Chemical Composition and Flavor Characteristics of Cider Fermented with Saccharomyces cerevisiae and Non-Saccharomyces cerevisiae

Abstract

:1. Introduction

2. Materials and Methods

2.1. Strains and Fermentation Media

2.2. Cider Fermentation

2.3. Physicochemical Property Analysis

2.4. Glucose and Glycerol Content

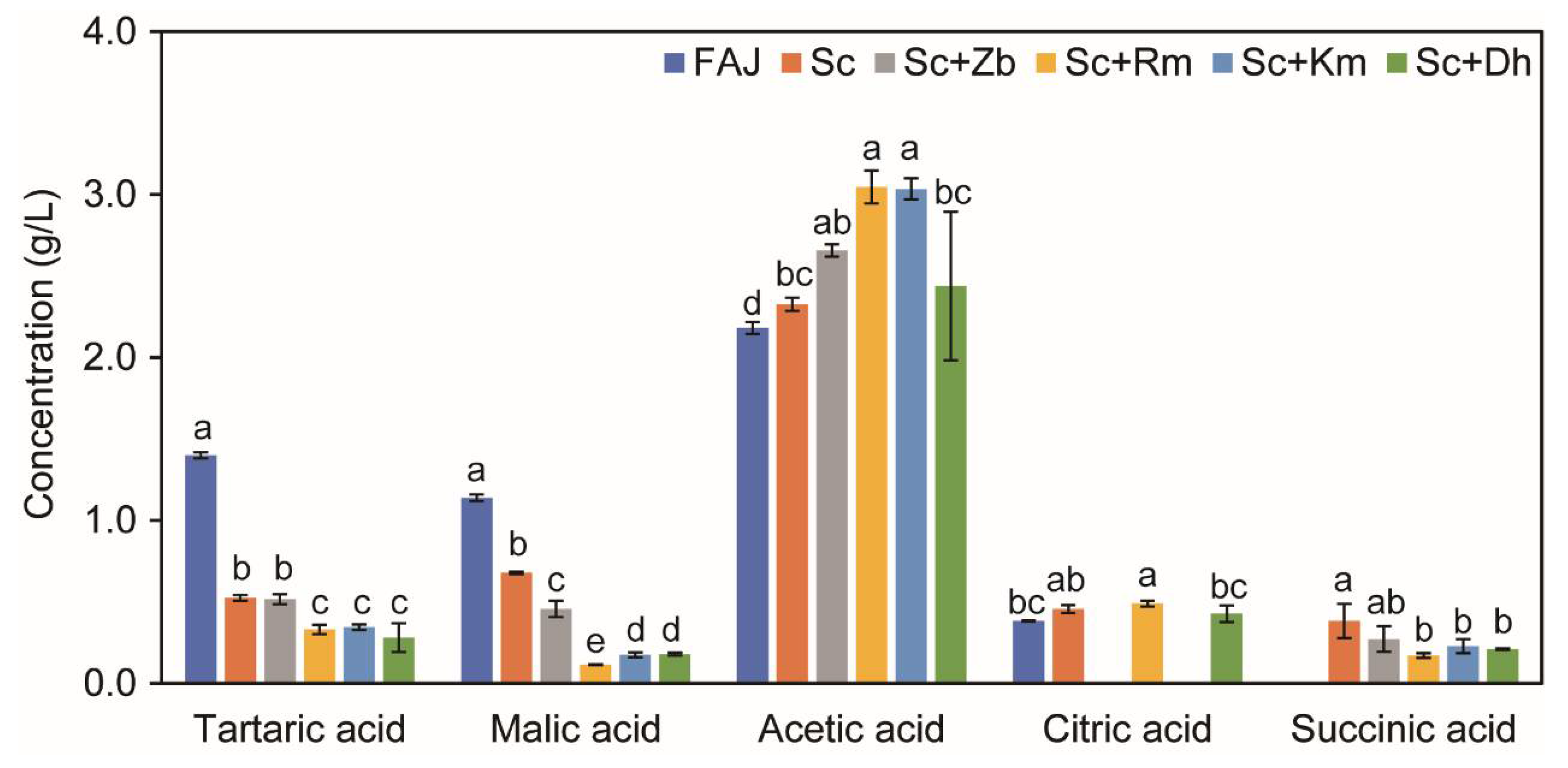

2.5. Organic Acid Content

2.6. Volatile Analysis

2.6.1. SPME-GC-MS Analytical Conditions

2.6.2. Parameters of GC-IMS Analysis

2.7. E-Tongue Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Characteristics of Cider Fermented with Different Non-Saccharomyces Yeasts

