Curcumin-Loaded Bamboo Shoot Cellulose Nanofibers: Characterization and In Vitro Studies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

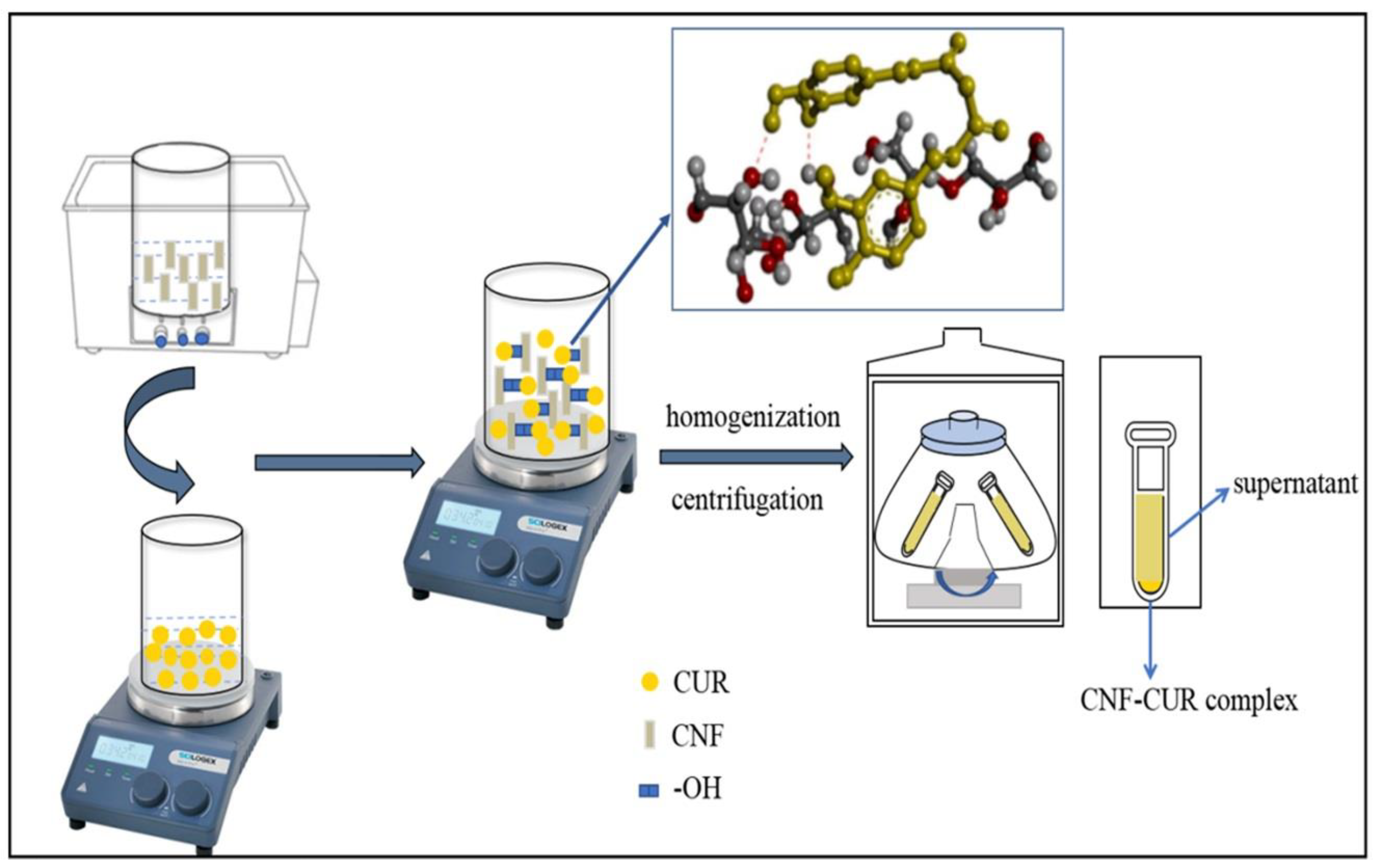

2.2. Preparation of the CNF–CUR Complex

2.3. Scanning Electron Microscopy (SEM)

2.4. Encapsulation Efficiency and Loading Capacity

2.5. Fourier Transform Infrared (FT-IR) Spectroscopy

2.6. Stability Measurements

2.7. In Vitro Release Profile of CUR from CNF–CUR Complex

2.8. Kinetic Study of In Vitro CUR Release

2.9. Statistical Analysis

3. Results

3.1. Characterization of CNF–CUR Complex

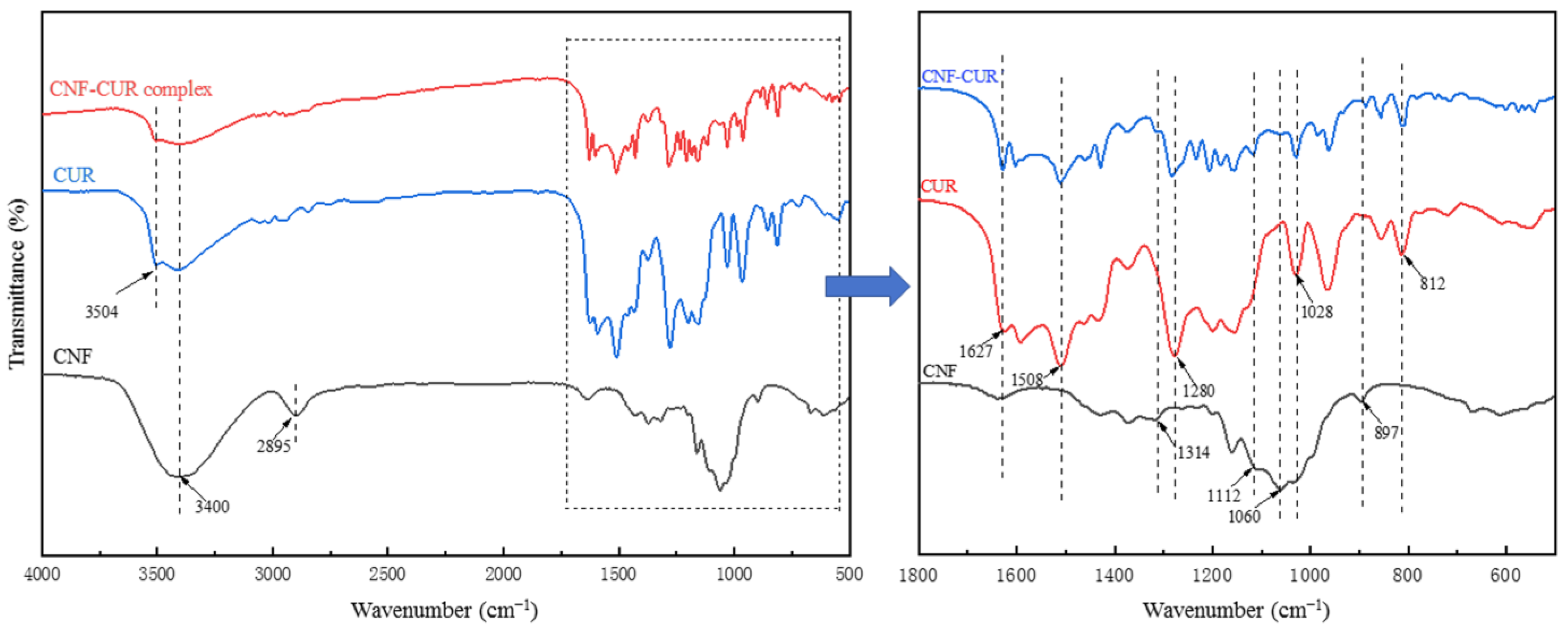

3.2. FT-IR Analysis

3.3. Improved Stability against UV and Heating

