Application of Composite Flour from Indonesian Local Tubers in Gluten-Free Pancakes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Arrowroot Flour Preparation

2.3. Suweg Flour Preparation

2.4. Pancake Preparation

2.5. Proximate and Crude Fiber Composition Analysis of Flours

2.6. Pasting Properties (RVA Analysis) of Flours

2.7. Color Evaluation of Flours and Pancakes

2.8. Water Absorption Capacity (WAC) Measurement of Flour

2.9. Swelling Volume and Solubility Measurement of Flours

2.10. Texture Evaluation (TPA) of Pancakes

2.11. Hedonic Sensory Test of Pancakes

2.12. Statistical Analysis

3. Results

3.1. Proximate and Crude Fiber Composition

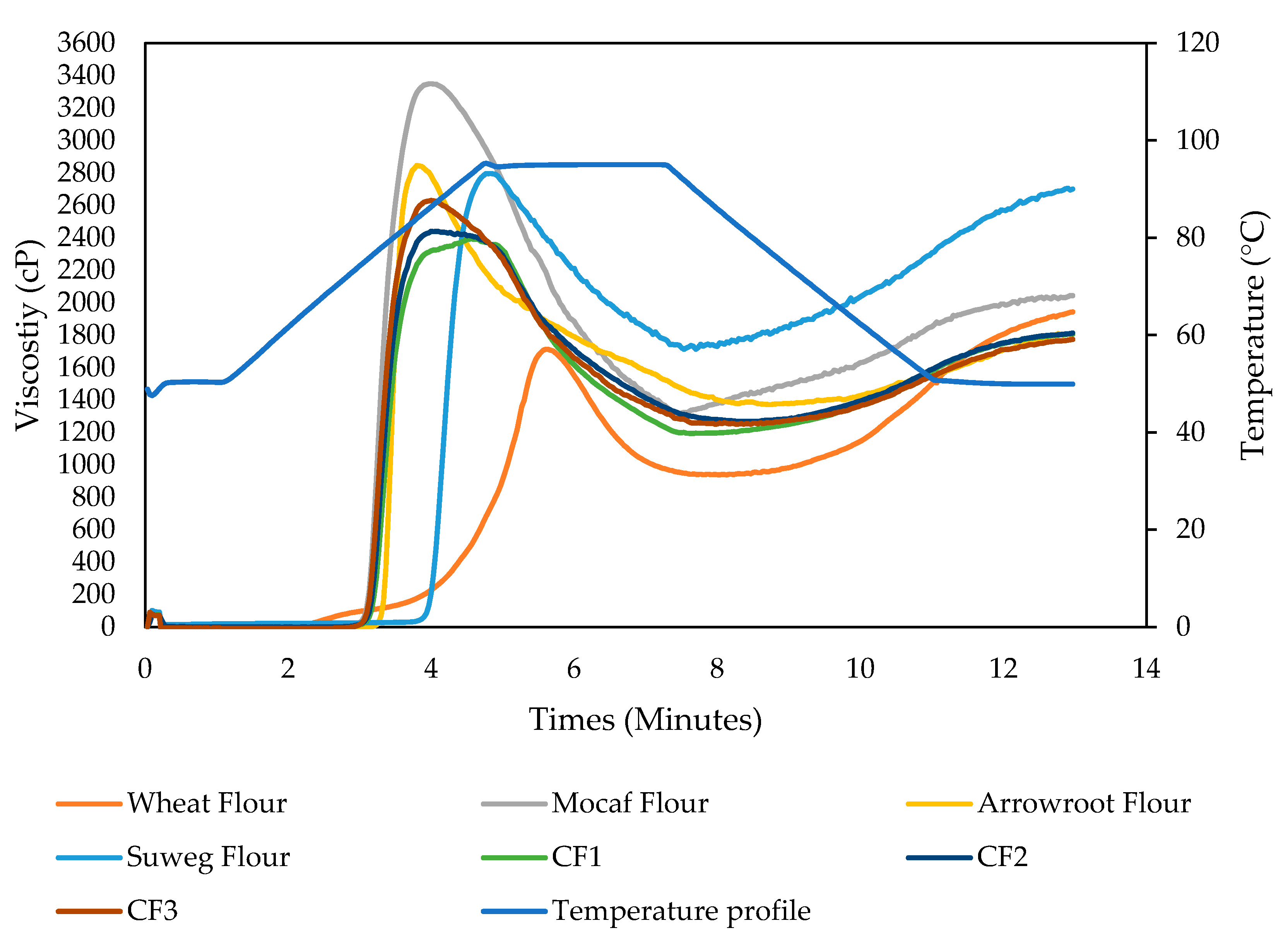

3.2. Pasting Properties

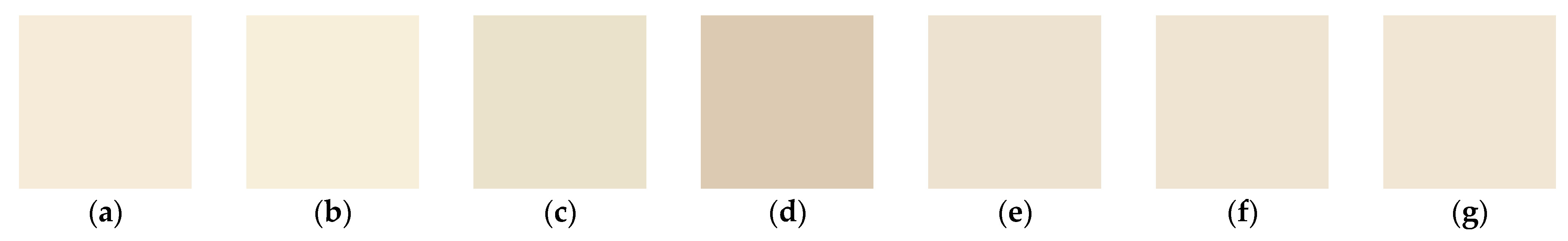

