Postharvest Handling and Storage Strategies for Preserving Jujube (Ziziphus jujuba Mill.) Fruit Quality: A Review

Abstract

1. Introduction

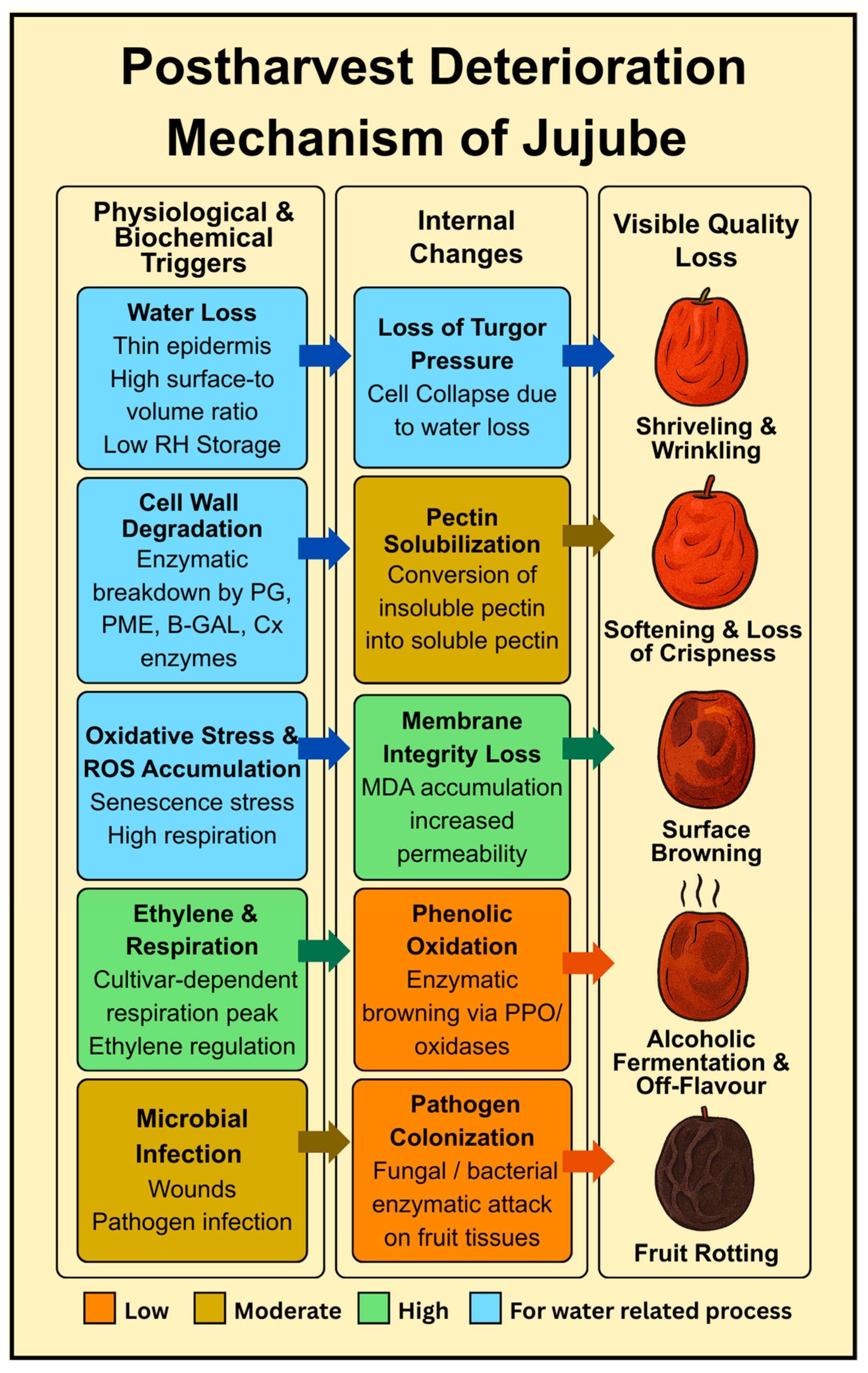

2. Postharvest Physiology and Deterioration Mechanism

3. Postharvest Handling Practices

3.1. Harvesting Techniques

3.2. Sorting and Grading

3.3. Cleaning and Sanitization

3.4. Packaging Systems

3.5. Postharvest Monitoring and Quality Assurance

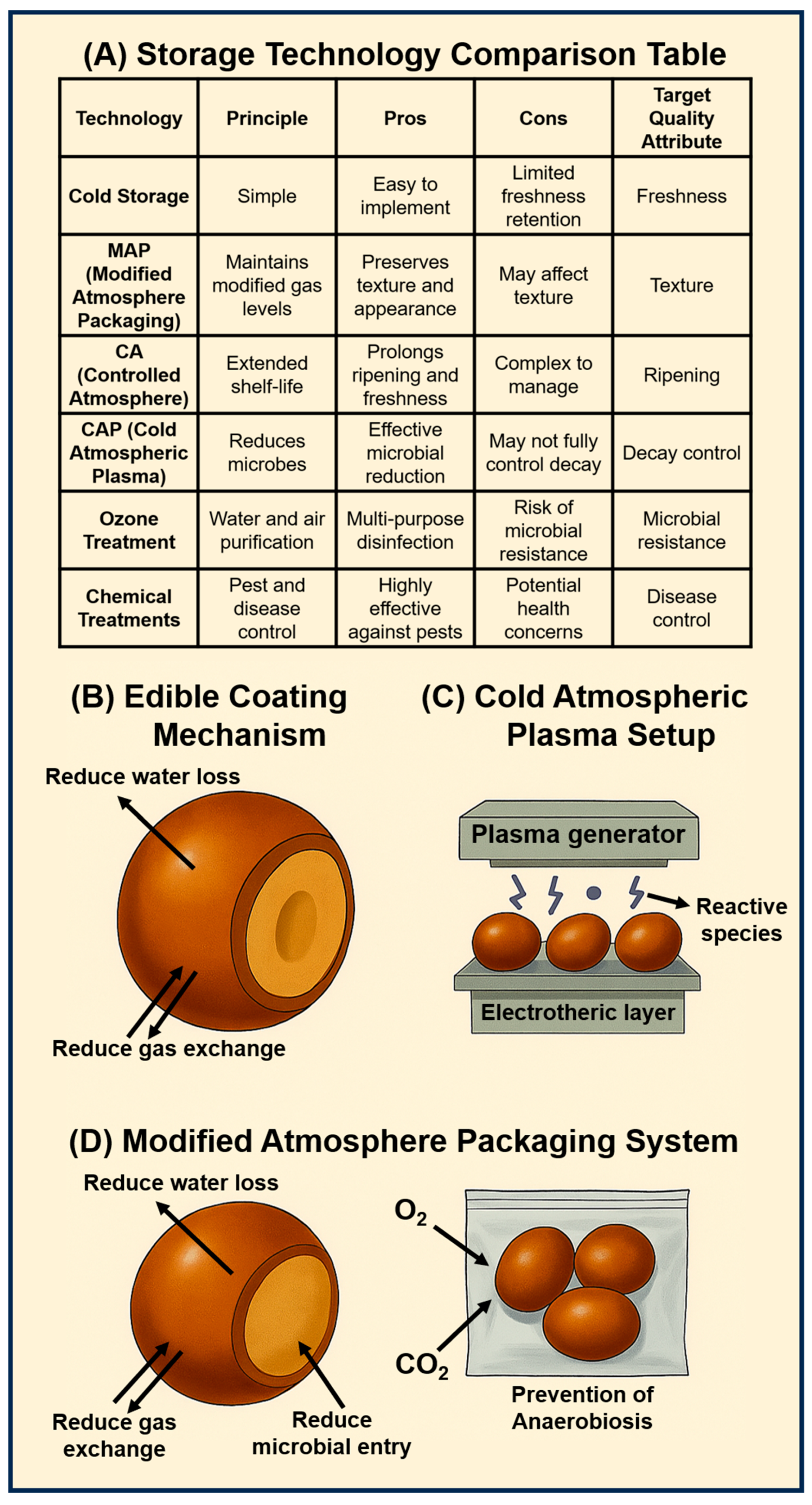

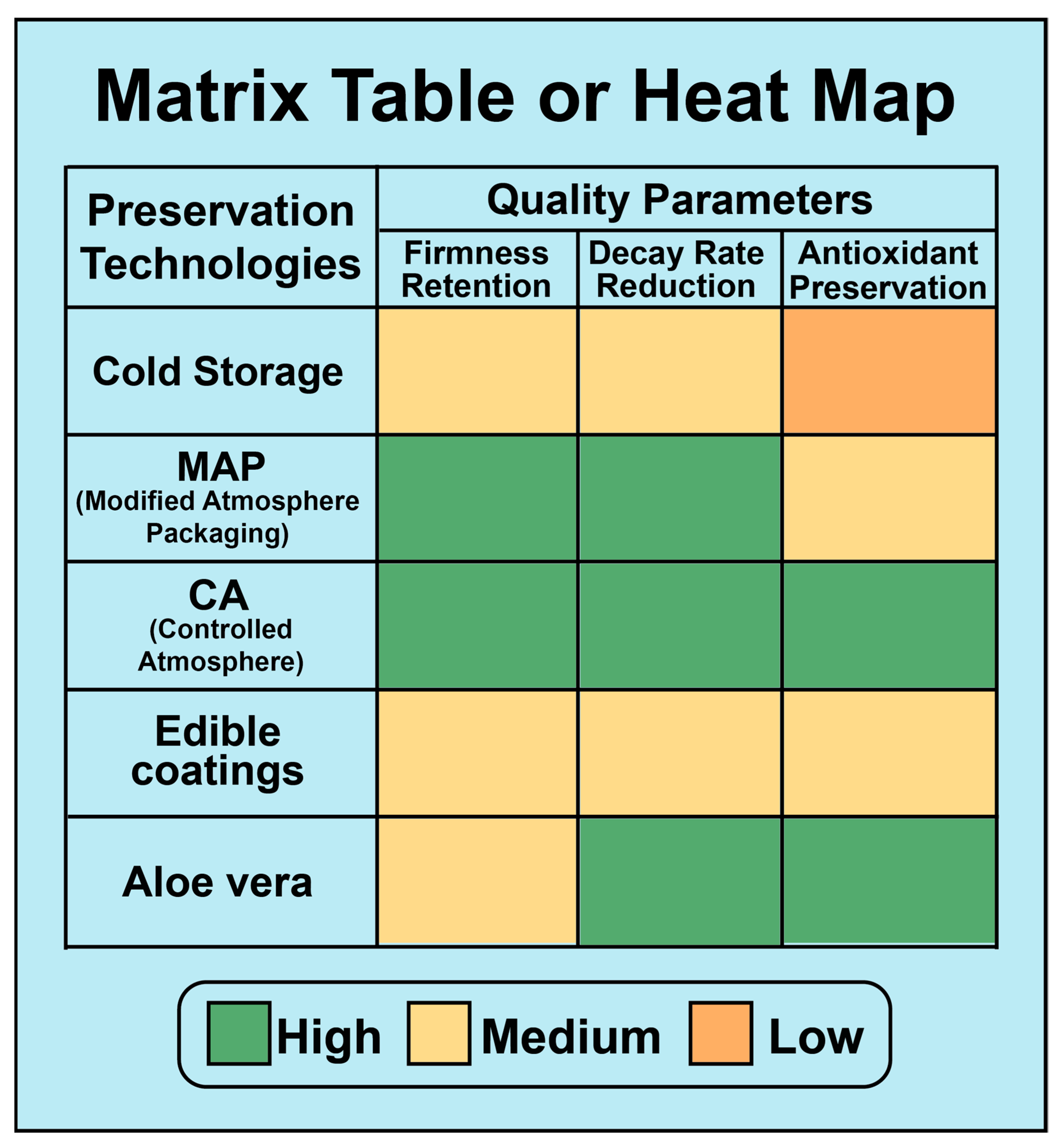

4. Storage Technologies for Shelf-Life Extension

4.1. Cold Storage

4.2. Modified Atmosphere Packaging (MAP)

4.3. Controlled Atmosphere (CA) Technology

4.4. Cold Atmospheric Plasma and Ozone Treatment

4.5. Novel/Non-Thermal Technologies

4.6. Edible Coatings

4.7. Chemical Treatments

| Category | Types/Material | Examples (Including Coating Agents, Chemicals, Non-Thermal Devices, etc.) | Main Effects/Purpose | Key Citations |

|---|---|---|---|---|

| Cold storage | Refrigerated storage (0–4 °C) | Cold storage at 0–4 °C for winter/Chinese jujube | Slows respiration, reduces weight loss and decay; delays reddening/senescence | [29] |

| MAP | Passive/active MAP (O2/CO2/N2) | MAP at ~15–25% O2 and 5–10% CO2; vacuum vs. active MAP | Lowers respiration and browning; extends shelf life and maintains firmness/flavor | [22] |

| Micro-perforated films (PMP-MAP) | Laser micro-perforated BOPP for winter jujube | Prevents anaerobiosis, preserves antioxidants and flavor; reduces reddening/decay | [22] | |

