Dough Rheological Behavior and Microstructure Characterization of Composite Dough with Wheat and Tomato Seed Flours

Abstract

1. Introduction

2. Materials and Methods

2.1. Flour Samples

2.2. Flour Composites

2.3. Evaluation of Wheat–Tomato Seed Composite Flours on Mixolab Dough Rheological Properties

2.4. Evaluation of Wheat–Tomato Seed Composite Flours on Rheological Properties

2.5. Microstructure of Flour Composite Dough

2.6. Statistical Analysis

3. Results and Discussions

3.1. Flour Characteristics

3.2. Wheat–Tomato Seed Composite Flours Physicochemical Characteristics

3.3. Influence of Tomato Seed Flour on Mixolab Dough Rheological Properties

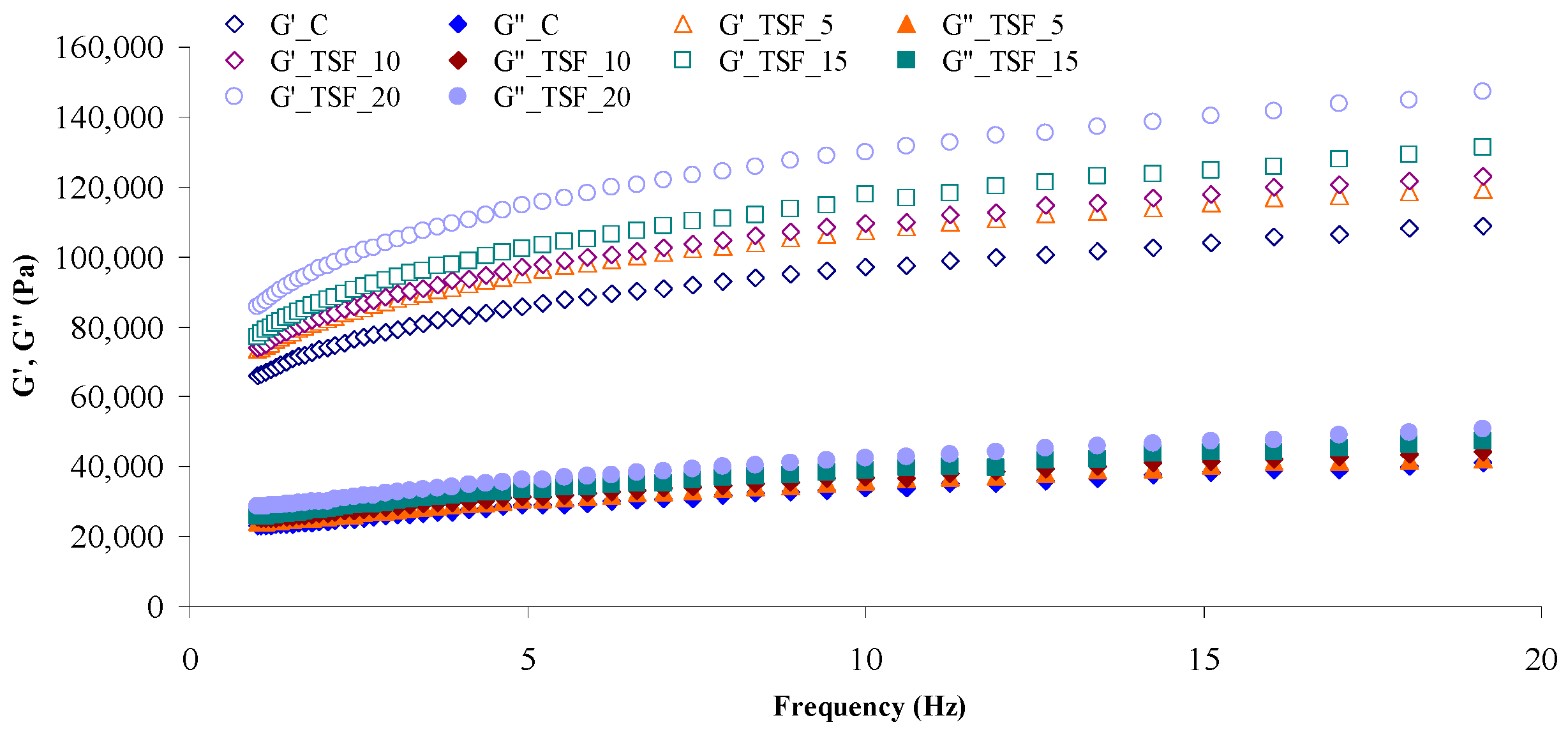

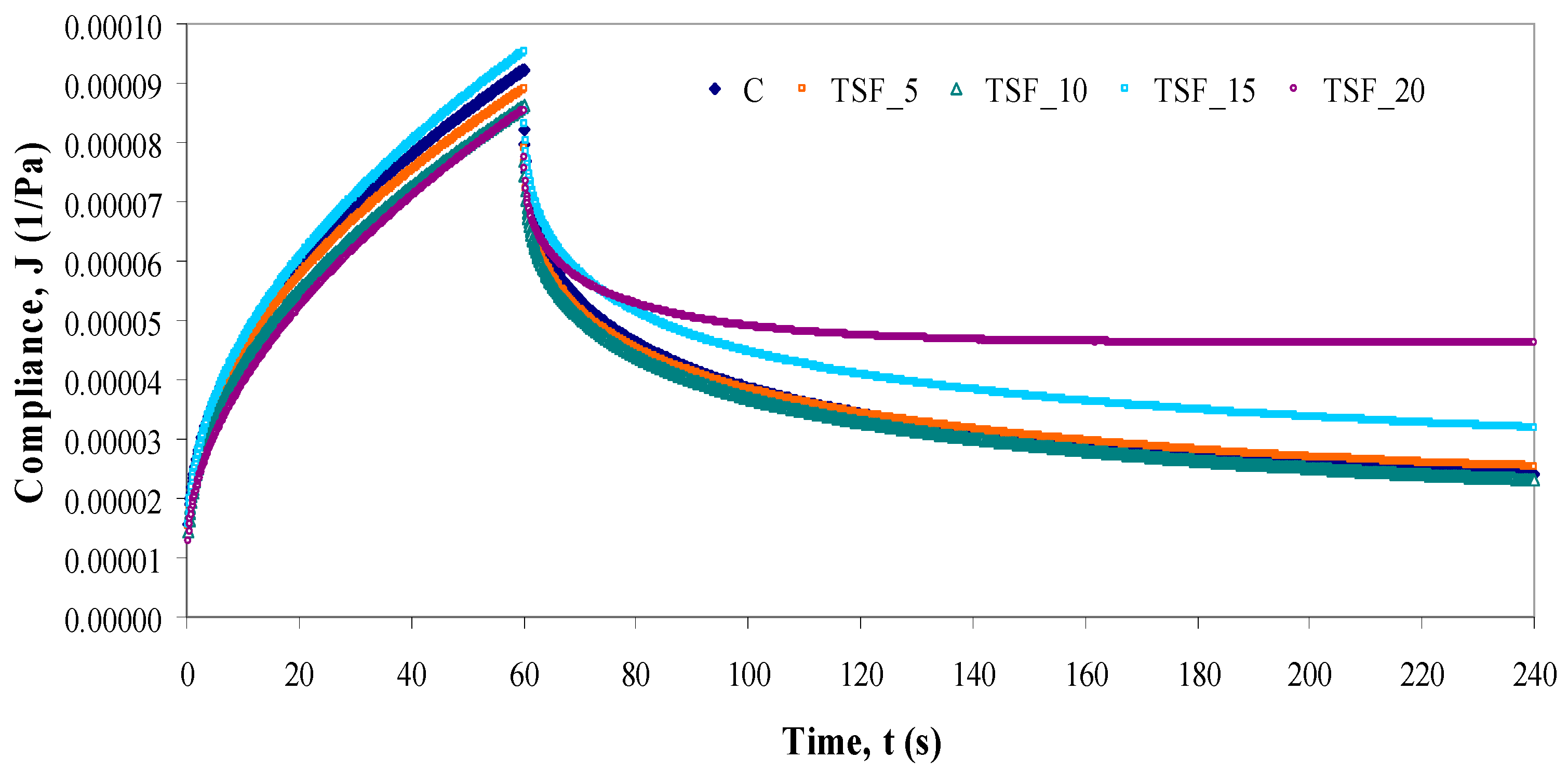

3.4. Influence of Tomato Seed Flour on Dynamic Dough Rheological Properties

3.5. Influence of Tomato Seed on Dough Microstructure

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Adalid, A.M.; Roselló, S.; Nuez, F. Evaluation and selection of tomato accessions (Solanum section Lycopersicon) for content of lycopene, β-carotene and ascorbic acid. J. Food Compos. Anal. 2010, 23, 613–618. [Google Scholar] [CrossRef]

