Study on the Diffusion and Optimization of Sucrose in Gaido Seak Based on Finite Element Analysis and Hyperspectral Imaging Technology

Abstract

1. Introduction

2. Materials and Methods

2.1. Biological and Chemical Materials

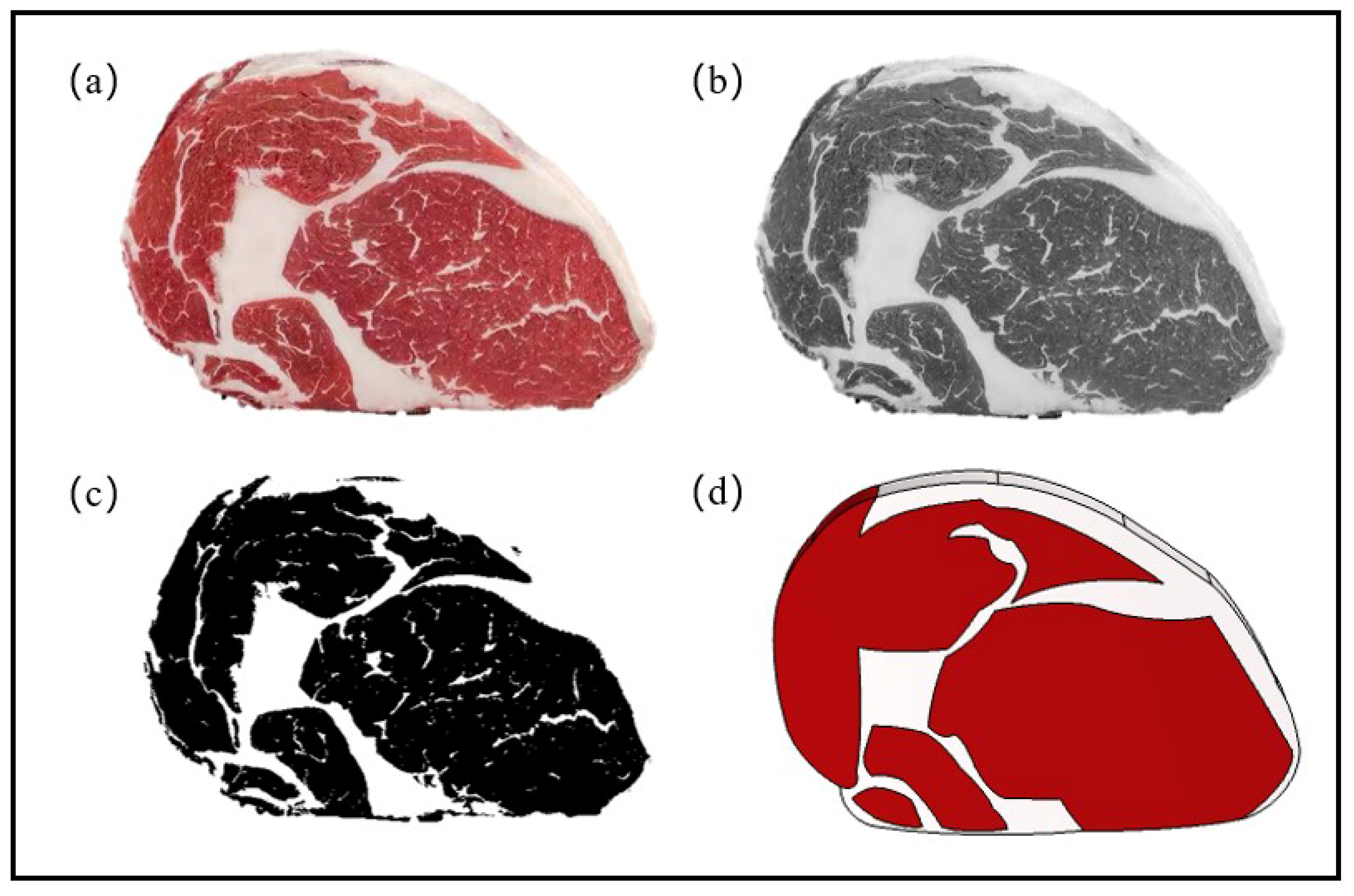

2.2. Building a 3-Dimensional Model of Beef

2.3. Finite Element Analysis

2.3.1. Determining the Physical Field and the Diffusion Equation

2.3.2. Materials for Simulation Models and Simulation Model Assumptions

- (1)

