Advancements in Chitosan–Anthocyanin Composite Films: Sustainable Food Preservation with Biodegradable Packaging

Abstract

:1. Introduction

2. Properties of Chitosan and Anthocyanins

2.1. Physical, Chemical, and Biological Properties of Chitosan

2.2. Physical, Chemical, and Biological Properties of Anthocyanins

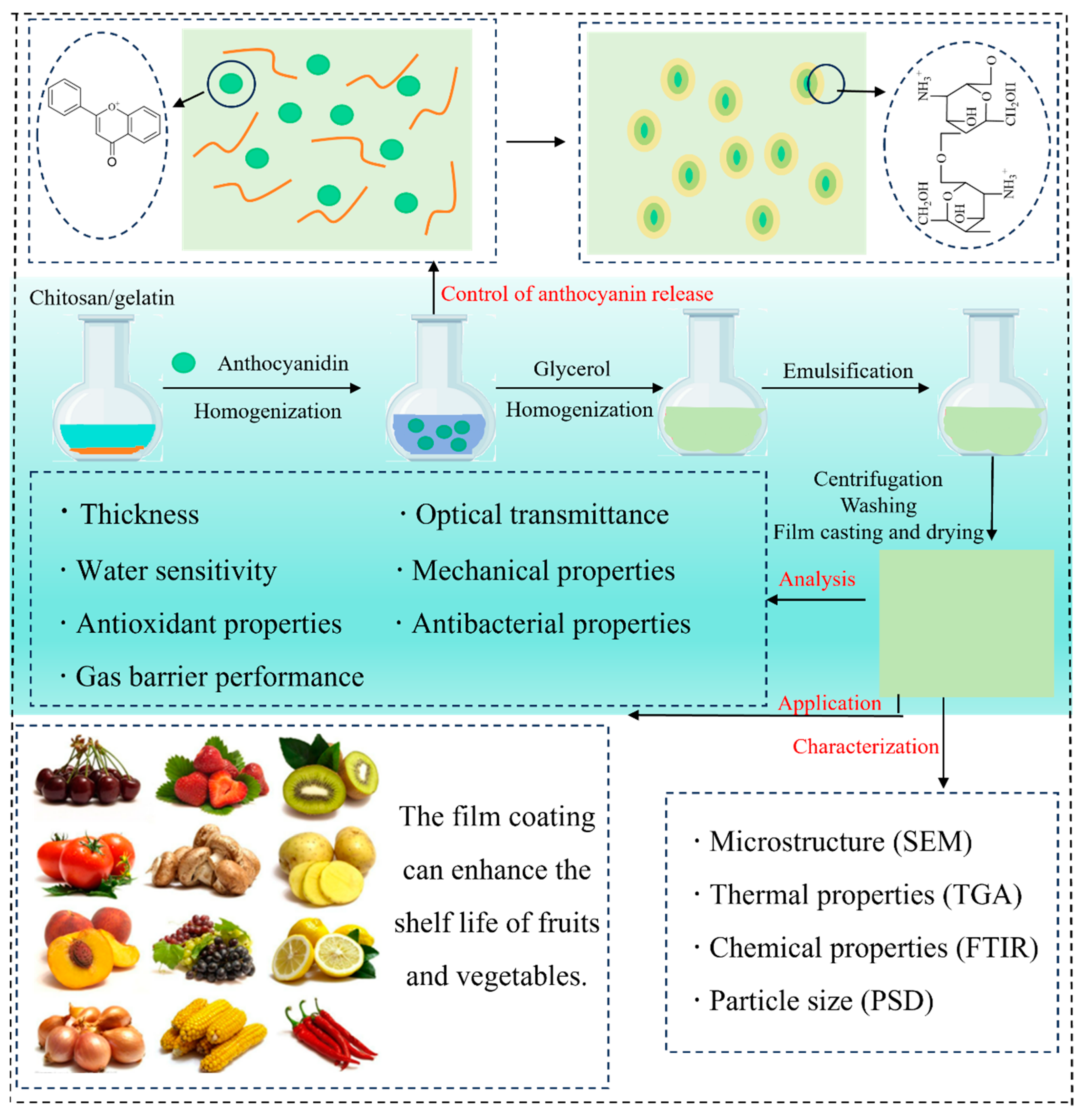

3. Effects of Anthocyanins on the Properties of C–As

3.1. Thickness

3.2. Optical Transmittance

3.3. Water Sensitivity

3.4. Gas Barrier Properties

3.5. Mechanical Properties

3.6. Thermal Properties

3.7. Microstructural Characteristics

4. Controlled Release of Anthocyanins and Their Potential Applications

5. Applications of Anthocyanin-Containing C–As in Fresh Food Preservation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Du, L.; Huang, X.; Li, Z.; Qin, Z.; Zhang, N.; Zhai, X.; Shi, J.; Zhang, J.; Shen, T.; Zhang, R.; et al. Application of Smart Packaging in Fruit and Vegetable Preservation: A Review. Foods 2025, 14, 447. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, S.; Liang, H.; Zhou, J.; Zong, M.; Cao, Y.; Lou, W. A review of advancements in chitosan-essential oil composite films: Better and sustainable food preservation with biodegradable packaging. Int. J. Biol. Macromol. 2024, 274, 133242. [Google Scholar] [CrossRef] [PubMed]

- Winiarska, E.; Jutel, M.; Zemelka-Wiacek, M. The potential impact of nano-and microplastics on human health: Understanding human health risks. Environ. Res. 2024, 251, 118535. [Google Scholar] [CrossRef]

- Maluin, F.N. Enhancing Chitosan Nanofilm with Agricultural Waste Fillers for Sustainable and Safe Functional Food Packaging. ACS Agric. Sci. Technol. 2024, 4, 1136–1162. [Google Scholar] [CrossRef]

