The Potential Application of Visible-Near Infrared (Vis-NIR) Hyperspectral Imaging for Classifying Typical Defective Goji Berry (Lycium barbarum L.)

Abstract

1. Introduction

2. Materials and Methods

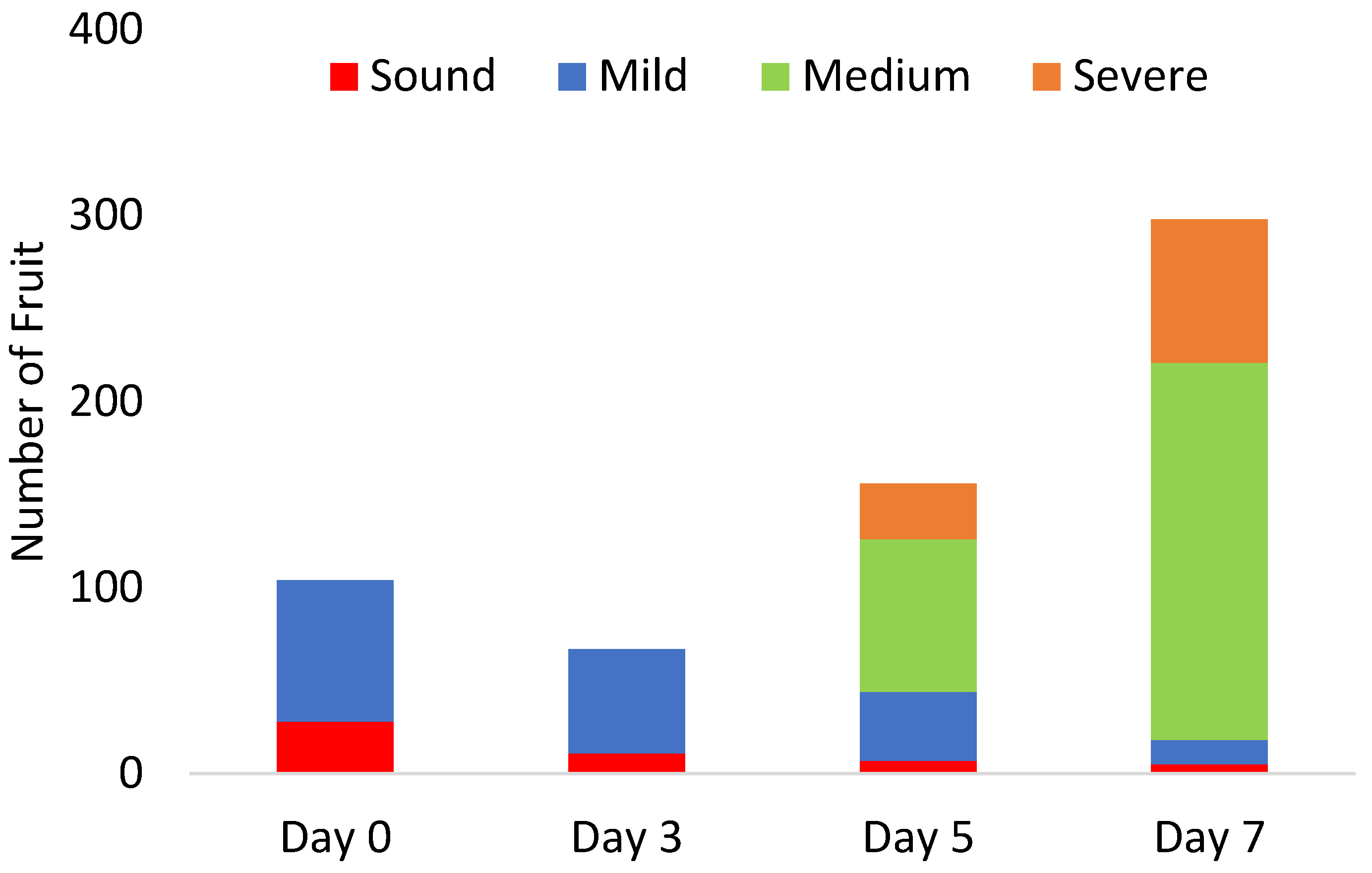

2.1. Quality Assessment

2.2. Fruit Samples

