Consumer Perception and Acceptability of Lupin-Derived Products: A Systematic Review

Abstract

1. Introduction

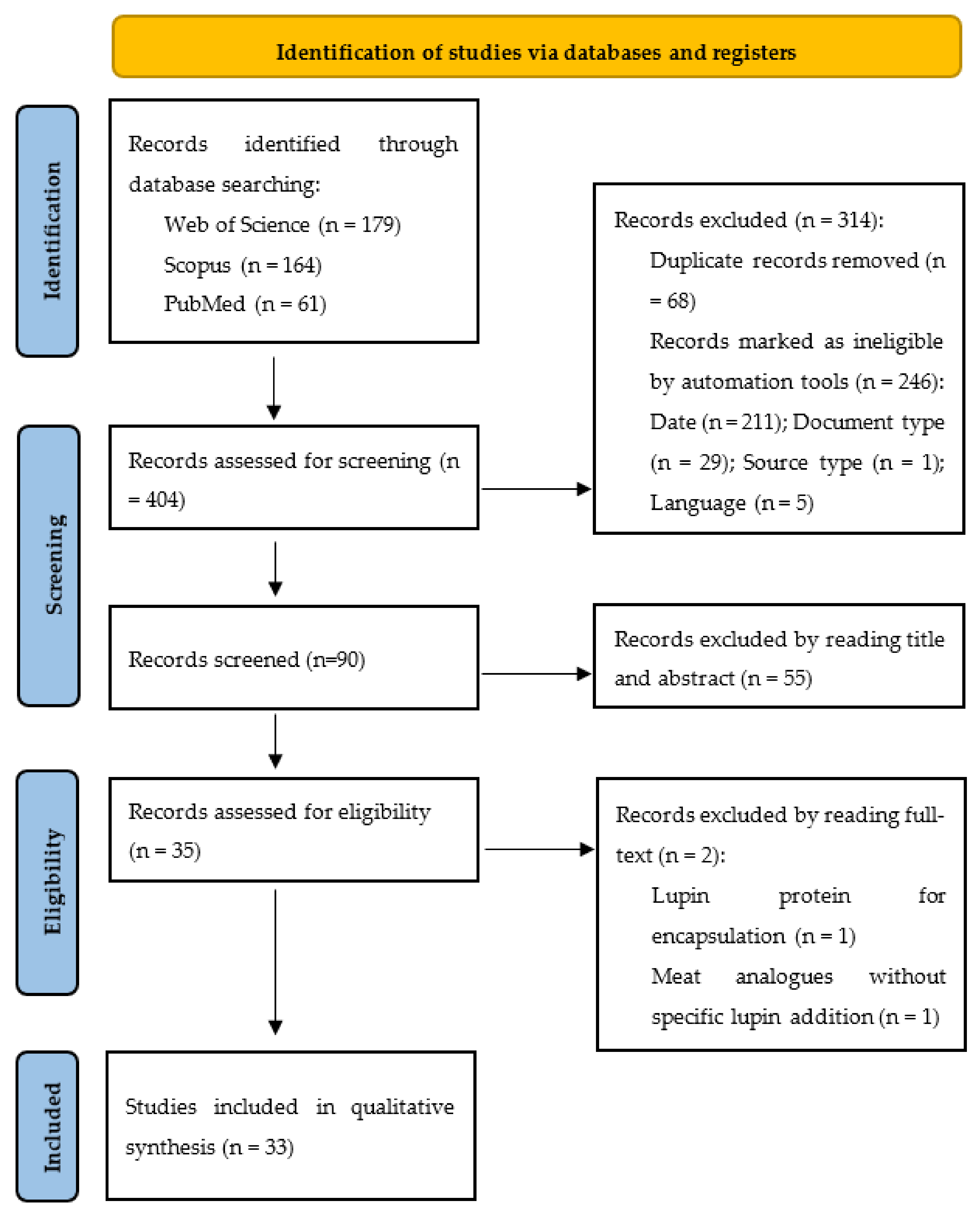

2. Materials and Methods

2.1. Eligibility Criteria

2.2. Search Strategy

2.3. Selection and Data Collection Processes

3. Results

3.1. Eligibility Criteria

3.2. Study Characteristics

3.3. Results of Syntheses

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Granato, D.; Barba, F.J.; Bursać Kovačević, D.; Lorenzo, J.M.; Cruz, A.G.; Putnik, P. Functional Foods: Product Development, Technological Trends, Efficacy Testing, and Safety. Annu. Rev. Food Sci. Technol. 2020, 11, 93–118. [Google Scholar] [CrossRef]

- Wahlqvist, M.L. Future food. Asia Pac. J. Clin. Nutr. 2016, 25, 706–715. [Google Scholar] [PubMed]

- Sivasankar, S.E.N.; Buruchara, R.; Henry, C.; Rubiales, D.; Sandhu, J.S.; Negra, C. 10-Year Research Strategy for Pulse Crops; Global Pulse Confederation: 2016; pp. 1–55. Available online: https://globalpulses.com/files/knowledge_center/20181108183145_iyp_10-year-research-strategy_pulse-crops_final_dec-8-2016.pdf (accessed on 10 February 2023).

- Hughes, J.; Pearson, E.; Grafenauer, S. Legumes-A Comprehensive Exploration of Global Food-Based Dietary Guidelines and Consumption. Nutrients 2022, 14, 3080. [Google Scholar] [CrossRef] [PubMed]

- Havemeier, S.; Erickson, J.; Slavin, J. Dietary guidance for pulses: The challenge and opportunity to be part of both the vegetable and protein food groups. Ann. N.Y. Acad. Sci. 2017, 1392, 58–66. [Google Scholar] [CrossRef]

- Ferreira, H.; Vasconcelos, M.; Gil, A.M.; Pinto, E. Benefits of pulse consumption on metabolism and health: A systematic review of randomized controlled trials. Crit. Rev. Food Sci. Nutr. 2021, 61, 85–96. [Google Scholar] [CrossRef]

- Ibsen, D.B.; Mogensen, L.; Corredig, M.; Dahm, C.C. Legumes in a sustainable healthy diet: (How) to be or not to be, that is the question. Int. J. Food Des. 2022, 7, 171–185. [Google Scholar] [CrossRef]

- Didinger, C.; Thompson, H.J. Defining Nutritional and Functional Niches of Legumes: A Call for Clarity to Distinguish a Future Role for Pulses in the Dietary Guidelines for Americans. Nutrients 2021, 13, 1100. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, S.S.P.; Franchini, B.M.; Pinho, I.S.M.; Graça, A.P.S.R. The Portuguese mediterranean diet wheel: Development considerations. Br. J. Nutr. 2022, 128, 1315–1321. [Google Scholar] [CrossRef]

- Zhong, L.Z.; Fang, Z.X.; Wahlqvist, M.L.; Wu, G.C.; Hodgson, J.M.; Johnson, S.K. Seed coats of pulses as a food ingredient: Characterization, processing, and applications. Trends Food Sci. Technol. 2018, 80, 35–42. [Google Scholar] [CrossRef]