- Bajerska, J.; Chmurzynska, A.; Mildner-Szkudlarz, S.; Drzymala-Czyz, S. Effect of rye bread enriched with tomato pomace on fat absorption and lipid metabolism in rats fed a high-fat diet. J. Sci. Food Agric. 2015, 95, 1918–1924. [Google Scholar] [CrossRef] [PubMed]

- Vinkovic Vrcek, I.; Samobor, V.; Bojic, M.; Medic-Saric, M.; Vukobratovic, M.; Erhatic, R.; Horvat, D.; Matotan, Z. The effect of grafting on the antioxidant properties of tomato (Solanum lycopersicum L.). Span. J. Agric. Res. 2011, 9, 844–851. [Google Scholar] [CrossRef]

- Maršić, N.K.; Gasperlin, L.; Abram, V.; Budic, M.; Vidrih, R. Quality parameters and total phenolic content in tomato fruits regarding cultivar and microclimatic conditions. Turk. J. Agric. For. 2011, 35, 185–194. [Google Scholar]

- Shao, D.; Atungulu, G.; Pan, Z.; Yue, T.; Zhang, A.; Fan, Z. Characteristics of isolation and functionality of protein from tomato pomace produced with different industrial processing methods. Food Bioprocess Technol. 2014, 7, 532–541. [Google Scholar] [CrossRef]

- Borguini, R.G.; Ferraz da Silva Torres, E.A. Tomatoes and tomato products as dietary sources of antioxidants. Food Rev. Int. 2009, 25, 313–325. [Google Scholar] [CrossRef]

- Ray, R.C.; El Sheikha, A.F.; Panda, S.H.; Montet, D. Anti-oxidant properties and other functional attributes of tomato: An overview. Int. J. Food Ferment. Technol. 2011, 1, 139–148. [Google Scholar]

- Zuorro, A.; Fidaleo, M.; Lavecchia, R. Enzyme-assisted extraction of lycopene from tomato processing waste. Enzym. Microb. Technol. 2011, 49, 567–573. [Google Scholar] [CrossRef]

- Del Valle, M.; Camara, M.; Torija, M.E. The nutritionaland functional potential of tomato by-products. Acta Hortic. 2007, 758, 165–172. [Google Scholar] [CrossRef]

- Celma, A.R.; Cuadros, F.; López-Rodríguez, F. Characterisation of industrial tomato by-products from infrared drying process. Food Bioprod. Process. 2009, 87, 282–291. [Google Scholar] [CrossRef]

- Migalatiev, O. Optimisation of operating parameters for supercritical carbon dioxide extraction of lycopene from industrial tomato waste. Ukr. Food J. 2017, 6, 698–716. [Google Scholar] [CrossRef]

- Sarkar, A.; Kaul, P. Evaluation of Tomato Processing By-Products: A Comparative Study in a Pilot Scale Setup. J. Food Process Eng. 2014, 37, 299–307. [Google Scholar] [CrossRef]

- Kumar, K.; Yadav, A.N.; Kumar, V.; Vyas, P.; Dhaliwal, H.S. Food waste: A potential bioresource for extraction of nutraceuticals and bioactive compounds. Bioresour. Bioprocess. 2017, 4, 18. [Google Scholar] [CrossRef]

- Knoblich, M.; Anderson, B.; Latshaw, D. Analyses of tomato peel and seed byproducts and their use as a source of carotenoids. J. Sci. Food Agric. 2005, 85, 1166–1170. [Google Scholar] [CrossRef]

