Applying Factorial Modeling to the Optimization of Textural Descriptors and Sensations Relative to Obtaining the Experimental Prototype of Chickpea Puree with Avocado

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Raw Materials

2.1.2. Preparing Avocado and Chickpea Puree

2.2. Methods of Analysis

2.2.1. Methods

2.2.2. Textural Analysis

2.2.3. Multidimensional, Factorial Study

2.2.4. Sensory Analysis

3. Results

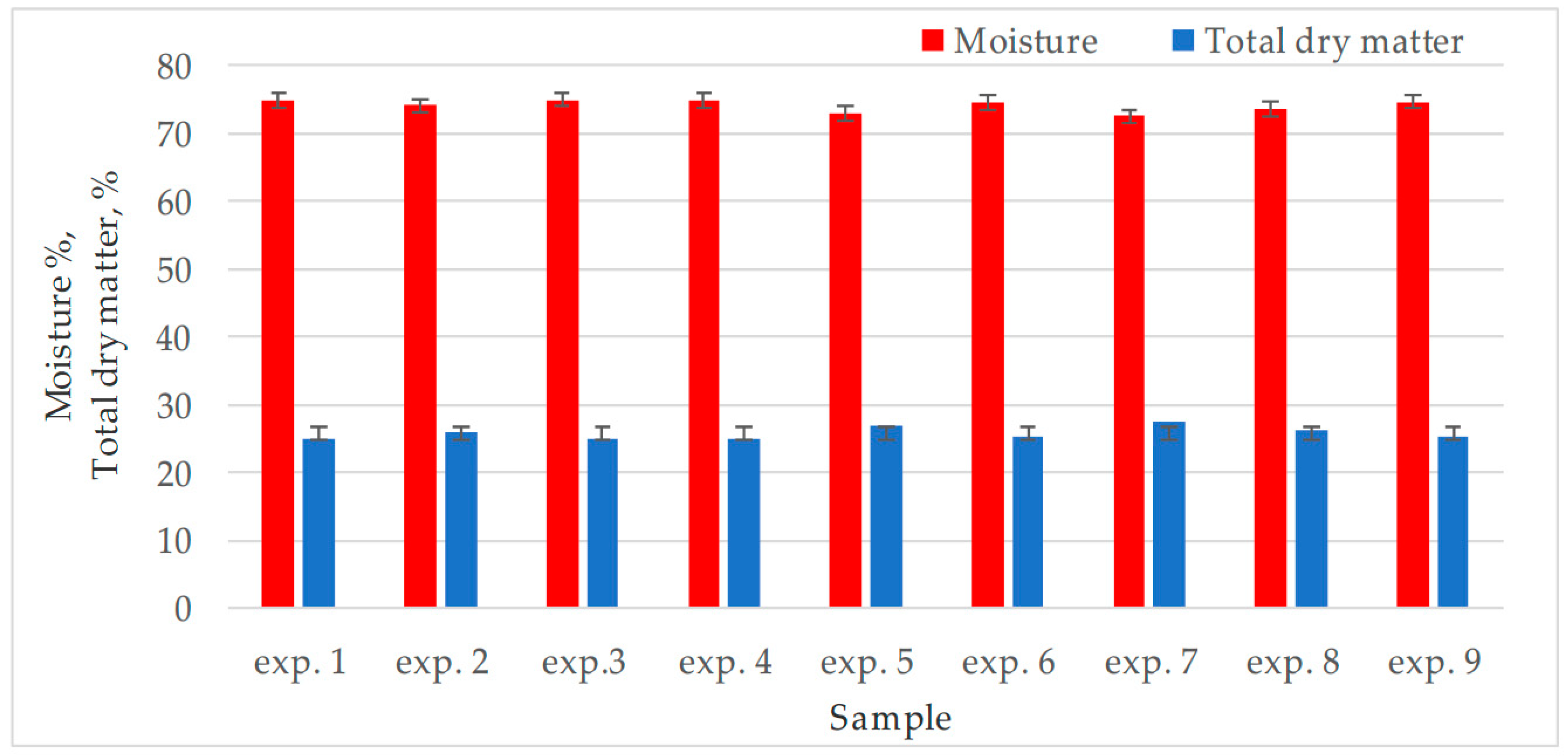

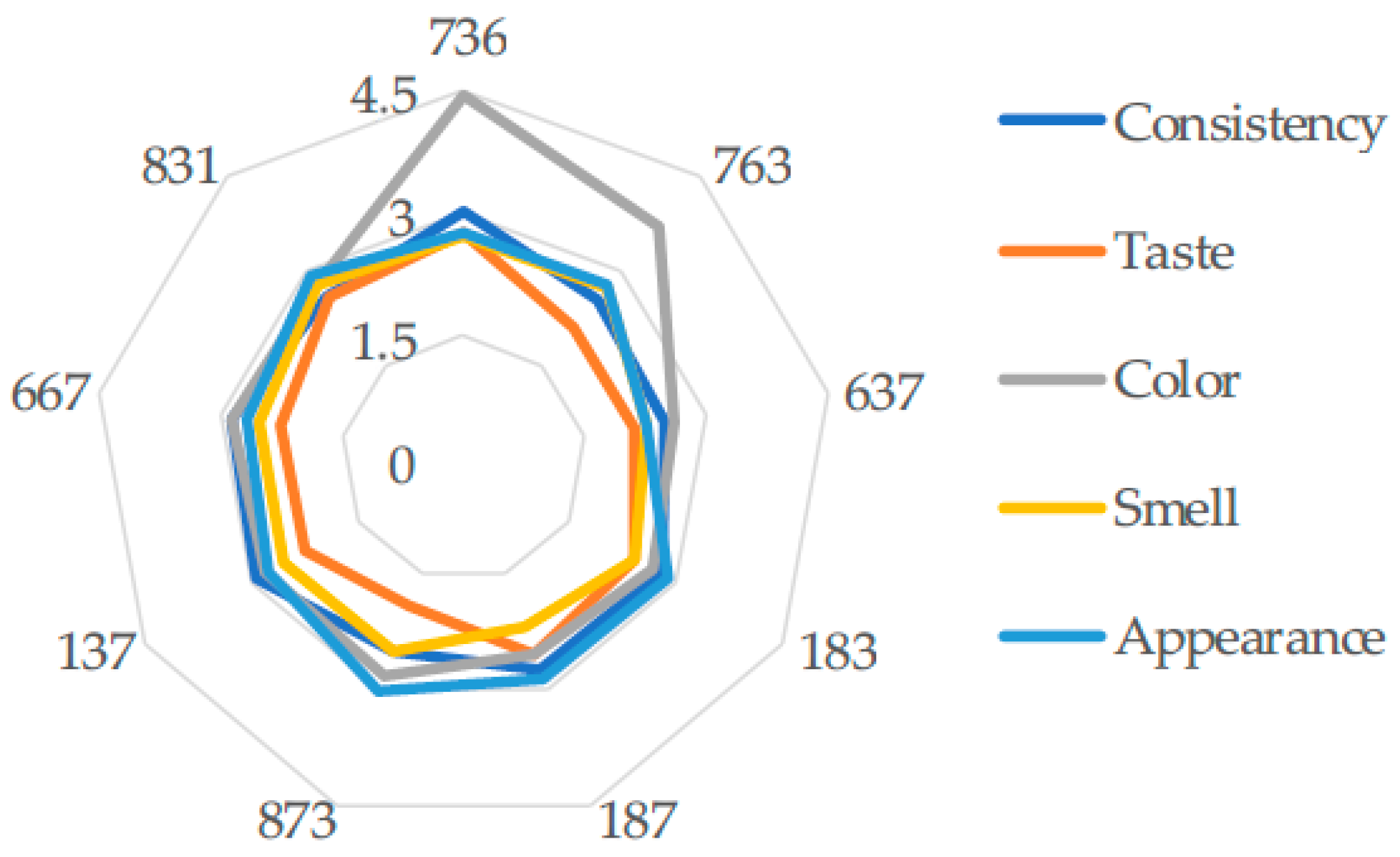

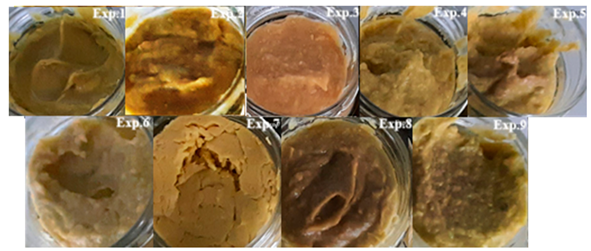

3.1. Technological Studies

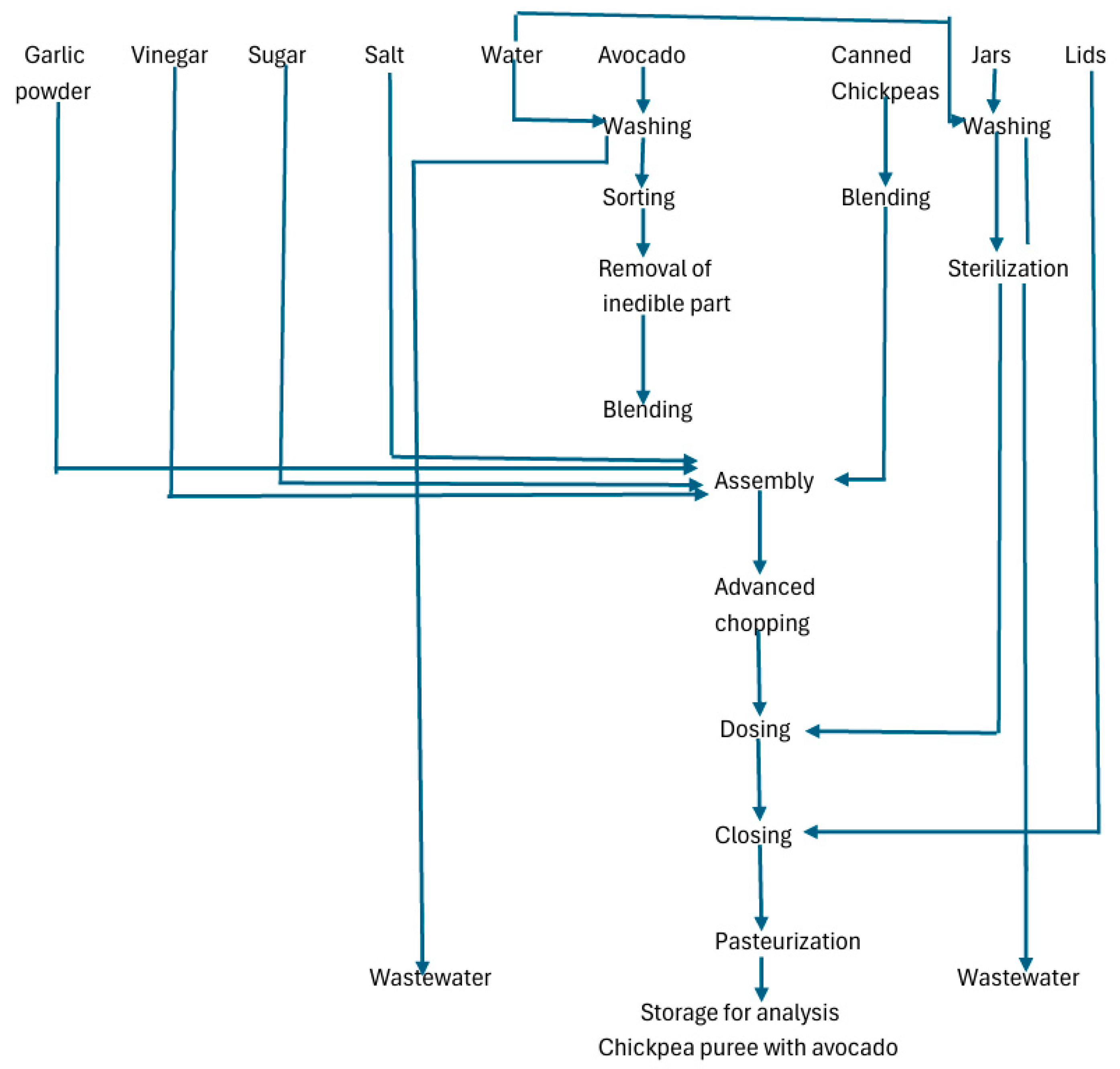

3.1.1. Technological Flow in the Manufacture of Chickpea Puree with Avocado

3.1.2. Physicochemical Indicators for Canned Chickpeas and Fresh Avocado

