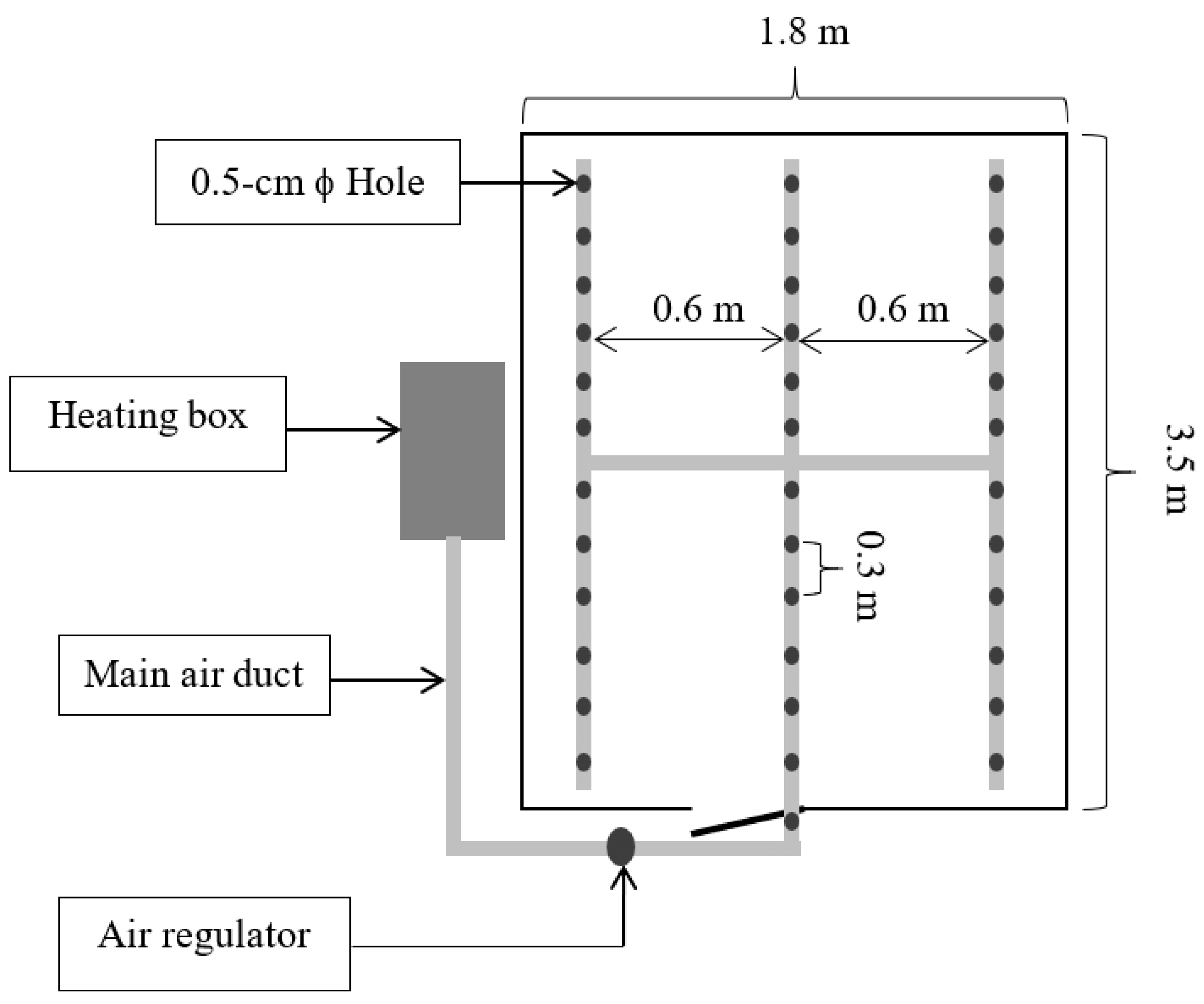

3.1. Analysis of Ducting Strategies for Optimized Air Distribution in Paddy Piles

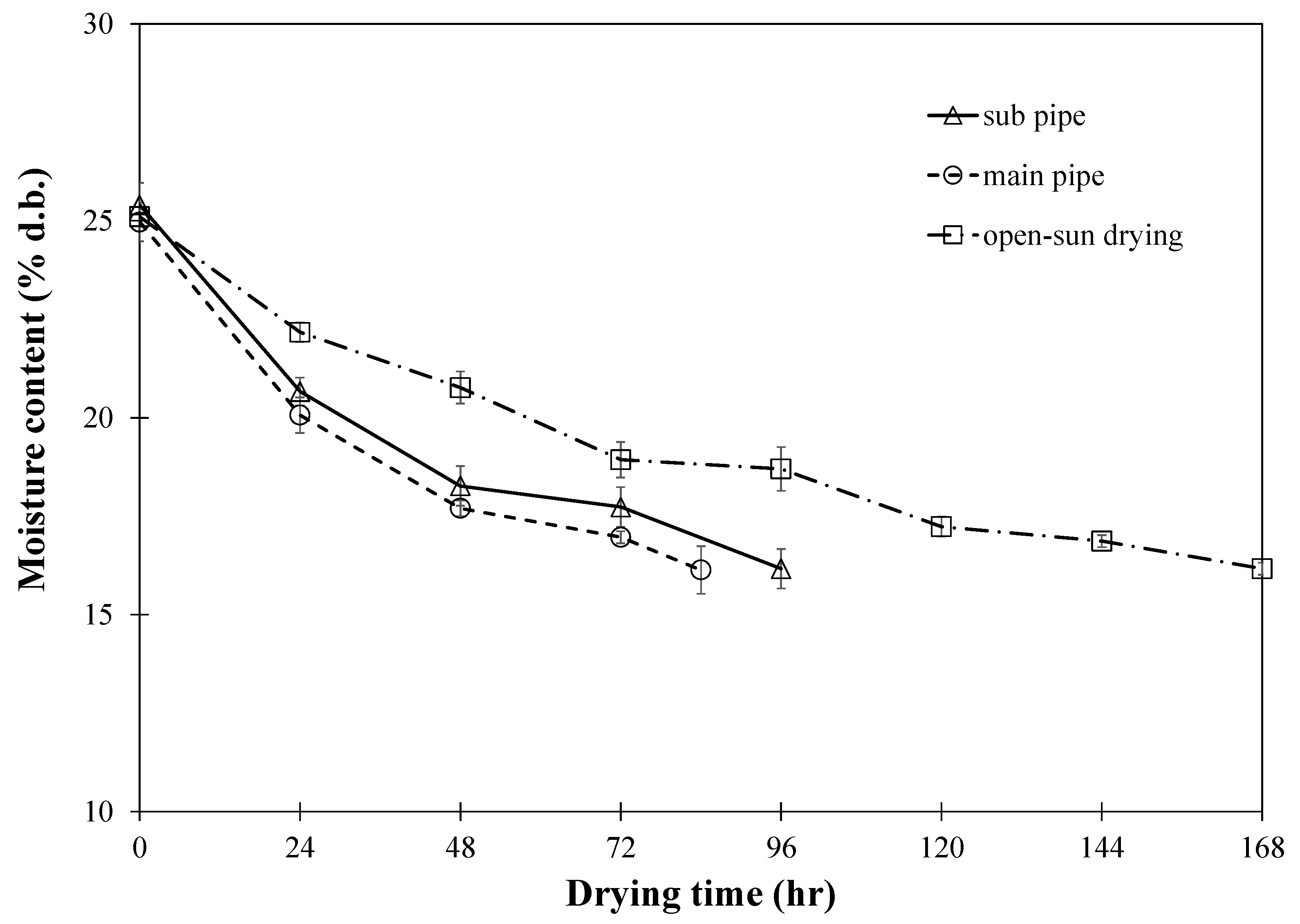

In our study, we monitored changes in the moisture content of paddy rice within a traditional small-scale barn, comparing the efficacy of two distinct hot air-drying systems against the traditional sun drying method, as illustrated in

