Effect of the Addition of Soybean Protein and Insect Flours on the Quality of Cooked Sausages

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Formulation and Manufacturing of the Cooked Sausages

2.3. Laboratory Analyses

2.3.1. pH and Colour Measurements of the Raw Batter and Cooked Sausages

2.3.2. Emulsion Stability

2.3.3. Texture Analysis

- K—constant of the tip (k = 1.853)

- F—weight of the holder system, g (107.8)

- h—depth, cm

- K—constant of the tip (k = 1.853)

- F—weight of the holder system, g (103.8)

- h—depth, cm

- h—recorded depth, cm

- h1—depth recorded after 60 s of rest, cm.

2.3.4. Proximate Composition of the Cooked Sausages

2.3.5. Acid Value

- V—volume of KOH used for titration, g

- F—factor of 0.1 NKOH, 0.996

- m—the weight of the sample, g.

2.3.6. Peroxide Value (PV)

2.3.7. TBARS Content

2.3.8. Sensory Analysis

2.3.9. Statistical Procedures

3. Results

3.1. Technological Characteristics of the Batter

3.1.1. pH and Instrumental Colour of the Batter

3.1.2. Stability and Texture Profile of the Batter

3.2. Proximate Composition of the Cooked Sausages

3.3. Technological Parameters of the Cooked Sausages

3.3.1. pH and Instrumental Colour

3.3.2. Texture Profile

3.3.3. Changes in Lipid Stability

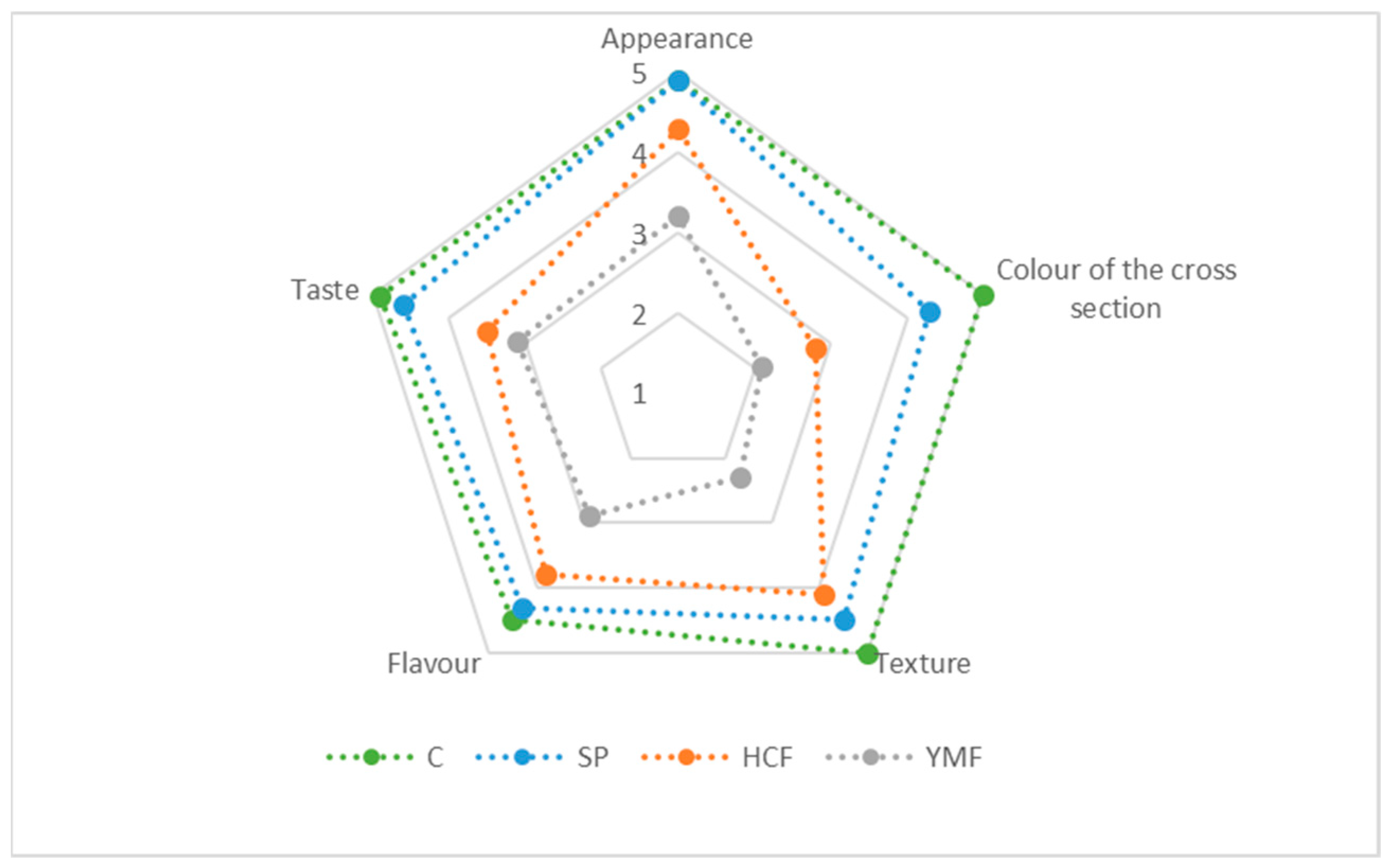

3.3.4. Sensory Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Population, United Nations. Available online: https://www.un.org/en/global-issues/population (accessed on 12 April 2024).

- Omuse, E.R.; Tonnang, H.E.Z.; Yusuf, A.A.; Machekano, H.; Egonyu, J.P.; Kimathi, E.; Mohamed, S.F.; Kassie, M.; Subramanian, S.; Onditi, J.; et al. The global atlas of edible insects: Analysis of diversity and commonality contributing to food systems and sustainability. Sci. Rep. 2024, 14, 5045. [Google Scholar] [CrossRef] [PubMed]