- Nasaj, M.; Chehelgerdi, M.; Asghari, B.; Ahmadieh-Yazdi, A.; Asgari, M.; Kabiri-Samani, S.; Sharifi, E.; Arabestani, M. Factors influencing the antimicrobial mechanism of chitosan action and its derivatives: A review. Int. J. Biol. Macromol. 2024, 277, 134321. [Google Scholar] [CrossRef] [PubMed]

- Farajinejad, Z.; Sani, I.K.; Alizadeh, M.; Amiri, S. A review of recent advances in the photocatalytic activity of protein and polysaccharide-based nanocomposite packaging films: Antimicrobial, antioxidant, mechanical, and strength properties. J. Polym. Environ. 2024, 32, 3437–3447. [Google Scholar] [CrossRef]

- Lakshmikanthan, M.; Muthu, S.; Krishnan, K.; Altemimi, A.B.; Haider, N.N.; Govindan, L.; Selvakumari, J.; Alkanan, Z.; Cacciola, F.; Francis, Y.M. A comprehensive review on anthocyanin-rich foods: Insights into extraction, medicinal potential, and sustainable applications. J. Agric. Food Res. 2024, 17, 101245. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, W.; Li, X.; Liu, D.; Zhong, Y. Chitosan-Based Natural Colorant Intelligent Freshness Indicator: Recent Advances, Properties, Novel Techniques, and Applications. Food Bioprocess Technol. 2024, 18, 4129–4152. [Google Scholar] [CrossRef]

- Atay, E.; Fabra, M.J.; Martínez-Sanz, M.; Gomez-Mascaraque, L.G.; Altan, A.; Lopez-Rubio, A. Development and characterization of chitosan/gelatin electrosprayed microparticles as food grade delivery vehicles for anthocyanin extracts. Food Hydrocoll. 2018, 77, 699–710. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, Z.; Wang, C.; Jiang, Z. N-acetyl-d-glucosamine-based oligosaccharides from chitin: Enzymatic production, characterization and biological activities. Carbohydr. Polym. 2023, 315, 121019. [Google Scholar] [CrossRef]

- Edo, G.I.; Yousif, E.; Al-Mashhadani, M.H. Chitosan: An overview of biological activities, derivatives, properties, and current advancements in biomedical applications. Carbohydr. Res. 2024, 542, 109199. [Google Scholar] [CrossRef]

