tapioca | |||||||||||||

| Crisp | |||||||||||||

| Bitter Nut | - | - | - | 1.29 ± 0.00 | 34.80 ± 0.05 | 8.32 ± 0.06 | - | - | - | 40.51 ± 0.02 | - | 13.39 ± 0.01 | - |

| Cracker with | |||||||||||||

| Chili | |||||||||||||

| Mini Love | 7.57 ± 0.07 | 7.37 ± 0.08 | 30.59 ± 0.05 | 19.15 ± 0.07 | 13.49 ± 0.05 | 5.16 ± 0.07 | - | - | - | 11.59 ± 0.03 | - | 3.88 ± 0.27 | - |

| letter | |||||||||||||

| Chocolate | - | - | - | 1.56 ± 0.00 | 34.77 ± 0.03 | 8.31 ± 0.01 | - | - | - | 34.53 ± 0.06 | - | 17.37 ± 0.00 | 1.40 ± 0.02 |

| wafer | |||||||||||||

| Bitter Nut | - | - | - | 1.51 ± 0.01 | 36.00 ± 0.29 | 7.04 ± 0.06 | - | - | - | 40.17 ± 0.14 | - | 13.60 ± 0.32 | - |

| Crackers | |||||||||||||

| Strawberry | - | - | - | 1.79 ± 0.06 | 34.92 ± 0.31 | 7.50 ± 0.17 | - | - | - | 35.96 ± 0.24 | - | 16.31 ± 0.14 | 1.15 ± 0.08 |

| Wafer | |||||||||||||

| Nyonya | - | - | - | 1.78 ± 0.09 | 40.11 ± 0.16 | 8.10 ± 0.04 | - | - | - | 35.83 ± 0.20 | - | 12.11 ± 0.02 | - |

| Pandan Egg | |||||||||||||

| Roll | |||||||||||||

| Peanut | - | - | - | - | 16.06 ± 0.13 | 5.73 ± 0.04 | 5.26 ± 0.03 | 2.61 ± 0.00 | - | 36.78 ± 0.25 | 1.59 ± 0.02 | 31.56 ± 0.46 | - |

| Cookies | |||||||||||||

| Kueh Bahulu | - | - | - | - | 27.62 ± 0.01 | 6.96 ± 0.10 | - | - | 1.97 ± 0.03 | 38.43 ± 0.05 | - | 21.08 ± 0.09 | 1.18 ± 0.01 |

| Sunflower | - | - | 11.08 ± 0.00 | 5.65 ± 0.03 | 33.21 ± 0.07 | 6.41 ± 0.01 | - | - | - | 30.98 ± 0.09 | - | 9.58 ± 0.20 | - |

| Pineapple | |||||||||||||

| Tart | |||||||||||||

| Nonya | - | - | 8.89 ± 0.32 | 4.86 ± 0.22 | 32.92 ± 0.05 | 7.58 ± 0.09 | - | - | - | 32.22 ± 0.27 | - | 10.66 ± 0.48 | - |

| Pineapple | |||||||||||||

| Roll | |||||||||||||

| Cake | 6.20 ± 0.09 | 6.01 ± 0.12 | 24.51 ± 0.29 | 15.95 ± 0.23 | 15.53 ± 0.41 | 5.79 ± 0.00 | - | - | - | 17.77 ± 0.33 | - | 6.07 ± 0.05 | - |

| Bangkit |

| Snack Item | Sodium (mg/100 g) | Magnesium (mg/100 g) | Aluminium (mg/100 g) | Potassium (mg/100 g) | Calcium (mg/100 g) | Manganese (mg/100 g) | Iron (mg/100 g) | Copper (mg/100 g) | Zinc (mg/100 g) |

|---|---|---|---|---|---|---|---|---|---|

| Salted Egg Fish Skin | 551.8 ± 29.0 | 10.1 ± 0.1 | 0.1 ± 0.0 | 61.8 ± 0.5 | 382.3 ± 26.0 | 0.0 ± 0.0 | 1.9 ± 0.3 | 0.0 ± 0.0 | 1.4 ± 0.0 |

