Characterisation of the Aroma Profile and Dynamic Changes in the Flavour of Stinky Tofu during Storage

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Quantitative Descriptive Analysis

2.3. E-Nose Detection

2.4. Aroma Extraction through HS-SPME

2.5. GC-MS Analysis

2.6. OAV Analysis

2.7. Statistical Analysis

3. Results and Discussion

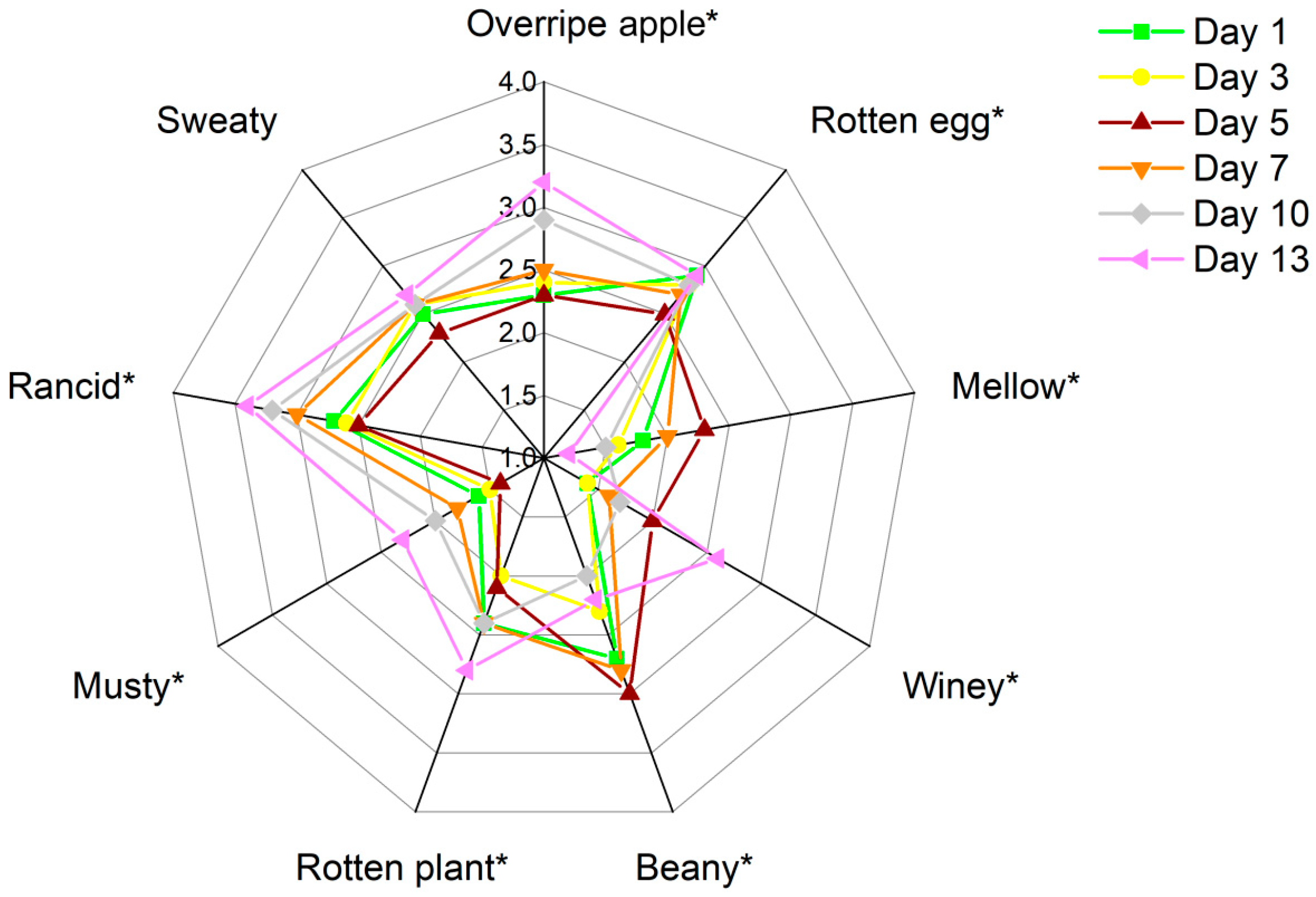

3.1. Sensory Analysis

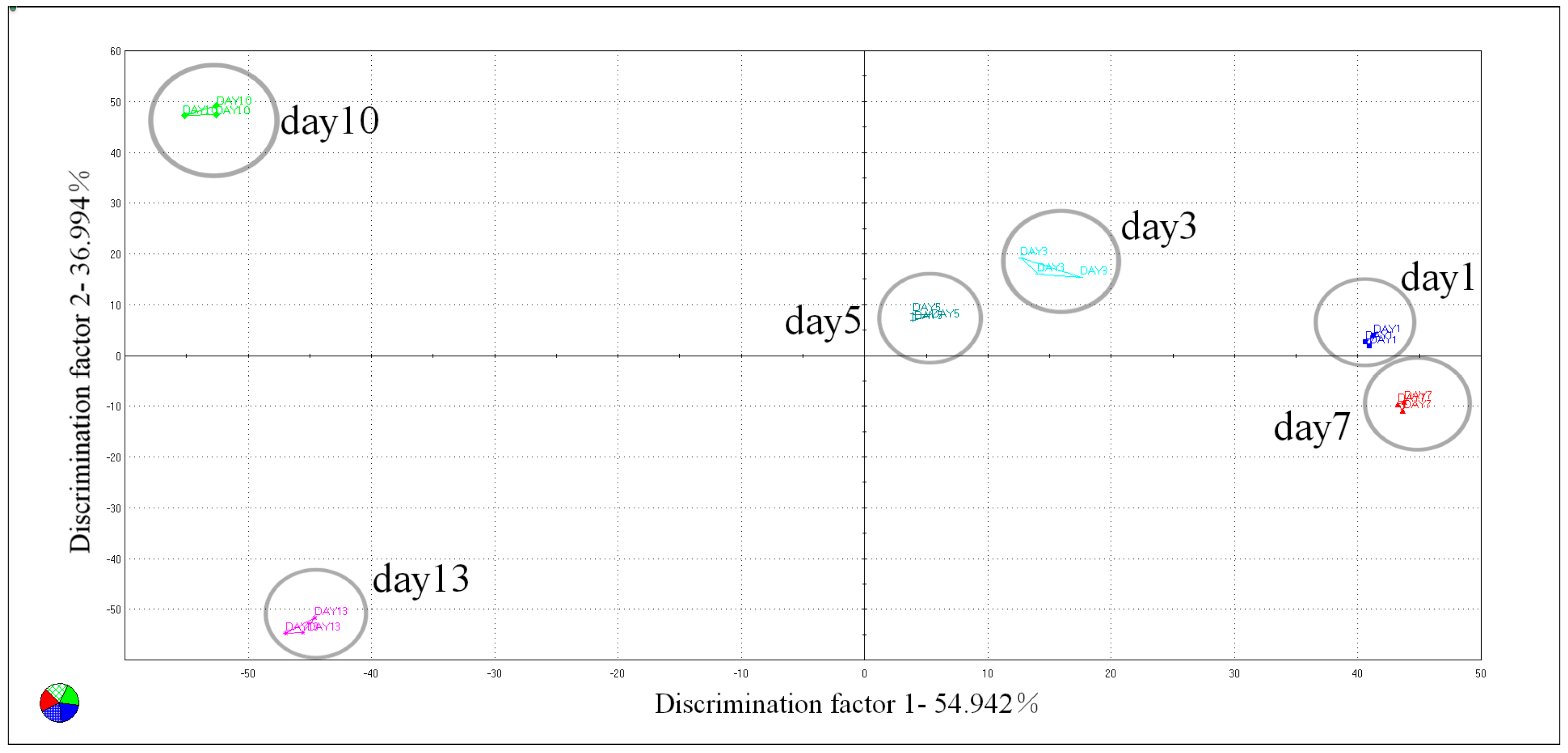

3.2. E-Nose Analysis

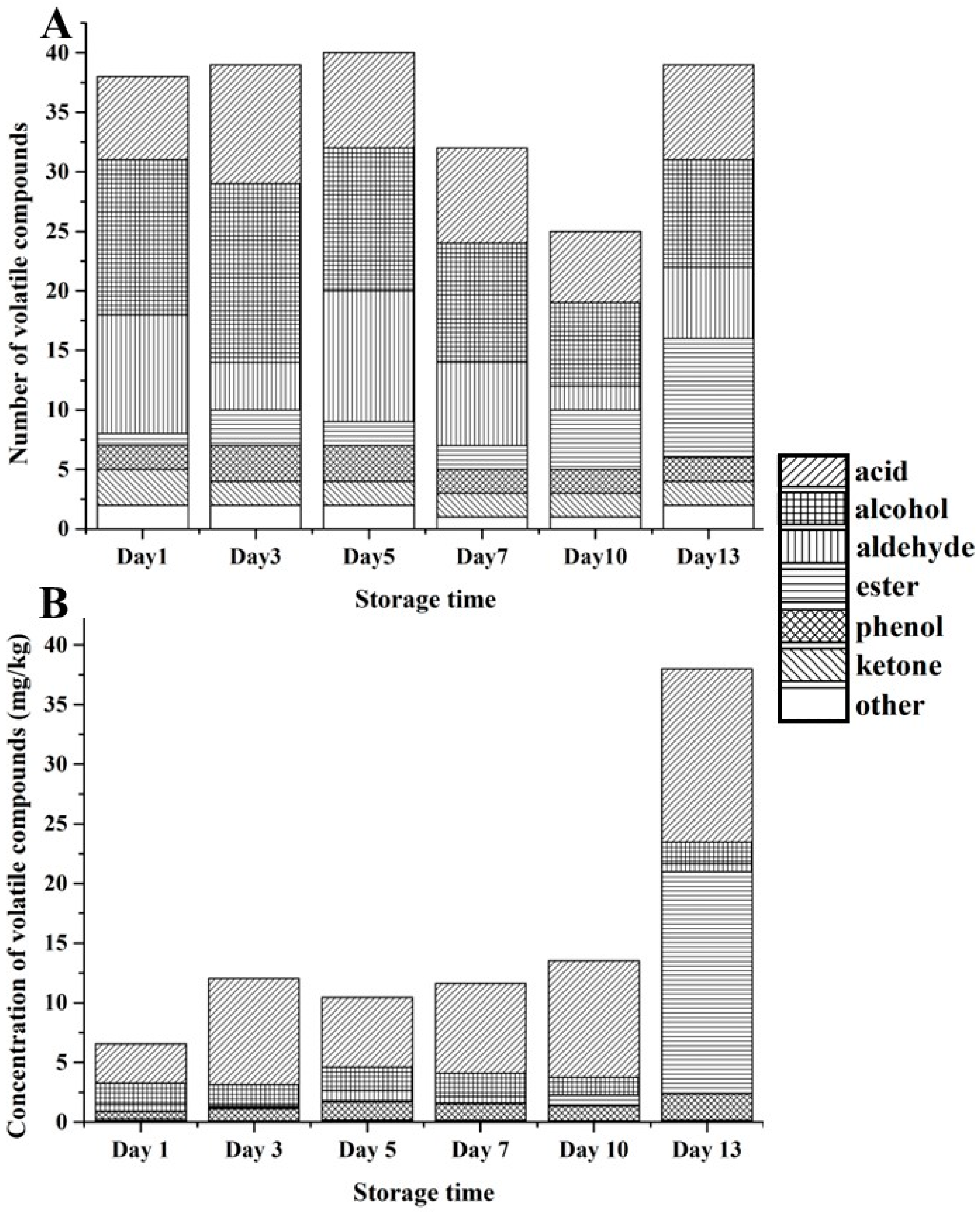

3.3. Volatile Compounds in the Stinky Tofu Samples

3.4. Changes in the Aroma Profile during Storage

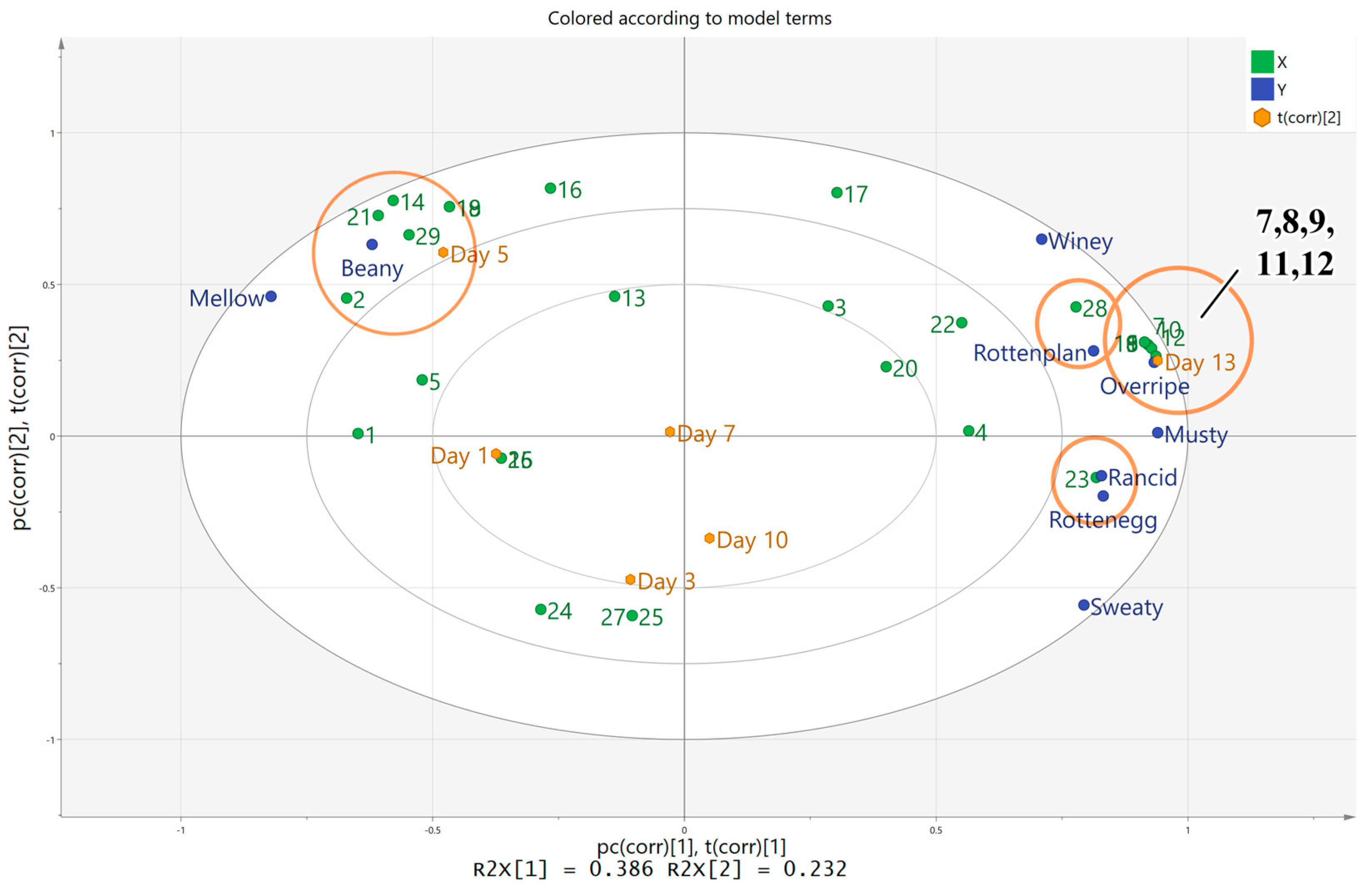

3.5. PLS Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gu, J.; Liu, T.; Sadiq, F.A.; Yang, H.; Yuan, L.; Zhang, G.; He, G. Biogenic amines content and assessment of bacterial and fungal diversity in stinky tofu—A traditional fermented soy curd. LWT 2018, 88, 26–34. [Google Scholar] [CrossRef]