| AEW + MAP combo | AEW rinse + MAP | Maintains firmness, delays softening; enhances antioxidant system | [30] | |

| CA | Low O2/low CO2 | 3–5% O2, <2% CO2, 2–0 °C, RH >95% | Extends storage (2–4 months reported); reduces decay and maintains quality | [51] |

| Elevated oxygen (≈60% O2) | 60% O2 atmosphere for winter jujube at 0–4 °C | Maintains antioxidant capacity; inhibits anaerobic metabolism and off-flavor | [30] | |

| Novel/non-thermal technology | CAP | DBD/plasma jet exposure | Reduces weight loss/decay; delays reddening and senescence; improves ROS balance | [26] |

| Ozone (gaseous) | 2.5–10 μL/L O3 exposure | Reduces decay by modulating fruit-surface microbiome | [56] | |

| Ozone (aqueous) | 1.5–3 mg/L dissolved O3 wash | Decontamination with minimal quality impact; extends shelf life | [53] | |

| UV-C (photochemical) | 5 kJ/m2 UV-C; storage at 4 °C | Delays senescence; regulates ROS and phenylpropanoid metabolism; lowers decay | [62] | |

| Ultrasound-assisted sanitizing | Ultrasound + low-chlorine wash | Prevents cross-contamination; effective decontamination without hurting quality | [32] | |

| UV-C + biocontrol | UV-C + Metschnikowia pulcherrima yeast | Controls Alternaria rot; reduces decay without quality loss | [67] | |

| Edible coatings | Chitosan (CTS) | 1% chitosan coating | Reduces weight loss, decay; preserves firmness | [20] |

| Chitosan + cinnamon oil | 1% CTS + 0.10–0.75% cinnamon oil | Antifungal, lowers decay and weight loss; maintains sensory quality | [76] | |

| Aloe vera gel | 33–50% Aloe vera | Cuts weight loss; preserves TSS/TA; better firmness | [28] | |

