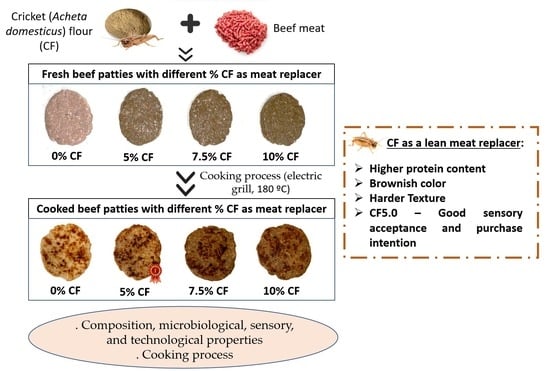

Potential of Cricket (Acheta domesticus) Flour as a Lean Meat Replacer in the Development of Beef Patties

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation and Formulation of Beef Patties

2.3. Proximate Composition of Raw Beef Patties

2.4. Microbiological Analysis

2.5. Cooking Process

2.6. Sensorial Analysis

2.7. Technological Properties

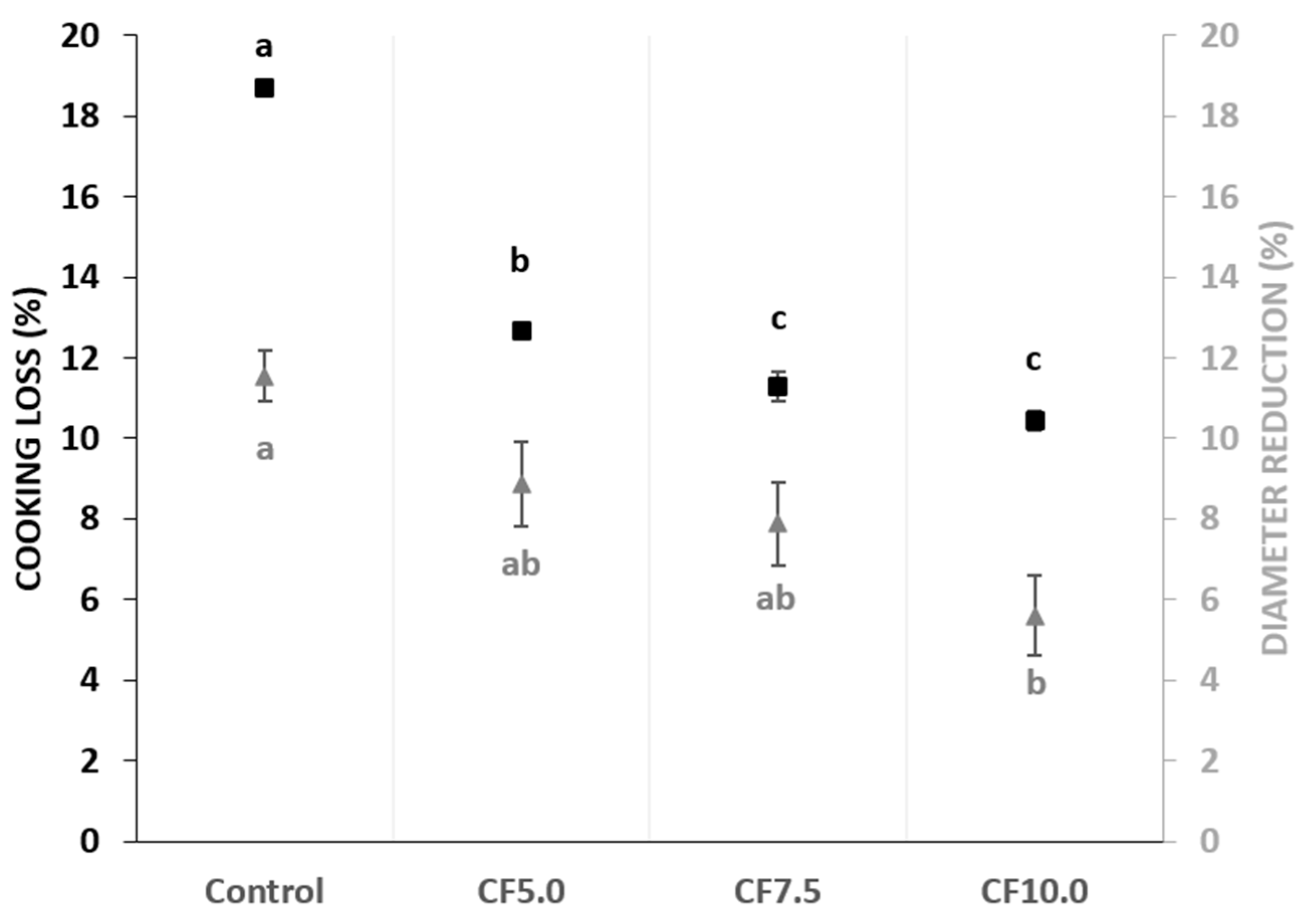

2.7.1. Cooking Yield: Weight Loss and Diameter Reduction

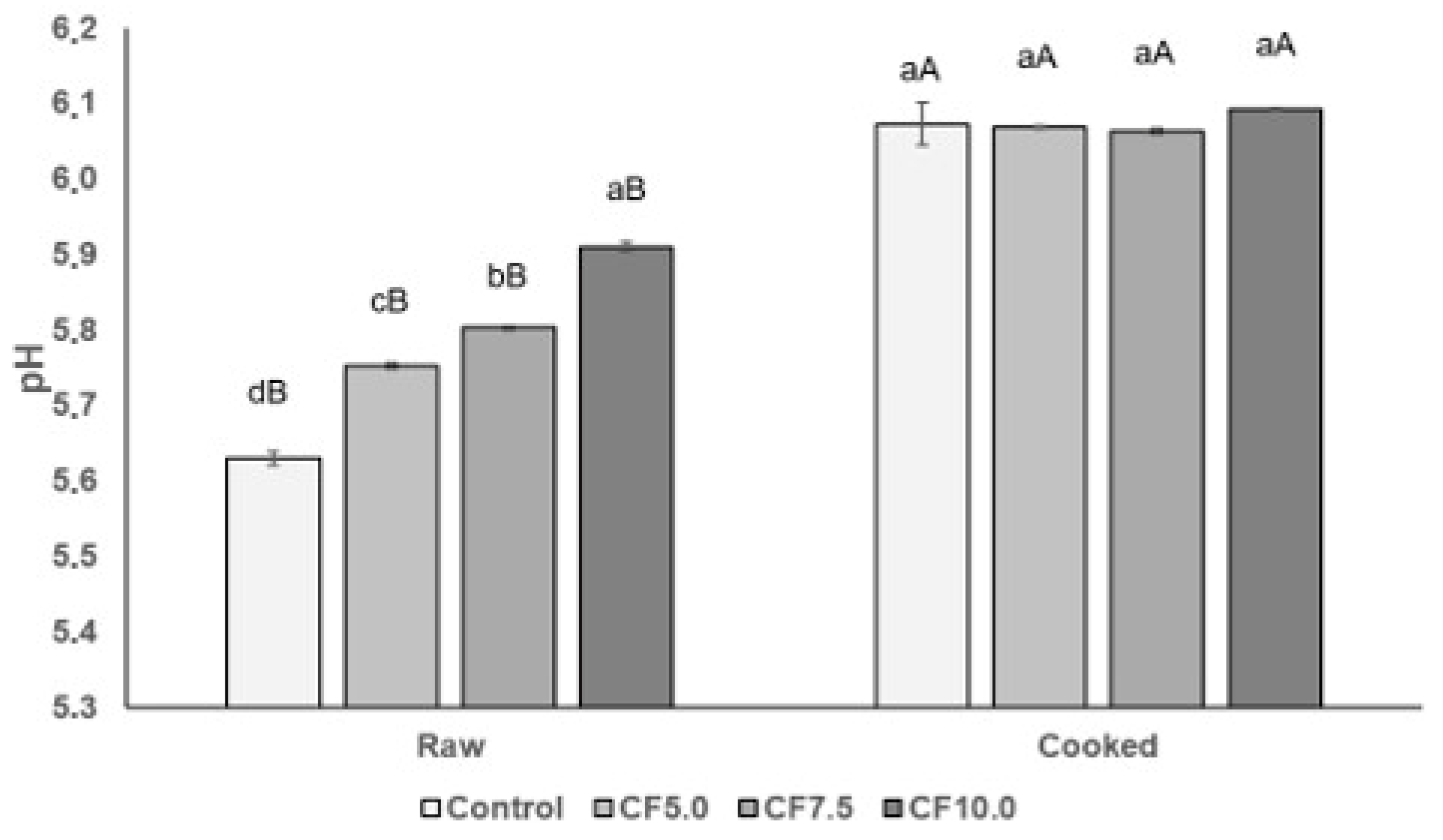

2.7.2. pH, Color Parameters, and Kramer Shear Force

2.8. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition of Raw Beef Patties

