Physicochemical and Rheological Properties of a Dairy Dessert, Enriched with Chickpea Flour

Abstract

1. Introduction

2. Materials and Methods

2.1. Composition and Preparation of the Dairy Dessert

2.2. Physicochemical Analysis

2.3. Rheological Properties

2.3.1. Flow Behavior

2.3.2. Viscoelastic Behavior

2.3.3. Texture Analysis

2.4. Resistant Starch

2.5. Statistical Analysis

3. Results and Discussion

3.1. Effect on Physicochemical Analysis

3.2. Effect on Color

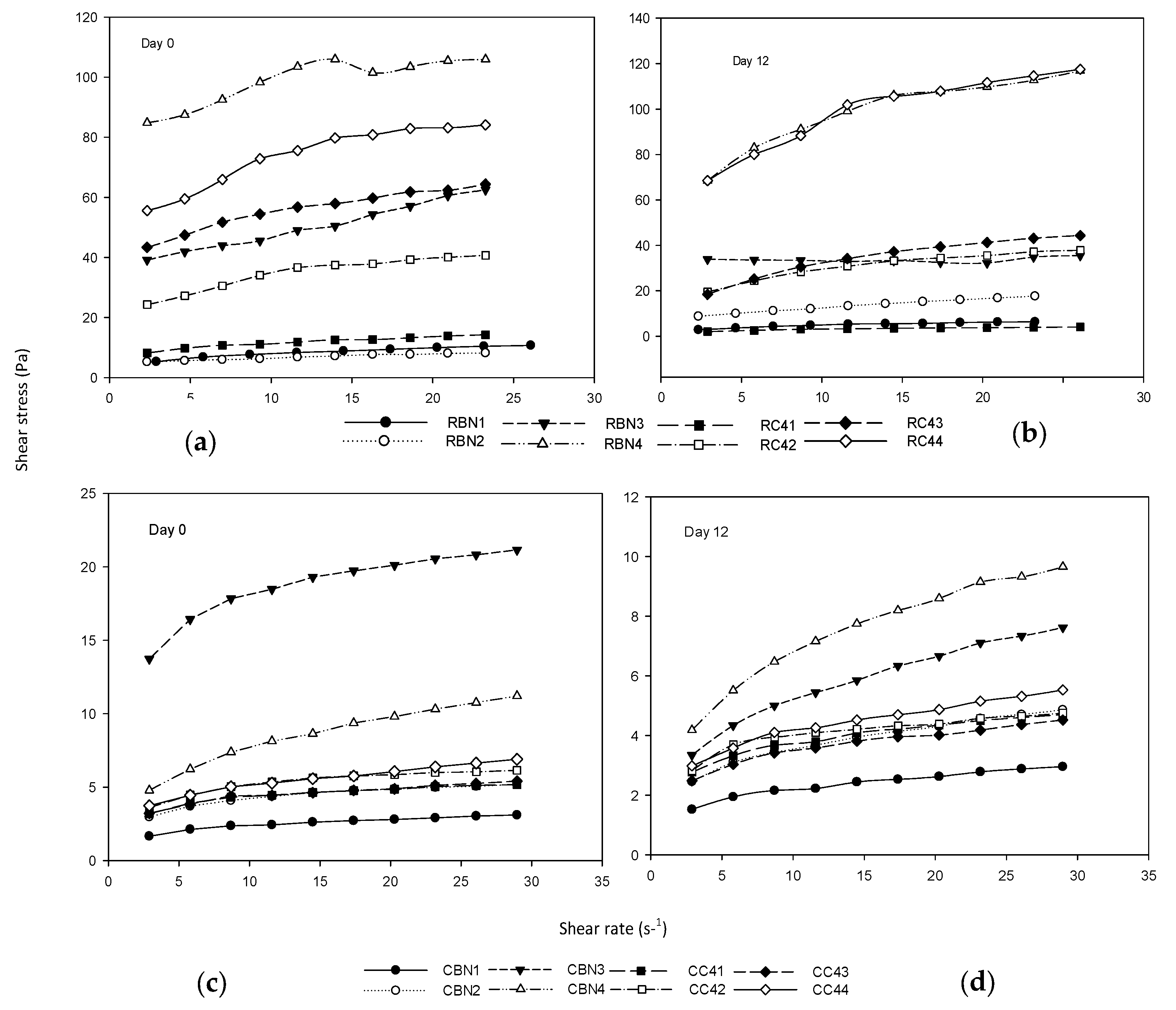

3.3. Flow Behavior Response

3.4. Viscoelastic Response