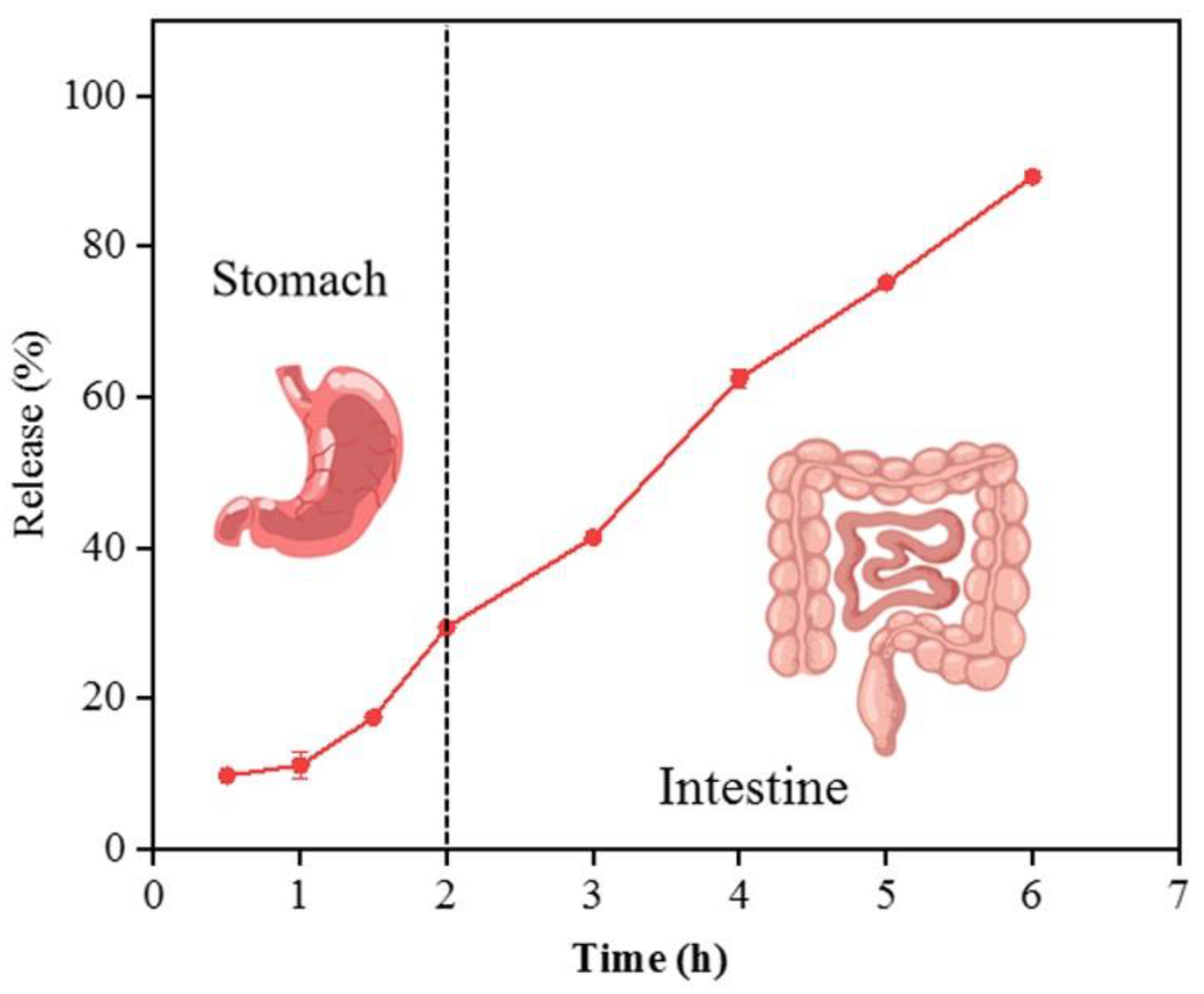

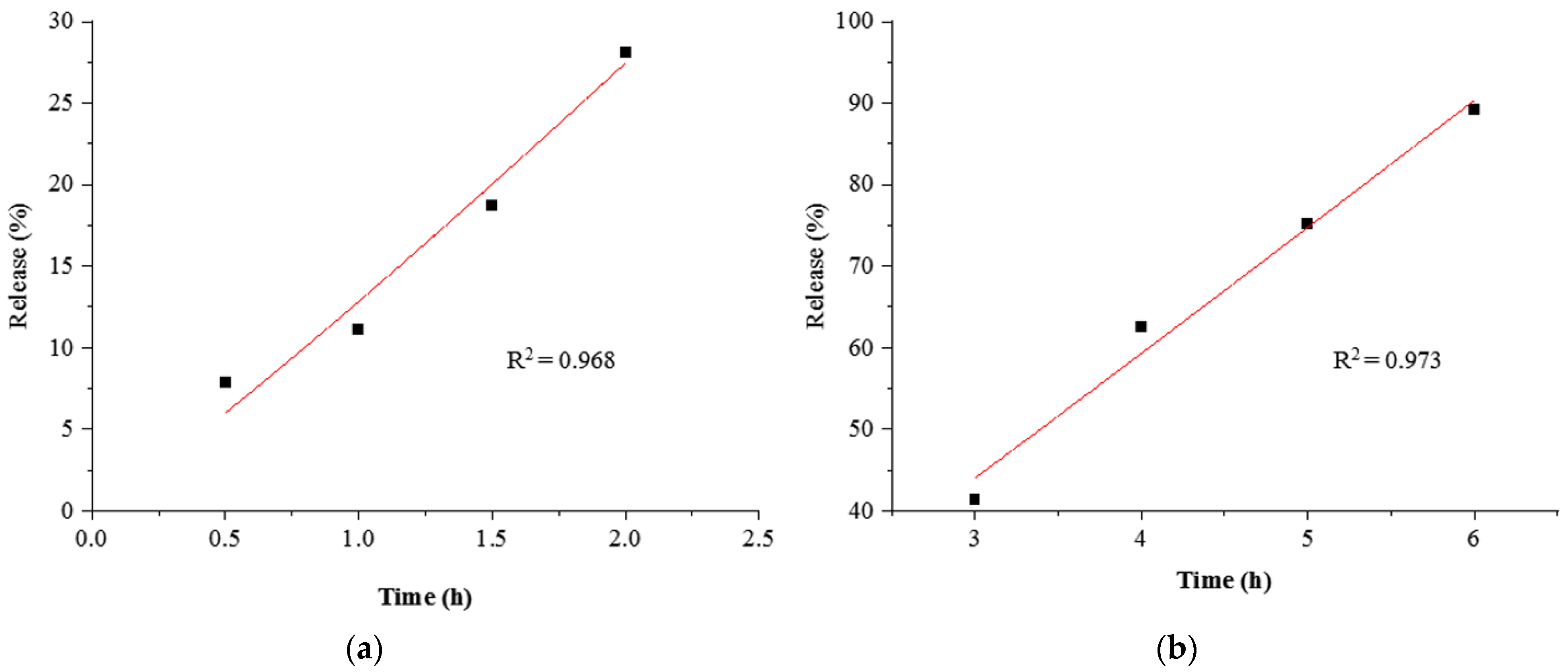

3.4. In Vitro Release Profile and Release Kinetics of CUR from the Complex

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, J.; Huang, K.; Lan, T.; Xie, X.; Shen, X.; Liu, P.; Huang, H. Curcumin ameliorates diabetic nephropathy by inhibiting the activation of the sphk1-s1p signaling pathway. Mol. Cell. Endocrinol. 2013, 365, 231–240. [Google Scholar] [CrossRef]

- Huang, Y.-L.; Tsai, Y.-H.; Chow, C.-J. Water-insoluble fiber-rich fraction from pineapple peel improves intestinal function in hamsters: Evidence from cecal and fecal indicators. Nutr. Res. 2014, 34, 346–354. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.