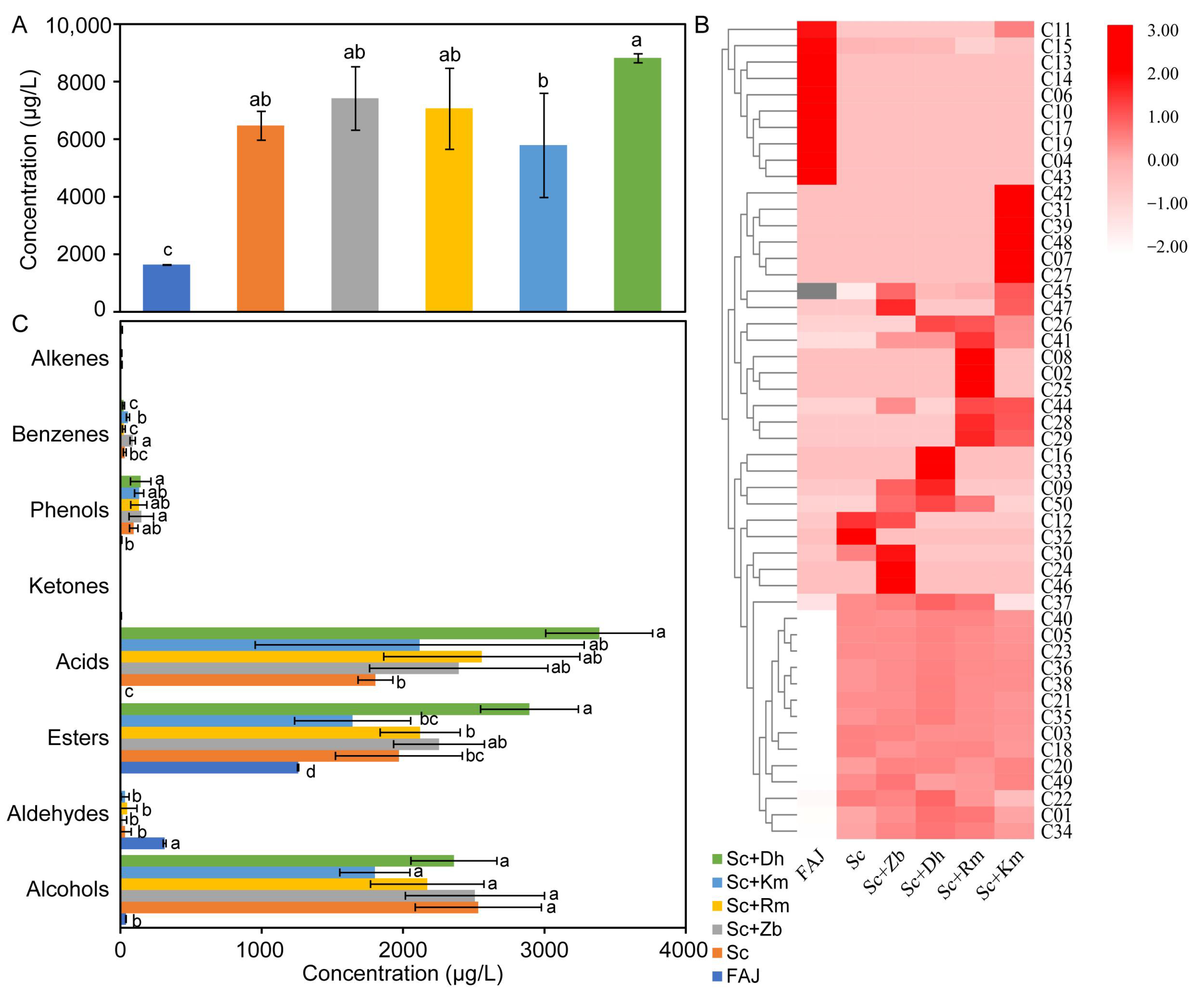

3.2. Volatile Compounds of Cider Fermented with Different Non-Saccharomyces Yeasts

3.2.1. SPME-GC-MS Analysis of Cider Fermented with Different Non-Saccharomyces Yeasts

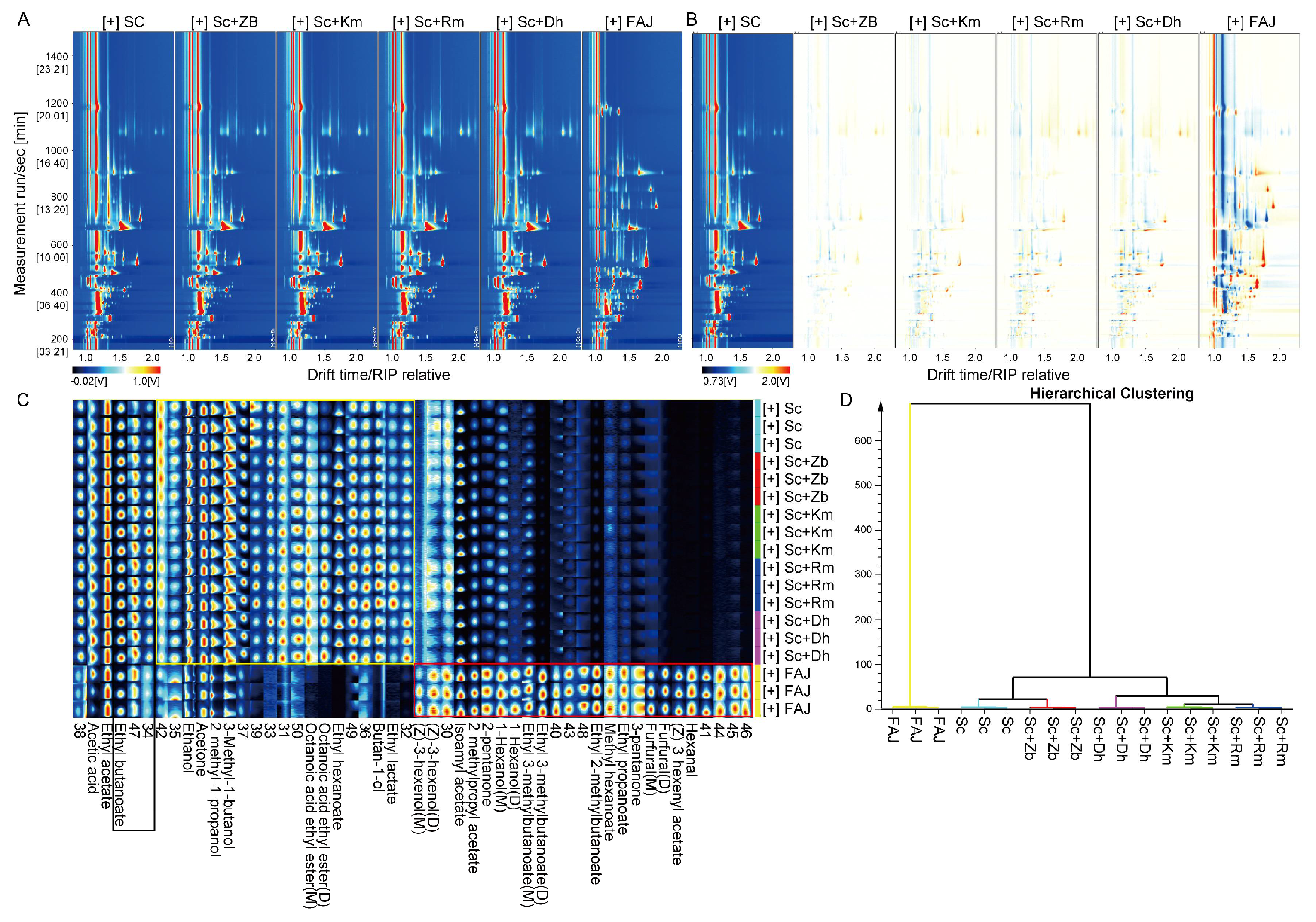

3.2.2. GC-IMS Analysis of Cider Fermented with Different Non-Saccharomyces Yeasts