3.1.3. Experimental Model for Creating a Prototype of a Chickpea and Avocado Puree Product Using Factorial Analysis

| Response | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Experiments | x0 | x1 | x2 | x3 | * Y1 | Y1calc | ** Y2 | Y2calc | *** Y3 | Y3calc |

| 1 | +1 | −1 | −1 | −1 | 63.7 | 66.350 | 11 | 10.75 | 0.960 | 1.0925 |

| 2 | +1 | +1 | −1 | −1 | 80.80 | 80.8 | 9.76 | 9.8863 | 1.200 | 1.2339 |

| 3 | +1 | −1 | +1 | −1 | 59.500 | 51.75 | 8.8 | 9.1387 | 1.320 | 1.1875 |

| 4 | +1 | +1 | +1 | −1 | 91.600 | 91.6 | 9.7 | 10.01 | 0.800 | 0.6673 |

| 5 | +1 | −1 | −1 | +1 | 108.300 | 108.3 | 10.50 | 10.011 | 0.800 | 0.9342 |

| 6 | +1 | +1 | −1 | +1 | 75.60 | 75.6 | 9.3 | 9.387 | 1.270 | 1.4027 |

| 7 | +1 | −1 | +1 | +1 | 75.8 | 75.6 | 10.19 | 9.8863 | 1.020 | 1.9851 |