Figure 7. Initial observations revealed a rapid decrease in moisture content, which slowed as the drying process progressed, reflecting the expected dynamics of moisture and heat transfer [

14]. The goal was to reduce moisture from 25% (db) to an optimal level of approximately 16% (db). Our findings indicate that the hot air-drying methods significantly reduced drying time compared to sun drying. The superiority of moisture removal by hot air-drying, irrespective of the air distribution technique used, can be attributed to its effectiveness in lowering the vapor pressure around the grains, thus facilitating more efficient moisture extraction [

15]. This process increases the grain temperature, enhancing the internal vapor pressure and promoting moisture migration from the interior to the surface [

15]. Consistent airflow in hot air-drying further aids in uniform moisture removal, demonstrating its advantage over conventional sun drying methods in terms of speed and efficiency [

16,

17]. Despite the anticipatory nature of these outcomes, they validate the benefits of hot air-drying for small-scale agricultural applications, emphasizing its role in enhancing post-harvest management.

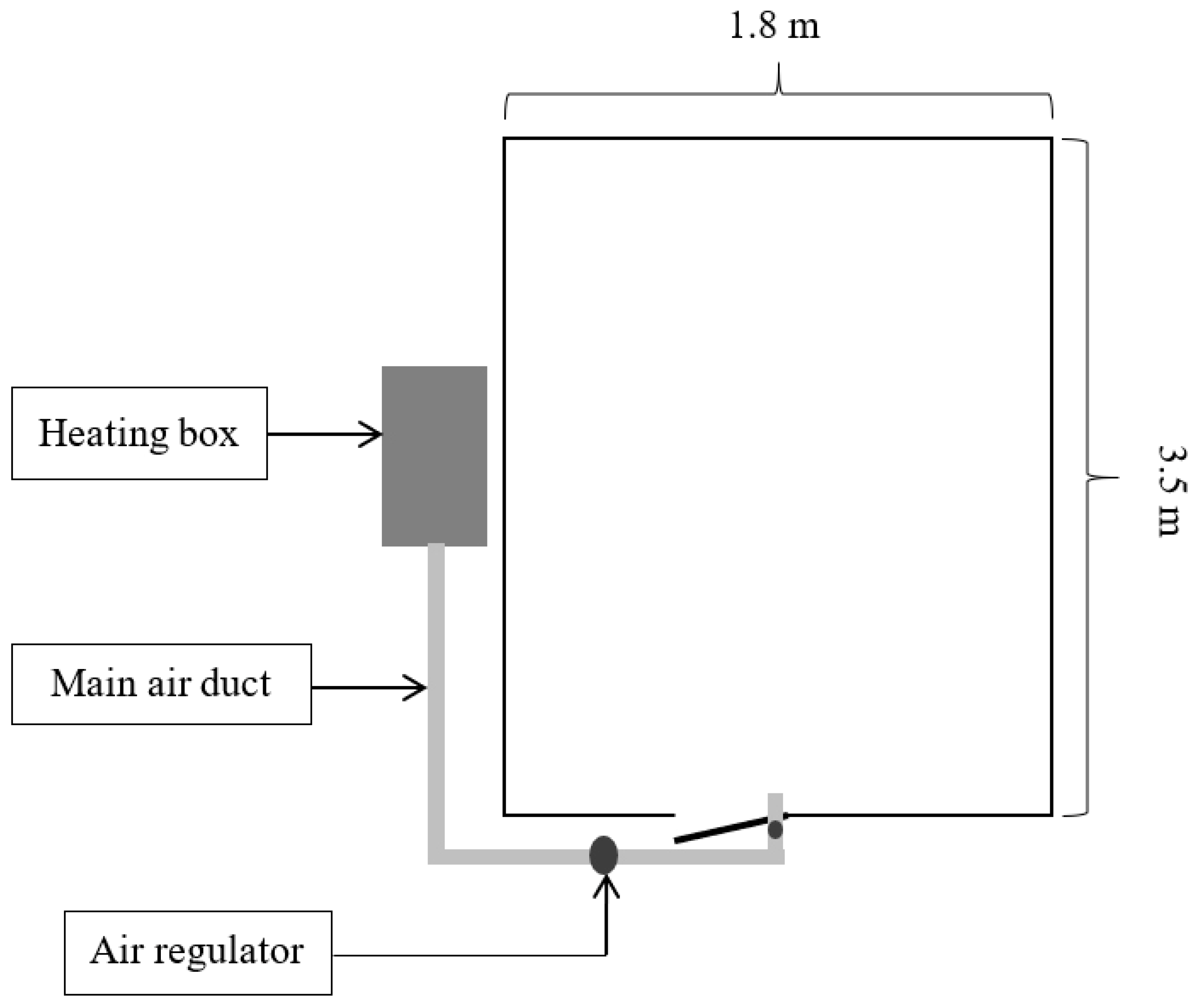

Considering the impact of hot air duct configurations, our findings showed that the method involving perforated sub-pipe distribution required approximately 96 h to achieve the target moisture content. In contrast, the system utilizing the main duct at the entrance proved to be more efficient, completing the drying process in roughly 84 h. The extended drying period associated with the perforated sub-air ducts can be attributed to a larger pressure drop within the drying system, as opposed to using the primary air pipe [

3]. This is because the presence of the sub-air duct system causes the hot air to disseminate more slowly across the different layers of the rice stack, resulting in a more prolonged drying process. According to Razavizadeh et al. [

3], this larger pressure drop, especially noted in configurations such as the F-duct due to increased turbulence and swirling, leads to slower hot air dissemination across the rice stack layers, thereby extending the drying duration. The H-duct configuration is recommended to minimize blind zones and ensure more uniform air distribution during continuous aeration processes, aligning with our objective to enhance drying efficiency and uniformity [

3,

18].

Hence, the in-barn paddy drying technique that utilized the perforated sub-pipe for hot air distribution was identified as the most suitable method for the subsequent research phases. This decision aligns with findings indicating that self-compaction plays a critical role in airflow resistance, which should be considered in the design and analysis of cooling aeration and low-temperature drying of in-store grain bulks [

18]. Future research should focus on assessing airflow resistances under self-compaction for other grains, moisture content, bulk configurations, and airflow velocity ranges [

18].