-M.; Luo, X.-L.; Pang, J.; Wang, Q.; Yan, Z.-M.; Zhuang, W.-J.; Zheng, B.-D.; Zheng, Y.-F. Structural properties and potential applications of cellulose nanofiber from bamboo shoot shell. Chin. J. Struct. Chem. 2017, 36, 533–542. [Google Scholar]

- Xia, Z.-h.; Zhang, S.-y.; Chen, Y.-s.; Li, K.; Chen, W.-b.; Liu, Y.-q. Curcumin anti-diabetic effect mainly correlates with its anti-apoptotic actions and pi3k/akt signal pathway regulation in the liver. Food Chem. Toxicol. 2020, 146, 111803. [Google Scholar] [CrossRef]

- Fu, Y.-S.; Chen, T.-H.; Weng, L.; Huang, L.; Lai, D.; Weng, C.-F. Pharmacological properties and underlying mechanisms of curcumin and prospects in medicinal potential. Biomed. Pharmacother. 2021, 141, 111888. [Google Scholar] [CrossRef] [PubMed]

- Shen, L.; Liu, C.-C.; An, C.-Y.; Ji, H.-F. How does curcumin work with poor bioavailability? Clues from experimental and theoretical studies. Sci. Rep. 2016, 6, 20872. [Google Scholar] [CrossRef]

- Sanidad, K.Z.; Zhu, J.; Wang, W.; Du, Z.; Zhang, G. Effects of stable degradation products of curcumin on cancer cell proliferation and inflammation. J. Agric. Food Chem. 2016, 64, 9189–9195. [Google Scholar] [CrossRef]

- Tabanelli, R.; Brogi, S.; Calderone, V. Improving curcumin bioavailability: Current strategies and future perspectives. Pharmaceutics 2021, 13, 1715. [Google Scholar] [CrossRef]