| Arrowhead Cracker | 36.3 ± 22.3 | 57.3 ± 27.4 | 0.1 ± 0.0 | 1300.6± 627.6 | 113.4 ± 54.4 | 0.4 ± 0.2 | 1.4 ± 0.7 | 0.1 ± 0.1 | 1.2 ± 0.8 |

| Peanut Puff | 77.2 ± 1.3 | 47.7 ± 0.9 | 0.4 ± 0.0 | 129.3 ± 1.7 | 146.5 ± 0.4 | 0.4 ± 0.0 | 2.0 ± 0.0 | 0.2 ± 0.0 | 1.2 ± 0.0 |

| Egg Crisp | 15.8 ± 0.0 | 26.8 ± 0.3 | 0.1 ± 0.0 | 69.6± 0.2 | 101.4 ± 1.7 | 0.2 ± 0.0 | 0.7 ± 0.0 | 0.1 ± 0.0 | 0.5 ± 0.0 |

| Plait Cookies | 225.5 ± 10.7 | 12.2 ± 0.6 | 0.1 ± 0.1 | 44.5± 1.4 | 45.1 ± 1.9 | 0.2 ± 0.0 | 0.5 ± 0.0 | 0.0 ± 0.0 | 0.3 ± 0.1 |

| Peanut Candy | 12.0 ± 0.5 | 83.8 ± 0.5 | 0.1 ± 0.0 | 204.1 ± 1.1 | 160.6 ± 0.4 | 0.5 ± 0.0 | 5.8 ± 5.5 | 0.2 ± 0.0 | 1.0 ± 0.0 |

| Cashew Nut Cookies | 146.0 ± 2.1 | 22.2 ± 0.3 | 0.1 ± 0.0 | 74.5 ± 48.4 | 95.8 ± 1.6 | 0.3 ± 0.0 | 0.7 ± 0.0 | 0.1 ± 0.0 | 0.5 ± 0.0 |

| Seaweed Roll | 413.4 ± 2.1 | 26.6 ± 0.5 | 0.6 ± 0.0 | 135.0 ± 5.7 | 183.9 ± 7.5 | 0.3 ± 0.0 | 1.4 ± 0.0 | 0.1 ± 0.0 | 0.3 ± 0.0 |

| Prawn Roll | 333.0 ± 4.3 | 46.2 ± 1.9 | 0.8 ± 0.0 | 93.4± 1.0 | 734.8 ± 32.9 | 0.3 ± 0.0 | 1.6 ± 0.4 | 0.3 ± 0.0 | 0.6 ± 0.0 |

| Green Pea Cookies | 171.6 ± 2.0 | 23.3 ± 0.5 | 0.3 ± 0.0 | 103.0 ± 0.9 | 92.2 ± 3.2 | 0.4 ± 0.0 | 0.9 ± 0.0 | 0.1 ± 0.0 | 0.5 ± 0.0 |

| Peanut Sesame | 34.3 ± 2.6 | 64.2 ± 6.5 | 0.2 ± 0.0 | 141.6 ± 18.5 | 225.4 ± 23.3 | 0.5 ± 0.0 | 1.4 ± 0.0 | 0.2 ± 0.0 | 0.8 ± 0.0 |

| Almond Cookies | 118.2 ± 5.8 | 18.3 ± 0.3 | 0.1 ± 0.0 | 63.1± 0.6 | 109.1 ± 4.2 | 0.3 ± 0.0 | 0.6 ± 0.2 | 0.1 ± 0.0 | 0.2 ± 0.0 |

| Almond Cashew Chocolate Cookies | 245.3 ± 2.0 | 43.6 ± 0.7 | 0.5 ± 0.0 | 167.0 ± 2.8 | 233.5 ± 6.2 | 0.4 ± 0.0 | 2.2 ± 0.1 | 0.3 ± 0.0 | 0.7 ± 0.0 |

| Vegetarian Almond cookies | 143.7 ± 2.7 | 22.7 ± 1.0 | 0.1 ± 0.0 | 62.6± 4.4 | 134.6 ± 10.9 | 0.2 ± 0.0 | 0.4 ± 0.1 | 0.1 ± 0.0 | 0.2 ± 0.0 |