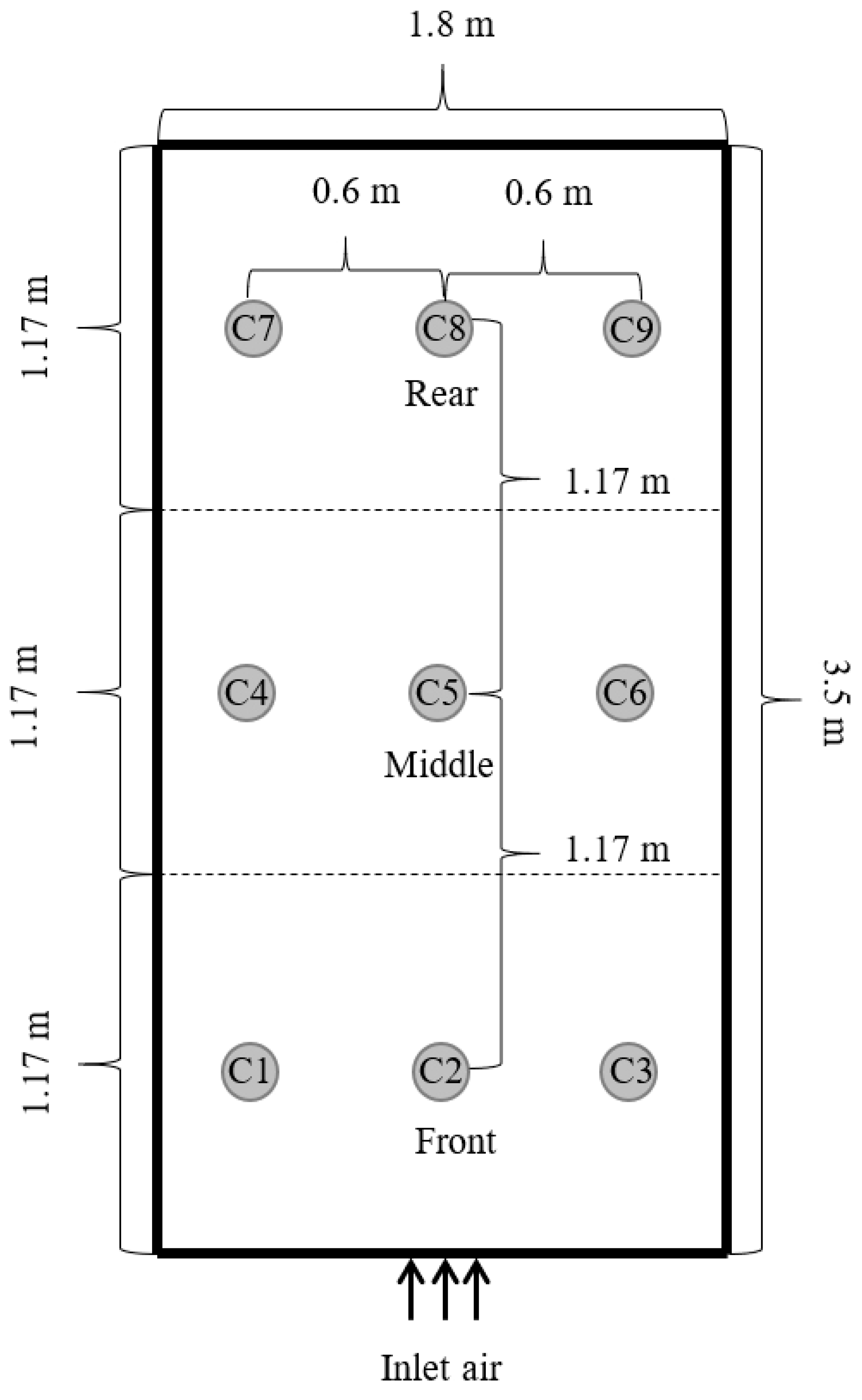

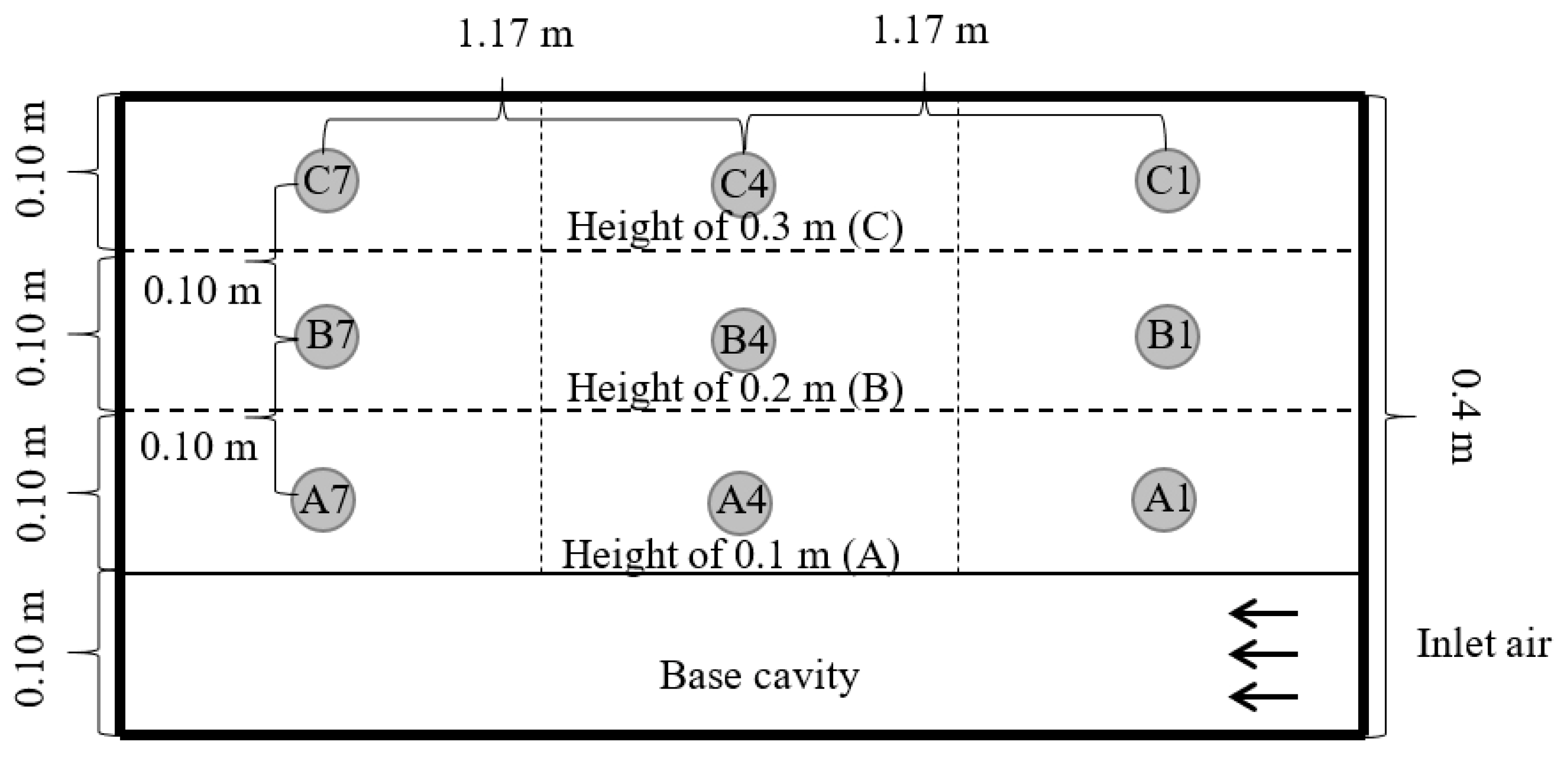

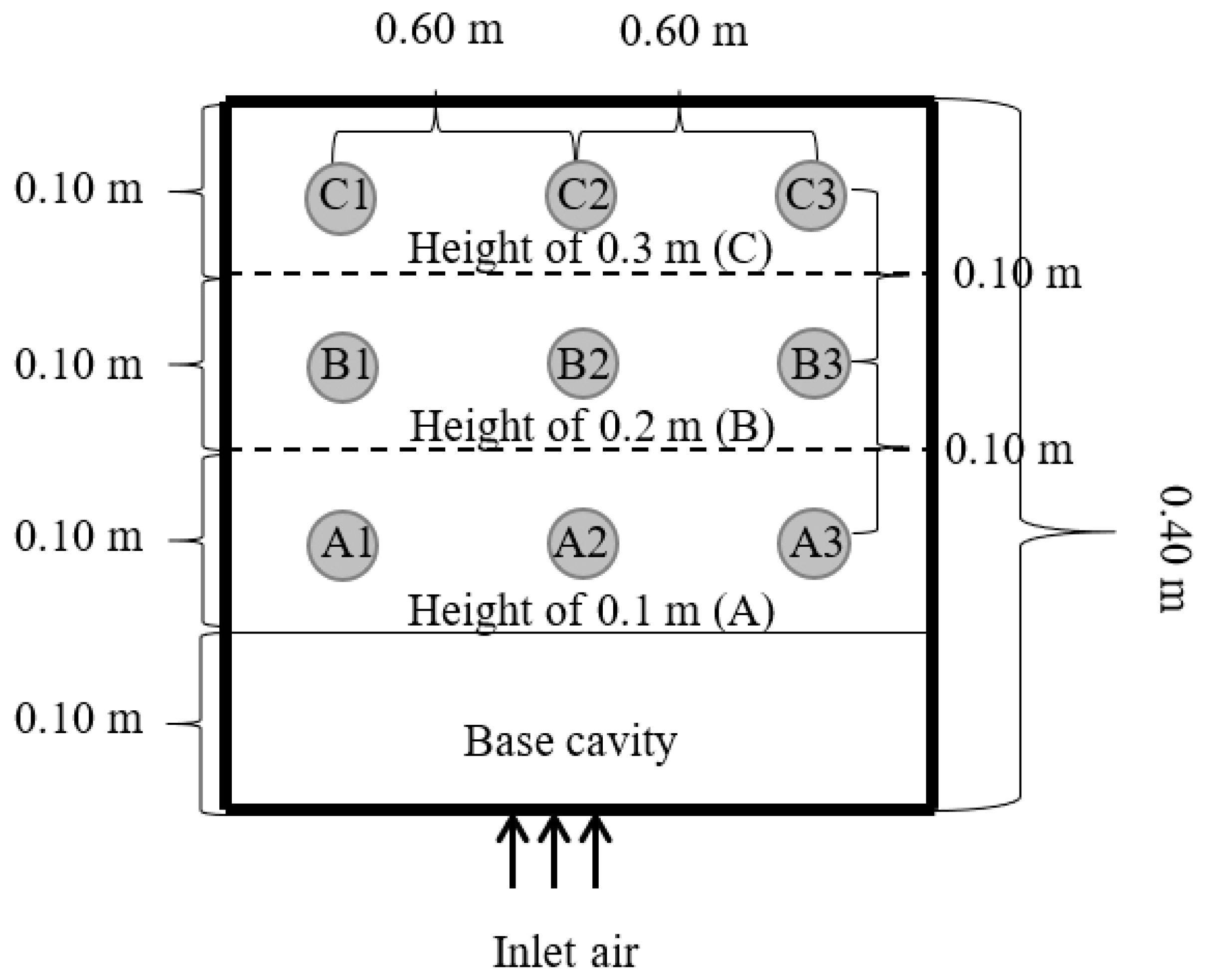

3.2. Temperature Distribution and Moisture Variation of the In-Barn Drying Paddy Process

In our study, we closely monitored the moisture content of paddy rice within a traditional small-scale barn, evaluating the performance of hot air supplied through perforated sub-air ducts at various horizontal and vertical locations in the pile. Our evaluations revealed uniform moisture levels across all vertical layers of the paddy pile (10, 20, and 30 cm), particularly noting that moisture content was consistent in the front, central, and rear sections of the barn. This uniformity in drying is critical, as consistent drying and preservation of rice grain quality have been underscored by studies such as those examining single-layer loading at low temperatures in silo-dryer-aerators [

6].

Notably, the paddy located at a height of 30 cm displayed a marginally higher moisture content compared to those at 10 and 20 cm, especially in the front and rear sections of the storage area. We attribute these seasonal fluctuations and the resultant temperature gradients as significant factors influencing moisture movement within the grain, potentially leading to quality deterioration if not carefully managed [

19]. Our findings support the notion that the specific inlet duct configuration and the resultant airflow pattern are paramount in effectively managing these temperature gradients and moisture movements.