- Nour, V.; Ionica, M.E.; Trandafir, I. Bread enriched in lycopene and other bioactive compounds by addition of dry tomato waste. J. Food Sci. Technol. 2015, 52, 8260–8267. [Google Scholar] [CrossRef] [PubMed]

- Kalogeropoulos, N.; Chiou, A.; Pyriochou, V.; Peristeraki, A.; Karathanos, V.T. Bioactive phytochemicals in industrial tomatoes and their processing byproducts. LWT-Food Sci. Technol. 2012, 49, 213–216. [Google Scholar] [CrossRef]

- Mehta, D.; Prasad, P.; Sangwan, R.S.; Yadav, S.K. Tomato processing byproduct valorization in bread and muffin: Improvement in physicochemical properties and shelf life stability. J. Food Sci. Technol. 2018, 55, 2560–2568. [Google Scholar] [CrossRef]

- Papaioannou, E.H.; Karabelas, A.J. Lycopene recovery from tomato peel under mild conditions assisted by enzymatic pre-treatment and non-ionic surfactants. Acta Biochim. Pol. 2012, 59, 71–74. [Google Scholar] [CrossRef]

- Stajčić, S.; Ćetković, G.; Čanadanović-Brunet, J.; Djilas, S.; Mandić, A.; Četojević-Simin, D. Tomato waste: Carotenoids content, antioxidant and cell growth activities. Food Chem. 2015, 172, 225–232. [Google Scholar] [CrossRef]

- Gupta, G.; Parihar, S.S.; Ahirwar, N.K.; Snehi, S.K.; Singh, V. Plant growth promoting rhizobacteria (PGPR): Current and future prospects for development of sustainable agriculture. J. Microb. Biochem. Technol. 2015, 7, 096–102. [Google Scholar]

- Sogi, D.S.; Garg, S.K.; Bawa, A.S. Functional properties of seed meals and protein concentrates from tomato-processing waste. J. Food Sci. 2002, 67, 2997–3001. [Google Scholar] [CrossRef]

- Sogi, D.S.; Sidhu, J.S.; Arora, M.S.; Garg, S.K.; Bawa, A.S. Effect of tomato seed meal supplementation on the dough and bread characteristics of wheat (PBW 343) flour. Int. J. Food Prop. 2002, 5, 563–571. [Google Scholar] [CrossRef]

- Kramer, A.; Kwee, W.H. Functional and nutritional properties of tomato protein concentrates. J. Food Sci. 1977, 42, 207–211. [Google Scholar] [CrossRef]

- Sogi, D.S.; Bhatia, R.; Garg, S.K.; Bawa, A.S. Biological evaluation of tomato waste seed meals and protein concentrate. Food Chem. 2005, 89, 53–56. [Google Scholar] [CrossRef]

- Mechmeche, M.; Kachouri, F.; Chouabi, M.; Ksontini, H.; Setti, K.; Hamdi, M. Optimization of extraction parameters of protein isolate from tomato seed using response surface methodology. Food Anal. Methods 2017, 10, 809–819. [Google Scholar] [CrossRef]

- Latlief, S.J.; Knorr, D. Tomato seed protein concentrates: Effects of methods of recovery upon yield and compositional characteristics. J. Food Sci. 2010, 48, 1583–1586. [Google Scholar] [CrossRef]

- Majzoobi, M.; Ghavi, F.S.; Farahnaky, A.; Jamalian, J.; Mesbahi, G. Effect of tomato pomace powder on the physicochemical properties of flat bread (barbari bread). J. Food Process. Preserv. 2011, 35, 247–256. [Google Scholar] [CrossRef]

- Brodowski, D.; Geisman, J.R. Protein content and amino acid composition of protein of seeds from tomatoes at various stages of ripeness. J. Food Sci. 1980, 45, 228–229. [Google Scholar] [CrossRef]

- Rahma, E.H.; Moharram, Y.G.; Mostafa, M.M. Chemical Characterisation of Tomato Seed Protein (Var. Pritchard). Egypt. J. Food Sci. 1986, 14, 221–230. [Google Scholar]

- Bhat, M.A.; Ahsan, H. Physico-chemical characteristics of cookies prepared with tomato pomace powder. J. Food Process. Technol. 2016, 7. [Google Scholar] [CrossRef]