- Kakkar, V.; Singh, S.; Singla, D.; Kaur, I.P. Exploring solid lipid nanoparticles to enhance the oral bioavailability of curcumin. Mol. Nutr. Food Res. 2011, 55, 495–503. [Google Scholar] [CrossRef]

- Luan, L.; Chi, Z.; Liu, C. Chinese white wax solid lipid nanoparticles as a novel nanocarrier of curcumin for inhibiting the formation of staphylococcus aureus biofilms. Nanomaterials 2019, 9, 763. [Google Scholar] [CrossRef]

- Liu, C.; Yuan, Y.; Ma, M.; Zhang, S.; Wang, S.; Li, H.; Xu, Y.; Wang, D. Self-assembled composite nanoparticles based on zein as delivery vehicles of curcumin: Role of chondroitin sulfate. Food Funct. 2020, 11, 5377–5388. [Google Scholar] [CrossRef] [PubMed]

- Marslin, G.; Prakash, J.; Qi, S.; Franklin, G. Oral delivery of curcumin polymeric nanoparticles ameliorates ccl4-induced subacute hepatotoxicity in wistar rats. Polymers 2018, 10, 541. [Google Scholar] [CrossRef]

- Zhan, X.; Dai, L.; Zhang, L.; Gao, Y. Entrapment of curcumin in whey protein isolate and zein composite nanoparticles using ph-driven method. Food Hydrocoll. 2020, 106, 105839. [Google Scholar] [CrossRef]

- Bahmani, M.; Akbarian, M.; Tayebi, L.; Farjadian, F. The inhibitory effect of curcumin loaded poly (vinyl caprolactam) nanohydrogel on insulin fibrillation. Process Biochem. 2022, 117, 209–218. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, N.S.; Sukumaran, H.G.; Dara, P.K.; Ganesan, B.; Ashraf, M.; Anandan, R.; Mathew, S.; Nagarajarao, R.C. Nano-encapsulation of curcumin in fish collagen grafted succinyl chitosan hydrogel accelerates wound healing process in experimental rats. Food Hydrocoll. Health 2022, 2, 100061. [Google Scholar] [CrossRef]

- Jose, J.; Pai, A.R.; Gopakumar, D.A.; Dalvi, Y.; Rubi, V.; Bhat, S.G.; Pasquini, D.; Kalarikkal, N.; Thomas, S. Novel 3d porous aerogels engineered at nano scale from cellulose nano fibers and curcumin: An effective treatment for chronic wounds. Carbohydr. Polym. 2022, 287, 119338. [Google Scholar] [CrossRef]

- Bharmoria, P.; Bisht, M.; Gomes, M.C.; Martins, M.; Neves, M.C.; Mano, J.F.; Bdikin, I.; Coutinho, J.A.P.; Ventura, S.P.M. Protein-olive oil-in-water nanoemulsions as encapsulation materials for curcumin acting as anticancer agent towards mda-mb-231 cells. Sci. Rep. 2021, 11, 9099. [Google Scholar] [CrossRef]

- Thomas, L.; Zakir, F.; Mirza, M.A.; Anwer, M.K.; Ahmad, F.J.; Iqbal, Z. Development of curcumin loaded chitosan polymer based nanoemulsion gel: In vitro, ex vivo evaluation and in vivo wound healing studies. Int. J. Biol. Macromol. 2017, 101, 569–579. [Google Scholar] [CrossRef]

- Ching, Y.C.; Gunathilake, T.M.S.U.; Chuah, C.H.; Ching, K.Y.; Singh, R.; Liou, N.-S. Curcumin/tween 20-incorporated cellulose nanoparticles with enhanced curcumin solubility for nano-drug delivery: Characterization and in vitro evaluation. Cellulose 2019, 26, 5467–5481. [Google Scholar] [CrossRef]

- Lin, T.; Wang, Q.; Zheng, X.; Chang, Y.; Cao, H.; Zheng, Y. Investigation of the structural, thermal, and physicochemical properties of nanocelluloses extracted from bamboo shoot processing byproducts. Front. Chem. 2022, 10, 922437. [Google Scholar] [CrossRef]

- Liu, W.; Liu, K.; Wang, Y.; Lin, Q.; Liu, J.; Du, H.; Pang, B.; Si, C. Sustainable production of cellulose nanofibrils from kraft pulp for the stabilization of oil-in-water pickering emulsions. Ind. Crops Prod. 2022, 185, 115123. [Google Scholar] [CrossRef]