- The shape of the model constructed by image binarization remains regular during the simulation

- (2)

- The temperature is constant throughout the marinating process

- (3)

- The concentration of marinade in all tissues of the whole beef at the start of the marination is 0

- (4)

- Only the transfer of marinade between muscle and fat tissues is considered

- (5)

- Ignoring the change in tissue structure and diffusion coefficient of the beef by marinade concentration

- (6)

- Ignore the effect of physical fields other than dilute material transfer on marination

- (1)

- Start COMSOL Multiphysics 5.6 with MATLAB software and invoke the Rare Matter Transfer module

- (2)

- Import the steak model from MATLAB and optimize its edges

- (3)

- Set material-related properties for the different tissue parts

- (4)

- Divide the mesh and define the inflow surface of the marinade

- (5)

- Set initial and boundary conditions for the model

- (6)

- Set the solution step according to the simulated marinating time and solve for the transient process

- (7)

- Analysis of simulation results and post-processing of results

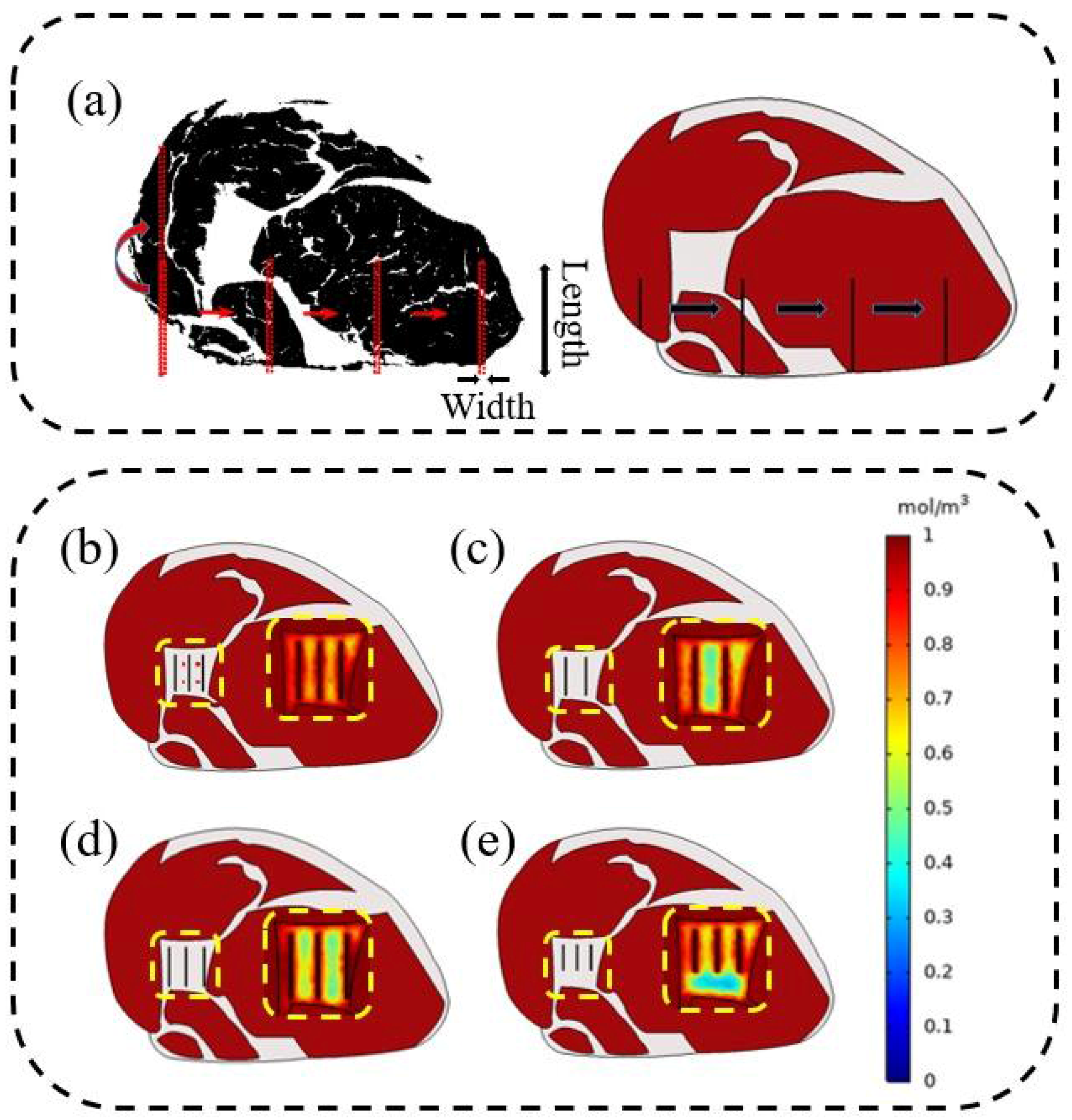

2.3.3. Optimization of Gaidao Parameters

2.4. Steak Marinated in Sucrose Solution

2.5. Hyperspectral Acquisition and Processing

2.5.1. Hyperspectral Imaging Systems

2.5.2. Hyperspectral Data Acquisition and Extraction

2.5.3. Sucrose Concentration Detection

2.5.4. Visualization of Sucrose Content

3. Results and Discussion

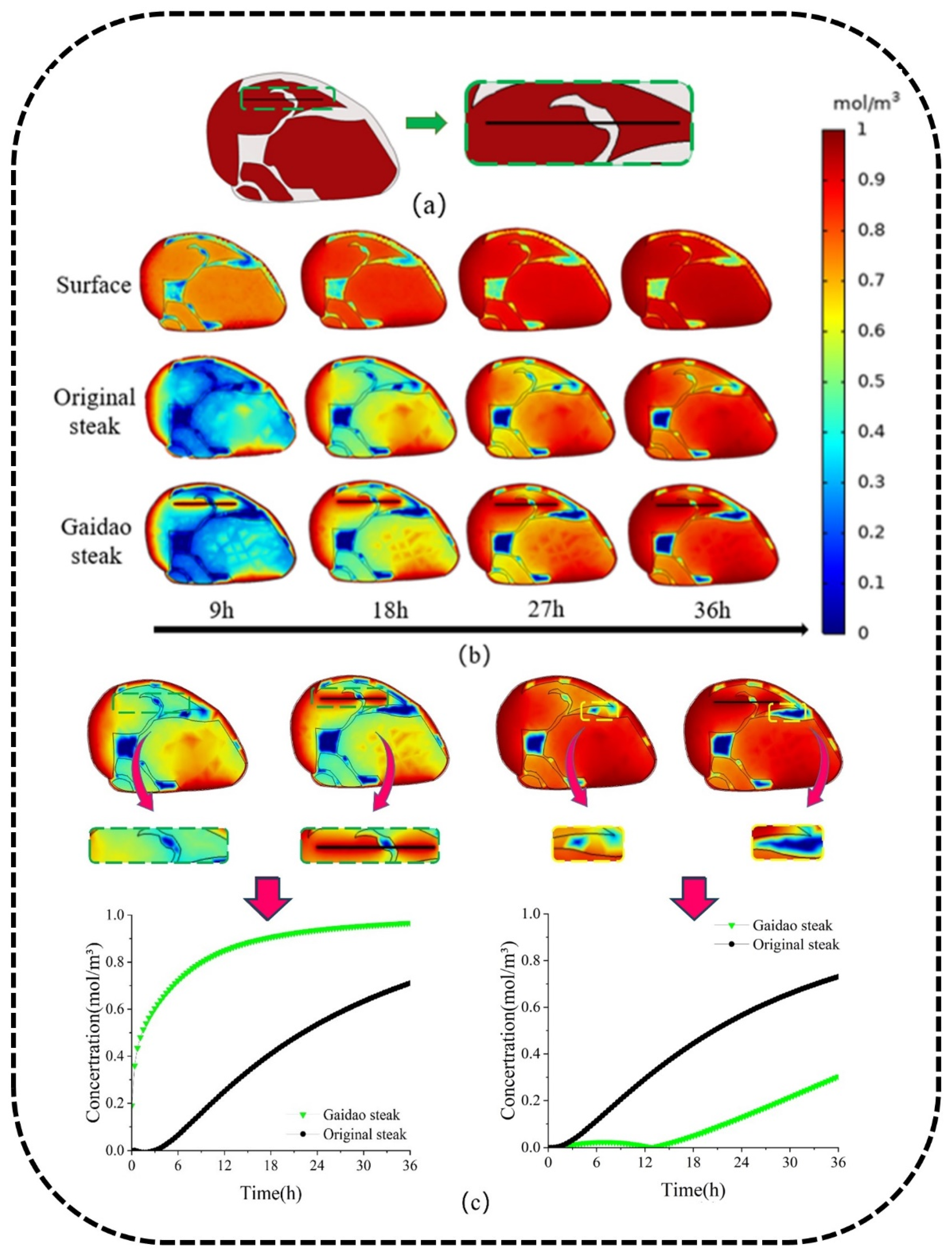

3.1. Steak Model Marinade Simulation

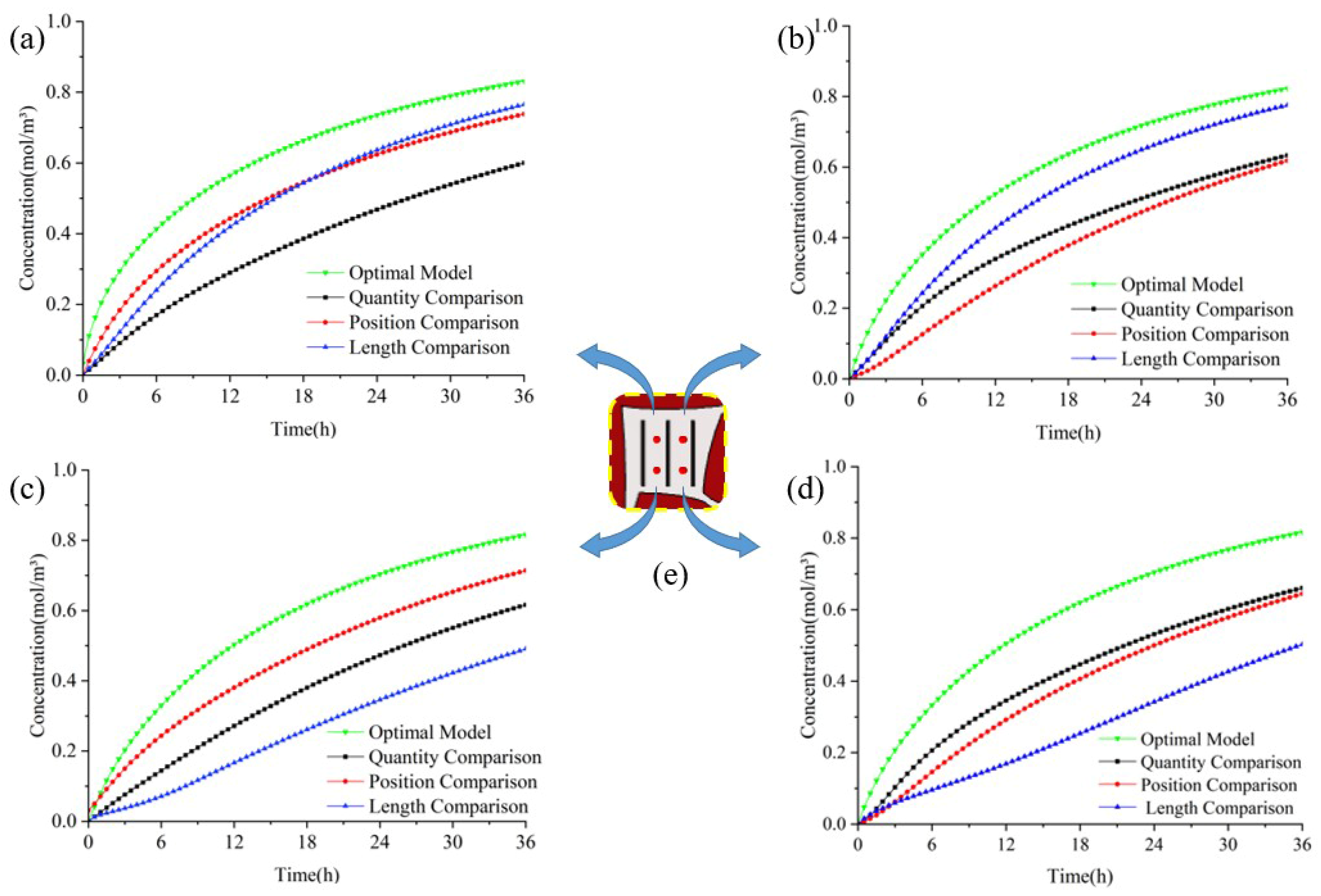

3.2. Optimization of Gaidao Parameters

3.3. Spectroscopic Data Analysis

3.4. Outlier Filtering

3.5. Constructing a Quantitative Model for Sucrose

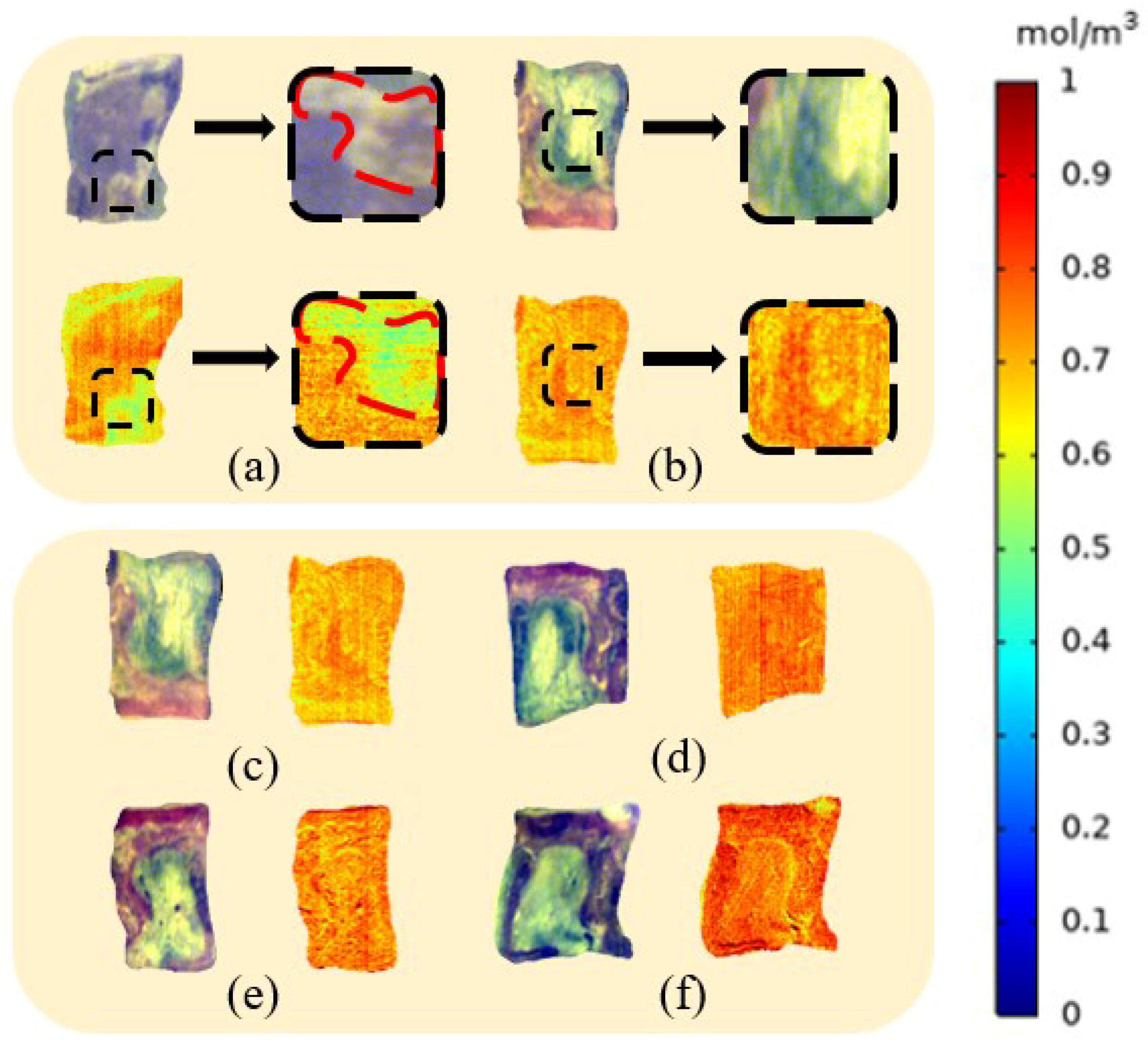

3.6. Visualization Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lebert, A.; Daudin, J.D. Modelling the distribution of a(w), pH and ions in marinated beef meat. Meat Sci. 2014, 97, 347–357. [Google Scholar] [CrossRef]