Further analysis revealed consistent temperatures within the rice piles across all barn areas, irrespective of height. An interesting observation was that the inner temperature of the rice stack at 30 cm was slightly cooler than that at both 10 and 20 cm across all sections of the barn. This consistency in temperature, along with the observed gradients, plays a crucial role in the grain drying process, echoing the significance of temperature and humidity control in grain quality preservation, as indicated by studies emphasizing the use of dehumidifiers in grain storage [

20].

The final moisture content data, presented in

Table 1, showed relative uniformity at the bottom region of the pile across different horizontal positions within the barn. However, discrepancies in moisture content were more pronounced in the upper sections. This observation aligns with the understanding that mold activity remains subdued below certain moisture content thresholds, highlighting the importance of meticulous moisture and temperature management in stored grain to prevent quality loss [

21]. Drying at specific temperatures, particularly higher temperatures, has been shown to significantly enhance seed longevity, assuming the seeds are harvested above a critical moisture content threshold [

22].

The variations in moisture content observed at different layers during the drying process are corroborated by recent studies in grain drying and storage. These studies highlight the impact of single-layer loading at low temperatures for consistent drying and quality preservation of rice grains, pointing out differences in drying rates between lower and upper layers due to moisture diffusivity [

6]. Additionally, the influence of seasonal atmospheric temperature fluctuations on moisture movement within the grain, leading to faster drying rates near air ducts and more uniform moisture content over time, further supports our findings [

19].

