Multi-Pulsed High Hydrostatic Pressure Treatment of Foods

Abstract

:1. Introduction

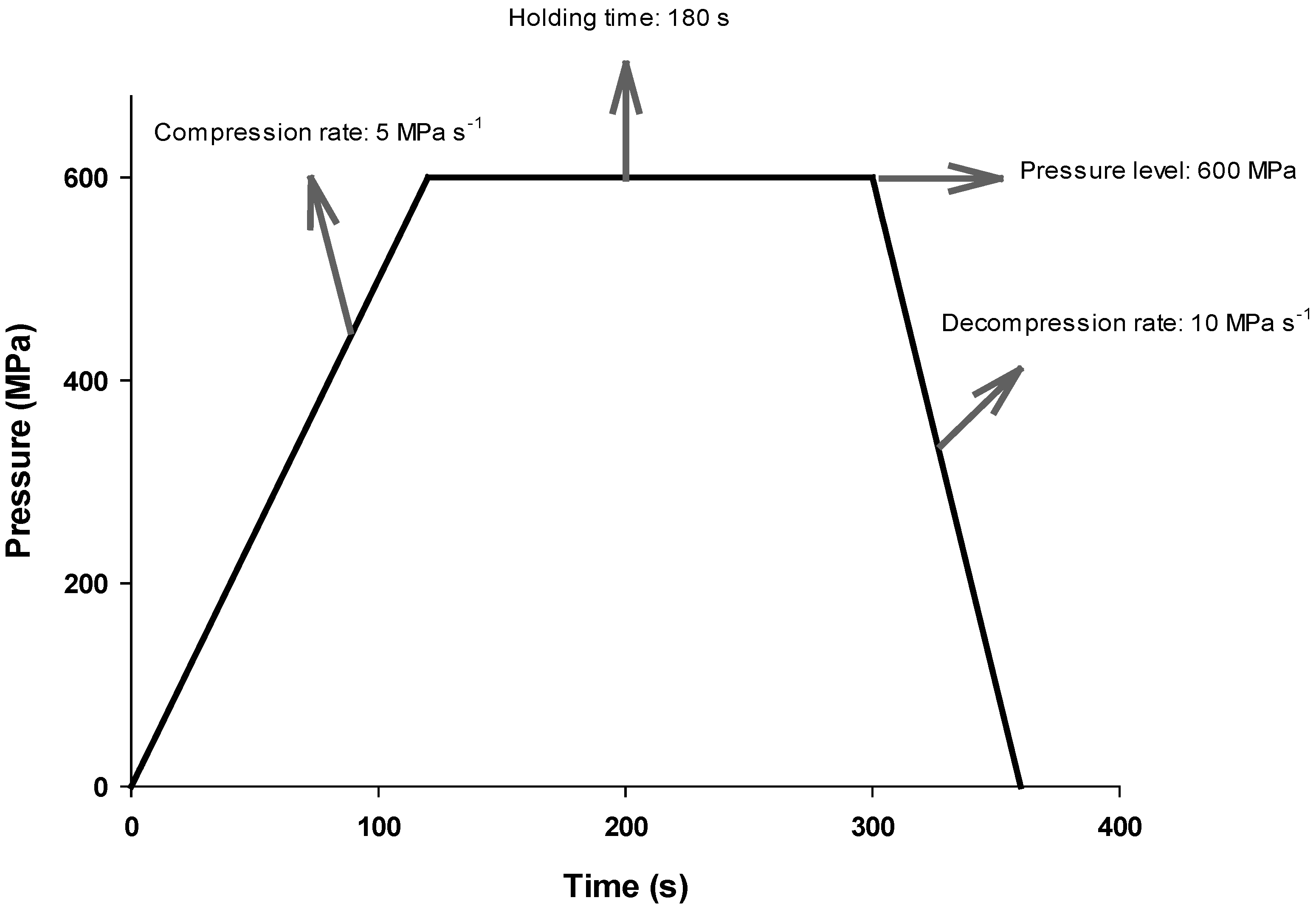

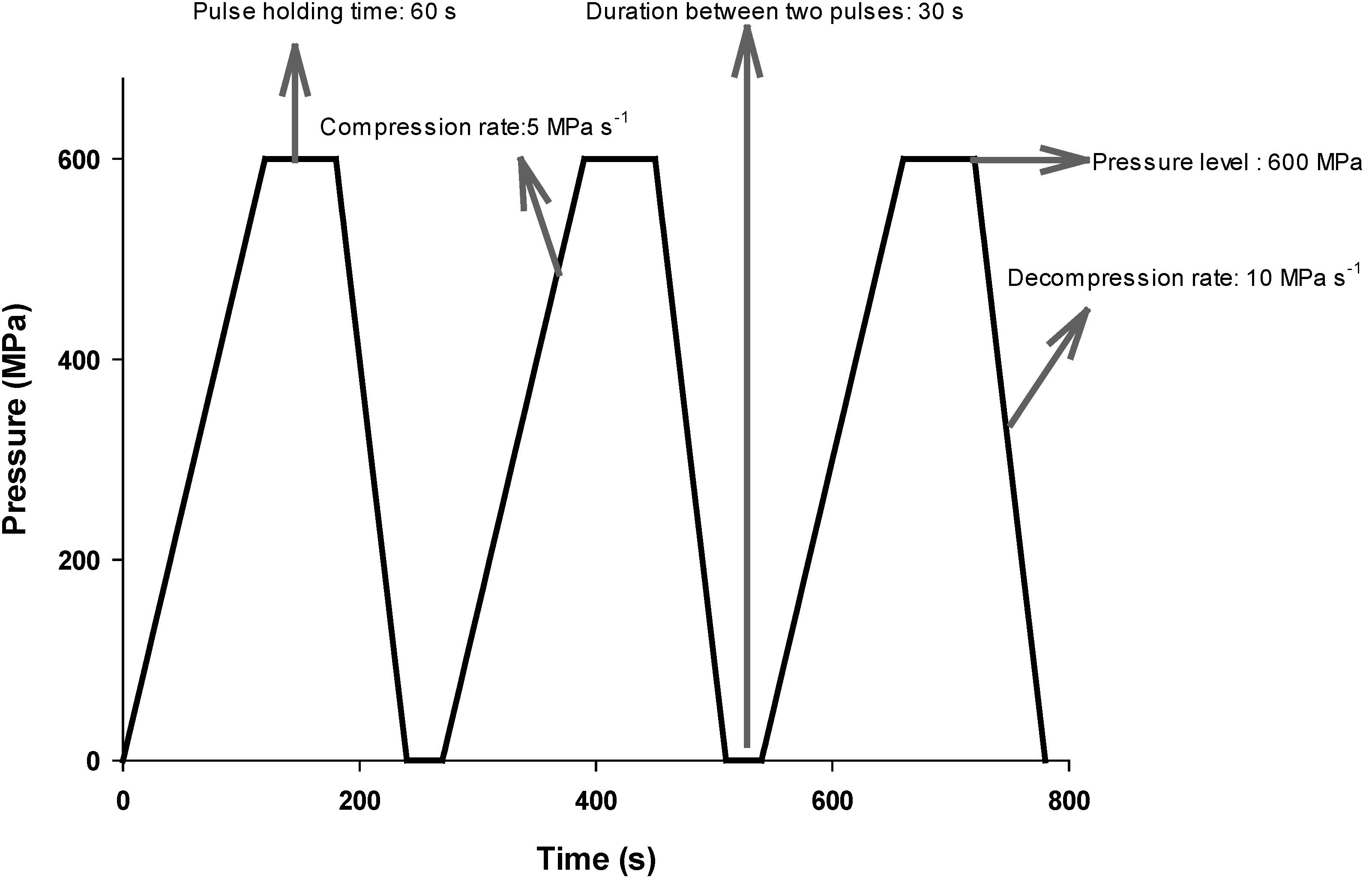

2. Process Parameters of the mpHHP Treatment

3. Application of the mpHHP on Foods

3.1. Fruit Juices

3.2. Dairy Products

3.3. Liquid Whole Egg

3.4. Meat Products

3.5. Sea Foods

3.6. Other Food Products

| Microorganism | Product | CR or CT a | DR or DT b | Process Conditions c | Log Reduction | Reference |

|---|---|---|---|---|---|---|

| Saccharomyces cerevisiae | Pineapple juice | 0.5 s | 0.2 s | 270 MPa, 23 °C, 10 pulses × 10 s | 3.3 | [17] |