| Pectin | 1.0–1.5% pectin | Reduces weight loss; maintains acidity | [28] | |

| CMC | 1–2% carboxymethyl cellulose | Delays browning and firmness loss | [28] | |

| Composite CTS/nano-SiO2/alginate | CTS + nano-SiO2 + alginate blend | Improves moisture barrier; prolongs shelf life | [13] | |

| Pectin + natamycin | Pectin matrix + natamycin | Controls decay while maintaining quality | [53] | |

| Chitosan + ε-PL | 1% CTS + ε-PL | Enhanced decay suppression; maintains firmness | [85] | |

| Chemical treatments | 1-MCP | 0.5–1.0 μL/L 1-MCP | Delays ripening/senescence; reduces decay | [85] |

| 1-MCP + CaCl2 | 1-MCP + 1–2% CaCl2 | Synergistic firmness and quality retention | [85] | |

| 1-MCP + SA | 1-MCP + salicylic acid | Best shelf-life extension via ROS regulation | [86] | |

| Salicylic acid | 1–2 mM SA | Controls Alternaria rot; induces resistance | [20] | |

| Calcium chloride | 1–2% CaCl2 | Supports cell wall integrity | [20] | |

| Calcium nitrate | 1% Ca(NO3)2 | Maintains firmness and quality | [83] | |

| SNP | SNP fumigation | Delays senescence; lowers browning | [16] | |

| NaHS | NaHS fumigation | Extends storage; regulates ROS | [7] | |

| Gibberellin (GA3) | ≈10 mg/L GA3 | Delays reddening; slows senescence | [87] | |

| Brassinolide (BR) ± CaCl2 | BR + CaCl2 | Maintains quality; reduces decay | [16] | |

| Ascorbic acid | 1–2% AA dip | Antioxidant; maintains firmness | [17] | |

| Citric acid | 0.5–1.5% CA | Reduces decay; maintains sugars/TA | [16] |

5. Challenges and Research Gaps

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| 1-MCP | 1-Methylcyclopropene |