| Oat and Bran Cookies | 185.7 ± 7.2 | 26.2 ± 0.1 | 0.1 ± 0.0 | 94.0± 1.0 | 138.3 ± 1.4 | 0.7 ± 0.0 | 0.8 ± 0.0 | 0.1 ± 0.0 | 0.4 ± 0.0 |

| Salted Egg Yolk Cookies | 267.3 ± 10.9 | 8.5 ± 0.0 | 0.3 ± 0.0 | 52.5± 0.3 | 120.0 ± 0.0 | 0.2 ± 0.0 | 1.2 ± 0.2 | 0.0 ± 0.0 | 0.3 ± 0.0 |

| Almond Delight | 268.2 ± 7.0 | 46.4 ± 0.1 | 27.8 ± 0.2 | 158.3 ± 0.6 | 409.1 ± 0.3 | 0.5 ± 0.0 | 1.7 ± 0.1 | 0.2 ± 0.0 | 0.6 ± 0.0 |

| Butter Cookies | 111.6 ± 0.4 | 11.1± 0.0 | 0.2 ± 0.2 | 45.6± 0.3 | 169.9 ± 1.4 | 0.2 ± 0.0 | 0.7 ± 0.1 | 0.0 ± 0.0 | 0.3 ± 0.0 |

| Sambal Chili Tapioca Crisp | 251.8 ± 14.2 | 16.5 ± 0.6 | 0.6 ± 0.6 | 169.2 ± 3.0 | 131.4 ± 3.8 | 0.1 ± 0.0 | 0.8 ± 0.1 | 0.0 ± 0.0 | 0.3 ± 0.1 |

| Bitter Nut Cracker with Chili | 98.1 ± 0.3 | 25.6 ± 0.1 | 0.6 ± 0.6 | 132.1 ± 1.1 | 102.1 ± 0.5 | 1.3 ± 0.0 | 1.2 ± 0.2 | 0.1 ± 0.0 | 0.5 ± 0.1 |

| Mini Love letter | 10.5 ± 0.0 | 27.3 ± 0.4 | 0.2 ± 0.0 | 141.2 ± 0.9 | 88.2 ± 0.9 | 0.5 ± 0.0 | 4.7 ± 0.0 | 0.1 ± 0.0 | 2.1 ± 0.0 |

| Chocolate wafer | 16.5 ± 0.3 | 24.3 ± 0.6 | 0.7 ± 0.0 | 123.6 ± 5.7 | 184.8 ± 7.8 | 0.3 ± 0.0 | 2.3 ± 0.2 | 0.1 ± 0.0 | 0.4 ± 0.0 |

| Bitter Nut Crackers | 0.4 ± 0.0 | 40.2 ± 1.0 | 1.2 ± 0.1 | 271.7 ± 1.2 | 168.8 ± 0.1 | 2.2 ± 0.1 | 1.9 ± 0.0 | 0.3 ± 0.0 | 0.8 ± 0.0 |

| Strawberry Wafer | 5.3 ± 0.1 | 11.9 ± 0.0 | 0.4 ± 0.0 | 62.9 ± 0.5 | 126.7 ± 1.2 | 0.2 ± 0.0 | 1.0 ± 0.1 | 0.0 ± 0.0 | 0.2 ± 0.0 |

| Nyonya Pandan Egg Roll | 137.1 ± 2.4 | 16.2 ± 0.8 | 0.1 ± 0.0 | 104.0 ± 1.7 | 344.6 ± 12.6 | 0.3 ± 0.0 | 0.5 ± 0.0 | 0.0 ± 0.0 | 0.2 ± 0.0 |

| Peanut Cookies | 3.0 ± 0.0 | 56.6 ± 0.1 | 0.1 ± 0.0 | 152.8 ± 2.1 | 109.1 ± 2.8 | 0.5 ± 0.0 | 0.9 ± 0.1 | 0.1 ± 0.0 | 1.0 ± 0.4 |