| 270 MPa, 23 °C, 100 pulses × 1 s | 3.5 | |||||

| 0.34 s | 0.18 s | 270 MPa, 23 °C, 167 pulses × 0.6 s | 3.9 | |||

| (0.2 s between the pulses) | ||||||

| Byssochlamys nivea | Cranberry juice | 2.4 MPa·s−1 | <10 s | 689 MPa, 60 °C, 3 pulses × 1 s | >4.0 * | [18] |

| ascospores | Apple juice | 689 MPa, 60 °C, 3 pulses × 1 s | >4.0 * | |||

| S. cerevisiae | Pineapple juice | 10.5 MPa·s−1 | ND d | 250 MPa, 25 °C, 10 pulses × 1 min | 4.0 | [19] |

| Orange juice | 250 MPa, 25 °C, 6 pulses × 1 min | >4.5 | ||||

| 250 MPa, 25 °C, 10 pulses × 1 min | >5.0 | |||||

| 200 MPa, 45 °C, 6 pulses × 1 min | >5.0 | |||||

| 200 MPa, 45 °C, 10 pulses × 1 min | ≈5.5 | |||||

| 2.5 MPa·s−1 | ND | 200 MPa, 25 °C, 10 pulses × 1 min | ≈2.7 | |||

| 25 MPa·s−1 | ND | 200 MPa, 25 °C, 10 pulses × 1 min | ≈2.2 | |||

| Escherichia coli | Pineapple juice | 5 MPa·s−1 | 5 MPa·s−1 | 300 MPa, 20 °C, 10 pulses × 30 s | 2.8 | [20] |

| 350 MPa, 20 °C, 5 pulses × 60 s | 2.6 | |||||

| Listeria innocua | 300 MPa, 20 °C, 10 pulses × 30 s | 3.4 | [20] | |||

| 350 MPa, 20 °C, 5 pulses × 60 s | 3.6 | |||||

| E. coli | Kiwifruit juice | 300 MPa, 20 °C, 10 pulses × 30 s | 4.7 | [20] | ||

| 350 MPa, 20 °C, 5 pulses × 60 s | 5.5 | |||||

| L. innocua | 300 MPa, 20 °C, 10 pulses × 30 s | 4.8 | [20] | |||

| 350 MPa, 20 °C, 5 pulses × 60 s | 5.6 | |||||

| E. coli | Skim milk | ND | ND | 550 MPa, 20 °C, 3 pulses × 10 min | 6.0 | [23] |

| Whole milk | 5 MPa·s−1 | 5 MPa·s−1 | 400 MPa, 20–25 °C, 10 pulses × 1 min | 4.0 | [25] | |

| 400 MPa, 20–25 °C, 10 pulses × 2 min | 4.6 | |||||

| L. innocua | 400 MPa, 20–25 °C, 5 pulses × 4 min | 3.9 | [25] | |||

| 400 MPa, 20–25 °C, 10 pulses × 2 min | 4.3 | |||||

| E. coli K-12 | Raw milk cheese | 2.25 MPa·s−1 | < 3s | 400 MPa, 25 °C, 4 pulses × 0 min | ≈3.4 | [26] |

| E. coli O157:H7 | 400 MPa, 25 °C, 4 pulses × 0 min | ≈1.4 | [26] | |||

| L. monocytogenes | 400 MPa, 25 °C, 4 pulses × 0 min | ≈3.8 | [26] | |||

| Bacillus cereus spores | Cheese | ND | ND | 60 MPa, 30 °C, 210 min + 400 MPa | 1.6 | [28] |

| 30 °C, 15 min | ||||||

| S. Enteritidis | Liquid whole egg | 180 s | 90 s | 350 MPa, 50 °C, 2 pulses × 5 min | 7.8 * | [30] |

| 240 s | 120 s | 450 MPa, 20 °C, 2 pulses × 5 min | 7.3 * | |||

| ND | ND | 138 MPa, 20 °C, 2 pulses × 4 min | 1.3 | [31] | ||

| 45 s | 6 s | 350 MPa, 50 °C, 4 pulses × 2 min | >8.0 * | [32] | ||

| E. coli O157:H7 | Ground beef | 2.2 min | 0.3 min | 400 MPa, 12 °C, 3 pulses × 5 min | ≈3.0 | [35] |

| S. Enteritidis | Chicken breast | 96 s | 16.2 s | 300 MPa, 12 °C, 2 pulses × 5 min | 2.5 | [36] |