- Roland, W.S.U.; Pouvreau, L.; Curran, J.; van de Velde, F.; de Kok, P.M.T. Flavor Aspects of Pulse Ingredients. Cereal Chem. 2017, 94, 58–65. [Google Scholar] [CrossRef]

- Chigwedere, C.M.; Wanasundara, J.P.D.; Shand, P.J. Sensory descriptors for pulses and pulse-derived ingredients: Toward a standardized lexicon and sensory wheel. Compr. Rev. Food Sci. Food Saf. 2022, 21, 999–1023. [Google Scholar] [CrossRef] [PubMed]

- Pfeuffer, M.; Erbersdobler, H.; Jahreis, G. Legumes in human nutrition. Health aspects—Part 1. Ernahr. Umsch. 2020, 67, 160–165. [Google Scholar]

- Pfeuffer, M.; Erbersdobler, H.; Jahreis, G. Legumes in human nutrition. Health aspects—Part 2. Ernahr. Umsch. 2020, 67, 184–189. [Google Scholar]

- Boukid, F.; Zannini, E.; Carini, E.; Vittadini, E. Pulses for bread fortification: A necessity or a choice? Trends Food Sci. Technol. 2019, 88, 416–428. [Google Scholar] [CrossRef]

- Cabanillas, B.; Jappe, U.; Novak, N. Allergy to Peanut, Soybean, and Other Legumes: Recent Advances in Allergen Characterization, Stability to Processing and IgE Cross-Reactivity. Mol. Nutr. Food Res. 2018, 62, 1700446. [Google Scholar] [CrossRef]

- Taylor, S.L.; Marsh, J.T.; Koppelman, S.J.; Kabourek, J.L.; Johnson, P.E.; Baumert, J.L. A perspective on pea allergy and pea allergens. Trends Food Sci. Technol. 2021, 116, 186–198. [Google Scholar] [CrossRef]

- Boeck, T.; Sahin, A.W.; Zannini, E.; Arendt, E.K. Nutritional properties and health aspects of pulses and their use in plant-based yogurt alternatives. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3858–3880. [Google Scholar] [CrossRef]

- Kouris-Blazos, A.; Belski, R. Health benefits of legumes and pulses with a focus on Australian sweet lupins. Asia Pac. J. Clin. Nutr. 2016, 25, 1–17. [Google Scholar]

- Carvajal-Larenas, F.E. Nutritional, rheological and sensory evaluation of Lupinus mutabilis food products-a Review. Czech J. Food Sci. 2019, 37, 301–311. [Google Scholar] [CrossRef]

- Villarino, C.B.; Jayasena, V.; Coorey, R.; Chakrabarti-Bell, S.; Johnson, S.K. Nutritional, Health, and Technological Functionality of Lupin Flour Addition to Bread and Other Baked Products: Benefits and Challenges. Crit. Rev. Food Sci. Nutr. 2016, 56, 835–857. [Google Scholar] [CrossRef]

- Todorov, N.A.; Pavlov, D.C.; Kostov, K.D. Lupin (Lupinus spp.). In Food and Feed from Legumes and Oilseeds; Nwokolo, E., Smartt, J., Eds.; Springer: Boston, MA, USA, 1996; pp. 113–123. [Google Scholar]

- Cowling, W. Lupins (Lupinus L.). In Plant Genetic Resources of Legumes in the Mediterranean; Maxted, N., Bennett, S.J., Eds.; Springer: Dordrecht, The Netherlands, 2001; pp. 191–206. [Google Scholar]

- Tabe, L.M.; Molvig, L. Lupins. In Transgenic Crops VI; Pua, E.-C., Davey, M.R., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 397–408. [Google Scholar]

- Lo, B.; Kasapis, S.; Farahnaky, A. Lupin protein: Isolation and techno-functional properties, a review. Food Hydrocoll. 2021, 112, 106318. [Google Scholar] [CrossRef]

- Guillamon, E.; Rodriguez, J.; Burbano, C.; Muzquiz, M.; Pedrosa, M.M.; Cabanillas, B.; Crespo, J.F.; Sancho, A.I.; Mills, E.N.C.; Cuadrado, C. Characterization of lupin major allergens (Lupinus albus L.). Mol. Nutr. Food Res. 2010, 54, 1668–1676. [Google Scholar] [CrossRef] [PubMed]

- Arnoldi, A.; Resta, D.; Brambilla, F.; Boschin, G.; D’Agostina, A.; Sirtori, E.; O’Kane, F. Parameters for the evaluation of the thermal damage and nutraceutical potential of lupin-based ingredients and food products. Mol. Nutr. Food Res. 2007, 51, 431–436. [Google Scholar] [CrossRef]

- Coisson, J.D.; Arlorio, M.; Locatelli, M.; Garino, C.; Resta, D.; Sirtori, E.; Arnoldi, A.; Boschin, G. The artificial intelligence-based chemometrical characterisation of genotype/chemotype of Lupinus albus and Lupinus angustifolius permits their identification and potentially their traceability. Food Chem. 2011, 129, 1806–1812. [Google Scholar] [CrossRef]

- Carvajal-Larenas, F.E.; Linnemann, A.R.; Nout, M.J.R.; Koziol, M.; van Boekel, M.A.J.S. Lupinus mutabilis: Composition, Uses, Toxicology, and Debittering. Crit. Rev. Food Sci. Nutr. 2016, 56, 1454–1487. [Google Scholar] [CrossRef] [PubMed]

- Al-Ali, H.A.; Shah, U.; Hackett, M.J.; Gulzar, M.; Karakyriakos, E.; Johnson, S.K. Technological strategies to improve gelation properties of legume proteins with the focus on lupin. Innov. Food Sci. Emerg. Technol. 2021, 68, 102634. [Google Scholar] [CrossRef]

- Kushnareva, A.V.; Shelenga, T.V.; Perchuk, I.N.; Egorova, G.P.; Malyshev, L.L.; Kerv, Y.A.; Shavarda, A.L.; Vishnyakova, M.A. Selection of an optimal method for screening the collection of narrow-leaved lupine held by the Vavilov Institute for the qualitative and quantitative composition of seed alkaloids. Vavilovskii Zhurnal Genet. Sel. 2020, 24, 829–835. [Google Scholar] [CrossRef]

- Leonte, A.; Florina Isticioaia, S.; Amarghioalei, R.G.; EȘAnu, S.A.; Pintilie, P.L. Behavior of White and Blue Lupine Varieties in Pedoclimatic Conditions of the A.R.D.S. Secuieni. Agron. Ser. Sci. Res./Lucr. Ştiinţifice Ser. Agron. 2021, 64, 105–108. [Google Scholar]

- Bryant, L.; Rangan, A.; Grafenauer, S. Lupins and Health Outcomes: A Systematic Literature Review. Nutrients 2022, 14, 327. [Google Scholar] [CrossRef]