3.2.3. Comparison of the Results of SPME-GC-MS and GC-IMS

3.2.4. Combination of SPME-GC-MS and GC-IMS Results for Multiple Analysis of Volatile Compounds

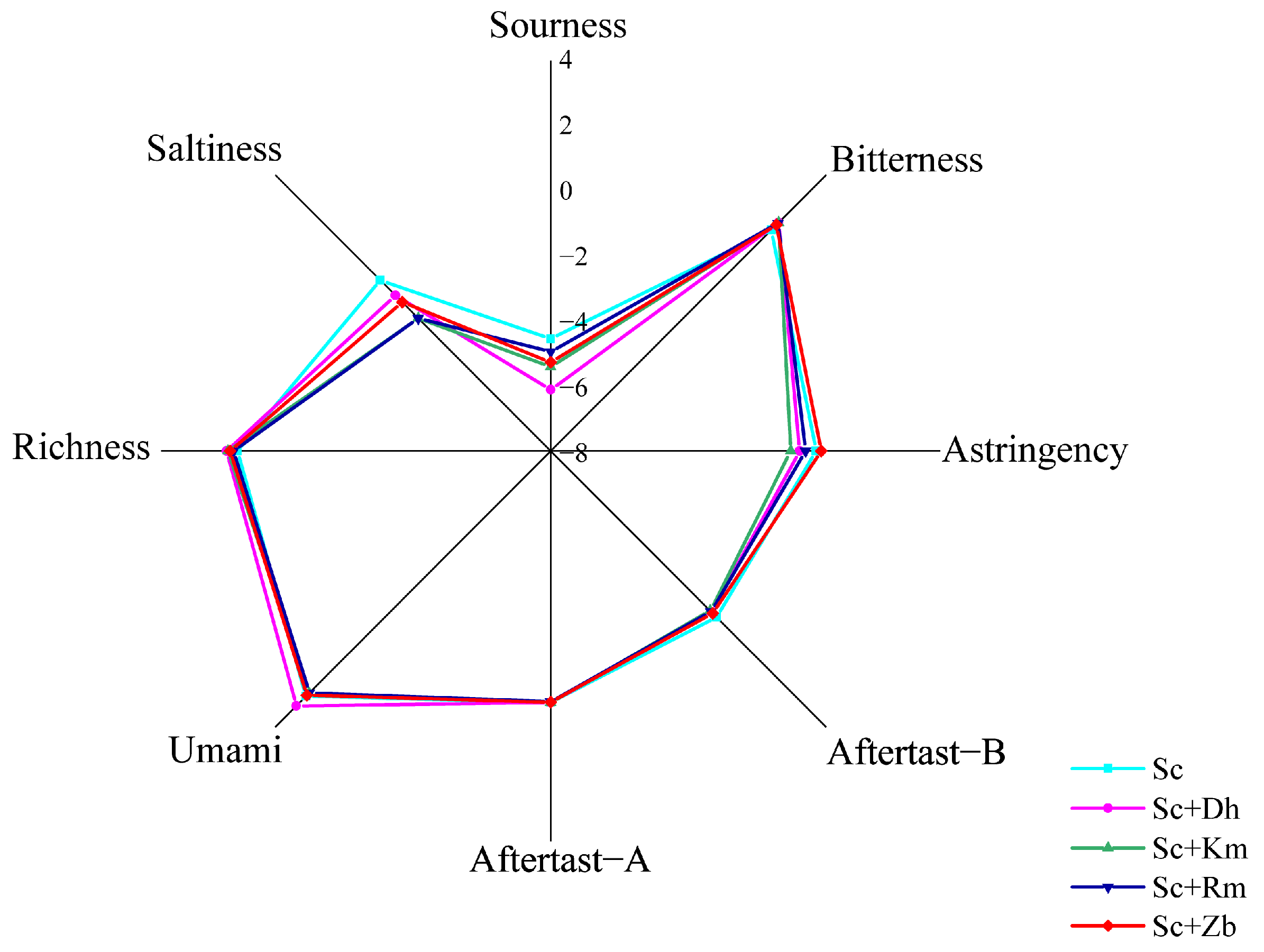

3.3. E-Tongue Analysis of Cider Fermented with Different Non-Saccharomyces Yeasts

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lorenzini, M.; Simonato, B.; Slaghenaufi, D.; Ugliano, M.; Zapparoli, G. Assessment of yeasts for apple juice fermentation and production of cider volatile compounds. LWT-Food Sci. Technol. 2019, 99, 224–230. [Google Scholar] [CrossRef]