| 8 | +1 | +1 | +1 | +1 | 80.8 | 83.8 | 10.34 | 10.7589 | 1.620 | 0.5877 |

| 9 | 0 | 0 | 0 | 0 | 81.2 | 10.46 | 1.020 | |||

| 9′ | 0 | 0 | 0 | 0 | 80.3 | 10.00 | 1.010 | |||

| 9′′ | 0 | 0 | 0 | 0 | 81.1 | 10.03 | 0.998 | |||

| Regime Coefficients | Y1calc | Y2calc | Y3calc |

|---|---|---|---|

| b0 | 79.8625 | 9.9488 | +1.1238 |

| b1 | 3.0875 | −0.1738 | +0.0988 |

| b2 | −2.2375 | −0.1913 | +0.0663 |

| b3 | 5.9625 | 0.1338 | +0.0538 |

| b4 | 6.9875 | 0.4363 | −0.0788 |

| b5 | −9.2125 | −0.0887 | + 0.1688 |

| b6 | −3.8875 | 0.3738 | + 0.0763 |

| b7 | 3.2375 | −0.0987 | + 0.1113 |

| Experiments | * Force [g] | Distance [mm] | Time [s] |

|---|---|---|---|

| 1 | −7.5 | 25.022 | 34.916 |

| 2 | ** nD | 29.835 | 29.842 |

| 3 | −8.52 | 25.9525 | 33.899 |

| 4 | −10.0 | 26.406 | 33.563 |

| 5 | −16.0 | 2.,051 | 32.545 |

| 6 | −9.6 | 25.614 | 34.3242 |

| 7 | −11.1 | 25.3165 | 34.535 |

| 8 | −14.3 | 27.009 | 32.759 |

| 9 | −5.4 | 2.6565 | 34.028 |

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Divis, P.; Smilek, J.; Porı’zka, J.; Stursa, V. The quality of ketchups from the Czech republic’s market in terms of their physico chemical properties. Potravinarstvo Slovak. J. Food Sci. 2018, 12, 233–240. [Google Scholar] [CrossRef]

- Martı’nez-Hue’lamo, M.; Tulipani, S.; Estruch, R.; Escribano, E.; Illa’n, M.; Corella, D.; Lamuela-Ravento’s, R.M. The tomato sauce making process affects the bioaccessibility and bioavailability of tomato phenolics: A pharmacokinetic study. Food Chem. 2015, 173, 864–872. [Google Scholar] [CrossRef]

