Intelligent Gas Sensors for Food Safety and Quality Monitoring: Advances, Applications, and Future Directions

Abstract

1. Introduction

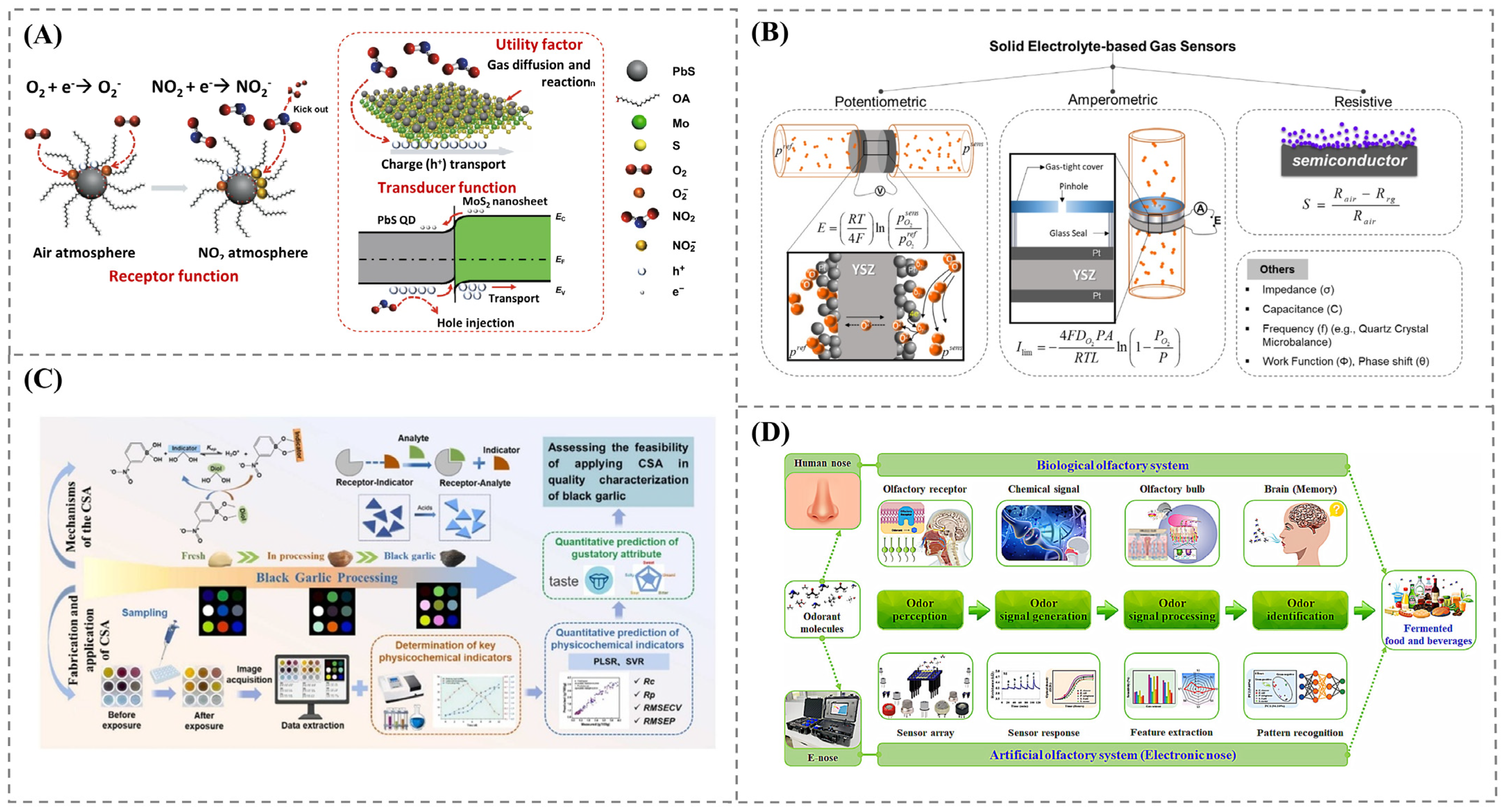

2. Gas Sensor Principles and Types

2.1. Metal-Oxide Semiconductor (MOS) Sensors

2.2. Electrochemical Sensors

2.3. Optical Sensors

2.3.1. Colorimetric

2.3.2. Fluorescence Sensor

2.4. Conducting Polymer Sensors

2.5. Sensor Array

3. Applications in Food Quality and Safety

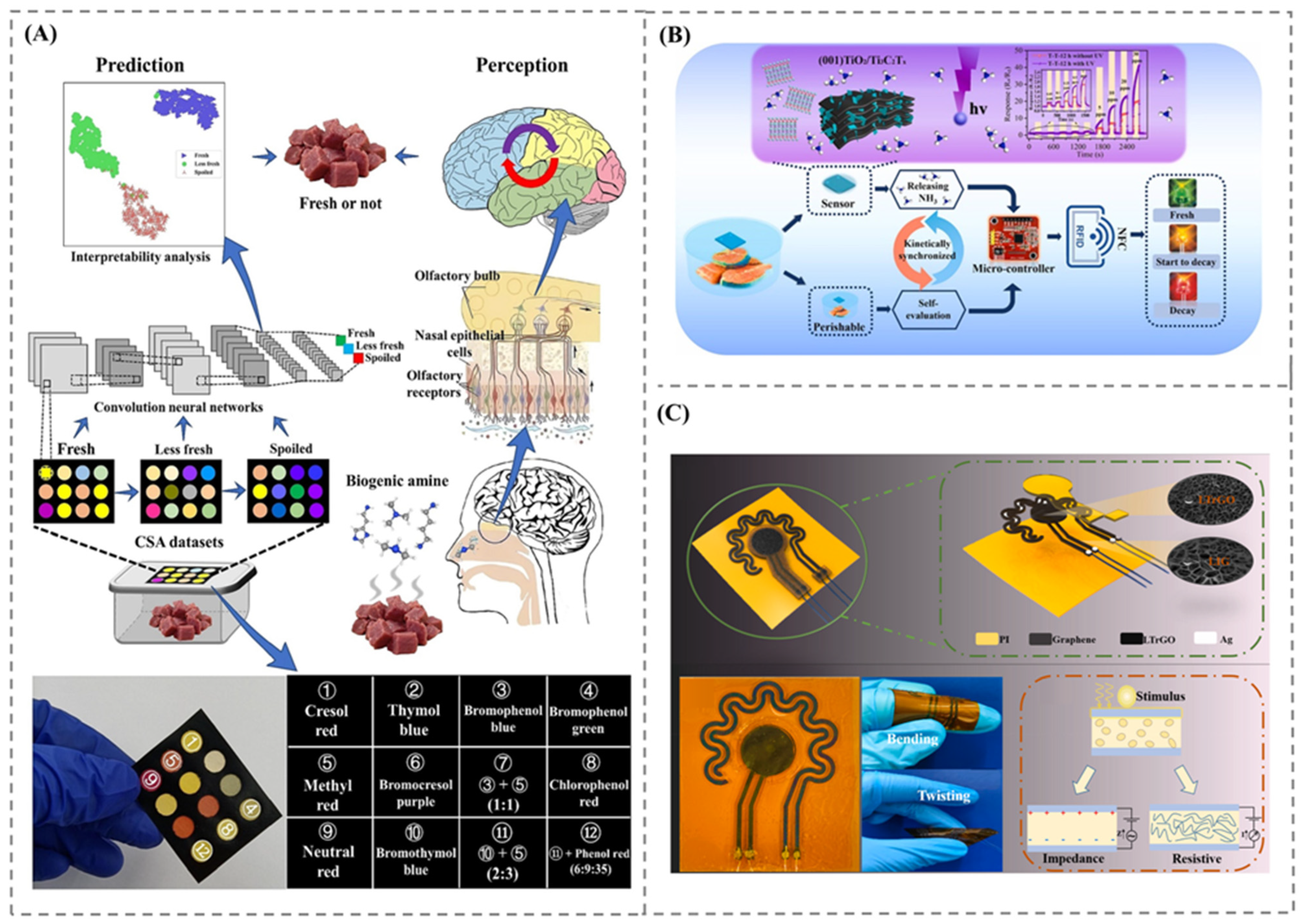

3.1. Spoilage and Freshness Monitoring

3.2. Authenticity and Adulteration Detection

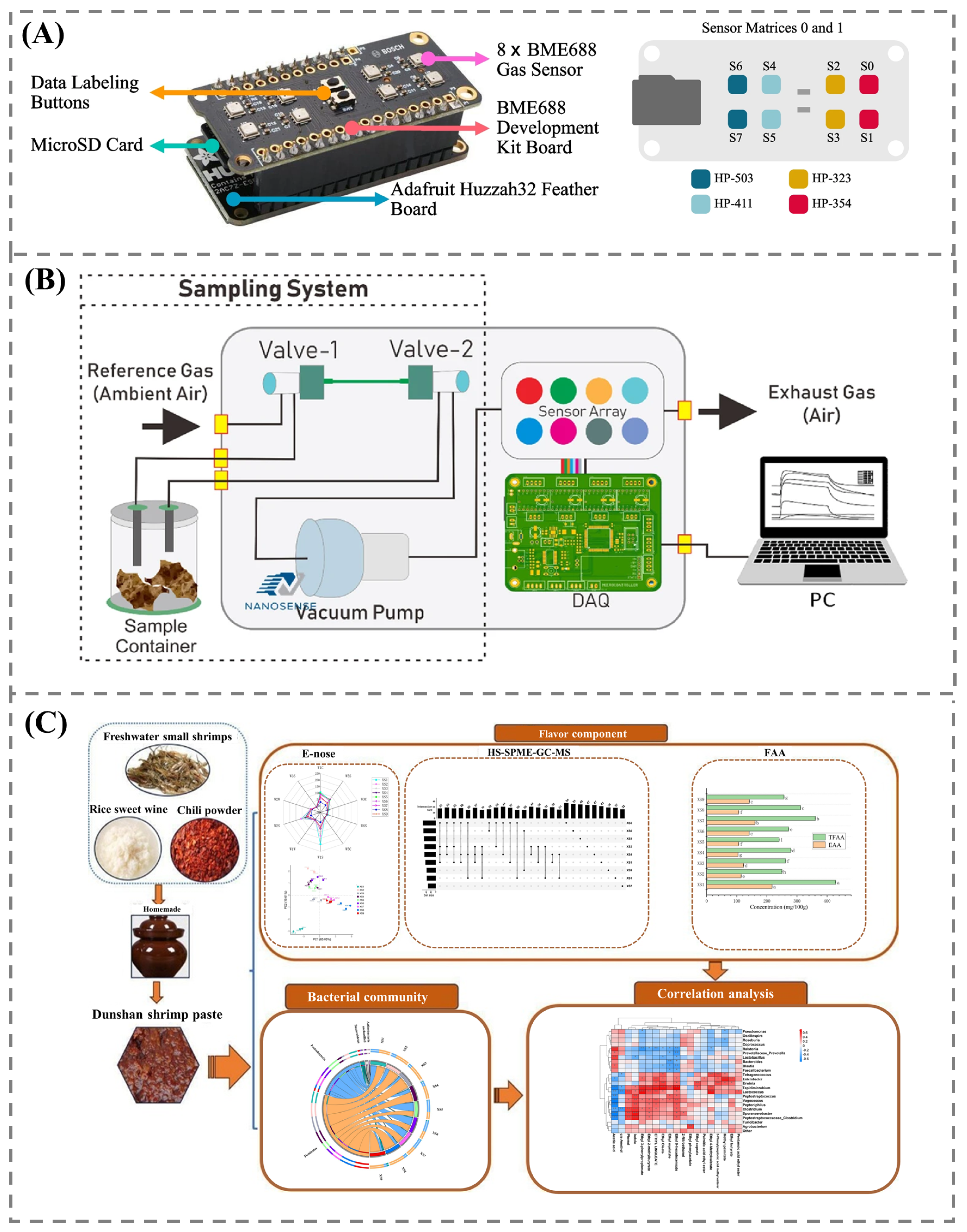

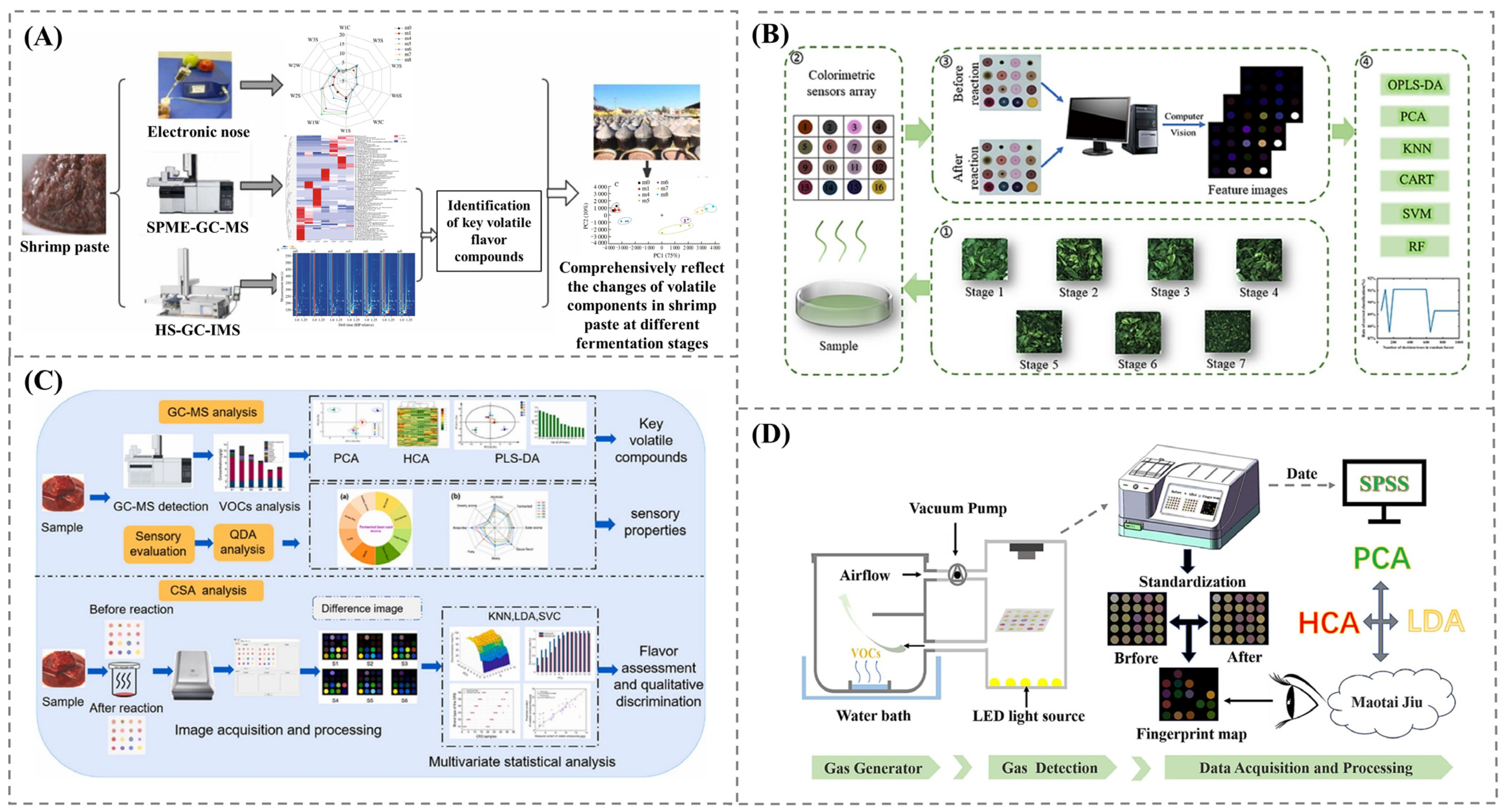

3.3. Profiling and Process Optimization

| Sensor Type | Sample | Application | Analyte | Study Duration | Result | Reference |

| Colorimetric Film | Pork | Quality evaluation | Amine | 60 h | Showed distinct color changes at different spoilage stages | [33] |

| Colorimetric solid-state sensor | Veal, chicken, fish | Spoilage detection | Ammonia | 5 days | Developed sensor with LOD of 0.02 ppm | [34] |

| Colorimetric sensor array | Wheat | Spoilage detection | VOCs | Mold infection in wheat | [68] | |

| Colorimetric sensor array | Chilled beef | Freshness monitoring | Trimethylamine | 18 days | Developed sensor with LOD of 8.02 ppb | [35] |