- Antón, M.J.; Suárez Valles, B.; García Hevia, A.; Picinelli Lobo, A. Aromatic profile of ciders by chemical quantitative, gas chromatography-olfactometry, and sensory analysis. J. Food Sci. 2014, 79, S92–S99. [Google Scholar] [CrossRef] [PubMed]

- Peng, B.; Yue, T.; Yuan, Y. Analysis of key aroma components in cider from Shaanxi (China) Fuji apple. Int. J. Food Sci. Technol. 2009, 44, 610–615. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, Y.; Qiu, Y.; Guo, H.; Ju, H.; Wang, Y.; Yue, T. Chemical composition, sensorial properties, and aroma-active compounds of ciders fermented with Hanseniaspora osmophila and Torulaspora quercuum in co-and sequential fermentations. Food Chem. 2020, 306, 125623. [Google Scholar] [CrossRef]

- Plata, C.; Millan, C.; Mauricio, J.C.; Ortega, J.M. Formation of ethyl acetate and isoamyl acetate by various species of wine yeasts. Food Microbiol. 2003, 20, 217–224. [Google Scholar] [CrossRef]

- Medina, K.; Boido, E.; Dellacassa, E. Growth of non-Saccharomyces yeasts affects nutrient availability for Saccharomyces cerevisiae during wine fermentation. Int. J. Food Microbiol. 2012, 157, 245–250. [Google Scholar] [CrossRef]

- Tanguler, H. Evaluation of Williopsis saturnus inoculum level on fermentation and flavor compounds of white wines made from Emir (Vitis vinifera L.) grown in Anatolia. Food Biotechnol. 2012, 26, 351–368. [Google Scholar] [CrossRef]

- Canonico, L.; Comitini, F.; Ciani, M. Torulaspora delbrueckii contribution in mixed brewing fermentations with different Saccharomyces cerevisiae strains. Int. J. Food Microbiol. 2017, 259, 7–13. [Google Scholar] [CrossRef]

- Xu, Y.; Fan, W.; Qian, M.C. Characterization of aroma compounds in apple cider using solvent-assisted flavor evaporation and headspace solid-phase microextraction. J. Agric. Food Chem. 2007, 55, 3051–3057. [Google Scholar] [CrossRef]

- Ebeler, S.E. Analytical chemistry: Unlocking the secrets of wine flavor. Food Rev. Int. 2001, 17, 45–64. [Google Scholar] [CrossRef]

- Roberts, D.D.; Pollien, P.; Milo, C. Solid-phase microextraction method development for headspace analysis of volatile flavor compounds. J. Agric. Food Chem. 2000, 48, 2430–2437. [Google Scholar] [CrossRef] [PubMed]

- Schieberle, P. Odour-active compounds in moderately roasted seasame. Food Chem. 1996, 55, 145–152. [Google Scholar] [CrossRef]

- He, F.; Duan, J.; Zhao, J.; Li, H.; Sun, J.; Huang, M.; Sun, B. Different distillation stages Baijiu classification by temperature-programmed headspace-gas chromatography-ion mobility spectrometry and gas chromatography-olfactometry-mass spectrometry combined with chemometric strategies. Food Chem. 2021, 365, 130430. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Chen, H.; Sun, B. Recent progress in food flavor analysis using gas chromatography-ion mobility spectrometry (GC-IMS). Food Chem. 2020, 315, 126158. [Google Scholar] [CrossRef] [PubMed]

- Liang, H.; He, Z.; Wang, X.; Song, G.; Chen, H.; Lin, X.; Zhang, S. Bacterial profiles and volatile flavor compounds in commercial Suancai with varying salt concentration from Northeastern China. Food Res. Int. 2020, 137, 109384. [Google Scholar] [CrossRef]

- Maturano, Y.P.; Assof, M.; Fabani, M.P.; Nally, M.C.; Jofr?e, V.; Assaf, L.A.R. Enzymatic activities produced by mixed Saccharomyces and non-Saccharomyces cultures: Relationship with wine volatile composition. Anton. Leeuw. Int. J. G. 2015, 108, 1239–1256. [Google Scholar] [CrossRef]