- Papastavropoulou, K.; Xiao, J.; Proestos, C. Edible insects: Tendency or necessity (a review). eFood 2023, 4, 58. [Google Scholar] [CrossRef]

- Olivadese, M.; Dindo, M.L. Edible Insects: A historical and cultural perspective on entomophagy with a focus on western societies. Insects 2023, 14, 690. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, S.A.; Osei-Owusu, J.; Yunusa, B.M.; Rahayu, T.; Fernando, I.; Shah, M.A.; Centoducati, G. Prospects of edible insects as sustainable protein for food and feed—A review. J. Insects Food Feed 2023, 10, 191–217. [Google Scholar] [CrossRef]

- Van Huis, A. Edible insects: Challenges and prospects. Entomol. Res. 2022, 52, 161–177. [Google Scholar] [CrossRef]

- Hammer, L.; Moretti, D.; Abbühl-Eng, L.; Kandiah, P.; Hilaj, N.; Portmann, R.; Egger, L. Mealworm larvae (Tenebrio molitor) and crickets (Acheta domesticus) show high total protein in vitro digestibility and can provide good-to-excellent protein quality as determined by in vitro DIAAS. Front. Nutr. 2023, 10, 1150581. [Google Scholar] [CrossRef] [PubMed]

- Bradbury, K.E.; Tong, T.Y.N.; Key, T.J. Dietary intake of high-protein foods and other major foods in meat-eaters, poultry-eaters, fish-eaters, vegetarians, and vegans in UK biobank. Nutrients 2017, 9, 1317. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Li, B.; Puolanne, E.; Heinonen, M. Hybrid sausages using pork and cricket flour: Texture and oxidative storage stability. Foods 2023, 12, 1262. [Google Scholar] [CrossRef]