| Colorimetric sensor array | Rice | Freshness evaluation | Alcohols, aldehydes, alkenes, alkanes, ketones, organic acid, heterocyclic compounds | - | Discrimination of aged and fresh rice (100%) | [69] |

| Colorimetric Film | Milk, fish | Spoilage detection | VOCs | 9 days | Biomaterial based edible and pH-sensitive film | [70] |

| Colorimetric Film | Pork, chicken, salmon, and shrimp | Spoilage detection | Ammonia, dimethylamine, and trimethylamine | 7 days | LODs were determined to be 0.26 μM for NH3, 0.24 μM for DMA, and 0.38 μM for TMA | [71] |

| Colorimetric Film | Beef | Spoilage detection | Ammonia | 8 days | Developed a photothermally stable and ammonia-responsive film | [72] |

| (001)TiO2/MXene sensor | Fish, pork and shrimp | Quality monitoring | Ammonia | 36 h | Developed sensor with LOD of 156 ppt | [36] |

| NiCo2O4-ZnO sensor | - | Quality evaluation | Trimethylamine | - | Improved response value | [37] |

| Electrochemical, infrared (IR), MOS | Lamp | Quality evaluation | O2, CO2, and NH3 | Gas composition analysis along with impedance | [38] | |

| Electrochemical sensor | Pork | Freshness monitoring | Trimethylamine | Range: 3.33 μg/L–1200 μg/L | [73] | |