2.3. Hyperspectral Image Acquisition and Spectral Extraction

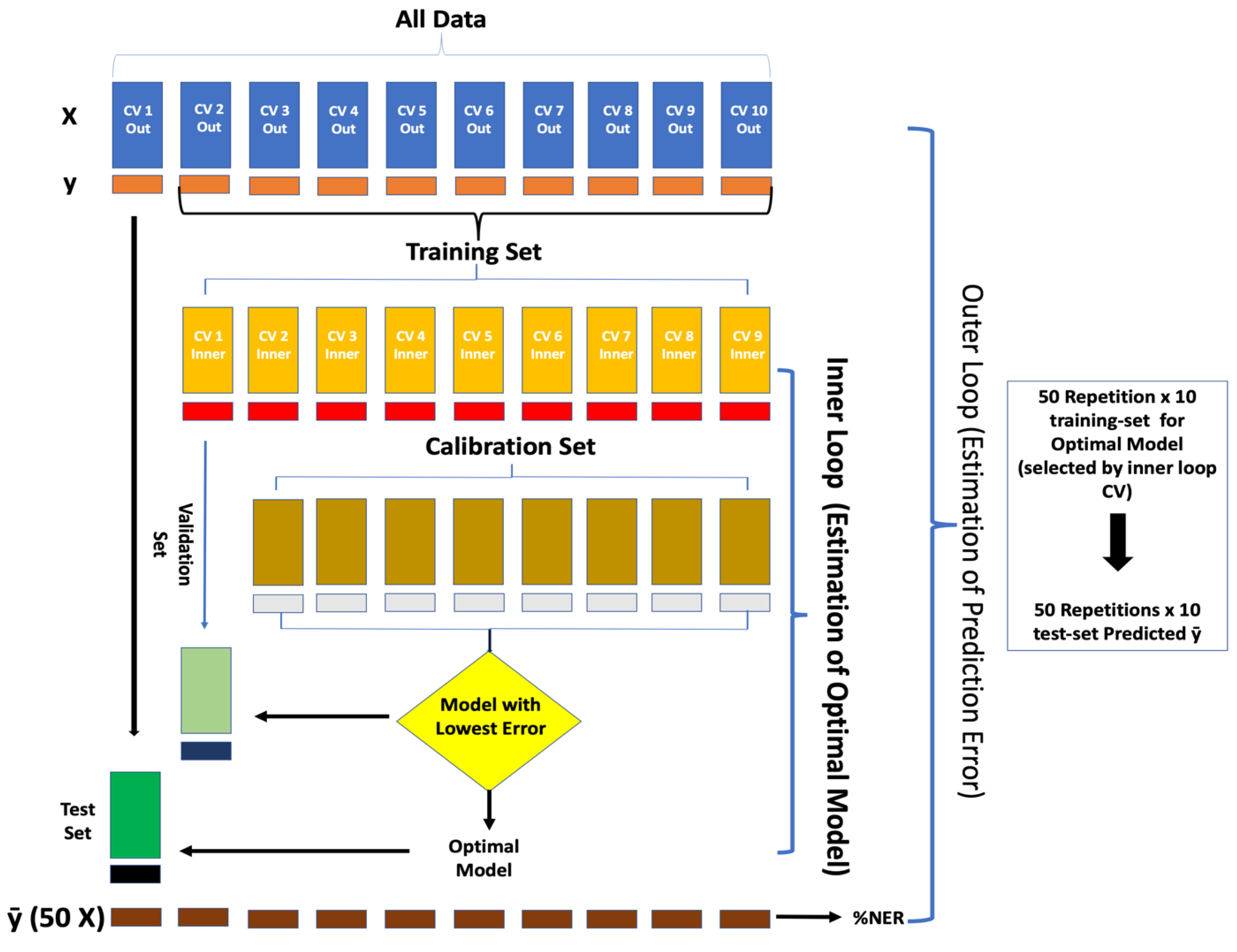

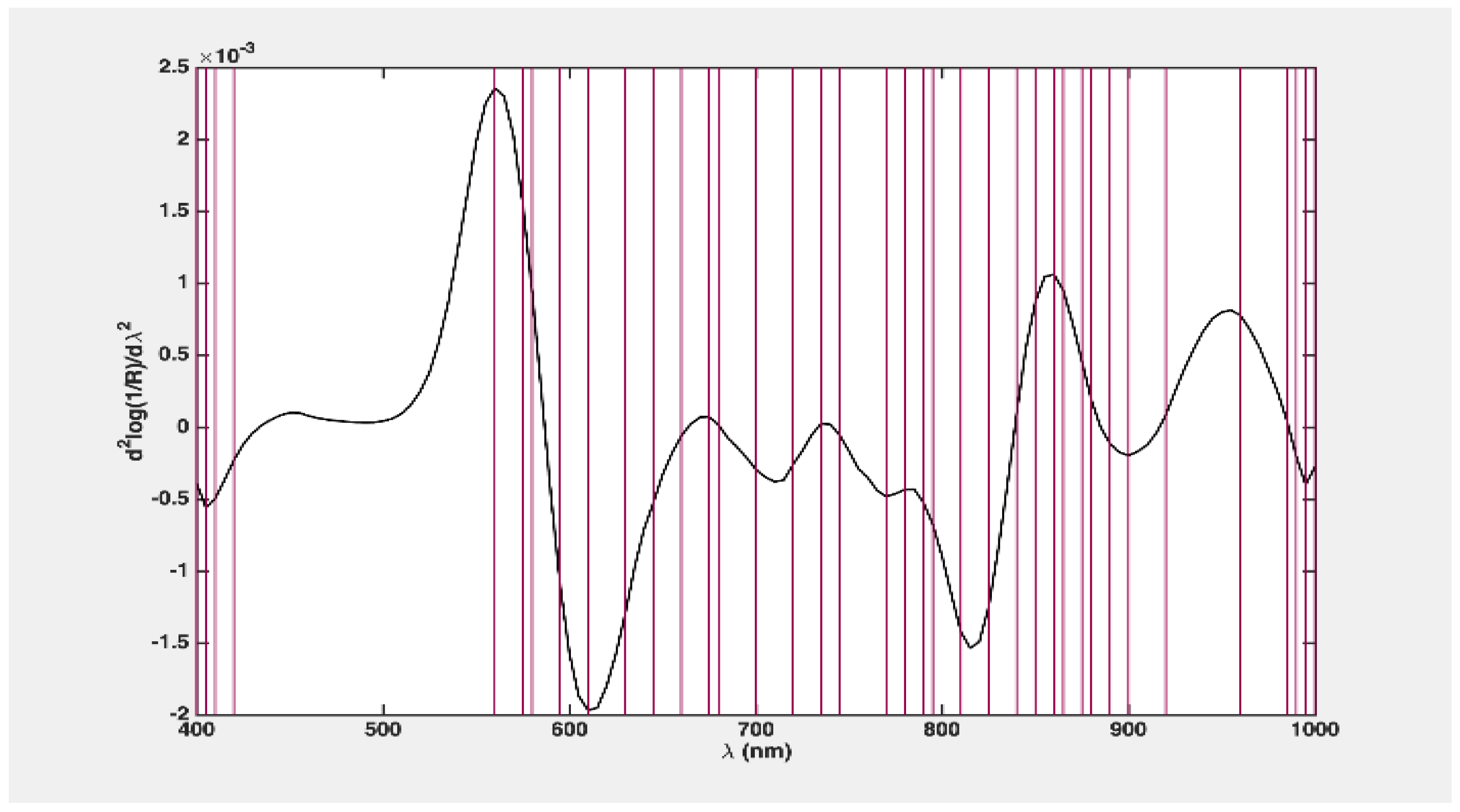

2.4. Assessment of Chemometric

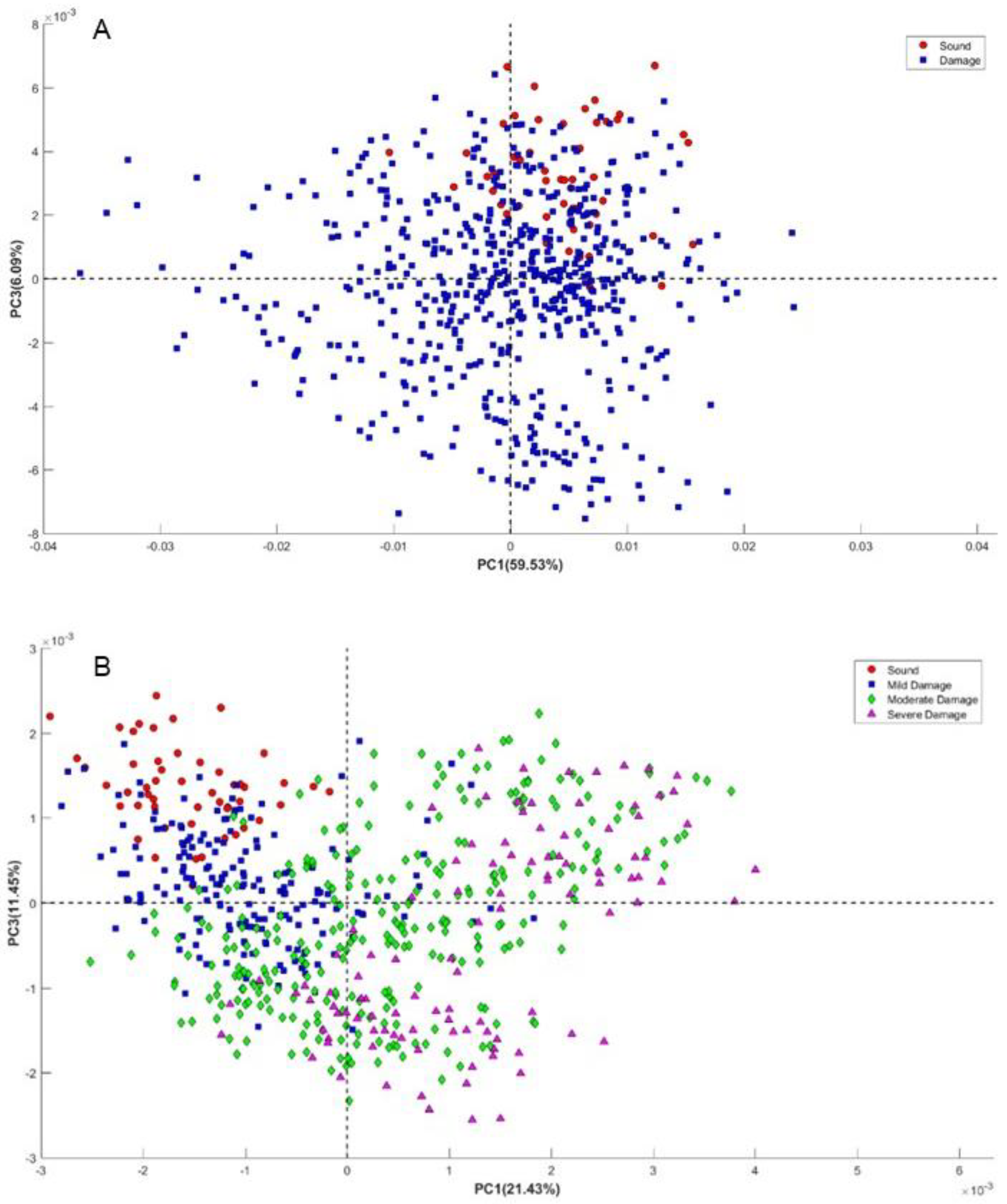

2.4.1. Principal Component Analysis (PCA)

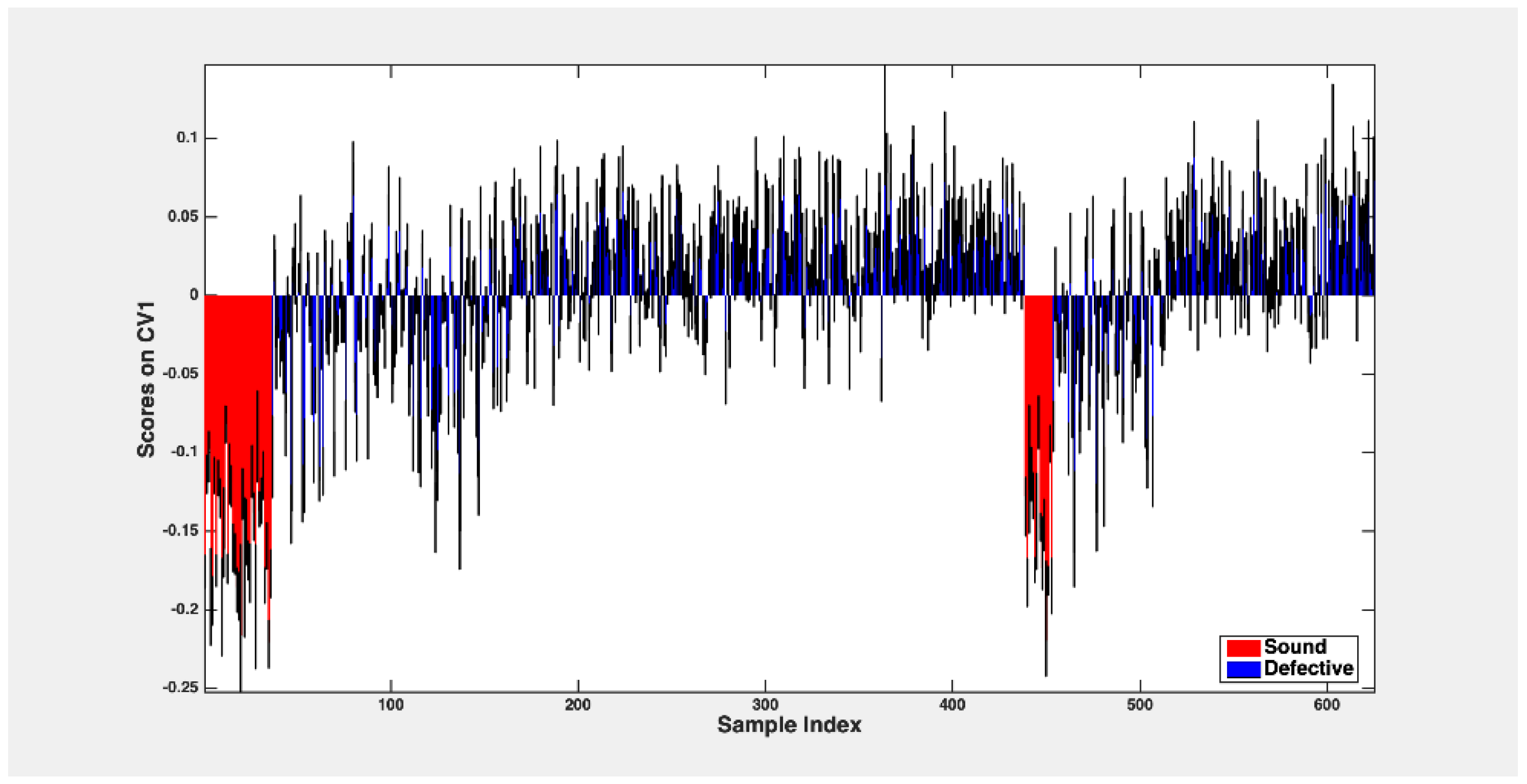