- Savadkoohi, S.; Hoogenkamp, H.; Shamsi, K.; Farahnaky, A. Color, sensory and textural attributes of beef frankfurter, beef ham and meat-free sausage containing tomato pomace. Meat Sci. 2014, 97, 410–418. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Xiong, Z.; Li, G.; Zhao, X.; Wu, H.; Ren, Y. Tomato peel powder as fat replacement in low-fat sausages: Formulations with mechanically crushed powder exhibit higher stability than those with airflow ultra-micro crushed powder. Eur. J. Lipid Sci. Technol. 2016, 118, 175–184. [Google Scholar] [CrossRef]

- Grassino, A.N.; Halambek, J.; Djakovic, S.; Brncic, S.R.; Dent, M.; Grabaric, Z. Utilization of tomato peel waste from canning factory as a potential source for pectin production and application as tin corrosion inhibitor. Food Hydrocoll. 2016, 52, 265–274. [Google Scholar] [CrossRef]

- Carlson, B.L.; Knorr, D.; Watkins, T.R. Influence of tomato seed addition on the quality of wheat-flour breads. J. Food Sci. 1981, 46, 1029–1031. [Google Scholar] [CrossRef]

- Mironeasa, S.; Codina, G.G.; Oroian, M.A. Bread quality characteristics as influenced by the addition of tomato seed flour. Bull. Univ. Agric. Sci. Vet. Med. 2016, 73, 77–84. [Google Scholar] [CrossRef][Green Version]

- Mironeasa, S.; Codină, G.G.; Mironeasa, C. Effect of Composite Flour Made from Tomato Seed and Wheat of 650 Type of a Strong Quality for Bread Making on Bread Quality and Alveograph Rheological Properties. Int. J. Food Eng. 2018, 4, 22–26. [Google Scholar] [CrossRef]

- Kowalczewski, P.Ł.; Walkowiak, K.; Masewicz, Ł.; Bartczak, O.; Lewandowicz, J.; Kubiak, P.; Baranowska, H.M. Gluten-Free Bread with Cricket Powder—Mechanical Properties and Molecular Water Dynamics in Dough and Ready Product. Foods 2019, 8, 240. [Google Scholar] [CrossRef]

- Korus, J.; Juszczak, L.; Ziobro, R.; Witczak, M.; Grzelak, K.; Sójka, M. Defatted strawberry and blackcurrant seeds as functional ingredients of gluten-free bread. J. Texture Stud. 2012, 43, 29–39. [Google Scholar] [CrossRef]

- Steffe, J.F. Rheological Methods in Food Process Engineering; Freeman Press: East Lansing, MI, USA, 1996; pp. 294–348. [Google Scholar]

- Mironeasa, S.; Iuga, M.; Zaharia, D.; Mironeasa, C. Rheological analysis of wheat flour dough as influenced by grape peels of different particle sizes and addition levels. Food Bioprocess Technol. 2019, 12, 228–245. [Google Scholar] [CrossRef]

- Moreira, R.; Chenlo, F.; Torres, M.D. Rheology of gluten-free doughs from blends of chestnut and rice flours. Food Bioprocess Technol. 2013, 6, 1476–1485. [Google Scholar] [CrossRef]

- Iuga, M.; Mironeasa, C.; Mironeasa, S. Oscillatory rheology and creep-recovery behaviour of grape seed-wheat flour dough: Effect of grape seed particle size, variety and addition level. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Food Sci. Technol. 2019, 76, 37–45. [Google Scholar] [CrossRef]

- Abebe, W.; Ronda, F.; Villanueva, M.; Collar, C. Effect of tef [Eragrostis tef (Zucc.) Trotter] grain flour addition on viscoelastic properties and stickiness of wheat dough matrices and bread loaf volume. Eur. Food Res. Technol. 2015, 241, 469–478. [Google Scholar] [CrossRef]

- Peighambardoust, S.H.; Dadpour, M.R.; Dokouhaki, M. Application of epifluorescence light microscopy (EFLM) to study the microstructure of wheat dough: A comparison with confocal scanning laser microscopy (CSLM) technique. J. Cereal Sci. 2010, 51, 21–27. [Google Scholar] [CrossRef]