- Mo, H.; Kariluoto, S.; Piironen, V.; Yang, Z.; Sanders, M.G.; Vincken, J.P. Effect of soybean processing on content and bioaccessibility of folate, vitamin B12 and isoflavones in tofu and tempe. Food Chem. 2013, 141, 2418–2425. [Google Scholar] [CrossRef]

- Abiru, Y.; Kumemura, M.; Ueno, T.; Uchiyama, S.; Masaki, K. Discovery of an S-equol rich food stinky tofu, a traditional fermented soy product in Taiwan. Int. J. Food Sci. Nutr. 2012, 63, 964–970. [Google Scholar] [CrossRef]

- Xu, L.; Du, B.; Xu, B. A systematic, comparative study on the beneficial health components and antioxidant activities of commercially fermented soy products marketed in China. Food Chem. 2015, 174, 202–213. [Google Scholar] [CrossRef] [PubMed]

- Chao, S.H.; Tomii, Y.; Watanabe, K.; Tsai, Y.C. Diversity of lactic acid bacteria in fermented brines used to make stinky tofu. Int. J. Food Micribiol. 2008, 123, 134–141. [Google Scholar] [CrossRef]

- Chang, H.O.; Wang, S.W.; Chen, J.C.; Hsu, L.F.; Hwang, S.M. Mutagenic analysis of fermenting strains and fermented brine for stinky tofu. J. Food Drug. Anal. 2020, 9, 45–49. [Google Scholar] [CrossRef]

- Lucas, S.; Omata, Y.; Hofmann, J.; Bttcher, M.; Iljazovic, A.; Sarter, K.; Albrecht, O.; Schulz, O.; Krishnacoumar, B.; Krnke, G. Short-chain fatty acids regulate systemic bone mass and protect from pathological bone loss. Nat. Commum. 2018, 9, 55. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Gao, Y.; Liang, W.; Liu, Y.; Gao, H. Identification and analysis of the flavor characteristics of unfermented stinky tofu brine during fermentation using SPME-GC–MS, e-nose, and sensory evaluation. J. Food Meas. Charact. 2020, 14, 597–612. [Google Scholar] [CrossRef]

- Li, P.; Xie, J.; Tang, H.; Shi, C.; Xie, Y.; He, J.; Zeng, Y.; Zhou, H.; Xia, B.; Zhang, C.; et al. Fingerprints of volatile flavor compounds from southern stinky tofu brine with headspace solid-phase microextraction/gas chromatography-mass spectrometry and chemometric methods. Food Sci. Nutr. 2019, 7, 890–896. [Google Scholar] [CrossRef]

- Deng, S.; Du, L.; Wei, D. Study of stinky tofu brine fermented with lactic acid bacteria and the analysis of its aroma components. Food Ferment. Ind. 2020, 46, 107–113+118. [Google Scholar]

- Tian, H.X.; Xu, X.L.; Chen, C.; Yu, H.Y. Flavoromics approach to identifying the key aroma compounds in traditional Chinese milk fan. J. Dairy Sci. 2019, 102, 9639–9650. [Google Scholar] [CrossRef]

- Poveda, J.M.; Palomo, E.S.; Sánchez-Palomo, M.S.; Cabezas, L. Volatile composition, olfactometry profile and sensory evaluation of semi-hard Spanish goat cheeses. Dairy Sci. Technol. 2008, 88, 355–367. [Google Scholar] [CrossRef]

- Pelin, S.; Gokce, G.; Perihan, K.; Deniz, B.; Zafer, E. Composition, proteolysis, lipolysis, volatile compound profile and sensory characteristics of ripened white cheeses manufactured in different geographical regions of Turkey. Int. Dairy J. 2018, 87, 26–36. [Google Scholar]

- Tang, H.; Ma, J.K.; Chen, L.; Jiang, L.W.; Xie, J.; Li, P.; He, J. GC-MS characterization of volatile flavor compounds in stinky tofu brine by optimization of headspace solid-phase microextraction conditions. Molecules 2018, 23, 3155. [Google Scholar] [CrossRef]

- Chen, C.; Huang, K.; Yu, H.Y.; Tang, H.X. The diversity of microbial communities in Chinese milk fan and their effects on volatile organic compound profiles. J. Dairy Sci. 2021, 104, 2581–2593. [Google Scholar] [CrossRef]

- Linstrom, P.J.; Mallard, W.G. NIST Standard Reference Database Number 69; National Institute of Standards & Technology: Gaithersburg, MD, USA, 2001. [Google Scholar]

- Tian, H.X.; Shen, Y.; Yu, H.Y.; He, Y.; Chen, C. Effects of 4 probiotic strains in coculture with traditional starters on the flavor profile of yogurt. J. Food Sci. 2017, 82, 1693–1701. [Google Scholar] [CrossRef]

- Gemert, L.J.V. Compilations of Odour Threshold Values in Air, Water and Other Media; Oliemans Punter & Partners BV: Houten, The Netherlands, 2003. [Google Scholar]

- Sun, J.; Yang, K.; Yanmin, L.I.; Chen, Y.; Liu, Y.; Zhang, Y. Analysis of characteristic aroma compounds in wangzhihe stinky tofu by simultaneous distillation-extraction and gas chromatography-mass spectrometry (SDE-GC-MS). Food Sci. 2015, 16, 127–131. [Google Scholar]

- Wang, Y.; Yang, X.; Li, L. A new style of fermented tofu by Lactobacillus casei combined with salt coagulant. 3 Biotech 2020, 10, 81. [Google Scholar] [CrossRef]