3.3. Color Evaluation of Flour

3.4. Functional Properties

3.5. Texture Evaluation of Pancake

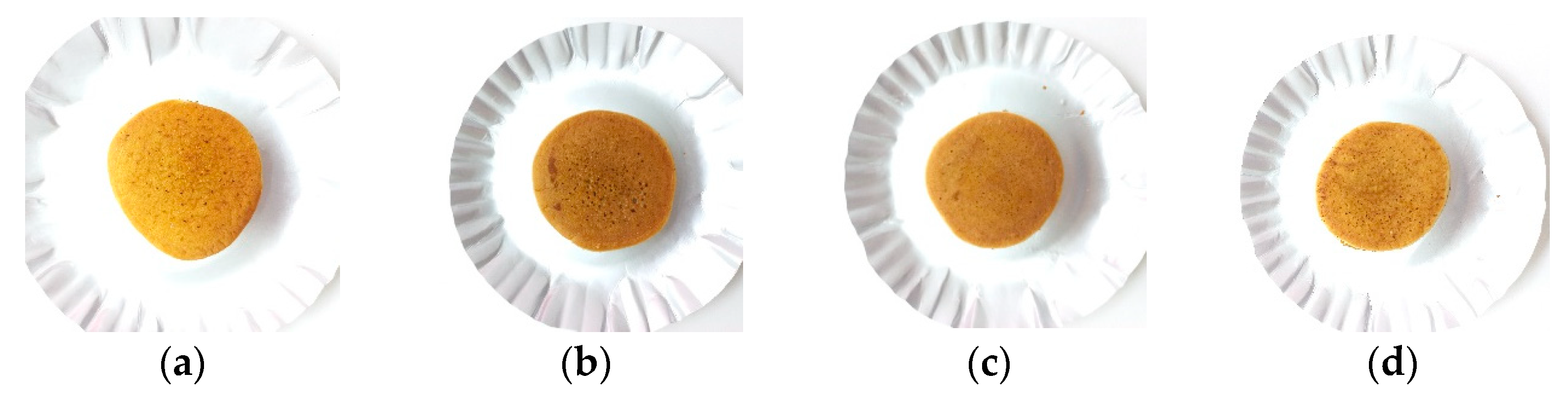

3.6. Color Evaluation of Pancakes

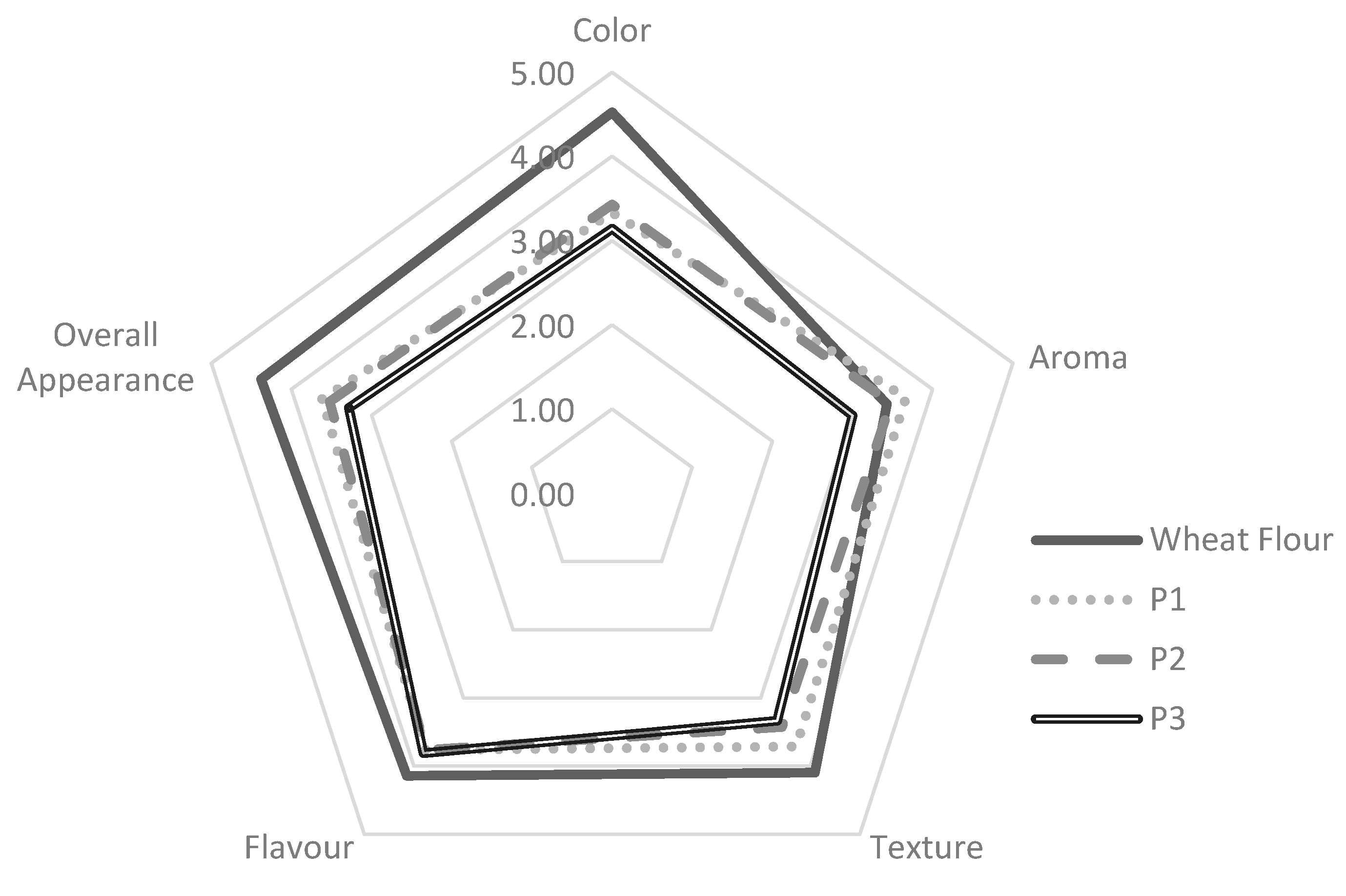

3.7. Hedonic Sensory

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- García-García, A.; Madrid, R.; Sohrabi, H.; de la Cruz, S.; García, T.; Martín, R.; González, I. A Sensitive and Specific Real-Time PCR Targeting DNA from Wheat, Barley and Rye to Track Gluten Contamination in Marketed Foods. LWT 2019, 114, 108378. [Google Scholar] [CrossRef]

- Ortolan, F.; Steel, C.J. Protein Characteristics That Affect the Quality of Vital Wheat Gluten to Be Used in Baking: A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 369–381. [Google Scholar] [CrossRef] [PubMed]

- Rakmai, J.; Haruthaithanasan, V.; Chompreeda, P.; Chatakanonda, P.; Yonkoksung, U. Development of Gluten-Free and Low Glycemic Index Rice Pancake: Impact of Dietary Fiber and Low-Calorie Sweeteners on Texture Profile, Sensory Properties, and Glycemic Index. Food Hydrocoll. Health 2021, 1, 100034. [Google Scholar] [CrossRef]

- Bascuñán, K.A.; Vespa, M.C.; Araya, M. Celiac Disease: Understanding the Gluten-Free Diet. Eur. J. Nutr. 2017, 56, 449–459. [Google Scholar] [CrossRef] [PubMed]

- Dale, H.F.; Biesiekierski, J.R.; Lied, G.A. Non-Coeliac Gluten Sensitivity and the Spectrum of Gluten-Related Disorders: An Updated Overview. Nutr. Res. Rev. 2019, 32, 28–37. [Google Scholar] [CrossRef] [PubMed]