| E-nose, fluorescence hyperspectral imaging | Pork | Freshness monitoring | Alcohols, aldehydes, ketones, alkanes, and sulfides | 7 days | End-to-end data fusion approach for freshness | [74] |

| E-nose | Spinach | Quality evaluation during storage | Hydrogen sulfide, methane, alcohol, ammonia, and carbon monoxide | 12 days | Optimized sensor array for odors classification | [40] |

| Color-sensitive gas sensor array | Wheat flour | Quality evaluation during storage | VOCs | 6 months | Odor information of flour samples of different storage periods | [75] |

| E-nose | Edible oil | Quality evaluation during storage | Hydrogen, carbon monoxide, methane, ethanol, toluene, acetone, and formaldehyde | 5 days | Change in quality during storage | [76] |

| E-nose | Green tea | Quality evaluation | Alcohols, aldehydes, and esters | - | Improved classification accuracy | [43] |

| E-nose | Apple | Spoilage monitoring | Nitrogen oxide, ammonia, hydrogen, alkanes, sulfides, alcohol, aromatic compounds, inorganic sulfur, organic compounds, methane, and aliphatic organic compounds | 7 days | Integrated terminal and remote platform enabled real-time monitoring | [77] |

| E-nose | Egg | Sensory quality traits evaluation | Ammonia | 42 days | Maturity level recognition at 95% accuracy | [44] |

| E-nose | Chicken drumstick | Quality evaluation | Alcohols, aldehydes, phenols, ketones, and cis-anethol | - | Optimum sugar smoking effects on flavors | [39] |

| Colorimetric film | Apple | Spoilage moni-toring | CO2 | 5 days | High recognition rate for spoilage | [78] |

| E-nose | Chilled Chicken | Quality evaluation | Sulfides, organic sulfides, and hydrides | 3 days | Difference in VOC produced by different species of bacteria | [79] |

| Gas sensor array | Apple | Quality of pathogen-contaminated apples | VOCs | 7 days | Prototype for early warning of apple spoilage | [80] |

| E-nose, Colorimetric sensor array | Fermented bean curd | Flavor quality analysis | VOCs | - | Determine ripeness and predict hardness | [81] |

| BME688 sensor | Olive oil | Adulteration detection | VOCs, carbon monoxide, and hydrogen | - | High sensitive detection of sunflower oil adulteration | [48] |

| E-nose | Powdered milk | Adulteration detection | 2-propanone, 5-methyl-2(3H) furanone | - | Whey adulteration in powdered milk | [47] |

| E-nose | Minced chicken meat | Adulteration detection | Alcohols, aldehydes, ketones, aromatics, and other organic vapors | - | Detection of soybean protein isolate adulteration | [49] |

| E-nose, GC-MS | Sesame oil | Adulteration detection | Alcohol, organic solvents, SO2, CO, alkenes, ammonia, benzene, sulfides, hydrogen, methane | - | Adulteration with soybean and corn oils | [46] |

| E-nose | Beef | Adulteration detection | VOCs | - | Adulteration with pork | [82] |

| E-nose | Zanthoxylum bungeanum Maxim | Discrimination based on geographical origin | VOCs | - | Discrimination based on geographical origin | [51] |

| E-nose and e-tongue | Red wine | Discrimination based on geographical origin | Alcohols, esters, aldehydes, and ketones | - | Discrimination based on geographical origins, brands, and grape varieties | [52] |

| Smartphone-based colorimetric sensor array | Rice | Discrimination based on geographical origin | VOCs | - | Discrimination based on geographical origin | [53] |

| Colorimetric sensor array | Edible bird’s nests | Discrimination based on geographical origin | Octadecanoic acid, propanetriol, and 4-terpenol | - | Discrimination based on geographical origin | [83] |

| E-nose | Meat floss | Classification | Hydrocarbons and alcohols | - | Differentiate beef, chicken, and pork meat floss | [50] |

| E-nose | Lemon juice | Quality evaluation | VOCs | 120 days | Freshness during storage | [84] |

| Proton-Transfer-Reaction Mass Spectrometry (PTR-MS) | Occidental pears | Fruit ripeness monitoring | VOCs (esters and terpenes) | - | Identification of three ripening stages of occidental pears | [85] |

| E-nose, e-tongue | Fermented soybean paste | Flavor quality analysis | VOCs | - | Evaluation of sensory properties and overall flavor quality | [55] |

| E-nose, e-tongue, GC-MS | Soybean paste | Flavor quality analysis | Nitrogen oxides, ammonia, hydrogen, methane, H2S, terpenes, alcohol, alkenes, and aromatic organic compounds | - | Evaluation of sensory properties and overall flavor quality | [56] |

| E-nose | White tea | Authentication | Alcohols, esters, aldehydes, ketones, alkenes, hydrocarbons, ammonia, and alkyl aromatic compounds | - | Vintage authentication by integrating appearance, taste and aroma assessments. | [86] |

| E-nose | Tea | Monitor fermentation | Isobutane, propane, methane, hydrogen, smoke, benzene, hydrogen, and alcohol | - | Detection of fermentation stages and detects aroma changes | [58] |

| MOS sensor | Oolong tea | Monitor fermentation | Air contaminants, odorous gases, hydrocarbons, solvents, and sulfur compounds | - | Control flavor quality during manufacturing | [60] |

| Generic resistive gas sensor | Black tea | Monitor fermentation | VOCs | - | Optimizes fermentation time | [59] |

| MOS sensor | Oolong tea | Monitor oxidation | Ammonia, hydrogen, ethanol, sulfides, benzene, methane, propane, butane, alkenes, toluene, acetone, ethanol, and formaldehyde | - | Monitor oxidation process | [87] |

| E-nose, e-tongue | Tremella aurantialba | Monitor and detect the fermentation process | Methane, ethane, dimethyl methane, hydrogen sulfide, and alcohol | - | Predict key chemical indicators | [88] |

| Gas sensor array | Sourdough | Monitor fermentation | Oxygen, carbon dioxide, and hydrogen sulfides | - | Online gas measurements predict pH and acidity | [61] |

| Headspace-gas chromatography-ion mobility spectrometry | Shrimp paste samples | Monitor fermentation | VOCs | - | Alcohols and amines dominated volatile compounds | [62] |

| E-nose | Bread | Monitor fermentation | Alcohols, aldehydes, esters, ketones, terpenoids, pyridines, hydrocarbons, and amides | - | Pyridines are characteristic for emissions during baking | [63] |

| E-nose | Rice and wheat crop residues | Understand bioethanol production dynamics | Ammonia, NO2, i-butane, propane, methane, alcohol, hydrogen, CO, toluene, and xylene | - | Artificial intelligence optimized sensor responses for classification and prediction | [64] |

| E-nose | Mulberry wine | Monitor fermentation | Alcohol, H2S, terpenes, organic sulfur, nitrogen, oxygen, ammonia, alkenes, and methane | - | Effect of selenium-enriched yeast fermentation on flavor profiles | [89] |

| E-nose, GC-MS | Steam bread | Aroma assessment | Alcohols, esters, aldehydes, and furan | - | Effects of multi-strain co-fermentation flavor profiles | [90] |

| Colorimetric sensor array | Tencha | Aroma assessment | VOCs | - | Developed an olfactory visualization system to optimize drying | [65] |

| Gas chromatography-ion mobility spectrometry (GC-IMS) and gas chromatography-mass spectrometry-olfactometry (GC-MS-O) techniques. | Sturgeon meat | Flavor stability analysis | VOCs | - | Identify optimal steaming conditions and formic acid as crucial volatile compounds contribute flavor | [91] |

| Colorimetric sensor array | Fermented bean curd | Flavor quality analysis | VOCs | - | Discrimination based on different brand | [66] |

| MQ-3 gas sensor | Glucose | Quantitatively assesses fermentation | Alcohol | - | Identified correlation between gas bubble formation and alcohol production | [92] |

| Colorimetric sensor array | Baijiu | Quality control | Ethyl caproate, ethyl lactate, n-propanol, n-butanol, isobutanol, isoamyl alcohol, acetic acid, butyric acid, and capric acid | - | Discrimination brands and authenticity | [67] |

| Colorimetric sensor array | Baijiu | Quality evaluation | VOCs | - | Discrimination of different grades | [93] |

| E-nose | Coffee leaves | Quality control | Nitrogen oxides, short-chain alkanes, sulfur-inorganic compounds, alcohols, aldehydes, ketones, and sulfur-containing organic compounds | - | Difference in aroma profiles of freeze-dried and hot-air dried leaves | [94] |

4. Data Acquisition and Pattern Recognition

5. Challenges and Future Trends

- Gas sensors exhibit low selectivity, making it challenging to accurately identify specific components for detection. Selectivity is a crucial factor in the effectiveness of gas sensors, as different food products exhibit distinct characteristic aroma profiles. The presence of VOCs with similar molecular structures may hinder the ability of basic gas sensors to accurately detect specific target compounds, resulting in false results. Therefore, it is crucial to focus on the development of gas sensors with high specificity in order to improve detection accuracy. Utilizing novel sensing materials, specifically metal-oxide nanoparticles, has been found to be an effective method for addressing the selectivity issue in gas sensors. The incorporation of these materials into mesoporous structures has been shown to enhance gas absorption and consequently increase sensor sensitivity, ultimately improving sensor selectivity.

