Technological Innovations and Circular Economy in the Valorization of Agri-Food By-Products: Advances, Challenges and Perspectives

Abstract

1. Introduction

2. PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) Methodology

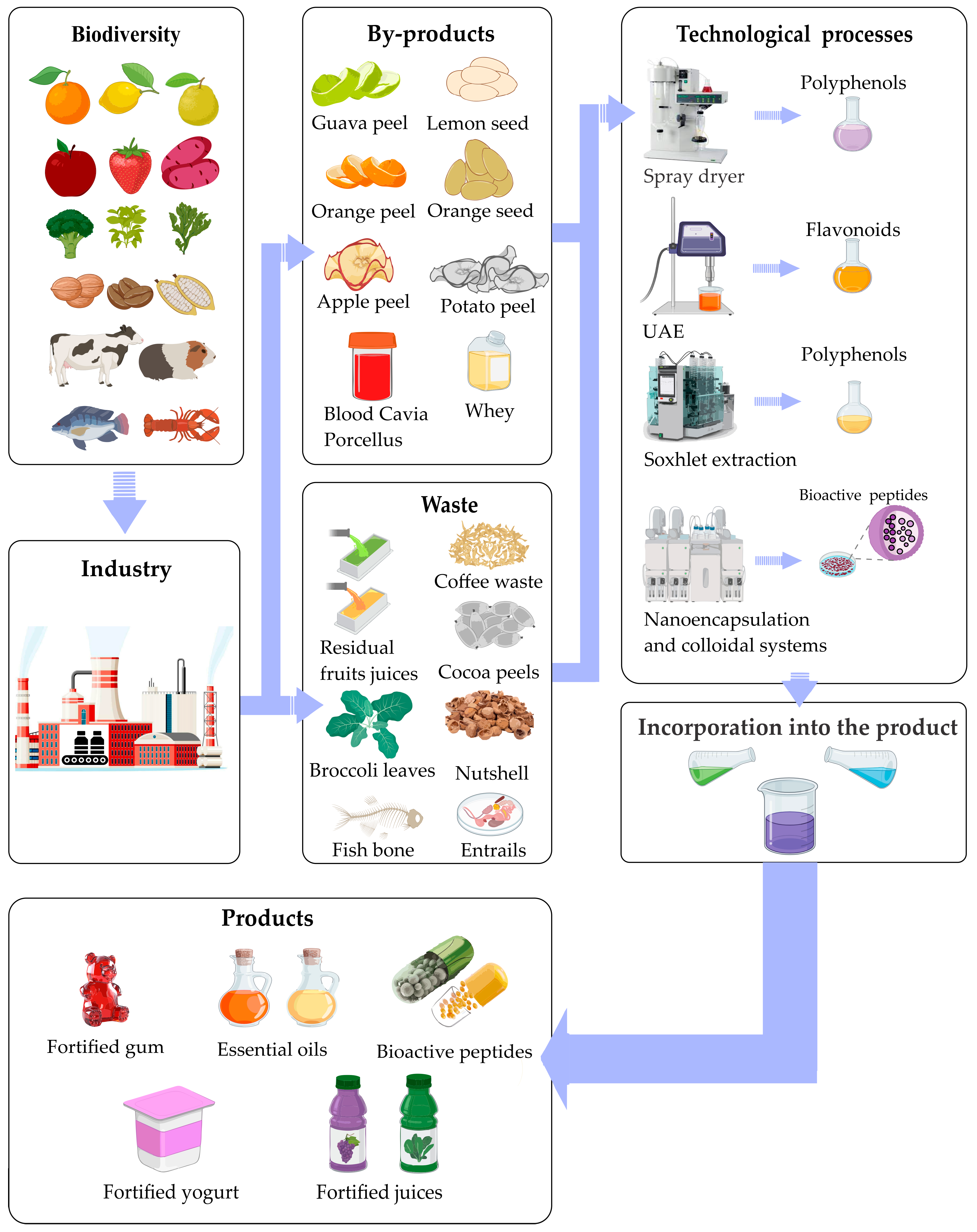

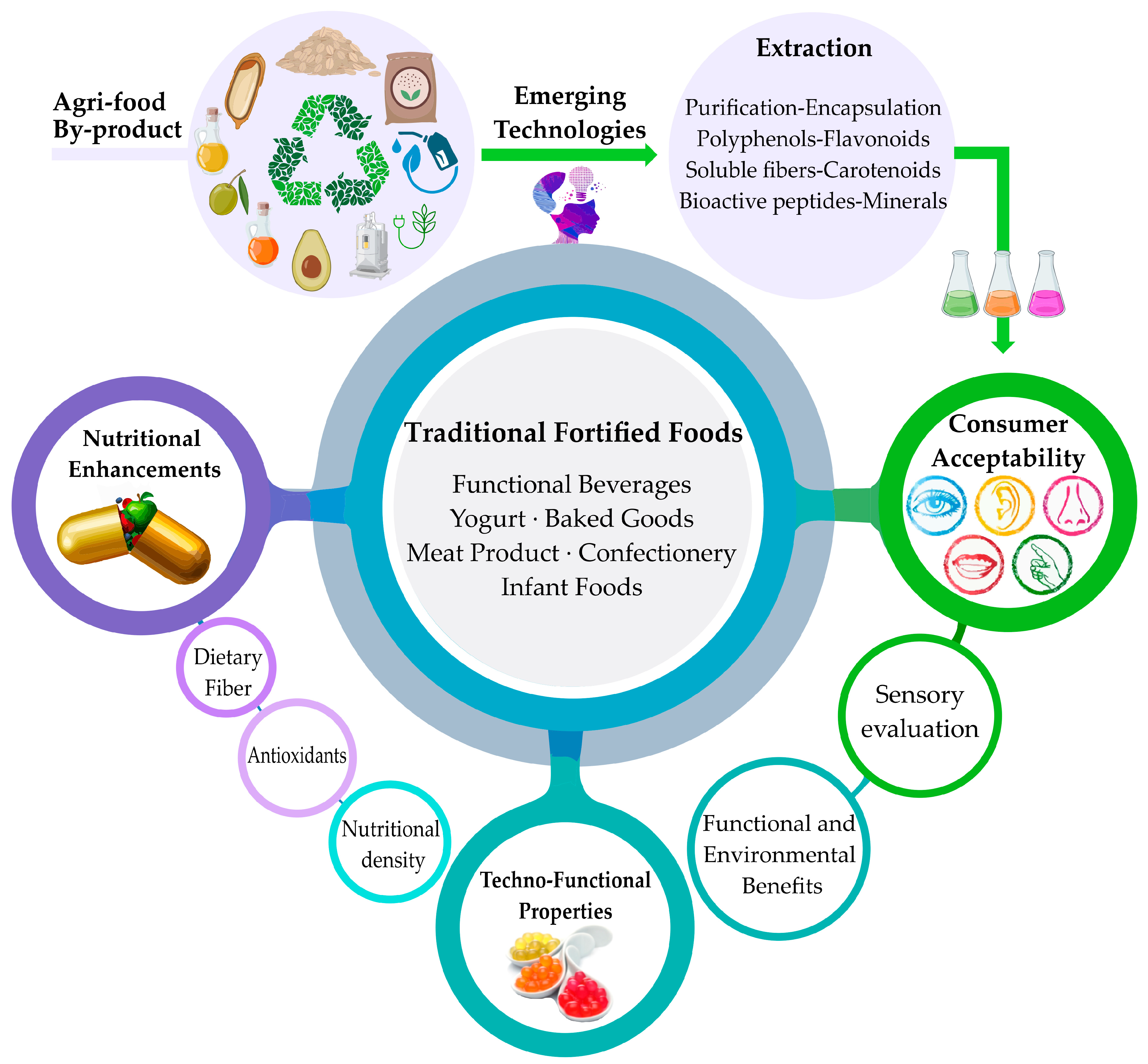

3. Fundamentals of the Valorization of Agri-Food By-Products

4. Technological Innovations Applied to the Processing of Agri-Food By-Products

4.1. Extraction and Recovery of Bioactive Compounds

4.2. Encapsulation and Stabilization

5. Application in the Development of New Products

6. Current Challenges and Barriers to Industrialization

7. Future Perspectives and Trends

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-Dimensional |

| AI | Artificial Intelligence |

| ASE | Accelerated Solvent Extraction |

| FD | Freeze Drying |

| GIT | Gastrointestinal Tract |

| GRAS | Generally Recognized As Safe |

| HBA | Hydrogen Bond Acceptor |

| HBD | Hydrogen Bond Donor |

| MAE | Microwave-Assisted Extraction |

| NADES | Natural Deep Eutectic Solvents |

| PLE | Pressurized Liquid Extraction |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| SD | Spray Drying |

| SFE | Supercritical Fluid Extraction |

| UAE | Ultrasound-Assisted Extraction |

| VD | Vacuum Drying |

References

- Gómez-García, R.; Campos, D.A.; Aguilar, C.N.; Madureira, A.R.; Pintado, M. Valorisation of food agro-industrial by-products: From the past to the present and perspectives. J. Environ. Manag. 2021, 299, 113571. [Google Scholar] [CrossRef]