- Wang, C.; Mas, A.; Esteve-Zarzoso, B. Interaction between Hanseniaspora uvarum and Saccharomyces cerevisiae during alcoholic fermentation. Int. J. Food Microbiol. 2015, 206, 67–74. [Google Scholar] [CrossRef]

- Volschenk, H.; Viljoen-Bloom, M.; Van Staden, J.; Husnik, J.; Van Vuuren, H.J.J. Genetic engineering of an industrial strain of Saccharomyces cerevisiae for L-malic acid degradation via an efficient malo-ethanolic pathway. S. Afr. J. Enol. Vitic. 2004, 25, 63–73. [Google Scholar] [CrossRef]

- Coulter, A.D. Succinic acid-How it is formed, what is its effect on titratable acidity, and what factors influence its concentration in wine. Wine Ind. J. 2004, 19, 16–25. [Google Scholar]

- Williams, A.A.; Tucknott, O.G. Volatile constituents of fermented cider I.—Draught dry cider blend. J. Sci. Food Agric. 1971, 22, 264–269. [Google Scholar] [CrossRef]

- Williams, A.A.; Tucknott, O.G. The volatile aroma components of fermented ciders: Minor neutral components from the fermentation of sweet coppin apple juice. J. Sci. Food Agric. 1978, 29, 381–397. [Google Scholar] [CrossRef]

- Kotseridis, Y.; Baumes, R. Identification of impact odorants in Bordeaux red grape juice, in the commercial yeast used for its fermentation, and in the produced wine. J. Agric. Food Chem. 2000, 48, 400–406. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Zhu, B.Q.; Wang, Y.H. Influence of pre-fermentation cold maceration treatment on aroma compounds of Cabernet Sauvignon wines fermented in different industrial scale fermenters. Food Chem. 2014, 154, 217–229. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.N.; Luo, Y.; Lu, Z.M.; Dong, Y.L.; Chai, L.J.; Shi, J.S.; Xu, Z.H. Metabolomic analysis of the effects of a mixed culture of Saccharomyces cerevisiae and Lactiplantibacillus plantarum on the physicochemical and quality characteristics of apple cider vinegar. Front. Nutr. 2023, 10, 1142517. [Google Scholar] [CrossRef]

- Wang, X.C.; Li, A.H.; Dizy, M. Evaluation of aroma enhancement for “Ecolly” dry white wines by mixed inoculation of selected Rhodotorula mucilaginosa and Saccharomyces cerevisiae. Food Chem. 2017, 228, 550–559. [Google Scholar] [CrossRef]

- Du, X.; Finn, C.E.; Qian, M.C. Volatile composition and odour-activity value of thornless ‘blank diamond’ and ‘marion’ blackberries. Food Chem. 2009, 119, 1127–1134. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, F.; Wang, L. Comparison of aroma-active volatiles in oolong tea infusions using GC-Olfactometry, GC-FPD and GC-MS. J. Agric. Food Chem. 2015, 63, 7499–7510. [Google Scholar] [CrossRef]

- Kliks, J.; Kawa, R.; Gasiński, A.; Rębas, J.; Szumny, A. Changes in the volatile composition of apple and apple/pear ciders affected by the different dilution rates in the continuous fermentation system. LWT 2021, 147, 111630. [Google Scholar] [CrossRef]

- Yang, R.; Lin, S.; Dong, Y.; Ye, H.; Zhang, T. Effect of microorganisms on the fingerprint of the volatile compounds in pine nut (Pinus koraiensis) peptide powder during storage. J. Food Biochem. 2021, 5, e13653. [Google Scholar] [CrossRef]

- Chen, S.; Lu, J.L.; Qian, M. Untargeted headspace-gas chromatography-ion mobility spectrometry in combination with chemometrics for detecting the age of Chinese liquor (Baijiu). Foods 2021, 10, 2888. [Google Scholar] [CrossRef]

- Mateo, J.J.; Jiménez, M.; Pastor, A.; Huerta, T. Yeast starter cultures affecting wine fermentation and volatiles. Food Res. Int. 2001, 34, 307–314. [Google Scholar] [CrossRef]

- Knoll, C.; Fritsch, S.; Schnell, S. Influence of pH and ethanol on malolactic fermentation and volatile aroma compound composition in white wines. LWT-Food Sci. Technol. 2011, 44, 2077–2086. [Google Scholar] [CrossRef]