- Kyodo, R.; Kudo, T.; Horiuchi, A.; Sakamoto, T.; Shimizu, T. Pureed diets containing a gelling agent to reduce the risk of aspiration in elderly patients with moderate to severe dysphagia A randomized, crossover trial. Medicine 2020, 99, e21165. [Google Scholar] [CrossRef]

- Sina, B.; Demissie, H.; Rezene, Y. Evaluation of smallholder farmers’ use of indigenous knowledge in Ethiopian avocado (Persea americana Mill.) production and fruit preference criteria. CABI Agric. Biosci. 2023, 4, 57. [Google Scholar] [CrossRef]

- Varol, I.S.; Kırnak, H.; Irik, H.A.; Ozaktan, H. Effects of supplementary drip irrigations applied in different growth stages on yield and yield components of chickpea plants grown under semiarid climate conditions. Gesunde Pflanz. 2023, 75, 1307–1314. [Google Scholar] [CrossRef]

- Migliore, G.; Farina, V.; Tinervia, S.; Matranga, G.; Schifani, G. Consumer interest towards tropical fruit: Factors affecting avocado fruit consumption in Italy. Agric. Food Econ. 2017, 5, 24. [Google Scholar] [CrossRef]

- Pereira, W.F.S.; De Oliveira Lemos, T.; Abreu, V.K.G.; Duarte de Vasconcelos, A.G.; Pinto, R.A.; Pereira, A.L.F. Effect of partial substitution of tomato for avocado on physico chemical and sensory aspects of sweet-and-sour sauce. J. Food Sci. Technol. 2022, 59, 3965–3975. [Google Scholar] [CrossRef]

- Mooliani, H.; Nouri, M. Optimization of oxidative, physical stability and microbial characteristics of salad dressing emulsions based on avocado and whey protein combined with mint (Mentha spicata L) extract. J. Food Meas. Charact. 2021, 15, 5713–5724. [Google Scholar] [CrossRef]

- Cho, B.H.; Koyama, K.; Diaz, E.O.; Koseki, S. Determination of ‘Hass’ avocado ripeness during storage by a smartphone camera using artificial neural network and support vector regression. J. Food Meas. Charact. 2021, 15, 2021–2030. [Google Scholar] [CrossRef]

- Patra, S.; Maurya, L.L.; Muradi, K.B.; Raghavan, M.; Krishnan, G.A.; Maurya, S.; Prusty, J.B.R.; Mohapatra, S.R.; Panda, A.K. Unlocking the Potential of Avocado in India: Exploring Diversity, Cultivation Practices, and Pathways to Progress. Appl. Fruit Sci. 2025, 67, 154. [Google Scholar] [CrossRef]

- Roden, C. A Book of Middle Eastern Food; Vintage: New York, NY, USA, 1985; pp. 45–46. ISBN 0394471814. [Google Scholar]

- Uvezian, S. Recipes and Remembrances from an Eastern Mediterranean Kitchen; The Siamanto Press: Princeton, NJ, USA, 2001; pp. 106–107. ISBN 9780970971685. [Google Scholar]

- Nguyen, D.; Carotenuto, M.; Khan, S.; Bhaduri, R.; Ghatak, K.; Navder, P. Effect of Avocado Fruit Puree as Fat Replacer on the Physical, Textural and Sensory Properties of Shortened Cakes. J. Acad. Nutr. Diet. 2013, 113, A59. [Google Scholar] [CrossRef]

- Adeyeye, S.A.O.; Bolaji, O.B.; Abegunde, T.A.; Emun, H.; Oyenubi, R.A. Quality evaluation and acceptability of cookies produced from wheat (Triticum aestivum) flour substituted with avocado puree as fat substitute. Nutr. Food Sci. 2023, 53, 929–945. [Google Scholar] [CrossRef]

- Giuggioli, N.R.; Chiaberto, G.; Mendez da Silva, T. Quality Evaluation of the Ready-to-Eat Avocado cv. Hass. International J. Food Sci. 2021, 6621449. [Google Scholar] [CrossRef] [PubMed]