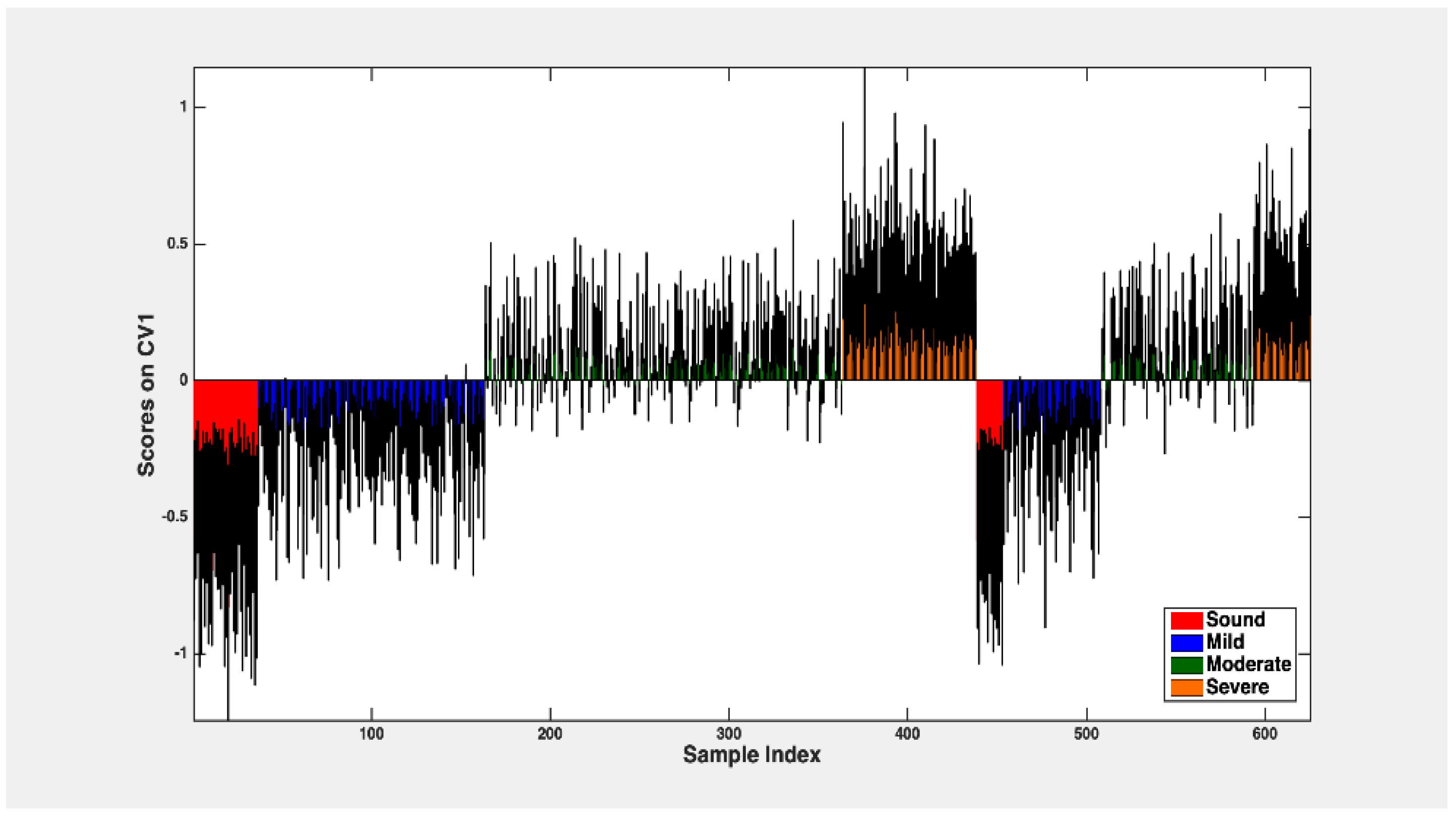

2.4.2. Analysis of Partial Least Square-Discriminant (PLS-DA)

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, D.; Li, S.; Han, X.; Li, C.; Ni, Y.; Hao, J. Physico-chemical properties and free amino acids profiles of six wolfberry cultivars in Zhongning. J. Food Compos. Anal. 2020, 88, 103460. [Google Scholar] [CrossRef]

- Wojdyło, A.; Nowicka, P.; Bąbelewski, P. Phenolic and carotenoid profile of new goji cultivars and their anti-hyperglycemic, anti-aging and antioxidant properties. J. Funct. Foods 2018, 48, 632–642. [Google Scholar] [CrossRef]

- Kruczek, A.; Ochmian, I.; Krupa-Małkiewicz, M.; Lachowicz, S. Comparison of Morphological, Antidiabetic and Antioxidant Properties of Goji Fruits. Acta Univ. Cibiniensis. Ser. E Food Technol. 2020, 24, 1–14. [Google Scholar] [CrossRef]