- Fulladosa, E.; Guerrero, L.; Illana, A.; Olmos, A.; Coll-Brasas, E.; Gou, P.; Munoz, I.; Arnau, J. Instrumental texture analysis on the surface of dry-cured ham to define the end of the process. Meat Sci. 2021, 172, 108334. [Google Scholar] [CrossRef] [PubMed]

- Figueroa, C.; Ramírez, C.; Núñez, H.; Jaques, A.; Simpson, R. Application of vacuum impregnation and CO2-laser microperforations in the potential acceleration of the pork marinating process. Innov. Food Sci. Emerg. Technol. 2020, 66, 102500. [Google Scholar] [CrossRef]

- Yang, Y.; Ye, Y.; Wang, Y.; Sun, Y.; Pan, D.; Cao, J. Effect of high pressure treatment on metabolite profile of marinated meat in soy sauce. Food Chem. 2018, 240, 662–669. [Google Scholar] [CrossRef] [PubMed]

- Shi, H.; Zhang, X.; Chen, X.; Fang, R.; Zou, Y.; Wang, D.; Xu, W. How ultrasound combined with potassium alginate marination tenderizes old chicken breast meat: Possible mechanisms from tissue to protein. Food Chem. 2020, 328, 127144. [Google Scholar] [CrossRef] [PubMed]