- Ali, G.; Sharma, M.; Salama, E.S.; Ling, Z.; Li, X. Applications of chitin and chitosan as natural biopolymer: Potential sources, pretreatments, and degradation pathways. Biomass Convers. Biorefin. 2024, 14, 4567–4581. [Google Scholar] [CrossRef]

- Mageshwaran, V.; Sivasubramanian, P.; Kumar, P.; Nagaraju, Y. Antibacterial response of nanostructured chitosan hybrid materials. In Chitosan Nanocomposites Bionanomechanical Applications; Springer: Singapore, 2023; pp. 161–179. [Google Scholar]

- Hu, B.; Ouyang, Y.; Zhao, T.; Wang, Z.; Yan, Q.; Qian, Q.; Wang, W.; Wang, S. Antioxidant Hydrogels: Antioxidant Mechanisms, Design Strategies, and Applications in the Treatment of Oxidative Stress-Related Diseases. Adv. Healthc. Mater. 2024, 13, 2303817. [Google Scholar] [CrossRef]

- Barik, M.; BhagyaRaj, G.V.S.; Dash, K.K.; Shams, R. A thorough evaluation of chitosan-based packaging film and coating for food product shelf-life extension. J. Agric. Food Res. 2024, 16, 101164. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Dong, H.; Wu, W.; Yang, X.; He, Q. Functional biopolymers for food packaging: Formation mechanism and performance improvement of chitosan-based composites. Food Biosci. 2023, 54, 102927. [Google Scholar] [CrossRef]

- Kowalczyk, T.; Muskała, M.; Merecz-Sadowska, A.; Sikora, J.; Picot, L.; Sitarek, P. Anti-Inflammatory and Anticancer Effects of Anthocyanins in In Vitro and In Vivo Studies. Antioxidants 2024, 13, 1143. [Google Scholar] [CrossRef]

- Zaa, C.A.; Marcelo, Á.J.; An, Z.; Medina-Franco, J.L.; Velasco-Velázquez, M.A. Anthocyanins: Molecular aspects on their neuroprotective activity. Biomolecules 2023, 13, 1598. [Google Scholar] [CrossRef]

- Chen, S.; Wang, X.; Cheng, Y.; Gao, H.; Chen, X. A review of classification, biosynthesis, biological activities and potential applications of flavonoids. Molecules 2023, 28, 4982. [Google Scholar] [CrossRef]

- Mohammadi, N.; Farrell, M.; O’Sullivan, L.; Langan, A.; Franchin, M.; Azevedo, L.; Granato, D. Effectiveness of anthocyanin-containing foods and nutraceuticals in mitigating oxidative stress, inflammation, and cardiovascular health-related biomarkers: A systematic review of animal and human interventions. Food Funct. 2024, 15, 3274–3299. [Google Scholar] [CrossRef]

- Xin, M.; Xu, A.; Tian, J.; Wang, L.; He, Y.; Jiang, H.; Yang, B.; Li, B.; Sun, Y. Anthocyanins as natural bioactives with anti-hypertensive and atherosclerotic potential: Health benefits and recent advances. Phytomedicine 2024, 132, 155889. [Google Scholar] [CrossRef]

- Chimento, A.; De Luca, A.; D’Amico, M.; De Amicis, F.; Pezzi, V. The involvement of natural polyphenols in molecular mechanisms inducing apoptosis in tumor cells: A promising adjuvant in cancer therapy. Int. J. Mol. Sci. 2023, 24, 1680. [Google Scholar] [CrossRef] [PubMed]

- Reshma, A.; Subramanian, A.; Kumarasamy, V.; Tamilanban, T.; Sekar, M.; Gan, S.; Subramaniyan, V.; Wong, L.; Rani, N.; Wu, Y. Neurocognitive effects of proanthocyanidin in Alzheimer’s disease: A systematic review of preclinical evidence. Braz. J. Med. Biol. Res. 2024, 57, e13587. [Google Scholar] [CrossRef] [PubMed]