| AA | Ascorbic Acid |

| AEW | Acidic Electrolyzed Water |

| APPJ | Atmospheric Pressure Plasma Jet |

| BABA | β-Aminobutyric Acid |

| BOPP | Biaxially Oriented Polypropylene |

| BR | Brassinolide |

| CA | Controlled Atmosphere |

| Ca(NO3)2 | Calcium Nitrate |

| CaCl2 | Calcium Chloride |

| CAP | Cold Atmospheric Plasma |

| CDPJ | Corona Discharge Plasma Jet |

| CMC | Carboxymethyl Cellulose |

| CTS | Chitosan |

| Cx | Cellulase |

| DBD | Dielectric Barrier Discharge |

| DPPH | 2,2-Diphenyl-1-picrylhydrazyl (radical scavenging assay) |

| EBI | Electron Beam Irradiation |

| FRAP | Ferric Reducing Antioxidant Power |

| GA3 | Gibberellic Acid |

| LDPE | Low-Density Polyethylene |

| MAP | Modified Atmosphere Packaging |

| MDA | Malondialdehyde |

| NaHS | Sodium Hydrosulfide (Hydrogen Sulfide donor) |

| O3 | Ozone |

| PE | Polyethylene |

| PEF | Pulsed Electric Field |

| PG | polygalacturonase |

| PMP-MAP | Perforated Micro-Perforated Modified Atmosphere Packaging |

| POD | Peroxidase |

| PPO | Polyphenol Oxidase |

| ROS | Reactive Oxygen Species |

| SA | Salicylic Acid |

| SNP | Sodium Nitroprusside (Nitric Oxide donor) |

| SOD | Superoxide Dismutase |

| TA | Titratable Acidity |

| TSS | Total Soluble Solids |

| UV-C | Ultraviolet-C |

| α-L-Af | α-L-Arabinofuranosidase |

| β-Gal | β-Galactosidase |

| β-Glu | β-Glucosidase |

| ε-PL | ε-Polylysine |

References

- Shen, D.; Kou, X.; Wu, C.; Fan, G.; Li, T.; Dou, J.; Wang, H.; Zhu, J. Cocktail enzyme-assisted alkaline extraction and identification of jujube peel pigments. Food Chem. 2018, 357, 129747. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Wang, J.; Wang, L.; Zhao, J.; Zhao, Z.; Yao, S.; Stănică, F.; Liu, Z.; Ao, C. The historical and current research progress on jujube—A superfruit for the future. Hortic. Res. 2020, 7, 119. [Google Scholar] [CrossRef]

- Bao, T.; Hao, X.; Shishir, M.R.I.; Karim, N.; Chen, W. Cold plasma: An emerging pretreatment technology for the drying of jujube slices. Food Chem. 2021, 337, 127783. [Google Scholar] [CrossRef]

- Cai, W.; Zhuang, H.; Wang, X.; Fu, X.; Chen, S.; Yao, L.; Sun, M.; Wang, H.; Yu, C.; Feng, T. Functional nutrients and jujube-based processed products in Ziziphus jujuba. Molecules 2024, 29, 3437. [Google Scholar] [CrossRef]

- Dou, J.F.; Kou, X.H.; Wu, C.E.; Fan, G.J.; Li, T.T.; Li, X.J.; Zhou, D.D.; Yan, Z.C.; Zhu, J.P. Recent advances and development of postharvest management research for fresh jujube fruit: A review. Sci. Hortic. 2023, 310, 111769. [Google Scholar] [CrossRef]

- Huang, Y.L.; Yen, G.C.; Sheu, F.; Chau, C.F. Effects of water-soluble carbohydrate concentrate from Chinese jujube on different intestinal and fecal indices. J. Agric. Food Chem. 2008, 56, 1734–1739. [Google Scholar] [CrossRef]

- Lu, Y.; Bao, T.; Mo, J.; Ni, J.; Chen, W. Research advances in bioactive components and health benefits of jujube (Ziziphus jujuba Mill.) fruit. J. Zhejiang Univ. Sci. B 2021, 22, 431–449. [Google Scholar] [CrossRef]

- Gao, Q.H.; Wu, C.S.; Wang, M. The jujube (Ziziphus jujuba Mill.) fruit: A review of current knowledge of fruit composition and health benefits. J. Agric. Food Chem. 2013, 61, 3351–3363. [Google Scholar] [CrossRef]

- Mahmoud, K.B.; Wasli, H.; Mansour, R.B.; Jemai, N.; Selmi, S.; Jemmali, A.; Ksouri, R. Antidiabetic, antioxidant and chemical functionalities of Ziziphus jujuba (Mill.) and Moringa oleifera (Lam.) plants using multivariate data treatment. S. Afr. J. Bot. 2022, 144, 219–228. [Google Scholar] [CrossRef]

- Taechakulwanijya, N.; Weerapreeyakul, N.; Barusrux, S.; Siriamornpun, S. Apoptosis-inducing effects of jujube (Zǎo) seed extracts on human Jurkat leukemia T cells. Chin. Med. 2016, 11, 15. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, B.S.; de Freitas, S.T. Maturity stage at harvest and storage temperature to maintain postharvest quality of acerola fruit. Sci. Hortic. 2020, 260, 108901. [Google Scholar] [CrossRef]

- Wakabayashi, K.; Chun, J.P.; Huber, D.J. Extensive solubilization and depolymerization of cell wall polysaccharides during avocado (Persea americana) ripening involves concerted action of polygalacturonase and pectin methyl esterase. Physiol. Plant. 2000, 108, 345–352. [Google Scholar]

- Kou, X.; Chai, L.; Yang, S.; He, Y.; Wu, C.E.; Liu, Y.; Zhou, J.; Xue, Z.; Wang, Z. Physiological and metabolic analysis of winter jujube after postharvest treatment with calcium chloride and a composite film. J. Sci. Food Agric. 2020, 101, 703–717. [Google Scholar] [CrossRef]

- Diskin, S.; Feygenberg, O.; Maurer, D.; Droby, S.; Prusky, D.; Alkan, N. Microbiome alterations are correlated with occurrence of postharvest stem-end rot in mango fruit. Phytobiomes 2017, 1, 117–127. [Google Scholar] [CrossRef]