- Boukid, F.; Pasqualone, A. Lupine (Lupinus spp.) proteins: Characteristics, safety and food applications. Eur. Food Res. Technol. 2022, 248, 345–356. [Google Scholar] [CrossRef]

- Pereira, A.; Ramos, F.; Silva, A.S. Lupin (Lupinus albus L.) Seeds: Balancing the Good and the Bad and Addressing Future Challenges. Molecules 2022, 27, 8557. [Google Scholar] [CrossRef] [PubMed]

- Sedlakova, K.; Strakova, E.; Suchy, P.; Krejcarova, J.; Herzig, I. Lupin as a perspective protein plant for animal and human nutrition-a review. Acta Vet. Brno 2016, 85, 165–175. [Google Scholar] [CrossRef]

- Romero-Espinoza, A.M.; Serna-Saldivar, S.O.; Vintimilla-Alvarez, M.C.; Briones-Garcia, M.; Lazo-Velez, M.A. Effects of fermentation with probiotics on anti-nutritional factors and proximate composition of lupin (Lupinus mutabilis sweet). Lwt-Food Sci. Technol. 2020, 130. [Google Scholar] [CrossRef]

- Malekipoor, R.; Johnson, S.K.; Bhattarai, R.R. Lupin Kernel Fibre: Nutritional Composition, Processing Methods, Physicochemical Properties, Consumer Acceptability and Health Effects of Its Enriched Products. Nutrients 2022, 14, 2845. [Google Scholar] [CrossRef]

- Okagu, I.U.; Ndefo, J.C.; Aham, E.C.; Obeme-Nmom, J.I.; Agboinghale, P.E.; Aguchem, R.N.; Nechi, R.N.; Lammi, C. Lupin-Derived Bioactive Peptides: Intestinal Transport, Bioavailability and Health Benefits. Nutrients 2021, 13, 3266. [Google Scholar] [CrossRef]

- Villa, C.; Costa, J.; Mafra, I. Lupine allergens: Clinical relevance, molecular characterization, cross-reactivity, and detection strategies. Compr. Rev. Food. Sci. Food Saf. 2020, 19, 3886–3915. [Google Scholar] [CrossRef]

- Johnson, S.K.; Clements, J.; Villarino CB, J.; Coorey, R. Chapter 8—Lupins: Their Unique Nutritional and Health-Promoting Attributes. In Gluten-Free Ancient Grains; Taylor, J.R.N., Awika, J.M., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 179–221. [Google Scholar]

- Guyomarc’h, F.; Arvisenet, G.; Bouhallab, S.; Canon, F.; Deutsch, S.-M.; Drigon, V.; Dupont, D.; Famelart, M.-H.; Garric, G.; Guédon, E.; et al. Mixing milk, egg and plant resources to obtain safe and tasty foods with environmental and health benefits. Trends Food Sci. Technol. 2021, 108, 119–132. [Google Scholar] [CrossRef]

- Mirmoghtadaie, L.; Shojaee Aliabadi, S.; Hosseini, S.M. Recent approaches in physical modification of protein functionality. Food Chem. 2016, 199, 619–627. [Google Scholar] [CrossRef]

- Ruiz-López, M.A.; Barrientos-Ramírez, L.; García-López, P.M.; Valdés-Miramontes, E.H.; Zamora-Natera, J.F.; Rodríguez-Macias, R.; Salcedo-Pérez, E.; Bañuelos-Pineda, J.; Vargas-Radillo, J.J. Nutritional and Bioactive Compounds in Mexican Lupin Beans Species: A Mini-Review. Nutrients 2019, 11, 1785. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef]

- Abreu, B.; Lima, J.; Rocha, A. Consumer Perception and Acceptability of Lupin-Derived Products: A Systematic Review; CRD42022379036; PROSPERO: 2022. Available online: https://www.crd.york.ac.uk/prospero/display_record.php?ID=CRD42022379036 (accessed on 27 February 2023).

- Abdullah QS, A.; Abass, K.S. Effect of the procedure of the sweet lupine powder as an alternative to the camel meat on the quality and sensory characteristics of the manufactured burgers. Indian J. Public Health Res. Dev. 2019, 10, 1900–1904. [Google Scholar] [CrossRef]

- Al-Saedi, N.; Agarwal, M.; Islam, S.; Ren, Y.L. Study on the Correlation between the Protein Profile of Lupin Milk and Its Cheese Production Compared with Cow’s Milk. Molecules 2021, 26, 2395. [Google Scholar] [CrossRef] [PubMed]

- Alqahtani, N.K.; Barbabosa-Pliego, A.; Alnemr, T.M. Influence of sweet lupine Husk’s addition on fat-free stirred yogurt properties. Int. J. Dairy Sci. 2021, 16, 41–47. [Google Scholar] [CrossRef]

- Canon, F.; Maillard, M.B.; Famelart, M.H.; Thierry, A.; Gagnaire, V. Mixed dairy and plant-based yogurt alternatives: Improving their physical and sensorial properties through formulation and lactic acid bacteria cocultures. Curr. Res. Food Sci. 2022, 5, 665–676. [Google Scholar] [CrossRef] [PubMed]

- Laaksonen, O.; Kahala, M.; Marsol-Vall, A.; Blasco, L.; Jarvenpaa, E.; Rosenvald, S.; Virtanen, M.; Tarvainen, M.; Yang, B.R. Impact of lactic acid fermentation on sensory and chemical quality of dairy analogues prepared from lupine (Lupinus angustifolius L.) seeds. Food Chem. 2021, 346, 9. [Google Scholar] [CrossRef]

- Alemayehu, G.F.; Forsido, S.F.; Tola, Y.B.; Amare, E. Optimization of nutritional and sensory properties of fermented oat-based composite beverage. Heliyon 2022, 8, e10771. [Google Scholar] [CrossRef]

- Lopes, M.; Pierrepont, C.; Duarte, C.M.; Filipe, A.; Medronho, B.; Sousa, I. Legume Beverages from Chickpea and Lupin, as New Milk Alternatives. Foods 2020, 9, 1458. [Google Scholar] [CrossRef]

- Márquez-Villacorta, L.; Pretell-Vásquez, C.; Hayayumi-Valdivia, M. Functional beverage design based on fresh milk, tarwi (Lupinus mutabilis) beverage and oatmeal (Avena sativa). Rev. Chil. Nutr. 2021, 48, 490–499. [Google Scholar] [CrossRef]

- Schlegel, K.; Lidzba, N.; Ueberham, E.; Eisner, P.; Schweiggert-Weisz, U. Fermentation of Lupin Protein Hydrolysates-Effects on Their Functional Properties, Sensory Profile and the Allergenic Potential of the Major Lupin Allergen Lup an 1. Foods 2021, 10, 281. [Google Scholar] [CrossRef]