- Jatoi, M.A.; Fruk, M.; Buhin, J.; Vinceković, M.; Vuković, M.; Jemrić, T. Effect of Different Storage Temperatures on Storage Life, Physico-chemical and Sensory Attributes of Goji Berry (Lycium barbarum L.) Fruits. Erwerbs-Obstbau 2018, 60, 119–126. [Google Scholar] [CrossRef]

- Munera, S.; Gómez-Sanchís, J.; Aleixos, N.; Vila-Francés, J.; Colelli, G.; Cubero, S.; Soler, E.; Blasco, J. Discrimination of common defects in loquat fruit cv. ‘Algerie’ using hyperspectral imaging and machine learning techniques. Postharvest Biol. Technol. 2021, 171, 111356. [Google Scholar] [CrossRef]

- Palumbo, M.; Capotorto, I.; Cefola, M.; Burbaci, S.; Pace, B. Modified atmosphere packaging to improve the shelf-life of Goji berries during cold storage. Adv. Hortic. Sci. 2020, 34, 21–26. [Google Scholar]

- Kulczyński, B.; Gramza-Michałowska, A. Goji Berry (Lycium barbarum): Composition and Health Effects—A Review. Pol. J. Food Nutr. Sci. 2016, 66, 67–75. [Google Scholar] [CrossRef]

- Pu, Y.Y.; Feng, Y.Z.; Sun, D.W. Recent progress of hyperspectral imaging on quality and safety inspection of fruits and vegetables: A review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 176–188. [Google Scholar] [CrossRef]

- Beghi, R.; Buratti, S.; Giovenzana, V.; Benedetti, S.; Guidetti, R. Electronic nose and visible-near infrared spectroscopy in fruit and vegetable monitoring. Rev. Anal. Chem. 2017, 36, 1–24. [Google Scholar] [CrossRef]

- Cen, H.; Lu, R.; Zhu, Q.; Mendoza, F. Nondestructive detection of chilling injury in cucumber fruit using hyperspectral imaging with feature selection and supervised classification. Postharvest Biol. Technol. 2016, 111, 352–361. [Google Scholar] [CrossRef]

- Hubo, X.; Jie, W.; Zhaopeng, W.; Yongmao, G.; Zhipeng, W.; Zhengqiang, Z. Discrimination of brownheart of Korla pear using vibration frequency spectrum technique. Int. J. Agric. Biol. Eng. 2017, 10, 259–266. [Google Scholar] [CrossRef]

- Kleynen, O.; Leemans, V.; Destain, M.F. Development of a multi-spectral vision system for the detection of defects on apples. J. Food Eng. 2005, 69, 41–49. [Google Scholar] [CrossRef]

- Yu, K.Q.; Zhao, Y.R.; Liu, Z.Y.; Li, X.L.; Liu, F.; He, Y. Application of Visible and Near-Infrared Hyperspectral Imaging for Detection of Defective Features in Loquat. Food Bioprocess Technol. 2014, 7, 3077–3087. [Google Scholar] [CrossRef]

- Ireri, D.; Belal, E.; Okinda, C.; Makange, N.; Ji, C. A computer vision system for defect discrimination and grading in tomatoes using machine learning and image processing. Artif. Intell. Agric. 2019, 2, 28–37. [Google Scholar] [CrossRef]

- Lu, Y.; Lu, R. Detection of Surface and Subsurface Defects of Apples Using Structured-Illumination Reflectance Imaging with Machine Learning Algorithms. In Proceedings of the 2018 ASABE Annual International Meeting, Detroit, MI, USA, 29 July 29–1 August 2018; Volume 61, pp. 1831–1842. [Google Scholar]

- Mahendran, R.; Gc, J.; Alagusundaram, K. Application of Computer Vision Technique on Sorting and Grading of Fruits and Vegetables. J. Food Process. Technol. 2015, S1, 1–7. [Google Scholar] [CrossRef]

- Sahu, D.; Potdar, R.M. Defect Identification and Maturity Detection of Mango Fruits Using Image Analysis. Am. J. Artif. Intell. 2017, 1, 5–14. [Google Scholar] [CrossRef]

- Maghoumi, M.; Fatchurrahman, D.; Amodio, M.L.; Quinto, M.; Cisneros-Zevallos, L.; Colelli, G. Is pomegranate husk scald during storage induced by water loss and mediated by ABA signaling? J. Sci. Food Agric. 2023, 103, 2914–2925. [Google Scholar] [CrossRef]

- Fatchurrahman, D.; Kuramoto, M.; Kondo, N.; Ogawa, Y.; Suzuki, T. Identification of UV-fluorescence components associated with and detection of surface damage in Green Pepper (Capsicum annum L). In Proceedings of the 23rd International Conference in Central Europe on Computer Graphics, Visualization and Computer Vision, WSCG 2015-Full Papers Proceedings, Plzen, Czech Republic, 8–12 June 2015. [Google Scholar]