- The integration of gas sensors into food packaging or processing lines is a complex task due to the rigid nature of most sensors which are not suitable for packaging systems or processing lines. It is challenging to incorporate sensors into various packaging materials and food containers without compromising the integrity of the system. Therefore, the development of flexible gas sensors is crucial for the successful integration of sensors into complete packaging systems.

- Certain sensors, such as MOS and surface acoustic wave sensors, have limitations in their application for the real-time analysis of food products, particularly perishable foods, due to their long recovery time. It is imperative to obtain information quickly in order to implement measures to prevent and address issues such as spoilage, adulteration, and changes in quality. The utilization of nanostructures as a sensitive material, as well as doping and composite material sensors, has been shown to be highly effective in reducing operation time and improving absorption and desorption kinetics. Incorporating a MEMS platform or layer onto an existing gas sensor is a crucial method for achieving faster cycling between the response and recovery phases.

- A portable detection device utilizing a wireless communication protocol is essential for the continuous monitoring of food freshness within the supply chain management system. This real-time monitoring will decrease the need for manual sampling and laboratory testing, while also aiding in the prediction of the maintenance required to ensure food quality and safety. To optimize supply chain management for perishable food over an extended period, low-power sensors are utilized in conjunction with IoT nodes to integrate data on temperature, humidity, and CO2 levels. This comprehensive dataset provides insight into the environmental conditions affecting food products, enabling informed decision-making based on the entirety of available information.

- Gas sensor readings are significantly influenced by environmental factors, particularly temperature and humidity. Unpredictable fluctuations in these factors can lead to unreliable readings. This attribute is of great importance for a gas sensor, particularly when utilized in monitoring food products in fluctuating storage environments. In the future, it is recommended to implement a system that incorporates humidity and temperature compensations to enhance the robustness of the sensor and enable its operation in diverse environmental conditions.

- The absence of a universal database for evaluating the VOCs associated with food spoilage hinders the utilization of gas sensors. In the future, there is a need for the establishment of a centralized Open Access database for referencing compounds detected using gases in order to facilitate reliable decision-making.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANN | Artificial neural networks |

| CP | Conducting polymers |

| CSA | Colorimetric sensor array |

| GCMS | Gas chromatography-mass spectrometry |

| GPR | Gaussian process regression |

| IoT | Internet of Things |

| LSTM | Long short-term memory |

| MEMS | Micro-electro-mechanical systems |

| MLP | Multi-layer perceptron |

| MOF | Metal–organic framework |

| MOS | Metal-oxide semiconductors |

| NFC | Near-field communication |

| PCA | Principal component analysis |

| QCM | Quartz crystal microbalance |

| SAW | Surface acoustic wave |

| SVM | Support vector machine |

| TMA | Trimethylamine |

| TVBN | Total volatile basic nitrogen |

| VOCs | Volatile organic compounds |

References

- United Nations Environment Programme. Food Waste Index Report 2024: Think Eat Save, Tracking Progress to Halve Global Food Waste; Nairobi, Kenya. 2024. Available online: https://wedocs.unep.org/hangle/20.500.11822/45230 (accessed on 25 July 2025).

- Shoaib, M.; Li, H.; Zareef, M.; Khan, I.M.; Iqbal, M.W.; Niazi, S.; Raza, H.; Yan, Y.; Chen, Q. Recent Advances in Food Safety Detection: Split Aptamer-Based Biosensors Development and Potential Applications. J. Agric. Food Chem. 2025, 73, 4397–4424. [Google Scholar] [CrossRef]

- Mohammed, H.H.H.; Khalifa, I.; Jin, G.; Ma, M.; Salah, M.; Maqsood, S. Arabic Gum-Nitroso-Hemoglobin as Natural Antimicrobial Conjugates for Enhanced Preservability of Minced Beef Subjected to Freeze–Thaw Process: Evidence from HS-SPME/GC–MS, LF-NMR, and Docking Analysis. J. Food Meas. Charact. 2025, 19, 2669–2683. [Google Scholar] [CrossRef]

- Lin, H.; Jiang, H.; Adade, S.Y.-S.S.; Kang, W.; Xue, Z.; Zareef, M.; Chen, Q. Overview of Advanced Technologies for Volatile Organic Compounds Measurement in Food Quality and Safety. Crit. Rev. Food Sci. Nutr. 2023, 63, 8226–8248. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, J.; Zhang, L.; Qin, Z.; Wang, T. Review of Recent Advances in Intelligent and Antibacterial Packaging for Meat Quality and Safety. Foods 2025, 14, 1157. [Google Scholar] [CrossRef]

- Liu, J.; Hu, Z.; Zhang, Y.; Li, H.-Y.; Gao, N.; Tian, Z.; Zhou, L.; Zhang, B.; Tang, J.; Zhang, J.; et al. MoS2 Nanosheets Sensitized with Quantum Dots for Room-Temperature Gas Sensors. Nanomicro Lett. 2020, 12, 59. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Zhu, Y.; Qian, L.; Yin, Y.; Yuan, Z.; Dai, Y.; Zhang, T.; Yang, D.; Qiu, F. Lamellar Ti3C2 MXene Composite Decorated with Platinum-Doped MoS2 Nanosheets as Electrochemical Sensing Functional Platform for Highly Sensitive Analysis of Organophosphorus Pesticides. Food Chem. 2024, 459, 140379. [Google Scholar] [CrossRef] [PubMed]

- Bin, Z.; Feng, L.; Yan, Y. Biomimetic Metalloporphyrin Oxidase Modified Carbon Nanotubes for Highly Sensitive and Stable Quantification of Anti-Oxidants Tert-Butylhydroquinone in Plant Oil. Food Chem. 2022, 388, 132898. [Google Scholar] [CrossRef]

- Mulmi, S.; Thangadurai, V. Editors’ Choice—Review—Solid-State Electrochemical Carbon Dioxide Sensors: Fundamentals, Materials and Applications. J. Electrochem. Soc. 2020, 167, 037567. [Google Scholar] [CrossRef]

- Han, E.; Pan, Y.; Li, L.; Cai, J. Bisphenol A Detection Based on Nano Gold-Doped Molecular Imprinting Electrochemical Sensor with Enhanced Sensitivity. Food Chem. 2023, 426, 136608. [Google Scholar] [CrossRef]

- Lerud, R.M.; Beseau, D.; Hale, C.M.; Noll, C.; Rananavare, S.B. Optimizing the Performance of a Commercial Electrochemical Ethylene Sensor via Controlled Ethylene Generation in Situ. Sens. Actuators B Chem. 2019, 281, 535–541. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, Y.; Yang, Z.; Rong, Q.; Yao, D.; Li, K.; Zhang, C.; Zheng, J.; Wang, C.; Guo, Y. An Affordable Amperometric Gas Sensor Based on Polyvinylidene Fluoride Solid-State Electrolyte for Highly Selective Detection of Ppm-Level H2 at Room Temperature. ACS Appl. Polym. Mater. 2024, 6, 12451–12458. [Google Scholar] [CrossRef]

- Tsai, M.-F.; Ding, R.-Y.; Hsueh, T.-J. Optimized Gallium Oxide/MEMS Gas Sensor for H2S Gas Detection That Exhibits Increased Sensitivity and Stability. Appl. Surf. Sci. 2025, 696, 162944. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, M.; Duan, H.; Bu, Q.; Dong, X. Recent Advances of Optical Sensors for Point-of-Care Detection of Phthalic Acid Esters. Front. Sustain. Food Syst. 2024, 8, 1474831. [Google Scholar] [CrossRef]

- Zhai, X.; Sun, Y.; Cen, S.; Wang, X.; Zhang, J.; Yang, Z.; Li, Y.; Wang, X.; Zhou, C.; Arslan, M.; et al. Anthocyanins-Encapsulated 3D-Printable Bigels: A Colorimetric and Leaching-Resistant Volatile Amines Sensor for Intelligent Food Packaging. Food Hydrocoll. 2022, 133, 107989. [Google Scholar] [CrossRef]

- Yu, S.; Huang, X.; Wang, Y.; Wang, L.; Chang, X.; Ren, Y.; Zhang, X. Characterization and Quantification of the Taste Profiles of Black Garlic via a Novel Multi-Channel Colorimetric Sensor Array and Chemometrics. J. Food Compos. Anal. 2025, 138, 107005. [Google Scholar] [CrossRef]

- Wang, L.; Xiong, F.; Huang, X.; Harrington Aheto, J.; Yu, S.; Wang, Y.; Zhang, X.; Ren, Y. Fast Monitoring the Dynamic Change of Total Acids during Apple Vinegar Fermentation Process Using a Colorimetric IDA Sensor Array. Food Chem. 2022, 387, 132867. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Shoaib, M.; Wang, J.; Lin, H.; Chen, Q.; Ouyang, Q. A Novel ZIF-8 Mediated Nanocomposite Colorimetric Sensor Array for Rapid Identification of Matcha Grades, Validated by Density Functional Theory. J. Food Compos. Anal. 2025, 137, 106864. [Google Scholar] [CrossRef]