3.2. Microbiological Analysis

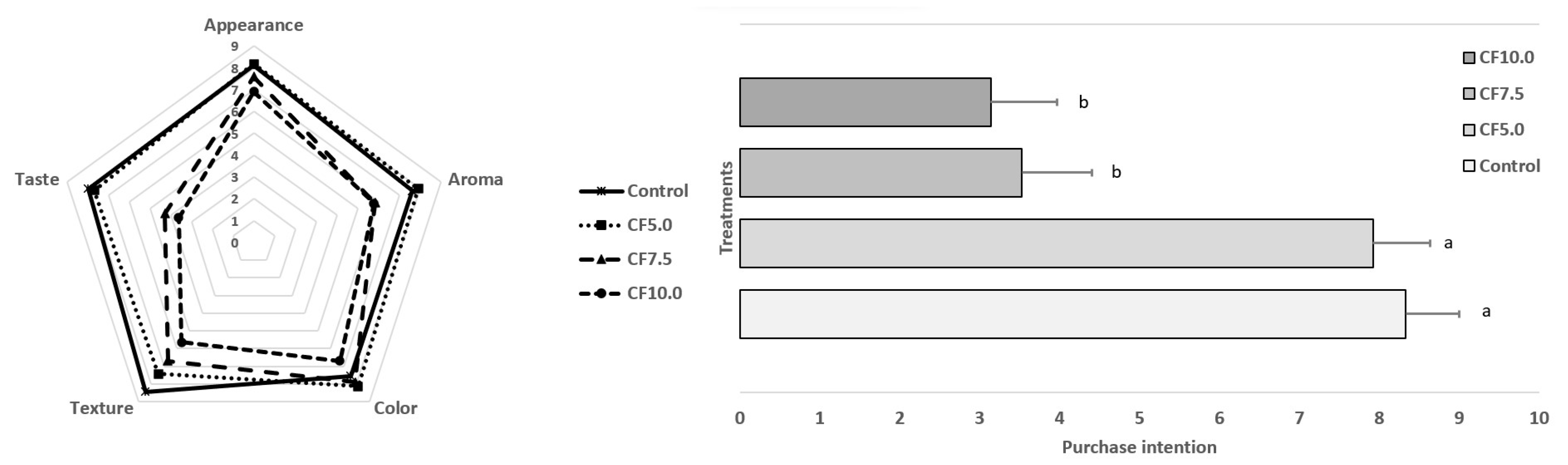

3.3. Sensory Characteristics

3.4. Technological Properties

3.4.1. Cooking Yield: Weight Loss and Diameter Reduction

3.4.2. pH, Color Parameters, and Kramer Shear Force

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations. 2050: A Third More Mouths to Feed; Food and Agriculture Organization of the United Nations: Rome, Italy, 2009. [Google Scholar]

- Nagai, N.F.; Lorenzo, J.M.; Ranalli, N.; Pérez-Álvarez, J.A.; Sepulveda, N.; Domínguez, R.; Santos, E.M.; Teixeira, A.; Andrés, S.C. Use of seaweed powder (Undaria sp.) as a functional ingredient in low-fat pork burgers. Algal Res. 2022, 67, 102862. [Google Scholar] [CrossRef]

- Zhang, T.; Dou, W.; Zhang, X.; Zhao, Y.; Zhang, Y.; Jiang, L.; Sui, X. The development history and recent updates on soy protein-based meat alternatives. Trends Food Sci. Technol. 2022, 109, 702–710. [Google Scholar] [CrossRef]

- Melgar-Lallane, G.; Hernández-Álvarez, A.J.; Salinas-Castro, A. Edible insects processing: Traditional and innovative technologies. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1166–1191. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Keppler, J.K.; van der Goot, A.J. Functionality of ingredients and additives in plant-based meat analogues. Foods 2021, 10, 600. [Google Scholar] [CrossRef]

- Belluco, S.; Losasso, C.; Maggioletti, M.; Alonzi, C.C.; Paoletti, M.B.; Ricci, A. Edible insects in a food safety and nutritional perspective: A critical review. Compr. Rev. Food Sci. Food Saf. 2013, 12, 296–313. [Google Scholar] [CrossRef]