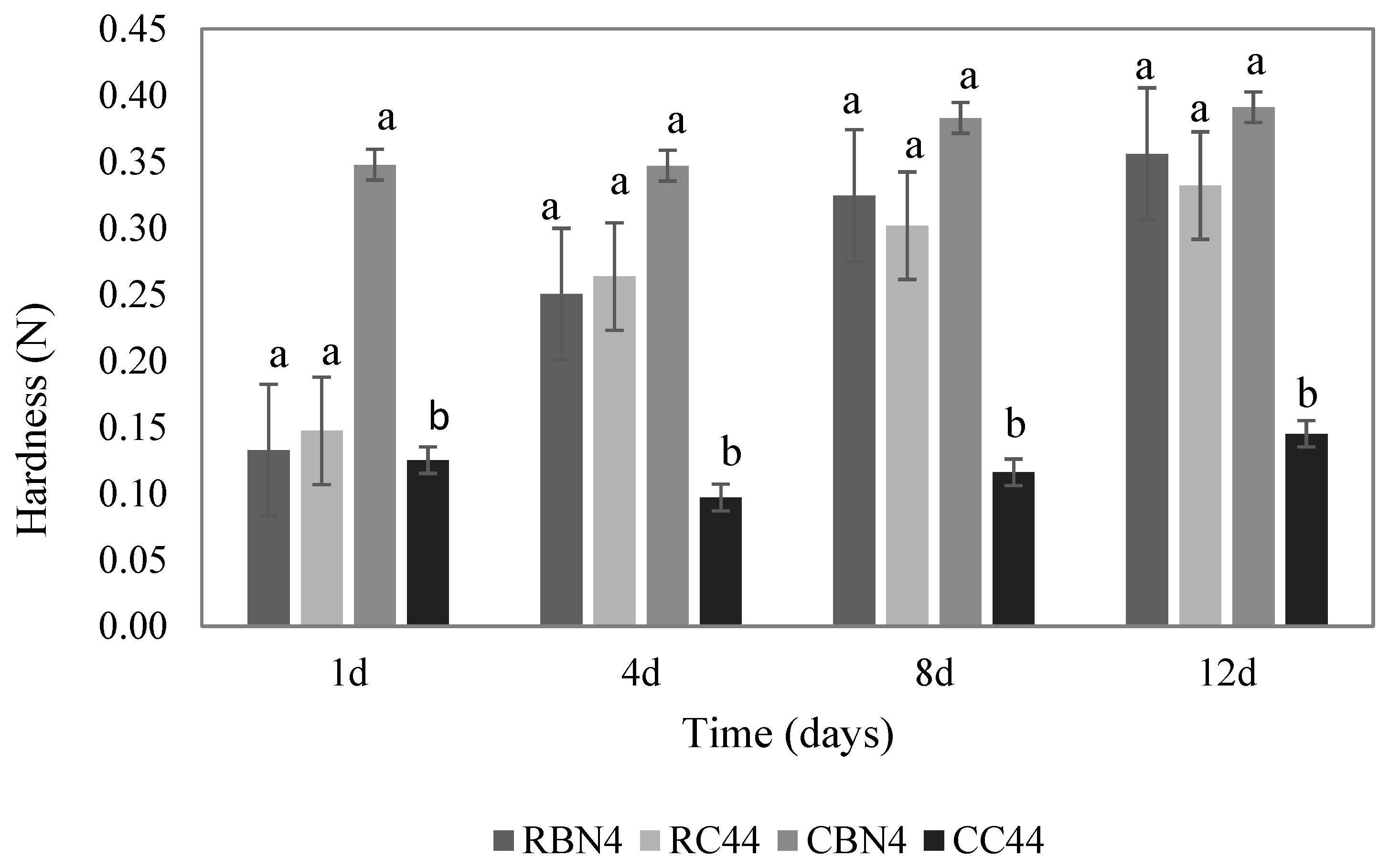

3.5. Textural Analysis

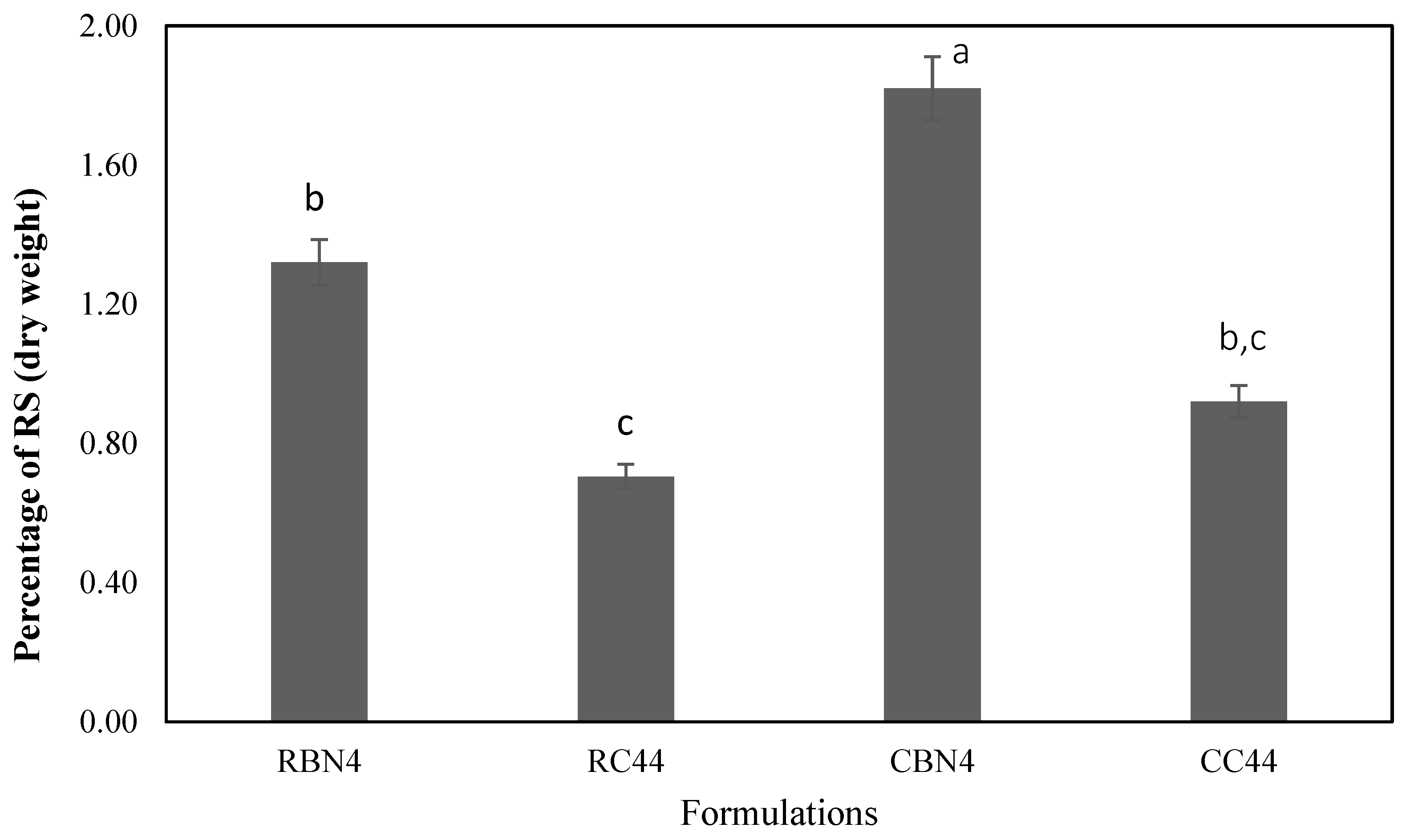

3.6. Resistant Starch (RS) Quantification

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| RC4 | raw flour Costa 2004 |

| RBN | raw flour Blanco Noroeste |

| CC4 | cooked flour Costa 2004 |

| CBN | cooked flour Blanco Noroeste |

| PL | power law model |

| HB | Herschel–Bulkley model |

| PB | Bingham plastic model |

References

- González-Tomás, L.; Bayarri, S.; Costell, E. Inulin-enriched dairy desserts: Physicochemical and sensory aspects. J. Dairy Sci. 2009, 92, 4188–4199. [Google Scholar] [CrossRef] [PubMed]

- González-Tomás, L.; Bayarri, S.; Costell, E. Flow behavior of inulin-enriched dairy desserts: Influence of inulin average chain length. Int. J. Food Sci. Technol. 2009, 44, 1214–1222. [Google Scholar] [CrossRef]

- Toker, O.S.; Dogan, M.; Caniyilmaz, E.; Ersöz, N.B.; Kaya, Y. The effects of different gums and their interactions on the rheological properties of a dairy dessert: A mixture design approach. Food Bioprocess Technol. 2013, 6, 896–908. [Google Scholar] [CrossRef]