Moreover, the critical role of controlling temperature and humidity to preserve grain quality during storage is underscored, particularly focusing on the effects of airflow through thermal space and grain parameters in a silo. These insights emphasize that proximity to airflow sources, such as air ducts, initially leads to significant variations in drying rates, which gradually even out to achieve uniform temperature and moisture levels throughout the storage [

20].

By integrating these broader findings and insights from the literature, our study illuminates the intricate interplay between inlet duct configurations, airflow patterns, and storage conditions essential for achieving efficient temperature distribution and moisture content variation during the in-barn drying process of paddy rice. These insights not only corroborate the observations made in our study but also offer a comprehensive context for the observed patterns in temperature and moisture content variations, enhancing our understanding of efficient drying and uniform moisture content achievement in stored grains.

In our study’s comparison of the final moisture content, Khao Dok Mali 105 paddy rice, when dried by forced hot air supplied from the main air duct at the entrance of the storage facility, required 84 h to reach the desired moisture level. Upon assessing the final moisture content across various locations within the barn—specifically at the front, middle, and rear sections—it was observed that the front area exhibited a lower moisture content compared to the middle and rear sections, particularly at pile heights of 20 and 30 cm. This spatial variation in moisture content underscores the influence of air duct placement on drying efficiency. Moreover, when analyzing the moisture content at different pile heights—10, 20, and 30 cm—it became evident that paddy located at a height of 30 cm retained a higher final moisture content than those at lower heights across all sections of the barn. This observation highlights the challenges in achieving uniform drying throughout the paddy stack, suggesting that moisture removal is less effective at higher pile levels.

Furthermore, in considering the temperature distribution of the Khao Dok Mali 105 paddy rice, it was noted that the paddy piles at the front of the barn registered higher temperatures than those in the middle and rear, especially at a pile height of 30 cm. However, an assessment across varying pile heights revealed that the temperature at 30 cm was consistently lower than at both 10 and 20 cm, across the front, middle, and rear sections of the barn. This temperature gradient suggests that heat penetration is more efficient at lower levels of the paddy stack, impacting the drying process’s overall effectiveness.

The analysis of the data from

Table 2 and

Table 3 clearly showed that the perforated sub-pipe system enabled a more uniform distribution of hot air throughout the paddy stored in the small-scale barn, compared to the main pipe system. Despite this, the rice dried using the main pipe system also reached moisture levels deemed acceptable for storage. The introduction of hot air through the main air pipe at the barn’s entrance was found to be significantly more efficient in reducing moisture content. This method quickly lowered the paddy’s moisture from an initial 25% db to approximately 16% db, surpassing the performance of the perforated duct technique. The superior efficiency of the main air pipe method is likely attributable to the reduced pressure drop in the system, unlike the arrangement that included perforated sub-air ducts. As a result, our study pinpointed the main air pipe approach as the most effective strategy for dehydrating paddy within an in-barn setting.

This finding suggests that while both methods fall within acceptable storage moisture ranges, the main pipe system’s efficiency in moisture reduction offers a promising avenue for enhancing drying practices in small-scale agricultural settings. The implications of this efficiency gain are significant, suggesting that future research and practical applications might prioritize optimizing air flow and system design to maximize drying effectiveness and energy efficiency. By refining these systems, we can potentially improve post-harvest processing, reduce losses, and enhance the overall quality of stored grain.

3.3. Quality Attributes of Paddy Rice as Affected by Different Hot Air Ducting Strategies

Quality attributes of paddy rice dehydrated by using direct entrance ducting and perforated sub-pipe distribution were compared in terms of head rice yield, whiteness index, and sensorial properties to those dried by traditional open-air sun drying, as presented in

Table 3.

Table 3 shows that the averaged head rice yield of paddy rice dried by all methods were not significantly different. This negligible variation can be attributed to the drying temperature set at 45 °C, which was relatively moderate. Consequently, the temperature disparity between the rice grain interior and exterior was minimal, resulting in a low moisture gradient and subsequently few instances of internal cracking within the grains. This led to a low percentage of broken rice, as reported by [

6]. This study detailed the drying of paddy rice in a silo-dryer-aerator, noting a reduction in moisture content due to natural airflow over three months. Drying was conducted at temperatures above 25 °C, which favored grain quality by reducing stresses that often lead to cracks and breakage. Equilibrium moisture content reached 12% and 14% in the lower and upper layers, respectively. However, prolonged high moisture content in the upper layers caused heating of the grain mass, potentially impacting rice quality. Despite the variance in drying intensity between layers, the moderate drying temperature of 45 °C led to a negligible variation in the head rice yield, attributed to minimal temperature disparity and consequently low moisture gradient within the grains. This method effectively maintained a low percentage of broken rice, underscoring the importance of controlled temperature in preserving the quality and yield of paddy rice during drying. Wongpornchai et al. [

23] investigated the impact of various drying methodologies and the duration of storage on the yield of head rice. It was observed that the yield of head rice was notably influenced by the drying techniques utilized. Particularly, when paddy was dried using hot air at 70 °C, the average yield of head rice was notably lower at 25.84%. Conversely, the yield was slightly improved when employing modified air at temperatures of 30 and 40 °C, and hot air at 40 and 50 °C, compared to traditional sun drying. The average yield for paddy dried using modified air (30 and 40 °C) and hot air (40 and 50 °C) was 56.48%, which is marginally higher than the 53.64% yield from sun drying. Furthermore, the study indicated minor variations in head rice yield across different drying treatments as the storage time progressed.

The study concludes that maintaining a moderate drying temperature, such as 45 °C, is pivotal in preserving the head rice yield during the drying process. This temperature regime minimizes the internal temperature disparity and moisture gradient within the grains, leading to fewer instances of internal cracking and a lower percentage of broken rice. While drying at excessively high temperatures, like 70 °C, significantly reduces the head rice yield, employing modified air at 30 to 40 °C or hot air at 40 to 50 °C slightly enhances the yield compared to traditional sun drying. Overall, the method and temperature of drying play a crucial role in maintaining the quality and yield of paddy rice, with moderate temperatures proving beneficial for minimizing grain damage and maximizing head rice yield.

When examining the average whiteness index of rice exposed to different drying techniques, the methods showed noticeable variations in whiteness. A marked difference in whiteness levels was statistically evident. Specifically, the rice dried through both hot air distribution strategies showed higher whiteness levels in contrast to those dried using the standard drying method, as highlighted in

Table 3. Rice from the standard drying often exhibited a reduced whiteness, taking on a yellowish hue. This color shift could be linked to extended drying periods, possibly triggering enzymatic browning reactions and allowing the pigments from the bran and husks to seep into the grain.