- Wu, W.; Lei, J.; Cao, S.; Du, B.; Wang, R. Structure and function of the fruit microbiome in healthy and diseased kiwifruit. Pak. J. Agric. Sci. 2019, 56, 577–585. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, X.; Hou, Y.; Pan, Y.; Shi, L.; Li, X. Effects of harvest maturity stage on postharvest quality of winter jujube (Ziziphus jujuba Mill. cv. Dongzao) fruit during cold storage. Sci. Hortic. 2021, 277, 109778. [Google Scholar] [CrossRef]

- Wu, C.S.; Gao, Q.H.; Guo, X.D.; Wang, M. Effect of ripening stage on physicochemical properties and antioxidant profiles of promising table fruit “pear-jujube” (Ziziphus jujuba Mill.). Sci. Hortic. 2012, 148, 177–184. [Google Scholar] [CrossRef]

- Wang, B.; Huang, Q.; Venkitasamy, C.; Chai, H.; Gao, H.; Cheng, N.; Cao, W.; Lv, X.; Pan, Z. Changes in phenolic compounds and their antioxidant capacities in jujube (Ziziphus jujuba Mill.) during three edible maturity stages. LWT 2016, 66, 56–62. [Google Scholar] [CrossRef]

- Zozio, S.; Servent, A.; Cazal, G.; Mbéguié-A-Mbéguié, D.; Ravion, S.; Pallet, D.; Abel, H. Changes in antioxidant activity during the ripening of jujube (Ziziphus mauritiana Lamk). Food Chem. 2014, 150, 448–456. [Google Scholar] [CrossRef]

- Liu, M. Chinese jujube: Botany and horticulture. Hortic. Rev. 2006, 32, 229–298. [Google Scholar]

- Islam, A.; Acıkalın, R.; Ozturk, B.; Aglar, E.; Kaiser, C. Combined effects of Aloe vera gel and modified atmosphere packaging treatments on fruit quality traits and bioactive compounds of jujube (Ziziphus jujuba Mill.) fruit during cold storage and shelf life. Postharvest Biol. Technol. 2022, 187, 111855. [Google Scholar] [CrossRef]

- Moradinezhad, F.; Dorostkar, M. Effect of vacuum and modified atmosphere packaging on the quality attributes and sensory evaluation of fresh jujube fruit. Int. J. Fruit Sci. 2021, 21, 82–94. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, J.; Li, X. Transcript analyses of ethylene pathway genes during ripening of Chinese jujube fruit. J. Plant Physiol. 2018, 224, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Jat, L.; Pareek, S.; Kaushik, R.A. Colour changes in Indian jujube fruit under modified atmosphere packaging. Curr. Opin. Agric. 2012, 1, 19. [Google Scholar]

- Li, X.; Zhao, X.; Wang, S.; Wu, B.; Du, Y.; Dong, C.; Wu, Z.; Sun, F.; Wu, J.; Wang, L.; et al. Qualities and bitter substances profile of Chinese winter jujube (Ziziphus jujuba Mill. cv. Dongzao) under the ultra-low oxygen environment. Postharvest Biol. Technol. 2025, 222, 113416. [Google Scholar] [CrossRef]

- Sheng, J.; Yunbo, L.; Lin, S. Storage of Chinese winter jujube fruit. In Proceedings of the XXVI International Horticultural Congress: Asian Plants with Unique Horticultural Potential: Genetic Resources, Cultural, Toronto, ON, Canada, 11–17 August 2002; Volume 620, pp. 203–208. [Google Scholar]

- Zhang, L.; Li, S.; Dong, Y.; Zhi, H.; Zong, W. Tea polyphenols incorporated into alginate-based edible coating for quality maintenance of Chinese winter jujube under ambient temperature. LWT 2016, 70, 155–161. [Google Scholar] [CrossRef]

- Moradinezhad, F.; Naeimi, A.; Farhangfar, H. Influence of edible coatings on postharvest quality of fresh Chinese jujube fruits during refrigerated storage. J. Hortic. Postharvest Res. 2018, 1, 1–14. [Google Scholar]

- Sang, Y.; Sun, P.; Wang, Y.; Guo, J.; Tang, Y.; Shen, P.; Guo, M.; Chen, G. Postharvest treatment with 1-methylcyclopropene and chitosan enhances the antioxidant capacity and maintains the quality of Hui jujube (Ziziphus jujuba Mill. cv. Huizao) during cold storage. J. Food Process. Preserv. 2022, 46, e16483. [Google Scholar] [CrossRef]

- Li, L.; Tu, M.; Li, W.; Bao, N.; Luo, Z. Elevated oxygen atmosphere maintains antioxidant capacity and inhibits cell wall metabolism in postharvest jujube. Postharvest Biol. Technol. 2023, 199, 112301. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, S.; Chen, F.; Xiao, G.; Fu, X.; Wang, R. Changes in pectin characteristics of jujube fruits cv. Dongzao and Jinsixiaozao during cold storage. J. Food Sci. 2021, 86, 3001–3013. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, J.; Ma, Q.; Zhang, X.; Luo, X.; Deng, Q. Exogenous melatonin treatment on postharvest jujube fruits maintains physicochemical qualities during extended cold storage. Plant Biol. 2022, 10, e14155. [Google Scholar]

- Gao, H.; Zhang, Z.K.; Chai, H.K.; Cheng, N.; Yang, Y.; Wang, D.N.; Yang, T.; Cao, W. Melatonin treatment delays postharvest senescence and regulates reactive oxygen species metabolism in peach fruit. Postharvest Biol. Technol. 2016, 118, 103–110. [Google Scholar] [CrossRef]

- Sharma, P.; Jha, A.B.; Dubey, R.S.; Pessarakli, M. Reactive oxygen species, oxidative damage, and antioxidative defense mechanism in plants under stressful conditions. J. Bot. 2012, 2012, 217037. [Google Scholar] [CrossRef]