- Cropotova, J.; Tappi, S.; Genovese, J.; Rocculi, P.; Laghi, L.; Dalla Rosa, M.; Rustad, T. Study of the influence of pulsed electric field pre-treatment on quality parameters of sea bass during brine salting. Innov. Food Sci. Emerg. Technol. 2021, 70, 102706. [Google Scholar] [CrossRef]

- Zhu, C.; Yin, F.; Tian, W.; Zhu, Y.; Zhao, L.; Zhao, G. Application of a pressure-transform tumbling assisted curing technique for improving the tenderness of restructured pork chops. LWT 2019, 111, 125–132. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.J.; Berry, T.M.; Ambaw, A.; Opara, U.L. The efficacy of finite element analysis (FEA) as a design tool for food packaging: A review. Biosyst. Eng. 2018, 174, 20–40. [Google Scholar] [CrossRef]

- Qin, J.; Chao, K.; Kim, M.S.; Lu, R.; Burks, T.F. Hyperspectral and multispectral imaging for evaluating food safety and quality. J. Food Eng. 2013, 118, 157–171. [Google Scholar] [CrossRef]

- Sarkar, S.; Singh, I.V.; Mishra, B.K. A simple and efficient implementation of localizing gradient damage method in COMSOL for fracture simulation. Eng. Fract. Mech. 2022, 269, 108552. [Google Scholar] [CrossRef]

- Jafari, A.; Broumand, P.; Vahab, M.; Khalili, N. An eXtended Finite Element Method implementation in COMSOL Multiphysics: Solid Mechanics. Finite Elem. Anal. Des. 2022, 202, 103707. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Y.; Hu, X.; Li, Z.; Huang, X.; Liang, J.; Zhang, X.; Zhang, D.; Zou, X.; Shi, J. Quantitative characterization of the diffusion behavior of sucrose in marinated beef by HSI and FEA. Meat Sci. 2023, 195, 109002. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Wang, Y.; Shi, J.; Li, Z.; Huang, X.; Liang, J.; Zhang, X.; Zhang, D.; Zou, X.; Hu, X. Simulation of diffusion behavior of NaCl in multi-tissue beef marination process. Food Chem. 2023, 402, 134164. [Google Scholar] [CrossRef]