- Zapata-Noreña, C.P.; Bayarri, S.E.; Costell, E. Effects of xanthan gum additions on the viscoelasticity, structure and storage stability characteristics of prebiotic custard desserts. Food Biophys. 2015, 10, 116–128. [Google Scholar] [CrossRef]

- Doublier, J.L.; Durand, S. A rheological characterization of semi-solid dairy systems. Food Chem. 2008, 108, 1169–1175. [Google Scholar] [CrossRef]

- Richter, R.F.; de Pereira-Netto, A.B.; Meira, S.J.L.; Isidoro, H.C.W.; Bilesky, C.L.M. Apparent viscosity of a skim milk based dessert: Optimization through response surface methodology. Food Nutr. Sci. 2011, 2, 90–95. [Google Scholar]

- Vélez-Ruiz, J.F.; González-Tomás, L.; Costell, E. Rheology of custard model systems: Influence of milk fat and hydrocolloid type. Eur. Food Res. Technol. 2005, 221, 342–347. [Google Scholar] [CrossRef]

- Tárrega, A.; Durán, L.; Costell, E. Flow behavior of semi-solid dairy desserts. Effect of temperature. Int. Dairy J. 2004, 14, 345–353. [Google Scholar] [CrossRef]

- Tárrega, A.; Vélez-Ruiz, J.F.; Costell, E. Influence of milk on the rheological behaviour of cross-linked waxy maize and tapioca starch dispersions. Food Res. Int. 2005, 38, 759–768. [Google Scholar] [CrossRef]

- Alamprese, C.; Mariotti, M. Effects of different milk substitutes on pasting, rheological and textural properties of puddings. LWT Food Sci. Technol. 2011, 44, 2019–2025. [Google Scholar] [CrossRef]

- Zare, F.; Boye, J.I.; Orsat, V.; Champagne, C.; Simpson, B.K. Microbial, physical and sensory properties of yogurt supplemented with lentil flour. Food Res. Int. 2011, 44, 2482–2488. [Google Scholar] [CrossRef]

- Jha, A.; Murli, P.; Ashok, A.; Gopal, T.K.S.R.; Chandragiri, N.R. Development of a process for shelf stable dairy dessert dalia and its physico-chemical properties. LWT Food Sci. Technol. 2012, 49, 80–88. [Google Scholar] [CrossRef]

- Qasem, A.A.A.; Alamri, M.S.; Mohamed, A.A.; Hussain, S.; Mahnood, K.; Braheem, M.A. High soluble-fiber pudding: Formulation, processing, texture and sensory properties. J. Food Process. Preserv. 2016. [Google Scholar] [CrossRef]

- Costa, K.K.F.D.; García, M.C.; Ribeiro, K.O.; Soares, M.S.; Caliari, M. Rheological properties of fermented rice extract with probiotic bacteria and different concentration of waxy maize starch. LWT Food Sci. Technol. 2016, 72, 71–77. [Google Scholar] [CrossRef]

- Seuvré, A.M.; Turci, C.; Voilley, A. Effect of the temperature on the release of aroma compounds and on the rheological behavior of model dairy custard. Food Chem. 2008, 108, 1176–1182. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists (AOAC). AOAC Official Methods of Analysis; AOAC International: Rockville, MD, USA, 2000. [Google Scholar]

- Nunes, M.C.; Raymundo, A.; Sousa, I. Gelled vegetable desserts containing pea protein, κ-carrageenan and starch. Eur. Food Res. Technol. 2006, 222, 622–628. [Google Scholar] [CrossRef]

- Brookfield Engineering Laboratories. Viscometer Handbook; Brookfield Engineering Laboratories Inc.: Middlebore, MA, USA, 1995. [Google Scholar]

- Goñi, I.; García-Díaz, L.; Mañas, E.; Saura-Calixto, F. Analysis of resistant starch: A method for foods and food products. Food Chem. 1996, 56, 445–449. [Google Scholar] [CrossRef]

- Sarmiento, T.R. Impact of Processing on Cells Wall Related with the Processing on the Hypoglycemic and Functional Properties from Legumes. Ph.D. Thesis, Universidad Autónoma de Madrid, Madrid, Spain, 2012. (In Spanish). [Google Scholar]