- Castagna, A.; Aboudia, A.; Guendouz, A.; Scieuzo, C.; Falabella, P.; Matthes, J.; Schmid, M.; Drissner, D.; Allais, F.; Chadni, M.; et al. Transforming Agricultural Waste from Mediterranean Fruits into Renewable Materials and Products with a Circular and Digital Approach. Materials 2025, 18, 1464. [Google Scholar] [CrossRef]

- Neves, C.M.B.; Fogeiro, É.; Cardoso, S.M.; Gonçalves, F.; Pinto, A.; Wessel, D.F. Towards the Valorization of Elderberry By-Product: Recovery and Use of Natural Ingredients for Sorbet Formulations. Appl. Sci. 2024, 14, 10328. [Google Scholar] [CrossRef]

- Dhiman, S.; Thakur, B.; Kaur, S.; Ahuja, M.; Gantayat, S.; Sarkar, S.; Singh, R.; Tripathi, M. Closing the loop: Technological innovations in food waste valorisation for global sustainability. Discov. Sustain. 2025, 6, 258. [Google Scholar] [CrossRef]

- Bishop, G.; Girón-Domínguez, C.; Gaffey, J.; Henchion, M.; Fealy, R.; Zimmermann, J.; Kargupta, W.; Styles, D. A life cycle thinking-based environmental risk framework for screening sustainable feedstocks in early-stage bioeconomy projects. Resour. Environ. Sustain. 2025, 20, 100201. [Google Scholar] [CrossRef]

- Sarker, A.; Ahmmed, R.; Ahsan, S.M.; Rana, J.; Ghosh, M.K.; Nandi, R. A comprehensive review of food waste valorization for the sustainable management of global food waste. Sustain. Food Technol. 2024, 2, 48–69. [Google Scholar] [CrossRef]

- Prado-Acebo, I.; Cubero-Cardoso, J.; Lu-Chau, T.A.; Eibes, G. Integral multi-valorization of agro-industrial wastes: A review. Waste Manag. 2024, 183, 42–52. [Google Scholar] [CrossRef]

- Yadav, S.; Malik, K.; Moore, J.M.; Kamboj, B.R.; Malik, S.; Malik, V.K.; Arya, S.; Singh, K.; Mahanta, S.; Bishnoi, D.K. Valorisation of Agri-Food Waste for Bioactive Compounds: Recent Trends and Future Sustainable Challenges. Molecules 2024, 29, 2055. [Google Scholar] [CrossRef]

- Bala, S.; Garg, D.; Sridhar, K.; Inbaraj, B.S.; Singh, R.; Kamma, S.; Tripathi, M.; Sharma, M. Transformation of Agro-Waste into Value-Added Bioproducts and Bioactive Compounds: Micro/Nano Formulations and Application in the Agri-Food-Pharma Sector. Bioengineering 2023, 10, 152. [Google Scholar] [CrossRef]

- Otoni, C.G.; Azeredo, H.M.C.; Mattos, B.D.; Beaumont, M.; Correa, D.S.; Rojas, O.J. The Food–Materials Nexus: Next Generation Bioplastics and Advanced Materials from Agri-Food Residues. Adv. Mater. 2021, 33, 2102520. [Google Scholar] [CrossRef]

- Ahmad, T.; Esposito, F.; Cirillo, T. Valorization of agro-food by-products: Advancing sustainability and sustainable development goals 2030 through functional compounds recovery. Food Biosci. 2024, 62, 105194. [Google Scholar] [CrossRef]

- Arriaga, M.; Pinar, F.J.; Izarra, I.; Amo, J.D.; Vicente, J.; Fernández-Morales, F.J.; Mena, J. Valorization of Agri-Food Waste into PHA and Bioplastics: From Waste Selection to Transformation. Appl. Sci. 2025, 15, 1008. [Google Scholar] [CrossRef]

- Tyupova, A.; Harasym, J. Valorization of Fruit and Vegetables Industry By-Streams for 3D Printing—A Review. Foods 2024, 13, 2186. [Google Scholar] [CrossRef] [PubMed]

- Peydayesh, M. Sustainable Materials via the Assembly of Biopolymeric Nanobuilding Blocks Valorized from Agri-Food Waste. Sustainability 2024, 16, 1286. [Google Scholar] [CrossRef]

- Okwu, M.O.; Tartibu, L.K.; Maware, C.; Enarevba, D.R.; Afenogho, J.O.; Essien, A. Emerging Technologies of Industry 4.0: Challenges and Opportunities. In Proceedings of the 2022 International Conference on Artificial Intelligence, Big Data, Computing and Data Communication Systems (icABCD), Durban, South Africa, 4–5 August 2022; pp. 1–13. [Google Scholar]

- Haleem, A.; Javaid, M.; Singh, R.P. Encouraging Safety 4.0 to enhance industrial culture: An extensive study of its technologies, roles, and challenges. Green Technol. Sustain. 2025, 3, 100158. [Google Scholar] [CrossRef]

- Ding, H.; Tian, J.; Yu, W.; Wilson, D.I.; Young, B.R.; Cui, X.; Xin, X.; Wang, Z.; Li, W. The Application of Artificial Intelligence and Big Data in the Food Industry. Foods 2023, 12, 4511. [Google Scholar] [CrossRef]

- Pattnaik, M.; Pandey, P.; Martin, G.J.O.; Mishra, H.N.; Ashokkumar, M. Innovative Technologies for Extraction and Microencapsulation of Bioactives from Plant-Based Food Waste and Their Applications in Functional Food Development. Foods 2021, 10, 279. [Google Scholar] [CrossRef]

- Magalhães, D.; Gonçalves, R.; Rodrigues, C.V.; Rocha, H.R.; Pintado, M.; Coelho, M.C. Natural Pigments Recovery from Food By-Products: Health Benefits towards the Food Industry. Foods 2024, 13, 2276. [Google Scholar] [CrossRef]

- Leichtweis, M.G.; Oliveira, M.B.P.P.; Ferreira, I.C.F.R.; Pereira, C.; Barros, L. Sustainable Recovery of Preservative and Bioactive Compounds from Food Industry Bioresidues. Antioxidants 2021, 10, 1827. [Google Scholar] [CrossRef]

- Sanna, D.; Fadda, A. Waste from Food and Agro-Food Industries as Pigment Sources: Recovery Techniques, Stability and Food Applications. Nutraceuticals 2022, 2, 365–383. [Google Scholar] [CrossRef]

- Wainaina, S.; Awasthi, M.K.; Sarsaiya, S.; Chen, H.; Singh, E.; Kumar, A.; Ravindran, B.; Awasthi, S.K.; Liu, T.; Duan, Y.; et al. Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies. Bioresour. Technol. 2020, 301, 122778. [Google Scholar] [CrossRef] [PubMed]

- Messinese, E.; Pitirollo, O.; Grimaldi, M.; Milanese, D.; Sciancalepore, C.; Cavazza, A. By-Products as Sustainable Source of Bioactive Compounds for Potential Application in the Field of Food and New Materials for Packaging Development. Food Bioprocess Technol. 2024, 17, 606–627. [Google Scholar] [CrossRef]

- Şahin, S.; Kurtulbaş, E. Green Extraction and Valorization of By-Products from Food Processing. Foods 2024, 13, 1589. [Google Scholar] [CrossRef] [PubMed]

- Hrelia, S.; Angeloni, C.; Barbalace, M.C. Agri-Food Wastes as Natural Source of Bioactive Antioxidants. Antioxidants 2023, 12, 351. [Google Scholar] [CrossRef]

- Bayram, B.; Ozkan, G.; Kostka, T.; Capanoglu, E.; Esatbeyoglu, T. Valorization and Application of Fruit and Vegetable Wastes and By-Products for Food Packaging Materials. Molecules 2021, 26, 4031. [Google Scholar] [CrossRef]

- Cinelli, P.; Seggiani, M.; Coltelli, M.B.; Danti, S.; Righetti, M.C.; Gigante, V.; Sandroni, M.; Signori, F.; Lazzeri, A. Overview of Agro-Food Waste and By-Products Valorization for Polymer Synthesis and Modification for Bio-Composite Production. Proceedings 2021, 69, 22. [Google Scholar] [CrossRef]

- Moshtaghian, H.; Bolton, K.; Rousta, K. Challenges for Upcycled Foods: Definition, Inclusion in the Food Waste Management Hierarchy and Public Acceptability. Foods 2021, 10, 2874. [Google Scholar] [CrossRef]

- Fierascu, R.C.; Fierascu, I.; Avramescu, S.M.; Sieniawska, E. Recovery of Natural Antioxidants from Agro-Industrial Side Streams through Advanced Extraction Techniques. Molecules 2019, 24, 4212. [Google Scholar] [CrossRef]