- Zhang, F.; Li, X.; Liang, X.; Kong, B.; Sun, F.; Cao, C.; Gong, H.; Zhang, H.; Lui, Q. Feasibility of Tenebrio molitor larvae protein to partially replace lean meat in the processing of hybrid frankfurters: Perspectives on quality profiles and in vitro digestibility. Food Res. Int. 2024, 176, 113846. [Google Scholar] [CrossRef] [PubMed]

- Ho, I.; Peterson, A.; Madden, J.; Huang, E.; Amin, S.; Lammert, A. Will it cricket? Product development and evaluation of cricket (Acheta domesticus) powder replacement in sausage, pasta, and brownies. Foods 2022, 11, 3128. [Google Scholar] [CrossRef] [PubMed]

- Kolev, N.; Vlahova-Vangelova, D.; Balev, D.; Gradinarska, D.; Dragoev, S. Quality characteristics of poultry meatballs with addition of cricket powder (Acheta domestica). J. Mount. Agric. Balk. 2022, 25, 15–32. [Google Scholar]

- Qin, P.; Wang, T.; Luo, Y. A review on plant-based proteins from soybean: Health benefits and soy product development. J. Agric. Food Res. 2022, 7, 100265. [Google Scholar] [CrossRef]

- Kang, K.M.; Lee, S.H.; Kim, H.Y. Effects of Using soybean protein emulsion as a meat substitute for chicken breast on physicochemical properties of Vienna sausage. Food Sci. Anim. Resour. 2022, 42, 73–83. [Google Scholar] [CrossRef] [PubMed]

- He, L.D.; Guo, X.N.; Zhu, K.X. Effect of soybean milk addition on the quality of frozen-cooked noodles. Food Hydrocoll. 2019, 87, 187–193. [Google Scholar] [CrossRef]

- Vlahova-Vangelova, D.; Balev, D.; Kolev, N.; Dragoev, S. Possibilities for partial replacement of pork meat in cooked sausages by mealworm flour. Carpathian J. Food Sci. Technol. 2023, 15, 5–14. [Google Scholar]

- Stanišić, N.; Parunović, N.; Petrović, M.; Radović, Č.; Lilić, S.; Stajić, S.; Gogić, M. Changes in chemical and physicochemical characteristics during the production of traditional Sremska sausage. Biotechnol. Anim. Husband. 2014, 30, 705–715. [Google Scholar] [CrossRef]

- Chen, H.H.; Chiu, E.M.; Huang, J.R. Color and gelforming properties of horse mackerel (Trachurus japonicus) asrelated to washing conditions. J. Food Sci. 1997, 62, 985–991. [Google Scholar] [CrossRef]

- Álvarez, D.; Delles, R.M.; Xiong, Y.L.; Castillo, M.; Payne, F.A.; Laencina, J. Influence of canola-olive oils, rice bran and walnut on functionality and emulsion stability of frankfurters. LWT-Food Sci. Technol. 2011, 44, 1435–1442. [Google Scholar] [CrossRef]

- Bourne, M.C. Food Textute and Viscosity. Concept and Measurement, 2nd ed.; A Volume if Food Science and Technology; Academic Press: Cambridge, MA, USA, 2002. [Google Scholar]

- Vassilev, K.; Balev, D.; Ivanov, G.; Yancova, Y.; Iliev, G. Effect of superchilling treatment and storage conditions on the technological properties of chicken breast meat. In Proceedings of the 59th Scientific Conference with International Participation Food Science, Engineering and Technology—2012 Scientific Works of University of Food Technologies, UFT, Plovdiv, Bulgaria, 19–20 October 2012; pp. 464–468. [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International. AOAC 984.13–1994 Protein (Crude) in Animal Feed and Pet Food; AOAC: Rockville, MD, USA, 1996. [Google Scholar]

- ISO 1444:1996; Meat and Meat Products—Determination of Free fat Content. ISO: Rome, Italy, 1996.