When analyzing the effects of different drying methods on the whiteness index of rice, it is evident from the provided studies that the drying technique, temperature, and storage period significantly influence the color attributes of rice, which include lightness (L*), redness–greenness (a*), yellowness–blueness (b*), and whiteness index (WI). Hanisa et al. [

24] highlighted that drying at higher temperatures can cause rice to darken due to enhanced browning reactions, reducing the whiteness index, mainly attributed to the browning reactions that occur at elevated temperatures during drying. Soponronnarit et al. [

25] indicated that as drying temperature increases, the whiteness of rice decreases due to enhanced browning reactions. It further notes the impact of initial moisture content and tempering time on the whiteness, where a higher initial moisture content and longer tempering time resulted in a darker color of rice. The work conducted by Chitsuthipakorn and Thanapornpoonpong [

26] delves into the changes in the whiteness index (WI) of white rice dried with different methods over a six-month storage period. It was observed that the whiteness index of white rice increased slightly during the storage, irrespective of the drying condition. This increase in whiteness index is potentially beneficial for rice trade negotiations. The subtle changes in color difference (ΔE*) throughout the storage suggest a certain degree of stability in the whiteness level. It was suggested that during drying and subsequent storage, starch granules in rice alter, forming a transparent layer that makes the rice grains appear shinier and reduces the enzymatic activity leading to browning.

In conclusion, while different drying methods and conditions affect the whiteness index of rice, carefully managing the drying temperature and moisture content can mitigate browning reactions and even improve whiteness over time. The increase in whiteness index during storage suggests that certain drying conditions can lead to a desirable shininess in rice, possibly due to changes in starch structure. This information is crucial for selecting drying methods that maintain or enhance the visual and marketable quality of rice.

Based on experimental findings from the two hot air distribution techniques in a traditional small-scale barn, the method using the main pipe system at the entrance proved quicker in reducing the moisture content from 25% db to the targeted 16% db compared to the perforated sub-air ducts. Yet, when assessing rice quality—particularly head rice yield and whiteness—both methods produced similar results. Given the research scope, the strategy deploying hot air from the entrance main duct was deemed most fitting for the traditional barn setup. Thus, rice dried using this method was further subjected to sensory quality evaluations and compared with rice dried via the conventional open-air sun method.

Table 3 reveals that the sensory attributes of the cooked rice dried using both hot air methods, such as aroma, whiteness, glossiness, cohesiveness, and tenderness, were on equivalence with rice dried traditionally in the sun. The prepared rice displayed a gentle aroma, bright and soft mature grains, and a mild cohesiveness. These features are consistent with the known characteristics of the KDM105 rice variety. Earlier studies have indicated that using lower drying temperatures (below 50 °C) helps preserve the volatile compound 2-acetyl-1-pyrroline, which gives the Khao Dawk Mali 105 rice its unique scent [

27]. Additionally, the observed brightness in cooked rice is linked to the inherent whiteness of the milled variant [

25]. As a result, this investigation determined that drying KDM 105 rice in a traditional barn yielded sensory qualities similar to the conventional open-air sun drying method. It underscored the feasibility of the in-barn paddy dehydration approach in preserving acceptable quality attributes.

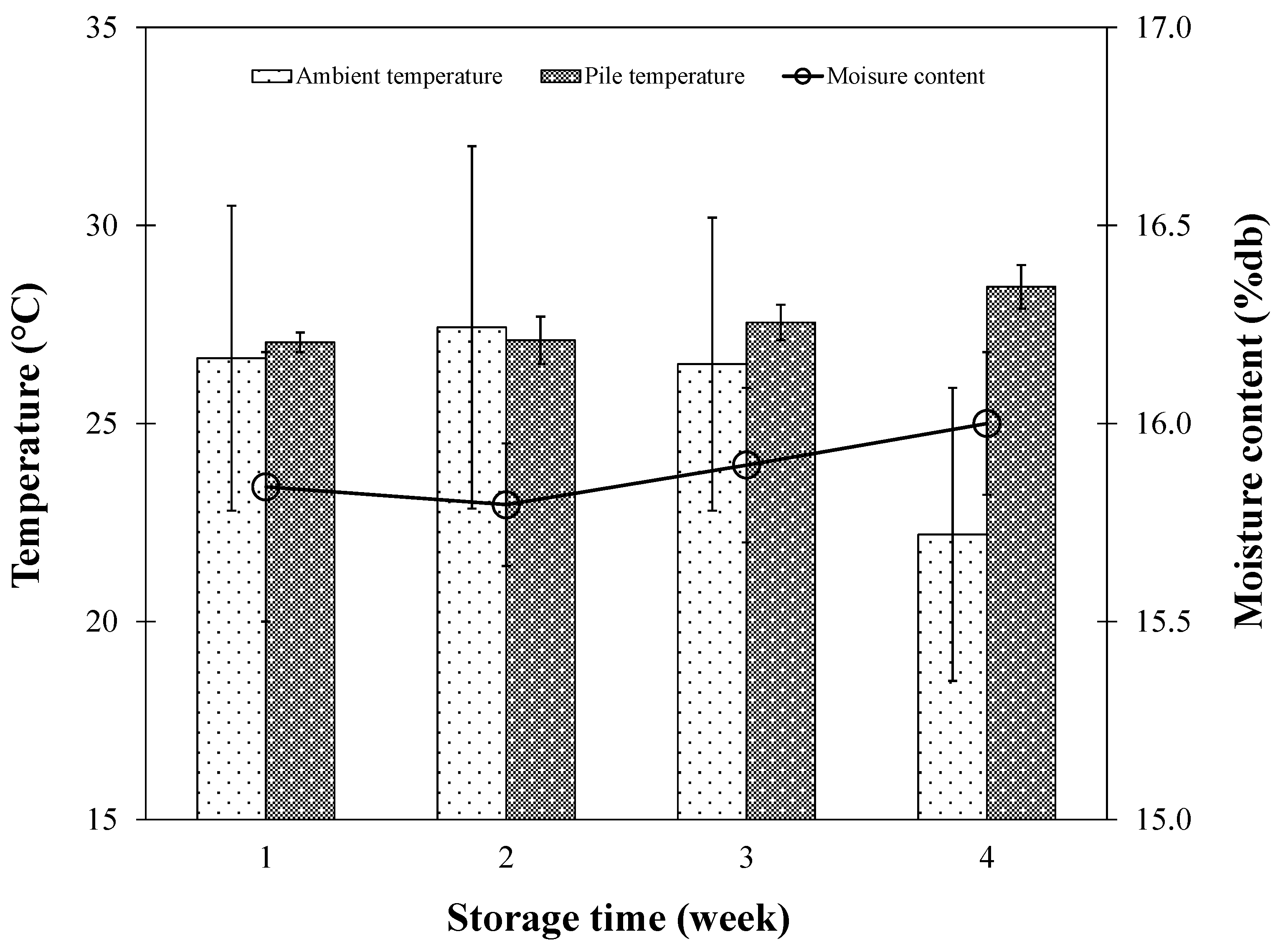

3.4. Changes in Temperature and Moisture Content during Short-Term Storage

In the initial month of storage within the traditional small-scale barn, the temperature within the rice pile showed an upward trend. Notably, during the final week, the temperature peaked at roughly 29 °C, noticeably surpassing the average ambient temperature, as depicted in

Figure 8. This temperature elevation was likely due to the heat generated by the rice grains’ respiration, similar to the observations made in the study on freshly harvested rice during storage, which highlighted the slight increase in temperature due to respiration heat, affecting various properties of the rice, such as water absorption capacity and protein content [

28].