- Liu, P.; Xiang, Q.; Gao, L.; Wang, X.; Li, J.; Cui, X.; Lin, J.; Che, Z. Effects of different fermentation strains on the flavor characteristics of fermented soybean curd: Effects of strains on flavor quality. J. Food Sci. 2019, 84, 154–164. [Google Scholar] [CrossRef] [PubMed]

- Wei, G.; Yang, Z.; Regenstein, J.M.; Liu, X.; Liu, D. Characterizing aroma profiles of fermented soybean curd with ageing solutions during fermentation. Food Biosci. 2020, 33, 100508. [Google Scholar] [CrossRef]

- Roh, H.S.; Park, J.Y.; Park, S.Y.; Chun, B.S. Isolation of off-flavors and odors from tuna fish oil using supercritical carbon dioxide. Biotechnol. Bioproc. E 2006, 11, 496–502. [Google Scholar] [CrossRef]

- Lin, S.; Yang, R.; Cheng, S.; Wang, K.; Qin, L. Decreased quality and off-flavour compound accumulation of 3–10 kDa fraction of pine nut (Pinus koraiensis) peptide during storage. LWT 2017, 84, 23–33. [Google Scholar] [CrossRef]

- Shi, Y.G.; Yang, Y.; Piekoszewski, W.; Zeng, J.H.; Guan, H.N.; Wang, B.; Liu, L.L.; Zhu, X.Q.; Chen, F.L.; Zhang, N. Influence of four different coagulants on the physicochemical properties, textural characteristics and flavour of tofu. Int. J. Food Sci. Tech. 2020, 55, 1218–1229. [Google Scholar] [CrossRef]

- Rêgo, E.; Rosa, C.A.; Freire, A.L.; Machado, A.; Padilha, F.F. Cashew wine and volatile compounds produced during fermentation by non-Saccharomyces and Saccharomyces yeast. LWT 2020, 126, 109291. [Google Scholar] [CrossRef]

- Montel, M.C.; Masson, F.; Talon, R. Bacterial role in flavour development. Meat. Sci. 1998, S49, S111–S123. [Google Scholar] [CrossRef]

- Yin, H.; Liu, L.P.; Yang, M.; Ding, X.T.; Jia, S.; Dong, J.J.; Zhong, C. Enhancing medium chain fatty acid ethyl ester production during beer fermentation through EEB1 and/or ETR1 overexpression in saccharomyces pastorianus. J. Agri. Food Chem. 2019, 7, 231. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Zhao, J.; Liu, X.; Zhang, C.; Sun, B. Flavor mystery of Chinese traditional fermented baijiu: The great contribution of ester compounds. Food Chem. 2021, 7, 130920. [Google Scholar] [CrossRef]

| No. | Sensor Name | Type of Sensitive Substance |

|---|---|---|

| 1 | LY2/LG | Chlorine, Fluorine, Sulfide |

| 2 | LY2/G | Ammonia, Amine compounds |

| 3 | LY2/AA | Ethanol, Ammonia |

| 4 | LY2/Gh | Ammonia, Amine compounds |

| 5 | LY2/gCTI | Sulfide |

| 6 | LY2/gCT | Propane, Butane |

| 7 | T30/1 | Propanol, Hydrogen chloride |

| 8 | P10/1 | Hydrocarbons, n-octane |

| 9 | P10/2 | Methane, n-heptane |

| 10 | P40/1 | Fluorine, Chlorine, Methyl furfural |

| 11 | T70/2 | Xylene, Toluene |

| 12 | PA/2 | Acetaldehyde, Amine compounds |

| 13 | P30/1 | Ammonia, Ethanol |

| 14 | P40/2 | Chlorine, Methyl mercaptan |

| 15 | P30/2 | Hydrogen sulfide, Copper |

| 16 | T40/2 | Chlorine |

| 17 | T40/1 | Fluorine |

| 18 | TA/2 | Alcohol |

| No. | RI ** | Compound | Concentration (mg/kg) * | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Calc | Ref | Day 1 | Day 3 | Day 5 | Day 7 | Day 10 | Day 13 | ||

| 1 | 1455 | 1461 | Acetic acid | 1.014 ± 0.822 a | 1.723 ± 0.132 a | 2.035 ± 0.242 a | 2.754 ± 0.003 c | 3.299 ± 0.597 b | 3.471 ± 0.320 c |

| 2 | 1541 | 1564 | Propanoic acid | 0.498 ± 0.310 a | 0.652 ± 0.319 bc | 0.906 ± 0.161 ab | 1.212 ± 0.010 c | 1.588 ± 0.467 c | 2.825 ± 0.258 d |

| 3 | 1571 | 1544 | 2-methyl-propanoic acid | 0.052 ± 0.019 b | 0.052 ± 0.013 b | 0.082 ± 0.010 ab | 0.088 ± 0.008 b | 0.036 ± 0.003 a | 0.027 ± 0.006 b |

| 4 | 1630 | 1639 | Butanoic acid | 1.367 ± 0.555 a | 2.495 ± 1.201 c | 3.471 ± 0.666 b | 4.173 ± 0.124 b | 5.692 ± 0.418 c | 7.501 ± 0.360 d |

| 5 | 1672 | 1674 | 2-methyl-butanoic acid | 0.182 ± 0.048 a | 0.374 ± 0.012 b | 0.263 ± 0.031 b | 0.118 ± 0.018 b | — | — |