- Rashwan, A.K.; Bai, H.; Osman, A.I.; Eltohamy, K.M.; Chen, Z.; Younis, H.A.; Al-Fatesh, A.; Rooney, D.W.; Yap, P.-S. Recycling food and agriculture by-products to mitigate climate change: A review. Environ. Chem. Lett. 2023, 21, 3351–3375. [Google Scholar] [CrossRef]

- Nadar, C.G.; Fletcher, A.; Moreira, B.R.d.A.; Hine, D.; Yadav, S. Waste to protein: A systematic review of a century of advancement in microbial fermentation of agro-industrial byproducts. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13375. [Google Scholar] [CrossRef]

- Difonzo, G.; Antonino, C.; Squeo, G.; Caponio, F.; Faccia, M. Application of Agri-Food By-Products in Cheesemaking. Antioxidants 2023, 12, 660. [Google Scholar] [CrossRef] [PubMed]

- Luntraru, C.M.; Apostol, L.; Oprea, O.B.; Neagu, M.; Popescu, A.F.; Tomescu, J.A.; Mulțescu, M.; Susman, I.E.; Gaceu, L. Reclaim and Valorization of Sea Buckthorn (Hippophae rhamnoides) By-Product: Antioxidant Activity and Chemical Characterization. Foods 2022, 11, 462. [Google Scholar] [CrossRef] [PubMed]

- Muti, L.; Nascimento, L.B.; Goracci, G.; Detti, C.; Brunetti, C.; Bilia, A.R.; Ferrini, F.; Gori, A. From Waste to Value: Optimization of Ultrasound-Assisted Extraction of Anthocyanins and Flavonols from Pistacia lentiscus L. Oilcakes. Molecules 2025, 30, 237. [Google Scholar] [CrossRef] [PubMed]

- Mangiapelo, L.; Pinna, N.; Blasi, F.; Ianni, F.; Verducci, G.; Cossignani, L. Harnessing Grape Pomace, a Multifunctional By-Product from the Wine Industry for High-Value Salad Dressings. Molecules 2025, 30, 693. [Google Scholar] [CrossRef]

- Boruah, B.; Ray, S. Current progress in the valorization of food industrial by-products for the development of functional food products. Food Sci. Appl. Biotechnol. 2024, 7, 349. [Google Scholar] [CrossRef]

- Spina, D.; Carbone, R.; Pulvirenti, A.; Rizzo, M.; D’Amico, M.; Di Vita, G. What Gets Measured Gets Managed-Circular Economy Indicators for the Valorization of By-Products in the Olive Oil Supply Chain: A Systematic Review. Agronomy 2024, 14, 2879. [Google Scholar] [CrossRef]

- Lopes, P.; Sobral, M.M.C.; Lopes, G.R.; Martins, Z.E.; Passos, C.P.; Petronilho, S.; Ferreira, I.M.P.L.V.O. Mycotoxins’ Prevalence in Food Industry By-Products: A Systematic Review. Toxins 2023, 15, 249. [Google Scholar] [CrossRef]

- Georgopoulos, V.P.; Gkikas, D.C.; Theodorou, J.A. Factors Influencing the Adoption of Artificial Intelligence Technologies in Agriculture, Livestock Farming and Aquaculture: A Systematic Literature Review Using PRISMA 2020. Sustainability 2023, 15, 16385. [Google Scholar] [CrossRef]

- Pal, P.; Singh, A.K.; Srivastava, R.K.; Rathore, S.S.; Sahoo, U.K.; Subudhi, S.; Sarangi, P.K.; Prus, P. Circular Bioeconomy in Action: Transforming Food Wastes into Renewable Food Resources. Foods 2024, 13, 3007. [Google Scholar] [CrossRef]

- Malenica, D.; Kass, M.; Bhat, R. Sustainable Management and Valorization of Agri-Food Industrial Wastes and By-Products as Animal Feed: For Ruminants, Non-Ruminants and as Poultry Feed. Sustainability 2023, 15, 117. [Google Scholar] [CrossRef]

- Râpă, M.; Darie-Niță, R.N.; Coman, G. Valorization of Fruit and Vegetable Waste into Sustainable and Value-Added Materials. Waste 2024, 2, 258–278. [Google Scholar] [CrossRef]

- Sorrenti, V.; Burò, I.; Consoli, V.; Vanella, L. Recent Advances in Health Benefits of Bioactive Compounds from Food Wastes and By-Products: Biochemical Aspects. Int. J. Mol. Sci. 2023, 24, 2019. [Google Scholar] [CrossRef] [PubMed]

- Pilafidis, S.; Diamantopoulou, P.; Gkatzionis, K.; Sarris, D. Valorization of Agro-Industrial Wastes and Residues through the Production of Bioactive Compounds by Macrofungi in Liquid State Cultures: Growing Circular Economy. Appl. Sci. 2022, 12, 11426. [Google Scholar] [CrossRef]

- Bibi, F.; Ilyas, N.; Saeed, M.; Shabir, S.; Shati, A.A.; Alfaifi, M.Y.; Amesho, K.T.T.; Chowdhury, S.; Sayyed, R.Z. Innovative production of value-added products using agro-industrial wastes via solid-state fermentation. Environ. Sci. Pollut. Res. 2023, 30, 125197–125213. [Google Scholar] [CrossRef]

- Trabelsi, N.; Mourtzinos, I.; Ramadan, M.F. Editorial: Valorization of bioactive compounds from bio-wastes of agro-food sector using green technologies. Front. Nutr. 2023, 10, 1334315. [Google Scholar] [CrossRef]

- Wen, L.; Zhihang, Z.; Da-Wen, S.; Periaswamy, S.S.; Tiwari, B.K. Combination of emerging technologies for the extraction of bioactive compounds. Crit. Rev. Food Sci. Nutr. 2020, 60, 1826–1841. [Google Scholar] [CrossRef]

- Carnaval, L.d.S.C.; Jaiswal, A.K.; Jaiswal, S. Agro-Food Waste Valorization for Sustainable Bio-Based Packaging. J. Compos. Sci. 2024, 8, 41. [Google Scholar] [CrossRef]

- Saorin Puton, B.M.; Demaman Oro, C.E.; Lisboa Bernardi, J.; Exenberger Finkler, D.; Venquiaruto, L.D.; Dallago, R.M.; Tres, M.V. Sustainable Valorization of Plant Residues Through Enzymatic Hydrolysis for the Extraction of Bioactive Compounds: Applications as Functional Ingredients in Cosmetics. Processes 2025, 13, 1314. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Moscoso-Moscoso, E.; Huamán-Carrión, M.L.; Ramos-Pacheco, B.S.; De la Cruz, G.; Arévalo-Quijano, J.C.; Muñoz-Saenz, J.C.; Muñoz-Melgarejo, M.; Quispe-Quezada, U.R.; et al. Microencapsulation of Propolis and Honey Using Mixtures of Maltodextrin/Tara Gum and Modified Native Potato Starch/Tara Gum. Foods 2023, 12, 1873. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Moscoso-Moscoso, E.; Palomino-Rincón, H.; Taipe-Pardo, F.; Aguirre Landa, J.P.; Arévalo-Quijano, J.C.; Muñoz-Saenz, J.C.; Quispe-Quezada, U.R.; Huamán-Carrión, M.L.; et al. Nanoencapsulation of Phenolic Extracts from Native Potato Clones (Solanum tuberosum spp. andigena) by Spray Drying. Molecules 2023, 28, 4961. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Moscoso-Moscoso, E.; Pozo, L.M.F.; Ramos-Pacheco, B.S.; Palomino-Rincón, H.; Gutiérrez, R.J.G.; Peralta-Guevara, D.E. Effect of Inlet Air Temperature and Quinoa Starch/Gum Arabic Ratio on Nanoencapsulation of Bioactive Compounds from Andean Potato Cultivars by Spray-Drying. Molecules 2023, 28, 7875. [Google Scholar] [CrossRef] [PubMed]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Palomino-Rincón, H.; Ramos-Pacheco, B.; Huamán Carrión, M.; Moscoso-Moscoso, E.; Obregón-Yupanqui, M.; Peralta-Guevara, D. Frutos Silvestres Altoandinos Compuestos Bioactivos y Capacidad Antioxidante; Atena Editora Edição de Livros Ltda: Parana, Brazil, 2022. [Google Scholar]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Ramos-Pacheco, B.S.; Yanahuillca-Vargas, A.; Huamán-Carrión, M.L.; Moscoso-Moscoso, E.; Palomino-Rincón, H.J.A.A. Taxonomic, physicochemical, phenolic and antioxidant comparison in species of high Andean wild fruits: Rubus hesperomeles. Acta Agron. 2023, 72, 30–37. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Choque-Quispe, D.; Rincón, H.; Ramos Pacheco, B.S.; Moscoso, E.; Huamán Carrión, M.; Peralta-Guevara, D. Compuestos bioactivos y capacidad antioxidante en frutos silvestres altoandinos. In Alimentos, Nutrição e Saúde 3; Atena Editora Edição de Livros Ltda: Parana, Brazil, 2021; pp. 16–28. [Google Scholar]