- Franco-San Sebastián, D.; Alaniz-Monreal, S.; Rabadán-Chávez, G.; Vázquez-Manjarrez, N.; Hernández-Ortega, M.; Gutiérrez-Salmeán, G. Anthocyanins: Potential therapeutic approaches towards obesity and diabetes mellitus type 2. Molecules 2023, 28, 1237. [Google Scholar] [CrossRef] [PubMed]

- Yong, H.; Wang, X.; Zhang, X.; Liu, Y.; Qin, Y.; Liu, J. Effects of anthocyanin-rich purple and black eggplant extracts on the physical, antioxidant and pH-sensitive properties of chitosan film. Food Hydrocoll. 2019, 94, 93–104. [Google Scholar] [CrossRef]

- Chen, D.; Lv, J.; Wang, A.; Yong, H.; Liu, J. Intelligent food packaging: Quaternary ammonium chitosan/gelatin blended films enriched with blueberry anthocyanin-derived cyanidin for shrimp and milk freshness monitoring. Foods 2024, 13, 2237. [Google Scholar] [CrossRef]

- Koosha, M.; Hamedi, S. Intelligent Chitosan/PVA nanocomposite films containing black carrot anthocyanin and bentonite nanoclays with improved mechanical, thermal and antibacterial properties. Prog. Org. Coat. 2019, 127, 338–347. [Google Scholar] [CrossRef]

- Khezerlou, A.; Tavassoli, M.; Alizadeh Sani, M.; Ehsani, A.; McClements, D.J. Smart packaging for food spoilage assessment based on Hibiscus sabdariffa L. anthocyanin-loaded chitosan films. J. Compos. Sci. 2023, 7, 404. [Google Scholar] [CrossRef]

- Luo, J.; Xia, G.; Liu, L.; Ji, A.; Luo, Q. Fabrication of chitosan/hydroxyethyl cellulose/TiO2 incorporated mulberry anthocyanin 3D-printed bilayer films for quality of litchis. Foods 2022, 11, 3286. [Google Scholar] [CrossRef]

- Xie, F.; Qin, Z.; Luo, Y.; He, Z.; Chen, Q.; Cai, J. Synergistically engineered starch-based composite films: Multifunctional platforms integrating quaternary ammonium chitosan and anthocyanins for intelligent food monitoring and sustainable packaging. Food Chem. 2025, 478, 143560. [Google Scholar] [CrossRef]

- Wang, F.; Xie, C.; Tang, H.; Hao, W.; Wu, J.; Sun, Y.; Sun, J.; Liu, Y.; Jiang, L. Development, characterization and application of intelligent/active packaging of chitosan/chitin nanofibers films containing eggplant anthocyanins. Food Hydrocoll. 2023, 139, 108496. [Google Scholar] [CrossRef]

- Tavassoli, M.; Khezerlou, A.; Moghaddam, T.N.; Firoozy, S.; Bakhshizadeh, M.; Sani, M.A.; Hashemi, M.; Ehsani, A.; Lorenzo, J.M. Sumac (Rhus coriaria L.) anthocyanin loaded-pectin and chitosan nanofiber matrices for real-time monitoring of shrimp freshness. Int. J. Biol. Macromol. 2023, 242, 125044. [Google Scholar] [CrossRef]

- Zheng, D.; Cao, S.; Li, D.; Wu, Y.; Duan, P.; Liu, S.; Li, X.; Zhang, X.; Chen, Y. Fabrication and characterization of chitosan/anthocyanin intelligent packaging film fortified by cellulose nanocrystal for shrimp preservation and visual freshness monitoring. Int. J. Biol. Macromol. 2024, 264, 130692. [Google Scholar] [CrossRef]

- Yong, H.; Liu, J.; Qin, Y.; Bai, R.; Zhang, X.; Liu, J. Antioxidant and pH-sensitive films developed by incorporating purple and black rice extracts into chitosan matrix. Int. J. Biol. Macromol. 2019, 137, 307–316. [Google Scholar] [CrossRef]