| 6 | 1673 | 1679 | 3-methyl-butanoic acid | — | 0.331 ± 0.060 | — | — | — | — |

| 7 | 1738 | 1734 | Pentanoic acid | 0.066 ± 0.015 a | 0.287 ± 0.051 c | 0.273 ± 0.007 a | 0.164 ± 0.007 a | 0.067 ± 0.018 a | 0.019 ± 0.012 b |

| 8 | 1801 | 1800 | 4-methyl-pentanoic acid | — | 0.021 ± 0.001 ab | 0.099 ± 0.003 c | 0.167 ± 0.013 bc | 0.149 ± 0.020 c | 0.132 ± 0.012 abc |

| 9 | 1843 | 1831 | Hexanoic acid | 0.125 ± 0.055 a | 0.266 ± 0.071 bc | 0.17 ± 0.047 ab | 0.162 ± 0.006 ab | 0.105 ± 0.039 a | 0.066 ± 0.004 cd |

| 10 | 2055 | 2039 | Octanoic acid | — | 0.038 ± 0.014 ab | 0.018 ± 0.002 a | — | — | — |

| 11 | 928 | 939 | Ethanol | 0.686 ± 0.087 bc | 0.585 ± 0.090 ab | 0.532 ± 0.088 ab | 0.553 ± 0.006 ab | 0.541 ± 0.490 c | 0.309 ± 0.035 a |

| 12 | 1033 | 1037 | 1-propanol | — | 0.011 ± 0.002 | — | 0.009 ± 0.001 | — | — |

| 13 | 1142 | 1150 | 1-butanol | — | 0.014 ± 0.001 | — | 0.012 ± 0.001 | — | — |

| 14 | 1205 | 1206 | 3-methyl-1-butanol | 0.041 ± 0.028 c | 0.029 ± 0.002 b | 0.011 ± 0.001 a | — | — | — |

| 15 | 1246 | 1254 | 1-pentanol | 0.016 ± 0.000 a | 0.023 ± 0.014 b | 0.022 ± 0.017 b | 0.022 ± 0.003 c | — | — |

| 16 | 1349 | 1340 | 1-hexanol | 0.704 ± 0.316 cd | 0.765 ± 0.013 bc | 0.827 ± 0.022 d | 0.955 ± 0.107 d | 0.234 ± 0.097 a | 0.157 ± 0.003 ab |

| 17 | 1389 | 1394 | 3-octanol | 0.035 ± 0.004 ab | 0.029 ± 0.020 a | 0.092 ± 0.002 d | 0.046 ± 0.010 bc | 0.034 ± 0.002 ab | 0.011 ± 0.001 c |

| 18 | 1447 | 1447 | 1-octen-3-ol | 0.186 ± 0.042 ab | 0.262 ± 0.070 d | 0.259 ± 0.021 d | 0.211 ± 0.005 c | 0.056 ± 0.001 a | — |

| 19 | 1451 | 1459 | 1-heptanol | 0.021 ± 0.048 a | 0.022 ± 0.030 a | 0.034 ± 0.008 a | 0.051 ± 0.022 d | 0.223 ± 0.015 c | 0.044 ± 0.007 b |

| 20 | 1508 | 1504 | (E)-2-hepten-1-ol | 0.037 ± 0.001 a | 0.029 ± 0.011 a | 0.015 ± 0.009 b | — | — | — |

| 21 | 1554 | 1554 | 1-octanol | 0.024 ± 0.009 | 0.017 ± 0.005 | — | — | — | — |

| 22 | 1609 | 1609 | (E)-2-octen-1-ol | 0.062 ± 0.001 a | 0.042 ± 0.003 b | 0.011 ± 0.001 c | — | — | — |

| 23 | 1656 | 1666 | 1-nonanol | — | 0.122 ± 0.001 a | 0.134 ± 0.007 a | 0.056 ± 0.001 b | 0.028 ± 0.001 c | — |

| 24 | 1912 | 1935 | Phenylethyl alcohol | 0.018 ± 0.009 a | 0.044 ± 0.006 a | 0.042 ± 0.001 a | 0.064 ± 0.040 a | 0.093 ± 0.035 a | 0.304 ± 0.068 b |

| 25 | 1957 | 1935 | 1-dodecanol | — | — | — | — | 0.128 ± 0.001 | 0.412 ± 0.012 |

| 26 | 1878 | 1889 | Benzyl alcohol | 0.032 ± 0.021 a | 0.021 ± 0.001 a | 0.025 ± 0.001 a | 0.027 ± 0.001 a | 0.031 ± 0.001 a | 0.049 ± 0.004 b |

| 27 | 1957 | 1935 | 1-Dodecanol | — | — | — | 0.138 ± 0.001 a | 0.228 ± 0.024 b | 0.412 ± 0.012 c |

| 28 | 1528 | 1529 | Benzaldehyde | 0.208 ± 0.197 b | 0.165 ± 0.006 a | 0.128 ± 0.001 ab | 0.055 ± 0.438 a | 0.027 ± 0.001 a | — |

| 29 | 1712 | 1730 | 4-ethyl-benzaldehyde | 0.056 ± 0.018 a | 0.042 ± 0.008 a | 0.032 ± 0.008 b | 0.013 ± 0.002 c | — | — |

| 30 | 1217 | 1220 | (E)-2-hexenal | 0.014 ± 0.000 | 0.002 ± 0.001 | — | — | — | — |

| 31 | 1322 | 1332 | (E)-2-heptenal | 0.052 ± 0.023 a | 0.059 ± 0.027 a | 0.064 ± 0.017 b | 0.054 ± 0.001 a | — | — |