A parallel observation was made by Phillips et al. [

29] in their examination of a one-ton paddy pile, which had a moisture content ranging from 16.3% to 17.6% db and a height of 80 cm. This paddy was dried under natural conditions, where temperatures fluctuated between 36 and 42 °C. They observed that the central temperature of the paddy pile jumped from 36 °C to 46 °C within the first 30 storage days. This is consistent with the findings from another study that emphasized the need for thorough rapid drying and proper temperature control in bins to maintain quality, as temperatures typical of certain harvest seasons may degrade kernel quality in moist top layers of rice in a drying bin [

30].

To counteract this heat buildup in paddy piles, it was crucial to introduce ambient air circulation to disperse this heat, particularly during the initial storage phase. The work of Millati et al. [

28] further supports this by highlighting that drying paddy rice in a single thick layer at low temperatures preserved the physical quality, physicochemical constituents, and starch morphology of rice grains, suggesting that controlled temperature and moisture are key to maintaining rice quality during storage [

6].

Nevertheless, this temperature surge during the early storage phase did not drastically influence the paddy moisture level, as indicated in

Figure 8. Throughout the first storage month, the moisture content of the paddy grains remained relatively stable on a weekly basis, maintaining a moisture content of approximately 15.9% db. This corroborates the third document’s recommendation for prompt drying to 16% MC or less and storage at or below 27 °C for up to 10 weeks to prevent fungal growth and quality degradation due to post-harvest storage-induced yellowing [

30].

3.5. Changes in Temperature and Moisture Content during Long-Term Storage under Occasional Forced-Air Ventilation

From the previously mentioned observations during the initial storage phase, the rise in the pile temperature had a negligible impact on moisture content. However, this temperature variation might have had implications beyond just moisture, potentially affecting the rice grain quality after extended storage. Notably, during the 6-month storage period covering the transition from winter to summer in Thailand, the relative humidity within the storage environment ranged from 52 to 78%. This fluctuation in humidity levels was carefully considered when selecting the optimal times for ventilation (11:00 a.m.–1:00 p.m.), during which the relative humidity was observed to be lower, ranging from 45 to 70%. This strategic choice in ventilation timing aimed to mitigate the impact of higher humidity levels on moisture content and grain quality, reflecting an understanding of the critical role that both temperature and humidity play in preserving rice integrity. In light of this, air ventilation was introduced to regulate the pile temperature and retain the paddy rice quality attributes. This approach resonates with findings from a study on drying paddy rice in a silo-dryer-aerator, which demonstrated the efficacy of low-temperature drying in preserving the physical and physicochemical quality of rice grains [

6].

Figure 8 illustrates the relationship between pile temperature and storage duration in comparison with the monthly average ambient temperature. A noticeable increasing trend in pile temperature over time was evident, which might have been influenced by the seasonal transition from winter to summer. Despite this gradual increase, the monthly temperatures within the paddy stacks consistently stayed within the bounds of that month’s average ambient temperature, never surpassing 37 °C—a threshold supported by the study on the accumulation of respiration heat, highlighting the importance of maintaining specific temperature ranges to prevent nutritional degradation [

28].

Research has indicated that during the static storage stage, grain respiration leads to initial heating at the bottom of the grain pile, forming a high-temperature core. In contrast, during the mechanical ventilation stage, as corroborated by a study using numerical simulations, cooling initiated from the air outlet spreads gradually to the entire silo, effectively lowering the grain pile temperature after significant ventilation [

31]. This emphasizes the profound effect of controlled ventilation on temperature management and supports the strategic arrangement of air ducts for uniform temperature distribution. In addition, the study by Liu et al. [

31] and the comprehensive storage study both emphasize that employing strategic air ventilation can effectively manage the temperature inside the paddy pile, aligning closer to the ambient temperature range and preventing excessive heat accumulation. This is critical, as even fully dried rice is susceptible to quality degradation under extreme temperature conditions. After ceasing the air circulation, a slight temperature increase in the paddy pile might be observed, possibly attributed to grain respiration. However, the overarching temperature management strategy remains effective, ensuring the preservation of rice quality throughout the storage period [

30]. These observations are in line with practical outcomes, illustrating the critical role of removing excess heat through air ventilation in sustaining rice quality during storage.

Moreover, in the present work, introducing ambient air ventilation once a month during a 6-month storage period resulted in only a minor change in the moisture content of the paddy rice grains, decreasing by approximately 0.4% db. Notably, the monthly moisture variations in the rice grains were not statistically significant, as depicted in

Figure 9. This finding further supports the efficacy of the occasional ventilation strategy employed and substantiates its role in maintaining rice quality without significantly affecting the moisture content.