- Lenaerts, S.; Van Der Borght, M.; Callens, A.; Van Campenhout, L. Suitability of microwave drying for mealworms (Tenebrio molitor) as alternative to freeze drying: Impact on nutritional quality and colour. Food Chem. 2018, 254, 129–136. [Google Scholar] [CrossRef] [PubMed]

- Vandeweyer, D.; Lenaerts, S.; Callens, A.; Van Campenhout, L. Effect of blanching followed by refrigerated storage or industrial microwave drying on the microbial load of yellow mealworm larvae (Tenebrio molitor). Food Control 2017, 71, 311–314. [Google Scholar] [CrossRef]

- Kardash, E.; Tur’yan, Y.I. Acid value determination in vegetable oils by indirect titration in aqueous-alcohol media. Croat. Chem. Acta 2005, 78, 99–103. [Google Scholar]

- Bligh, E.G.; Dyer, W.J. A rapid method of total lipid extraction and purification. Can. J. Biochem. Physiol. 1959, 37, 911–917. [Google Scholar] [CrossRef] [PubMed]

- Shantha, N.C.; Decker, E.A. Rapid, sensitive, iron-based spectrophotometric methods for determination of peroxide values of food lipids. J. AOAC Int. 1994, 7, 421–424. [Google Scholar] [CrossRef]

- Botsoglou, N.A.; Fletouris, D.J.; Papageorgiou, G.E.; Vassilopoulos, V.N.; Mantis, A.J.; Trakatellis, A.G. Rapid, sensitive, and specific thiobarbituric acid method for measuring lipid peroxidation in animal tissue, food, and feedstuff samples. J. Agric. Food Chem. 1994, 42, 1931–1937. [Google Scholar] [CrossRef]

- Kolev, N.D.; Vlahova-Vangelova, D.B.; Balev, D.K.; Dragoev, S.G. Stabilization of oxidative processes in cooked sausages by optimization of incorporated biologically active substances. Carpathian J. Food Sci. Technol. 2022, 14, 180–188. [Google Scholar]

- Meilgaard, M.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques, 5th ed.; CRC Press: Boca Raton, FL, USA, 2016; p. 632. [Google Scholar]

- Sinkinson, C. Triangle test. In Discrimination Testing in Sensory Science: A Practical Handbook, 1st ed.; Rogers, L., Ed.; Woodhead Publishing: Duxford, UK, 2017; pp. 153–170. [Google Scholar]

- SAS Institute Inc. JMP, version 7; SAS Institute Inc.: Cary, NC, USA, 2007. [Google Scholar]

- Vlahova-Vangelova, D.; Balev, D.; Kolev, N. Cricket powder (Acheta domesticus) as a lean pork meat replacer in cooked sausages. Future Food: J. Food Agric. Soc. 2023, 11, 1–12. [Google Scholar] [CrossRef]

- Kim, T.K.; Yong, H.I.; Jung, S.; Sung, J.M.; Jang, H.W.; Choi, Y.S. Physicochemical and textural properties of emulsions prepared from the larvae of the edible insects Tenebrio molitor, Allomyrina dichotoma, and Protaetia brevitarsis seulensis. J. Anim. Sci. Technol. 2021, 63, 417. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.S.; Kim, T.K.; Choi, H.D.; Park, J.D.; Sung, J.M.; Jeon, K.H.; Paik, H.D.; Kim, Y.B. Optimization of replacing pork meat with yellow worm (Tenebrio molitor L.) for frankfurters. Korean J. Food Sci. Anim. Resour. 2017, 37, 617–625. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-W.; Setyabrata, D.; Lee, Y.J.; Jones, O.G.; Kim, Y.H.B. Effect of house cricket (Acheta domesticus) flour addition on physicochemical and textural properties of meat emulsion under various formulations. J. Food Sci. 2017, 82, 2787–2793. [Google Scholar] [CrossRef] [PubMed]