- Yaver, E.; Bilgicli, N. Utilisation of cereal-legume flour blends in commercial and traditional bread. Qual. Assur. Saf. Crop. Foods 2018, 10, 297–306. [Google Scholar] [CrossRef]

- Kaczmarska, K.T.; Chandra-Hioe, M.V.; Frank, D.; Arcot, J. Aroma characteristics of lupin and soybean after germination and effect of fermentation on lupin aroma. LWT-Food Sci. Technol. 2018, 87, 225–233. [Google Scholar] [CrossRef]

- Wandersleben, T.; Morales, E.; Burgos-Diaz, C.; Barahona, T.; Labra, E.; Rubilar, M.; Salvo-Garrido, H. Enhancement of functional and nutritional properties of bread using a mix of natural ingredients from novel varieties of flaxseed and lupine. LWT-Food Sci. Technol. 2018, 91, 48–54. [Google Scholar] [CrossRef]

- Atudorei, D.; Ropciuc, S.; Codina, G.G. Possibilities to Use Germinated Lupine Flour as an Ingredient in Breadmaking to Improve the Final Product Quality. Agronomy 2022, 12, 667. [Google Scholar] [CrossRef]

- Alshehry, G.; Algarni, E.; Aljumayi, H.; Algheshairy, R.M.; Alharbi, H.F. Development and Characterization of Multigrain Pan Bread Prepared Using Quinoa, Lupin, and Fenugreek Seeds with Yellow Maize as a Gluten-Free Diet. J. Food Qual. 2022, 2022, 4331353. [Google Scholar] [CrossRef]

- Calderón, A.; Bonilla, S.; Schmiele, M.; Navarrete, D.; Vernaza, M.G. Study of Lupinus mutabilis sweet flour incorporation on the rheological, physical, chemical, and sensory properties of wheat bread. J. Food Process. Preserv. 2022, 46, e17027. [Google Scholar] [CrossRef]

- Omran, A.A.; Mahgoub, S.A. Quality evaluation of gluten-free flat bread prepared by using rice and millet flour. Br. Food J. 2022, 124, 12. [Google Scholar] [CrossRef]

- Hoehnel, A.; Bez, J.; Amarowicz, R.; Arendt, E.K.; Zannini, E. Combining high-protein ingredients from pseudocereals and legumes for the development of fresh high-protein hybrid pasta: Maintained technological quality and adequate sensory attributes. J. Sci. Food Agric. 2022, 102, 4977–4987. [Google Scholar] [CrossRef] [PubMed]

- Yaver, E.; Bilgicli, N. Development of Quality Characteristics of Pasta Enriched with Lupin (Lupinus albus L.) Flour and Resistant Starch Type 4. J. Tekirdag. Agric. Fac. 2021, 18, 557–568. [Google Scholar] [CrossRef]

- Yaver, E.; Bilgicli, N. Effect of ultrasonicated lupin flour and resistant starch (type 4) on the physical and chemical properties of pasta. Food Chem. 2021, 357, 11. [Google Scholar] [CrossRef]

- Albuja-Vaca, D.; Yepez, C.; Vernaza, M.G.; Navarrete, D. Gluten-free pasta: Development of a new formulation based on rice and lupine bean flour (Lupinus mutabilis) using a mixture-process design. Food Sci. Technol. 2020, 40, 408–414. [Google Scholar] [CrossRef]

- Yegrem, L.; Abera, S.; Temesgen, M. Nutritional composition and sensory quality of injera prepared from tef (Eragrostis tef (Zucc.) Trotter) complemented with lupine (Lupinus spp.). Cogent Food Agric. 2021, 7, 20. [Google Scholar] [CrossRef]

- Çevik, A.; Ertaş, N. Effect of quinoa, buckwheat and lupine on nutritional properties and consumer preferences of tarhana. Qual. Assur. Saf. Crops Foods 2019, 11, 145–155. [Google Scholar] [CrossRef]

- Keskin, H.K.; Bilgicli, N.; Yaver, E. Development of gluten-free tarhana formulations: Part I. effect of legume flour type and level on physical, chemical, and sensory properties. J. Food Process. Preserv. 2022, 46, 9. [Google Scholar] [CrossRef]

- Stefanikova, J.; Valkova, V.; Nagyova, V.; Hynst, M.; Miskeje, M.; Borotova, P.; Vietoris, V.; Arvay, J.; Bojnanska, T. The influence of lupine flour on selected parameters of novel bakery products. Czech J. Food Sci. 2020, 38, 367–374. [Google Scholar] [CrossRef]

- Beshir, E.O.; Khallaf, M.F.; Abd El-daim, Y.; Awad, R.A.; Kamel, M.A.A. Sweet Lupin and Whey Protein Concentrate as Supplementants for Utilizing in Semi-Hard Biscuit and Its Chemical Properties. Egypt. J. Chem. 2021, 64, 7417–7427. [Google Scholar]

- Csutoras, C.; Giran, L.; Hudak, O.; Racz, L. Development and evaluation of potential functional food biscuits made from White Lupin. Prog. Agric. Eng. Sci. 2021, 17, 89–100. [Google Scholar]

- Koukoumaki, D.I.; Giannoutsos, K.; Devanthi, P.V.P.; Karmiris, P.; Bourni, S.; Monemvasioti, A.; Psimouli, V.; Sarris, D.; Gkatzionis, K. Effect of Wheat Replacement by Pulse Flours on the Texture, Color, and Sensorial Characteristics of Crackers: Flash Profile Analysis. Int. J. Food Sci. 2022, 2022, 14. [Google Scholar] [CrossRef] [PubMed]

- Ozcan, M.M.; Ipek, D.; Ghafoor, K.; Al Juhaimi, F.; Uslu, N.; Babiker, E.E.; Ahmed, I.A.M.; Alsawmahi, O.N. Physico-chemical and sensory properties of chips produced using different lupin (Lupinus albus L.) flour formulations and cooking methods. Int. J. Food Sci. Technol. 2021, 56, 2780–2788. [Google Scholar] [CrossRef]

- Martin, A.; Schmidt, V.; Osen, R.; Bez, J.; Ortner, E.; Mittermaier, S. Texture, sensory properties and functionality of extruded snacks from pulses and pseudocereal proteins. J. Sci. Food Agric. 2022, 102, 5011–5021. [Google Scholar] [CrossRef]

- Adem, M.; Sadik, J.A.; Worku, A.; Neela, S. Optimization of lupine (Lupinus albus L.) composition, feed moisture content and barrel temperatures for best quality maize based extruded snack food. Nutr. Food Sci. 2020, 50, 853–869. [Google Scholar] [CrossRef]

- Aslan, M.; Bilgicli, N. Improvement of functional cake formulation with fermented soy (Glycine max) and lupin (Lupinus albus L.) powders. Int. J. Gastron. Food Sci. 2021, 26, 7. [Google Scholar] [CrossRef]

- Aslan, M.; Bilgicli, N. The comparison of lupin milk with soy milk as an alternative egg substitute for cake production. J. Food Process. Preserv. 2022, 46, 11. [Google Scholar] [CrossRef]