- Osimani, A.; Milanovic, V.; Cardinali, F.; Roncolini, A.; Garofalo, C.; Clementi, F.; Pasquini, M.; Mozzon, M.; Foligni, R.; Raffaelli, N.; et al. Bread enriched with cricket powder (Acheta domesticus): A technological, microbiological and nutritional evaluation. Innov. Food Sci. Emerg. Technol. 2018, 48, 150–163. [Google Scholar] [CrossRef]

- Erhard, A.L.; Silva, M.A.; Damsbo-Svendsen, M.; Karpantschof, B.M.; Sorensen, H.; Frost, M.B. Acceptance of insect foods among Danish children: Effects of information provision, food neophobia, disgust sensitivity, and species on willingness to try. Food Qual. Prefer. 2022, 104, 104713. [Google Scholar] [CrossRef]

- van Huis, A.; Rumpold, B. Strategies to convince consumers to eat insects? A review. Food Qual. Prefer. 2023, 110, 104927. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Bahmid, N.A.; Mahmud, C.M.M.; Boukid, F.; Lamri, M.; Gagaoua, M. Consumer acceptability of plant-, seaweed-, and insect-based foods as alternatives to meat: A critical compilation of a decade of research. Crit. Rev. Food Sci. Nutr. 2023, 62, 6630–6651. [Google Scholar] [CrossRef]

- Mishyna, M.; Keppler, J.K.; Chen, J. Techno-functional properties of edible insect proteins and effects of processing. Curr. Opin. Colloid Interface Sci. 2021, 56, 101508. [Google Scholar] [CrossRef]

- Cavalheiro, C.P.; Ruiz-Capillas, C.; Herrero, A.M.; Pintado, T.; Cruz, T.M.P.; Silva, M.C.A. Cricket (Acheta domesticus) flour as meat replacer in frankfurters: Nutritional, technological, structural, and sensory characteristics. Innov. Food Sci. Emerg. Technol. 2022, 83, 103245. [Google Scholar] [CrossRef]

- Kim, H.W.; Setyabrata, D.; Lee, Y.; Jones, O.G.; Kim, Y.H.B. Pre-treated mealworm larvae and silkworm pupae as a novel protein ingredient in emulsion sausages. Innov. Food Sci. Emerg. Technol. 2016, 38, 116–123. [Google Scholar] [CrossRef]

- Scholliers, J.; Steen, L.; Fraeye, I. Partial replacement of meat by superworm (Zophobas morio larvae) in cooked sausages: Effect of heating temperature and insect:Meat ratio on structure and physical stability. Innov. Food Sci. Emerg. Technol. 2020, 66, 102535. [Google Scholar] [CrossRef]

- Zhang, F.; Cao, C.; Kong, B.; Sun, F.; Shen, X.; Yao, X.; Liu, Q. Pre-dried mealworm larvae flour could partially replace lean meat in frankfurters: Effect of pre-drying methods and replacement ratios. Meat Sci. 2022, 188, 108802. [Google Scholar] [CrossRef]

- Cruz-López, S.O.; Álvarez-Cisneros, Y.M.; Domínguez-Soberanes, J.; Escalona-Buendía, H.B.; Sánchez, C.N. Physicochemical and sensory characteristics of sausages made with grasshopper (Sphenarium purpurascens) flour. Foods 2022, 11, 704. [Google Scholar] [CrossRef] [PubMed]

- European Union (EU). Regulation (EU) 2022/188 of 10 February 2022 authorizing the placing on the market of frozen, dried and powder forms of Acheta domesticus as a novel food under Regulation (EU) 2015/2283 of the European Parliament and of the Council, and amending Commission Implementing Regulation (EU) 2017/2470. 2022. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32022R0188&qid=1705256358189 (accessed on 28 November 2023).