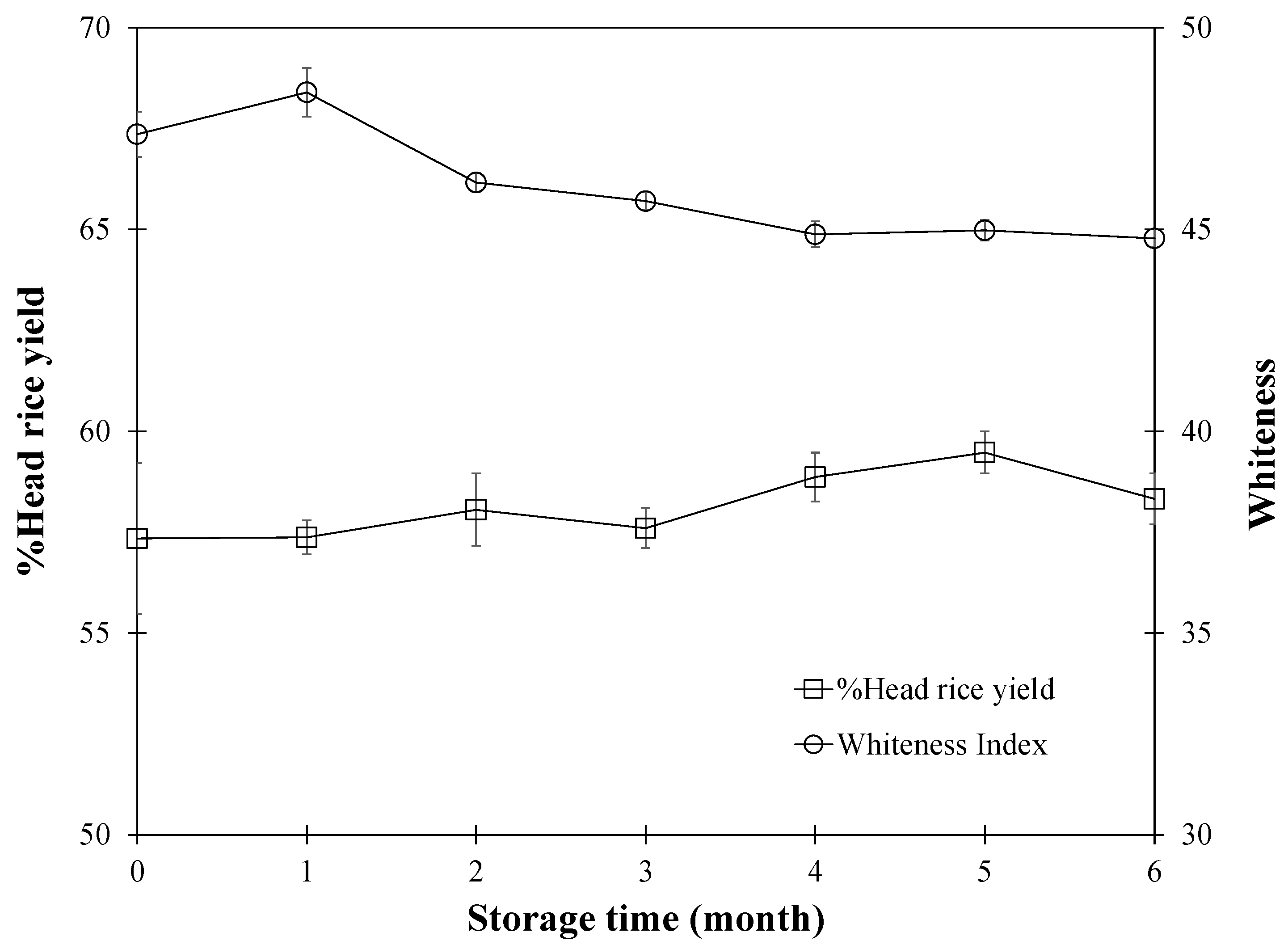

3.6. Quality Attributes of Paddy Rice during 6-Month Storage Associated with Air Ventilation

Figure 10 illustrates the percentage of head rice yield (%HRY) throughout a six-month period, in conjunction with periodic ambient air ventilation. The data indicates that the %HRY remained largely constant, averaging 58.43%. This constancy is likely due to the regulated temperature and moisture levels within the storage environment, safeguarding the rice grains from milling damage. While this study focused on %HRY, whiteness, and moisture content as primary quality indicators due to their significant influence on consumer preferences and milling factory assessments, it is important to note that cooking properties and gelatinization characteristics were not examined in depth. The decision was based on the understanding that under our controlled storage conditions—ambient temperature and low storage temperature—significant changes in starch structure impacting these properties are unlikely. This approach aligns with industry standards for rice quality evaluation, emphasizing attributes that directly affect marketability and consumer acceptance. Future studies may explore these aspects under varying conditions to provide a more comprehensive understanding of rice quality dynamics [

32]. This trend aligns with other studies indicating minimal fluctuations in head rice yield over storage durations [

5,

19,

23]. Notably, there is evidence suggesting that %HRY may indeed increase during storage, as indicated by Soponronnarit et al. [

25] and further supported by observations from Scariot et al. [

4], who noted an enhanced whole grain yield and reduced broken grain percentage over time when white subgroup grains were dried at higher temperatures [

4]. The underlying mechanism might involve the fusion of starch granules in the rice grains, reducing their susceptibility to breakage. Nevertheless, a decline in %HRY was observed after the initial three-month period, potentially due to the gradual moisture loss making the grains more brittle during milling.

With extended storage, the paddy rice is prone to discoloration, becoming more yellowish as a result of enzymatic reactions. The study’s examination of rice whiteness over six months revealed a decrease in whiteness of approximately 3.50% by the final month, yet maintaining a level above 37–38%, which falls within consumer-acceptable criteria [

25]. A contributing factor to this reduction in whiteness could be the progressive rise in temperature within the paddy pile, a concern also highlighted by Moraes et al. [

6], emphasizing the critical role of temperature regulation during drying and storage to prevent quality deterioration, such as grain breakage [

6]. The empirical data indicates a notable rise in the paddy pile temperature during the latter months, likely accelerating enzymatic browning of the rice grains.

Moreover, the ambient conditions under which paddy is stored can significantly impact the rice’s whiteness, primarily due to the respiration process of the grains. This biological activity generates heat, raising the temperature inside the paddy pile. Consistent with findings from Prasantha et al. [

33], rice stored in polypropylene and hermetic storage bags at a constant 30 °C showed a marked decrease in whiteness over nine months. The decline was from a range of 51.3–40.7% to 38.8–28.1% in polypropylene bags and to 36.1–23.6% in hermetic storage bags. Similarly, a study on Khao Dawk Mali 105 paddy rice stored at room temperature for six months reported a decrease in whiteness from 46% to 44% [

25].

In summarizing, the investigation into paddy rice’s quality attributes during six-month storage with air ventilation concludes that %HRY predominantly exhibits stability, averaging at 58.43%. This steady state is largely credited to well-maintained temperature and moisture levels within the storage environment, which play a crucial role in preventing significant damage to the rice grains during milling. Nevertheless, the research points to the possibility of %HRY experiencing initial increases during storage, which eventually taper off, reflecting the intricate balance between storage duration and grain quality. Additionally, the study notes a gradual decrease in rice whiteness, particularly as the storage period concludes, primarily due to enzymatic browning and temperature elevation within the paddy pile. These insights underline the significance of optimal storage conditions for preserving paddy rice quality over time and contribute valuable knowledge to understanding the effects of ambient air ventilation on rice quality during storage. Such insights are instrumental in refining post-harvest handling and storage strategies.

3.7. Techno-Economic Results

An analysis of electric energy consumption for drying 1000 kg of paddy with an initial moisture content of 25% db reduced to roughly 16% db was conducted within the traditional small-scale barn using hot air distributed by two ducting systems. This analysis, as shown in

Table 4, revealed that the paddy rice sample consumed less energy when dried using the main air duct method, registering an approximate specific energy consumption value of 1.87–1.94 MJ·kg

−1. In contrast, using perforated sub-ducts resulted in a higher energy consumption of about 2.23–2.25 MJ·kg

−1. This disparity can be attributed to the reduced drying time required by the main duct method, leading to decreased overall energy usage [

34]. However, previous studies have shown that industrial-scale paddy storage facilities demand a specific energy consumption of roughly 2.88 MJ·kg

−1 when utilizing forced ambient air to decrease paddy moisture from an initial 22% db (with a paddy stack height of 1.6 m) to approximately 16% db [

35]. Furthermore, a study from a Malaysian rice mill employing an inclined bed dryer at approximately 42 °C found that drying 15 tons of paddy (with a stack height of 1 m) from an initial moisture content of 30% db to around 13.6% db necessitated about 5 MJ per kg of evaporated water [

36].

During our six-month assessment of the traditional small-scale barn used for paddy storage, we monitored the electrical energy usage. Each two-hour session of introducing ambient air into the paddy stack consumed approximately 0.70 kWh per 1000 kg of paddy. This translated to an expenditure of 2.10 baht each time. Over the six-month period, the total electricity cost accumulated to 12.60 baht per ton of paddy stored.