- Cavalheiro, C.P.; Ruiz-Capillas, C.; Herrero, A.M.; Pintado, T.; Cruz, T.M.P.; Silva, M.C.A. Cricket (Acheta domesticus) flour as meat replacer in frankfurters: Nutritional, technological, structural, and sensory characteristics. Innov. Food Sci. Emerg. Technol. 2023, 83, 103245. [Google Scholar] [CrossRef]

- Cavalheiro, C.P.; Ruiz-Capillas, C.; Herrero, A.M.; Pintado, T.; Avelar de Sousa, C.C.; Sant’Ana Falcão Leite, J.; Costa Alves da Silva, M. Potential of cricket (Acheta domesticus) flour as a lean meat replacer in the development of beef patties. Foods 2024, 13, 286. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Cao, C.; Kong, B.; Sun, F.; Shen, X.; Yao, X.; Liu, Q. Pre-dried mealworm larvae flour could partially replace lean meat in frankfurters: Effect of pre-drying methods and replacement ratios. Meat Sci. 2022, 188, 108802. [Google Scholar] [CrossRef] [PubMed]

- Lemke, B.; Siekmann, L.; Grabowski, N.T.; Plötz, M.; Krischek, C. Impact of the addition of Tenebrio molitor and Hermetia illucens on the physicochemical and sensory quality of cooked meat products. Insects 2023, 14, 487. [Google Scholar] [CrossRef] [PubMed]

- Gomes Martins, V.M.; Milano, P.; Pollonio, M.A.R.; dos Santos, M.; de Oliveira, A.P.; Savay-da-Silva, L.K.; Câmara, A.K.F.I.; Paglarini, C.S. Adding cricket (Gryllus assimilis) flour in hybrid beef patties: Physicochemical, technological and sensory challenges. Int. J. Food Sci. Technol. 2024, 59, 450–459. [Google Scholar] [CrossRef]

- Scholliers, J.; Steen, L.; Glorieux, S.; Van de Walle, D.; Dewettinck, K.; Fraeye, I. The effect of temperature on structure formation in three insect batters. Food Res. Int. 2019, 122, 411–418. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-W.; Setyabrata, D.; Lee, Y.J.; Jones, O.G.; Kim, Y.H.B. Pre-treated mealworm larvae and silkworm pupae as a novel protein ingredient in emulsion sausages. Innov. Food Sci. Emerg. Technol. 2016, 38, 116–123. [Google Scholar] [CrossRef]

- Cruz-López, S.O.; Álvarez-Cisneros, Y.M.; Domínguez-Soberanes, J.; Escalona-Buendía, H.B.; Sánchez, C.N. Physicochemical and sensory characteristics of sausages made with grasshopper (Sphenarium purpurascens) flour. Foods 2022, 11, 704. [Google Scholar] [CrossRef]

- Jeon, J.H.; Jung, S.E.; Hong, Y.K.; Lee, D.H.; Shin, T.S. Influence on the Physico-chemical qualities of emulsified sausages added different levels of Tenebrio Molitor L. powder. J. Agric. Life Sci. 2024, 58, 51–60. [Google Scholar] [CrossRef]

- Kim, S.M.; An, C.W.; Han, J.A. Characterization and application of the proteins isolated from edible insects. Korean J. Food Sci. Technol. 2019, 51, 537–542. [Google Scholar]

- Vlahova-Vangelova, D.; Balev, D.; Kolev, N.; Dragoev, S.; Petkov, E.; Popova, T. Comparison of the effect of drying treatments on the physicochemical parameters, oxidative stability, and microbiological status of yellow mealworm (Tenebrio molitor L.) flours as an alternative protein source. Agriculture 2024, 14, 436. [Google Scholar] [CrossRef]

- European Food Safety Authority (EFSA). Scientific opinion on fish oil for human consumption. Food hygiene, including rancidity. EFSA J. 2010, 8, 1874. [Google Scholar]