- Ligarda-Samanez, C.A.; Moscoso-Moscoso, E.; Choque-Quispe, D.; Ramos-Pacheco, B.S.; Arévalo-Quijano, J.C.; Cruz, G.D.; Huamán-Carrión, M.L.; Quispe-Quezada, U.R.; Gutiérrez-Gómez, E.; Cabel-Moscoso, D.J.; et al. Native Potato Starch and Tara Gum as Polymeric Matrices to Obtain Iron-Loaded Microcapsules from Ovine and Bovine Erythrocytes. Polymers 2023, 15, 3985. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Palomino-Rincón, H.; Choque-Quispe, D.; Moscoso-Moscoso, E.; Arévalo-Quijano, J.C.; Huamán-Carrión, M.L.; Quispe-Quezada, U.R.; Muñoz-Saenz, J.C.; Gutiérrez-Gómez, E.; Cabel-Moscoso, D.J.; et al. Bioactive Compounds and Sensory Quality in Chips of Native Potato Clones (Solanum tuberosum spp. andigena) Grown in the High Andean Region of PERU. Foods 2023, 12, 2511. [Google Scholar] [CrossRef] [PubMed]

- Berenguer, C.V.; Andrade, C.; Pereira, J.A.M.; Perestrelo, R.; Câmara, J.S. Current Challenges in the Sustainable Valorisation of Agri-Food Wastes: A Review. Processes 2023, 11, 20. [Google Scholar] [CrossRef]

- Martins, R.; Barbosa, A.; Advinha, B.; Sales, H.; Pontes, R.; Nunes, J. Green Extraction Techniques of Bioactive Compounds: A State-of-the-Art Review. Processes 2023, 11, 2255. [Google Scholar] [CrossRef]

- Liu, Z.; de Souza, T.S.P.; Holland, B.; Dunshea, F.; Barrow, C.; Suleria, H.A.R. Valorization of Food Waste to Produce Value-Added Products Based on Its Bioactive Compounds. Processes 2023, 11, 840. [Google Scholar] [CrossRef]

- ‘Aqilah, N.M.; Rovina, K.; Felicia, W.X.; Vonnie, J.M. A Review on the Potential Bioactive Components in Fruits and Vegetable Wastes as Value-Added Products in the Food Industry. Molecules 2023, 28, 2631. [Google Scholar] [CrossRef]

- Nirmal, N.P.; Khanashyam, A.C.; Mundanat, A.S.; Shah, K.; Babu, K.S.; Thorakkattu, P.; Al-Asmari, F.; Pandiselvam, R. Valorization of Fruit Waste for Bioactive Compounds and Their Applications in the Food Industry. Foods 2023, 12, 556. [Google Scholar] [CrossRef]

- Alazaiza, M.Y.D.; Bin Mokaizh, A.A.; Baarimah, A.O.; Al-Zghoul, T. From agro-waste to bioactive wealth: Analyzing nutraceutical extraction and applications. Case Stud. Chem. Environ. Eng. 2025, 11, 101066. [Google Scholar] [CrossRef]

- Mohd Basri, M.S.; Abdul Karim Shah, N.N.; Sulaiman, A.; Mohamed Amin Tawakkal, I.S.; Mohd Nor, M.Z.; Ariffin, S.H.; Abdul Ghani, N.H.; Mohd Salleh, F.S. Progress in the Valorization of Fruit and Vegetable Wastes: Active Packaging, Biocomposites, By-Products, and Innovative Technologies Used for Bioactive Compound Extraction. Polymers 2021, 13, 3503. [Google Scholar] [CrossRef] [PubMed]

- Nieto, J.A.; Santoyo, S.; de Sá, M.; Baoshan, S.; Reglero, G.; Jaime, L. Comprehensive Study of Sustainable Pressurized Liquid Extractions to Obtain Bioavailable Antioxidant Phenolic Compounds from Grape Seed By-Products. Processes 2024, 12, 2308. [Google Scholar] [CrossRef]

- Vilas-Franquesa, A.; Melania, C.; Anna, T.-R.; Anna, V.-Q.; Torres-León, C. Recent advances in bio-based extraction processes for the recovery of bound phenolics from agro-industrial by-products and their biological activity. Crit. Rev. Food Sci. Nutr. 2024, 64, 10643–10667. [Google Scholar] [CrossRef] [PubMed]

- Soni, N.; Yadav, M.; Malarvannan, M.; Sharma, D.; Paul, D. Current developments and trends in hybrid extraction techniques for green analytical applications in natural products. J. Chromatogr. B 2025, 1256, 124543. [Google Scholar] [CrossRef]

- Pereira, T.C.; Souza, V.P.; Padilha, A.P.F.; Duarte, F.A.; Flores, E.M.M. Trends and perspectives on the ultrasound-assisted extraction of bioactive compounds using natural deep eutectic solvents. Curr. Opin. Chem. Eng. 2025, 47, 101088. [Google Scholar] [CrossRef]

- Zhang, X.-J.; Liu, Z.-T.; Chen, X.-Q.; Zhang, T.-T.; Zhang, Y. Deep eutectic solvent combined with ultrasound technology: A promising integrated extraction strategy for anthocyanins and polyphenols from blueberry pomace. Food Chem. 2023, 422, 136224. [Google Scholar] [CrossRef]

- Peron, G. Green Extraction and Valorisation of Bioactive Compounds from Food and Food Waste. Appl. Sci. 2024, 14, 11619. [Google Scholar] [CrossRef]

- Soares, C.; Moreira, M.M.; Ramos, S.; Ramalhosa, M.J.; Correia, M.; Svarc-Gajić, J.; Delerue-Matos, C.; Barroso, M.F. A Critical Assessment of Extraction Methodologies for the Valorization of Agricultural Wastes: Polyphenolic Profile and Bioactivity. Processes 2023, 11, 1767. [Google Scholar] [CrossRef]

- Gutierrez Montiel, D.; Guerrero Barrera, A.L.; Martínez Ávila, G.C.; Gonzalez Hernandez, M.D.; Chavez Vela, N.A.; Avelar Gonzalez, F.J.; Ramírez Castillo, F.Y. Influence of the Extraction Method on the Polyphenolic Profile and the Antioxidant Activity of Psidium guajava L. Leaf Extracts. Molecules 2024, 29, 85. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, S.; Milliron, H.; Han, Q. The Efficacy of Phenolic Compound Extraction from Potato Peel Waste. Processes 2022, 10, 2326. [Google Scholar] [CrossRef]

- Cerino, M.C.; Pinela, J.; Caleja, C.; Saux, C.; Pereira, E.; Barros, L. Dynamic Maceration of Acerola (Malpighia emarginata DC.) Fruit Waste: An Optimization Study to Recover Anthocyanins. Agronomy 2023, 13, 2202. [Google Scholar] [CrossRef]

- Savić, I.M.; Savić Gajić, I.M. Extraction and Characterization of Antioxidants and Cellulose from Green Walnut Husks. Foods 2025, 14, 409. [Google Scholar] [CrossRef] [PubMed]

- Koskinakis, S.E.; Stergiopoulos, C.; Vasileiou, C.; Krokida, M. Sustainable Valorization of Coffee Silverskin Waste: Pressurized Liquid Extraction of Bioactive Compounds. Foods 2025, 14, 615. [Google Scholar] [CrossRef] [PubMed]

- Huamán-Castilla, N.L.; Díaz Huamaní, K.S.; Palomino Villegas, Y.C.; Allcca-Alca, E.E.; León-Calvo, N.C.; Colque Ayma, E.J.; Zirena Vilca, F.; Mariotti-Celis, M.S. Exploring a Sustainable Process for Polyphenol Extraction from Olive Leaves. Foods 2024, 13, 265. [Google Scholar] [CrossRef]

- Machado, T.d.O.X.; Portugal, I.; Kodel, H.d.A.C.; Fathi, A.; Fathi, F.; Oliveira, M.B.P.P.; Dariva, C.; Souto, E.B. Pressurized liquid extraction as an innovative high-yield greener technique for phenolic compounds recovery from grape pomace. Sustain. Chem. Pharm. 2024, 40, 101635. [Google Scholar] [CrossRef]

- Perez-Vazquez, A.; Carpena, M.; Barciela, P.; Cassani, L.; Simal-Gandara, J.; Prieto, M.A. Pressurized Liquid Extraction for the Recovery of Bioactive Compounds from Seaweeds for Food Industry Application: A Review. Antioxidants 2023, 12, 612. [Google Scholar] [CrossRef]

- Malenica, D.; Kass, M.; Bhat, R. Optimization of antioxidant extraction from agro-industrial wastes using ultrasound & response surface methodology. Food Chem. Adv. 2025, 7, 100966. [Google Scholar] [CrossRef]

- Briones-Labarca, V.; Giovagnoli-Vicuña, C. Enhanced Bioaccessibility of Carotenoids, Antioxidants, and Minerals from Red Lobster By-Products Through High-Hydrostatic Pressure and Ultrasound Extraction. Processes 2025, 13, 10. [Google Scholar] [CrossRef]