- Lähteenmäki-Uutela, A.; Grmelová, N.; Hénault-Ethier, L.; Deschamps, M.-H.; Vandenberg, G.W.; Ai, Z.; Zhang, Y.; Baoru, Y.; Nemane, V. Insects as food and feed: Laws of the European Union, United Stated, Canada, Mexico, Australia, and China. Eur. Food Feed Law Rev. 2017, 12, 22–36. [Google Scholar]

- Lähteenmkäki-Uutela, A.; Marimuthu, S.B.; Meijer, N. Regulations on insects as food and feed: A global comparison. J. Insects as Food Feed 2021, 7, 849–856. [Google Scholar] [CrossRef]

- Larouce, J.; Campbell, B.; Hénault-Éthier, L.; Banks, I.J.; Tomberlin, J.K.; Preyer, C.; Deschamps, M.-H.; Vandenberg, G.W. The edible insec sector in Canada and the United States. Anim. Front. 2023, 13, 16–25. [Google Scholar] [CrossRef]

- Government of Canada. List of Non-Novel Determinations for Food and Food Ingredients; Government of Canada: Ottawa, ON, Canada, 2022. [Google Scholar]

- Brogan, E.N.; Park, Y.L.; Matak, K.E.; Jaczynski, J. Characterization of protein in cricket (Acheta domesticus), locust (Locusta migratoria), and silkworm pupae (Bombyx mori) insect powders. LWT 2018, 152, 112314. [Google Scholar] [CrossRef]

- Pilco-Romero, G.; Chisaguano-Tonato, A.M.; Herrera-Fontana, M.E.; Chimbo-Gándara, L.F.; Sharifi-Rad, M.; Giampieri, F.; Battino, M.; Vernaza, M.G.; Álvarez-Suárez, J.M. House cricket (Acheta domesticus): A review based on its nutritional composition, quality, and potential uses in the foods industry. Trends Food Sci. Technol. 2023, 142, 104226. [Google Scholar] [CrossRef]

- Kim, H.W.; Setyabrata, D.; Lee, Y.; Jones, O.G.; Kim, Y.H.B. Effect of house cricket (Acheta domesticus) flour addition on physicochemical and textural properties of meat emulsion under various formulations. J. Food Sci. 2017, 82, 2787–2793. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 18th ed.; Association of Official Analytical Chemistry: Rockville, MA, USA, 2005. [Google Scholar]

- Bligh, E.G.; Dyer, W.J.A. Rapid method of total lipid extraction and purification. Can. J. Biochem. Physiol. 1959, 37, 911–917. [Google Scholar] [CrossRef]

- Pematilleke, N.; Kaur, M.; Rai Wai, C.T.; Adhikari, B.; Torley, P.J. Effect of the addition of hydrocolloids on beef texture: Targeted to the needs of people with dysphagia. Food Hydrocol. 2021, 113, 106413. [Google Scholar] [CrossRef]

- Vermeiren, L.; Devlieghere, F.; De Graef, V.; Debevere, J. In vitro and in situ growth characteristics and behaviour of spoilage organisms associated with anaerobically stored cooked meat products. J. Appl. Microbiol. 2005, 98, 33–42. [Google Scholar] [CrossRef]

- Ververis, E.; Boué, G.; Poulsen, M.; Pires, S.M.; Niforou, A.; Thomsen, S.T.; Tesson, V.; Federighi, M.; Naska, A. A systematic review of the nutrient composition, microbiological and toxicological profile of Acheta domesticus (house cricket). J. Food Compos. Anal. 2022, 114, 104859. [Google Scholar] [CrossRef]

- Kumar, P.; Mehta, N.; Abubakar, A.A.; Verma, A.K.; Kaka, U.; Sharma, N.; Sazili, A.Q.; Pateiro, M.; Kumar, M.; Lorenzo, J.M. Potential alternatives of animal proteins for sustainability in the food sector. Food Rev. Int. 2023, 39, 5703–5728. [Google Scholar] [CrossRef]

- Gomes Martins, V.M.; Milano, P.; Pollonio, M.A.R.; dos Santos, M.; de Oliveira, A.P.; Savay-da-Silva, L.K.; Câmara, A.K.F.I.; Paglarini, C.S. Adding cricket (Gryllus assimilis) flour in hybrid beef patties: Physicochemical, technological and sensory challenges. Int. J. Food Sci. Technol. 2024, 59, 450–459. [Google Scholar] [CrossRef]

- Fiebelkorn, F.; Dupont, J.; Lammers, P. Acceptance of insects and in vitro meat as a sustainable meat substitute in Germany: In search of the decisive nutritional-psychological factors. In Bioeconomy and Sustainability; Lanzerath, D., Schurr, U., Pinsdorf, C., Stake, M., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 77–92. [Google Scholar]

- McClements, D.J. Bug meat: Assembling meat from insects. In Meat Less: The Next Food Revolution; Copernicus Books; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 185–212. [Google Scholar]