- Woldemariam, H.W.; Asres, A.M.; Gemechu, F.G. Physicochemical and sensory properties of ice cream prepared using sweet lupin and soymilk as alternatives to cow milk. Int. J. Food Prop. 2022, 25, 278–287. [Google Scholar]

- Food and Agriculture Organization of the United Nations. FAOSTAT. Available online: https://www.fao.org/faostat (accessed on 27 February 2023).

| Reference | Food Product Developed | Formulation Ingredients | Nutritional Composition (g/100 g Dry Weight Basis or %s) | Subjects (n) for Sensory Analysis | Sensory Analysis Scale Used and Outcomes | Processing/Functionality Used for Lupin Incorporation |

|---|---|---|---|---|---|---|

| MEAT ALTERNATIVES | ||||||

| [47] | Camel burgers with lupin powder | Camel meat, lupin, garlic, a mixture of spices (black pepper, coriander, cumin, desserts and nutmeg) and salt | 21.6 g protein 6.2 g fat 10.2 g carbohydrates 0.8 g fibre | Not specified | 9-point hedonic scale Juicer (7.2), coolness (7.2), flavour (7.7), colour (7.6), textures (7.7) and general acceptance (7.9) Good rate of all sensory characteristics studied | Lupin seed powder Seeds were processed and ground; the sample was kept frozen until used |

| DAIRY ALTERNATIVES | ||||||

| [48] | Lupin cheese | Lupin milk and different coagulations (vinegar, lemon juice, starter culture or rennet enzyme) | 27.3 g protein 9.9 g fat 4.0 g carbohydrates | 20 trained panellists (10 males and 10 females) | 5-point hedonic scale Appearance (4.4), colour (4.2), flavour (4.2), texture (4.2), overall acceptability (4.7) Lupin cheese produced from PBA Jurien using vinegar was the most acceptable | Lupin seed ground Seeds were cleaned, broken into halves, and the hull removed with mortar and pestle; Seeds were soaked overnight in water and then ground with a stainless-steel gas-tight blender |

| [49] | Fat-free stirred yoghurt with lupin hull powder | Fat-free cow milk and lupin husk powder | Not specified | Not specified | 9-point hedonic scale Appearance (8.4), consistency (8.8), flavour (8.2) and overall acceptance (8.8) The addition of 1% lupine hull scored the highest sensory characteristics | Lupin hull powder The hull was removed from the seeds and passed through a lab hammer mill; Grounded hull fibres were then re-milled and passed through a 500 μm sieve; the sample was packed and kept under refrigeration |

| [50] | Plant-based yoghurt alternative | Skim milk powder, whey protein isolate, lupin protein isolate, coconut oil, anhydrous milk, fat, sucrose and distilled water | Not specified | 30 untrained panellists | Sorting task With a protein ratio of 67:33, were characterised as pleasant and non-homogenous; The others with 50:50 were described as unpleasant and bitter The ones with anhydrous milk fat were described as milky and “goaty”; The others containing coconut oil were characterised as fruity and fresh | Lupin protein isolate Isolate was purchased already processed |

| [51] | Yoghurt and milk analogues prepared from lupin | Lupin liquid fraction, lactic acid bacteria starters and barley starch | Not specified | 14 trained panellists (7 males and 7 females) and 22 untrained panellists (9 males and 13 females, 21–61 years old) | Line scale of 0 to 10 intensities Appearance yellowness (4.3), appearance homogeneity (6.5), odour intensity (3.8), odour vinegar (2.8), odour beaniness (2.9), flavour intensity (6.3), flavour beaniness (3.3), sweetness (1.1), sourness (5.4), bitterness (3.1), umami (2.6), astringency (3.9), texture graininess (2.3) and texture thickness (3.3) 9-point hedonic scale Colour (6.3), appearance (6.2), odour (5.0), flavour (4.2) and overall (4.5) The sample with Lactococcus lactis and ssp. Lactis was the most accepted by the two panels | Lupin liquid fraction Seeds were first rinsed and soaked overnight in excess tap water; after de-hulling and rinsing, soaked seeds were ground with tap water using a cutter to form a slurry; The slurry was filtered through a washable and reusable fine mesh plastic cheese filter inserted in a screen bowl of centrifuge at 4000 rpm; Centrifugation took 10 min, allowing easy and hygienic collection of both liquid and solid fractions |

| [52] | Oat-based with lupin and stinging nettle fermented beverage | Oat, lupin, stinging nettle and premix flour (black cardamom, malted wheat, pumpkin, spiced chilli peppers and table salt) | 19.9% protein 10.1% fat 66.9% carbohydrates 3.6 g fibre | 50 untrained panellists. | 5-point hedonic scale Taste (4.2), appearance (4.2), aroma (3.5), mouth feel (3.6), consistency (4.5) and overall acceptability (4.3) The blending of 15% lupin resulted in the best overall sensory acceptance | Lupin seed flour The cleaned lupin was first roasted for 10 min in a metal pan; after cooling, the roasted lupin grain was soaked for 8 days changing the water twice a day; lupin was de-hulled and sun-dried before grind in a lab mill and passed through a 0.5 mm sieve |

| [53] | Legume beverage from chickpea and lupin | Lupin, chickpeas, green and yellow peas | 5.4 g carbohydrates | 29 untrained panellists | 5-point hedonic scale Colour (3.8), appearance (3.9), taste (4.0), flavour (3.1), consistency (3.3) and overall appreciation (3.0) The legume mixture-based beverages with both chickpea and lupin evidenced the highest sensory characteristics | Lupin liquid fraction The dried seeds were soaked twice in warm tap water (30–35 °C) and once in cold tap water (15–20 °C) for 16 h; the water was removed, and the soaked seeds were cooked for 30 min after boiling in a pressure pan with fresh tap water; the sample was drained, and fresh tap water was added; the mixture was milled in the food processor at 20,500 rpm for 4 min |

| [54] | Functional beverage with milk, tarwi and oatmeal | Fresh milk, de-bittered lupin grains, oatmeal, honey bee, bottled water and probiotic culture | 3.6 g protein 0.2 g fibre | 30 untrained panellists (20–30 years old) | 9-point hedonic scale Overall acceptability (8.5) The major perception of sensory characteristics was found in the sample with 30% lupin | Lupin liquid fraction Grains were combined with water and homogenised in an industrial blender at 3600 rpm for 5 min; then, the sample was filtered using a stainless-steel mesh and sterile gauze cloth, separating the retained solids from the supernatant to obtain a homogeneous solution; the solution was pasteurised at 85 °C for 15 min, cooled, and stored in refrigeration at 4 °C |