- Yin, L.; Hu, X.; Hao, M.; Shi, J.; Zou, X.; Dusabe, K.D. Upconversion Nanoparticles-Based Background-Free Selective Fluorescence Sensor Developed for Immunoassay of Fipronil Pesticide. J. Food Meas. Charact. 2023, 17, 3125–3133. [Google Scholar] [CrossRef]

- Cai, Y.; Cao, L.; Cai, H.; Yang, W.; Lu, H.; Adila, A.; Zhang, B.; Cao, Y.; Huang, W.; Xu, W.; et al. A Rapid Microfluidic Paper-Based Chip Sensor Using Ratiometric Fluorescence and Molecularly Imprinted Polymers for Visual Detection of Sulfadiazine in Actual Samples. J. Food Compos. Anal. 2025, 139, 107108. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, S.; Peng, J.; Fan, Y.; Wang, F.; Lu, L.; Fu, H.; Chen, X.; She, Y. Ratiometric Pyrene-Based Fluorescent Sensor for on-Site Monitoring of Formaldehyde in Foods and Living Cells. Sens. Actuators B Chem. 2023, 392, 134064. [Google Scholar] [CrossRef]

- Wang, X.; Hu, X.; Zhai, X.; Huang, X.; Li, Z.; Zou, X.; Shi, J. A Simple and Sensitive Electrochemical Sensing Based on Amine-Functionalized Metal–Organic Framework and Polypyrrole Composite for Detection of Lead Ions in Meat Samples. J. Food Meas. Charact. 2024, 18, 5813–5825. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, X.; Shi, J.; Zou, X.; Huang, X.; Tahir, H.E. Preparation of Conducting Polyaniline/Protoporphyrin Composites and Their Application for Sensing VOCs. Food Chem. 2019, 276, 291–297. [Google Scholar] [CrossRef]

- Roh, H.; Kim, D.; Cho, Y.; Jo, Y.; del Alamo, J.A.; Kulik, H.J.; Dincă, M.; Gumyusenge, A. Robust Chemiresistive Behavior in Conductive Polymer/MOF Composites. Adv. Mater. 2024, 36, e2312382. [Google Scholar] [CrossRef]

- Ryan, K.R.; Down, M.P.; Hurst, N.J.; Keefe, E.M.; Banks, C.E. Additive Manufacturing (3D Printing) of Electrically Conductive Polymers and Polymer Nanocomposites and Their Applications. eScience 2022, 2, 365–381. [Google Scholar] [CrossRef]

- Pirsa, S. Design of a Portable Gas Chromatography with a Conducting Polymer Nanocomposite Detector Device and a Method to Analyze a Gas Mixture. J. Sep. Sci. 2017, 40, 1724–1730. [Google Scholar] [CrossRef]

- Seesaard, T.; Wongchoosuk, C. Recent Progress in Electronic Noses for Fermented Foods and Beverages Applications. Fermentation 2022, 8, 302. [Google Scholar] [CrossRef]

- Bonah, E.; Huang, X.; Aheto, J.H.; Osae, R. Application of Electronic Nose as a Non-Invasive Technique for Odor Fingerprinting and Detection of Bacterial Foodborne Pathogens: A Review. J. Food Sci. Technol. 2020, 57, 1977–1990. [Google Scholar] [CrossRef]

- Lu, B.; Han, F.; Aheto, J.H.; Rashed, M.M.A.; Pan, Z. Artificial Bionic Taste Sensors Coupled with Chemometrics for Rapid Detection of Beef Adulteration. Food Sci. Nutr. 2021, 9, 5220–5228. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, Q.; Yang, Y.; Wu, J.; Chen, Q.; Guo, Z.; Li, H. Measurement of Total Free Amino Acids Content in Black Tea Using Electronic Tongue Technology Coupled with Chemometrics. LWT 2020, 118, 108768. [Google Scholar] [CrossRef]

- Zong, B.; Wu, S.; Yang, Y.; Li, Q.; Tao, T.; Mao, S. Smart Gas Sensors: Recent Developments and Future Prospective. Nanomicro Lett. 2025, 17, 54. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Liang, X.; Wang, Y.; Wu, B.; Sun, J. Non-Destructive Techniques for the Analysis and Evaluation of Meat Quality and Safety: A Review. Foods 2022, 11, 3713. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, X.; Huang, Y.; Li, H.; Chen, L.; Liu, X. Two Colorimetric Films Based on Chitin Whiskers and Sodium Alginate/Gelatin Incorporated with Anthocyanins for Monitoring Food Freshness. Food Hydrocoll. 2022, 127, 107517. [Google Scholar] [CrossRef]

- Hashemian, H.; Ghaedi, M.; Dashtian, K.; Mosleh, S.; Hajati, S.; Razmjoue, D.; Khan, S. Cellulose Acetate/MOF Film-Based Colorimetric Ammonia Sensor for Non-Destructive Remote Monitoring of Meat Product Spoilage. Int. J. Biol. Macromol. 2023, 249, 126065. [Google Scholar] [CrossRef]

- Lin, Y.; Ma, J.; Cheng, J.-H.; Sun, D.-W. Visible Detection of Chilled Beef Freshness Using a Paper-Based Colourimetric Sensor Array Combining with Deep Learning Algorithms. Food Chem. 2024, 441, 138344. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, S.; Wang, X.; Huang, J.; Pan, W.; Zhang, J.; Meteku, B.E.; Zeng, J. UV Illumination-Enhanced Ultrasensitive Ammonia Gas Sensor Based on (001)TiO2/MXene Heterostructure for Food Spoilage Detection. J. Hazard. Mater. 2022, 423, 127160. [Google Scholar] [CrossRef]

- Yue, Q.; Liu, T.; Mu, Y.; Chen, X.; Yin, X.T. Highly Responsive and Swift Recovery Triethylamine Gas Sensor Based on NiCo2O4-ZnO p-n Heterojunction. Sens. Actuators B Chem. 2024, 410, 135666. [Google Scholar] [CrossRef]

- Huang, W.; Xia, J.; Wang, X.; Zhao, Q.; Zhang, M.; Zhang, X. Improvement of Non-Destructive Detection of Lamb Freshness Based on Dual-Parameter Flexible Temperature-Impedance Sensor. Food Control 2023, 153, 109963. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Y.; Wang, Y.; Kong, B.; Chen, Q. Evaluation of the Flavour Properties of Cooked Chicken Drumsticks as Affected by Sugar Smoking Times Using an Electronic Nose, Electronic Tongue, and HS-SPME/GC-MS. LWT 2021, 140, 110764. [Google Scholar] [CrossRef]

- Huang, X.; Yu, S.; Xu, H.; Aheto, J.H.; Bonah, E.; Ma, M.; Wu, M.; Zhang, X. Rapid and Nondestructive Detection of Freshness Quality of Postharvest Spinaches Based on Machine Vision and Electronic Nose. J. Food Saf. 2019, 39, e12708. [Google Scholar] [CrossRef]

- Guo, Z.; Guo, C.; Sun, L.; Zuo, M.; Chen, Q.; El-Seedi, H.R.; Zou, X. Identification of the Apple Spoilage Causative Fungi and Prediction of the Spoilage Degree Using Electronic Nose. J. Food Process Eng. 2021, 44, e13816. [Google Scholar] [CrossRef]

- Adade, S.Y.-S.S.; Lin, H.; Johnson, N.A.N.; Nunekpeku, X.; Aheto, J.H.; Ekumah, J.-N.; Kwadzokpui, B.A.; Teye, E.; Ahmad, W.; Chen, Q. Advanced Food Contaminant Detection through Multi-Source Data Fusion: Strategies, Applications, and Future Perspectives. Trends Food Sci. Technol. 2025, 156, 104851. [Google Scholar] [CrossRef]

- Li, L.; Xie, S.; Ning, J.; Chen, Q.; Zhang, Z. Evaluating Green Tea Quality Based on Multisensor Data Fusion Combining Hyperspectral Imaging and Olfactory Visualization Systems. J. Sci. Food Agric. 2019, 99, 1787–1794. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, X.; Aheto, J.H.; Jiang, L.; Qian, C.; Wang, Y.; Zhang, X.; Yu, S.; Wang, L. Development and Test of a Smart Multisensory Device for Preserved Eggs. J. Food Process Eng. 2022, 45, e14093. [Google Scholar] [CrossRef]

- Huang, X.; Pan, S.; Sun, Z.; Ye, W.; Aheto, J.H. Evaluating Quality of Tomato during Storage Using Fusion Information of Computer Vision and Electronic Nose. J. Food Process Eng. 2018, 41, e12832. [Google Scholar] [CrossRef]