- Sandhu, H.K.; Sinha, P.; Emanuel, N.; Kumar, N.; Sami, R.; Khojah, E.; Al-Mushhin, A.A.M. Effect of Ultrasound-Assisted Pretreatment on Extraction Efficiency of Essential Oil and Bioactive Compounds from Citrus Waste By-Products. Separations 2021, 8, 244. [Google Scholar] [CrossRef]

- Villamil-Galindo, E.; Gastélum-Estrada, A.; Chuck-Hernandez, C.; Antunes-Ricardo, M.; Reza-Zaldivar, E.E.; Piagentini, A.; Jacobo-Velázquez, D.A. Kinetic Ultrasound-Assisted Extraction as a Sustainable Approach for the Recovery of Phenolics Accumulated through UVA Treatment in Strawberry By-Products. Foods 2023, 12, 2989. [Google Scholar] [CrossRef]

- Oufighou, A.; Brahmi, F.; Achat, S.; Yekene, S.; Slimani, S.; Arroul, Y.; Boulekbache-Makhlouf, L.; Blando, F. Optimization of Microwave-Assisted Extraction of Phenolic Compounds from Opuntia ficus-indica Cladodes. Processes 2025, 13, 724. [Google Scholar] [CrossRef]

- Hashemi, S.; Martínez-Zamora, L.; Cano-Lamadrid, M.; Bello, E.; Ayuso, M.; Artés-Hernández, F. Microwave-Assisted Ethanolic and Aqueous Extraction of Antioxidant Compounds from Pomegranate Peel and Broccoli Leaves By-Products. Biol. Biol. Life Sci. Sci. Forum 2023, 26, 54. [Google Scholar] [CrossRef]

- Coelho, J.P.; Robalo, M.P.; Boyadzhieva, S.; Stateva, R.P. Microwave-Assisted Extraction of Phenolic Compounds from Spent Coffee Grounds. Process Optimization Applying Design of Experiments. Molecules 2021, 26, 7320. [Google Scholar] [CrossRef] [PubMed]

- Sumpavapol, P.; Waehayee, A.; Suklim, P.; Rachpirom, M.; Puttarak, P. Box–Behnken Design to Optimize Standardized Mangiferin-Rich Mango Peel Extract from Agro-Industrial Waste Product. Sustainability 2023, 15, 16629. [Google Scholar] [CrossRef]

- Martínez-Abad, A.; Ramos, M.; Hamzaoui, M.; Kohnen, S.; Jiménez, A.; Garrigós, M.C. Optimisation of Sequential Microwave-Assisted Extraction of Essential Oil and Pigment from Lemon Peels Waste. Foods 2020, 9, 1493. [Google Scholar] [CrossRef]

- Uquiche, E.; Arias, J.; del Valle, J.M. Application of Response Surface Methodology to Supercritical CO2 Extraction: Case Study on Coextraction of Carotenoids and Oil from Rosehip Shells and Seeds. Food Eng. Eng. Rev. Rev. 2023, 15, 643–666. [Google Scholar] [CrossRef]

- Nagybákay, N.E.; Syrpas, M.; Vilimaitė, V.; Tamkutė, L.; Pukalskas, A.; Venskutonis, P.R.; Kitrytė, V. Optimized Supercritical CO2 Extraction Enhances the Recovery of Valuable Lipophilic Antioxidants and Other Constituents from Dual-Purpose Hop (Humulus lupulus L.) Variety Ella. Antioxidants 2021, 10, 918. [Google Scholar] [CrossRef]

- Cuéllar, L.M.; Escobedo-Avellaneda, Z.; del Valle, J.M. Effect of supercritical CO2 modified with ethanol on the extraction yield and antimicrobial activity of bioactive compounds from aerial parts of Berberis microphylla G. Fort. LWT 2024, 211, 116885. [Google Scholar] [CrossRef]

- Sarv, V.; Bhat, R.; Jūrienė, L.; Baranauskienė, R.; Urbonavičienė, D.; Viškelis, P.; Venskutonis, P.R. Supercritical Fluid Extraction of Lipids from Rowanberry Pomace with Pure CO2 and Its Mixtures with Ethanol Followed by the On-Line Separation of Fractions. Molecules 2025, 30, 964. [Google Scholar] [CrossRef]

- Pavlić, B.; Mrkonjić, Ž.; Teslić, N.; Kljakić, A.C.; Pojić, M.; Mandić, A.; Stupar, A.; Santos, F.; Duarte, A.R.C.; Mišan, A. Natural Deep Eutectic Solvent (NADES) Extraction Improves Polyphenol Yield and Antioxidant Activity of Wild Thyme (Thymus serpyllum L.) Extracts. Molecules 2022, 27, 1508. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D.; Fang, J.; Song, Z.; Geng, J.; Zhao, J.; Fang, Y.; Wang, C.; Li, M. Green and efficient extraction of flavonoids from Perilla frutescens (L.) Britt. leaves based on natural deep eutectic solvents: Process optimization, component identification, and biological activity. Food Chem. Chem. 2024, 452, 139508. [Google Scholar] [CrossRef]

- Silva, C.N.; Silva, R.M.; Lemes, A.C.; Ribeiro, B.D. Recovery of Phenolic Compounds by Deep Eutectic Solvents in Orange By-Products and Spent Coffee Grounds. Sustainability 2024, 16, 7403. [Google Scholar] [CrossRef]

- Morgana, N.M.; Magdalena, E.; Fernandez, M.d.l.A.; Fernanda, S.M. NADES for food industry innovation: Novel bioadditives based on olive oil byproducts. Food Bioprod. Process. 2022, 134, 193–201. [Google Scholar] [CrossRef]

- Xu, M.; Ran, L.; Chen, N.; Fan, X.; Ren, D.; Yi, L. Polarity-dependent extraction of flavonoids from citrus peel waste using a tailor-made deep eutectic solvent. Food Chem. 2019, 297, 124970. [Google Scholar] [CrossRef]

- Bencresciuto, G.F.; Carnevale, M.; Paris, E.; Gallucci, F.; Santangelo, E.; Migliori, C.A. A Sustainable Alternative for Cosmetic Applications: NADES Extraction of Bioactive Compounds from Hazelnut By-Products. Sustainability 2025, 17, 1516. [Google Scholar] [CrossRef]

- Grillo, G.; Gunjević, V.; Radošević, K.; Redovniković, I.R.; Cravotto, G. Deep Eutectic Solvents and Nonconventional Technologies for Blueberry-Peel Extraction: Kinetics, Anthocyanin Stability, and Antiproliferative Activity. Antioxidants 2020, 9, 1069. [Google Scholar] [CrossRef]

- Xue, H.; Tan, J.; Li, Q.; Tang, J.; Cai, X. Ultrasound-Assisted Deep Eutectic Solvent Extraction of Anthocyanins from Blueberry Wine Residues: Optimization, Identification, and HepG2 Antitumor Activity. Molecules 2020, 25, 5456. [Google Scholar] [CrossRef]

- Zhou, M.; Fakayode, O.A.; Li, H. Green Extraction of Polyphenols via Deep Eutectic Solvents and Assisted Technologies from Agri-Food By-Products. Molecules 2023, 28, 6852. [Google Scholar] [CrossRef]

- Tapia-Quirós, P.; Granados, M.; Sentellas, S.; Saurina, J. Microwave-assisted extraction with natural deep eutectic solvents for polyphenol recovery from agrifood waste: Mature for scaling-up? Sci. Total Environ. 2024, 912, 168716. [Google Scholar] [CrossRef]

- Velásquez, P.; Bustos, D.; Montenegro, G.; Giordano, A. Ultrasound-Assisted Extraction of Anthocyanins Using Natural Deep Eutectic Solvents and Their Incorporation in Edible Films. Molecules 2021, 26, 984. [Google Scholar] [CrossRef]

- Ramzan, K.; Zehra, S.H.; Balciunaitiene, A.; Viskelis, P.; Viskelis, J. Valorization of Fruit and Vegetable Waste: An Approach to Focusing on Extraction of Natural Pigments. Foods 2025, 14, 1402. [Google Scholar] [CrossRef] [PubMed]

- Marcillo-Parra, V.; Tupuna-Yerovi, D.S.; González, Z.; Ruales, J. Encapsulation of bioactive compounds from fruit and vegetable by-products for food application—A review. Trends Food Sci. Technol. 2021, 116, 11–23. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Moscoso-Moscoso, E.; Choque-Quispe, D.; Palomino-Rincón, H.; Martínez-Huamán, E.L.; Huamán-Carrión, M.L.; Peralta-Guevara, D.E.; Aroni-Huamán, J.; Arévalo-Quijano, J.C.; Palomino-Rincón, W.; et al. Microencapsulation of Erythrocytes Extracted from Cavia porcellus Blood in Matrices of Tara Gum and Native Potato Starch. Foods 2022, 11, 2107. [Google Scholar] [CrossRef] [PubMed]