- Marta, H.; Cahyana, Y.; Bintang, S.; Soeherman, G.P.; Djali, M. Physicochemical and Pasting Properties of Corn Starch as Affected by Hydrothermal Modification by Various Methods. Int. J. Food Prop. 2022, 25, 792–812. [Google Scholar] [CrossRef]

- Marta, H.; Cahyana, Y.; Djali, M.; Pramafisi, G. The Properties, Modification, and Application of Banana Starch. Polymers 2022, 14, 3092. [Google Scholar] [CrossRef] [PubMed]

- Marta, H.; Hasya, H.N.L.; Lestari, Z.I.; Cahyana, Y.; Arifin, H.R.; Nurhasanah, S. Study of Changes in Crystallinity and Functional Properties of Modified Sago Starch (Metroxylon Sp.) Using Physical and Chemical Treatment. Polymers 2022, 14, 4845. [Google Scholar] [CrossRef]

- Marta, H.; Cahyana, Y.; Arifin, H.R.; Khairani, L. Comparing the Effect of Four Different Thermal Modifications on Physicochemical and Pasting Properties of Breadfruit (Artocarpus Altilis) Starch. Int. Food Res. J. 2019, 26, 269–276. [Google Scholar]

- Marta, H.; Cahyana, Y.; Djali, M. Densely Packed-Matrices of Heat Moisture Treated-Starch Determine the Digestion Rate Constant as Revealed by Logarithm of Slope Plots. J. Food Sci. Technol. 2021, 58, 2237–2245. [Google Scholar] [CrossRef]

- Marta, H.; Cahyana, Y.; Djali, M. Pectin Interaction with Thermally Modified Starch Affects Physicochemical Properties and Digestibility of Starch as Revealed by Logarithm of Slop Plot. CYTA-J. Food 2021, 19, 63–71. [Google Scholar] [CrossRef]

- Yamashita, S.; Matsumiya, K.; Kogo, Y.; Takamatsu, K.; Matsumura, Y. Emulsifiers Efficiently Prevent Hardening of Pancakes under Refrigerated Conditions via Inclusion Complexes with Starch Molecules. Food Hydrocoll. 2020, 100, 105432. [Google Scholar] [CrossRef]

- Duodu, K.G.; Taylor, J.R.N. The Quality of Breads Made with Non-Wheat Flours, 2nd ed.; Woodhead Publishing Limited: Sawston, Cambridge, UK, 2012; ISBN 9780857090607. [Google Scholar]

- Ren, Y.; Linter, B.R.; Linforth, R.; Foster, T.J. A Comprehensive Investigation of Gluten Free Bread Dough Rheology, Proving and Baking Performance and Bread Qualities by Response Surface Design and Principal Component Analysis. Food Funct. 2020, 11, 5333–5345. [Google Scholar] [CrossRef]

- Shih, F.F.; Truong, V.D.; Daigle, K.W. Physicochemical Properties of Gluten-Free Pancakes from Rice and Sweet Potato Flours. J. Food Qual. 2006, 29, 97–107. [Google Scholar] [CrossRef]

- Kiprushkina, E.I.; Golovinskaia, O.V.; Ovsyuk, E.A.; Baklanova, V.V.; Alekseeva, L.A.; Tulina, A.K.; Beloded, V.R.; Shestopalova, I.A. Pancakes for a Healthy Diet: Low-Carb, Prebiotic, Gluten-Free. Agron. Res. 2020, 18, 2410–2424. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Cini, E. A Systematic Review of Gluten-Free Dough and Bread: Dough Rheology, Bread Characteristics, and Improvement Strategies. Appl. Sci. 2020, 10, 6559. [Google Scholar] [CrossRef]

- Arendt, E.K.; Dal Bello, F. Functional Cereal Products for Those with Gluten Intolerance; Woodhead Publishing Limited: Sawston, Cambridge, UK, 2007; ISBN 9781845691776. [Google Scholar]

- Morrissey, A.; Moore, M.M. Gluten-Free Cereal Products and Beverages; Elsevier Inc.: Amsterdam, The Netherlands, 2008; ISBN 9780123737397. [Google Scholar]

- Matos, M.E.; Rosell, C.M. Understanding Gluten-Free Dough for Reaching Breads with Physical Quality and Nutritional Balance. J. Sci. Food Agric. 2015, 95, 653–661. [Google Scholar] [CrossRef]

- Das, A.B.; Bhattacharya, S. Characterization of the Batter and Gluten-Free Cake from Extruded Red Rice Flour. LWT 2019, 102, 197–204. [Google Scholar] [CrossRef]