- Aghili, N.S.; Rasekh, M.; Karami, H.; Edriss, O.; Wilson, A.D.; Ramos, J. Aromatic Fingerprints: VOC Analysis with E-Nose and GC-MS for Rapid Detection of Adulteration in Sesame Oil. Sensors 2023, 23, 6294. [Google Scholar] [CrossRef]

- Darvishi, P.; Mirzaee-Ghaleh, E.; Ramedani, Z.; Karami, H.; Wilson, A.D. Detecting Whey Adulteration of Powdered Milk by Analysis of Volatile Emissions Using a MOS Electronic Nose. Int. Dairy. J. 2024, 157, 106012. [Google Scholar] [CrossRef]

- Parlak, İ.H.; Milli, M.; Milli, N.S. Machine Learning–Based Detection of Olive Oil Adulteration Using BME688 Gas Sensor Matrix. Food Anal. Methods 2025, 18, 1454–1464. [Google Scholar] [CrossRef]

- Zhou, M.; Dai, C.; Aheto, J.H.; Zhang, X. Design of a Portable Electronic Nose for Identification of Minced Chicken Meat Adulterated With Soybean Protein Isolate. J. Food Saf. 2024, 44, e13163. [Google Scholar] [CrossRef]

- Putri, L.A.; Rahman, I.; Puspita, M.; Hidayat, S.N.; Dharmawan, A.B.; Rianjanu, A.; Wibirama, S.; Roto, R.; Triyana, K.; Wasisto, H.S. Rapid Analysis of Meat Floss Origin Using a Supervised Machine Learning-Based Electronic Nose towards Food Authentication. NPJ Sci. Food 2023, 7, 31. [Google Scholar] [CrossRef] [PubMed]

- Zeng, C.; Wei, Q.; Pu, F.; Liu, Y.; Sun, W.; Che, Z.; Huang, Y. Discrimination of Zanthoxylum Bungeanum Maxim through Volatile Aroma Compounds Analysis with Artificial Neural Network. J. Food Biochem. 2021, 45, e13621. [Google Scholar] [CrossRef] [PubMed]

- Han, F.; Zhang, D.; Aheto, J.H.; Feng, F.; Duan, T. Integration of a Low-Cost Electronic Nose and a Voltammetric Electronic Tongue for Red Wines Identification. Food Sci. Nutr. 2020, 8, 4330–4339. [Google Scholar] [CrossRef]

- Arslan, M.; Zareef, M.; Tahir, H.E.; Guo, Z.; Rakha, A.; Xuetao, H.; Shi, J.; Zhihua, L.; Xiaobo, Z.; Khan, M.R. Discrimination of Rice Varieties Using Smartphone-Based Colorimetric Sensor Arrays and Gas Chromatography Techniques. Food Chem. 2022, 368, 130783. [Google Scholar] [CrossRef]

- Wu, J.; Ouyang, Q.; Park, B.; Kang, R.; Wang, Z.; Wang, L.; Chen, Q. Physicochemical Indicators Coupled with Multivariate Analysis for Comprehensive Evaluation of Matcha Sensory Quality. Food Chem. 2022, 371, 131100. [Google Scholar] [CrossRef]

- Yu, S.; Huang, X.; Wang, L.; Chang, X.; Ren, Y.; Zhang, X.; Wang, Y. Qualitative and Quantitative Assessment of Flavor Quality of Chinese Soybean Paste Using Multiple Sensor Technologies Combined with Chemometrics and a Data Fusion Strategy. Food Chem. 2023, 405, 134859. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Huang, X.; Wang, L.; Ren, Y.; Zhang, X.; Wang, Y. Characterization of Selected Chinese Soybean Paste Based on Flavor Profiles Using HS-SPME-GC/MS, E-Nose and E-Tongue Combined with Chemometrics. Food Chem. 2022, 375, 131840. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Liao, D.; Zhou, Y.; Huang, Q.; Lei, S.; Li, X. Correlation between Physicochemical Properties, Flavor Characteristics and Microbial Community Structure in Dushan Shrimp Sour Paste. Food Chem. X 2024, 23, 101543. [Google Scholar] [CrossRef]

- Sharmilan, T.; Premarathne, I.; Wanniarachchi, I.; Kumari, S.; Wanniarachchi, D. Application of Electronic Nose to Predict the Optimum Fermentation Time for Low-Country Sri Lankan Tea. J. Food Qual. 2022, 2022, 7703352. [Google Scholar] [CrossRef]

- Hosseini-Golgoo, S.M.; Saeedi-Mirakmahaleh, M.; Saberi, H. Black Tea Quality Determination Using a Generic Resistive Gas Sensor. Meas. Sci. Technol. 2022, 33, 125115. [Google Scholar] [CrossRef]

- Tseng, T.S.; Hsiao, M.H.; Chen, P.A.; Lin, S.Y.; Chiu, S.W.; Yao, D.J. Utilization of a Gas-Sensing System to Discriminate Smell and to Monitor Fermentation during the Manufacture of Oolong Tea Leaves. Micromachines 2021, 12, 93. [Google Scholar] [CrossRef] [PubMed]

- Anker, M.; Yousefi-Darani, A.; Zettel, V.; Paquet-Durand, O.; Hitzmann, B.; Krupitzer, C. Online Monitoring of Sourdough Fermentation Using a Gas Sensor Array with Multivariate Data Analysis. Sensors 2023, 23, 7681. [Google Scholar] [CrossRef]

- Li, Y.; Yuan, L.; Liu, H.; Liu, H.; Zhou, Y.; Li, M.; Gao, R. Analysis of the Changes of Volatile Flavor Compounds in a Traditional Chinese Shrimp Paste during Fermentation Based on Electronic Nose, SPME-GC-MS and HS-GC-IMS. Food Sci. Human. Wellness 2022, 12, 173–182. [Google Scholar] [CrossRef]

- Gancarz, M.; Malaga-Toboła, U.; Oniszczuk, A.; Tabor, S.; Oniszczuk, T.; Gawrysiak-Witulska, M.; Rusinek, R. Detection and Measurement of Aroma Compounds with the Electronic Nose and a Novel Method for MOS Sensor Signal Analysis during the Wheat Bread Making Process. Food Bioprod. Process. 2021, 127, 90–98. [Google Scholar] [CrossRef]

- Yoosefian, S.H.; Ebrahimi, R.; Bakhshipour, A.; Mohammad-Razdari, A.; Maleki, A. Real-Time Monitoring of Agricultural Waste Conversion to Bioethanol in a Pneumatic System by Optimized Electronic Nose. J. Mater. Cycles Waste Manag. 2024, 26, 421–434. [Google Scholar] [CrossRef]

- Liu, S.; Rong, Y.; Chen, Q.; Ouyang, Q. Colorimetric Sensor Array Combined with Chemometric Methods for the Assessment of Aroma Produced during the Drying of Tencha. Food Chem. 2024, 432, 137190. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Huang, X.; Aheto, J.H.; Ren, Y.; Wang, L.; Yu, S.; Wang, Y. Comparable Analysis of Flavor Compounds and Quality Assessment of Fermented Bean Curd Using HS-SPME-GC/MS and Colorimetric Sensor Array. Food Biosci. 2024, 60, 104291. [Google Scholar] [CrossRef]

- Shui, Z.; Zhao, J.; Zheng, J.; Luo, H.; Ma, Y.; Hou, C.; Huo, D. Pattern-Based Colorimetric Sensor Array Chip for Discrimination of Baijiu Aromas. Food Chem. 2024, 446, 138845. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Lin, H.; Wang, F.; Adade, S.Y.-S.S.; Peng, T.; Chen, Q. Discrimination of Toxigenic and Non-Toxigenic Aspergillus Flavus in Wheat Based on Nanocomposite Colorimetric Sensor Array. Food Chem. 2024, 430, 137048. [Google Scholar] [CrossRef]

- Lin, H.; Yan, S.; Song, B.T.; Wang, Z.; Sun, L. Discrimination of Aged Rice Using Colorimetric Sensor Array Combined with Volatile Organic Compounds. J. Food Process Eng. 2019, 42, e13037. [Google Scholar] [CrossRef]

- Zhai, X.; Li, Z.; Zhang, J.; Shi, J.; Zou, X.; Huang, X.; Zhang, D.; Sun, Y.; Yang, Z.; Holmes, M.; et al. Natural Biomaterial-Based Edible and PH-Sensitive Films Combined with Electrochemical Writing for Intelligent Food Packaging. J. Agric. Food Chem. 2018, 66, 12836–12846. [Google Scholar] [CrossRef]

- Zhai, X.; Xue, Y.; Song, W.; Sun, Y.; Shen, T.; Zhang, X.; Li, Y.; Zhang, D.; Zhou, C.; Zhang, J.; et al. Rapid and Facile Synthesis of Homoporous Colorimetric Films Using Leaf Vein-Mediated Emulsion Evaporation Method for Visual Monitoring of Food Freshness. J. Agric. Food Chem. 2024, 72, 21854–21868. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, J.; Zhang, X.; Huang, X.; Shi, J.; Sobhy, R.; Khalifa, I.; Zou, X. Ammonia-Responsive Colorimetric Film of Phytochemical Formulation (Alizarin) Grafted onto ZIF-8 Carrier with Poly(Vinyl Alcohol) and Sodium Alginate for Beef Freshness Monitoring. J. Agric. Food Chem. 2024, 72, 11706–11715. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Shi, J.; Li, Z.; Wang, X.; Hu, X.; Gong, Y.; Zou, X. A Novel Gas Sensor for Detecting Pork Freshness Based on PANI/AgNWs/Silk. Foods 2022, 11, 2372. [Google Scholar] [CrossRef]