- Wang, H.; Ni, Z.J.; Ma, W.P. Effect of sodium sulfite, tartaric acid, tannin, and glucose on rheological properties, release of aroma compounds, and color characteristics of red wine. Food Sci. Biotechnol. 2019, 28, 395–403. [Google Scholar] [CrossRef]

- Romano, P.; Fiore, C.; Paraggio, M.; Caruso, M.; Capece, A. Function of yeast species and strains in wine flavor. Int. J. Food Microbiol. 2003, 86, 169–180. [Google Scholar] [CrossRef]

- Li, E.; Liu, Y.L. Evaluation of yeast diversity during wine fermentations with direct inoculation and pied de cuve method at an industrial scale. J. Microbiol. Biotechnol. 2012, 22, 960–966. [Google Scholar] [CrossRef] [PubMed]

- Schreier, P.; Drawert, F.; Schenid, M.C. Changes in the composition of neutral volatile components during the production of apple brandy. J. Sci. Food Agric. 1978, 29, 728–736. [Google Scholar] [CrossRef]

| Samples 1 | FAJ | Ciders | ||||

|---|---|---|---|---|---|---|

| Sc | Sc+Zb | Sc+Rm | Sc+Km | Sc+Dh | ||

| Glucose (g/L) | 140.00 ± 0.00 c | 0.50 ± 0.08 a | 0.45 ± 0.07 a | 0.30 ± 0.00 b | 0.29 ± 0.02 b | 0.33 ± 0.03 b |

| Alcohol (%, v/v) | ND | 10.03 ± 0.76 ab | 9.17 ± 0.06 b | 10.47 ± 0.68 a | 9.37 ± 0.29 b | 9.43 ± 0.40 b |

| pH | 3.76 ± 0.02 d | 3.94 ± 0.01 c | 4.06 ± 0.02 b | 3.98 ± 0.03 a | 4.03 ± 0.04 b | 4.03 ± 0.05 b |

| TA (g/L) | 5.37 ± 0.07 b | 6.40 ± 0.33 c | 5.16 ± 0.44 b | 5.94 ± 0.15 a | 5.28 ± 0.09 b | 4.89 ± 0.22 b |

| Glycerol (g/L) | 5.97 ± 0.36 a | 6.25 ± 0.38 a | 6.24 ± 0.66 a | 6.48 ± 0.36 a | 6.25 ± 0.47 a | 6.34 ± 0.40 a |

| Total yeast count (log CFU/mL) | ND | 6.79 ± 0.01 a | 6.78 ± 0.01 a | 6.79 ± 0.01 a | 6.19 ± 0.04 c | 6.62 ± 0.02 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Li, Z.; Zou, S.; Dong, L.; Lin, X.; Chen, Y.; Zhang, S.; Ji, C.; Liang, H. Chemical Composition and Flavor Characteristics of Cider Fermented with Saccharomyces cerevisiae and Non-Saccharomyces cerevisiae. Foods 2023, 12, 3565. https://doi.org/10.3390/foods12193565

Wu Y, Li Z, Zou S, Dong L, Lin X, Chen Y, Zhang S, Ji C, Liang H. Chemical Composition and Flavor Characteristics of Cider Fermented with Saccharomyces cerevisiae and Non-Saccharomyces cerevisiae. Foods. 2023; 12(19):3565. https://doi.org/10.3390/foods12193565

Chicago/Turabian StyleWu, Yuzheng, Zhigao Li, Sibo Zou, Liang Dong, Xinping Lin, Yingxi Chen, Sufang Zhang, Chaofan Ji, and Huipeng Liang. 2023. "Chemical Composition and Flavor Characteristics of Cider Fermented with Saccharomyces cerevisiae and Non-Saccharomyces cerevisiae" Foods 12, no. 19: 3565. https://doi.org/10.3390/foods12193565

APA StyleWu, Y., Li, Z., Zou, S., Dong, L., Lin, X., Chen, Y., Zhang, S., Ji, C., & Liang, H. (2023). Chemical Composition and Flavor Characteristics of Cider Fermented with Saccharomyces cerevisiae and Non-Saccharomyces cerevisiae. Foods, 12(19), 3565. https://doi.org/10.3390/foods12193565