- Otálora, M.C.; Wilches-Torres, A.; Gómez Castaño, J.A. Spray-dried microencapsulation of anthocyanins from mangosteen fruit peel: Investigating the impact of pitahaya peel mucilage and/or maltodextrin as wall materials. Powder Technol. 2025, 452, 120580. [Google Scholar] [CrossRef]

- Bińkowska, W.; Szpicer, A.; Stelmasiak, A.; Wojtasik-Kalinowska, I.; Półtorak, A. Microencapsulation of Polyphenols and Their Application in Food Technology. Appl. Sci. 2024, 14, 11954. [Google Scholar] [CrossRef]

- Gheonea, I.; Aprodu, I.; Cîrciumaru, A.; Râpeanu, G.; Bahrim, G.E.; Stănciuc, N. Microencapsulation of lycopene from tomatoes peels by complex coacervation and freeze-drying: Evidences on phytochemical profile, stability and food applications. J. Food Eng. 2021, 288, 110166. [Google Scholar] [CrossRef]

- da Rocha, C.B.; Noreña, C.P.Z. Microencapsulation and controlled release of bioactive compounds from grape pomace. Dry. Technol. 2021, 39, 1018–1032. [Google Scholar] [CrossRef]

- Ligarda-Samanez, C.A.; Villano-Limache, E.; Pichihua-Oscco, W.; Choque-Quispe, D.; Sucari-León, R.; Calderón Huamaní, D.F.; Cruz, G.D.; Luciano-Alipio, R.; Calsina Ponce, W.C.; Aroquipa-Durán, Y.; et al. Physicochemical and Sensory Evaluation of Gummy Candies Fortified with Microcapsules of Guinea Pig (Cavia porcellus) Blood Erythrocytes and Tumbo (Passiflora tarminiana) Juice. Appl. Sci. 2025, 15, 917. [Google Scholar] [CrossRef]

- Pant, K.; Thakur, M.; Chopra, H.K.; Nanda, V. Encapsulated bee propolis powder: Drying process optimization and physicochemical characterization. LWT 2022, 155, 112956. [Google Scholar] [CrossRef]

- Gaber Ahmed, G.H.; Fernández-González, A.; Díaz García, M.E. Nano-encapsulation of grape and apple pomace phenolic extract in chitosan and soy protein via nanoemulsification. Food Hydrocoll. 2020, 108, 105806. [Google Scholar] [CrossRef]

- Lee, Y.S.; Tarté, R.; Acevedo, N.C. Curcumin encapsulation in Pickering emulsions co-stabilized by starch nanoparticles and chitin nanofibers. RSC Adv. 2021, 11, 16275–16284. [Google Scholar] [CrossRef] [PubMed]

- Rashid, R.; Masoodi, F.A.; Wani, S.M.; Manzoor, S.; Gull, A. Ultrasound assisted extraction of bioactive compounds from pomegranate peel, their nanoencapsulation and application for improvement in shelf life extension of edible oils. Food Chem. 2022, 385, 132608. [Google Scholar] [CrossRef] [PubMed]

- De Guzman, J.J.; Monserate, J.J.; Panajon, N.M.; Salazar, J.R.; Eugenio, P.J.G.; Sarong, M.M. Nanoencapsulation of Lycopene from Tomato Waste Using Chitosan and Alginate for Enhanced Stability and Antioxidant Activity. Int. J. Des. Nat. Ecodyn. 2024, 19, 1261–1267. [Google Scholar] [CrossRef]

- Šeregelj, V.; Pezo, L.; Šovljanski, O.; Lević, S.; Nedović, V.; Markov, S.; Tomić, A.; Čanadanović-Brunet, J.; Vulić, J.; Šaponjac, V.T.; et al. New concept of fortified yogurt formulation with encapsulated carrot waste extract. LWT 2021, 138, 110732. [Google Scholar] [CrossRef]

- Rifna, E.J.; Dwivedi, M. Encapsulated pomegranate peel extract as a potential antimicrobial ingredient from food waste. J. Sci. Food Agric. 2024, 104, 8720–8733. [Google Scholar] [CrossRef]

- Rajam, R.; Karthik, P.; Parthasarathi, S.; Joseph, G.S.; Anandharamakrishnan, C. Effect of whey protein—Alginate wall systems on survival of microencapsulated Lactobacillus plantarum in simulated gastrointestinal conditions. J. Funct. Foods 2012, 4, 891–898. [Google Scholar] [CrossRef]

- Dissanayake, T.; Bandara, N. Protein-based encapsulation systems for codelivery of bioactive compounds: Recent studies and potential applications. Curr. Opin. Food Sci. 2024, 57, 101181. [Google Scholar] [CrossRef]

- Kučuk, N.; Primožič, M.; Knez, Ž.; Leitgeb, M. Alginate Beads with Encapsulated Bioactive Substances from Mangifera indica Peels as Promising Peroral Delivery Systems. Foods 2024, 13, 2404. [Google Scholar] [CrossRef]

- Dobroslavić, E.; Zorić, Z.; Dragović-Uzelac, V.; Elez Garofulić, I. Microencapsulation of Laurus nobilis L. Leaf Extract in Alginate-Based System via Electrostatic Extrusion. Foods 2023, 12, 3242. [Google Scholar] [CrossRef]

- Meng, Y.; Chao, Q.; Xiaojing, L.; Julian, M.D.; Shangyuan, S.; Aiquan, J.; Jin, Z. Polysaccharide-based nano-delivery systems for encapsulation, delivery, and pH-responsive release of bioactive ingredients. Crit. Rev. Food Sci. Nutr. 2024, 64, 187–201. [Google Scholar] [CrossRef]

- Zabot, G.L.; Schaefer Rodrigues, F.; Polano Ody, L.; Vinícius Tres, M.; Herrera, E.; Palacin, H.; Córdova-Ramos, J.S.; Best, I.; Olivera-Montenegro, L. Encapsulation of Bioactive Compounds for Food and Agricultural Applications. Polymers 2022, 14, 4194. [Google Scholar] [CrossRef] [PubMed]

- Kurtulbaş, E.; Albarri, R.; Torun, M.; Şahin, S. Encapsulation of Moringa oleifera leaf extract in chitosan-coated alginate microbeads produced by ionic gelation. Food Biosci. 2022, 50, 102158. [Google Scholar] [CrossRef]

- Peanparkdee, M.; Iwamoto, S. Encapsulation for Improving in Vitro Gastrointestinal Digestion of Plant Polyphenols and Their Applications in Food Products. Food Rev. Int. 2022, 38, 335–353. [Google Scholar] [CrossRef]

- Pereira Silveira, M.; Lucas Chaves Almeida, F.; Dutra Alvim, I.; Silvia Prata, A. Encapsulation of pomegranate polyphenols by ionic gelation: Strategies for improved retention and controlled release. Food Res. Int. 2023, 174, 113590. [Google Scholar] [CrossRef]

- Kaderides, K.; Mourtzinos, I.; Goula, A.M. Stability of pomegranate peel polyphenols encapsulated in orange juice industry by-product and their incorporation in cookies. Food Chem. 2020, 310, 125849. [Google Scholar] [CrossRef]

- Šavikin, K.; Nastić, N.; Janković, T.; Bigović, D.; Miličević, B.; Vidović, S.; Menković, N.; Vladić, J. Effect of Type and Concentration of Carrier Material on the Encapsulation of Pomegranate Peel Using Spray Drying Method. Foods 2021, 10, 1968. [Google Scholar] [CrossRef]

- Ferreira, L.M.; Pereira, R.R.; Carvalho, F.B.; Silva Santos, A.; Ribeiro-Costa, R.M.; Carréra Silva Júnior, J.O. Green Extraction by Ultrasound, Microencapsulation by Spray Drying and Antioxidant Activity of the Tucuma Coproduct (Astrocaryum vulgare Mart.) Almonds. Biomolecules 2021, 11, 545. [Google Scholar] [CrossRef]

- da Silva Júnior, M.E.; Araújo, M.V.R.L.; Martins, A.C.S.; dos Santos Lima, M.; da Silva, F.L.H.; Converti, A.; Maciel, M.I.S. Microencapsulation by spray-drying and freeze-drying of extract of phenolic compounds obtained from ciriguela peel. Sci. Rep. 2023, 13, 15222. [Google Scholar] [CrossRef]

- Ferreira, L.M.; Pereira, R.R.; Carvalho-Guimarães, F.B.; Remígio, M.S.; Barbosa, W.L.; Ribeiro-Costa, R.M.; Silva-Júnior, J.O. Microencapsulation by Spray Drying and Antioxidant Activity of Phenolic Compounds from Tucuma Coproduct (Astrocaryum vulgare Mart.) Almonds. Polymers 2022, 14, 2905. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Li, X.; Ma, A.; Gao, X.; Zhu, S.; Li, B. Characteristics of pomegranate (Punica granatum L.) peel polyphenols encapsulated with whey protein isolate and β-cyclodextrin by spray-drying. Int. J. Biol. Macromol. 2024, 278, 135279. [Google Scholar] [CrossRef]