- Campo, M.M.; Nute, G.R.; Hughes, S.I.; Enser, M.; Wood, J.D.; Richardson, R.I. Flavour perception of oxidation in beef. Meat Sci. 2006, 72, 303–311. [Google Scholar] [CrossRef] [PubMed]

- Talens, C.; Llorente, R.; Simó-Boyle, L.; Odriozola-Serrano, I.; Tueros, I.; Ibargüen, M. Hybrid sausages: Modelling the effect of partial meat replacement with broccoli, upcycled brewer’s spent grain and insect flours. Foods 2022, 11, 3396. [Google Scholar] [CrossRef] [PubMed]

- Schreuders, F.K.; Schlangen, M.; Kyriakopoulou, K.; Boom, R.M.; van der Goot, A.J. Texture methods for evaluating meat and meat analogue structures: A review. Food Control. 2021, 127, 108103. [Google Scholar] [CrossRef]

- Zahari, I.; Östbring, K.; Purhagen, J.K.; Rayner, M. Plant-based meat analogues from alternative protein: A systematic literature review. Foods 2022, 11, 2870. [Google Scholar] [CrossRef] [PubMed]

- Grasso, S.; Smith, G.; Bowers, S.; Ajayi, O.M.; Swainson, M. Effect of texturised soy protein and yeast on the instrumental and sensory quality of hybrid beef meatballs. J. Food Sci. Technol. 2019, 56, 3126–3135. [Google Scholar] [CrossRef] [PubMed]

- Starowicz, M.; Poznar, K.K.; Zieliński, H. What are the main sensory attributes that determine the acceptance of meat alternatives? Curr. Opin. Food Sci. 2022, 48, 100924. [Google Scholar] [CrossRef]

| Item | Soybean Protein (SP) * | House-Cricket Flour (HCF) * | Yellow Mealworm Flour (YMF) ** |

|---|---|---|---|

| Moisture, % | 8.52 | 10.47 | 1.03 |

| Ash, % | 5.92 | 4.10 | 3.00 |

| Protein, % | 60.00 | 58.10 | 62.46 |

| Fat, % | 10.16 | 14.43 | 14.04 |

| Carbohydrates and fibres, % | 15.40 | 12.90 | 19.47 |

| Ingredients | Groups | |||

|---|---|---|---|---|

| Control (C) | SP | HCF | YMF | |

| Pork (lean), g | 3000 | 3000 | 3000 | 3000 |

| Pork (semifat) g | 3000 | 3000 | 3000 | 3000 |

| Water/ice, g | 900 | 900 | 900 | 900 |

| Salt (0.55% NaNO2), g/kg | 20 | 20 | 20 | 20 |

| Phosphates, g/kg | 2.0 | 2.0 | 2.0 | 2.0 |

| Soybean granular in the cooked sausage, g | - | 34.5 | - | - |

| House-cricket flour in the cooked sausage, g | - | - | 34.5 | - |

| Yellow mealworm flour in the cooked sausage, g | - | - | - | 34.5 |

| Treatment | pH | L* | a* | b* | a*/b* | ΔE |

|---|---|---|---|---|---|---|

| C | 5.80 b | 65.07 a | 9.13 a | 12.48 c | 0.73 a | - |

| SP | 5.90 a | 61.79 c | 7.07 b | 13.07 b | 0.54 b | 3.92 b |

| HCF | 5.93 a | 62.33 b | 6.92 c | 13.39 a | 0.52 c | 3.63 b |

| YMF | 5.90 a | 61.37 d | 6.99 bc | 12.94 b | 0.54 b | 4.30 a |

| SEM | 0.03 | 0.12 | 0.05 | 0.06 | 0.004 | 0.13 |

| Sig. (p) | 0.0025 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | 0.0019 |

| Treatment | TEF, % | Water from TEF, % | Fat from TEF, % | Plasticity, g/cm2 | Structural Strength, g/cm2 |