- Duan, A.; Yang, J.; Wu, L.; Wang, T.; Liu, Q.; Liu, Y. Preparation, physicochemical and application evaluation of raspberry anthocyanin and curcumin based on chitosan/starch/gelatin film. Int. J. Biol. Macromol. 2022, 220, 147–158. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Yong, H.; Qin, Y.; Liu, J.; Liu, J. Development of multifunctional food packaging films based on chitosan, TiO2 nanoparticles and anthocyanin-rich black plum peel extract. Food Hydrocoll. 2019, 94, 80–92. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, Y.; Lu, D.; Gao, W.; Zhao, Q.; Shi, X. Multifunctional intelligent film integrated with purple sweet potato anthocyanin and quercetin-loaded chitosan nanoparticles for monitoring and maintaining freshness of shrimp. Food Packag. Shelf Life 2023, 35, 101022. [Google Scholar] [CrossRef]

- Li, Y.; Wu, K.; Wang, B.; Li, X. Colorimetric indicator based on purple tomato anthocyanins and chitosan for application in intelligent packaging. Int. J. Biol. Macromol. 2021, 174, 370–376. [Google Scholar] [CrossRef]

- Gasti, T.; Dixit, S.; D’Souza, O.J.; Hiremani, V.D.; Vootla, S.K.; Masti, S.P.; Chougale, R.B.; Malabadi, R.B. Smart biodegradable films based on chitosan/methylcellulose containing Phyllanthus reticulatus anthocyanin for monitoring the freshness of fish fillet. Int. J. Biol. Macromol. 2021, 187, 451–461. [Google Scholar] [CrossRef]

- Hidayati, N.A.; Wijaya, M.W.; Bintoro, V.P.; Mulyani, S.; Pratama, Y. Development of biodegradable smart packaging from chitosan, polyvinyl alcohol (PVA) and butterfly pea flower’s (Clitoria ternatea L.) anthocyanin extract. Food Res. 2021, 5, 307–314. [Google Scholar] [CrossRef]

- Pan, J.; Li, C.; Liu, J.; Jiao, Z.; Zhang, Q.; Lv, Z.; Yang, W.; Chen, D.; Liu, H. Polysaccharide-Based Packaging Coatings and Films with Phenolic Compounds in Preservation of Fruits and Vegetables—A Review. Foods 2024, 13, 3896. [Google Scholar] [CrossRef]

- Xu, M.; Fang, D.; Kimatu, B.M.; Lyu, L.; Wu, W.; Cao, F.; Li, W. Recent advances in anthocyanin-based films and its application in sustainable intelligent food packaging: A review. Food Control 2024, 162, 110431. [Google Scholar] [CrossRef]

- Oancea, S. A review of the current knowledge of thermal stability of anthocyanins and approaches to their stabilization to heat. Antioxidants 2021, 10, 1337. [Google Scholar] [CrossRef]

- Enaru, B.; Drețcanu, G.; Pop, T.D.; Stǎnilǎ, A.; Diaconeasa, Z. Anthocyanins: Factors affecting their stability and degradation. Antioxidants 2021, 10, 1967. [Google Scholar] [CrossRef]

- Chen, L.; Wang, W.; Wang, W.; Zhang, J. Effect of anthocyanins on colorimetric indicator film properties. Coatings 2023, 13, 1682. [Google Scholar] [CrossRef]

- Wang, J.; Zhuang, S. Chitosan-based materials: Preparation, modification and application. J. Clean. Prod. 2022, 355, 131825. [Google Scholar] [CrossRef]

- Zang, Z.; Tang, S.; Li, Z.; Chou, S.; Shu, C.; Chen, Y.; Chen, W.; Yang, S.; Yang, Y.; Tian, J.; et al. An updated review on the stability of anthocyanins regarding the interaction with food proteins and polysaccharides. Compr. Rev. Food Sci. Food Saf. 2022, 21, 4378–4401. [Google Scholar] [CrossRef]

- Tukenmez Emre, U.; Sirin, S.; Nigdelioglu Dolanbay, S.; Aslim, B. Harnessing polysaccharides for sustainable food packaging. Polym. Bull. 2025, 1–47. [Google Scholar] [CrossRef]