- Wang, L.; Shan, T.M.; Xie, B.; Ling, C.; Shao, S.; Jin, P.; Zheng, Y.H. Glycine betaine reduces chilling injury in peach fruit by enhancing phenolic and sugar metabolisms. Food Chem. 2019, 272, 530–538. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Wang, J.W.; Zhou, B.; Li, G.D.; Liu, Y.F.; Xia, X.L.; Xiao, Z.G.; Lu, F.; Ji, S.J. Calcium inhibited peel browning by regulating enzymes in membrane metabolism of ‘Nanguo’ pears during post-ripeness after refrigerated storage. Sci. Hortic. 2019, 244, 15–21. [Google Scholar] [CrossRef]

- Fan, M.C.; Li, W.X.; Hu, X.L.; Sun, Y.; Yu, G.; Zhang, X. Effect of micro-vacuum storage on active oxygen metabolism, internal browning and related enzyme activities in Laiyang pear (Pyrus bretschneideri Rehd.). LWT 2016, 72, 467–474. [Google Scholar] [CrossRef]

- Li, Q.; Xie, F.; Zhao, Y.; Cao, J. Inhibitory effect of postharvest yeast mannan treatment on Alternaria rot of tomato fruit involving the enhancement of hemicellulose polysaccharides and antioxidant metabolism. Sci. Hortic. 2021, 277, 109798. [Google Scholar] [CrossRef]

- Wang, D.; Yeats, T.H.; Uluisik, S.; Rose, J.K.; Seymour, G.B. Fruit softening: Revisiting the role of pectin. Trends Plant Sci. 2018, 23, 302–310. [Google Scholar] [CrossRef]

- Vicente, A.R.; Saladie, M.; Rose, J.K.; Labavitch, J.M. The linkage between cell wall metabolism and fruit softening: Looking to the future. J. Sci. Food Agric. 2007, 87, 1435–1448. [Google Scholar] [CrossRef]

- Zhao, L.; Li, H.; Liu, Z.; Hu, L.; Xu, D.; Zhu, X.; Mo, H. Quality changes and fungal microbiota dynamics in stored jujube fruits: Insights from high-throughput sequencing for food preservation. Foods 2024, 13, 1473. [Google Scholar] [CrossRef]

- Jin, T.; Dai, C.; Xu, Y.; Chen, Y.; Xu, Q.; Wu, Z. Applying cold atmospheric plasma to preserve the postharvest qualities of winter jujube (Ziziphus jujuba Mill. cv. Dongzao) during cold storage. Front. Nutr. 2022, 9, 934841. [Google Scholar] [CrossRef]

- Hu, C.; Lu, B.; Hou, S.L.; Yi, X.K.; Wang, X.F. Research status and development countermeasures on harvesting machinery of jujube in Xinjiang. J. Chin. Agric. Mech. 2016, 37, 222–225. (In Chinese) [Google Scholar]

- Fu, L.S.; Ai-Mallahi, A.; Peng, J.; Sun, S.P.; Feng, Y.L.; Li, R.; He, D.J.; Cui, Y.J. Harvesting technologies for Chinese jujube fruits: A review. Eng. Agric. Environ. Food 2017, 10, 171–177. [Google Scholar] [CrossRef]

- Peng, J.; Xie, H.; Feng, Y.; Fu, L.; Sun, S.; Cui, Y. Simulation study of vibratory harvesting of Chinese winter jujube (Ziziphus jujuba Mill. cv. Dongzao). Comput. Electron. Agric. 2017, 143, 57–65. [Google Scholar] [CrossRef]

- Ni, H.; Zhang, J.; Zhao, N.; Wang, C.; Lv, S.; Ren, F.; Wang, X. Design on the winter jujubes harvesting and sorting device. Appl. Sci. 2019, 9, 5546. [Google Scholar] [CrossRef]

- Kondo, N. Automation on fruit and vegetable grading system and food traceability. Trends Food Sci. Technol. 2010, 21, 145–152. [Google Scholar] [CrossRef]

- Irtwange, S.V. Application of modified atmosphere packaging and related technology in postharvest handling of fresh fruits and vegetables. Agric. Eng. Int. CIGR J. 2006, 8, 1–13. [Google Scholar]

- Reche, J.; García-Pastor, M.E.; Valero, D.; Hernández, F.; Almansa, M.S.; Legua, P.; Amorós, A. Effect of modified atmosphere packaging on the physiological and functional characteristics of Spanish jujube (Ziziphus jujuba Mill.) cv. Phoenix during cold storage. Sci. Hortic. 2019, 258, 108743. [Google Scholar] [CrossRef]

- Falagan, N.; Terry, L.A. Recent advances in controlled and modified atmosphere of fresh produce. Johns. Matthey Technol. Rev. 2018, 62, 107–117. [Google Scholar] [CrossRef]

- Guo, X.; Li, Q.; Luo, T.; Han, D.; Zhu, D.; Wu, Z. Postharvest calcium chloride treatment strengthens cell wall structure to maintain litchi fruit quality. Foods 2023, 12, 2478. [Google Scholar] [CrossRef] [PubMed]

- Chung, H.J. Investigation of packaging of fresh jujube (Ziziphus jujuba) on quality during storage. J. Korean Soc. Food Sci. Nutr. 2013, 42, 1296–1302. [Google Scholar] [CrossRef]

- Liu, H.; Yang, W.; Zhang, Q.; Lv, Z.; Zhang, G.; Jiao, Z.; Liu, J. Comprehensive evaluation method to reveal the combined effects of maturity and modified atmosphere packaging on jujube storage qualities. J. Food Meas. Charact. 2025, 19, 3552–3566. [Google Scholar] [CrossRef]

- Jat, L.; Lakhawat, S.S.; Gathala, S.; Singh, V. Postharvest physiology of Indian jujube fruit under different storage temperature. J. Plant Dev. Sci. 2021, 13, 875–879. [Google Scholar]