| Kueh Bahulu | 98.5 ± 7.0 | 10.5 ± 0.6 | 0.1 ± 0.0 | 72.0 ± 5.1 | 117.7 ± 6.1 | 0.2 ± 0.0 | 1.0 ± 0.0 | 0.0 ± 0.0 | 0.3 ± 0.0 |

| Sunflower Pineapple Tart | 123.3 ± 0.5 | 10.4 ± 0.2 | 0.0 ± 0.0 | 63.8 ± 0.1 | 76.6 ± 1.1 | 0.7 ± 0.0 | 0.5 ± 0.1 | 0.0 ± 0.0 | 0.1 ± 0.1 |

| Nonya Pineapple Roll | 152.6 ± 4.3 | 10.5 ± 0.4 | 0.0 ± 0.0 | 66.8 ± 2.2 | 67.8 ± 0.5 | 0.6 ± 0.0 | 0.5 ± 0.3 | 0.0 ± 0.0 | 0.1 ± 0.1 |

| Cake Bangkit | 11.5 ± 0.2 | 8.2 ± 0.2 | 0.5 ± 0.0 | 47.5 ± 1.0 | 163.1 ± 2.1 | 0.2 ± 0.0 | 0.6 ± 0.0 | 0.0 ± 0.0 | 0.2 ± 0.0 |

| Amount | % Daily Value | Amount | % Daily Value | Amount | % Daily Value | Amount | % Daily Value | Amount | % Daily Value |

|---|---|---|---|---|---|---|---|---|---|

| Salted Egg Fish Skin | Peanut Candy | Prawn Roll | Mini Love Letter | Sunflower Pineapple Tart | |||||

| Energy 1372 kJ | 16% | Energy 1166 kJ | 14% | Energy 1124 kJ | 13% | Energy 1006 kJ | 12% | Energy 893 kJ | 11% |

| Total CHO 2 g | 1% | Total CHO 24 g | 8% | Total CHO 25 g | 8% | Total CHO 29 g | 10% | Total CHO 43 g | 14% |

| Total Fat 26 g | 40% | Total Fat 16 g | 25% | Total Fat 14 g | 22% | Total Fat 9 g | 14% | Total Fat 5 g | 8% |

| Sat Fat 12 g | 60% | Sat Fat 5 g | 25% | Sat Fat 6 g | 30% | Sat Fat 8 g | 67% | Sat Fat 3 g | 25% |

| Na 276 mg | 11% | Na 6 mg | 0.3% | Na 167 mg | 7% | Na 5 mg | 0.2% | Na 62 mg | 3% |

| Ca 191 mg | 19% | Ca 80 mg | 8% | Ca 367 mg | 37% | Ca 44 mg | 4% | Ca 38 mg | 4% |

| Fe 1.0 mg | 12% | Fe 2.9 mg | 36% | Fe 0.8 mg | 10% | Fe 2.4 mg | 30% | Fe 0.2 mg | 3% |

| Zn 0.7 mg | 7% | Zn 0.5 mg | 5% | Zn 0.3 mg | 3% | Zn 1.0 mg | 10% | Zn 0.05 mg | 0.5% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeo, M.T.Y.; Yeo, P.L.Q.; Bi, X.; Henry, C.J. Energy Density and Nutrient Contents of Selective Chinese New Year Snacks. Foods 2020, 9, 1137. https://doi.org/10.3390/foods9081137

Yeo MTY, Yeo PLQ, Bi X, Henry CJ. Energy Density and Nutrient Contents of Selective Chinese New Year Snacks. Foods. 2020; 9(8):1137. https://doi.org/10.3390/foods9081137

Chicago/Turabian StyleYeo, Michelle Ting Yun, Penny Liu Qing Yeo, Xinyan Bi, and Christiani Jeyakumar Henry. 2020. "Energy Density and Nutrient Contents of Selective Chinese New Year Snacks" Foods 9, no. 8: 1137. https://doi.org/10.3390/foods9081137

APA StyleYeo, M. T. Y., Yeo, P. L. Q., Bi, X., & Henry, C. J. (2020). Energy Density and Nutrient Contents of Selective Chinese New Year Snacks. Foods, 9(8), 1137. https://doi.org/10.3390/foods9081137