- Xu, C.; Zhou, S.; Song, H.; Hu, H.; Yang, Y.; Zhang, X.; Ma, S.; Feng, X.; Pan, Y.; Gong, S.; et al. Green tea polyphenols-derived hybrid materials in manufacturing, environment, food and healthcare. Nano Today 2023, 52, 101990. [Google Scholar] [CrossRef]

- Su, J.; Zhang, W.; Moradi, Z.; Rouhi, M.; Parandi, E.; Garavand, F. Recent functionality developments of carboxymethyl chitosan as an active food packaging film material. Food Chem. 2024, 463, 141356. [Google Scholar] [CrossRef]

- Kossyvaki, D.; Contardi, M.; Athanassiou, A.; Fragouli, D. Colorimetric indicators based on anthocyanin polymer composites: A review. Polymers 2022, 14, 4129. [Google Scholar] [CrossRef]

- Lan, W.; Li, S.; Shama, S.; Zhao, Y.; Sameen, D.E.; He, L.; Liu, Y. Investigation of ultrasonic treatment on physicochemical, structural and morphological properties of sodium alginate/AgNPs/apple polyphenol films and its preservation effect on strawberry. Polymers 2020, 12, 2096. [Google Scholar] [CrossRef]

- Zhao, R.; Chen, J.; Yu, S.; Niu, R.; Yang, Z.; Wang, H.; Cheng, H.; Ye, X.; Liu, D.; Wang, W. Active chitosan/gum Arabic-based emulsion films reinforced with thyme oil encapsulating blood orange anthocyanins: Improving multi-functionality. Food Hydrocoll. 2023, 134, 108094. [Google Scholar] [CrossRef]

- Xie, Q.; Luo, D.; Mu, K.; Xue, W. Preparation and characterization of carboxymethyl chitosan/nano-MgO/red cabbage anthocyanins multifunctional films via colloid formation and its application on shrimp preservation. Food Packag. Shelf Life 2023, 37, 101074. [Google Scholar] [CrossRef]

- Huang, J.; Hu, Z.; Li, G.; Hu, L.; Chen, J.; Hu, Y. Make your packaging colorful and multifunctional: The molecular interaction and properties characterization of natural colorant-based films and their applications in food industry. Trends Food Sci. Technol. 2022, 124, 259–277. [Google Scholar] [CrossRef]

- Nazri, F.; Tawakkal, I.S.M.A.; Basri, M.S.M.; Basha, R.K.; Othman, S.H. Characterization of active and pH-sensitive poly (lactic acid)(PLA)/nanofibrillated cellulose (NFC) films containing essential oils and anthocyanin for food packaging application. Int. J. Biol. Macromol. 2022, 212, 220–231. [Google Scholar]

- Jayakumar, A.; Radoor, S.; Shin, G.H.; Siengchin, S.; Kim, J.T. Active and intelligent packaging films based on PVA/chitosan/zinc oxide nanoparticles/sweet purple potato extract as pH sensing and antibacterial wraps. Food Biosci. 2023, 56, 103432. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; D’Anna, F. Anti-/pro-oxidant behavior of naturally occurring molecules in polymers and biopolymers: A brief review. ACS Sustain. Chem. Eng. 2019, 7, 12656–12670. [Google Scholar] [CrossRef]

- Yu, Z.; Jiang, Q.; Yu, D.; Dong, J.; Xu, Y.; Xia, W. Physical, antioxidant, and preservation properties of chitosan film doped with proanthocyanidins-loaded nanoparticles. Food Hydrocoll. 2022, 130, 107686. [Google Scholar] [CrossRef]

- Li, R.; Wang, S.; Feng, H.; Zhuang, D.; Zhu, J. An intelligent chitosan/gelatin film via improving the anthocyanin-induced color recognition accuracy for beef sub-freshness differentiation monitoring. Food Hydrocoll. 2024, 146, 109219. [Google Scholar] [CrossRef]