|---|---|---|---|---|---|

| C | 4.00 a | 31.98 a | 68.02 b | 1.01 b | 4.58 ab |

| SP | 3.25 b | 30.93 a | 69.07 b | 2.91 a | 4.78 a |

| HCF | 0.28 d | 25.04 b | 74.96 a | 1.09 b | 3.62 ab |

| YMF | 1.65 c | 23.46 b | 76.54 a | 0.95 b | 3.43 b |

| SEM | 0.14 | 1.24 | 1.24 | 0.44 | 0.51 |

| Sig. (p) | <0.0001 | <0.0001 | <0.0001 | 0.0017 | 0.0274 |

| Treatment | Moisture, % | Ash, % | Protein, % | Fat, % | Carbohydrate, % |

|---|---|---|---|---|---|

| C | 68.72 a | 0.70 d | 16.81 c | 12.28 d | 1.49 |

| SP | 65.16 ab | 1.00 c | 17.53 b | 13.65 c | 2.66 |

| HCF | 62.74 b | 1.30 b | 18.99 a | 14.48 b | 2.49 |

| YMF | 60.07 b | 2.00 a | 18.40 a | 15.64 a | 3.89 |

| SEM | 1.97 | 0.05 | 0.23 | 0.097 | 2.02 |

| Significance (p) | 0.0039 | <0.0001 | <0.0001 | <0.0001 | 0.5690 |

| Treatment | Storage | pH | L* | a* | b* | a*/b* | ΔE |

|---|---|---|---|---|---|---|---|

| C | 1 d | 6.10 c | 66.64 a | 12.83 a | 7.17 d | 1.79 a | - |

| 7 d | 6.20 b | 64.66 b | 13.01 a | 7.66 c | 1.70 b | - | |

| SP | 1 d | 6.10 c | 65.94 a | 12.07 b | 7.98 bc | 1.51 c | 1.41 c |

| 7 d | 6.27 a | 64.34 b | 12.14 b | 8.14 b | 1.49 c | 1.10 c | |

| HCF | 1 d | 6.20 b | 64.52 b | 10.92 c | 7.18 d | 1.52 c | 2.86 b |

| 7 d | 6.30 a | 61.70 cd | 9.95 d | 7.20 d | 1.38 d | 4.31 a | |

| YMF | 1 d | 6.20 b | 62.44 c | 10.69 c | 8.10 b | 1.32 d | 4.80 a |

| 7 d | 6.20 b | 61.08 d | 10.45 cd | 8.57 a | 1.22 e | 4.52 a | |

| Effects | |||||||

| Treatment | C | 6.15 | 65.65 | 12.92 | 7.42 | 1.74 | - |

| SP | 6.18 | 65.14 | 12.11 | 8.06 | 1.50 | 1.25 | |

| HCF | 6.25 | 63.11 | 10.44 | 7.19 | 1.45 | 3.59 | |

| YMF | 6.20 | 61.76 | 10.57 | 8.34 | 1.27 | 4.66 | |

| Storage | 1 d | 6.15 | 64.89 | 11.63 | 7.61 | 1.54 | 3.02 |

| 7 d | 6.24 | 62.95 | 11.39 | 7.89 | 1.45 | 3.31 | |

| RMSE | 0.02 | 0.32 | 0.22 | 0.15 | 0.03 | 0.38 | |

| Sig. (p) | Treatment | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Storage | <0.0001 | <0.0001 | 0.0158 | 0.0003 | <0.0001 | 0.1389 | |

| Treatment × Storage | <0.0001 | 0.0060 | 0.0014 | 0.0406 | 0.0263 | 0.0024 | |

| Treatment | Storage | Plasticity, g/cm2 | Structural Strength, g/cm2 | Elasticity, % |