- Szwajgier, D.; Gustaw, W. The addition of malt to milk-based desserts: Influence on rheological properties and phenolic acid content. LWT Food Sci. Technol. 2015. [Google Scholar] [CrossRef]

- Acquarone, V.M.; Rao, M.A. Influence of sucrose on the rheology and granule size of cross-linked waxy maize starch dispersions heated at two temperatures. Carbohydr. Polym. 2003, 51, 451–458. [Google Scholar] [CrossRef]

- Tattiyakul, J.; Rao, M.A. Rheological behavior of cross-linked waxy maize starch dispersions during and after heating. Carbohydr. Polym. 2000, 43, 215–222. [Google Scholar] [CrossRef]

- Nayouf, M.; Loisel, C.; Doublier, J.L. Effect of thermomechanical treatment on the rheological properties of crosslinked waxy corn starch. J. Food Eng. 2003, 59, 209–219. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mohameed, H. Time-dependent flow properties of starch–milk–sugar pastes. Eur. Food Res. Technol. 2004, 218, 123–127. [Google Scholar] [CrossRef]

- Tárrega, A.; Costell, E. Effect of inulin addition on rheological and sensory properties of fat-free starch-based dairy desserts. Int. Dairy J. 2006, 16, 1104–1112. [Google Scholar] [CrossRef]

- Vélez-Ruiz, J.F. Rheological and Dynamic Properties. In Introduction to the Physical Properties of Foods; Editorial Académica Española: Saarbrücken, Germany, 2013; pp. 152–194. (In Spanish) [Google Scholar]

- Puvanenthiran, A.; Goddard, S.J.; McKinnon, I.R.; Augustin, M.A. Milk-based gels made with κ-carrageenan. J. Food Sci. 2003, 68, 137–141. [Google Scholar] [CrossRef]

- Keršienė, M.; Adams, A.; Dubra, A.; De Kimpe, N.; Leskauskaitė, D. Interactions between flavour release and rheological properties in model custard desserts: Effects of starch concentration and milk fat. Food Chem. 2008, 108, 1183–1191. [Google Scholar] [CrossRef]

- Torres, J.D.; Tárrega, A.; Costell, E. Storage stability of starch-based dairy desserts containing long-chain inulin: Rheology and particle size distribution. Int. Dairy J. 2010, 20, 46–52. [Google Scholar] [CrossRef]

- Hemar, Y.; Hall, C.E.; Munro, P.A.; Singh, H. Small and large deformation rheology and microstructure of κ-carrageenan gels containing commercial milk proteins products. Int. Dairy J. 2002, 12, 371–381. [Google Scholar] [CrossRef]

- Alamri, M.S.; Mohamed, A.A.; Hussain, S. High-fiber date pits pudding: Formulation, processing, and textural properties. Eur. Food Res. Technol. 2014, 239, 755–763. [Google Scholar] [CrossRef]

- Pereira, K.D. Amido resistente, a última geração no controle de energía e digestão saudável. Ciênc. Tecnol. Aliment. 2007, 27, 88–92. (In Portuguese) [Google Scholar] [CrossRef]

- Morales-Medina, R.; Muñio, M.D.M.; Guadix, E.M.; Guadix, A. Production of resistant starch by enzymatic debranching in legume flours. Carbohydr. Polym. 2014, 101, 1176–1183. [Google Scholar] [CrossRef] [PubMed]

- Brumovsky, L.A.; Brumovsky, J.O.; Fretes, M.R.; Peralta, J.M. Quantification of resistant starch in several starch sources treated thermally. Int. J. Food Prop. 2009, 12, 451–460. [Google Scholar] [CrossRef]

- Ratnayake, W.S.; Hoover, R.; Shahid, F.; Perera, C.; Jane, J. Composition, molecular structure, and physicochemical properties of starches from four field peas (Pisum sativum L.) cultivars. Food Chem. 2001, 74, 189–202. [Google Scholar] [CrossRef]

- Osorio-Díaz, P.; Bello-Pérez, L.A.; Sayago-Ayerdi, S.G.; Benítez-Reyes, M.D.P.; Tovar, J.; Paredes-López, O. Effect of processing and storage time on in vitro digestibility and resistant starch content of two bean (Phaseolus vulgaris L.) varieties. J. Sci. Food Agric. 2003, 83, 1283–1288. [Google Scholar] [CrossRef]

- Tharanathan, R.N.; Mahadevamma, S. Grain legumes—A boon to human nutrition. Trends Food Sci. Technol. 2003, 14, 507–518. [Google Scholar] [CrossRef]