- Li, F.; Sun, Q.; Chen, L.; Zhang, R.; Zhang, Z. Unlocking the health potential of anthocyanins: A structural insight into their varied biological effects. Crit. Rev. Food Sci. Nutr. 2024, 65, 2134–2154. [Google Scholar] [CrossRef] [PubMed]

- Deng, H.; Meng, X.; Xue, B.; Li, L. Unveiling the antibacterial potential of anthocyanins—A comprehensive review on this natural plant extract. Crit. Rev. Food Sci. Nutr. 2024, 2024, 1–14. [Google Scholar] [CrossRef]

- Zhang, D.; Cao, G.; Bu, N.; Huang, L.; Lin, H.; Mu, R.; Pang, J.; Wang, L. Multi-functional konjac glucomannan/chitosan bilayer films reinforced with oregano essential oil loaded β-cyclodextrin and anthocyanins for cheese preservation. Int. J. Biol. Macromol. 2023, 244, 125365. [Google Scholar] [CrossRef]

- Liu, T.; Zheng, N.; Ma, Y.; Zhang, Y.; Lei, H.; Zhen, X.; Wang, Y.; Gou, D.; Zhao, J. Recent advancements in chitosan-based intelligent food freshness indicators: Categorization, advantages, and applications. Int. J. Biol. Macromol. 2024, 275, 133554. [Google Scholar] [CrossRef] [PubMed]

- Neves, D.; Andrade, P.B.; Videira, R.A.; de Freitas, V.; Cruz, L. Berry anthocyanin-based films in smart food packaging: A mini-review. Food Hydrocoll. 2022, 133, 107885. [Google Scholar] [CrossRef]

- Song, L.; Wang, P.; Xu, M.; Zhang, C.; Wu, H.; Wang, M.; Liu, W. Fabrication of black wolfberry anthocyanin-based hydrogels for monitoring freshness and extending shelf-life of Dolang lamb. Int. J. Biol. Macromol. 2024, 276, 133917. [Google Scholar] [CrossRef]

- Li, Y.; Li, Z.; Wang, Y.; Sun, L.; Pei, H. Anthocyanins/chitosan films doped by nano zinc oxide for active and intelligent packaging: Comparison of anthocyanins source from purple tomato or black wolfberry. Front. Chem. Sci. Eng. 2023, 17, 704–715. [Google Scholar] [CrossRef]

- Zhu, B.; Zhong, Y.; Wang, D.; Deng, Y. Active and intelligent biodegradable packaging based on anthocyanins for preserving and monitoring protein-rich foods. Foods 2023, 12, 4491. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, Y.; Tang, Z.; Chen, K.; Wang, Z.; Cheng, G.; Chi, H.; Soteyome, T. A pH-sensitive film based on chitosan/gelatin and anthocyanin from Zingiber striolatum Diels for monitoring fish freshness. Food Chem. X 2024, 23, 101639. [Google Scholar] [CrossRef]

- Hu, D.; Liu, X.; Qin, Y.; Yan, J.; Li, J.; Yang, Q. A novel edible packaging film based on chitosan incorporated with persimmon peel extract for the postharvest preservation of banana. Food Qual. Saf. 2022, 6, fyac028. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Zhang, F.; Mi, S.; Yu, W.; Sang, Y.; Wang, X. Preparation of chitosan/polyvinyl alcohol antibacterial indicator composite film loaded with AgNPs and purple sweet potato anthocyanins and its application in strawberry preservation. Food Chem. 2025, 463, 141442. [Google Scholar] [CrossRef]

| Type of Polymer | Type of Anthocyanin | Dose of Anthocyanin | Effects on CEOs | Reference |

|---|---|---|---|---|

| Chitosan | Purple eggplant anthocyanin | 1%, 3%, 5% (w/w) | Thickness (↑), UV (↓), WVP (↑), TS (↑), EB (↓), Thermal properties (↓) | [25] |

| Chitosan | Black eggplant anthocyanin | 1%, 3%, 5% (w/w) | Thickness (↑), UV (↓), WVP (↑), TS (↑), EB (↓), Thermal properties (↓) | [25] |