| fillets | 132 s | 19.2 s | 400 MPa, 12 °C, 3 pulses × 3 min | 4.6 | ||

| Enterobacteriaceae | Octopus muscle | 4 min | ≈2 s | 400 MPa, 7 °C, 3 pulses × 5 min | ≈3.0 | [39] |

| 400 MPa, 40 °C, 3 pulses × 5 min | ≈3.0 | |||||

| S. Enteritidis | Sturgeon caviar | ND | ND | 450 MPa, 20 °C, 3 pulses × 5 min | >4.1 | [40] |

| Trout caviar | 450 MPa, 20 °C, 3 pulses × 5 min | >2.7 | ||||

| S. aureus | Sturgeon caviar | ND | ND | 450 MPa, 20 °C, 3 pulses × 5 min | >3.5 | [40] |

| Trout caviar | 450 MPa, 20 °C, 3 pulses × 5 min | >3.7 | ||||

| S. Enteriditis | Raw almonds | ≈3.6 min | 1 min | 414 MPa, 50 °C, 6 pulses × 20 s | 1.3 | [42] |

| (30 s between the pulses) | ||||||

| E. coli | Egg white | ND | ND | 300 MPa, 20 °C, 3 pulses × 2 min | >7.0 * | [43] |

| B. cereus | Macaroni and | ND | ND | 690 MPa, 90 °C, 2 pulses × 1 min | >6.0 * | [44] |

| spores | cheese | (1 min between the pulses) | ||||

| Clostridium sporogenes spores | 690 MPa, 90 °C, 2 pulses × 1 min | > 6.0 * | [44] | |||

| (1 min between the pulses) |

| Product | CR or CT a | DR or DT b | Process conditions c | Achievement | Reference |

|---|---|---|---|---|---|

| Oyster | 2.5 MPa·s−1 | 15 s | 400 MPa, 7 °C, 2 pulses × 5 min | No apparent advantages over | [14] |

| spHHP treatment | |||||

| Orange juice | 2.8 min | ≈10 s | 400 MPa, 20 °C, 3 pulses × 0 s | 92.4% inactivation of PME | [21] |

| 10.5 MPa·s−1 | 4 s | 250 MPa, 45 °C, 6 pulses × 60 s | 21 days of shelf-life at 4 °C | [22] | |

| Apple juice | 10.5 MPa·s−1 | 5 s | 300 MPa, 50 °C, 6 pulses × 60 s | 21 days of shelf-life at 4 °C | |

| Cheese | ND d | ND | 800 MPa, ND, 3 pulses × 5 min | 4–6 log10 inactivation of microorganisms | [27] |

| Inactivation of proteases | |||||

| No growth of inactivated | |||||

| microorganisms at 5 °C for 12 weeks | |||||

| Yogurt | ND d | ND | 400 MPa, ND, 3 pulses × 5 min | Complete inactivation of | [29] |

| Lactobacillus bulgaricus | |||||

| No acidity change at 1 and 20 °C | |||||

| for 3 weeks | |||||

| Ground beef | 2.2 min | 0.3 min | 400 MPa, 12 °C, 2 pulses × 60 s | Significant color and texture changes | [35] |

| Chicken breast fillets | 2.2 min | 17 s | 400 MPa, 5 °C, 2 pulses × 60 s | Significant color and texture changes | [37] |

4. Commercial Application of the mpHHP

5. Conclusions

Conflicts of Interest

References

- Bermúdez-Aguirre, D.; Barbosa-Cánovas, G.V. An update on high hydrostatic pressure, from laboratory to industrial applications. Food Eng. Rev. 2011, 3, 44–61. [Google Scholar] [CrossRef]

- Tonello, C. Case studies on high-pressure processing of foods. In Nonthermal Processing Technologies for Food; Zhang, H.Q., Barbosa-Cánovas, G.V., Balasubramaniam, V.M., Dunne, C.P., Farkas, D.F., Yuan, J.T.C., Eds.; Woodhead Publishing Limited: Cambridge, London, UK, 2011; pp. 36–50. [Google Scholar]

- Curl, A.L.; Jansen, E.F. Effect of high pressures on trypsin and chymotrypsin. J. Biol. Chem. 1949, 184, 45–54. [Google Scholar]

- Curl, A.L.; Jansen, E.F. The effect of high pressures on pepsin and chymotrypsinogen. J. Biol. Chem. 1950, 185, 713–723. [Google Scholar] [PubMed]