- Flamminii, F.; D’Alessio, G.; Chiarini, M.; Di Michele, A.; De Bruno, A.; Mastrocola, D.; Di Mattia, C.D. Valorization of Onion By-Products Bioactive Compounds by Spray Drying Encapsulation Technique. Foods 2025, 14, 425. [Google Scholar] [CrossRef] [PubMed]

- Santos, N.C.; Almeida, R.L.J.; Monteiro, S.S.; Lima, T.L.B.d.; Figueira, J.G.d.S.; Martins, A.N.A.; Paiva, Y.F.; Pinheiro, L.d.S.S.; Morais, S.K.Q.; Carvalho, R.d.O.; et al. Ultrasound combined with chemical hydrolysis as a pretreatment for microencapsulation of beetroot waste by spray and freeze drying. Chem. Eng. Process.-Process Intensif. 2025, 208, 110082. [Google Scholar] [CrossRef]

- Pashazadeh, H.; Ali Redha, A.; Johnson, J.B.; Koca, I. Valorization of okra waste: Microencapsulation of okra flower polyphenol-rich extract with maltodextrin and gum Arabic by freeze drying, spray drying, and microwave drying. J. Food Sci. 2025, 90, e70111. [Google Scholar] [CrossRef] [PubMed]

- Stabrauskiene, J.; Pudziuvelyte, L.; Bernatoniene, J. Optimizing Encapsulation: Comparative Analysis of Spray-Drying and Freeze-Drying for Sustainable Recovery of Bioactive Compounds from Citrus x paradisi L. Peels. Pharmaceuticals 2024, 17, 596. [Google Scholar] [CrossRef]

- Lachowicz, S.; Michalska-Ciechanowska, A.; Oszmiański, J. The Impact of Maltodextrin and Inulin on the Protection of Natural Antioxidants in Powders Made of Saskatoon Berry Fruit, Juice, and Pomace as Functional Food Ingredients. Molecules 2020, 25, 1805. [Google Scholar] [CrossRef]

- Gallegos-Tintoré, S.; May-Canché, M.; Chel-Guerrero, L.; Castellanos-Ruelas, A.; Betancur-Ancona, D. Preservation by ionic gelation encapsulation of the antioxidant activity of protein hydrolysate derived from Lionfish (Pterois volitans, L.) muscle proteins. Food Sci. Biotechnol. 2024, 33, 2979–2987. [Google Scholar] [CrossRef]

- Fierri, I.; De Marchi, L.; Chignola, R.; Rossin, G.; Bellumori, M.; Perbellini, A.; Mancini, I.; Romeo, A.; Ischia, G.; Saorin, A.; et al. Nanoencapsulation of Anthocyanins from Red Cabbage (Brassica oleracea L. var. Capitata f. rubra) through Coacervation of Whey Protein Isolate and Apple High Methoxyl Pectin. Antioxidants 2023, 12, 1757. [Google Scholar] [CrossRef]

- Soliman, T.N.; Mohammed, D.M.; El-Messery, T.M.; Elaaser, M.; Zaky, A.A.; Eun, J.-B.; Shim, J.-H.; El-Said, M.M. Microencapsulation of Plant Phenolic Extracts Using Complex Coacervation Incorporated in Ultrafiltered Cheese Against AlCl3-Induced Neuroinflammation in Rats. Front. Nutr. 2022, 9, 929977. [Google Scholar] [CrossRef]

- Sukri, N.; Marin, P.T.T.; Mahani; Nurhadi, B. Characteristics of propolis encapsulated with gelatin and sodium alginate by complex coacervation method. Int. J. Food Prop. 2023, 26, 696–707. [Google Scholar] [CrossRef]

- Tropea, A. Food Waste Valorization. Fermentation 2022, 8, 168. [Google Scholar] [CrossRef]

- Pereira, J.; Ahmed, B.S.; Sathuvan, M.; Wangang, Z.; Zhou, G.-H. Quality of fat-reduced frankfurter formulated with unripe banana by-products and pre-emulsified sunflower oil. Int. J. Food Prop. 2020, 23, 420–433. [Google Scholar] [CrossRef]

- Toshkov, N.G.; Nenov, V.N.; Bozadjiev, B.; Delchev, N.; Valov, E. Extrusion of wheat semolina and cocoa shells. Food Sci. Appl. Biotechnol. 2021, 4, 133. [Google Scholar] [CrossRef]

- Benvenutti, L.; Moura, F.M.; Zanghelini, G.; Barrera, C.; Seguí, L.; Zielinski, A.A. An Upcycling Approach from Fruit Processing By-Products: Flour for Use in Food Products. Foods 2025, 14, 153. [Google Scholar] [CrossRef] [PubMed]

- Borah, M.S.; Tiwari, A.; Sridhar, K.; Narsaiah, K.; Nayak, P.K.; Stephen Inbaraj, B. Recent Trends in Valorization of Food Industry Waste and By-Products: Encapsulation and In Vitro Release of Bioactive Compounds. Foods 2023, 12, 3823. [Google Scholar] [CrossRef]

- Tsiapali, O.I.; Ayfantopoulou, E.; Tzourouni, A.; Ofrydopoulou, A.; Letsiou, S.; Tsoupras, A. Unveiling the Utilization of Grape and Winery By-Products in Cosmetics with Health Promoting Properties. Appl. Sci. 2025, 15, 1007. [Google Scholar] [CrossRef]

- Islam, M.Z.; Zheng, L. Why is it necessary to integrate circular economy practices for agri-food sustainability from a global perspective? Sustain. Dev. 2025, 33, 600–620. [Google Scholar] [CrossRef]

- Dieguez-Santana, K.; Sarduy-Pereira, L.; Ruiz-Reyes, E.; Sablón Cossío, N. Application of the Circular Economy in Research in the Agri-Food Supply Chain: Bibliometric, Network, and Content Analysis. Sustainability 2025, 17, 1899. [Google Scholar] [CrossRef]

- Rațu, R.N.; Veleșcu, I.D.; Stoica, F.; Usturoi, A.; Arsenoaia, V.N.; Crivei, I.C.; Postolache, A.N.; Lipșa, F.D.; Filipov, F.; Florea, A.M.; et al. Application of Agri-Food By-Products in the Food Industry. Agriculture 2023, 13, 1559. [Google Scholar] [CrossRef]

- Pedisić, S.; Zorić, Z.; Repajić, M.; Levaj, B.; Dobrinčić, A.; Balbino, S.; Čošić, Z.; Dragović-Uzelac, V.; Elez Garofulić, I. Valorization of Berry Fruit By-Products: Bioactive Compounds, Extraction, Health Benefits, Encapsulation and Food Applications. Foods 2025, 14, 1354. [Google Scholar] [CrossRef]

- Chen, H.-S.; Chao, C.-T. Solutions to food waste: Investigating Taiwanese consumer attitudes and behavioral drivers toward upcycled food. Br. Food J. 2025, 127, 971–989. [Google Scholar] [CrossRef]

- Marques, C.; Güneş, S.; Vilela, A.; Gomes, R. Life-Cycle Assessment in Agri-Food Systems and the Wine Industry—A Circular Economy Perspective. Foods 2025, 14, 1553. [Google Scholar] [CrossRef] [PubMed]

- Marotta, A.; Borriello, A.; Khan, M.R.; Cavella, S.; Ambrogi, V.; Torrieri, E. Boosting Food Packaging Sustainability Through the Valorization of Agri-Food Waste and By-Products. Polymers 2025, 17, 735. [Google Scholar] [CrossRef] [PubMed]

- Vicente-Zurdo, D.; Gómez-Mejía, E.; Morante-Zarcero, S.; Rosales-Conrado, N.; Sierra, I. Analytical Strategies for Green Extraction, Characterization, and Bioactive Evaluation of Polyphenols, Tocopherols, Carotenoids, and Fatty Acids in Agri-Food Bio-Residues. Molecules 2025, 30, 1326. [Google Scholar] [CrossRef] [PubMed]

- Paul, B.; Lianghua, X.; Ould, Y.Z.; Chen, W. Recent Review on the Stability of Bioactive Substances Through Encapsulation and Their Application in Dairy Products. Food Rev. Int. 2025, 1–27. [Google Scholar] [CrossRef]