- Lü, Q.; Tang, M. Detection of Hidden Bruise on Kiwi fruit Using Hyperspectral Imaging and Parallelepiped Classification. Procedia Environ. Sci. 2012, 12, 1172–1179. [Google Scholar] [CrossRef]

- Vélez Rivera, N.; Gómez-Sanchis, J.; Chanona-Pérez, J.; Carrasco, J.J.; Millán-Giraldo, M.; Lorente, D.; Cubero, S.; Blasco, J. Early detection of mechanical damage in mango using NIR hyperspectral images and machine learning. Biosyst. Eng. 2014, 122, 91–98. [Google Scholar] [CrossRef]

- Yuan, R.; Liu, G.; He, J.; Wan, G.; Fan, N.; Li, Y.; Sun, Y. Classification of Lingwu long jujube internal bruise over time based on visible near-infrared hyperspectral imaging combined with partial least squares-discriminant analysis. Comput. Electron. Agric. 2021, 182, 106043. [Google Scholar] [CrossRef]

- Amodio, M.L.; Ceglie, F.; Chaudhry, M.M.A.; Piazzolla, F.; Colelli, G. Potential of NIR spectroscopy for predicting internal quality and discriminating among strawberry fruits from different production systems. Postharvest Biol. Technol. 2017, 125, 112–121. [Google Scholar] [CrossRef]

- Tsouvaltzis, P.; Babellahi, F.; Amodio, M.L.; Colelli, G. Early detection of eggplant fruit stored at chilling temperature using different non-destructive optical techniques and supervised classification algorithms. Postharvest Biol. Technol. 2020, 159, 111001. [Google Scholar] [CrossRef]

- Shao, Y.; Liu, Y.; Xuan, G.; Shi, Y.; Li, Q.; Hu, Z. Detection and analysis of sweet potato defects based on hyperspectral imaging technology. Infrared Phys. Technol. 2022, 127, 104403. [Google Scholar] [CrossRef]

- Lu, Y.; Guo, S.; Zhang, F.; Yan, H.; Qian, D.W.; Shang, E.X.; Wang, H.Q.; Duan, J.A. Nutritional components characterization of Goji berries from different regions in China. J. Pharm. Biomed. Anal. 2021, 195, 113859. [Google Scholar] [CrossRef] [PubMed]

- Kader, A.A.; Cantwell, M. Produce Quality Rating Scales and Color Charts (Appendix 1); Postharvest Horticulture Series No. 23; University of California: Davis, CA, USA, 2007. [Google Scholar]

- Xu, J.-L.; Esquerre, C.; Sun, D. Methods for performing dimensionality reduction in hyperspectral image classification. J. Near Infrared Spectrosc. 2018, 26, 61–75. [Google Scholar] [CrossRef]

- Brereton, R.G.; Lloyd, G.R. Partial least squares discriminant analysis: Taking the magic away. J. Chemom. 2014, 28, 213–225. [Google Scholar] [CrossRef]

- Olivieri, A. Introduction to Multivariate Calibration. A Practical Approach; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 3319970976. [Google Scholar]

- Filzmoser, P.; Liebmann, B.; Varmuza, K. Repeated double cross validation. J. Chemom. 2009, 23, 160–171. [Google Scholar] [CrossRef]

- Fernandes, J.A.; Irigoien, X.; Boyra, G.; Lozano, J.A.; Inza, I. Optimizing the number of classes in automated zooplankton classification. J. Plankton Res. 2009, 31, 19–29. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, D.; Liu, Y.; Zhou, H.; Sun, Y. Measurement of early disease blueberries based on vis/nir hyperspectral imaging system. Sensors 2020, 20, 5783. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, S.; Dong, W.; Luo, W.; Huang, Y.; Zhan, B.; Liu, X. Detection of common defects on mandarins by using visible and near infrared hyperspectral imaging. Infrared Phys. Technol. 2020, 108, 103341. [Google Scholar] [CrossRef]

- Nguyen, N.M.T.; Liou, N.S. Detecting Surface Defects of Achacha Fruit (Garcinia humilis) with Hyperspectral Images. Horticulturae 2023, 9, 869. [Google Scholar] [CrossRef]

- Abdul-Hammed, M.; Bello, I.A.; Oladoye, S.O. Simultaneous spectrophotometric determination of lycopene and beta-carotene concentrations in carotenoid mixtures of the extracts from tomatoes, papaya and orange juice. Pak. J. Sci. Ind. Res. Ser. B Biol. Sci. 2013, 56, 90–97. [Google Scholar] [CrossRef]

- Lombardelli, C.; Benucci, I.; Esti, M. Novel food colorants from tomatoes: Stability of carotenoid-containing chromoplasts under different storage conditions. LWT 2021, 140, 110725. [Google Scholar] [CrossRef]