- Pereira, B.B.L.; Leonel, M. Resistant starch in cassava products. Food Sci. Technol. 2014. [Google Scholar] [CrossRef]

| Raw flour (R) | RBN1 | RBN2 | RBN3 | RBN4 |

| RC41 | RC42 | RC43 | RC44 | |

| Cooked flour (C) | CBN1 | CBN2 | CBN3 | CBN4 |

| CC41 | CC42 | CC43 | CC44 | |

| Chickpea flour (g) | 8.3 | 9.3 | 10.3 | 11.3 |

| Samples | Brix | pH | Acidity (g/L) | Syneresis (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Day 0 | Day 12 | Day 0 | Day 12 | Day 0 | Day 12 | Day 0 | Day 12 | |

| RBN1 | 24.93 ± 0.04 abA | 21.27 ± 0.08 abB | 6.80 ± 0.01 aA | 6.98 ± 0.10 aA | 1.80 ± 0.17 cZ | 1.43 ± 0.01 cZ | 42.58 A | 46.75 B |

| RBN2 | 24.07 ± 0.65 abA | 22.63 ± 0.13 abB | 6.70 ± 0.00 aA | 6.96 ± 0.05 aA | 1.77 ± 0.01 cZ | 1.13 ± 0.15 cZ | 46.43 A | 39.55 B |

| RBN3 | 23.93 ± 0.06 abA | 21.83 ± 0.28 abB | 6.68 ± 0.01 aA | 7.12 ± 0.01 aA | 1.44 ± 0.06 cZ | 1.20 ± 0.03 cZ | 47.55 A | 27.30 B |

| RBN4 | 24.13 ± 0.94 abA | 22.07 ± 0.17 abB | 6.74 ± 0.03 aA | 7.06 ± 0.23 aA | 1.56 ± 0.14 cZ | 1.10 ± 0.01 cZ | 34.19 A | 31.90 B |

| RC41 | 25.10 ± 0.08 aA | 20.60 ± 0.27 aB | 6.86 ± 0.01 aA | 6.99 ± 0.32 aA | 1.80 ± 0.13 cZ | 1.40 ± 0.12 cZ | 46.52 A | 70.39 aB |

| RC42 | 24.93 ± 0.17 aA | 21.10 ± 0.53 aB | 6.91 ± 0.03 aA | 6.96 ± 0.54 aA | 1.77 ± 0.16 cZ | 1.60 ± 0.07 cZ | 43.03 A | 70.24 aB |

| RC43 | 26.73 ± 0.17 aA | 21.17 ± 0.11 aB | 6.95 ± 0.03 aA | 6.95 ± 0.21 aA | 1.44 ± 0.10 cZ | 1.20 ± 0.56 cZ | 39.35 A | 69.10 aB |

| RC44 | 27.87 ± 0.06 aA | 21.20 ± 0.21 aB | 7.11 ±0.01 abA | 6.95 ± 0.12 aA | 1.56 ± 0.01 cZ | 1.37 ± 0.32 cZ | 28.35 A | 67.23 aB |

| CBN1 | 20.40 ± 0.63 bcA | 20.10 ± 0.63 bcB | 6.97 ±0.03 abA | 6.67 ± 0.15 abA | 2.75 ± 0.16 aZ | 3.56 ± 0.31 aZ | 55.40 A | 50.75 B |

| CBN2 | 21.53 ± 0.21 bcA | 21.00 ± 0.21 bcB | 7.01 ±0.01 abA | 6.61 ± 0.11 abA | 2.80 ± 0.07 aZ | 3.11 ± 0.34 aZ | 50.95 A | 46.55 B |

| CBN3 | 21.91 ± 0.08 bcA | 20.50 ± 0.08 bcB | 6.97 ± 0.05 abA | 6.64 ± 0.01 abA | 2.82 ± 0.47 aZ | 3.15 ± 0.56 aZ | 44.85 A | 38.30 B |

| CBN4 | 21.13 ± 0.10 bcA | 20.13 ± 0.10 bcB | 7.05 ± 0.21 abA | 6.67 ± 0.07 abA | 2.91 ± 0.21 aZ | 3.24 ± 0.78 aZ | 43.00 A | 50.90 B |

| CC41 | 20.50 ± 0.27 cA | 20.00 ± 0.27 cB | 6.84 ± 0.17 bA | 6.43 ± 0.11 bA | 2.12 ± 0.06 bZ | 2.43 ± 0.04 bZ | 51.82 A | 42.30 B |