- Bhat, R. Valorization of Agri-Food Wastes and By-Products: Recent Trends, Innovations and Sustainability Challenges; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Mor, R.S.; Panghal, A.; Kumar, V. Challenges and Opportunities of Circular Economy in Agri-Food Sector; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

| Extraction Technique | Principle | Advantages | Disadvantages | Types of Recovered Bioactive Compounds | Agri-Food By-Products and Waste (Examples) | References |

|---|---|---|---|---|---|---|

| Traditional methods (Soxhlet extraction, maceration, infusion, etc.) | Based on heat-driven diffusion using conventional organic solvents. | Simple operation, low cost, and widely established techniques. | Use of toxic solvents, low efficiency, and long extraction times. | Polyphenols, essential oils, tannins, anthocyanins. | Guava leaves, potato peel, acerola waste, green walnut husks. | [71,72,73,74,75] |

| Pressurized liquid extraction (PLE/ASE) | Involves liquid solvents at elevated temperature and pressure to improve diffusion and solubility of bioactive compounds. | Fast, automatable, and efficient for extracting polar and phenolic compounds, with reduced solvent consumption. | Expensive equipment, potential thermal degradation if temperature is not controlled. | Phenolic acids, flavonoids, lignans, alkaloids, antioxidant compounds. | Grape seed, coffee silverskin, olive leaves, grape pomace, seaweeds. | [65,76,77,78,79] |

| Ultrasound-assisted extraction (UAE) | Ultrasound generates acoustic cavitation, enhancing solvent penetration and facilitating cell disruption. | High efficiency, low solvent consumption, suitable for thermolabile compounds. | Challenges for industrial scalability, potential degradation due to intense cavitation. | Polyphenols, flavonoids, carotenoids, essential oils. | Pistachio oilcakes, grape pomace, red lobster by-products, citrus waste, strawberry by-products. | [33,34,35,80,81,82,83] |

| Microwave-assisted extraction (MAE) | Microwaves generate electromagnetic fields that interact with polar molecules, producing internal heating. | Fast, efficient, and energy-saving. | Requires precise temperature control; some equipment is expensive. | Phenolic compounds, carotenoids, essential oils. | Opuntia cladodes, pomegranate peel, broccoli leaves, spent coffee grounds, mango peel, lemon peel. | [84,85,86,87,88] |

| Supercritical CO2 extraction (SFE) | Involves the use of CO2 in a supercritical state as a green, non-toxic, and recyclable solvent. | High selectivity, no toxic residues, clean extraction. | High initial investment, limited efficiency for polar compounds. | Carotenoids, tocopherols, lipophilic bioactives, antioxidants. | Rosehip shells and seeds, hop cones, Berberis microphylla, rowanberry pomace. | [89,90,91,92] |

| Natural deep eutectic solvents (NADES) | Formed by combining hydrogen bond donors and acceptors to produce eutectic liquids. | Eco-friendly, biodegradable, customizable for specific compounds. | High viscosity, complex recovery of extracted compounds. | Alkaloids, polyphenols, flavonoids, terpenoids. | Wild thyme, perilla leaves, orange peel, coffee grounds, citrus peel waste, hazelnut by-products. | [93,94,95,96,97,98] |

| UAE combined with NADES | Combines acoustic cavitation with natural deep eutectic solvents to enable selective extraction. | High efficiency, low toxicity, low-temperature extraction, good selectivity depending on HBA-HBD (hydrogen bond acceptor/donor), useful in plant matrices. | High NADES viscosity, solute recovery may require SPE or lyophilization; scalability challenges. | Polyphenols, flavonoids, anthocyanins, carotenoids (astaxanthin), asiaticoside, oleuropein, lignin, modified pectin, betalains. | Blueberry pomace, blueberry peel, blueberry wine residues. | [68,69,99,100,101,102,103] |

| Technique/Method | Operating Principle | Encapsulating/Stabilizing Materials | Encapsulated Compounds | Key Advantages | Main Limitations | References |

|---|---|---|---|---|---|---|

| Spray Drying (SD) | Atomization of liquid mixtures into a hot air stream to produce a powder in a single step. | Maltodextrin (cassava starch), inulin (chicory root), gum arabic (Acacia senegal), trehalose (maize starch), soy protein isolate (soybean meal), β-cyclodextrin (corn starch), starch (cassava), tara gum (Caesalpinia spinosa), mucilage (chia, basil, cactus seeds, pitahaya peel) | Punicalagin, lycopene, β-carotene, polyphenols, flavonoids, anthocyanins, heme iron. | Cost-effective, scalable, good powder stability, suitable for heat-stable compounds | Thermal degradation of heat-sensitive compounds | [56,106,107,128,129,130,131,132,133,134] |

| Freeze Drying (FD) | Freezing followed by sublimation of water under vacuum conditions. | Maltodextrin (cassava starch), gum arabic (Acacia senegal), whey protein (bovine milk), gelatin (porcine or bovine collagen), casein (skim milk), β-cyclodextrin (corn starch), carboxymethylcellulose (plant cellulose). | Lycopene, flavonoids (naringin, naringenin), anthocyanins. | Excellent preservation of thermosensitive compounds, formation of porous and lightweight matrices. | High operational cost, time-consuming process. | [8,109,110,131,135,136,137] |

| Vacuum Drying (VD) | Water removal under low pressure and temperature. | Maltodextrin (cassava starch), inulin (chicory root), tara gum (Caesalpinia spinosa). | Anthocyanins, polyphenols, flavonoids, heme iron. | Preservation of organoleptic properties, reduced energy consumption. | Slower drying rate compared to spray drying. | [111,112,138] |

| Nanoencapsulation (Emulsion/Colloidal) | Formation of emulsions or colloidal nanostructures (<1000 nm) through high-energy methods such as high-pressure homogenization, ultrasonication, or high-shear mixing. | Chitosan (crustacean shells), soy protein (soybean meal), alginate (brown seaweed), starch nanoparticles (cassava or corn starch), chitin nanofibers (insect or crustacean exoskeletons) | Polyphenols, curcumin, lycopene. | High bioavailability, targeted release, antioxidant protection. | Complex formulation, sensitivity to pH and temperature. | [113,114,115,116] |

| Ionic Gelation | Formation of hydrogels via ionic cross-linking between anionic polymers and divalent cations such as Ca2+. | Sodium alginate (brown seaweed). | Polyphenols, β-carotene, hydrolysable tannins, protein hydrolysates. | Efficient taste masking, antioxidant and antimicrobial protection, high encapsulation efficiency, and storage stability. | Limited structural stability under uncontrolled humidity or high ionic strength conditions | [117,118,121,139] |

| Coacervation Encapsulation | Phase separation of polymers through electrostatic interactions between oppositely charged biopolymers. | Whey protein isolate (bovine milk), pectin (apple or citrus peel), gelatin (porcine or fish skin), gum arabic (Acacia senegal), sodium alginate (brown seaweed). | Phenolic compounds, anthocyanins. | Formation of monodisperse particles, good initial stability, antioxidant protection, simple and eco-friendly technique. | Sensitive to extreme pH and ionic strength conditions. | [8,140,141,142] |

| Extrusion Encapsulation | Dropping the core solution into a calcium chloride (CaCl2) gelling bath to form hydrogel beads. | Sodium alginate (brown seaweed), chitosan (crustacean shells). | Carotenoids, polyphenols, probiotics. | Simple and economical technique, provides good protection for probiotic viability. | Produces large particle sizes; less suitable for clear or transparent liquid matrices. | [8,117,122] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ligarda-Samanez, C.A.; Huamán-Carrión, M.L.; Calsina-Ponce, W.C.; Cruz, G.D.l.; Calderón Huamaní, D.F.; Cabel-Moscoso, D.J.; Garcia-Espinoza, A.J.; Sucari-León, R.; Aroquipa-Durán, Y.; Muñoz-Saenz, J.C.; et al. Technological Innovations and Circular Economy in the Valorization of Agri-Food By-Products: Advances, Challenges and Perspectives. Foods 2025, 14, 1950. https://doi.org/10.3390/foods14111950

Ligarda-Samanez CA, Huamán-Carrión ML, Calsina-Ponce WC, Cruz GDl, Calderón Huamaní DF, Cabel-Moscoso DJ, Garcia-Espinoza AJ, Sucari-León R, Aroquipa-Durán Y, Muñoz-Saenz JC, et al. Technological Innovations and Circular Economy in the Valorization of Agri-Food By-Products: Advances, Challenges and Perspectives. Foods. 2025; 14(11):1950. https://doi.org/10.3390/foods14111950

Chicago/Turabian StyleLigarda-Samanez, Carlos A., Mary L. Huamán-Carrión, Wilber Cesar Calsina-Ponce, Germán De la Cruz, Dante Fermín Calderón Huamaní, Domingo J. Cabel-Moscoso, Antonina J. Garcia-Espinoza, Reynaldo Sucari-León, Yolanda Aroquipa-Durán, Jenny C. Muñoz-Saenz, and et al. 2025. "Technological Innovations and Circular Economy in the Valorization of Agri-Food By-Products: Advances, Challenges and Perspectives" Foods 14, no. 11: 1950. https://doi.org/10.3390/foods14111950

APA StyleLigarda-Samanez, C. A., Huamán-Carrión, M. L., Calsina-Ponce, W. C., Cruz, G. D. l., Calderón Huamaní, D. F., Cabel-Moscoso, D. J., Garcia-Espinoza, A. J., Sucari-León, R., Aroquipa-Durán, Y., Muñoz-Saenz, J. C., Muñoz-Melgarejo, M., & Jilaja-Carita, E. E. (2025). Technological Innovations and Circular Economy in the Valorization of Agri-Food By-Products: Advances, Challenges and Perspectives. Foods, 14(11), 1950. https://doi.org/10.3390/foods14111950