- Amado, D.A.V.; Detoni, A.M.; De Carvalho, S.L.C.; Torquato, A.S.; Martin, C.A.; Tiuman, T.S.; Aguiar, C.M.; Cottica, S.M. Tocopherol and fatty acids content and proximal composi-tion of four avocado cultivars (Persea americana Mill). Acta Aliment. 2019, 48, 47–55. [Google Scholar] [CrossRef]

- Shulman, M.R. Mediterranean Harvest: Vegetarian Recipes from the World’s Healthiest Cuisine: A Cookbook; Potter/Ten Speed/Harmony/Rodale: Westminster, MD, USA, 2010; p. 103. ISBN 978-1-60529-619-7. [Google Scholar]

- Sm’ykal, B.P.; CoyneJ, C.; Ambrose, J.M.; Maxted, N.; Schaefer, H.; Blair, W.M.; Berger, J.; Greene, L.S.; Nelson, N.M.; Besharat, N.; et al. Legume Crops Phylogeny and Genetic Diversity for Science and Breeding. Plant Sci. 2015, 34, 43–104. [Google Scholar] [CrossRef]

- FAO (Food and Agriculture Organization of the United Nations). Data of Crops Production. 2018. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 30 November 2018).

- Summoa, C.; De Angelisa, D.; Rochetteb, I.; Mouquet-Rivierb, C.; Pasqualone, A. Influence of the preparation process on the chemical composition and nutritional value of canned puree of kabuli and Apulian black chickpeas. Heliyon 2019, 5, e01361. [Google Scholar] [CrossRef]

- Vasishtha, H.; Srivastava, R.P. Changes in lipids and fatty acids during soaking and germination of chickpea (Cicer arietinum). Indian J. Agr. Biochem. 2012, 25, 14–19. [Google Scholar]

- Gisslen, W.; Griffin, M.E.; Bleu, L.C. Professional Cooking for Canadian Chefs; John Wiley & Sons: Hoboken, NJ, USA, 2006; p. 762. ISBN 978-0-471-66377-5. [Google Scholar]

- Deng, J.W.; Bhaduri, S.; Ghatak, R.; Navder, K.P. Effect of Chickpea Puree as a Fat Replacer on the Physical, Textural and Sensory Properties of Cheesecake. J. Am. Diet. Assoc. 2011, 111, A63. [Google Scholar] [CrossRef]

- Vinod, B.R.; Asrey, R.; Rudra, S.; Urhe, S. Chickpea as a promising ingredient substitute in gluten-free bread making: An overview of technological and nutritional benefits. Food Chem. Adv. 2017, 3, 100473. [Google Scholar] [CrossRef]

- Keller, H.; Chambers, L.; Niezgoda, H.; Duizer, L. Issues associated with the use of modified texture foods. J. Nutr. Health Aging 2012, 16, 195–200. [Google Scholar] [CrossRef]

- Martinez, O.; Vicente, M.S.; De Vega, M.C.; Salmeron, J. Sensory perception and flow properties of dysphagia thickening formulas with different composition. Food Hydrocoll. 2019, 90, 508–514. [Google Scholar] [CrossRef]

- Peh, J.X.; Lim, W.; Goh, K.K.; Dharmawan, J. Correlation between instrumental and sensory properties of texture-modified carrot puree. J. Texture Stud. 2021, 53, 72–80. [Google Scholar] [CrossRef]

- Nasaruddin, F.; Chin, N.L.; Yusof, Y.A. Effect of processing on instrumental textural properties of traditional Docol using back extrusion. Int. J. Food Prop. 2012, 15, 495–506. [Google Scholar] [CrossRef]

- SR 2714:2003; Fructe și Legume Proaspete. Asociația de Standardizare din România: Bucharest, Romania, 2003.

- Analytical Methods: Determination of Moisture Content; AOAC: Rockville, MD, USA, 2000.

- EN 12147:1998; Fruit and Vegetable Juice—Determination of Titrable Acidity of Fruit and Vegetable Juice and Related Product. European Committee for Standardization: Brussels, Belgium, 1998.