- Liu, Y.; Dixit, Y.; Reis, M.M.; Prabakar, S. Towards the non-invasive assessment of staling in bovine hides with hyperspectral imaging. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2023, 289, 122220. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Li, Y.; Wei, W.; Peng, Y. Detection of adulteration with duck meat in minced lamb meat by using visible near-infrared hyperspectral imaging. Meat Sci. 2019, 149, 55–62. [Google Scholar] [CrossRef]

- Tang, X.; Rao, L.; Xie, L.; Yan, M.; Chen, Z.; Liu, S.; Chen, L.; Xiao, S.; Ding, N.; Zhang, Z.; et al. Quantification and visualization of meat quality traits in pork using hyperspectral imaging. Meat Sci. 2023, 196, 109052. [Google Scholar] [CrossRef]

- He, H.J.; Wang, Y.; Wang, Y.; Liu, H.; Zhang, M.; Ou, X. Simultaneous quantifying and visualizing moisture, ash and protein distribution in sweet potato [Ipomoea batatas (L.) Lam] by NIR hyperspectral imaging. Food Chem. X 2023, 18, 100631. [Google Scholar] [CrossRef]

- Hashim, F.A.; Mostafa, R.R.; Hussien, A.G.; Mirjalili, S.; Sallam, K.M. Fick’s Law Algorithm: A physical law-based algorithm for numerical optimization. Knowl.-Based Syst. 2023, 260, 110146. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, R.; Wen, Q.-H.; Rahaman, A.; Zeng, X.-A. Effects of pulsed electric field pretreatment on mass transfer and quality of beef during marination process. Innov. Food Sci. Emerg. Technol. 2022, 80, 103061. [Google Scholar] [CrossRef]

- Nunez, H.; Cavada, G.; Ramirez, C.; Moreno, J.; Cornejo, G.; Jaques, A.; Pinto, M.; Vega, O.; Simpson, R. Effect of a moderate electric field on the salting of Atlantic Salmon (Salmo salar): An experimental study and phenomenological understanding. Food Res. Int. 2020, 137, 109475. [Google Scholar] [CrossRef]

- Dimakopoulou-Papazoglou, D.; Katsanidis, E. Diffusion coefficients and volume changes of beef meat during osmotic dehydration in binary and ternary solutions. Food Bioprod. Process. 2019, 116, 10–19. [Google Scholar] [CrossRef]

- Anderssen, K.E.; Stormo, S.K.; Skåra, T.; Skjelvareid, M.H.; Heia, K. Predicting liquid loss of frozen and thawed cod from hyperspectral imaging. LWT 2020, 133, 110093. [Google Scholar] [CrossRef]

- Yang, W.; Xiong, Y.; Xu, Z.; Li, L.; Du, Y. Piecewise preprocessing of near-infrared spectra for improving prediction ability of a PLS model. Infrared Phys. Technol. 2022, 126, 104359. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Zhang, Y.; Qi, H.; Yang, X.; Wang, Q.; Li, D. Quantitative analysis of the oil mixture using PLS combined with spectroscopy detection. Optik 2021, 244, 167611. [Google Scholar] [CrossRef]

- Saidi, F.; Khetari, S.; Yahia, I.S.; Zahran, H.Y.; Hidouri, T.; Ameur, N. The use of principal component analysis (PCA) and partial least square (PLS) for designing new hard inverse perovskites materials. Comput. Condens. Matter 2022, 31, e00667. [Google Scholar] [CrossRef]

- Da Silva, D.J.; Wiebeck, H. Using PLS, iPLS and siPLS linear regressions to determine the composition of LDPE/HDPE blends: A comparison between confocal Raman and ATR-FTIR spectroscopies. Vib. Spectrosc. 2017, 92, 259–266. [Google Scholar] [CrossRef]