- Fatchurrahman, D.; Nosrati, M.; Amodio, M.L.; Chaudhry, M.M.A.; de Chiara, M.L.V.; Mastrandrea, L.; Colelli, G. Comparison performance of visible-nir and near-infrared hyperspectral imaging for prediction of nutritional quality of goji berry (Lycium barbarum L.). Foods 2021, 10, 1676. [Google Scholar] [CrossRef] [PubMed]

- Gower, J.; King, S.; Borstad, G.; Brown, L. The importance of a band at 709 nm for interpreting water-leaving spectral radiance. Can. J. Remote Sens. 2008, 34, 287–295. [Google Scholar] [CrossRef]

- Folch-Fortuny, A.; Prats-Montalbán, J.M.; Cubero, S.; Blasco, J.; Ferrer, A. VIS/NIR hyperspectral imaging and N-way PLS-DA models for detection of decay lesions in citrus fruits. Chemom. Intell. Lab. Syst. 2016, 156, 241–248. [Google Scholar] [CrossRef]

| True Class | Sensitivity (%) | Specificity (%) | Accuracy %) | Error (%) |

|---|---|---|---|---|

| Sound | 96.1 ± 2.1 | 93.7 ± 0.6 | 93.9 ± 0.6 | 5.1 ± 1.1 |

| Defective | 93.7 ± 0.6 | 96.1 ± 2.1 |

| True Class | Sensitivity (%) | Specificity (%) | Accuracy (%) | Error (%) |

|---|---|---|---|---|

| Sound | 99.3 ± 1.1 | 94.5 ± 0.4 | 94.9 ± 0.4 | 3.1 ± 0.7 |

| Defective | 94.5 ± 0.4 | 99.3 ± 1.1 |

| True Class | Sensitivity (%) | Specificity (%) | Accuracy (%) | Error (%) |

|---|---|---|---|---|

| Sound | 86.6 ± 2.3 | 95.3 ± 0.6 | 74.5 ± 1.1 | 22.1 ± 1.1 |

| Mild | 70.2 ± 2.3 | 88.6 ± 0.8 | ||

| Moderate | 71.9 ± 1.7 | 86.6 ± 0.9 | ||

| Severe | 83.1 ± 1.7 | 93.1 ± 0.7 |

| True Class | Sensitivity (%) | Specificity (%) | Accuracy (%) | Error (%) |

|---|---|---|---|---|

| Sound | 90.1 ± 1.5 | 96.0 ± 0.4 | 75.7 ± 0.7 | 20.4 ± 0.7 |

| Mild | 71.5 ± 1.7 | 89.3 ± 0.6 | ||

| Moderate | 72.5 ± 1.4 | 86.5 ± 0.9 | ||

| Severe | 84.3 ± 1.7 | 93.1 ± 0.6 |

| Predicted Class (%) | |||||

|---|---|---|---|---|---|

| Sound | Mild | Moderate | Severe | ||

| True Class | Sound | 90.1 ± 1.5 | 9.9 ± 1.5 | 0.0 ± 0.0 | 0.0 ± 0.0 |

| Mild | 12.4 ± 1.1 | 71.5 ± 1.7 | 16.0 ± 1.3 | 0.0 ± 0.0 | |

| Moderate | 0.1 ± 0.1 | 14.8 ± 0.9 | 72.4 ± 1.3 | 12.6 ± 0.9 | |

| Severe | 0.0 ± 0.0 | 0.1 ± 0.3 | 15.6 ± 1.7 | 84.3 ± 1.7 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fatchurrahman, D.; Marini, F.; Nosrati, M.; Peruzzi, A.; Castellano, S.; Amodio, M.L.; Colelli, G. The Potential Application of Visible-Near Infrared (Vis-NIR) Hyperspectral Imaging for Classifying Typical Defective Goji Berry (Lycium barbarum L.). Foods 2024, 13, 3469. https://doi.org/10.3390/foods13213469

Fatchurrahman D, Marini F, Nosrati M, Peruzzi A, Castellano S, Amodio ML, Colelli G. The Potential Application of Visible-Near Infrared (Vis-NIR) Hyperspectral Imaging for Classifying Typical Defective Goji Berry (Lycium barbarum L.). Foods. 2024; 13(21):3469. https://doi.org/10.3390/foods13213469

Chicago/Turabian StyleFatchurrahman, Danial, Federico Marini, Mojtaba Nosrati, Andrea Peruzzi, Sergio Castellano, Maria Luisa Amodio, and Giancarlo Colelli. 2024. "The Potential Application of Visible-Near Infrared (Vis-NIR) Hyperspectral Imaging for Classifying Typical Defective Goji Berry (Lycium barbarum L.)" Foods 13, no. 21: 3469. https://doi.org/10.3390/foods13213469

APA StyleFatchurrahman, D., Marini, F., Nosrati, M., Peruzzi, A., Castellano, S., Amodio, M. L., & Colelli, G. (2024). The Potential Application of Visible-Near Infrared (Vis-NIR) Hyperspectral Imaging for Classifying Typical Defective Goji Berry (Lycium barbarum L.). Foods, 13(21), 3469. https://doi.org/10.3390/foods13213469