| CC42 | 21.07 ± 0.02 cA | 20.10 ± 0.02 cB | 6.74 ± 0.51 bA | 6.35 ± 0.32 bA | 2.52 ± 0.12 bZ | 2.57 ± 0.02 bZ | 48.33 A | 38.52 B |

| CC43 | 22.03 ± 0.05 cA | 21.23 ± 0.05 cB | 6.83 ± 0.01 bA | 6.44 ± 0.29 bA | 2.43 ± 0.32 bZ | 2.43 ± 0.09 bZ | 52.15 A | 40.39 B |

| CC44 | 21.32 ± 0.01 cA | 21.32 ± 0.01 cB | 6.87 ± 0.40 bA | 6.45 ± 0.08 bA | 2.57 ± 0.09 bZ | 2.57 ± 0.11 bZ | 48.94 A | 39.43 B |

| Samples | L* | a* | b* | ∆E | |||

|---|---|---|---|---|---|---|---|

| Day 0 | Day 12 | Day 0 | Day 12 | Day 0 | Day 12 | ||

| RBN1 | 81.54 ± 0.73 a | 81.89 ± 0.52 a | −3.98 ± 0.05 c | −4.26 ± 0.07 c | 17.09 ± 0.47 C | 16.65 ± 0.44 C | 0.63 a |

| RBN2 | 80.80 ± 0.14 a | 80.80 ± 0.15 a | −3.88 ± 0.02 c | −4.13 ± 0.22 c | 19.30 ± 0.41 C | 17.97 ± 0.20 C | 0.80 a |

| RBN3 | 81.54 ± 0.83 a | 79.71 ± 1.28 a | −4.16 ± 0.05 c | −3.57 ± 0.14 c | 19.52 ± 0.08 C | 20.08 ± 0.02 C | 2.00 a |

| RBN4 | 75.94 ± 1.21 a | 79.29 ± 0.29 a | −3.43 ± 0.12 c | −4.00 ± 0.16 c | 21.52 ± 0.61 C | 20.31 ± 1.98 C | 3.61 a |

| RC41 | 83.29 ± 0.54 a | 80.63 ± 0.11 a | −4.05 ± 0.45 c | −4.20 ± 0.16 c | 18.17 ± 0.27 BC | 18.20 ± 1.19 BC | 3.53 ab |

| RC42 | 82.80 ± 0.03 a | 79.77 ± 0.35 a | −4.15 ± 0.10 c | −4.07 ± 0.16 c | 19.74 ± 0.22 BC | 18.74 ± 0.38 BC | 4.02 ab |

| RC43 | 82.93 ± 0.11 a | 78.69 ± 0.15 a | −3.87 ± 0.10 c | −3.93 ± 0.08c | 20.67 ± 0.24 BC | 19.95 ± 0.55 BC | 4.89 ab |

| RC44 | 81.37 ± 0.54 a | 78.42 ± 0.11 a | −3.77 ± 0.05 c | −4.04 ± 0.02 c | 21.35 ± 0.65 BC | 21.49 ± 0.43 BC | 4.53 ab |

| CBN1 | 66.48 ± 0.31 b | 62.80 ± 0.76 b | 0.05 ± 0.05 a | 0.64 ± 0.01 a | 18.85 ± 0.25 AB | 21.10 ± 0.21 AB | 3.68 a |

| CBN2 | 66.76 ± 0.65 b | 64.59 ± 0.32 b | 0.39 ± 0.06 a | 1.15 ± 0.14 a | 19.46 ± 0.38 AB | 22.00 ± 0.01 AB | 2.39 a |

| CBN3 | 64.63 ± 0.96 b | 62.75 ± 1.01 b | 1.21 ± 0. 27 a | 1.65 ± 0.02 a | 20.11 ± 0.21 AB | 22.50 ± 0.12 AB | 2.01 a |

| CBN4 | 64.11 ± 0.59 b | 63.56 ± 0.78 b | 1.35 ± 0.03 a | 2.89 ± 0.09 a | 20.22 ± 0.10 AB | 23.30 ± 0.27 AB | 0.63 a |

| CC41 | 73.46 ± 0.83 c | 69.26 ± 0.22 c | −0.89 ± 0.38 b | −1.19 ± 0.04 b | 19.28 ± 0.12 A | 17.30 ± 0.07 A | 4.65 b |