|---|---|---|---|---|

| C | 1 d | 40.48 | 362.77 | 1.00 |

| 7 d | 42.15 | 512.33 | 1.00 | |

| SP | 1 d | 35.62 | 164.23 | 1.00 |

| 7 d | 84.19 | 506.26 | 1.00 | |

| HCF | 1 d | 19.98 | 195.39 | 1.00 |

| 7 d | 40.14 | 587.18 | 1.00 | |

| YMF | 1 d | 9.73 | 109.55 | 0.63 |

| 7 d | 13.73 | 176.63 | 0.65 | |

| Effects | ||||

| Treatment | C | 41.31 ab | 437.55 | 1.00 a |

| SP | 59.91 a | 335.24 | 1.00 a | |

| HCF | 30.06 bc | 391.29 | 1.00 a | |

| YMF | 11.73 c | 143.09 | 0.64 b | |

| Storage | 1 d | 26.45 b | 207.99 b | 0.90 |

| 7 d | 45.05 a | 445.60 a | 0.91 | |

| RMSE | 16.42 | 263.13 | 0.06 | |

| Sig. (p) | Treatment | 0.0010 | 0.2652 | < 0.0001 |

| Storage | 0.0136 | 0.0419 | 0.8399 | |

| Treatment × Storage | 0.0885 | 0.6769 | 0.9880 | |

| Treatment | Storage | AV, mg KOH/g | PV, meqO2 /kg | TBARS, mg MDA/kg |

|---|---|---|---|---|

| C | 1 d | 0.47 | 1.66 | 0.83 ab |

| 7 d | 0.66 | 1.41 | 0.83 ab | |

| SP | 1 d | 0.59 | 1.67 | 0.75 c |

| 7 d | 0.87 | 1.18 | 0.67 d | |

| HCF | 1 d | 0.84 | 1.61 | 0.86 a |

| 7 d | 0.89 | 1.31 | 0.78 bc | |

| YMF | 1 d | 0.85 | 1.59 | 0.51 e |

| 7 d | 0.97 | 1.25 | 0.49 e | |

| Effect | ||||

| Treatment | C | 0.56 c | 1.54 | 0.83 |

| SP | 0.73 b | 1.42 | 0.71 | |

| HCF | 0.87 a | 1.46 | 0.82 | |

| YMF | 0.91 a | 1.42 | 0.50 | |

| Storage | 1 d | 0.69 b | 1.63 a | 0.74 |

| 7 d | 0.85 a | 1.29 b | 0.69 | |

| RMSE | 0.08 | 0.08 | 0.03 | |

| Sig. (p) | Treatment | < 0.0001 | 0.0780 | < 0.0001 |

| Storage | 0.0001 | < 0.0001 | 0.0010 | |

| Treatment × Storage | 0.1093 | 0.0969 | 0.0309 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolev, N.; Vlahova-Vangelova, D.; Balev, D.; Dragoev, S.; Dimov, K.; Petkov, E.; Popova, T. Effect of the Addition of Soybean Protein and Insect Flours on the Quality of Cooked Sausages. Foods 2024, 13, 2194. https://doi.org/10.3390/foods13142194

Kolev N, Vlahova-Vangelova D, Balev D, Dragoev S, Dimov K, Petkov E, Popova T. Effect of the Addition of Soybean Protein and Insect Flours on the Quality of Cooked Sausages. Foods. 2024; 13(14):2194. https://doi.org/10.3390/foods13142194

Chicago/Turabian StyleKolev, Nikolay, Desislava Vlahova-Vangelova, Desislav Balev, Stefan Dragoev, Krasimir Dimov, Evgeni Petkov, and Teodora Popova. 2024. "Effect of the Addition of Soybean Protein and Insect Flours on the Quality of Cooked Sausages" Foods 13, no. 14: 2194. https://doi.org/10.3390/foods13142194

APA StyleKolev, N., Vlahova-Vangelova, D., Balev, D., Dragoev, S., Dimov, K., Petkov, E., & Popova, T. (2024). Effect of the Addition of Soybean Protein and Insect Flours on the Quality of Cooked Sausages. Foods, 13(14), 2194. https://doi.org/10.3390/foods13142194