- Codina, G.G.; Mironeasa, S. Influence of mixing speed on dough microstructure and rheology. Food Technol. Biotechnol. 2013, 51, 509–519. [Google Scholar]

- Codină, G.G.; Mironeasa, S. Use of response surface methodology to investigate the effects of brown and golden flaxseed on wheat flour dough microstructure and rheological properties. J. Food Sci. Technol. 2016, 53, 4149–4158. [Google Scholar] [CrossRef]

- Ionescu, V.; Stoenescu, G.; Vasilean, I.; Aprodu, I.; Banu, I. Comparative evaluation of wet gluten quantity and quality through different methods. Food Technol. 2010, 34, 44–48. [Google Scholar]

- Struyf, N.; Verspreet, J.; Courtin, C.M. The effect of amylolytic activity and substrate availability on sugar release in non-yeasted dough. J. Cereal Sci. 2016, 69, 111–118. [Google Scholar] [CrossRef]

- Kundu, H.; Grewal, R.B.; Goyal, A.; Upadhyay, N.; Prakash, S. Effect of incorporation of pumpkin (Cucurbita moshchata) powder and guar gum on the rheological properties of wheatflour. J. Food Sci. Technol. 2014, 51, 2600–2607. [Google Scholar] [CrossRef]

- Chin, N.L.; Goh, S.K.; Rahman, R.A.; Hashim, D.M. Functional effect of fullyhydrogenated palm oil-based emulsifiers on baking performance of whitebread. Int. J. Food Eng. 2007, 3. [Google Scholar] [CrossRef]

- Majzoobi, M.; Mesbahi, G.; Farahnaky, A.; Jamalian, J.; Sariri, F. Effects of tomato pulp and sugar beet pulp powders on the farinograph properties of bread dough. Food Sci. Technol. 2011, 8, 1–9. [Google Scholar]

- Guo, H.; Lin, Y.H.; Wan, S.W.; Guo, S.Y. Application of emulsifier in baking food. Mod. Food Sci. Technol. 2006, 22, 297–298. [Google Scholar]

- Pareyt, B.; Finnie, S.M.; Putseys, J.A.; Delcour, J.A. Lipids in bread making. Sources, intercations and impact on bread quality. J. Cereal Sci. 2011, 54, 266–279. [Google Scholar] [CrossRef]

- Piyakina, G.A.; Maksimov, V.V.; Yunusov, T.S. Some properties of the protein fractions of tomato seeds. Chem. Nat. Compd. 1998, 34, 492–495. [Google Scholar] [CrossRef]

- Sarkar, A.; Kamaruddin, H.; Bentley, A.; Wang, S. Emulsion stabilization by tomato seed protein isolate: Influence of pH, ionic strength and thermal treatment. Food Hydrocoll. 2016, 57, 160–168. [Google Scholar] [CrossRef]

- Savadkoohi, S.; Farahnaky, A. Dynamic rheological and thermal study of the heat-induced gelation of tomato-seed proteins. J. Food Eng. 2012, 113, 479–485. [Google Scholar] [CrossRef]

- Moza, J.; Gujral, S. Influence of barley non-starchy polysaccharides on selected quality attributes of sponge cakes. LWT-Food Sci. Technol. 2017, 85, 252–261. [Google Scholar] [CrossRef]

- Gujral, H.S.; Sharma, B.; Khatri, M. Influence of replacing wheat bran with barley bran on dough rheology, digestibility and retrogradation behavior of chapatti. Food Chem. 2018, 240, 1154–1160. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch retrogradation: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Watanabe, A.; Yokomizo, K.; Eliasson, A.-C. Effect of physical states of nonpolar lipids on rheology, ultracentrifugation, and microstructure of wheat flour dough. Cereal Chem. 2003, 80, 281–284. [Google Scholar] [CrossRef]

- Guadarrama-Lezama, A.Y.; Carillo-Navas, H.; Vernon-Carter, E.J.; Alverez-Ramirez, J. Rheological and thermal properties of dough and textural and microstructural features of bread obtained from nixtamalized corn/wheat flour blends. J. Cereal Sci. 2016, 69, 158–165. [Google Scholar] [CrossRef]