- AOAC Official Method 932.12; Solids (Soluble)in Fruits and Fruit Products, Refractometer. AOAC: Rockville, MD, USA, 1980.

- NMKL 179:2005; pH-Value. Nordic Committee on Food Analysis: Bergen, Norway, 2005.

- Helmenstine, A.M. Vitamin C Determination by Iodine Titration; Science, Techology, Math; ThoughtCo: New York, NY, USA, 2019. [Google Scholar]

- SR ISO 3634:2009; Produse Din Legume. Determinarea Conținutului de Clorura de Sodiu. Asociația de Standardizare din România: Bucharest, Romania, 2009.

- STAS 5951-83; Produse din Legume și Fructe. Determinarea Masei Nete a Conținutului Total de Legume sau Fructe și a Conținutului Unui Component Raportat la Masa Netă. Institutul Român de Standardizare: Bucharest, Romania, 1983.

- Destouches, J.L. Basic concepts of System theory. Cybern. Syst. 1980, 11, 195–214. [Google Scholar] [CrossRef]

- Mironescu, M.; Iancu, M.L.; Mironescu, V. Quality assurance at the obtaining pregelatinised starches. Ann. Univ. Craiova 2006, XI, 133–138. [Google Scholar]

- STAS 12656-88; Produse Alimentare. Analiza Senzorială. Metoda Scării de Punctaj. Institutul Român de Standardizare: Bucharest, Romania, 1988.

- Zhang, F.; Gu, Y.; Aaqil, M.; Huang, A.; Zheng, Z.; Shi, Z.; Tian, Y.; Zhuang, L.; Zhao, C. Process optimization and flavor characteristics of cream cheese fermented with avocado co-cultures. Food Chem. X 2025, 29, 102745. [Google Scholar] [CrossRef]

- Liu, D.; Wang, X.; Zhou, Q.; Zhu, Y.; Chen, Z.; Zhou, J.H.P. Investigating the role of water in rheological and friction properties of pureed foods: A deep dive into avocado puree. J. Food Eng. 2025, 385, 112268. [Google Scholar] [CrossRef]

- Martinez-Padilla, L.P.; Franke, L.; Juliano, P. Characterisation of the viscoelastic properties of avocado puree for process design applications. Biosyst. Eng. 2017, 161, 62–69. [Google Scholar] [CrossRef]

- Marconati, M.; Lopez, F.; Tuleu, C.; Orlu, M.; Rancaioli, M. In vitro and sensory tests to design easy-to-swallow multi-particulate formulation. Eur. J. Pharm. Sci. 2019, 132, 157–162. [Google Scholar] [CrossRef]

- Qiu, L.; Zhang, M.; Bhandari, B.; Chitrakar, B.; Chang, L. Investigation of 3D printing of apple and edible rose blends as a dysphagia food. Food Hydrocoll. 2023, 135, 108184. [Google Scholar] [CrossRef]

- Shewan, M.H.; Stokes, R.J. Viscosity of soft spherical micro-hydrogel suspensions. J. Colloid. Interface Sci. 2015, 442, 75–81. [Google Scholar] [CrossRef] [PubMed]

| Rating | Basis for Assessing Organoleptic Characteristics | Number of Points |

|---|---|---|

| Very good | Specific positive characteristic, very well-defined, without defects | 5 |

| Good | Specific positive characteristic, fairly well-defined, with very small defects | 4 |

| Satisfactory | Specific positive characteristic, very poorly defined, with small defects due to which it is at the minimum level allowed by the standard | 3 |

| Unsatisfactory | Presents deficiencies or defects of the characteristic due to which it does not meet the minimum condition of the standard; the product can be used for direct consumption | 2 |

| Inadequate | Presents defects, obvious deficiencies of the characteristic that it can no longer be used for consumption except after appropriate processing | 1 |

| Altered | Presents accentuated defects of the characteristic, specific to an altered product that can no longer be consumed | 0 |