| 32 | 1390 | 1396 | Nonanal | 0.049 ± 0.011 a | 0.062 ± 0.001 b | 0.189 ± 0.020 c | 0.049 ± 0.032 ab | 0.014 ± 0.001 b | — |

| 33 | 1429 | 1434 | (E)-2-octenal | 0.056 ± 0.000 a | 0.071 ± 0.001 a | 0.097 ± 0.007 b | 0.052 ± 0.001 a | — | — |

| 34 | 1496 | 1500 | Decanal | — | — | 0.035 ± 0.008 | — | — | — |

| 35 | 1535 | 1542 | (E)-2-nonenal | — | — | 0.048 ± 0.007 | — | — | — |

| 36 | 1642 | 1643 | (E)-2-decenal | 0.022 ± 0.001 a | 0.037 ± 0.008 a | 0.055 ± 0.438 b | 0.085 ± 0.001 c | 0.074 ± 0.011 c | 0.051 ± 0.001 b |

| 37 | 1701 | 1706 | (E,E)-2,4-nonadienal | 0.007 ± 0.001 a | 0.014 ± 0.002 a | 0.018 ± 0.002 b | — | — | — |

| 38 | 1809 | 1827 | (E,E)-2,4-decadienal | 0.043 ± 0.033 a | 0.065 ± 0.002 a | 0.113 ± 0.019 ab | 0.298 ± 0.044 c | 0.314 ± 0.001 c | 0.241 ± 0.021 bc |

| 39 | 889 | 891 | Ethyl acetate | — | — | — | — | 0.011 ± 0.001 | 0.329 ± 0.001 |

| 40 | 951 | 964 | Propanoic acid ethyl ester | — | — | — | — | — | 0.094 ± 0.011 |

| 41 | 1069 | 964 | Acetic acid butyl ester | — | — | — | — | — | 0.014 ± 0.002 |

| 42 | 1171 | 1176 | Acetic acid pentyl ester | — | — | — | — | — | 0.074 ± 0.002 |

| 43 | 1268 | 1269 | Acetic acid hexyl ester | — | 0.011 ± 0.001 a | 0.014 ± 0.003 a | 0.019 ± 0.001 a | 0.095 ± 0.055 b | 1.862 ± 0.032 c |

| 44 | 1336 | 1342 | Propanoic acid, hexyl ester | — | — | — | — | — | 0.327 ± 0.012 |

| 45 | 1349 | 1336 | Formic acid, hexyl ester | — | — | — | — | — | 0.197 ± 0.004 |

| 46 | 1371 | 1392 | Acetic acid heptyl ester | — | — | — | — | — | 0.018 ± 0.001 |

| 47 | 1554 | 1560 | Formic acid octyl ester | — | — | 0.057 ± 0.001 | 0.025 ± 0.003 | — | — |

| 48 | 1580 | 1579 | Bornyl acetate | — | 0.005 ± 0.001 a | 0.018 ± 0.009 a | 0.002 ± 0.001 a | — | — |

| 49 | 1638 | 1635 | Butyrolactone | 0.032 ± 0.002 a | 0.069 ± 0.009 b | 0.031 ± 0.001 a | — | — | — |

| 50 | 1818 | 1825 | 2-phenylethyl acetate | — | — | — | — | 0.734 ± 0.169 | 12.172 ± 0.684 |

| 51 | 1884 | / | 2-phenyl ethyl propanoate | — | — | — | — | 0.078 ± 0.022 | 3.515 ± 0.699 |

| 52 | 1864 | 1889 | 2-methoxy phenol | — | 0.017 ± 0.001 a | 0.041 ± 0.007 b | 0.018 ± 0.004 a | — | — |

| 53 | 2009 | 2004 | Phenol | 0.119 ± 0.050 a | 0.125 ± 0.022 a | 0.178 ± 0.001 ab | 0.105 ± 0.514 ab | 0.077 ± 0.021 a | 0.061 ± 0.010 c |

| 54 | 2086 | 2094 | P-cresol | 0.367 ± 0.189 a | 1.014 ± 0.141 b | 1.316 ± 0.255 b | 1.716 ± 0.102 b | 1.807 ± 0.503 b | 2.031 ± 0.080 c |

| 55 | 1281 | 1278 | 2-octanone | 0.041 ± 0.011 a | 0.022 ± 0.002 b | 0.028 ± 0.014 b | 0.023 ± 0.514 b | 0.022 ± 0.002 b | 0.017 ± 0.004 a |

| 56 | 1656 | 1647 | Acetophenone | 0.124 ± 0.012 a | 0.082 ± 0.008 b | 0.039 ± 0.009 b | — | — | — |

| 57 | 1968 | 1988 | Maltol | 0.019 ± 0.013 b | 0.026 ± 0.014 b | 0.022 ± 0.010 b | 0.045 ± 0.027 bc | 0.003 ± 0.002 a | — |

| 58 | 1224 | 1244 | 2-pentyl-furan | 0.088 ± 0.032 cd | 0.084 ± 0.002 a | 0.102 ± 0.016 d | 0.082 ± 0.001 cd | 0.062 ± 0.008 bc | 0.046 ± 0.029 b |

| 59 | 1257 | 1257 | Styrene | 0.051 ± 0.016 a | 0.011 ± 0.008 b | 0.005 ± 0.001 c | — | — | — |

| 60 | 1618 | 1619 | 2-(2-ethoxyethoxy)-ethanol | 0.046 ± 0.002 a | 0.077 ± 0.031 b | 0.031 ± 0.001 a | — | — | — |