- Moradinezhad, F.; Ghesmati, M.; Khayat, M. Pre-storage calcium salts treatment maintained postharvest quality and bioactive compounds of fresh jujube fruit. Fundam. Appl. Agric. 2019, 4, 890–897. [Google Scholar] [CrossRef]

- Zhang, B.; Lin, X.; Zhang, X.; Yi, X.; Ma, S.; Ding, Y. Research on jujube storage and preservation system based on Internet of Things (IoT). Sci. Rep. 2024, 14, 19808. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Ding, Y.; Sun, C.; Li, X.; Yuan, S.; Guo, F.; Zeng, X.; Fan, X.; Sun, S. Improving the storage quality and suppressing off-flavor generation of winter jujube by precise micro-perforated MAP. Front. Plant Sci. 2024, 15, 1372638. [Google Scholar]

- Zuo, Z.; Jiang, P.; Chen, D.; Zhang, C.; Guo, F.; Nie, X.; Wu, D.; Fan, X.; Zhao, H. Improving the storage quality and antioxidant capacity of postharvest winter jujube by laser microporous modified atmosphere packaging. Sci. Hortic. 2024, 337, 113477. [Google Scholar] [CrossRef]

- Ozturk, B.; Aglar, E.; Karakaya, O.; Olcer, M.A. Impact of different modified atmosphere packaging on physiological and phytochemical traits of jujube fruit during cold storage. Appl. Fruit Sci. 2025, 67, 284. [Google Scholar] [CrossRef]

- Stanica, F.; Dicianu, D.E.; Butcaru, A.C.; Liu, M.J. Jujube fruits behavior at controlled atmosphere storage. In Proceedings of the XXX International Horticultural Congress IHC2018: International Symposium on Medicinal and Aromatic Plants, Culinary Herbs and Edible Fungi, Istanbul, Turkey, 12–16 August 2018; Volume 1287, pp. 317–320. [Google Scholar]

- Nikzadfar, M.; Kazemi, A.; Abooei, R.; Abbaszadeh, R.; Firouz, M.S.; Akbarnia, A.; Rashvand, M. Application of cold plasma technology on the postharvest preservation of in-packaged fresh fruit and vegetables: Recent challenges and development. Food Bioprocess Technol. 2024, 17, 4473–4505. [Google Scholar] [CrossRef]

- Jia, S.; Zhang, N.; Dong, C.; Zheng, P.; Ji, H.; Yu, J.; Yan, S.; Chen, C.; Liang, L. Effect of cold plasma treatment on the softening of winter jujubes (Ziziphus jujuba Mill. cv. Dongzao). Horticulturae 2023, 9, 986. [Google Scholar] [CrossRef]

- Mohammad, A.A.; Salem, S.H.; Amer, H.M.; Hussein, M.S. Ozone as a postharvest treatment to maintain the quality characteristics of fresh-cut plants. J. Food Meas. Charact. 2025, 19, 4325–4336. [Google Scholar] [CrossRef]

- Zong, W.; An, G.J. Effect of ultra high pressure on softening of fresh cut jujube fruit during storage. Acta Hortic. 2009, 840, 493–498. [Google Scholar] [CrossRef]

- Ding, H.; Wang, T.; Sun, Y.; Zhang, Y.; Wei, J.; Cai, R.; Guo, C.; Yuan, Y.; Yue, T. Role and mechanism of cold plasma in inactivating Alicyclobacillus acidoterrestris in apple juice. Foods 2023, 12, 1531. [Google Scholar] [CrossRef]

- Gabric, D.; Kurek, M.; Ščetar, M.; Brnčić, M.; Galić, K. Effect of non-thermal food processing techniques on selected packaging materials. Polymers 2022, 14, 5069. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Guo, Y.; Yu, J.; Gu, T.; Russo, H.B.; Liu, Q.; Du, J.; Bai, J.; Zhang, B.; Kou, L. X-ray irradiation—Nonthermal processing and preservation of fresh winter jujube (Zizyphus jujuba Mill. cv. Dalidongzao). Innov. Food Sci. Emerg. Technol. 2022, 81, 103151. [Google Scholar] [CrossRef]

- Sani, M.A.; Velayati, N.; Yazdi, N.B.; Khezerlou, A.; Jafari, S.M. Electron beam irradiation: A non-thermal technology for food safety and quality control. Compr. Rev. Food Sci. Food Saf. 2025, 24, e70205. [Google Scholar] [CrossRef] [PubMed]

- Smetanska, I.; Hunaefi, D.; Barbosa-Cánovas, G.V. Nonthermal technologies to extend the shelf life of fresh-cut fruits and vegetables. In Advances in Food Process Engineering Research and Applications; Springer: Boston, MA, USA, 2013; pp. 375–413. [Google Scholar]

- Su, W.; Wang, Q.; Li, J.; Qiu, Z.; Qiu, Y. Effects of pulsed electric field technology on the nutritional value and biological function of plant food. Front. Sustain. Food Syst. 2024, 8, 1385533. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, Y.; Yang, S.; Yang, E.N.; Yang, B.; Prasad, K.N. Effects of ultrasonic treatment on pericarp browning of postharvest litchi fruit. J. Food Biochem. 2012, 36, 613–620. [Google Scholar] [CrossRef]

- Silva, F.V.M.; Sulaiman, A. Control of enzymatic browning in strawberry, apple, and pear by physical food preservation methods: Comparing ultrasound and high-pressure inactivation of polyphenoloxidase. Foods 2022, 11, 1942. [Google Scholar] [CrossRef]

- Yildiz, G.; Khan, M.R.; Aadil, R.M. High-intensity ultrasound treatment to produce and preserve the quality of fresh-cut kiwifruit. J. Food Process. Preserv. 2022, 46, e16542. [Google Scholar] [CrossRef]