- Uthayakumaran, S.; Newberry, M.; Phan-Thien, N.; Tanner, R. Small and large strain rheology of wheat gluten. Rheol. Acta 2002, 41, 162–172. [Google Scholar] [CrossRef]

- Chouaibi, M.; Rezig, I.; Boussaid, A.; Hamdi, S. Insoluble tomato-fiber effect on wheat dough rheology and cookies’quality. Ital. J. Food Sci. 2018, 31. [Google Scholar] [CrossRef]

- Miś, A. Interpretation of mechanical spectra of carob fibre and oat wholemeal-enriched wheat dough using non-linear regression models. J. Food Eng. 2011, 102, 369–379. [Google Scholar] [CrossRef]

- Wang, F.C.; Sun, X.S. Creep-recovery of wheat flour doughs and relationship to other physical dough tests and breadmaking performance. Cereal Chem. 2002, 70, 567–571. [Google Scholar] [CrossRef]

- Chompoorat, P.; Ambardekar, A.; Mulvaney, S.; Rayas-Duarte, P. Rheological characteristics of gluten after modified by DATEM, ascorbic acid, urea and DTT using creep-recovery test. J. Mod. Phys. 2013, 4, 1–8. [Google Scholar] [CrossRef]

| Sample | Protein (%) | Lipids (%) | Ash (%) | Moisture (%) | Falling Number (s) |

|---|---|---|---|---|---|

| Control | 12.40 a (0.20) | 1.60 a (0.10) | 0.65 a (0.01) | 14.50 a (0.30) | 445.00 a (14.00) |

| TSF_5 | 13.25 b (0.19) | 2.49 b (0.09) | 0.80 a (0.00) | 13.83 a (0.29) | 467.00 ab (14.00) |

| TSF_10 | 14.11 c (0.18) | 3.39 c (0.09) | 0.97 a (0.00) | 13.47 d (0.27) | 478.00 b (12.00) |

| TSF_15 | 14.96 d (0.17) | 4.28 d (0.09) | 1.13 a (0.00) | 13.11 c (0.25) | 445.00 a (15.00) |

| TSF_20 | 15.82 e (0.16) | 5.18 e (0.08) | 1.30 b (0.00) | 12.74 b (0.24) | 434.00 ac (16.00) |

| Sample | WA (%) | ST (min) | DT (min) | C2 (N-m) | C1-2 (N-m) | C3 (N-m) | C3-2 (N-m) | C4 (N-m) | C3-4 (N-m) | C5 (N-m) | C5-4 (N-m) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 60.70 a (2.20) | 8.53 a (0.01) | 3.85 a (0.62) | 0.49 a (0.02) | 0.60 a (0.02) | 1.82 a (0.07) | 1.33 a (0.06) | 1.55 a (0.09) | 0.27 a (0.02) | 2.36 a (0.06) | 0.81 a (0.03) |

| TSF_5 | 59.20 e (0.02) | 8.73 e (0.02) | 3.98 d (0.03) | 0.54 b (0.03) | 0.64 b (0.03) | 1.73 d (0.06) | 1.19 d (0.03) | 1.59 d (0.07) | 0.14 c (0.02) | 2.81 b (0.05) | 1.22 b (0.02) |

| TSF_10 | 58.50 d (2.20) | 9.18 b (0.02) | 4.05 c (0.05) | 0.55 b (0.03) | 0.62 c (0.01) | 1.67 c (0.02) | 1.12 c (0.01) | 1.57 d (0.04) | 0.10 b (0.02) | 2.78 b (0.05) | 1.21 b (0.01) |

| TSF_15 | 57.60 c (2.20) | 9.08 c (0.01) | 4.32 b (0.17) | 0.53 c (0.02) | 0.64 b (0.02) | 1.52 b (0.05) | 0.99 b (0.03) | 1.35 b (0.03) | 0.17 c (0.02) | 2.57 c (0.05) | 1.22 b (0.02) |

| TSF_20 | 56.80 b (2.20) | 8.90 d (0.10) | 4.55 b (0.01) | 0.53 c (0.02) | 0.65 b (0.01) | 1.50 b (0.03) | 0.97 b (0.01) | 1.40 c (0.01) | 0.10 b (0.02) | 2.53 d (0.04) | 1.13 c (0.03) |