- Onyango, C.; Mutungi, C.; Unbehend, G.; Lindhauer, M.G. Modification of Gluten-Free Sorghum Batter and Bread Using Maize, Potato, Cassava or Rice Starch. LWT 2011, 44, 681–686. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Wang, W.; Li, Y. Advanced Properties of Gluten-Free Cookies, Cakes, and Crackers: A Review. Trends Food Sci. Technol. 2020, 103, 200–213. [Google Scholar] [CrossRef]

- Coronel, E.B.; Guiotto, E.N.; Aspiroz, M.C.; Tomás, M.C.; Nolasco, S.M.; Capitani, M.I. Development of Gluten-Free Premixes with Buckwheat and Chia Flours: Application in a Bread Product. LWT 2021, 141, 110916. [Google Scholar] [CrossRef]

- Monthe, O.C.; Grosmaire, L.; Nguimbou, R.M.; Dahdouh, L.; Ricci, J.; Tran, T.; Ndjouenkeu, R. Rheological and Textural Properties of Gluten-Free Doughs and Breads Based on Fermented Cassava, Sweet Potato and Sorghum Mixed Flours. LWT 2019, 101, 575–582. [Google Scholar] [CrossRef]

- Cayres, C.A.; Ramírez Ascheri, J.L.; Peixoto Gimenes Couto, M.A.; Almeida, E.L.; Melo, L. Consumers’ Acceptance of Optimized Gluten-Free Sorghum-Based Cakes and Their Drivers of Liking and Disliking. J. Cereal Sci. 2020, 93, 102938. [Google Scholar] [CrossRef]

- Paesani, C.; Bravo-Núñez, Á.; Gómez, M. Effect of Stabilized Wholegrain Maize Flours on the Quality Characteristics of Gluten-Free Layer Cakes. LWT 2021, 135, 109959. [Google Scholar] [CrossRef]

- Marta, H.; Cahyana, Y.; Djali, M.; Arcot, J.; Tensiska, T. A Comparative Study on the Physicochemical and Pasting Properties of Starch and Flour from Different Banana (Musa Spp.) Cultivars Grown in Indonesia. Int. J. Food Prop. 2019, 22, 1562–1575. [Google Scholar] [CrossRef]

- AOAC Official Method of Analysis; AOAC International: Rockville, MD, USA, 2005.

- Cahyana, Y.; Rangkuti, A.; Siti Halimah, T.; Marta, H.; Yuliana, T. Application of Heat-Moisture-Treated Banana Flour as Composite Material in Hard Biscuit. CYTA-J. Food 2020, 18, 599–605. [Google Scholar] [CrossRef]

- Sumardiono, S.; Jos, B.; Antoni, M.F.Z.; Nadila, Y.; Handayani, N.A. Physicochemical Properties of Novel Artificial Rice Produced from Sago, Arrowroot, and Mung Bean Flour Using Hot Extrusion Technology. Heliyon 2022, 8, e08969. [Google Scholar] [CrossRef] [PubMed]

- Sholichah, E.; Deswina, P.; Sarifudin, A.; Andriansyah, C.E.; Rahman, N. Physicochemical, Structural and Morphological Properties of Some Arrowroot (Maranta Arundinacea) Accessions Growth in Indonesia. AIP Conf. Proc. 2019, 2175, 020008. [Google Scholar] [CrossRef]

- Sudaryati, E.; Nasution, E.; Ardiani, F. Nutritional Quality of Bread from Mixture of Arrowroot Flour (Marantha Arundinacea L.) and Wheat Flour. In Proceedings of the 2nd Public Health International Conference (PHICo 2017); Atlantis Press: Amsterdam, The Netherlands, 2018; Volume 9, pp. 186–189. [Google Scholar] [CrossRef]

- Kumar, R.; Khatkar, B.S. Thermal, Pasting and Morphological Properties of Starch Granules of Wheat (Triticum Aestivum L.) Varieties. J. Food Sci. Technol. 2017, 54, 2403–2410. [Google Scholar] [CrossRef]

- Qadir, N.; Wani, I.A. Functional Properties, Antioxidant Activity and in-Vitro Digestibility Characteristics of Brown and Polished Rice Flours of Indian Temperate Region. Grain Oil Sci. Technol. 2023, 6, 43–57. [Google Scholar] [CrossRef]

- Alamu, E.O.; Maziya-Dixon, B.; Dixon, A.G. Evaluation of Proximate Composition and Pasting Properties of High Quality Cassava Flour (HQCF) from Cassava Genotypes (Manihot Esculenta Crantz) of β-Carotene-Enriched Roots. LWT 2017, 86, 501–506. [Google Scholar] [CrossRef]