- Duarte, L.M.; Paschoal, D.; Izumi CM, S.; Dolzan, M.D.; Alves, V.R.; Micke, G.A.; Dos Santos, H.F.; de Oliveira MA, L. Simultaneous determination of aspartame, cyclamate, saccharin and acesulfame-K in powder tabletop sweeteners by FT-Raman spectroscopy associated with the multivariate calibration: PLS, iPLS and siPLS models were compared. Food Res. Int. 2017, 99 Pt 1, 106–114. [Google Scholar] [CrossRef]

| Raw | 1st-Der | 2nd-Der | SG | SNVT | MSC | ||

|---|---|---|---|---|---|---|---|

| BiPLS | PLS factors | 11 | 17 | 12 | 18 | 16 | 20 |

| Interval | {22 24 18 21} | {18 11 13 19} | {17 13 14 20} | {10 16 13 14} | {14 7 22 21} | {13 14 12 20} | |

| 0.94 | 0.93 | 0.93 | 0.94 | 0.94 | 0.94 | ||

| RMSEC | 2.51 | 2.6 | 2.72 | 2.56 | 2.51 | 2.50 | |

| 0.93 | 0.93 | 0.88 | 0.94 | 0.91 | 0.93 | ||

| RMSEP | 2.68 | 2.75 | 3.52 | 2.72 | 3.06 | 2.73 | |

| iPLS | PLS factors | 8 | 8 | 7 | 11 | 6 | 5 |

| Interval | {14} | {14} | {14} | {14} | {20} | {14} | |

| 0.84 | 0.83 | 0.82 | 0.85 | 0.78 | 0.77 | ||

| RMSEC | 4.09 | 4.08 | 4.21 | 3.96 | 4.61 | 4.7 | |

| 0.82 | 0.82 | 0.80 | 0.83 | 0.76 | 0.75 | ||

| RMSEP | 4.33 | 4.31 | 4.51 | 4.15 | 4.82 | 4.99 | |

| PLS | PLS factors | {15} | {13} | {15} | {15} | {15} | {15} |

| 0.89 | 0.93 | 0.91 | 0.89 | 0.89 | 0.89 | ||

| RMSEC | 3.28 | 2.73 | 3.00 | 3.29 | 3.41 | 3.44 | |

| 0.91 | 0.92 | 0.91 | 0.91 | 0.89 | 0.89 | ||

| RMSEP | 3.17 | 2.83 | 3.10 | 3.22 | 3.33 | 3.41 | |

| SiPLS | PLS factors | 11 | 15 | 11 | 10 | 13 | 13 |

| Interval | {14 17 18 20} | {13 14 16 19} | {13 14 17 20} | {14 17 18 20} | {8 13 17 20} | {8 13 17 20} | |

| 0.94 | 0.94 | 0.93 | 0.93 | 0.94 | 0.94 | ||

| RMSEC | 2.49 | 2.54 | 2.71 | 2.65 | 2.48 | 2.48 | |

| 0.93 | 0.91 | 0.88 | 0.92 | 0.90 | 0.89 | ||

| RMSEP | 2.73 | 3.06 | 3.56 | 2.90 | 3.38 | 3.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Shi, Y.; Huang, X.; Li, Z.; Zhang, X.; Zou, X.; Hu, X.; Shi, J. Study on the Diffusion and Optimization of Sucrose in Gaido Seak Based on Finite Element Analysis and Hyperspectral Imaging Technology. Foods 2024, 13, 249. https://doi.org/10.3390/foods13020249

Li W, Shi Y, Huang X, Li Z, Zhang X, Zou X, Hu X, Shi J. Study on the Diffusion and Optimization of Sucrose in Gaido Seak Based on Finite Element Analysis and Hyperspectral Imaging Technology. Foods. 2024; 13(2):249. https://doi.org/10.3390/foods13020249

Chicago/Turabian StyleLi, Wenlong, Yu Shi, Xiaowei Huang, Zhihua Li, Xinai Zhang, Xiaobo Zou, Xuetao Hu, and Jiyong Shi. 2024. "Study on the Diffusion and Optimization of Sucrose in Gaido Seak Based on Finite Element Analysis and Hyperspectral Imaging Technology" Foods 13, no. 2: 249. https://doi.org/10.3390/foods13020249

APA StyleLi, W., Shi, Y., Huang, X., Li, Z., Zhang, X., Zou, X., Hu, X., & Shi, J. (2024). Study on the Diffusion and Optimization of Sucrose in Gaido Seak Based on Finite Element Analysis and Hyperspectral Imaging Technology. Foods, 13(2), 249. https://doi.org/10.3390/foods13020249