- Ludikhuyze, L.R.; van den Broeck, I.; Weemaes, C.A.; Hendrickx, M.E. Kinetic parameters for pressuretemperature inactivation of Bacillus subtilis α-amylase under dynamic conditions. Biotechnol. Prog. 1997, 13, 617–623. [Google Scholar] [CrossRef]

- Palou, E.; López-Malo, A.; Barbosa-Cánovas, G.V.; Welti-Chanes, J.; Swanson, B.G. Oscillatory high hydrostatic pressure inactivation of Zygosaccharomyces bailii. J. Food Prot. 1998, 61, 1213–1215. [Google Scholar] [PubMed]

- Masschalck, B.; García-Graells, C.; van Haver, E.; Michiels, C.W. Inactivation of high pressure resistant Escherichia coli by lysozyme and nişin under high pressure. Innov. Food Sci. Emerg. Technol. 2000, 1, 39–47. [Google Scholar] [CrossRef]

- Rivalain, N.; Roquain, J.; Boiron, J.M.; Maurel, J.P.; Largeteau, A.; Ivanovic, Z.; Demazeau, G. High hydrostatic pressure treatment for the inactivation of Staphylococcus aureus in human blood plasma. New Biotechnol. 2012, 29, 409–414. [Google Scholar] [CrossRef]

- Hayakawa, I.; Kanno, T.; Yoshiyama, K.; Fujio, Y. Oscillatory compared with continuous high pressure sterilization on Bacillus stearothermophilus spores. J. Food Sci. 1994, 59, 164–167. [Google Scholar] [CrossRef]

- Furukawa, S.; Nakahara, A.; Hayakawa, I. Effect of reciprocal pressurization on germination and killing of bacterial spores. Int. J. Food Sci. Technol. 2000, 35, 529–532. [Google Scholar] [CrossRef]

- Ahn, J.; Balasubramaniam, V.M. Effects of inoculum level and pressure pulse on the inactivation of Clostridium sporogenes spores by pressure-assisted thermal processing. J. Microbiol. Biotechnol. 2007, 17, 616–623. [Google Scholar] [PubMed]

- Pilavtepe-Çelik, M.; Buzrul, S.; Alpas, H.; Largeteau, A.; Demazeau, G. Multi-pulsed high hydrostatic pressure treatment for inactivation and injury of Escherichia Coli. J. Verbrauch. Lebensm. 2011, 6, 343–348. [Google Scholar] [CrossRef]

- Kingsley, D.H.; Guan, D.; Hoover, D.G.; Chen, H. Inactivation of Hepatitis A virus by high-pressure processing: The role of temperature and pressure oscillation. J. Food Prot. 2006, 69, 2454–2459. [Google Scholar] [PubMed]

- López-Caballero, M.E.; Pérez-Mateos, M.; Montero, P.; Borderías, A.J. Oyster preservation by high-pressure treatment. J. Food Prot. 2000, 63, 196–201. [Google Scholar] [PubMed]

- Yuste, J.; Pla, R.; Capellas, M.; Sendra, E.; Beltran, E.; Mor-Mur, M. Oscillatory high pressure processing applied to mechanically recovered poultry meat for bacterial inactivation. J. Food Sci. 2001, 66, 482–484. [Google Scholar] [CrossRef]

- Buzrul, S. Multi-pulsed high hydrostatic pressure treatment of microorganisms: A review. Innov. Food Sci. Emerg. Technol. 2014, 26, 1–11. [Google Scholar] [CrossRef]

- Alemán, G.D.; Ting, E.Y.; Mordre, S.C.; Hawes, A.C.O.; Walker, M.; Farkas, D.F.; Torres, J.A. Pulsed ultra high pressure treatments for pasteurization of pineapple juice. J. Food Sci. 1996, 61, 388–390. [Google Scholar] [CrossRef]

- Palou, E.; López-Malo, A.; Barbosa-Cánovas, G.V.; Welti-Chanes, J.; Davidson, P.M.; Swanson, B.G. Effect of oscillatory high hydrostatic pressure treatments on Byssochlamys nivea ascospores suspended in fruit juice concentrates. Lett. Appl. Microbiol. 1998, 27, 375–378. [Google Scholar] [CrossRef] [PubMed]