| CC42 | 76.01 ± 0.78 c | 69.95 ± 0.64 c | −0.55 ± 0.21 b | −0.75 ± 0.07 b | 20.05 ± 0.32 A | 18.19 ± 0.34 A | 6.34 b |

| CC43 | 75.95 ± 0.76 c | 67.47 ± 0.37 c | −0.41 ± 0.01 b | −0.65 ± 0.00 b | 20.38 ± 0.19 A | 17.97 ± 0.03 A | 8.86 b |

| CC44 | 76.23 ± 0.31 c | 65.99 ± 0.01 c | −0.55 ± 0.07 b | −0.34 ± 0.07 b | 21.36 ± 0.57 A | 17.46 ± 0.13 A | 10.95 b |

| Muestras | Day 0 | Day 12 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PL | HB | BP | PL | HB | BP | |||||||||

| n | K (Pa·sn) | τ0 (Pa) | n | K (Pa·sn) | τ0 (Pa) | ɳp (Pa·s) | n | K (Pa·sn) | τ0 (Pa) | n | K (Pa·sn) | τ0 (Pa) | ɳp (Pa·s) | |

| RBN1 | 0.31 | 4.13 | 0.36 | 2.12 | ||||||||||

| RBN2 | 4.97 | 0.15 | 8.14 | 0.42 | ||||||||||

| RBN3 | 36.02 | 1.13 | 32.35 | 0.12 | ||||||||||

| RBN4 | 76.50 | 0.59 | 5.52 | 55.72 | 0.51 | 0.09 | ||||||||

| RC41 | 6.41 | 0.61 | 1.20 | 1.50 | 0.54 | 0.58 | ||||||||

| RC42 | 18.81 | 0.62 | 3.45 | 14.45 | 0.50 | 1.54 | ||||||||

| RC43 | 36.08 | 0.58 | 4.73 | 12.07 | 0.70 | 2.35 | ||||||||

| RC44 | 56.18 | 1.39 | 72.29 | 2.28 | ||||||||||

| CBN1 | 0.26 | 1.13 | 0.28 | 1.16 | ||||||||||

| CBN2 | 0.23 | 2.42 | 0.29 | 1.82 | ||||||||||

| CBN3 | 0.18 | 11.76 | 0.36 | 2.30 | ||||||||||

| CBN4 | 0.37 | 3.28 | 0.36 | 2.91 | ||||||||||

| CC41 | 2.78 | 0.28 | 0.68 | 2.24 | 0.74 | 0.45 | ||||||||

| CC42 | 4.05 | 0.08 | 3.20 | 0.06 | ||||||||||

| CC43 | 2.69 | 0.64 | 0.33 | 1.96 | 0.74 | 0.43 | ||||||||

| CC44 | 2.81 | 0.61 | 0.54 | 2.26 | 0.62 | 0.41 | ||||||||

| Formulation | G’ (Pa) | G’’ (Pa) | Tan δ | G* (Pa) |

|---|---|---|---|---|

| RBN4 | 418 ± 31 a | 83.4 ± 3.3 a | 0.200 a | 426 ± 16 a |

| RC44 | 156 ± 23 ab | 36.9 ± 4.6 ab | 0.235 a | 160 ± 12 ab |

| CBN4 | 45 ± 2.2 b | 10.5 ± 3.8 b | 0.231 a | 46 ± 2.32 b |

| CC44 | 37 ± 5.9 b | 9.0 ± 2.2 b | 0.239 a | 38 ± 6.05 b |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguilar-Raymundo, V.G.; Vélez-Ruiz, J.F. Physicochemical and Rheological Properties of a Dairy Dessert, Enriched with Chickpea Flour. Foods 2018, 7, 25. https://doi.org/10.3390/foods7020025

Aguilar-Raymundo VG, Vélez-Ruiz JF. Physicochemical and Rheological Properties of a Dairy Dessert, Enriched with Chickpea Flour. Foods. 2018; 7(2):25. https://doi.org/10.3390/foods7020025

Chicago/Turabian StyleAguilar-Raymundo, Victoria Guadalupe, and Jorge Fernando Vélez-Ruiz. 2018. "Physicochemical and Rheological Properties of a Dairy Dessert, Enriched with Chickpea Flour" Foods 7, no. 2: 25. https://doi.org/10.3390/foods7020025

APA StyleAguilar-Raymundo, V. G., & Vélez-Ruiz, J. F. (2018). Physicochemical and Rheological Properties of a Dairy Dessert, Enriched with Chickpea Flour. Foods, 7(2), 25. https://doi.org/10.3390/foods7020025