- Sánchez-Zapata, E.; Pérez-Alvarez, J.A.; Fernández-López, J. Effects of tiger nut (Cyperus esculentus) milk liquid co-products on the quality of pork burgers. Int. J. Food Sci. Technol. 2012, 47, 2198–2204. [Google Scholar] [CrossRef]

- Afshari, R.; Hosseini, H.; Khaksar, R.; Mohammadifar, M.A.; Amiri, Z.; Komelli, R.; Khaneghah, A.M. Investigation of the effects of inulin and β-glucan on the physical and sensory properties of low-fat beef burgers containing vegetable oils: Optimization of the formulation using D-optimal mixture design. Food Technol. Biotechnol. 2015, 53, 436–445. [Google Scholar] [CrossRef]

- Belucci, E.R.B.; dos Santos, J.M.; Carvalho, L.T.; Borgonovi, T.F.; Lorenzo, J.M.; da Silva-Barretto, A.C. Açaí extract powder as natural antioxidant on pork patties during the refrigerated storage. Meat Sci. 2022, 184, 108667. [Google Scholar] [CrossRef] [PubMed]

- Al-Juhaimi, F.; Babtain, I.A.; Mohamed Ahmed, I.A.; Alsawmahi, O.N.; Ghafoor, K.; Adiamo, O.Q.; Babiker, E.E. Assessment of oxidative and physicochemical, microbiological, and sensory properties of beef patties formulated with baobab seed (Adansonia digitata) extract. Meat Sci. 2020, 162, 108044. [Google Scholar] [CrossRef]

- Choi, Y.S.; Kim, T.K.; Choi, H.D.; Park, J.D.; Sung, J.M.; Jeon, K.H.; Paik, H.D.; Kim, Y.B. Optimization of replacing pork meat with yellow worm (Tenebrio molitor) for frankfurters. Korean J. Food Sci. Anim. Resour. 2020, 37, 617–625. [Google Scholar] [CrossRef]

- Kim, T.K.; Lee, M.Y.; Yong, H.I.; Jung, S.; Paik, H.D.; Jang, H.W.; Choi, Y.S. Effect of interaction between mealworm protein and myofibrillar protein on the rheological properties and thermal stability of the prepared emulsion systems. Foods 2020, 9, 1443. [Google Scholar] [CrossRef]

- Parvin, R.; Seo, J.K.; Eom, J.U.; Ahamed, Z.; Yang, H.S. Inhibitory and antioxidative capacity of nutmeg extracts on reduction of lipid oxidation and heterocyclic amines in pan-roasted beef patties. Meat Sci. 2023, 197, 109064. [Google Scholar] [CrossRef]

- Park, Y.S.; Choi, Y.S.; Hwang, K.E.; Kim, T.K.; Lee, C.W.; Shin, D.M.; Han, S.G. Physicochemical properties of meat batter added with edible silkworm pupae (Bombyx mori) and transglutaminase. Korean J. Food Sci. Anim. Res. 2017, 37, 351–359. [Google Scholar] [CrossRef]

- Youssef, M.K.; Barbut, S.; Smith, A. Effects of pre-emulsifying fat/oil on meat batter stability, texture and microstructure. Int. J Food Sci. Technol. 2011, 46, 1216–1224. [Google Scholar] [CrossRef]

- Kim, T.K.; Yong, H.I.; Jung, S.; Sung, J.M.; Jang, H.W.; Choi, Y.S. Physicochemical and textural properties of emulsion prepared from the larvae of the edible insects Tenebrio molitor, Allomyrina dichotona, and Protaetia brevitarsis seulensis. J. Anim. Sci. Technol. 2021, 63, 417–425. [Google Scholar] [CrossRef]

- Freire, M.; Cofrades, S.; Serrano-Casas, V.; Pintado, T.; Jimenez, M.J.; Jiménez-Colmenero, F. Gelled double emulsions as delivery systems for hydroxytyrosol and n-3 fatty acids in healthy pork patties. J. Food Sci. Technol. 2017, 54, 3959–3968. [Google Scholar] [CrossRef] [PubMed]