- Donsì, G.; Ferrari, G.; Maresca, P. Pulsed high pressure treatment of Saccharomyces cerevisiae: The effect of process parameters. J. Food Eng. 2007, 78, 984–990. [Google Scholar] [CrossRef]

- Buzrul, S.; Largeteau, A.; Alpas, H.; Demazeau, G. Inactivation of Escherichia coli and Listeria innocua in kiwifruit and pineapple juices by high hydrostatic pressure. Int. J. Food Microbiol. 2008, 124, 275–278. [Google Scholar] [CrossRef] [PubMed]

- Basak, S.; Ramaswamy, H.S. Pulsed high pressure inactivation of pectin methyl esterase in single strength and concentrated orange juices. Can. Biosyst. Eng. 2001, 43, 3.25–3.29. [Google Scholar]

- Donsì, G.; Ferrari, G.; Maresca, P. Pasteurization of fruit juices by means of a pulsed high pressure process. J. Food Sci. 2010, 75, E169–E177. [Google Scholar] [CrossRef] [PubMed]

- García-Graells, C.; Masschalck, N.; Moonjai, N.; Michiels, C. High pressure inactivation and survival of pressure-resistant Escherichia coli mutants in milk. In Advances in High Pressure Bioscience and Biotechnology; Ludwig, H., Ed.; Springer-Verlag: Berlin, Germany, 1999; pp. 133–136. [Google Scholar]

- Buzrul, S.; Largeteau, A.; Alpas, H.; Demazeau, G. Pulsed pressure treatment for inactivation of Escherichia coli and Listeria innocua in whole milk. J. Phys. Conf. Ser. 2008, 121. Art. No: 142001. [Google Scholar] [CrossRef]

- Buzrul, S.; Alpas, H.; Largeteau, A.; Demazeau, G. Efficiency of pulse pressure treatment for inactivation of Escherichia coli and Listeria innocua in whole milk. Eur. Food Res. Technol. 2009, 229, 127–131. [Google Scholar] [CrossRef]

- Shao, Y.; Ramaswamy, H.S.; Zhu, S. High-pressure destruction kinetics of spoilage and pathogenic bacteria in raw milk cheese. J. Food Proc. Eng. 2007, 30, 357–374. [Google Scholar] [CrossRef]

- Reps, A.; Kołakowski, P.; Dajnowiec, F. The effect of high pressure on microorganisms and enzymes of ripening cheeses. In High Pressure Food Science, Bioscience & Chemistry; Isaacs, N.S., Ed.; The Royal Society of Chemistry: Cambridge, London, UK, 1998; pp. 265–270. [Google Scholar]

- López-Pedemonte, T.J.; Roig-Sagués, A.X.; Trujillo, A.J.; Capellas, M.; Guamis, B. Inactivation of spores of Bacillus cereus in cheese by high hydrostatic pressure with the addition of nisin or lysozyme. J. Dairy Sci. 2003, 86, 3075–3081. [Google Scholar] [CrossRef] [PubMed]

- Reps, A.; Warminska-Radyko, I.; Dajnowiec, F. Effect of high pressure on yogurt. In Advances in High Pressure Bioscience and Biotechnology; Ludwig, H., Ed.; Springer-Verlag: Berlin, Germany, 1999; pp. 453–456. [Google Scholar]

- Ponce, E.; Pla, R.; Sendra, E.; Guamis, B.; Mor-Mur, M. Destruction of Salmonella enteritidis inoculated in liquid whole egg by high hydrostatic pressure: Comprative study in selective and non-selective media. Food Microbiol. 1999, 16, 357–365. [Google Scholar] [CrossRef]

- Huang, E.; Mittal, G.S.; Griffiths, M.W. Inactivation of Salmonella enteritidis in liquid whole egg using combination of pulsed electrical field, high pressure and ultrasound. Biosyst. Eng. 2006, 94, 403–413. [Google Scholar] [CrossRef]

- Bari, M.L.; Ukuku, D.O.; Mori, M.; Kawamoto, S.; Yamamoto, K. Effect of hydrostatic pressure pulsing on the inactivation of Salmonella Enteritidis in liquid whole egg. Foodborne Path. Dis. 2008, 5, 175–182. [Google Scholar] [CrossRef] [PubMed]

- Ponce, E.; Pla, R.; Capellas, M.; Guamis, B.; Mor-Mur, M. Inactivation of Escherichia coli inoculated in liquid whole egg by high hydrostatic pressure. Food Microbiol. 1998, 15, 265–272. [Google Scholar] [CrossRef]