- Qi, W.; Wu, J.; Shu, Y.; Wang, H.; Rao, W.; Xu, H.-N.; Zhang, Z. Microstructure and physiochemical properties of meat sausages based on nanocellulose-stabilized emulsions. Int. J. Biol. Macromol. 2020, 152, 567–575. [Google Scholar] [CrossRef]

- Kumari, P.; Meena, A. Application of enzyme-mediated cellulose nanofibers from lemongrass waste for the controlled release of anticancer drugs. Environ. Sci. Pollut. Res. 2021, 28, 46343–46355. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Liu, Y.; Yu, Y.; Chen, W.; Liu, Y.; Yu, H. Nanoformulations of quercetin and cellulose nanofibers as healthcare supplements with sustained antioxidant activity. Carbohydr. Polym. 2019, 207, 160–168. [Google Scholar] [CrossRef] [PubMed]

- Lehi, A.Y.; Shagholani, H.; Ghorbani, M.; Nikpay, A.; Lashkenari, M.S.; Soltani, M. Chitosan nanocapsule-mounted cellulose nanofibrils as nanoships for smart drug delivery systems and treatment of avian trichomoniasis. J. Taiwan Inst. Chem. Eng. 2019, 95, 290–299. [Google Scholar] [CrossRef]

- Sun, B.; Tian, Y.; Chen, L.; Jin, Z. Linear dextrin as curcumin delivery system: Effect of degree of polymerization on the functional stability of curcumin. Food Hydrocoll. 2018, 77, 911–920. [Google Scholar] [CrossRef]

- Li, D.; Wei, Z.; Sun, J.; Xue, C. Tremella polysaccharides-coated zein nanoparticles for enhancing stability and bioaccessibility of curcumin. Curr. Res. Food Sci. 2022, 5, 611–618. [Google Scholar] [CrossRef]

- Fathi, M.; Emam-Djomeh, Z.; Aliabbasi, N. Developing two new types of nanostructured vehicles to improve biological activity and functionality of curcumin. Food Biosci. 2021, 44, 101386. [Google Scholar] [CrossRef]

- Siepmann, J.; Peppas, N.A. Modeling of drug release from delivery systems based on hydroxypropyl methylcellulose (hpmc). Adv. Drug Deliv. Rev. 2001, 48, 139–157. [Google Scholar] [CrossRef]

- Kumari, P.; Raza, W.; Meena, A. Lemongrass derived cellulose nanofibers for controlled release of curcumin and its mechanism of action. Ind. Crops Prod. 2021, 173, 114099. [Google Scholar] [CrossRef]

- Ngwabebhoh, F.A.; Erdagi, S.I.; Yildiz, U. Pickering emulsions stabilized nanocellulosic-based nanoparticles for coumarin and curcumin nanoencapsulations: In vitro release, anticancer and antimicrobial activities. Carbohydr. Polym. 2018, 201, 317–328. [Google Scholar] [CrossRef] [PubMed]

- Hasibuan, P.A.Z.; Yuandani; Tanjung, M.; Gea, S.; Pasaribu, K.M.; Harahap, M.; Perangin-Angin, Y.A.; Prayoga, A.; Ginting, J.G. Antimicrobial and antihemolytic properties of a cnf/agnp-chitosan film: A potential wound dressing material. Heliyon 2021, 7, e08197. [Google Scholar] [CrossRef] [PubMed]

- Syazwani, N.S.; Efzan, M.N.E.; Kok, C.K.; Nurhidayatullaili, M.J. Analysis on extracted jute cellulose nanofibers by fourier transform infrared and x-ray diffraction. J. Build. Eng. 2022, 48, 103744. [Google Scholar] [CrossRef]

- Roozbehi, S.; Dadashzadeh, S.; Sajedi, R.H. An enzyme-mediated controlled release system for curcumin based on cyclodextrin/cyclodextrin degrading enzyme. Enzym. Microb. Technol. 2021, 144, 109727. [Google Scholar] [CrossRef]

- Deepika; Prasad, M.; Salar, A.; Salar, R.K. In vitro anticancer activity of curcumin loaded chitosan nanoparticles (clcnps) against vero cells. Pharmacol. Res.-Mod. Chin. Med. 2022, 3, 100116. [Google Scholar] [CrossRef]