| Chitosan/Gelatin | Blueberry anthocyanin | 5%, 10%, 15% (w/w) | Thickness (↑), UV (↑), WVP (↑), TS (↑), EB (↓), Thermal properties (↓) | [26] |

| Chitosan/Polyvinyl Alcohol | Black carrot anthocyanins | - | TS (↓), Thermal properties (↑) | [27] |

| Chitosan | Hibiscus sabdariffa L.anthocyanin | - | UV (↓) | [28] |

| Chitosan/hydroxyethyl cellulose/titanium dioxide nanoparticles | Mulberry anthocyanins | UV (↓) | [29] | |

| Starch/Chitosan | Black wolfberry anthocyanin | UV (↓), WVP (↑), TS (↑) | [30] | |

| Carboxymethyl chitosan/nano magnesium oxide | Red kale anthocyanins | 0.2% (w/w) | UV (↓), Gas Barrier Performance (↑), Thermal properties (↑), TS (↑), EB (↓) | [30] |

| Chitosan/chitin nanofibers | Eggplant skin anthocyanin | 0.1% (w/w) | UV (↓), Gas Barrier Performance (↑), Thermal properties (↑) | [31] |

| Pectin/chitosan nanofibers | lacC-Ase anthocyanin | 3% (w/v) | UV (↓), Gas Barrier Performance (↓), TS (↑), EB (↑), Thermal properties (↑) | [32] |

| Chitosan/Cellulose Nanocrystals | - | 0.2% (w/w) | Thickness (↑), UV (↓), Gas Barrier Performance (↑), Thermal properties (↑) | [33] |

| Chitosan | purple rice anthocyanin | 1%, 3%, 5% (w/w) | Thickness (↑), UV (↓), Gas Barrier Performance (↑), WVP (↑), TS (↑), Thermal properties (↑) | [34] |

| Chitosan | Black Rice anthocyanin | 1%, 3%, 5% (w/w) | Thickness (↑), UV (↓), Gas Barrier Performance (↑), WVP (↑), TS (↑), Thermal properties (↑) | [34] |

| Chitosan/Starch/Gelatin | Raspberry anthocyanin | - | Thickness (↑), UV (↑) | [35] |

| Chitosan/titanium dioxide nanoparticles | black plum peel anthocyanins | - | UV (↓), Gas Barrier Performance (↑), Thermal properties (↑) | [36] |

| Agar/Sodium Alginate Chitosan | purple yam anthocyanin | - | UV (↓), Gas Barrier Performance (↑), WVP (↑), Thermal properties (↑) | [37] |

| Chitosan | Purple Tomato anthocyanin | Thickness (↑), UV (↓), Gas Barrier Performance (↑), WVP (↑), TS (↑), EB (↓), Thermal properties (↑) | [38] | |

| Chitosan/Methylcellulose | Phyllanthus reticulatus anthocyanin | - | UV (↓), WVP (↑) | [39] |

| Chitosan/polyvinyl alcohol | Clitoria ternatea L. anthocyanin | Thickness (↑), UV (↑), WVP (↑) | [40] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Li, Q. Advancements in Chitosan–Anthocyanin Composite Films: Sustainable Food Preservation with Biodegradable Packaging. Foods 2025, 14, 1721. https://doi.org/10.3390/foods14101721

Li L, Li Q. Advancements in Chitosan–Anthocyanin Composite Films: Sustainable Food Preservation with Biodegradable Packaging. Foods. 2025; 14(10):1721. https://doi.org/10.3390/foods14101721

Chicago/Turabian StyleLi, Le, and Quanhong Li. 2025. "Advancements in Chitosan–Anthocyanin Composite Films: Sustainable Food Preservation with Biodegradable Packaging" Foods 14, no. 10: 1721. https://doi.org/10.3390/foods14101721

APA StyleLi, L., & Li, Q. (2025). Advancements in Chitosan–Anthocyanin Composite Films: Sustainable Food Preservation with Biodegradable Packaging. Foods, 14(10), 1721. https://doi.org/10.3390/foods14101721