| [55] | Fermented protein isolate hydrolysates | Lupin isolate protein, enzymes (cysteine endopeptidase, serine endopeptidase and aspartic endopeptidase) and water | 74.8% protein | 10 trained panellists (healthy) | Scale from 0 to 10 Oatmeal-like (3.8), cocoa-like (6.2), malty (5.9), green grassy (2.3), pea-like (5.8), fatty (2.1), cardboard-like cucumber-like (2.8), roasty (3.0), cooked potato-like (1.6) and earthy (2.6) The sample with Lactobacillus sakei carnosus was found on the positive side and was the best rated | Lupin isolate protein Seeds were de-hulled, separated and passed through a roller mill; the resulting flakes were de-oiled in n-hexane and extracted with hydrochloric acid for 1 h; Suspension was separated using a decanter centrifuge at 4 °C for 1 h, and the supernatant was discarded; the acid pre-extracted flakes were dispersed in sodium hydroxide for 1 h at room temperature while stirring and separated by centrifugation at 4 °C for 1 h; the precipitated proteins were separated by centrifugation for 130 min and neutralised with sodium hydroxide, pasteurised at 70 ° C for 10 min and spray-dried with an inlet temperature of 180 °C and an outlet temperature of 80 °C |

| GRAINS | ||||||

| [56] | Cereal-legume flour blend | Wheat, rye, barley, oat, chickpea, soybean, lupin, yeast, water and salt | 12.9 g protein 1.3 g fat | 25 untrained panellists (22–48 years old) | 7-point hedonic scale Symmetry (7.0), pore structure (6.9), taste (7.0), odour (6.7), appearance (6.7) and overall acceptability (7.0) The highest overall acceptability scores were obtained using 5% of flour developed in breads | Whole lupin seed flour Lupin was milled (<500 μm) using a hammer mill into whole grain flour with a 100% extraction rate |

| [57] | Germinated and fermented lupin flour | Lupin, soybean and flour | Not specified | 5 trained panellists | 10-point computerised time-intensity scale (0–350) for odour intensity Beany green (175), floral (0), meaty (250), nutty (50), woody green (225), sweet (175), baked (75) and mushroom soil (225) Germination significantly affected the aroma profile of lupin | Lupin seed flour After removal of damaged material, seeds were sanitised in hydrogen peroxide solution and rinsed with water until a neutral pH was obtained; seeds were soaked in water for 8 h; then, seeds were placed on trays covered with germination paper and germinated for 72 h in 22 °C and humidity 50–60% with access to natural daylight (12 h) and darkness (1 h); soaked and germinated samples were dried in a cabinet dryer for 18 h at 50 °C, and the temperature was increased by 10 °C every hour until 80 °C; after cooling to room temperature, dried seeds were ground using a lab mill (0.5 mm sieve); finally, stored in sealed air-tight packs at 4 °C until analysis |

| [58] | Bread dough | Lupin grit flour, lupin hulls flour, wheat flour and flaxseed expeller four | 11.1% protein 2.5% fat 43.6% carbohydrates 6.3% fibre | 259 untrained panellists (5 categories based on age: 20–29 years old, 30–39 years old, 40–49 years old, 50–59 years old and >60 years old; and based on gender: 147 female and 112 male) | 5-point hedonic scale Like extremely/like/neither like nor dislike/dislike/dislike extremely Colour (60%/31%/5%/2%/2%) flavour (56%/36%/5%/1%/2%), texture (64%/25%/10%/1%/0%) and overall acceptability (60%/35%/4%/1%/0%) The individuals under 40 years old showed a slightly lower acceptance than the ones over that age | Whole and hulled lupin seed flour The lupin seeds were de-hulled, and the kernel and hulls were milled separately (<0.3 mm particle size) with a lab mill; the obtained was to be incorporated afterwards as flours on the different flour blends |

| [59] | Bread dough | White wheat flour, lupin flour, compressed yeast, salt and water | Not specified | 30 semi-trained panellists | 9-point hedonic scale Appearance (8.0), colour (7.9), taste (7.9), smell (8.5), texture (7.5), flavour (6.5) and global acceptability (8.5) A 10% of lupin flour addition in wheat flour had the highest effect of improving the sensory characteristics | Lupin seed flour The germination process was performed at a constant humidity of 80% and 25 °C in dark conditions; seed grains with rootlets were freeze-dried to lower the moisture using a lyophiliser at −50 °C and 10 Pa for 24 h; Then, seeds were ground with a lab mill |

| [60] | Multigrain pan bread | Quinoa, lupin, fenugreek, yellow maise and psyllium | 17%g protein 6.4% fat 59.1% carbohydrates 15.2% fibre | 10 trained panellists | 9-point hedonic scale Taste (6.5), odour (6.5), texture (7.0), crust colour (6.5), crumb colour (6.5), appearance (7.5) and overall acceptability (6.9) The fortification with 15% of lupin positively influenced the acceptance | Lupin seed powder Lupin seeds were soaked in water for 12 h to remove bitterness; Seeds were germinated for 3 days in an incubator at 25 °C; the seeds were dried to obtain a fine powder, and the sample was stored at 5 °C |

| [61] | Wheat bread | Wheat flour, de-bittered lupin sweet flour, yeast extract, guar gum, salt, sugar, fat, bread-improver and water | 12.9 g protein | 112 untrained panellists | 9-point hedonic scale Appearance (7.1), flavour (7.0), texture (7.1) and overall liking (7.0) A 20% substitution of lupin flour in wheat flour caused a good sensory evaluation | Lupin seed flour Flour was purchased already processed |

| [62] | Gluten-free flatbread | Rice flour, lupin powder, sweet potato powder, millet flour, salt, baking powder, sunflower oil and corn oil | 10.4% protein 3.3% fat 83.6% carbohydrates | 10 untrained panellists | 9-point hedonic scale Appearance (8.2), crust colour (8.5), crumb colour (8.3), texture (8.3), taste (8.6), odour (8.7) and overall acceptability (8.6) Using sweet lupin powder to 10% proved the highest acceptability | Lupin seed powder Firstly, seeds were carefully cleaned and freed from broken seeds and extraneous matter; then, they were soaked in water for 12 h, soaked water was discarded; seeds were cooked in boiling water for 10 min and manually de-hulled and dried in a drying oven at 45–58 °C overnight (18–20 h); The result obtained was milled using a lab mill followed by sieving to obtain a fine powder and then packed in polyethene bags and kept for further analyses |

| [63] | High-protein hybrid pasta | Wheat semolina, buckwheat flour, faba bean flour, lupin protein isolate, sodium chloride and water | Not specified | 8 trained panellists | Quantitative descriptive analysis with continuous scales of 10 Flour odour (4.0), legume odour (4.8), beige colour (5.2), flour flavour (5.0), legume flavour (3.8), sweat taste (1.6), bitter taste (1.5), aftertaste (2.8), elasticity (4.3), hardness (2.9), chewiness (3.0), adhesiveness (2.5), overall quality (8.3) The results obtained suggest high consumer acceptance | Lupin isolate protein Isolate was purchased already processed |