- Cheng, J.; Sun, J.; Shi, L.; Dai, C. An Effective Method Fusing Electronic Nose and Fluorescence Hyperspectral Imaging for the Detection of Pork Freshness. Food Biosci. 2024, 59, 103880. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, T.; He, P.; Ding, Y.; Chen, Q. Rapid Measurement of Fatty Acid Content during Flour Storage Using a Color-Sensitive Gas Sensor Array: Comparing the Effects of Swarm Intelligence Optimization Algorithms on Sensor Features. Food Chem. 2021, 338, 127828. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; He, Y.; Chen, Q. Qualitative Identification of the Edible Oil Storage Period Using a Homemade Portable Electronic Nose Combined with Multivariate Analysis. J. Sci. Food Agric. 2021, 101, 3448–3456. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Zhang, Y.; Xiao, H.; Jayan, H.; Majeed, U.; Ashiagbor, K.; Jiang, S.; Zou, X. Multi-Sensor Fusion and Deep Learning for Batch Monitoring and Real-Time Warning of Apple Spoilage. Food Control 2025, 172, 111174. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Wang, C.; Liu, X.; El-Seedi, H.R.; Gómez, P.L.; Alzamora, S.M.; Zou, X.; Guo, Z. Enhanced Composite Co-MOF-Derived Sodium Carboxymethyl Cellulose Visual Films for Real-Time and in Situ Monitoring Fresh-cut Apple Freshness. Food Hydrocoll 2024, 157, 110475. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Sun, Z.; Wang, D.; Liu, F.; Lin, L. In Vitro and In Situ Characterization of Psychrotrophic Spoilage Bacteria Recovered from Chilled Chicken. Foods 2022, 12, 95. [Google Scholar] [CrossRef]

- Yin, L.; Jayan, H.; Cai, J.; El-Seedi, H.R.; Guo, Z.; Zou, X. Spoilage Monitoring and Early Warning for Apples in Storage Using Gas Sensors and Chemometrics. Foods 2023, 12, 2968. [Google Scholar] [CrossRef]

- Huang Zhang, X.; Huang, X.; Dai, C.; Tian, X.; Wang, C.; Ren, Y.; Wang, L.; Yu, S.; Aheto, J.H.; Chang, X. Characterization of Volatile Flavor Profiles and Quantitative Assessment of Key Physicochemical In-dicators for Fermented Bean Curd Using GC-IMS, E-Nose and Multi-Channel Colorimetric Sensor Array Combined with Chemometrics. Food Biosci. 2025, 69, 106879. [Google Scholar] [CrossRef]

- Han, F.; Huang, X.; Aheto, J.H.; Zhang, D.; Feng, F. Detection of Beef Adulterated with Pork Using a Low-Cost Electronic Nose Based on Colorimetric Sensors. Foods 2020, 9, 193. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Li, Z.; Xiaobo, Z.; Shi, J.; Tahir, H.E.; Xu, Y.; Zhai, X.; Hu, X. Geographical Origin Discrimination of Edible Bird’s Nests Using Smart Handheld Device Based on Colorimetric Sensor Array. J. Food Meas. Charact. 2020, 14, 514–526. [Google Scholar] [CrossRef]

- Mohammadian, N.; Ziaiifar, A.M.; Mirzaee-Ghaleh, E.; Kashaninejad, M.; Karami, H. Gas Sensor Technology and AI: Forecasting Lemon Juice Quality Dynamics during the Storage Period. J. Stored Prod. Res. 2024, 109, 102449. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Q.; Liu, S.; Jiao, L.; Dong, D. Rapid Determination of Different Ripening Stages of Occidental Pears (Pyrus communis L.) by Volatile Organic Compounds Using Proton-Transfer-Reaction Mass Spectrometry (PTR-MS). Foods 2024, 13, 620. [Google Scholar] [CrossRef]

- Tian, J.; Xu, S.; Wu, Y.; Shi, Y.; Duan, Y.; Li, Z.; Cao, H.; Zeng, J.; Shen, T.; Pan, L.; et al. Authenticating Vintage in White Tea: Appearance-Taste-Aroma-Based Three-in-One Non-Invasive Anticipation. Food Res. Int. 2025, 199, 115394. [Google Scholar] [CrossRef]

- Han, Z.; Ahmad, W.; Rong, Y.; Chen, X.; Zhao, S.; Yu, J.; Zheng, P.; Huang, C.; Li, H. A Gas Sensors Detection System for Real-Time Monitoring of Changes in Volatile Organic Compounds during Oolong Tea Processing. Foods 2024, 13, 1721. [Google Scholar] [CrossRef]

- Dai, C.; Huang, X.; Huang, D.; Lv, R.; Sun, J.; Zhang, Z.; Ma, M.; Aheto, J.H. Detection of Submerged Fermentation of Tremella Aurantialba Using Data Fusion of Electronic Nose and Tongue. J. Food Process Eng. 2019, 42, e13002. [Google Scholar] [CrossRef]

- Congcong, W.; Vinothkanna, A.; Yongkun, M.; Jie, H.; Rai, A.K.; Jindong, X.; Dahai, L. Production of Mulberry Wine Using Selenium-Enriched Saccharomyces Cerevisiae: Implications from Sensory Analysis, Phytochemical and Antioxidant Activities. J. Food Sci. Technol. 2024, 61, 366–384. [Google Scholar] [CrossRef]

- Ding, X.; Yue, M.; Gu, H.; Li, S.; Chen, S.; Wang, L.; Sun, L. Effects of Wickerhamomyces Anomalus Co-Fermented with Saccharomyces Cerevisiae on Volatile Flavor Profiles during Steamed Bread Making Using Electronic Nose and HS-SPME-GC-MS. Foods 2024, 13, 2490. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Xie, W.; Bai, F.; Wang, J.; Zhou, X.; Gao, R.; Xu, X.; Zhao, Y. Influence of Thermal Processing on Flavor and Sensory Profile of Sturgeon Meat. Food Chem. 2022, 374, 131689. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.; Kim, S. Application of Machine Learning for Quantitative Analysis of Industrial Fermentation Using Image Processing. Food Sci. Biotechnol. 2024, 34, 373–381. [Google Scholar] [CrossRef]

- Lin, H.; Kang, W.C.; Jin, H.J.; Man, Z.X.; Chen, Q.S. Discrimination of Chinese Baijiu Grades Based on Colorimetric Sensor Arrays. Food Sci. Biotechnol. 2020, 29, 1037–1043. [Google Scholar] [CrossRef]

- Huang, Y.; Sun, Y.; Mehmood, A.; Lu, T.; Chen, X. Unraveling the Temporal Changes of Maillard Reaction Products and Aroma Profile in Coffee Leaves during Hot-Air Drying. J. Food Compos. Anal. 2024, 128, 106055. [Google Scholar] [CrossRef]

- Xu, Q.; Su, Y.; Sun, L.; Cai, J. Detection of Citrus Huanglongbing at Different Stages of Infection Using a Homemade Electronic Nose System. Comput. Electron. Agric. 2025, 229, 109845. [Google Scholar] [CrossRef]

- Chun, S.Y.; Song, Y.G.; Kim, J.E.; Kwon, J.U.; Soh, K.; Kwon, J.Y.; Kang, C.; Yoon, J.H. An Artificial Olfactory System Based on a Chemi-Memristive Device. Adv. Mater. 2023, 35, e2302219. [Google Scholar] [CrossRef]

- Andrews, B.; Chakrabarti, A.; Dauphin, M.; Speck, A. Application of Machine Learning for Calibrating Gas Sensors for Methane Emissions Monitoring. Sensors 2023, 23, 9898. [Google Scholar] [CrossRef]

- Ng, K.Y.; Ngo, D.T.; Chao, P.C.-P.; Horng, R.H.; Shieh, J.-M. High-Precision Prediction of NOx, NO2 and C6H6 by Multiple Gas Sensors Using a Novel Cascaded MLP-LSTM Model. In Proceedings of the 2024 IEEE SENSORS, Kobe, Japan, 20 October 2024; pp. 1–4. [Google Scholar]