- Nardoia, M.; Ruiz-Capillas, C.; Casamassima, D.; Herrero, A.M.; Pintado, T.; Jiménez-Colmenero, F.; Chamorro, S.; Brenes, A. Effect of polyphenols dietary grape by-products on chicken patties. Eur. Food Res. Technol. 2017, 244, 367–377. [Google Scholar] [CrossRef]

| Parameter | Treatments | |||

|---|---|---|---|---|

| Control | CF5.0 | CF7.5 | CF10.0 | |

| Moisture | 68.05 ± 0.20 a | 65.39 ± 0.03 b | 64.94 ± 0.04 b | 62.87 ± 0.17 c |

| Protein | 19.53 ± 0.03 d | 21.82 ± 0.08 c | 22.70 ± 0.14 b | 23.68 ± 0.04 a |

| Fat | 8.54 ± 0.16 a | 8.79 ± 0.20 a | 9.09 ± 0.21 a | 9.20 ± 0.14 a |

| Microorganisms | Treatments | |||

|---|---|---|---|---|

| Control | CF5.0 | CF7.5 | CF10.0 | |

| Total viable count | 4.59 ± 0.12 c | 6.36 ± 0.07 ab | 6.23 ± 0.00 b | 6.62 ± 0.00 a |

| Lactic acid bacteria | 3.95 ± 0.02 b | 4.24 ± 0.17 ab | 4.21 ± 0.02 ab | 4.37 ± 0.03 a |

| Enterobacteriaceae | 1.73 ± 0.16 a | 1.77 ± 0.10 a | 1.75 ± 0.21 a | 1.94 ± 0.33 a |

| Parameters | Cooking | Treatments | |||

|---|---|---|---|---|---|

| Control | CF5.0 | CF7.5 | CF10.0 | ||

| Lightness | Raw | 61.05 ± 1.10 a,A | 52.99 ± 1.35 b,A | 49.75 ± 1.47 c,A | 47.71 ± 1.60 c,A |

| Cooked | 55.97 ± 2.84 a,B | 50.32 ± 1.78 b,B | 50.11 ± 2.42 b,A | 48.40 ± 0.48 b,A | |

| Redness | Raw | 3.62 ± 0.34 a,B | 3.08 ± 0.37 b,B | 3.20 ± 0.16 a,b,B | 2.78 ± 0.31 b,B |

| Cooked | 5.26 ± 1.06 a,A | 5.15 ± 0.54 a,A | 4.55 ± 0.71 a,A | 4.28 ± 0.30 a,A | |

| Yellowness | Raw | 9.80 ± 0.73 a,B | 7.74 ± 0.84 b,A | 7.63 ± 0.75 b,A | 6.94 ± 0.94 b,A |

| Cooked | 11.77 ± 1.21 a,A | 6.61 ± 0.68 b,B | 4.71 ± 0.75 c,B | 4.19 ± 0.89 c,B | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasqualin Cavalheiro, C.; Ruiz-Capillas, C.; Herrero, A.M.; Pintado, T.; Avelar de Sousa, C.C.; Sant’Ana Falcão Leite, J.; Costa Alves da Silva, M. Potential of Cricket (Acheta domesticus) Flour as a Lean Meat Replacer in the Development of Beef Patties. Foods 2024, 13, 286. https://doi.org/10.3390/foods13020286

Pasqualin Cavalheiro C, Ruiz-Capillas C, Herrero AM, Pintado T, Avelar de Sousa CC, Sant’Ana Falcão Leite J, Costa Alves da Silva M. Potential of Cricket (Acheta domesticus) Flour as a Lean Meat Replacer in the Development of Beef Patties. Foods. 2024; 13(2):286. https://doi.org/10.3390/foods13020286

Chicago/Turabian StylePasqualin Cavalheiro, Carlos, Claudia Ruiz-Capillas, Ana M. Herrero, Tatiana Pintado, Camila Cristina Avelar de Sousa, Juliana Sant’Ana Falcão Leite, and Maurício Costa Alves da Silva. 2024. "Potential of Cricket (Acheta domesticus) Flour as a Lean Meat Replacer in the Development of Beef Patties" Foods 13, no. 2: 286. https://doi.org/10.3390/foods13020286

APA StylePasqualin Cavalheiro, C., Ruiz-Capillas, C., Herrero, A. M., Pintado, T., Avelar de Sousa, C. C., Sant’Ana Falcão Leite, J., & Costa Alves da Silva, M. (2024). Potential of Cricket (Acheta domesticus) Flour as a Lean Meat Replacer in the Development of Beef Patties. Foods, 13(2), 286. https://doi.org/10.3390/foods13020286