| [64] | Enriched pasta | Durum wheat, semolina, de-bittered lupin flour, phosphorylated cross-linked wheat starch, vital wheat gluten and microbial transglutaminase | Not specified | 12 untrained panellists | 9-point hedonic scale Colour (8.3), taste (8.1), odour (7.5), appearance (8.3), stickiness (8.6) and overall acceptability (8.3) The addition of 15% lupin flour proved high sensory analyses results | Whole lupin seed flour Ultrasound application: boiled seeds were soaked in 25 °C water for 60 h and were sonicated for 25 min every 4 h; seeds were dried in a hot-air oven at 50 °C; Then, were ground into whole flour (<500 μm); After that, the flour sample was stabilised by dry roasting method at 160 °C for 30 min |

| [65] | Enriched pasta | Durum wheat, semolina, de-bittered lupin flour, phosphorylated cross-linked wheat starch, wheat flour, baker’s yeast, salt and water | 14.2 g protein 1.8 g fat 13.1 g fibre | 12 untrained panellists (25–45 years old) | 9-point hedonic scale Colour (7.5), taste (8.2), odour (8.0), appearance (7.4), stickiness (8.2) and overall acceptability (7.8) The sample enriched with 10% lupin flour had the highest overall acceptability score | Whole lupin seed flour Ultrasound application: bitter seeds were boiled in water for 75 °C; seeds were soaked in 25 °C water for 60 h and were sonicated for 25 min every 4 h with an ultrasonic probe in a glass beaker; the soaking water was changed every 4 h during the soaking; de-bittered seeds were dried in a hot-air oven at 50 °C; then, they were ground (<500 μm) using a hammer mill into whole lupin flour with a 100% extraction rate; after that, the flour sample was stabilised by dry roasting method at 160 °C for 30 min in the hot-air oven |

| [66] | Gluten-free pasta with lupin flour | Rice flour, whole eggs, lupin flour and guar gum | 18.6% protein 7.0% fat 62.7% carbohydrates 0.7% fibre | 112 consumers (62 males and 50 females) | 9-point hedonic scale Flavour (6.2), texture (5.9), overall appearance (6.1), overall results (6.1) The most accepted sample was the one with 20 g of lupin flour | Lupin seed flour De-bittered flour was purchased already processed |

| [67] | Injera from tef complemented with lupin | Tef grain, lupin, water and ersho | 15.5% protein 2.8% fat 76.9% carbohydrates | 50 untrained panellists (20 males and 30 females) | 7-point hedonic scale Colour (6.2), texture (5.7), taste (6.0), rollability (5.8), no eye (5.7), eye size (5.8), eye distribution (6.0), top and bottom surface (6.0), aroma (6.2) and overall acceptability (6.2) The sample developed with the addition of 10% lupin flour had the highest overall acceptability score | Lupin seed flour The de-bittering process for the seeds consisted of cleaning, boiling and de-bittering; seeds were boiled in water for 50 min to destroy thermolabile antinutritional factors and to soften the seeds’ hulls; the boiled lupine seeds were de-bittered with water at room temperature; The soaking water was changed every 12 h for 144 h; Afterwards, the whole seed was de-hulled manually, and the kernel was dried at 105 °C for 3 h in an oven; the seeds were dried and milled into a fine powder by using a disk attrition mill; then, they were sieved with a sieve size of 750μm and packed in polyethene bags, kept for further analyses at 4 °C |

| [68] | Tarhana soup | Wheat flour, buckwheat, quinoa, lupin, full-fat concentrated set yoghurt, bakers’ yeast, peeled and chopped dry onions, tomato paste, red pepper and salt | 19.7 g protein | 25 trained panellists | 5-point hedonic scale Taste (4.5), odour (4.7), colour (4.6), grittiness (4.6), sourness (4.0) and overall acceptability (4.6) More than 20% lupin flour incorporation produced negative effects on the acceptability | Lupin seed flour Seeds used after grinding to <500 μm size |

| [69] | Gluten-free tarhana soup | Corn flour, rice flour, legumes (chickpea, common bean, lentil, soybean and lupin) flour, yoghurt, tomato paste, onion, baker’s yeast, ground paprika and salt | Not specified | 6 untrained panellists (30–55 years old) | 9-point hedonic scale Taste, odour, colour, consistency, mouthfeel and overall acceptability The sample with lupin flour was not subjected to sensory evaluation because of lower technological characteristics than other legume samples | Whole lupin seed flour Dried de-bittered seeds were ground to <500 μm size by a lab hammer mill |

| SNACKS | ||||||

| [70] | Biscuits | Lupin flour, wheat flour, vegetable shortening and powdered sugar | Not specified | 12 trained panellists | 5-point hedonic scale Round shape stability after baking (5.0), colour intensity (2.2), odour intensity (2.5), odour intensity of legumes (1.0), flavour intensity (2.0), flavour intensity of legumes (2.2) and acceptability (4.5) 25% of lupin flour addition was considered the most appropriate | Lupin seed flour Not specified |

| [71] | Semi-hard biscuits | Soft wheat flour, whey protein, lupin, margarine, baking powder, sugar, milk, egg and salt | 13.2% protein 13.0% fat 71.2% carbohydrates | 10 trained panellists | 100-degree test with 5 factors (0–20) Colour (19.3), crust appearance (18.7), texture (18.3), aroma (19.0), taste (18.3) and overall acceptability (93.7) The sample with 15% lupin powder had the highest score of acceptance | Lupin seed flour Lupin seeds were powdered using a custom electric mill |

| [72] | Gluten-free biscuits and salty crackers | Rice flour, lupin, corn starch, sugar, butter, salt, tartaric acid and water | Not specified | 15 trained panellists | 9-point hedonic scale A high sensory score (7.9) obtained in the biscuits sample with 40 g of lupin flour A high sensory score (7.7) was obtained in the crackers sample with 40 g of lupin flour | Lupin seed flour Seeds were ground fine in a domestic mill, and the flour was filtered with a 0.4 mm filter |

| [73] | Crackers of legume flour | Wheat flour, chickpea flour and lupin flour, water, canola oil, baking powder, salt and sugar | Not specified | 24 untrained panellists (10 males and 14 females) 22 untrained panellists (5 males and 17 females) | Flash profile First session: each judge creates a self-list of attributes Other sessions: all attributes were pooled into a single list and presented to the judges Sensory attributes generated and used by more than one judge: crispy (6), floury (4), sweety (4), roasted chickpea (3), dietary (2), fatty (2), legumes (2) and neutral (2) | Lupin seed flour Flour was purchased already processed |

| [74] | Chips | Lupin flour, corn flour, whole wheat flour, salt, various spices (thyme, red pepper and sunflower oil), guar gum and monosodium glutamate | Not specified | 10 trained panellists | 5-point hedonic scale Taste (3.2), crispness (3.3), colour (3.5), odour (3.3), oiliness (3.5) and general appearance characteristics (3.7) The most liked formulation for overall general acceptability was the fried ones with 50–60% of whole lupin flour | Whole and hulled lupin seed flour Lupin seeds were dried at 40 °C for 10 h in two different forms, hulled manually peeled and whole grain; after drying, lupin seeds were milled using a mechanical mill to obtain flour which was passed through a 0.5 mm sieve before further use |