- Yulianti, L.E.; Afifah, N.; Ekafitri, R. Physicochemical and Pasting Properties of Composite Flours for Making Gluten-Free Bread. AIP Conf. Proc. 2019, 2175, 020064. [Google Scholar] [CrossRef]

- Ayetigbo, O.; Latif, S.; Abass, A.; Müller, J. Preparation, Optimization and Characterization of Foam from White-Flesh and Yellow-Flesh Cassava (Manihot Esculenta) for Powder Production. Food Hydrocoll. 2019, 97, 105205. [Google Scholar] [CrossRef]

- Shete, C.C.; Wadkar, S.S.; Gaikwad, N.B.; Patil, K.S.; Ghosh, J.S. Phenolic Contents and Antioxidant Capacity of Amorphophallus Commutatus and Amorphophallus Paeonifolius. Int. Food Res. J. 2015, 22, 1939–1944. [Google Scholar]

- Ieamkheng, S.; Santibenchakul, S.; Sooksawat, N. Potential of Maranta Arundinacea Residues for Recycling: Analysis of Total Phenolic, Flavonoid, and Tannin Contents. Biodiversitas 2022, 23, 1204–1210. [Google Scholar] [CrossRef]

- Adebowale, A.A.; Adegoke, M.T.; Sanni, S.A.; Adegunwa, M.; Fetuga, G.O. Functional Properties and Biscuit Making Potentials of Sorghum-Wheat Flour Composite. Am. J. Food Technol. 2012, 7, 372–379. [Google Scholar] [CrossRef]

- Chandra, S. Samsher Assessment of Functional Properties of Different Flours. African J. Agric. Res. 2013, 8, 4849–4852. [Google Scholar] [CrossRef]

- Chandra, S.; Singh, S.; Kumari, D. Evaluation of Functional Properties of Composite Flours and Sensorial Attributes of Composite Flour Biscuits. J. Food Sci. Technol. 2015, 52, 3681–3688. [Google Scholar] [CrossRef]

- Kaur, R.; Kaur, M. Microstructural, Physicochemical, Antioxidant, Textural and Quality Characteristics of Wheat Muffins as Influenced by Partial Replacement with Ground Flaxseed. LWT 2018, 91, 278–285. [Google Scholar] [CrossRef]

- Kumar, P.K.; Parhi, A.; Sablani, S.S. Development of High-Fiber and Sugar-Free Frozen Pancakes: Influence of State and Phase Transitions on the Instrumental Textural Quality of Pancakes during Storage. LWT 2021, 146, 111454. [Google Scholar] [CrossRef]

- Valcarcel, M.; Ghatak, R.; Bhaduri, S.; Navder, K.P. Physical, Textural and Sensory Characteristics of Gluten-Free Muffins Prepared with Teff Flour (Eragrostis Tef (Zucc) Trotter). J. Acad. Nutr. Diet. 2012, 112, A58. [Google Scholar] [CrossRef]

- Lestari, L.A.; Huriyati, E.; Marsono, Y. The Development of Low Glycemic Index Cookie Bars from Foxtail Millet (Setaria Italica), Arrowroot (Maranta Arundinacea) Flour, and Kidney Beans (Phaseolus Vulgaris). J. Food Sci. Technol. 2017, 54, 1406–1413. [Google Scholar] [CrossRef] [PubMed]

- Sofyan, A.; Ikhsani, A.Y.; Purwani, E.; Hasanah, L.E.N.; Febriyadin, F. The Effect of Suweg (Amorphophallus Paeoniifolius) Flour and Incubation Temperature on Characteristics of Yogurt with the Addition of Bifidobacterium Bifidum as Probiotic. Mater. Today Proc. 2022, 63, S507–S512. [Google Scholar] [CrossRef]

| Formulation | Mocaf (g) | Arrowroot Tuber (g) | Suweg (g) | Powdered Sugar (g) | Powdered Milk (g) | Baking Powder (g) | Egg (pcs) | Water (mL) |

|---|---|---|---|---|---|---|---|---|

| Pancake 1 (P1) | 70 | 15 | 15 | 90 | 26 | 9 | 1 | 170 |

| Pancake 2 (P2) | 70 | 20 | 10 | 90 | 26 | 9 | 1 | 170 |

| Pancake 3 (P3) | 70 | 25 | 5 | 90 | 26 | 9 | 1 | 170 |

| Sample | Water (%db) | Ash (%db) | Fat (%db) | Protein (%db) | Crude Fiber (%db) |

|---|---|---|---|---|---|

| WF | 14.52 ± 0.16 a | 0.69 ± 0.01 e | 1.36 ± 0.43 a | 10.55 ± 0.18 a | 0.38 ± 0.15 e |