- Yuste, J.; Mor-Mur, M.; Capellas, M.; Guamis, B.; Pla, R. Microbiological quality of mechanically recovered poultry meat treated with high hydrostatic pressure and nisin. Food Microbiol. 1998, 15, 407–414. [Google Scholar] [CrossRef]

- Morales, P.; Calzada, J.; Ávila, M.; Nuñez, M. Inactivation of Escherichia coli O157:H7 in ground beef by single-cycle and multiple-cycle high-pressure treatments. J. Food Prot. 2008, 71, 811–815. [Google Scholar] [PubMed]

- Morales, P.; Calzada, J.; Rodríguez, B.; de Paz, M.; Nuñez, M. Inactivation of Salmonella Enteritidis in chicken breast fillets by single-cycle and multiple-cycle high pressure treatments. Foodborne Path. Dis. 2009, 6, 577–581. [Google Scholar] [CrossRef] [PubMed]

- Del Olmo, A.; Morales, P.; Ávila, M.; Calzada, J.; Nuñez, M. Effect of single-cycle and multiple-cycle high-pressure treatments on the colour and texture of chicken breast fillets. Innov. Food Sci. Emerg. Technol. 2010, 11, 441–444. [Google Scholar] [CrossRef]

- Hurtado, J.L.; Montero, P.; Borderías, A.J. Influence of high isostatic pressure on muscle of octopus (Octopus vulgaris). In Advances in High Pressure Bioscience and Biotechnology; Ludwig, H., Ed.; Springer-Verlag: Berlin, Germany, 1999; pp. 409–412. [Google Scholar]

- Hurtado, J.L.; Montero, P.; Borderías, J.; Solas, M. High-pressure/temperature treatment effect on the characteristics of octopus (Octopus vulgaris) arm muscle. Eur. Food Res. Technol. 2001, 213, 22–29. [Google Scholar] [CrossRef]

- Fioretto, F.; Cruz, C.; Largeteau, A.; Sarli, T.A.; Demazeau, G.; El Moueffak, A. Inactivation of Staphylococcus aureus and Salmonella enteritidis in tryptic soy broth and caviar samples by high pressure processing. Braz. J. Med. Biol. Res. 2005, 38, 1259–1265. [Google Scholar] [CrossRef] [PubMed]

- Alemán, G.D.; Ting, E.Y.; Farkas, D.F.; Mordre, S.C.; Hawes, A.C.O.; Torres, J.A. Comparison of static and step-pulsed ultra-high pressure on the microbial stability of fresh cut pineapple. J. Sci. Food Agric. 1998, 76, 383–388. [Google Scholar] [CrossRef]

- Goodridge, L.D.; Willford, J.; Kalchayanand, N. Destruction of Salmonella Enteriditis inoculated onto raw almonds by high hydrostatic pressure. Food Res. Int. 2006, 39, 408–412. [Google Scholar] [CrossRef]

- Homma, K.; Haga, N. Effect of high pressure-treatment on sterilization and physical properties of egg white. In High Pressure Science for Food; Hayashi, R., Ed.; San-Ei Publishing: Kyoto, Japan, 1990; pp. 317–324. [Google Scholar]

- Meyer, R. Ultra High Pressure, High Temperature Food Preservation Process. US 6,017,572A, 25 January 2000. [Google Scholar]

- Farkas, D.R.; Hoover, D.G. High pressure processing. J. Food Sci. 2000, 65, 47–64. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buzrul, S. Multi-Pulsed High Hydrostatic Pressure Treatment of Foods. Foods 2015, 4, 173-183. https://doi.org/10.3390/foods4020173

Buzrul S. Multi-Pulsed High Hydrostatic Pressure Treatment of Foods. Foods. 2015; 4(2):173-183. https://doi.org/10.3390/foods4020173

Chicago/Turabian StyleBuzrul, Sencer. 2015. "Multi-Pulsed High Hydrostatic Pressure Treatment of Foods" Foods 4, no. 2: 173-183. https://doi.org/10.3390/foods4020173

APA StyleBuzrul, S. (2015). Multi-Pulsed High Hydrostatic Pressure Treatment of Foods. Foods, 4(2), 173-183. https://doi.org/10.3390/foods4020173