- Xue, J.; Zhang, Y.; Huang, G.; Liu, J.; Slavin, M.; Yu, L. Zein-caseinate composite nanoparticles for bioactive delivery using curcumin as a probe compound. Food Hydrocoll. 2018, 83, 25–35. [Google Scholar] [CrossRef]

- Tan, C.; Xie, J.; Zhang, X.; Cai, J.; Xia, S. Polysaccharide-based nanoparticles by chitosan and gum arabic polyelectrolyte complexation as carriers for curcumin. Food Hydrocoll. 2016, 57, 236–245. [Google Scholar] [CrossRef]

- do Nascimento Soares, G.O.; Ribeiro Lima Machado, R.; Mendonca Diniz, M.; da Silva, A.B. Electrospun progesterone-loaded cellulose acetate nanofibers and their drug sustained-release profiles. Polym. Eng. Sci. 2020, 60, 3231–3243. [Google Scholar] [CrossRef]

- Moydeen, A.M.; Ali Padusha, M.S.; Aboelfetoh, E.F.; Al-Deyab, S.S.; El-Newehy, M.H. Fabrication of electrospun poly(vinyl alcohol)/dextran nanofibers via emulsion process as drug delivery system: Kinetics and in vitro release study. Int. J. Biol. Macromol. 2018, 116, 1250–1259. [Google Scholar] [CrossRef]

- Liu, J.; Xu, L.; Liu, C.; Zhang, D.; Wang, S.; Deng, Z.; Lou, W.; Xu, H.; Bai, Q.; Ma, J. Preparation and characterization of cationic curcumin nanoparticles for improvement of cellular uptake. Carbohydr. Polym. 2012, 90, 16–22. [Google Scholar] [CrossRef]

- Sari, T.P.; Mann, B.; Kumar, R.; Singh, R.R.B.; Sharma, R.; Bhardwaj, M.; Athira, S. Preparation and characterization of nanoemulsion encapsulating curcumin. Food Hydrocoll. 2015, 43, 540–546. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, J.; Ji, F.; Liu, H.; Wang, C.; Luo, S.; Zheng, Z. Glycated soy β-conglycinin nanoparticle for efficient nanocarrier of curcumin: Formation mechanism, thermal stability, and storage stability. Foods 2022, 11, 3703. [Google Scholar] [CrossRef] [PubMed]

| Medium | Model | R2 | Adj-R2 | RMSE | k | n |

|---|---|---|---|---|---|---|

| Stomach | Zero-order | 0.805 | 0.787 | 1.636 | 0.417 | - |

| Intestine | Zero-order | 0.870 | 0.858 | 0.560 | 0.311 | - |

| Stomach | Higuchi | 0.941 | 0.935 | 0.498 | 2.654 | - |

| Intestine | Higuchi | 0.970 | 0.968 | 0.128 | 1.932 | - |

| Stomach | Korsmeyer–Peppas | 0.968 | 0.965 | 0.266 | 9.378 | 1.09 |

| Intestine | Korsmeyer–Peppas | 0.973 | 0.971 | 0.115 | 8.968 | 1.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, Y.; Wang, Q.; Huang, J.; Luo, X.; Huang, Y.; Wu, Y.; Chen, P.; Zheng, Y. Curcumin-Loaded Bamboo Shoot Cellulose Nanofibers: Characterization and In Vitro Studies. Foods 2023, 12, 3512. https://doi.org/10.3390/foods12183512

Chang Y, Wang Q, Huang J, Luo X, Huang Y, Wu Y, Chen P, Zheng Y. Curcumin-Loaded Bamboo Shoot Cellulose Nanofibers: Characterization and In Vitro Studies. Foods. 2023; 12(18):3512. https://doi.org/10.3390/foods12183512

Chicago/Turabian StyleChang, Yu, Qi Wang, Juqing Huang, Xianliang Luo, Yajuan Huang, Yirui Wu, Peng Chen, and Yafeng Zheng. 2023. "Curcumin-Loaded Bamboo Shoot Cellulose Nanofibers: Characterization and In Vitro Studies" Foods 12, no. 18: 3512. https://doi.org/10.3390/foods12183512

APA StyleChang, Y., Wang, Q., Huang, J., Luo, X., Huang, Y., Wu, Y., Chen, P., & Zheng, Y. (2023). Curcumin-Loaded Bamboo Shoot Cellulose Nanofibers: Characterization and In Vitro Studies. Foods, 12(18), 3512. https://doi.org/10.3390/foods12183512