| MF | 14.33 ± 0.25 a | 1.46 ± 0.20 d | 1.05 ± 0.06 ab | 1.13 ± 0.22 d | 1.18 ± 0.09 d |

| AF | 7.32 ± 0.05 c | 5.34 ± 0.02 a | 0.54 ± 0.28 bc | 4.40 ± 0.10 b | 1.79 ± 0.05 b |

| SF | 10.21 ± 0.71 b | 4.05 ± 0.06 b | 0.53 ± 0.34 bc | 4.44 ± 0.06 b | 3.15 ± 0.25 a |

| CF1 | 10.87 ± 0.25 b | 2.45 ± 0.07 c | 0.56 ± 0.01 bc | 1.75 ± 0.07 c | 1.38 ± 0.01 cd |

| CF2 | 10.26 ± 0.83 b | 2.40 ± 0.02 c | 0.36 ± 0.07 c | 1.74 ± 0.05 c | 1.50 ± 0.01 bc |

| CF3 | 10.05 ± 0.10 b | 2.43 ± 0.02 c | 0.43 ± 0.20 bc | 1.81 ± 0.10 c | 1.44 ± 0.13 cd |

| Sample | Pasting Temperature (°C) | Peak Viscosity (cP) | Hold Viscosity (cP) | Final Viscosity (cP) | Breakdown (cP) | Setback (cP) |

|---|---|---|---|---|---|---|

| WF | 64.91 ± 0.60 e | 1718.67 ± 4.93 g | 935.67 ± 14.50 e | 1943.00 ± 24.06 c | 783.00 ± 10.15 f | 1007.33 ± 9.71 a |

| MF | 73.17 ± 0.24 d | 3351.33 ± 17.79 a | 1312.00 ± 39.40 bc | 2042.33 ± 10.02 b | 2039.33 ± 56.22 a | 730.33 ± 34.93 b |

| AF | 76.62 ± 0.04 b | 2851.33 ± 29.87 b | 1368.67 ± 55.64 b | 1804.33 ± 98.54 d | 1483.00 ± 25.24 b | 436.00 ± 45.92 e |

| SF | 84.07 ± 0.15 a | 2798.67 ± 10.97 c | 1705.33 ± 55.23 a | 2701.00 ± 12.12 a | 1093.33 ± 47.26 e | 995.67 ± 53.93 a |

| CF1 | 74.06 ± 0.47 c | 2394.67 ± 38.03 f | 1191.67 ± 14.01 d | 1806.67 ± 36.12 d | 1203.00 ± 24.02 d | 615.00 ± 22.11 c |

| CF2 | 73.79 ± 0.10 cd | 2445.67 ± 15.50 e | 1264.00 ± 5.20 c | 1813.00 ± 16.46 d | 1181.67 ± 12.86 d | 549.00 ± 19.47 d |

| CF3 | 73.24 ± 0.47 d | 2632.00 ± 24.56 d | 1245.67 ± 44.64 cd | 1772.67 ± 6.03 d | 1386.33 ± 39.80 c | 527.00 ± 33.63 d |

| Sample | L* | a* | b* | Hue | Whiteness Index | ∆E |

|---|---|---|---|---|---|---|

| WF | 93.09 ± 0.21 b | 0.45 ± 0.01 e | 9.81 ± 0.12 c | 1.53 ± 0.00 a | 87.99 ± 0.03 b | 0.00 ± 0.00 f |

| MF | 94.17 ± 0.16 a | 0.43 ± 0.02 e | 9.75 ± 0.13 c | 1.53 ± 0.00 a | 88.63 ± 0.07 a | 1.09 ± 0.31 e |

| AF | 89.48 ± 0.21 e | −0.36 ± 0.02 f | 11.35 ± 0.16 b | −1.54 ± 0.00 f | 84.52 ± 0.12 f | 4.01 ± 0.27 b |

| SF | 81.64 ± 0.42 f | 1.78 ± 0.02 a | 12.96 ± 0.28 a | 1.43 ± 0.00 e | 77.46 ± 0.18 g | 11.94 ± 0.19 a |

| CF1 | 89.58 ± 0.37 e | 1.06 ± 0.01 b | 9.04 ± 0.03 d | 1.45 ± 0.00 d | 86.16 ± 0.28 e | 3.65 ± 0.51 b |

| CF2 | 90.37 ± 0.16 d | 0.88 ± 0.03 c | 9.13 ± 0.26 d | 1.47 ± 0.00 c | 86.70 ± 0.28 d | 2.84 ± 0.34 c |