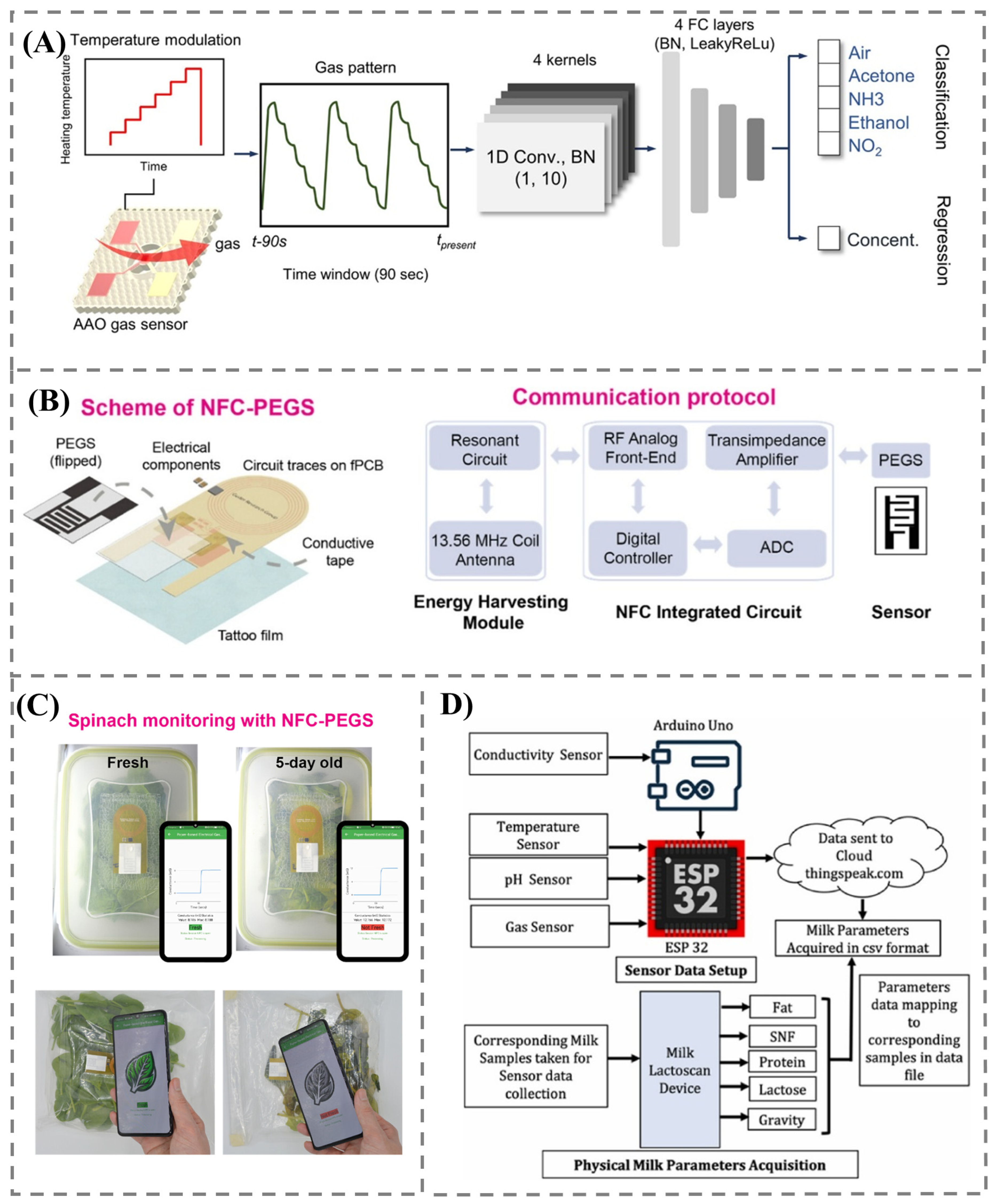

- Lee, B.; Kang, M.; Lee, K.; Chae, Y.; Yoon, K.-J.; Lee, D.-S.; Park, I. Multigas Identification by Temperature-Modulated Operation of a Single Anodic Aluminum Oxide Gas Sensor Platform and Deep Learning Algorithm. ACS Sens. 2025, 10, 954–964. [Google Scholar] [CrossRef] [PubMed]

- Naik, A.; Lee, H.S.; Herrington, J.; Barandun, G.; Flock, G.; Güder, F.; Gonzalez-Macia, L. Smart Packaging with Disposable NFC-Enabled Wireless Gas Sensors for Monitoring Food Spoilage. ACS Sens. 2024, 9, 6789–6799. [Google Scholar] [CrossRef] [PubMed]

- Dinesh Kumar, M.; Lakshmi, A.; Atchaya, S.; Harish, S.; Pradiksha, S. Wireless Sensor Networks Based Monitoring and Controlling of Food Storage System. In Proceedings of the Conference on Emerging Trends In Engineering Design & Manufacturing (ETEDM-22), Coimbatore, India, 15–16 June 2022. [Google Scholar]

- Wang, C.; Gu, C.; Zhao, X.; Yu, S.; Zhang, X.; Xu, F.; Ding, L.; Huang, X.; Qian, J. Self-Designed Portable Dual-Mode Fluorescence Device with Custom Python-Based Analysis Software for Rapid Detection via Dual-Color FRET Aptasensor with IoT Capabilities. Food Chem. 2024, 457, 140190. [Google Scholar] [CrossRef]

- Damdam, A.N.; Ozay, L.O.; Ozcan, C.K.; Alzahrani, A.; Helabi, R.; Salama, K.N. IoT-Enabled Electronic Nose System for Beef Quality Monitoring and Spoilage Detection. Foods 2023, 12, 2227. [Google Scholar] [CrossRef] [PubMed]

- Goyal, K.; Kumar, P.; Verma, K. XAI-Empowered IoT Multi-Sensor System for Real-Time Milk Adulteration Detection. Food Control 2024, 164, 110495. [Google Scholar] [CrossRef]

| Technique | Key Characteristics | Fabrication Method | Advantages | Limitations |

|---|---|---|---|---|

| MOS Sensor | Detect gases by measuring changes in electrical resistance due to reversible interactions between gases and the metal-oxide surface | Wafer fabrication, oxidation, mask generation, photolithography, diffusion, and deposition | High gas response, reversible reactions, cost-effective, sensitive to freshness marker gases, operable across a range of temperatures, and compatible with sensor array integration | Limited selectivity, slow response and recovery times, and limited mass transfer in the gas phase |

| Electrochemical sensor | Convert chemical concentrations into electrical signals via redox reactions, enabling selective and accurate gas detection | Electrochemical deposition, electroless deposition, microspotting, dip-pen lithography, and self-assembly | Highly sensitive, selective, rapid response, portable, and adaptable to various conditions, with compatibility for sensor array integration | Cross-sensitivity to various gases, limited lifespan, and sensitivity to temperature and humidity |

| Optical sensor | Detect gases through chemical reactions between the gas and a chromogenic dye, which results in absorbance or fluorescence shifts. | Dip-coating technique, electrospun nanofibers, electrochemical writing, inkjet printing, and sol–gel techniques | Simple, cost-effective, and provides visual results for gas detection | Environmental interference, poor long-term stability, single-use design, rapid consumption of sensing materials, and challenges in calibration |

| Conducting Polymer Sensor | Detect gases through chemiresistive behavior, where electrical resistance changes upon gas exposure. | Sol–gel, in situ oxidative polymerization, template-based methods, solid-state synthesis, and oxidative chemical vapor deposition | Large-scale production, tunable electrical properties, flexibility, biocompatibility, ease of fabrication, and high sensitivity to gases like ammonia and hydrogen sulfide | Poor long-term stability, environmental interference, potential irreversible changes upon gas exposure, and high production costs |

| Sensor Array | Detect multiple VOCs simultaneously, mimicking the human olfactory system through a combination of diverse gas sensors. | Fabrication of patterned devices using engineered nanomaterials and integration of sensors into array systems via micro-electro-mechanical systems (MEMS) | Rapid detection, stability, portability, compactness, ability to identify complex gas mixtures, and adaptable for multiple applications | Response time issues, partial sensor specificity, interference from overlapping compounds, and need for advanced pattern recognition for accurate odor classification |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jayan, H.; Zhou, R.; Sun, C.; Wang, C.; Yin, L.; Zou, X.; Guo, Z. Intelligent Gas Sensors for Food Safety and Quality Monitoring: Advances, Applications, and Future Directions. Foods 2025, 14, 2706. https://doi.org/10.3390/foods14152706

Jayan H, Zhou R, Sun C, Wang C, Yin L, Zou X, Guo Z. Intelligent Gas Sensors for Food Safety and Quality Monitoring: Advances, Applications, and Future Directions. Foods. 2025; 14(15):2706. https://doi.org/10.3390/foods14152706

Chicago/Turabian StyleJayan, Heera, Ruiyun Zhou, Chanjun Sun, Chen Wang, Limei Yin, Xiaobo Zou, and Zhiming Guo. 2025. "Intelligent Gas Sensors for Food Safety and Quality Monitoring: Advances, Applications, and Future Directions" Foods 14, no. 15: 2706. https://doi.org/10.3390/foods14152706

APA StyleJayan, H., Zhou, R., Sun, C., Wang, C., Yin, L., Zou, X., & Guo, Z. (2025). Intelligent Gas Sensors for Food Safety and Quality Monitoring: Advances, Applications, and Future Directions. Foods, 14(15), 2706. https://doi.org/10.3390/foods14152706