| Sample | G’ = K’·ωn” | G” = K”·ωn” | ||

|---|---|---|---|---|

| K’ (Pa sn’) | n’ | K” (Pa sn”) | n” | |

| Control | 65,707.45 a (7373.07) | 0.168 a (0.008) | 21,489.72 a (3403.12) | 0.196 a (0.008) |

| TSF_5 | 73,158.88 a (3875.74) | 0.167 a (0.001) | 22,721.65 a (439.82) | 0.199 a (0.001) |

| TSF_10 | 73,711.68 a (2893.63) | 0.172 a (0.004) | 23,469.96 a (2119.38) | 0.197 a (0.005) |

| TSF_15 | 77,350.93 b (2412.14) | 0.177 c (0.002) | 24,470.72 a (1762.34) | 0.205 b (0.003) |

| TSF_20 | 85,702.71 c (7512.53) | 0.182 b (0.002) | 26,867.43 b (2610.38) | 0.198 a (0.004) |

| Sample | Creep Phase | Recovery Phase | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| JCo⋅ 105 (Pa−1) | JCm⋅ 105 (Pa−1) | λC (s) | μCo⋅ 10−6 (Pa ⋅ s) | Jmax⋅ 105 (Pa-1) | JRo⋅ 105 (Pa−1) | JRm⋅ 105 (Pa−1) | λR (s) | Jr⋅ 105 (Pa−1) | Jr/Jmax (%) | |

| Control | 2.50 a (0.16) | 8.13 a (0.04) | 36.97 a (0.48) | 1.48 a (0.01) | 9.13 a (0.33) | 2.30 a (0.20) | 3.90 a (0.29) | 38.19 a (3.47) | 6.20 a (0.10) | 67.98 a (3.50) |

| TSF_5 | 2.45 b (0.03) | 7.80 b (1.07) | 36.60 b (2.93) | 1.60 b (0.24) | 8.80 d (0.61) | 2.62 b (1.28) | 3.61 b (0.45) | 37.10b (9.63) | 6.22 b (0.83) | 70.37 a (4.55) |

| TSF_10 | 2.32 e (0.12) | 7.69 c (0.64) | 37.95 c (0.21) | 1.54 c (0.14) | 8.51 a (0.54) | 2.42 e (0.16) | 3.60 a (0.54) | 39.11 c (4.74) | 6.01 a (0.39) | 70.66 a (0.14) |

| TSF_15 | 2.51 c (0.36) | 8.64 d (1.24) | 38.56 e (0.96) | 1.45 e (0.22) | 9.41 b (1.32) | 3.32 c (0.28) | 3.49 a (0.74) | 36.02d (3.66) | 6.81 c (1.02) | 72.27 a (0.70) |

| TSF_20 | 2.04 d (0.15) | 8.41 e (1.60) | 42.54 d (3.33) | 1.54 d (0.26) | 8.48 c (1.27) | 4.51 d (2.04) | 2.32 c (0.45) | 22.48 e (17.21) | 6.83 d (1.59) | 79.56 a (6.89) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mironeasa, S.; Codină, G.G. Dough Rheological Behavior and Microstructure Characterization of Composite Dough with Wheat and Tomato Seed Flours. Foods 2019, 8, 626. https://doi.org/10.3390/foods8120626

Mironeasa S, Codină GG. Dough Rheological Behavior and Microstructure Characterization of Composite Dough with Wheat and Tomato Seed Flours. Foods. 2019; 8(12):626. https://doi.org/10.3390/foods8120626

Chicago/Turabian StyleMironeasa, Silvia, and Georgiana Gabriela Codină. 2019. "Dough Rheological Behavior and Microstructure Characterization of Composite Dough with Wheat and Tomato Seed Flours" Foods 8, no. 12: 626. https://doi.org/10.3390/foods8120626

APA StyleMironeasa, S., & Codină, G. G. (2019). Dough Rheological Behavior and Microstructure Characterization of Composite Dough with Wheat and Tomato Seed Flours. Foods, 8(12), 626. https://doi.org/10.3390/foods8120626