| CF3 | 91.19 ± 0.05 c | 0.70 ± 0.03 d | 9.17 ± 0.27 d | 1.49 ± 0.00 b | 87.27 ± 0.22 c | 2.03 ± 0.19 d |

| Sample | WAC (g/g) | Swelling Volume (mL/g) | Solubility (%) |

|---|---|---|---|

| WF | 1.11 ± 0.13 d | 11.52 ± 0.31 e | 14.17 ± 2.00 c |

| MF | 1.68 ± 0.01 b | 16.65 ± 0.24 d | 9.20 ± 0.36 d |

| AF | 1.48 ± 0.04 c | 22.19 ± 0.42 b | 19.05 ± 0.36 a |

| SF | 2.01 ± 0.07 a | 16.55 ± 0.22 d | 17.35 ± 0.17 b |

| CF1 | 1.63 ± 0.03 b | 25.33 ± 0.62 a | 12.86 ± 0.80 c |

| CF2 | 1.65 ± 0.02 b | 21.10 ± 0.16 c | 16.20 ± 0.10 b |

| Cf3 | 1.62 ± 0.03 b | 21.01 ± 0.32 c | 16.11 ± 0.37 b |

| Sample | Hardness (g) | Adhesiveness (g.sec) | Springiness | Cohesiveness | Chewiness | Resilience |

|---|---|---|---|---|---|---|

| Wheat flour | 2632.36 ± 232.56 ab | −14.19 ± 2.73 bc | 0.99 ± 0.00 a | 0.85 ± 0.01 a | 2211.92 ± 206.55 a | 0.66 ± 0.04 a |

| P1 | 2698.16 ± 162.34 a | −19.92 ± 3.51 c | 0.98 ± 0.01 b | 0.84 ± 0.00 a | 2199.06 ± 112.78 a | 0.62 ± 0.04 a |

| P2 | 2372.49 ± 27.47 b | −17.24 ± 4.77 bc | 0.98 ± 0.01 ab | 0.83 ± 0.00 a | 1926.63 ± 14.80 b | 0.62 ± 0.04 a |

| P3 | 2035.74 ± 64.56 c | −11.42 ± 0.20 a | 0.98 ± 0.01 ab | 0.84 ± 0.00 a | 1677.32 ± 32.45 c | 0.64 ± 0.04 a |

| Sample | L* | a* | b* | Hue | Whiteness | ∆E |

|---|---|---|---|---|---|---|

| Wheat Flour | 52.20 ± 3.24 a | 14.13 ± 1.35 a | 37.77 ± 2.27 a | 1.21 ± 0.05 ab | 37.38 ± 1.41 b | 0.00 ± 0.00 d |

| P1 | 43.70 ± 1.64 c | 12.11 ± 0.07 b | 31.41 ± 2.58 d | 1.20 ± 0.03 ab | 34.36 ± 0.21 c | 12.93 ± 1.18 a |

| P2 | 47.06 ± 2.79 bc | 13.74 ± 0.55 a | 35.24 ± 1.63 d | 1.20 ± 0.03 b | 34.89 ± 1.47 c | 5.27 ± 0.49 c |

| P3 | 49.52 ± 0.56 ab | 9.47 ± 0.78 c | 29.89 ± 2.56 d | 1.26 ± 0.02 a | 40.54 ± 1.28 a | 7.75 ± 0.52 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marta, H.; Febiola, C.; Cahyana, Y.; Arifin, H.R.; Fetriyuna, F.; Sondari, D. Application of Composite Flour from Indonesian Local Tubers in Gluten-Free Pancakes. Foods 2023, 12, 1892. https://doi.org/10.3390/foods12091892

Marta H, Febiola C, Cahyana Y, Arifin HR, Fetriyuna F, Sondari D. Application of Composite Flour from Indonesian Local Tubers in Gluten-Free Pancakes. Foods. 2023; 12(9):1892. https://doi.org/10.3390/foods12091892

Chicago/Turabian StyleMarta, Herlina, Christine Febiola, Yana Cahyana, Heni Radiani Arifin, Fetriyuna Fetriyuna, and Dewi Sondari. 2023. "Application of Composite Flour from Indonesian Local Tubers in Gluten-Free Pancakes" Foods 12, no. 9: 1892. https://doi.org/10.3390/foods12091892

APA StyleMarta, H., Febiola, C., Cahyana, Y., Arifin, H. R., Fetriyuna, F., & Sondari, D. (2023). Application of Composite Flour from Indonesian Local Tubers in Gluten-Free Pancakes. Foods, 12(9), 1892. https://doi.org/10.3390/foods12091892