| NO. | Compound A | Threshold (mg/kg) B | OAV | Description | |||||

|---|---|---|---|---|---|---|---|---|---|

| Day 1 | Day 3 | Day 5 | Day 7 | Day 10 | Day 13 | ||||

| 1 | 3-methyl-1-butanol | 0.02 | 2 | 1 | 1 | — | — | — | Apple brandy-like, spicy |

| 2 | 1-hexanol | 0.07 | 10 | 7 | 7 | 6 | 3 | 2 | Resin-like, flowery, green |

| 3 | 1-octen-3-ol | 0.0015 | 57 | 74 | 93 | 120 | 137 | 182 | Mushroom-like |

| 4 | 1-heptanol | 0.003 | 7 | 7 | — | 12 | — | 15 | Green, chemical-like |

| 5 | (E)-2-octen-1-ol | 0.02 | 3 | 2 | 1 | 1 | — | — | Mellow |

| 6 | 1-dodecanol | 0.016 | — | — | — | 11 | 16 | 26 | Mellow |

| 7 | Ethyl acetate | 0.005 | — | — | — | — | 21 | 66 | Mellow, fruity |

| 8 | Propanoic acid ethyl ester | 0.01 | — | — | — | — | — | 9 | Mellow, fruity |

| 9 | Acetic acid pentyl ester | 0.043 | — | — | — | — | — | 2 | Fruity, banana- and pear-like |

| 10 | Acetic acid hexyl ester | 0.002 | — | 6 | 8 | 10 | 48 | 931 | Fruity |

| 11 | Propanoic acid, hexyl ester | 0.008 | — | — | — | 7 | 21 | 41 | Sweet, fruity |

| 12 | 2-phenylethyl acetate | 0.24959 | — | — | — | — | 13 | 24 | Sweet, slightly green leafy |

| 13 | 4-ethyl-benzaldehyde | 0.013 | 4 | 2 | 2 | — | — | 2 | Bitter almond-like, slightly sweet |

| 14 | Hexanal | 0.005 | 10 | 17 | 44 | 26 | 11 | — | Green, citrusy and fatty |

| 15 | (E)-2-octenal | 0.003 | 19 | 9 | — | — | — | — | Green, citrusy, and fatty |

| 16 | Nonanal | 0.0011 | 45 | 57 | 172 | 41 | 17 | — | Green, citrusy, and fatty |

| 17 | (E)-2-heptenal | 0.013 | 5 | 5 | 5 | 4 | — | 7 | Irritating, green grass-like |

| 18 | Decanal | 0.003 | — | — | 10 | 1 | — | — | Green and fatty |

| 19 | (E)-2-nonenal | 0.00019 | 97 | 162 | 251 | 180 | 97 | 12 | Green |

| 20 | (E)-2-decenal | 0.0003 | 73 | 108 | 167 | 284 | 220 | 169 | Green and fatty |

| 21 | (E,E)-2,4-nonadienal | 0.0001 | 70 | 123 | 180 | 110 | 42 | — | Green and fatty |

| 22 | (E,E)-2,4-decadienal | 0.000027 | 1593 | 1928 | 4169 | 11,032 | 4235 | 2924 | Spicy, geranium-like |

| 23 | Butanoic acid | 0.204 | 7 | 12 | 17 | 22 | 28 | 37 | Strongly sour, cheese-like |

| 24 | 2-methyl-butanoic acid | 0.1 | 2 | 4 | 3 | 3 | — | — | Sour, cheese-like |

| 25 | 3-methyl-butanoic acid | 0.046 | — | 7 | 12 | 4 | — | — | Milk-like, sour, slightly sweet |

| 26 | Acetophenone | 0.065 | 2 | — | — | — | — | — | Hawthorn-like |

| 27 | 2-methoxyphenol | 0.0016 | 3 | 11 | 18 | 8 | — | — | Sweet, woody, slightly smoky |

| 28 | P-cresol | 0.01 | 37 | 101 | 132 | 122 | 111 | 103 | Phenolic, sour |

| 29 | 2-pentyl-furan | 0.0058 | 5 | 14 | 18 | 14 | 11 | 8 | Oily, soy, green |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, H.; Zou, L.; Li, L.; Chen, C.; Yu, H.; Ma, X.; Huang, J.; Lou, X.; Yuan, H. Characterisation of the Aroma Profile and Dynamic Changes in the Flavour of Stinky Tofu during Storage. Foods 2023, 12, 1410. https://doi.org/10.3390/foods12071410

Tian H, Zou L, Li L, Chen C, Yu H, Ma X, Huang J, Lou X, Yuan H. Characterisation of the Aroma Profile and Dynamic Changes in the Flavour of Stinky Tofu during Storage. Foods. 2023; 12(7):1410. https://doi.org/10.3390/foods12071410

Chicago/Turabian StyleTian, Huaixiang, Ling Zou, Li Li, Chen Chen, Haiyan Yu, Xinxin Ma, Juan Huang, Xinman Lou, and Haibin Yuan. 2023. "Characterisation of the Aroma Profile and Dynamic Changes in the Flavour of Stinky Tofu during Storage" Foods 12, no. 7: 1410. https://doi.org/10.3390/foods12071410

APA StyleTian, H., Zou, L., Li, L., Chen, C., Yu, H., Ma, X., Huang, J., Lou, X., & Yuan, H. (2023). Characterisation of the Aroma Profile and Dynamic Changes in the Flavour of Stinky Tofu during Storage. Foods, 12(7), 1410. https://doi.org/10.3390/foods12071410