| Quality Indicators | Canned Chickpeas | Avocado Fruit |

|---|---|---|

| Net mass, g | 425 ± * 21.79 | 247.3 ± 5.1 |

| Liquid fraction, % | 42.6 ± 2.02 | - |

| Solid fraction, % | 57 ± 2.00 | - |

| Circumference, cm | - | 27.9 ± 9.13 |

| Fruit length, cm | - | 12.7 ± 2.494 |

| Peel, % | - | 15.16 ± 0.78 |

| Stone, % | - | 14.79 ± 0.406 |

| Pulp, % | - | 69.24 ± 0.360 |

| pH | 4.58 ± 0.01 | 6.34 ± 0.09 |

| Titratable acidity, g/100 g expressed as citric acid | 0.20 ± 0.03 | 0.12 ± 0.034 |

| Total soluble solid, oBx | 9.60 ± 0.23 | - |

| Vitamin C, mg/100 g | 2.26 ± 0.41 | 15.1 ± 1.35 |

| Salt, % | 0.29 ± 0.016 | - |

| Moisture, % | 66.53 ± 0.83 | 88.66 ± 0.38 |

| Total dry matter, % | 33.47 ± 0.81 | 10.9 ± 0.33 |

| Variable Level Code | ||||

|---|---|---|---|---|

| Variable | Symbol | −1 | 0 | +1 |

| Chickpea content | x1 | 45 | 50 | 55 |

| Avocado content | x2 | 45 | 50 | 55 |

| Sugar/vinegar ratio | x3 | 32.5 | 37.5 | 42.5 |

| Experiments and Macroscopic Images | x1 | x2 | x3 | |

|---|---|---|---|---|

| 1 | 450 | 450 | 32.5 |

| 2 | 550 | 450 | 32.5 | |

| 3 | 450 | 550 | 32.5 | |

| 4 | 550 | 550 | 32.5 | |

| 5 | 450 | 450 | 42.5 | |

| 6 | 550 | 450 | 42.5 | |

| 7 | 450 | 550 | 42.5 | |

| 8 | 550 | 550 | 42.5 | |

| 9 | 500 | 500 | 37.5 | |

| 9′ | 500 | 500 | 37.5 | |

| 9′′ | 500 | 500 | 37.5 | |

| Texture Attribute | Sensory Attribute | Pearson Correlation Coefficient (r) | R2 | p-Value | T Statistic | Distribution | Significance Level (α) |

|---|---|---|---|---|---|---|---|

| Force(g) | Consistency(points) | −0.8239 | 0.6788 | 0.00002636 | −5.8145 | Two-tailed | 0.05 |

| Force(g) | Appearance(points) | −0.8072 | 0.6516 | 0.0000514 | −5.4698 | Two-tailed | 0.05 |

| Force(g) | Taste(points) | −0.6912 | 0.4777 | 0.001491 | −3.8254 | Two-tailed | 0.05 |

| Force(g) | Color(points) | −0.9281 | 0.8613 | 2.872 × 10−8 | −9.968 | Two-tailed | 0.05 |

| Force(g) | Smell(points) | −0.8072 | 0.6516 | 0.0000514 | −5.4698 | Two-tailed | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iancu, M.L.; Mironescu, I.D. Applying Factorial Modeling to the Optimization of Textural Descriptors and Sensations Relative to Obtaining the Experimental Prototype of Chickpea Puree with Avocado. Foods 2025, 14, 4082. https://doi.org/10.3390/foods14234082

Iancu ML, Mironescu ID. Applying Factorial Modeling to the Optimization of Textural Descriptors and Sensations Relative to Obtaining the Experimental Prototype of Chickpea Puree with Avocado. Foods. 2025; 14(23):4082. https://doi.org/10.3390/foods14234082

Chicago/Turabian StyleIancu, Maria Lidia, and Ion Dan Mironescu. 2025. "Applying Factorial Modeling to the Optimization of Textural Descriptors and Sensations Relative to Obtaining the Experimental Prototype of Chickpea Puree with Avocado" Foods 14, no. 23: 4082. https://doi.org/10.3390/foods14234082

APA StyleIancu, M. L., & Mironescu, I. D. (2025). Applying Factorial Modeling to the Optimization of Textural Descriptors and Sensations Relative to Obtaining the Experimental Prototype of Chickpea Puree with Avocado. Foods, 14(23), 4082. https://doi.org/10.3390/foods14234082