| [75] | Legumes and Pseudocereal protein snacks | Lupin protein isolate, lentil protein isolate, faba bean concentrate, pseudocereal flours, wheat starch, maise starch and pea starch | Not specified | 15 trained panellists (22–54 years old) | Visual analogue scale ranging from 0 to 100 Pea-like (18), fishy (12), cheesy sweaty (15), roasty popcorn-like (7), rancid (37), fatty cardboard-like (25), crunchiness (60), elasticity (35), firmness (95), porosity (46), umami (20), salty (8), preference (18) and overall intensity (55) Lupin protein-based extrudates exhibited satisfactory texture and sensory properties | Lupin isolate protein Isolate was purchased already processed and produced by aqueous extraction and isoelectric precipitation |

| [76] | Maise-based extruded snack food | Maise flour, lupin flour, | 17.8% protein 5.7% fat 64.9% carbohydrates 2.6% fibre | 50 semi-trained panellists (19–50 years old) | 9-point hedonic scale Colour (7.3), flavour (6.2), texture (6.1), taste (6.2) and overall acceptability (6.8) Overall acceptability scores of the samples demonstrated a significant positive effect of lupin flour addition up to 20% | Lupin seed flour The seeds were cleaned, washed and pre-soaked in water for 12 h; the soaked seeds were boiled for one hour to eliminate heat-sensitive antinutritional factors; The boiled seeds were in a de-bitter process by soaking for 5 days at room temperature; the soaked water was changed every 6 h; then, whole seeds were de-hulled manually, and the seeds were dried at 65 °C for 24 h in hot air oven; the dried samples were milled using a batch miller to a particle size of 0.5 mm, packed in a polyethene bag and stored at 4 °C until use |

| DESSERTS | ||||||

| [77] | Functional cake | Whole egg, sugar, all-purpose shortening, skimmed milk powder, baking powder, wheat flour, lupin and soy | 10.8 g protein 19.0 g fat | 12 untrained panellists (25–55 years old, healthy and non-smokers) | 7-point hedonic scale Colour (6.9), pore structure (6.6), taste (7.0), odour (7.0) and overall acceptability (6.8) The use of a 10% ratio of lupin increased the overall acceptability scores of the cake | Lupin seed powder Hulls of lupin seeds were removed manually; Seeds were dried in a hot air oven at 65 °C for 8 h; then, they were ground in a hammer mill equipped with a 500 μm sieve |

| [78] | Sponge cake | Wheat flour, sugar, shortening, cow milk, egg, salt, baking powder, vanilla, lupin, soy, diacetyl tartaric acid ester, monoglycerides, diglycerides and xanthan gum | 9.8 g protein 18.8 g fat | 12 untrained panellists (25–55 years old) | 7-point hedonic scale Colour (7.0), appearance (6.8), pore structure (6.9), taste (6.7), odour (6.9) and overall acceptability (6.9) The substitution of egg with 25% lupin milk had the highest overall score | Lupin seed ground Hulls of seeds were manually removed; Seeds were dried at 50 °C for 12 h before ground; mixed with hot water at 90–95 °C for 15 min; After cooling, it was homogenised again at 10,000 rpm for 1 min; the sample was stored in a refrigerated condition |

| [79] | Ice cream | Soybean, lupin and cow milk | 4.3 g protein 6.3 g fat 21.4 g carbohydrates | 15 untrained panellists | 7-point hedonic scale Appearance (5.8), taste (5.5), flavour (6.0), texture (6.2) and overall acceptability (6.1) The 50:50 blend ratio of lupin milk to cow milk had the best overall acceptability | Lupin seed ground For 18 h at room temperature, seeds were cleaned, weighed, washed and soaked in water; lupins were repeatedly rinsed and drained with cold water; the amount of water needed to produce the milk was weighed back; the remaining water was used to prepare lupin milk for molten grinding; the mix was then filtered and was boiled for 10 min |

| Country: Lupin Acquisition | Reference | Specific Specie: Lupinus | Product Type: Meat Alternative (MA) or Dairy Alternative (DA) or Grain (G) or Snack (S) or Dessert (D) | Lupin Form: Seed (S) or Hull (H) or Isolate Protein (IP) |

|---|---|---|---|---|

| Egypt | [49] | Albus | DA | H |

| [71] | Albus | S | S | |

| [62] | Albus | G | S | |

| [67] | Albus and Angustifolius | G | S | |

| Ethiopia | [52] | Albus | DA | S |

| [79] | Not specified | D | S | |

| [76] | Albus | S | S | |

| Australia | [48] | Angustifolius | DA | S |

| [57] | Angustifolius | G | S/H | |

| Iraq | [47] | Albus | MA | S |

| Saudi Arabia | [60] | Not specified | G | S |

| Turkey | [77] | Albus | D | S |

| [78] | Not specified | D | S | |

| [68] | Albus | G | S | |

| [69] | Albus | G | S/H | |

| [74] | Albus | S | S/H | |

| [56] | Not specified | G | S/H | |

| [64] | Albus | G | S/H | |

| [65] | Albus | G | S/H | |

| Finland | [51] | Angustifolius | DA | S |

| Romania | [59] | Albus | G | S |

| Germany | [50] | Not specified | DA | IP |

| [63] | Not specified | G | IP | |

| [75] | Albus and Angustifolius | S | IP | |

| [55] | Angustifolius | DA | IP | |

| Greece | [73] | Albus | S | S |

| Hungary | [72] | Albus | S | S |

| Portugal | [53] | Albus | DA | S |

| Slovakia | [70] | Not specified | S | S |

| Chile | [58] | Luteus | G | S/H |

| Ecuador | [66] | Mutabilis | G | S |

| [61] | Mutabilis | G | S | |

| Peru | [54] | Mutabilis | DA | S |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abreu, B.; Lima, J.; Rocha, A. Consumer Perception and Acceptability of Lupin-Derived Products: A Systematic Review. Foods 2023, 12, 1241. https://doi.org/10.3390/foods12061241

Abreu B, Lima J, Rocha A. Consumer Perception and Acceptability of Lupin-Derived Products: A Systematic Review. Foods. 2023; 12(6):1241. https://doi.org/10.3390/foods12061241

Chicago/Turabian StyleAbreu, Bruno, João Lima, and Ada Rocha. 2023. "Consumer Perception and Acceptability of Lupin-Derived Products: A Systematic Review" Foods 12, no. 6: 1241. https://doi.org/10.3390/foods12061241

APA StyleAbreu, B., Lima, J., & Rocha, A. (2023). Consumer Perception and Acceptability of Lupin-Derived Products: A Systematic Review. Foods, 12(6), 1241. https://doi.org/10.3390/foods12061241