- Iahtisham-Ul-Haq; Zulfiqar, S.; Hadiya; Shahbaz, S.; Alsulami, T.; Sharma, A.; Jagdale, Y.D.; Mugabi, R.; Nayik, G.A. Aloe vera and chitosan-based coatings: A strategy to enhance quality and shelf life of fresh jujube (Ziziphus mauritiana). Int. J. Food Prop. 2025, 28, 2504659. [Google Scholar] [CrossRef]

- Gupta, D.; Lall, A.; Kumar, S.; Patil, T.D.; Gaikwad, K.K. Plant-based edible films and coatings for food-packaging applications: Recent advances, applications, and trends. Sustain. Food Technol. 2024, 2, 1428–1455. [Google Scholar] [CrossRef]

- Xing, Y.; Lin, H.; Cao, D.; Xu, Q.; Han, W.; Wang, R.; Che, Z.; Li, X. Effect of chitosan coating with cinnamon oil on the quality and physiological attributes of China jujube fruits. Biomed. Res. Int. 2015, 2015, 835151. [Google Scholar] [CrossRef]

- Sarkar, A.; Sadaf, N.; Alam, M.; Miah, M.S.; Roy, P.; Rahman, M. Enhancing the postharvest quality of Indian jujube (Ziziphus mauritiana) using Aloe vera gel and ascorbic acid-based edible coatings. Asian Food Sci. J. 2025, 24, 22–33. [Google Scholar] [CrossRef]

- Rao, R.T.V.; Baraiya, N.S.; Vyas, B.; Patel, D.M. Composite coating of alginate-olive oil enriched with antioxidants enhances postharvest quality and shelf life of Ber fruit (Ziziphus mauritiana Lamk. var. Gola). J. Food Sci. Technol. 2016, 53, 748–756. [Google Scholar]

- Perez-Vazquez, A.; Barciela, P.; Carpena, M.; Prieto, M.A. Edible coatings as a natural packaging system to improve fruit and vegetable shelf life and quality. Foods 2023, 12, 3570. [Google Scholar] [CrossRef]

- Moradinezhad, F.; Adiba, A.; Ranjbar, A.; Dorostkar, M. Edible coatings to prolong the shelf life and improve the quality of subtropical fresh/fresh-cut fruits: A review. Horticulturae 2025, 11, 577. [Google Scholar] [CrossRef]

- Ozturk, B.; Yildiz, M.; Yildiz, K.; Gun, S. Maintaining the postharvest quality and bioactive compounds of jujube (Ziziphus jujuba Mill. cv. Li) fruit by applying 1-methylcyclopropene. Sci. Hortic. 2021, 275, 109671. [Google Scholar] [CrossRef]

- Taain, D.A. Effect of storage temperatures and postharvest calcium salts treatments on storability of jujube fruits (Ziziphus mauritiana Lam. cv. Tufahi). Ann. Agric. Sci. Moshtohor 2011, 49, 447–453. [Google Scholar]

- Moradinezhad, F.; Ghesmati, M.; Khayyat, M. Postharvest calcium salt treatment of fresh jujube fruit and its effects on biochemical characteristics and quality after cold storage. J. Hortic. Res. 2019, 27, 39–46. [Google Scholar] [CrossRef]

- Pan, S.; Liu, X.; Zheng, X.; Wu, J.; Tan, M.; Cao, N.; Zhao, X.; Wu, M.; Han, Y.; Yan, X.; et al. Impact of long-term cold storage on the physicochemical properties, volatile composition, and sensory attributes of dried jujube (Ziziphus jujuba Mill.). Foods 2024, 14, 50. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Du, J.; Hou, D.; Guo, X.; Liu, Q.; Liu, L.; Kou, L. Quality retention and delay postharvest senescence of figs (Ficus carica L.) using 1-methylcyclopropene and modified atmosphere packaging during cold storage. Food Biosci. 2023, 53, 102748. [Google Scholar] [CrossRef]

- Zhang, W.; Kang, J.; Yang, W.; Guo, H.; Guo, M.; Chen, G. Incorporation of 1-methylcyclopropene and salicylic acid improves quality and shelf life of winter jujube (Ziziphus jujuba Mill. cv. Dongzao) through regulating reactive oxygen species metabolism. Front. Nutr. 2022, 9, 940494. [Google Scholar]

- Chen, Q.; Li, G.; Duan, J.; Tang, Z.; Song, Z.; Liu, H.; Shi, X. Gibberellin-induced germination enhancement in Chinese sour jujube seeds under cold stress. Plant Stress 2025, 17, 100936. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muqaddas; Mengaya, L.; Ahmed, M.M.; Hamid, S.M.; Yanju, X.; Asim, M.; Yunfeng, P. Postharvest Handling and Storage Strategies for Preserving Jujube (Ziziphus jujuba Mill.) Fruit Quality: A Review. Foods 2025, 14, 3370. https://doi.org/10.3390/foods14193370

Muqaddas, Mengaya L, Ahmed MM, Hamid SM, Yanju X, Asim M, Yunfeng P. Postharvest Handling and Storage Strategies for Preserving Jujube (Ziziphus jujuba Mill.) Fruit Quality: A Review. Foods. 2025; 14(19):3370. https://doi.org/10.3390/foods14193370

Chicago/Turabian StyleMuqaddas, Li Mengaya, Mian Muhammad Ahmed, Syeda Maira Hamid, Xiang Yanju, Muhammad Asim, and Pu Yunfeng. 2025. "Postharvest Handling and Storage Strategies for Preserving Jujube (Ziziphus jujuba Mill.) Fruit Quality: A Review" Foods 14, no. 19: 3370. https://doi.org/10.3390/foods14193370

APA StyleMuqaddas, Mengaya, L., Ahmed, M. M., Hamid, S. M., Yanju, X., Asim, M., & Yunfeng, P. (2025). Postharvest Handling and Storage Strategies for Preserving Jujube (Ziziphus jujuba Mill.) Fruit Quality: A Review. Foods, 14(19), 3370. https://doi.org/10.3390/foods14193370